Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Easy to stain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite door structure and method of forming a composite door structure

InactiveUS7178308B2Improve thermal performanceImprove impact resistanceAdhesivesDoor leavesThermoplastic polymerSurface plate

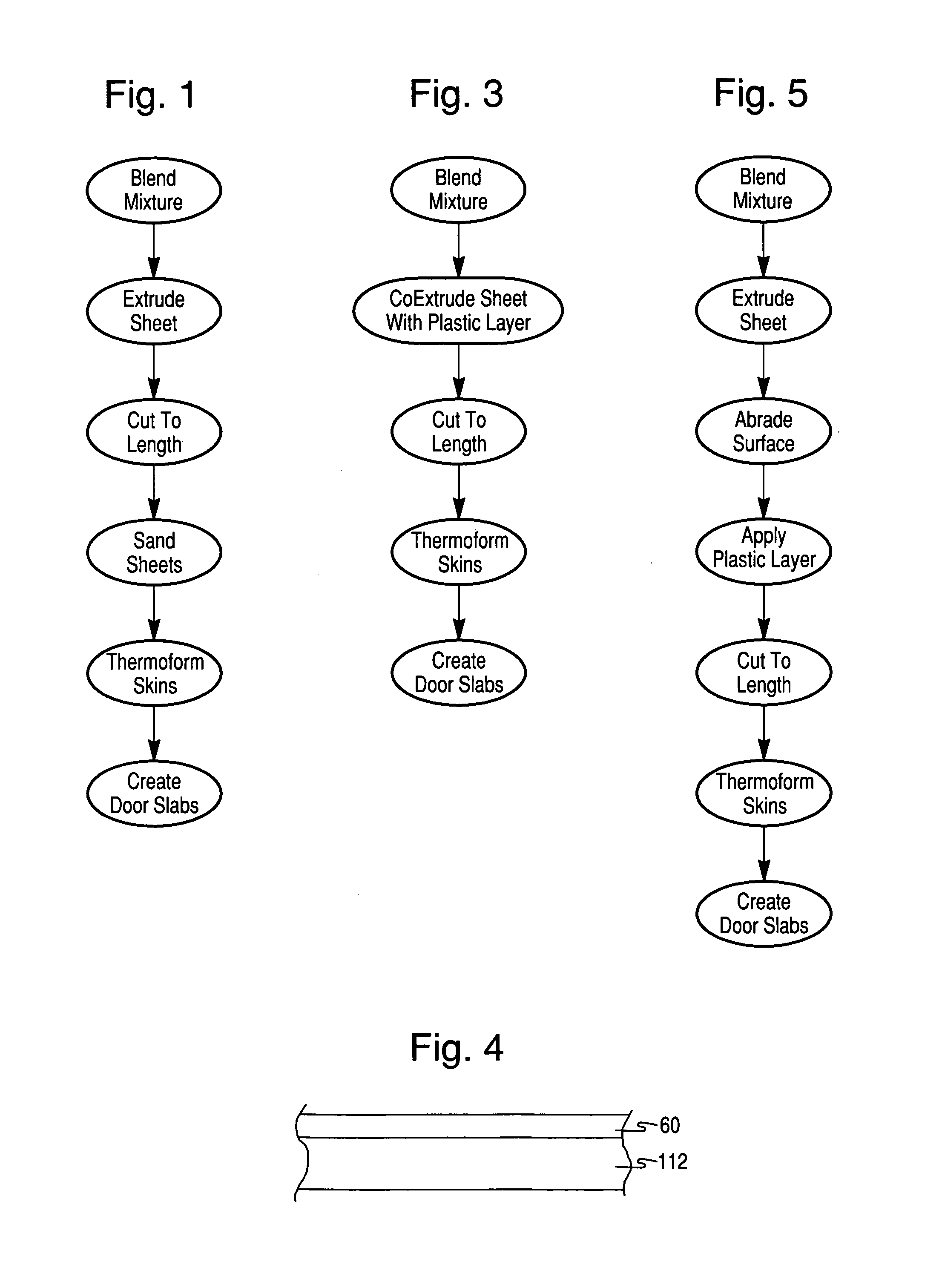

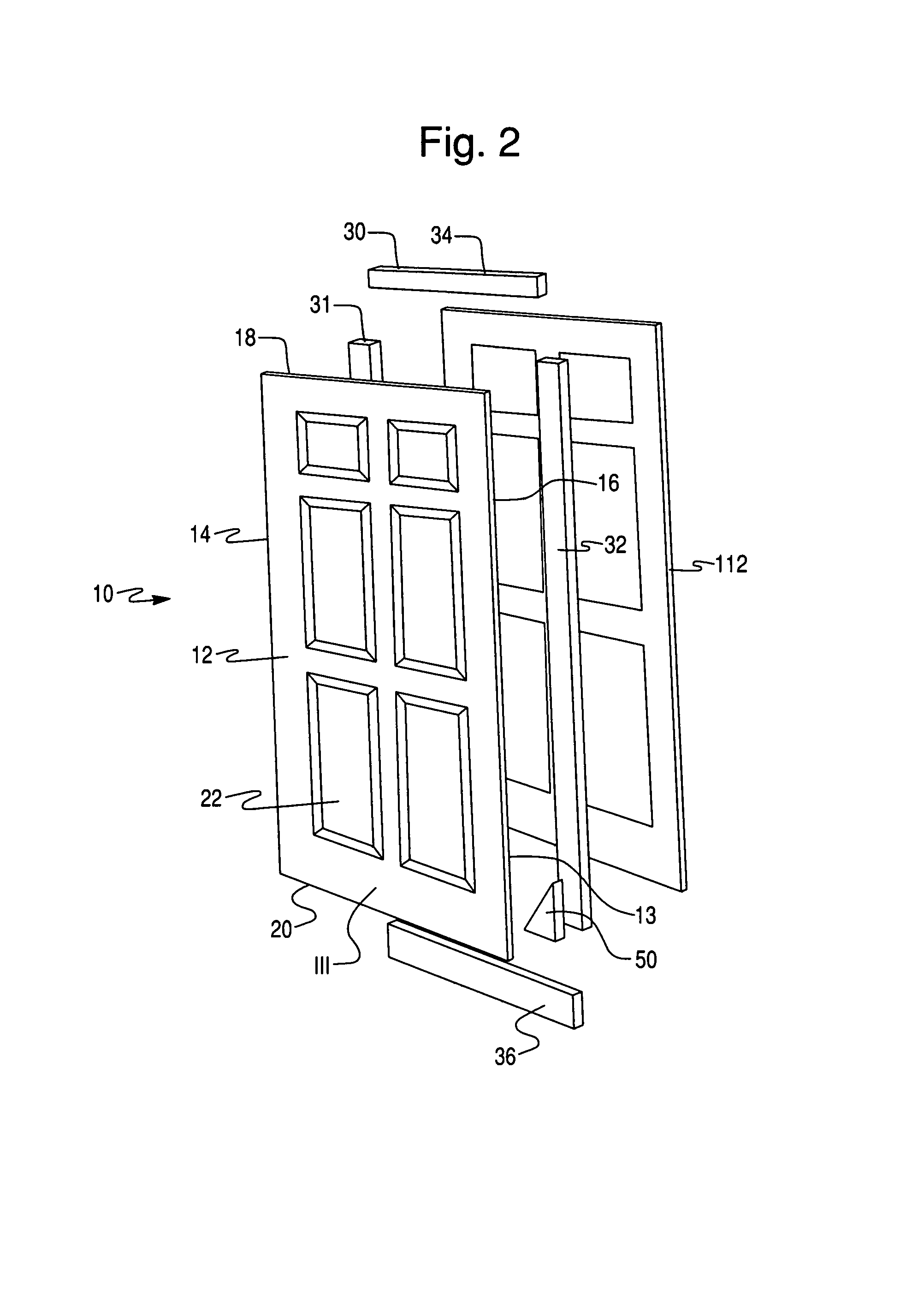

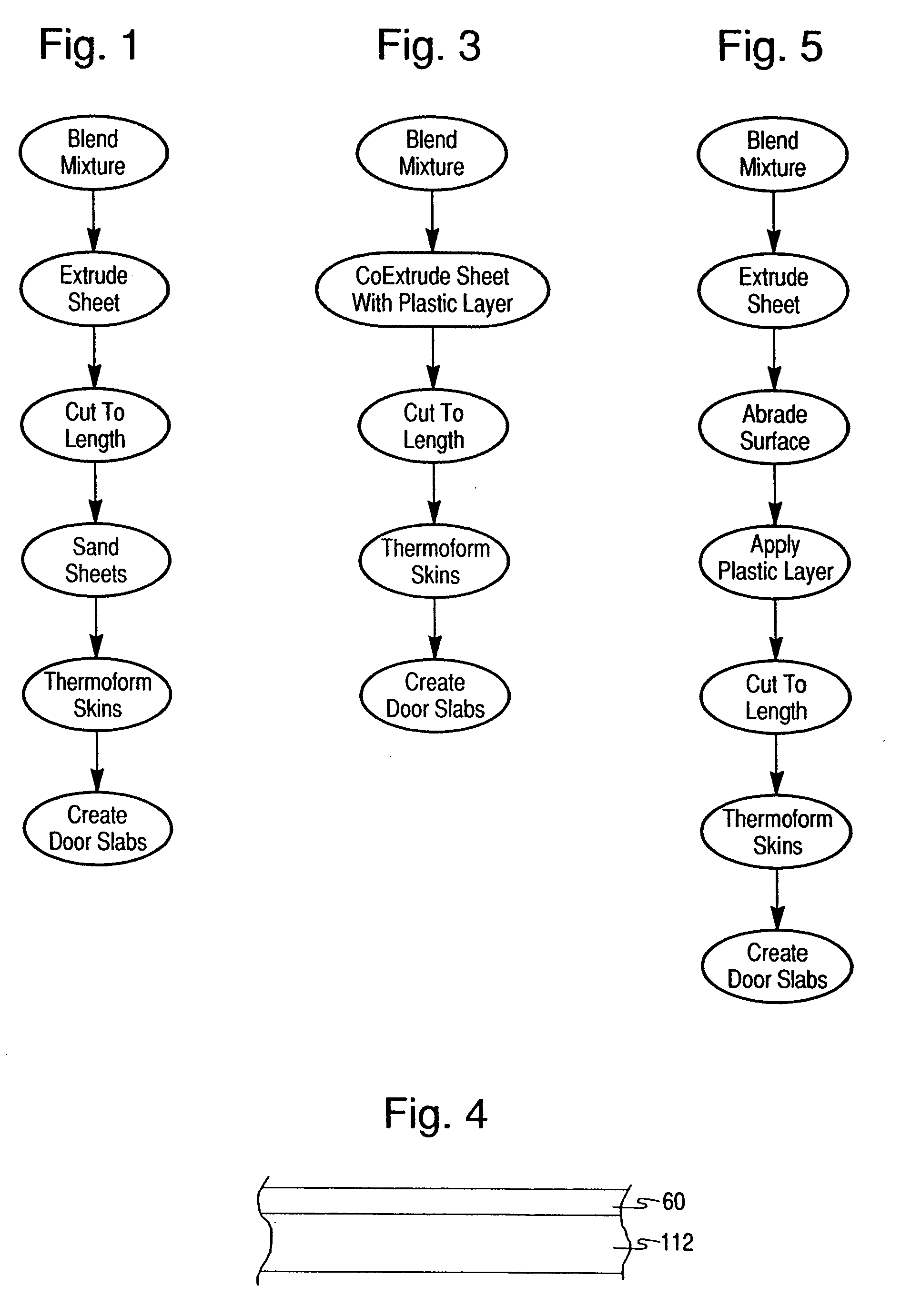

A method of forming a composite door is disclosed. The method comprises: mixing together a thermoplastic polymer with an organic fibrous material in a ratio such that the organic fibrous material constitutes 40 to 60 percent by weight of the mixture; extruding the mixture under heat and pressure to create a thin sheet form; cutting the sheet to a predetermined size; removing material from at least one surface of the sheet to create a homogeneous appearance devoid of obvious fibrous particles; thermoforming the sheet to impart to the at least one surface an exterior three dimensional door surface to create a thin door facing; and assembling two of the thermoformed thin door facings, a peripheral frame and a core material into a door.

Owner:CCB RE HLDG

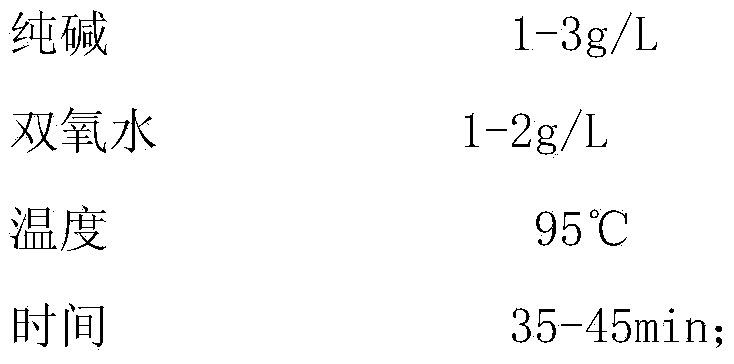

Natural bamboo fiber shirt fabric and manufacture method thereof

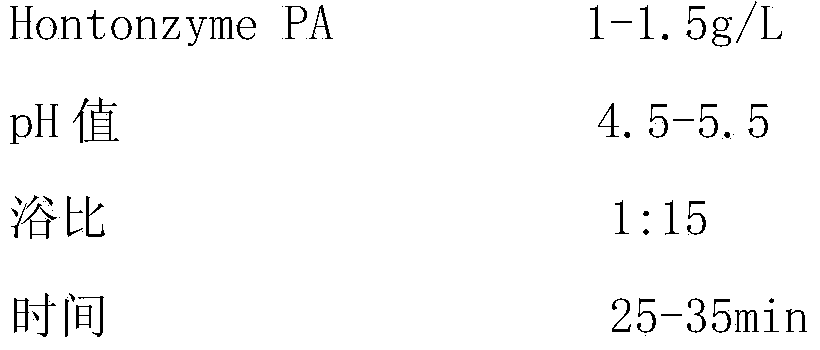

The invention provides natural bamboo fiber shirt fabric which has silky gloss, good feel and drapability, and is rich in graceful feeling, antibiosis, moisture-adsorption and ventilating. Warps and wefts of the fabric are both natural fiber / bamboo viscose blended yarns, the blending ratio of the warps and the wefts is 1:1, the warp density is 512 / 10cm, and the weft density is 338.5 / 10cm. A manufacture method of the natural bamboo fiber shirt fabric comprises the following steps: a, blending: opening picking, carding cotton, drawing out, roving and spun yarn; b, drum yarn dying: tube loosening, pretreatment, dying, dehydration and drying, wherein the pretreatment comprises bleaching and enzyme treatment; during bleaching: soda ash is 1-3g / L, hydrogen peroxide is 1-2g / L, the temperature is 95 DEG C, the time is 35-45min; and during the enzyme treatment, HontonezymePA is 1-1.5g / L, pH value is 4.5-5.5, the bath ratio is 1:15, and the time is 25-35min; and during dying, the drum yarn density is 0.33-0.35g / cm<3>, and MegafixB type reactive dying is adopted; c, weaving: winding, warp pulp connection, drawing in or warp tying and weaving; and d, after treatment: singeing, desizing, sizing and preshrinking.

Owner:JIANGSU YDTEX GRP LTD

Acid bath dyeing method of chinlon 56 fiber fabric

ActiveCN105970688ALower glass transition temperatureReduce the temperatureDyeing processDisperse dyeVitrification

The invention discloses an acid bath dyeing method of chinlon 56 fiber fabric. The method includes the following step that the chinlon 56 fiber fabric is dyed by means of a weak-acidity acidic dye, a 1:2 metal complex dye, a reactive dye or a dispersed dye, wherein the chinlon 56 fiber fabric is chinlon 56 filament or chinlon 56 short fiber fabric. The dyeing method of chinlon fiber has the advantages that vitrification temperature of chinlon 56 is 46 DEG C, vitrification temperature of chinlon 66 is 52 DEG C, and chinlon 56 is lower in vitrification temperature, higher in hygroscopicity and capable of being easily dyed. Normal dyeing temperature of chinlon 66 is 40-98 DEG C, and dyeing temperature of the chinlon 56 fiber fabric can be reduced to 40-80 DEG C. It is indicated from the dyeing process that temperature of chinlon 56 during dyeing is lower, so that more energy is saved; besides, the temperature of chinlon 56 during dyeing is lower, so damage to the fabric is smaller.

Owner:优纤科技(丹东)有限公司 +3

Polyester fully-drawn slub yarn and preparation method thereof

InactiveCN102828278AGood orientationEnsure productivityNew-spun product collectionFilament forming substance formingPolyesterBreaking strength

The invention discloses a polyester fully-drawn slub yarn and a preparation method thereof. On the basis of not changing the conventional FDY (fully-drawn yarn) production device, the polyester fully-drawn slub yarn is produced by using a one-step method implemented through adding a polymethyl methacrylate additive (mass percentage: 0.5-3.0%) into a polyester chip and then carrying out drawing on an obtained mixture at a drawing speed of 4600-5000m / min. The radial fineness ratio of the obtained slub yarn is 1.20-1.60 / l, the length of a thick section of the slub yarn is 15-40mm, and the slub density is 5-15 / m; and the breaking strength is 2.70-3.40 cN / dtex, and the breaking elongation is 40-80%. The polyester fully-drawn slub yarn prepared by using the technical scheme of the invention has the characteristics of high output, low cost, good quality, stable performance, high added values of products, and obvious price-performance advantages, and achieves the purposes of energy conservation, emission reduction, environmental protection, clean production and benefit incensement.

Owner:SUZHOU UNIV

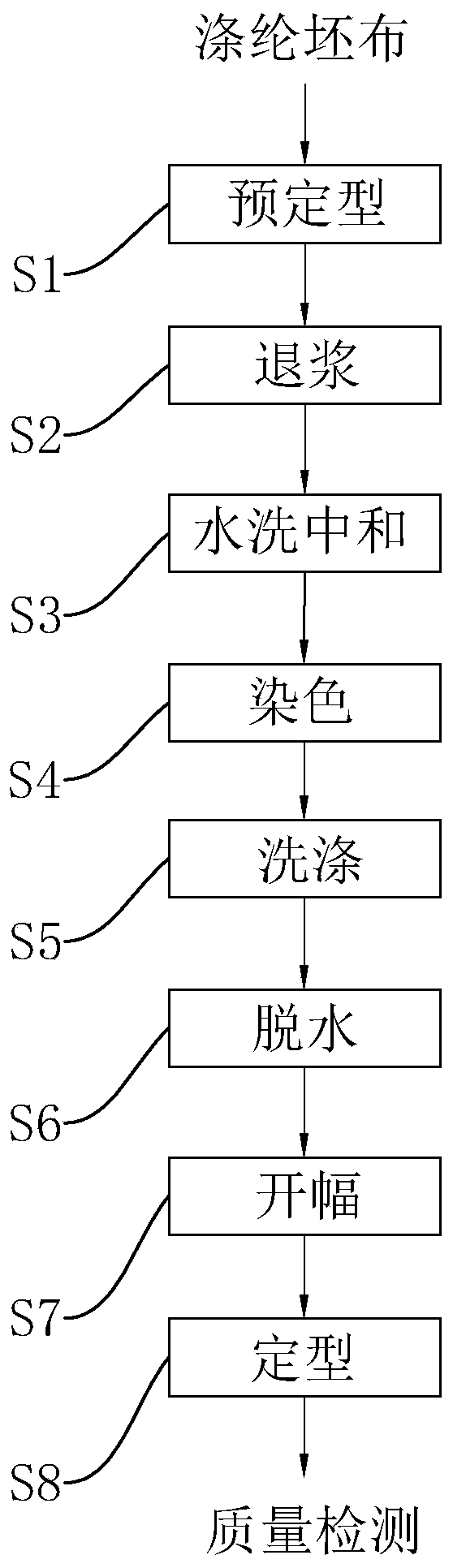

Dyeing process for polyester fabric

The invention relates to the technical field of textile processing, and discloses a dyeing process for polyester fabric. The unrolled polyester fabric is processed by the steps of S1, presetting greycloth; S2, desizing the grey cloth after presetting; S3, rinsing to neutralize the desized grey cloth; S4, dyeing the grey cloth which is neutralized by rinsing, wherein dyestuff comprises chemical components: by weight, 20-30 parts of disperse dyes, 18-26 parts of wetting agents, 70-90 parts of high temperature levelling agents, 10-15 parts of ethylic acid, 12-16 parts of aminopropyl laurylglutamine, 2-6 parts of trisodium sulfosuccinate and 250-300 parts of water, and dyeing temperature is controlled within 100-130 DEG C; S5, washing; S6, dewatering; S7, scutching; S8, sizing to obtain the dyed polyester fabric. With application of aminopropyl laurylglutamine and trisodium sulfosuccinate, the dye-uptake rate of the polyester fabric is increased.

Owner:HANGZHOU XINSHENG PRINTING & DYEING

Novel polylactic acid fiber fabric

InactiveCN105239204AGood hygroscopicityEasy to stainBiochemical fibre treatmentWoven fabricsMicroorganismPolymer science

The invention discloses a novel easy-dyeing modified polylactic acid fiber with good hygroscopicity. The fiber is prepared by the following method: adding a variety of raw materials into a high speed mixing machine, and conducting high speed dispersion to obtain a modified polylactic acid mixture; conducting melt blending and extrusion on the uniformly mixed modified poly lactic acid mixture by a double screw extruder to prepare modified polylactic acid masterbatch, and conducting vacuum drying; adding the modified polylactic acid functional masterbatch slice and vacuum drying ordinary polylactic acid slice into a high-speed mixer, and evenly mixing; spinning the mixture in a melt spinning machine by a circular spinneret orifice to obtain modified polylactic acid fiber; then conducting microorganism modification and strictly controlling the fermentation parameters; and spraying water to wet he prepared polylactic acid fiber water, evenly spraying a composite bacteria liquid, fermenting under constant temperature of 38.5 DEG C for 72-79 h.

Owner:HUZHOU HAOMING TEXTILE CO LTD

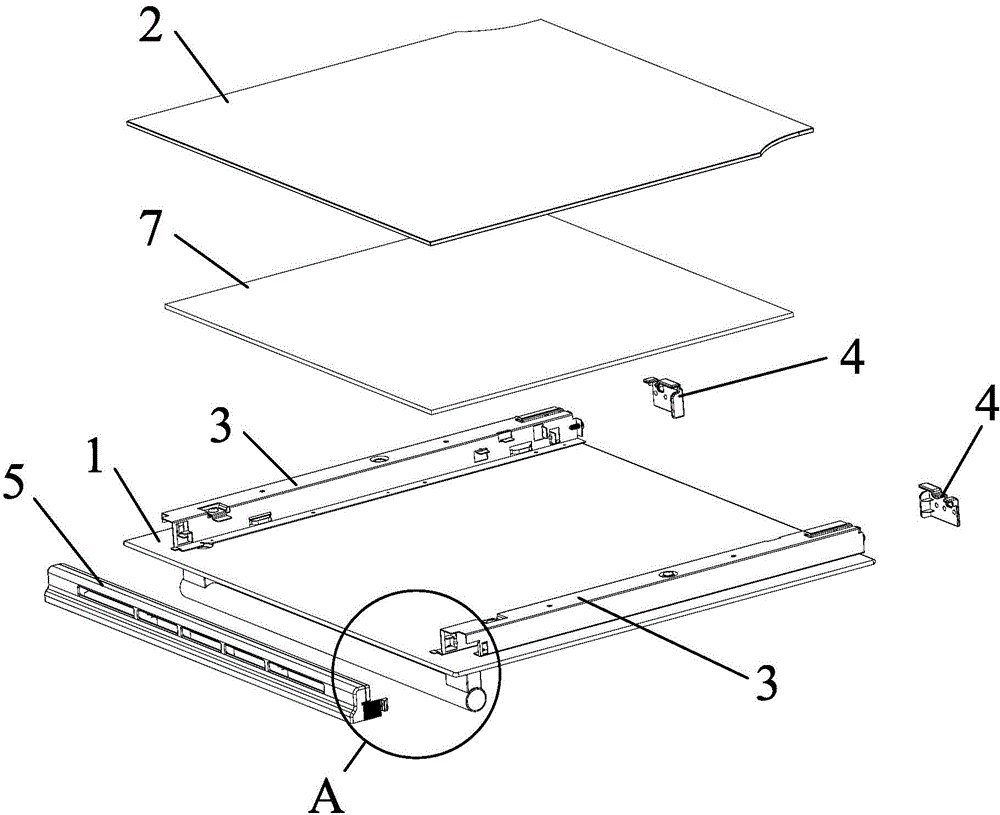

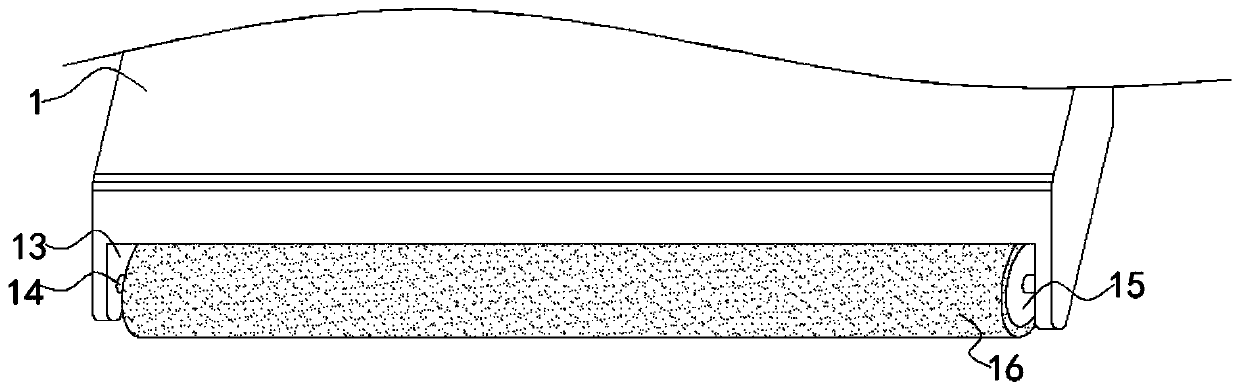

Oven firedoor and oven

InactiveCN105317340ASimple structureEasy to disassembleDoors/windowsRoasters/grillsEngineeringMechanical engineering

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Device for surface treatment of eggs

The invention discloses a device for surface treatment of eggs. The device includes a shell provided with a conveying channel penetrating two sides of the shell; a support; a conveying belt mounted on the support and whose middle part disposed on the inner side of the shell; a gear teeth mounted on the support and arranged along the length direction of the conveying belt; a plurality of clamping units arranged in the length direction of the conveying belt. Each clamping unit includes two clamp units arranged symmetrically. Each clamp unit includes a driven gear, a sleeve pipe, a connection rod, a spring and a clamp sheet, wherein the driven gear meshes with the gear teeth; the sleeve pipe is mounted on the driven gear; the first end of the sleeve pipe is in rotary connection with the conveying belt; the second end of the sleeve pipe extends in the direction away from the conveying belt; the length direction of the sleeve pipe is perpendicular or inclined to the length direction of the conveying belt; the first end of the connection rod is disposed on the inner side of the sleeve pipe; and the connection rod and the sleeve pipe are in flexible connection. The device provided by the invention is good in egg cleaning effect.

Owner:SUSONG XIANGYUAN POULTRY TRADE

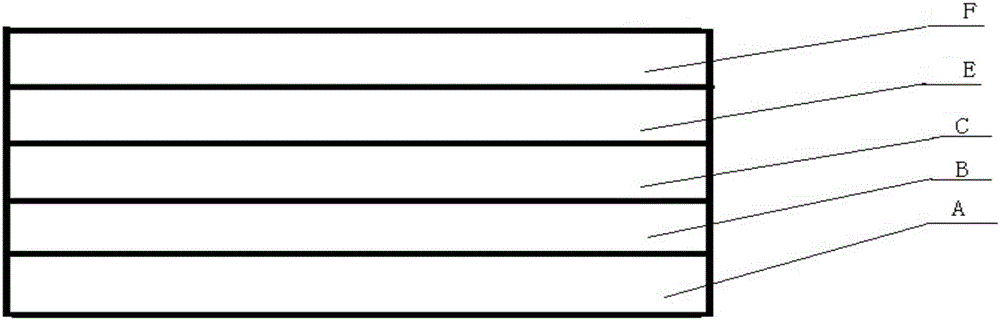

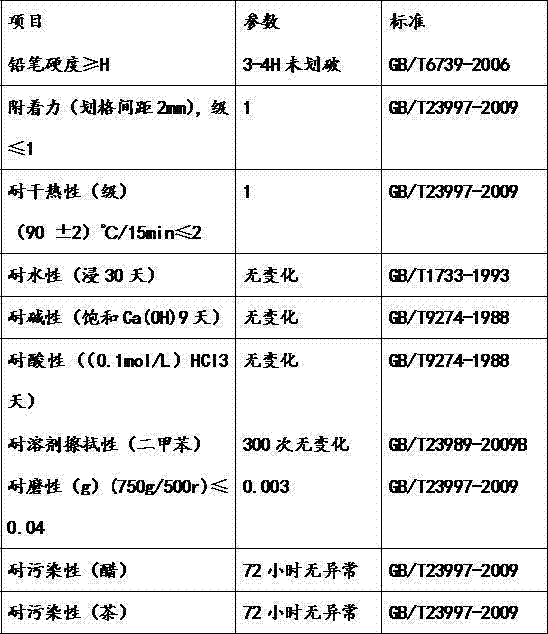

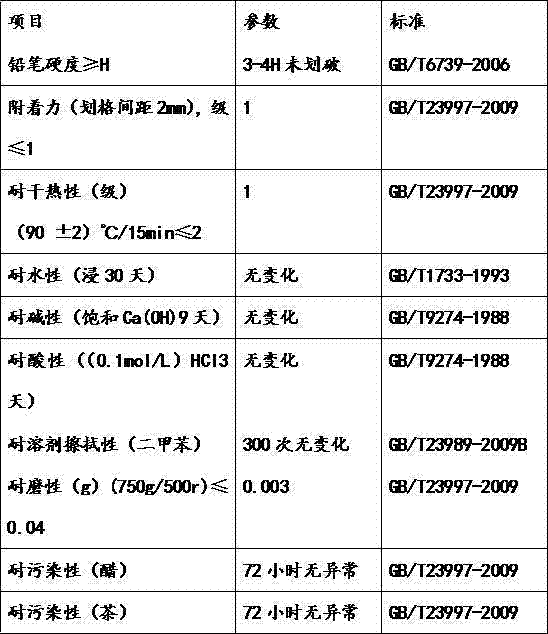

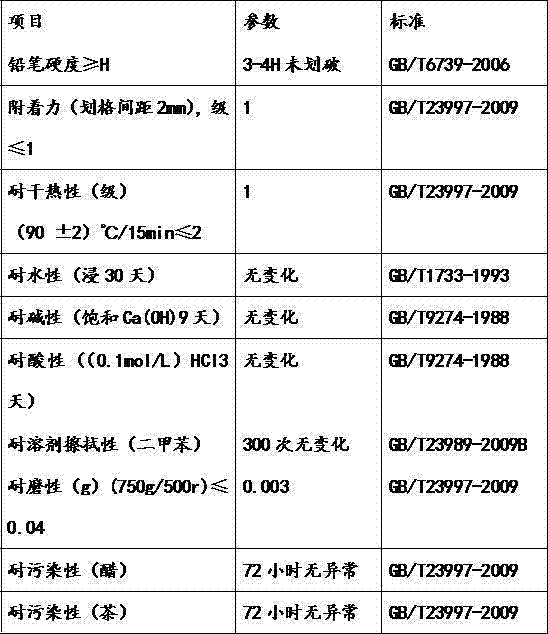

Radiation curable coating decorative board

InactiveCN106013672ALow costRaw materials are easy to getAntifouling/underwater paintsCovering/liningsWater basedHardness

The invention discloses a radiation curable coating decorative board. The radiation curable coating decorative board comprises a decorative board base body A. The surface of the decorative board base body A is coated with a radiation curable color primer layer B and a radiation curable color coating or printing ink layer C in sequence. Preferably, the surface of the radiation curable color coating or printing ink layer C is also coated with a transparent varnish layer D, a water-based inorganic gel layer E and a water-based photocatalyst sterilizing and anti-staining layer F. Compared with the prior art, an oriented strand board or an oriented stalk board or a wood-wool board or a straw board or a bamboo wool board is adopted as the base body of the decorative board, raw materials are easy to get, the cost is low, and the radiation curable coating decorative board has the advantages of being good in wear-resisting property and environmental protection property, rich in color and pattern, strong in three-dimensional sense, high in hardness, resistant to scratches, contamination and bacteria, easy to clean, capable of killing bacteria and the like and can be widely used in the fields such as partition walls, partitions, ceilings, walls, furniture and office table tops.

Owner:ZHUHAI JIAWEILI ENVIRONMENTAL PROTECTION SCI & TECH

Ecological textile auxiliary

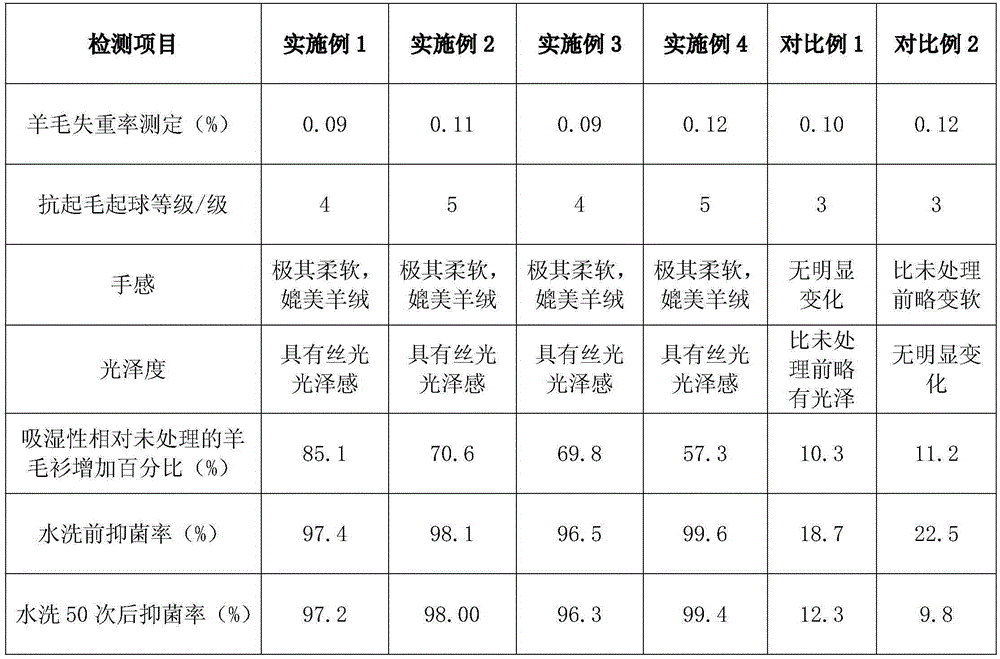

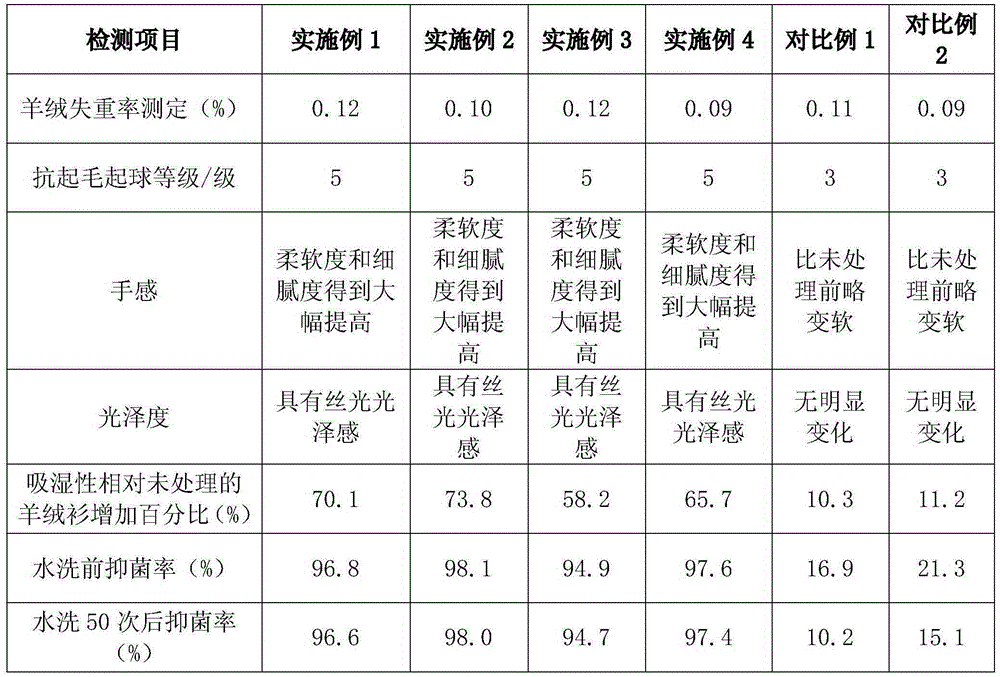

InactiveCN105256590AImprove antibacterial propertiesDelicate feelBiochemical fibre treatmentAnimal fibresEcologyWater soluble

The invention discloses an ecological auxiliary which comprises an agent A and an agent B. According to the agent A, pediococcus acidilactici, bacillus subtilis and candida are prepared into 1-1.5*105 bacterium suspension according to the strain number ratio of 1:0.3:0.5, and the bacterium suspension further contains, by mass, 0.3% of trehalose, 0.2% of stachyose and 0.05% of nanometer titanium dioxide; the agent B is prepared from, by mass, 1.0-1.5% of silk fibroin, 0.6-0.9% of pigskin collagen, 0.2% of water-soluble chitosan and 0.08% of nanometer titanium dioxide. The ecological auxiliary contains the combined living bacterium agents, the natural protein, the natural chitosan and the like, contains no chemical reagent and is easy to use, finished fabric has a good antibacterial effect and resists pilling, hand feeling of the fabric is fine and smooth, the fabric has gloss, mechanical strength is enhanced, the fabric is easy to dye, and the auxiliary has no influence on whiteness.

Owner:长兴千尺度纺织品有限公司

Wood surface protection nano coating and manufacturing technology thereof

ActiveCN104774548APrevent diseaseHigh fullnessAntifouling/underwater paintsPolyurea/polyurethane coatingsManufacturing technologyPolyethylene glycol

The invention discloses a wood surface protection nano coating. The coating comprises, by weight, 25-27 parts of nano silica, 25.5-26.5 parts of n-butyl alcohol, 5.5-6.5 parts of butyl acetate, 3.5-4.5 parts of TEOS, 1.5-2.5 parts of sodium carboxymethylcellulose, 3.5-4.5 parts of silane coupling agents, 15.5-16.5 parts of isocyanate and 15.5-16.5 parts of polyglycol ether. Meanwhile, the invention discloses a technology for preparing the wood surface protection nano coating. The wood surface protection nano coating can be used for surface protection of various sorts of wood for furniture, building wood structures, outdoor wood structures, wood floors and the like. At a normal temperature, the surface of wood can be deeply permeated, a compact and hard inertia protecting film is formed on the surface of the protected wood, various lesion problems of the wood are solved, the fullness, color saturation, texture, permeability and surface hardness of the surface of the wood are improved, and the wood surface protection nano coating further has the advantages of being easy to clean, resistant to contamination, waterproof, resistant to abrasion and the like.

Owner:中基为(重庆)新材料技术研究院有限公司

Archaistic ivory white ceramic censer and preparation process thereof

The invention belongs to the field of ceramic products, and particularly relates to an archaistic ivory white ceramic censer and a preparation process thereof. The archaistic ivory white ceramic censer comprises a censer green body and an archaistic ivory white glaze layer arranged outside the censer green body, and the archaistic ivory white glaze is prepared from strictly proportioned raw ore kaolin, feldspar, plant ash, quartz, clay, limestone powder, nano water and other raw materials. The use of the traditional Dehua kaolin is reduced through the combination of the raw materials; the traditional Dehua kaolin is replaced by the composition; and meanwhile, the effect closest to the antique ivory white ceramic is achieved by adding the plant ash, the ceramic is fine, smooth, compact, mild and light tooth yellow, the antique ivory white ceramic censer is not prone to adhering to oily soot, and therefore the antique ivory white ceramic censer has the performance of being not prone to contamination and easy to clean, and is durable and convenient to use.

Owner:泉州市万虔堂艺术陶瓷有限公司

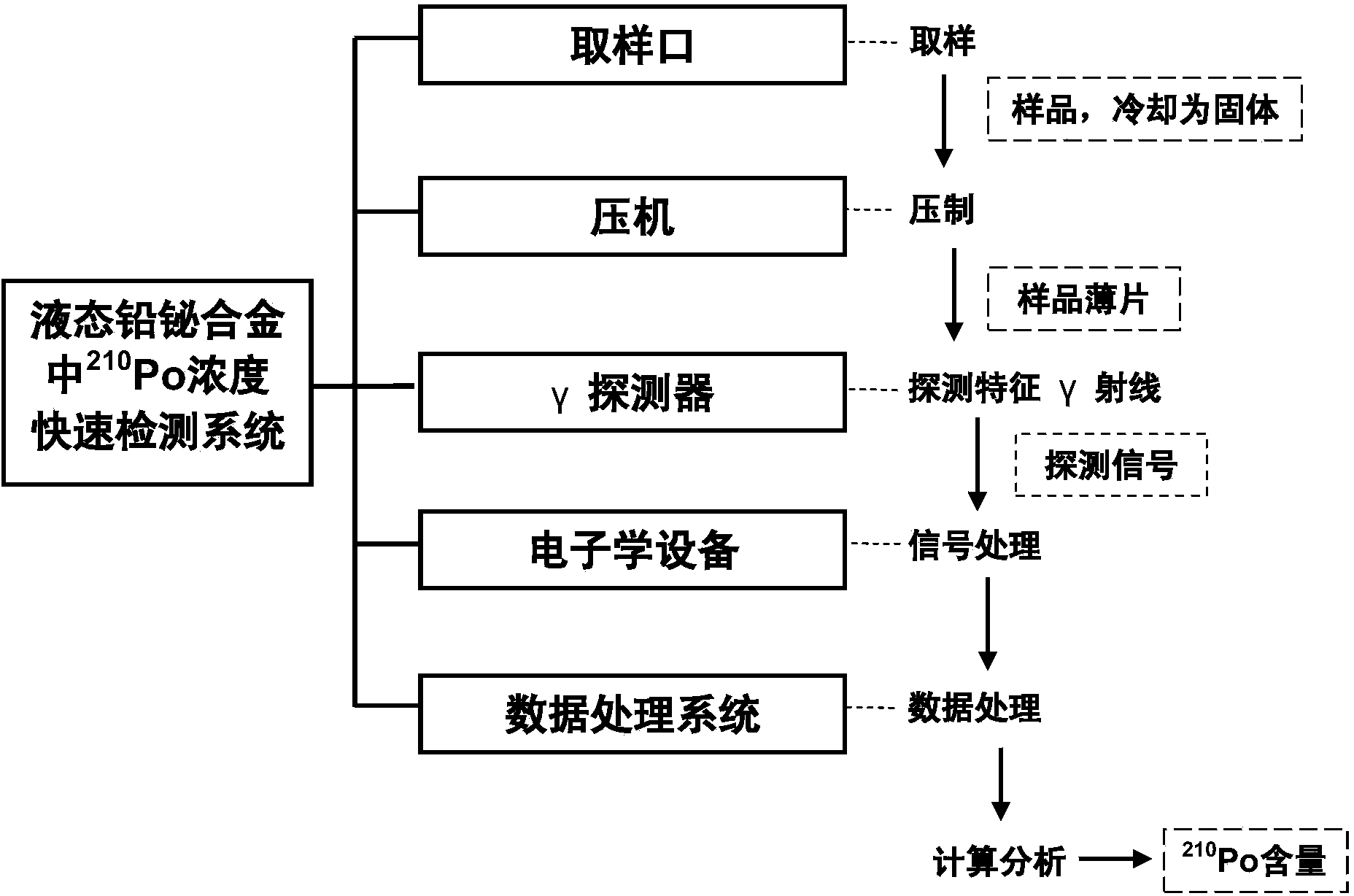

System and method for rapidly detecting concentration of 210Po in molten lead bismuth alloy

ActiveCN104407371AThe principle is simpleAnalysis process is shortX/gamma/cosmic radiation measurmentLead bismuthGamma ray

The invention relates to a system and method for rapidly detecting the concentration of 210Po in a molten lead bismuth alloy. By measuring a characteristic gamma ray generated during 210Po decay, the content of 210Po in the molten lead bismuth alloy is quantitatively analyzed. The system and the method which are simple in principle and high in operability are provided for analyzing and detecting the concentration of 210Po, and the system and the method are applicable to rapid detection on the concentration of 210Po in a coolant of a fast reactor primary coolant circuit taking molten lead bismuth alloy as a coolant.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Fabric printing and dyeing process

InactiveCN104389154AGood uniformitySave printing and dyeing timeFibre treatmentBleaching apparatusDyeingEngineering

The invention discloses a fabric printing and dyeing process. The fabric printing and dyeing process comprises the steps of gray fabric inspection, cylinder matching, sewing, scouring and bleaching, and dyeing. The step of scouring and bleaching comprises the following sub-steps: (1) adding 1.2-1.8 percent owf (On Weight of Fabric) of refining agent, 0.8-1.0 percent owf of a stabilizing agent and 5.0-6.0 percent owf of caustic soda into an overflow dyeing machine, controlling the temperature in the overflow dyeing machine to be 60 DEG C, and scouring for 30 min; (2) heating at the heating speed of 1.5 DEG C per minute, maintaining the temperature when the temperature reaches 80 DEG C, adding 7.0-9.0 percent owf of hydrogen peroxide, and maintaining the temperature for 30 min; (3) heating at the heating speed of 1.5 DEG C per minute until the temperature reaches 95-98 DEG C, and maintaining the temperature for 30 min; (4) cleaning a gray fabric in the overflow dyeing machine by using normal-temperature clean water, so that the step of scouring and bleaching is completed. According to the fabric printing and dyeing process, the gray fabric can be more easily dyed, the dyeing uniformity is higher, the printing and dyeing time is shortened, and the environmental friendliness of the process is good.

Owner:常熟市创裕印染有限公司

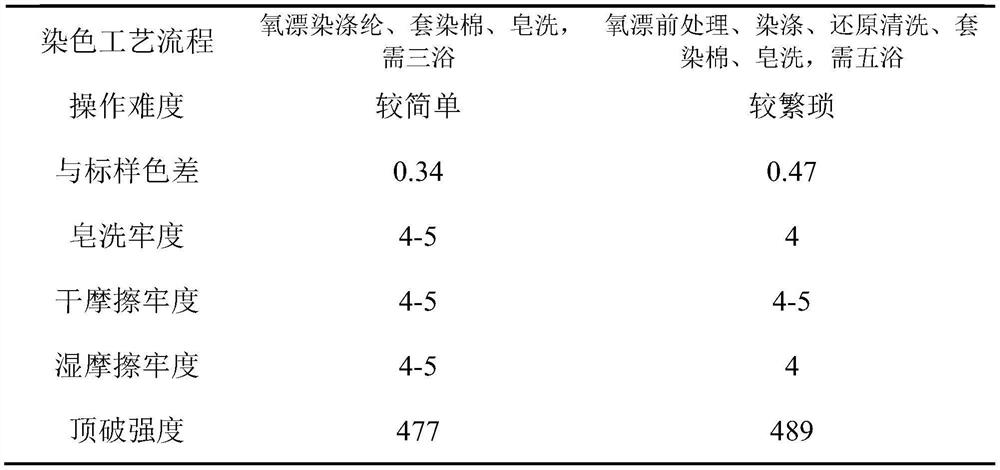

Dyeing and washing one bath process for pretreatment of polyester-cotton fabric

PendingCN111607992AReduce generationReduce consumptionDry-cleaning apparatus for textilesDyeing processDisperse dyePolymer science

The invention provides a dyeing and washing one bath process for pretreatment of polyester-cotton fabric. The dying and washing one bath process for pretreatment of the polyester-cotton fabric includes the following steps that bath dyeing of polyester is carried out, specifically, hydrogen peroxide and an alkaline levelling agent are added into polyester fabric in sequence, disperse dyes are usedfor dyeing, and the bath-dyed polyester is obtained; over dyeing of cotton is carried out, specifically, reactive dyes and a sodium sulfate solution are added in cotton fabric in sequence, the sodiumsulfate solution is used for dyeing, and the over-dyed cotton is obtained; one bath soaping is carried out, specifically, RCLN is added to the bath-dyed polyester and the over-dyed cotton for soaping,and the pretreated polyester-cotton fabric is obtained. According to the dyeing and washing one bath process for pretreatment of the polyester-cotton fabric, the specific alkaline disperse dyes are selected, meanwhile, auxiliaries are used for carrying out oxygen bleaching, dyeing and washing one bath process treatment on the polyester-cotton knitted fabric, the process and technology are simplified and shortened, the production efficiency is improved, the quality is guaranteed, and the effect of saving energy and reducing emission are achieved.

Owner:SHANGHAI JIALE

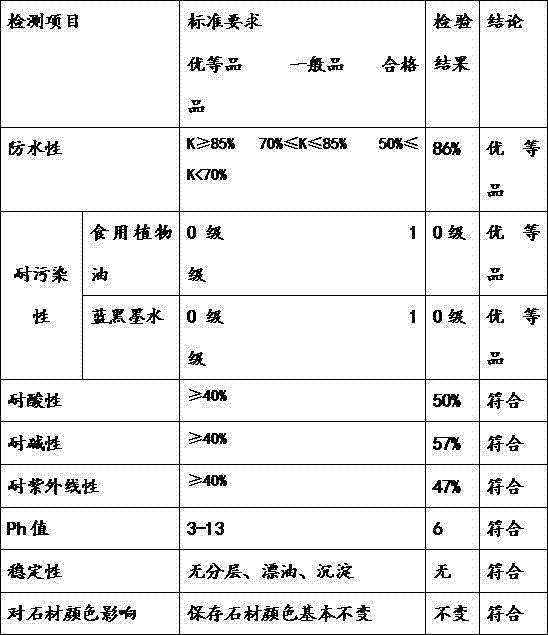

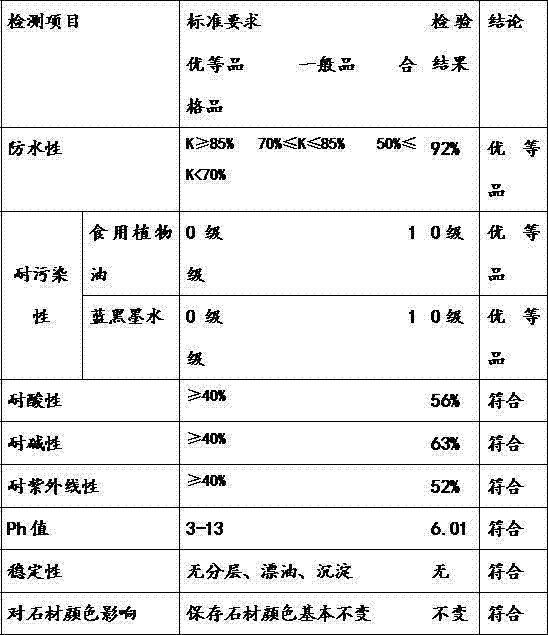

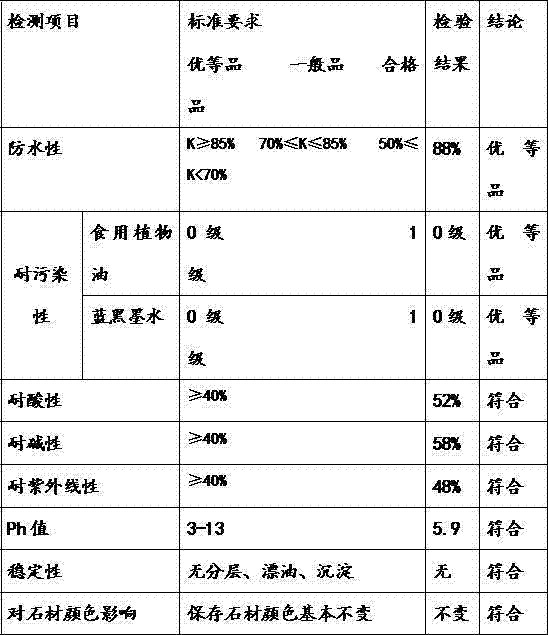

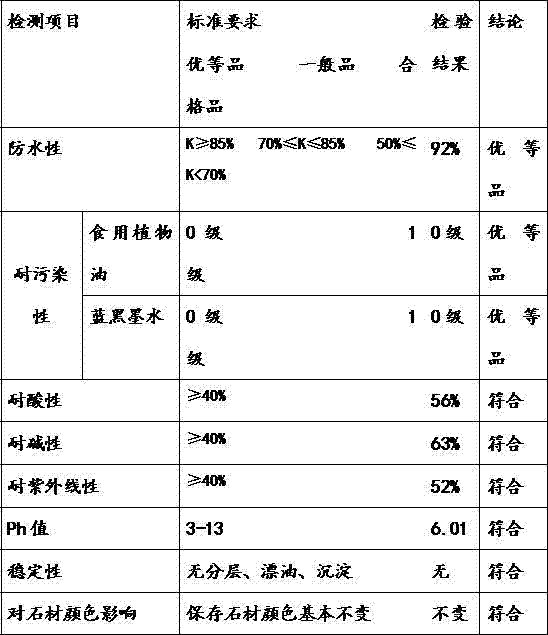

Stone surface protection nano coating and preparing process thereof

ActiveCN104761939APrevent diseaseHigh fullnessAntifouling/underwater paintsPaints with biocidesDiethylene glycol monobutyl etherSodium sulfate

The invention discloses a stone surface protection nano coating. The coating comprises, by weight, 24-26 parts of nano silica, 24-26 parts of butanol, 4.5-5.5 parts of butyl acetate, 3.5-4.5 parts of ethyl orthosilicate, 2.5-3.5 parts of ethyl carbamate, 1.5-2.5 parts of methyl methacrylate, 14.5-15.5 parts of acrylic acid, 5.5-6.5 parts of butyl acrylate, 6.5-7.5 parts of hydroxyethyl acrylate, 4.5-5.5 parts of lauryl sodium sulfate and 3.5-4.5 parts of diethylene glycol monobutyl ether. The invention further discloses a process for making the stone surface protection nano coating. The coating is capable of being applied to surface protection of various stone products such as building internal and external wall stones, stone floors, stone guardrails and stone table facets; under the normal temperature, the coating can penetrate into the surface of a stone deeply, a dense, transparent and hard protection film is formed on the surface of the stone, the problem of various diseases of stones is prevented, the fullness, color saturation, texture, permeability and surface hardness of the stones are improved, and the coating is easy to clean and resistant to stain.

Owner:CHONGQING XINGYU POLYMER PAINT

Reactive dyeing method for pearl viscose fibers

The invention provides a reactive dyeing method for pearl viscose fibers. The reactive dyeing method mainly comprises the following steps of: dyeing, wherein reactive dyes, sodium carbonate and sodium sulfate are added in water to form dye liquor, pearl viscose fiber fabric is put into the dye liquor after the dye liquor is heated to be at a temperature ranging from 50 DEG C to 60 DEG C, the liquor ratio equals to (25-30):1, the pH of the dye liquor equals to 6 to 7.5, and then the dye liquor is heated continually to reach a temperature ranging from 70 DEG C to 100 DEG C and is kept at the temperature for 80 minutes to 100 minutes, thereby dyeing the fabric; washing the dyed fabric till the fabric is neutral; and drying the fabric. According to the dyeing method, the composition and component proportion of the dye liquor are optimized, the parameters of the dyeing process are adjusted, the dyeing is easy, and the dye-uptake and color fastness of the pearl viscose fibers are improved.

Owner:TAICANG RONGWEN SYNTHETIC FIBER

Biological modification process of lactic acid fibers with good spinnability

ActiveCN105256401AGood hygroscopicityEasy to stainBiochemical fibre treatmentFibre typesBiologyFermentation

The invention discloses a biological modification method of lactic acid fibers with good spinnabillity. The method comprises the following steps: charging various raw materials in to a high-speed mixer, and dispersing the raw materials at a high speed to obtain a modified polylactic acid mixture; melt blending and extruding the uniformly-mixed modified polylactic acid mixture by virtue of a dual-screw extruder to obtain modified polylactic acid master batch, and vacuum drying; placing the modified polylactic acid master batch and vacuum dried ordinary polylactic acid slices into a high-speed mixer, uniformly mixing, spinning the mixture on a melt spinning machine by virtue of a circular spinning hole to obtain the modified polylactic acid fibers, then carrying out the microorganism modification, and strictly controlling fermentation parameters. Different from the ordinary constant-temperature fermentation, by adopting the instantaneous heat treatment, a purpose of shortening the fermentation time and obtaining an unexpected modification effect can be achieved.

Owner:浙江逸蓓新材料科技有限公司

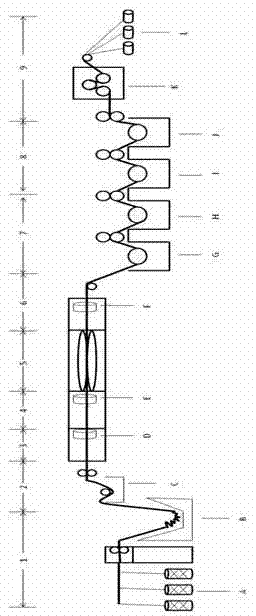

Laser engraving and printing process as well as equipment for implementing laser engraving and printing process

PendingCN109514110ANot easy to fadeRich color patternsLaser beam welding apparatusLaser engravingSlurry

The invention provides a laser engraving and printing process as well as equipment for implementing the laser engraving and printing process, and relates the field of printing. The laser engraving andprinting process comprises the following steps: S1, selecting a substrate; S2, analyzing the pore structure of the substrate; S3, manufacturing a screen plate for printing through color separation; S4, engraving a pattern by using a laser; S5, carrying out printing processing; and S6, carrying out paint spraying, polishing and grinding. The laser engraving and printing process provided by the invention has the beneficial effects that through the analysis of the structure of the substrate, the laser micro-engraving treatment on the surface of a to-be-processed product, and the printing in a micropore formed by laser engraving, slurry can penetrate into the substrate according to the set pattern and the color fading possibility of the pattern can be lowered; through the design, the continuous production can be achieved; and the color pattern of the printing product can be richly changed. The laser engraving and printing equipment comprises a laser engraving device, a printing device anda drying device which are connected in sequence, wherein the drying device comprises a multi-stage drying device and a total drying device; and a stable chemical bond is formed between the slurry andthe substrate, and prevented from falling off easily during use.

Owner:JIANGMEN POLYTECHNIC

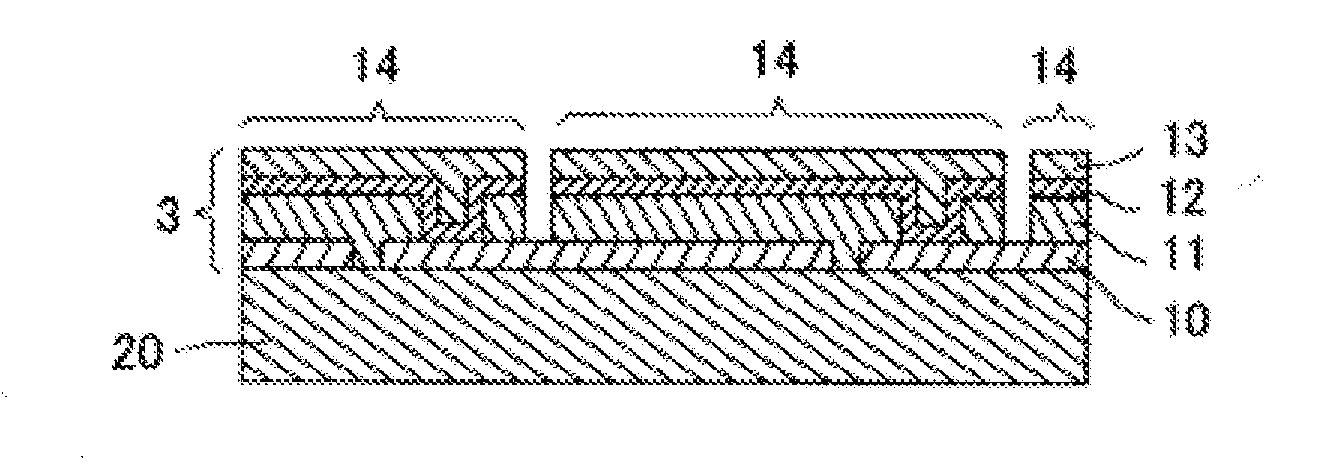

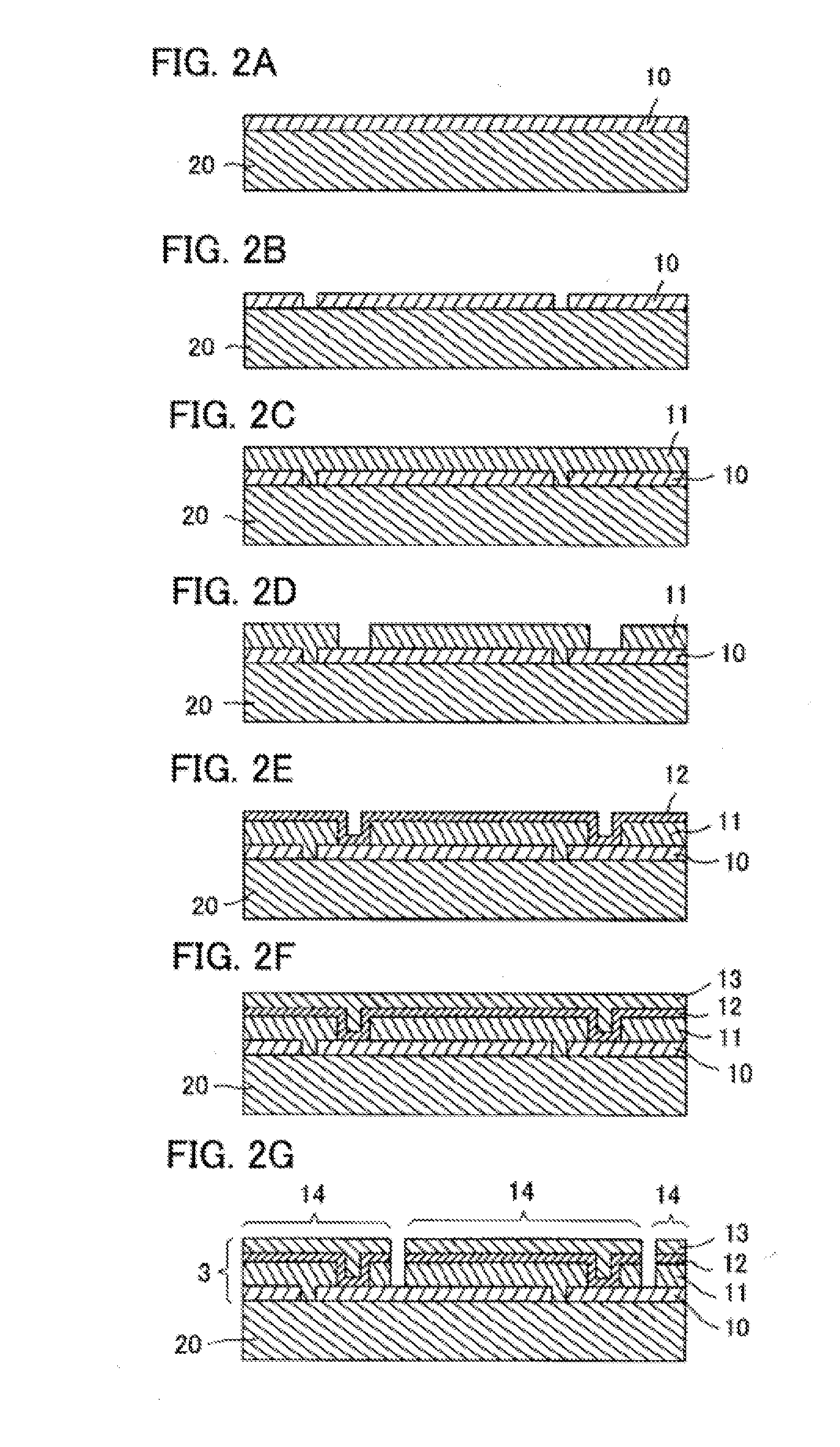

Solar cell module and method for producing solar cell module

InactiveUS20160141432A1Good anti-glare effectImprove antifouling performancePV power plantsAbrasion apparatusSteep slopeMicrometer

A solar cell module with an anti-glare property, capable of exhibiting a high antifouling property. A surface of a plate body made of glass in the module is roughened, and an antireflection film is laminated thereon. A change point at which the slope of the contour line of the surface changes steeply exists on a cross-section cutting through the plate body in the thickness direction. With the change point as a boundary, straight lines obtained by pseudo-leveling of the contour lines existing within 0.7 micrometer on one side and 0.7 micrometer on another side, are a one-side pseudo-straight line and an other-side pseudo-straight line, respectively, a steep slope portion in which an angle formed by the pseudo-straight lines is 135 degrees or less, and a total number of less than 5 large cracks having an opening width of 0.2 micrometer or more are distributed per 58-micrometer compartment range.

Owner:KANEKA CORP

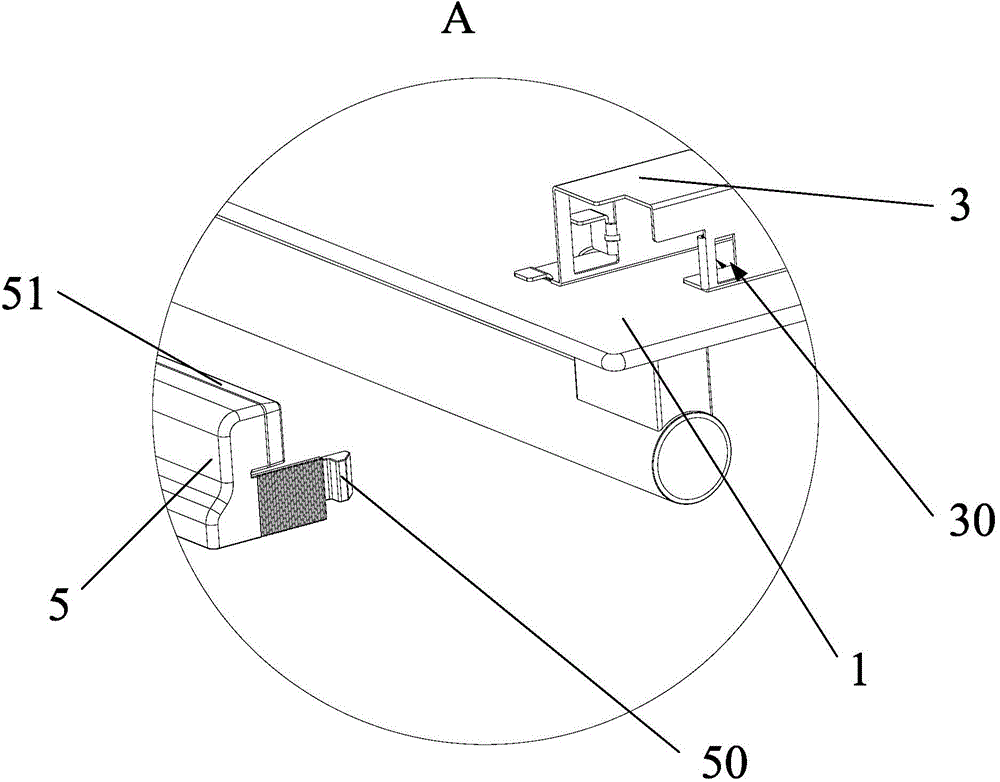

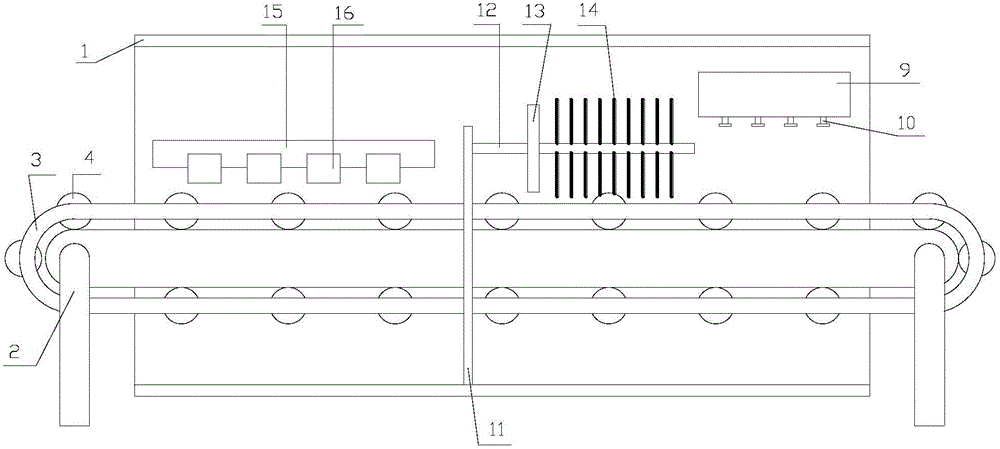

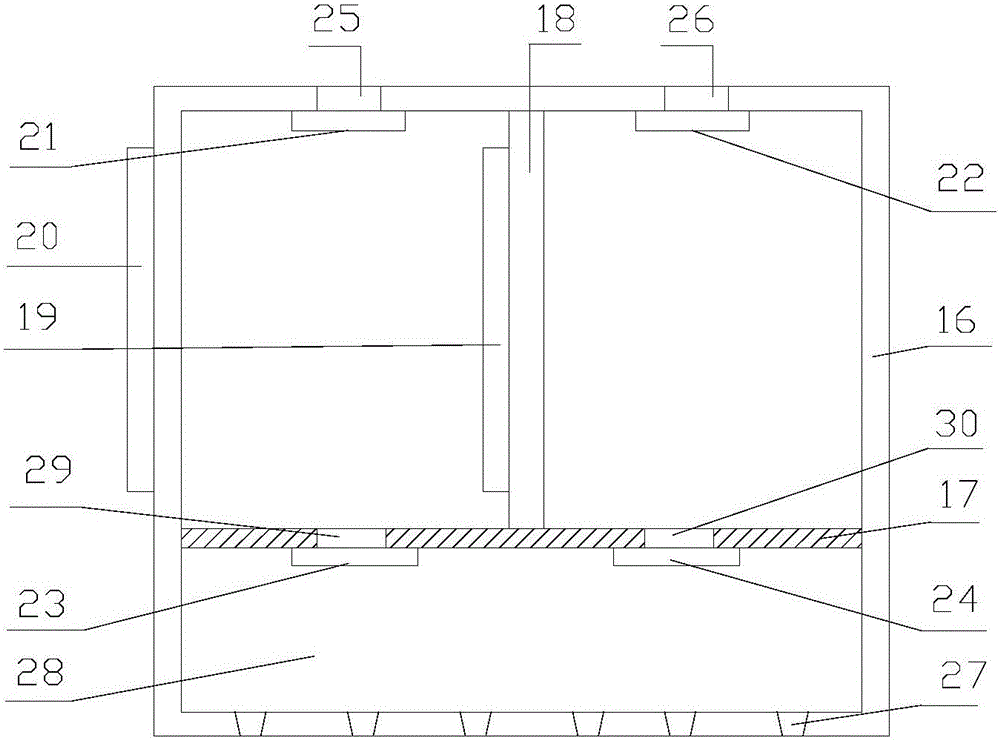

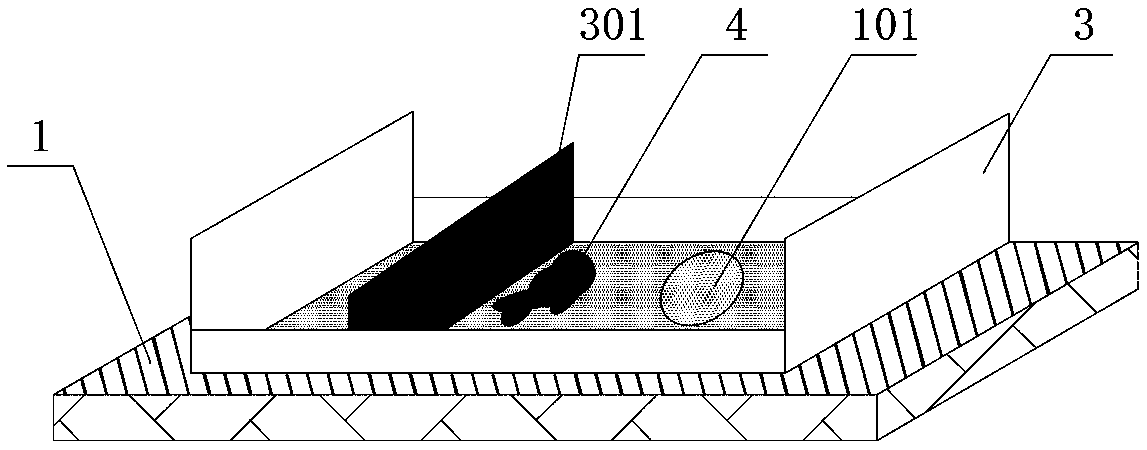

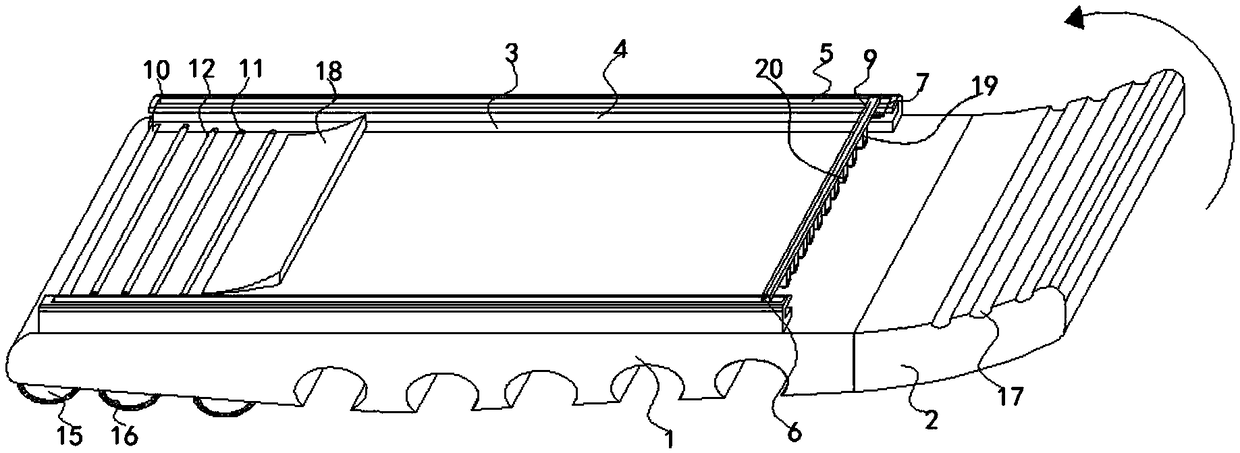

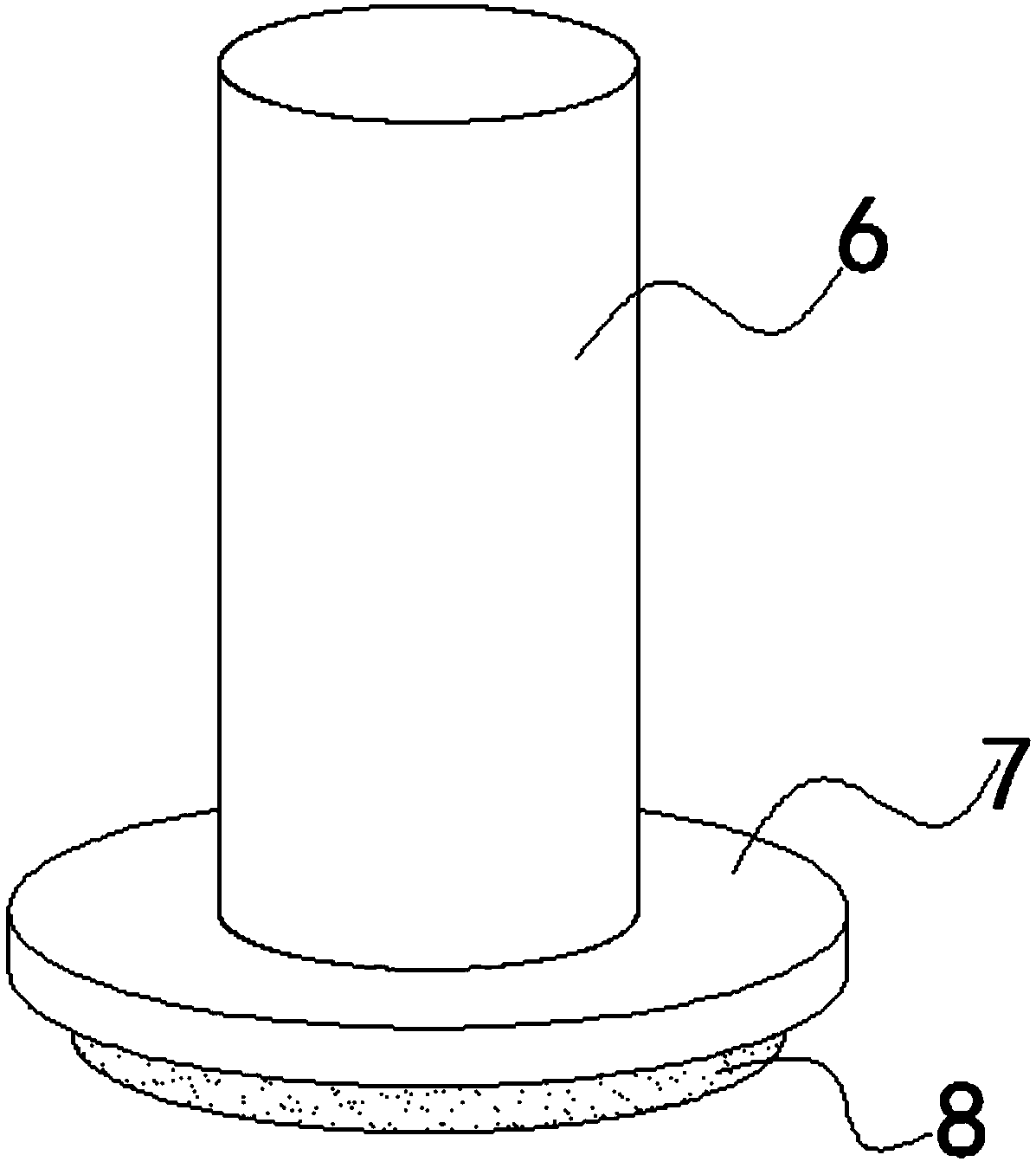

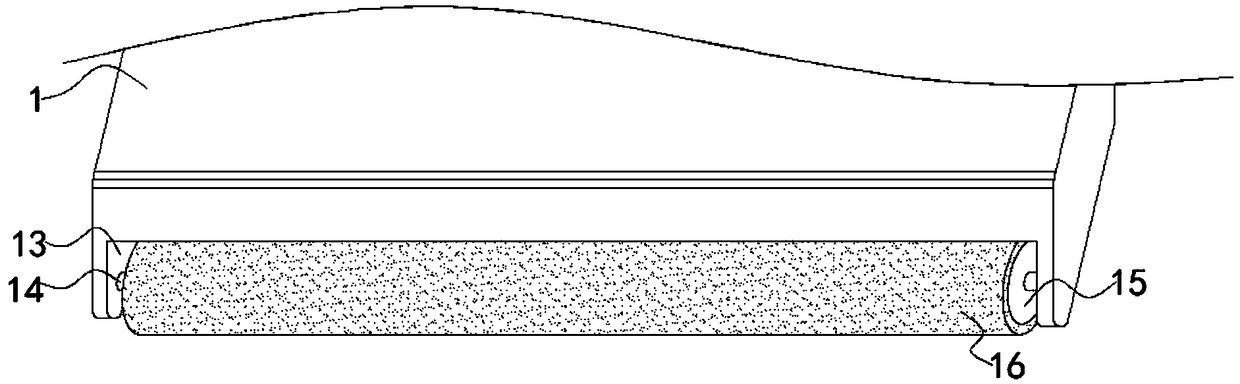

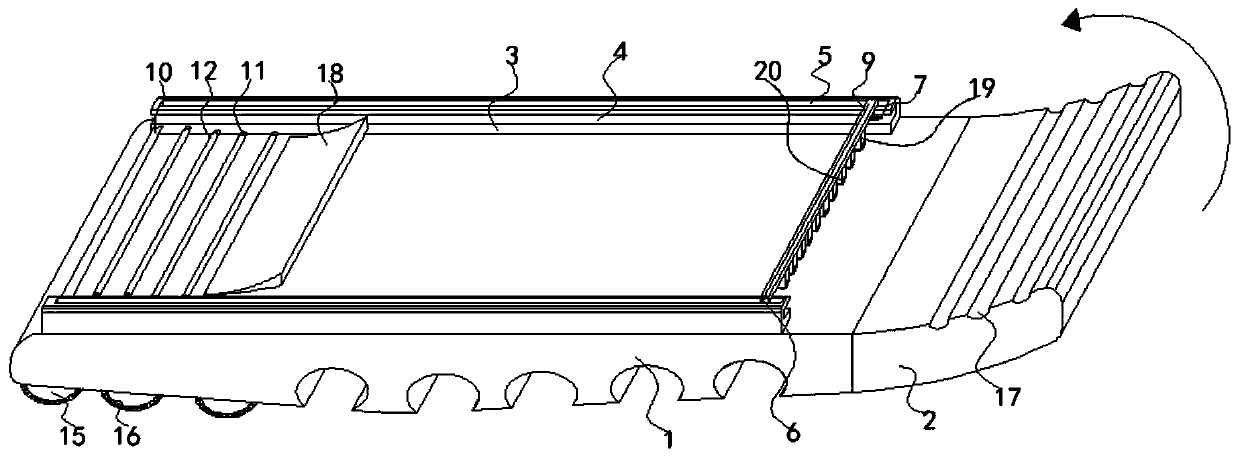

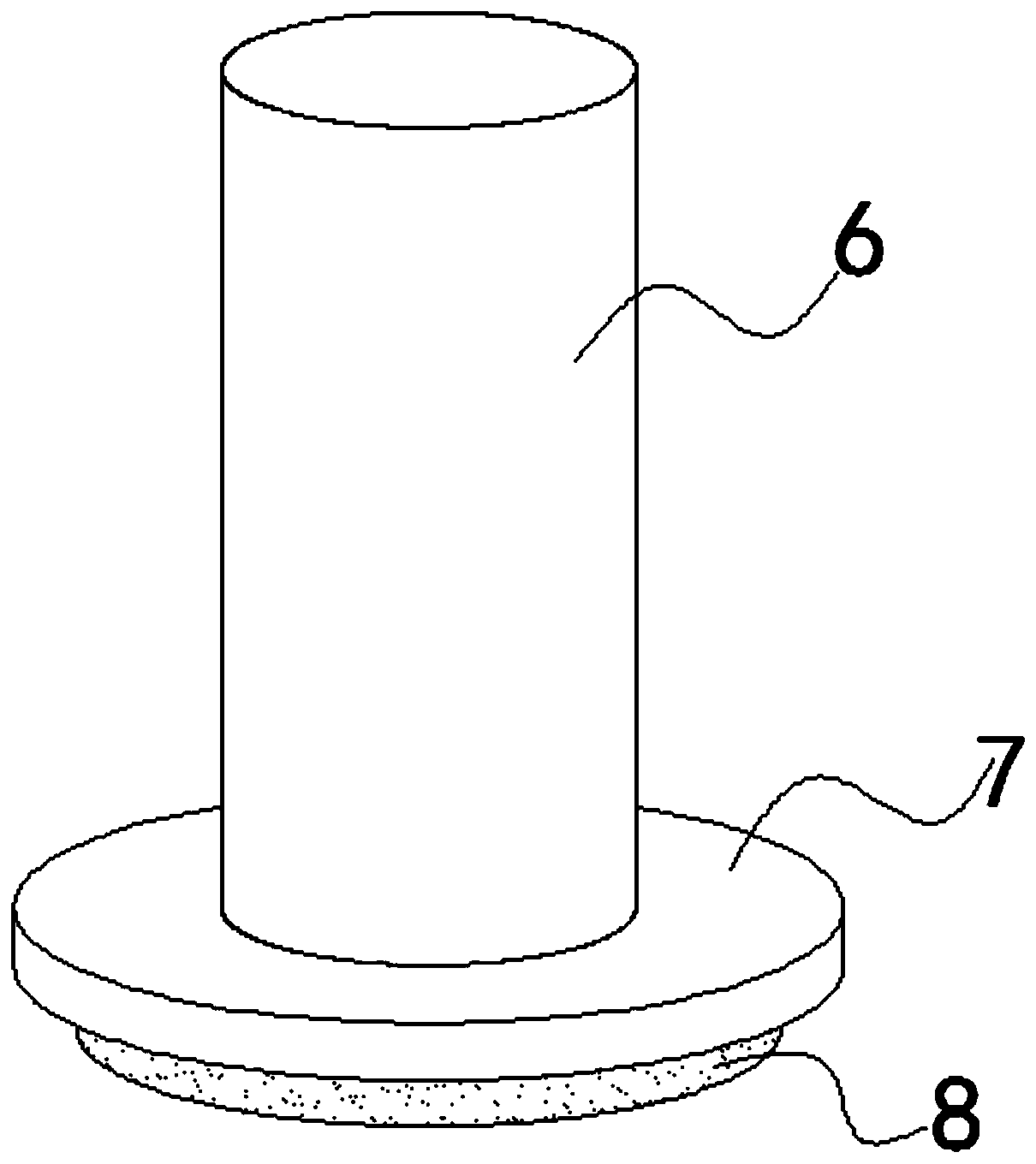

Simple mobile phone membrane sticking device

ActiveCN109229616ASolve cleanupSolve the problem that the film is inconvenient to carry out at the same timeCleaning using toolsPackaging protectionEngineeringMechanical engineering

The invention relates to the technical field of mobile phone membrane sticking devices, in particular to a simple mobile phone membrane sticking device. The device aims to solve the technical problemthat cleaning and membrane sticking are inconvenient to conduct at the same time through an existing mobile phone membrane sticking device. In order to solve the technical problem, the invention provides the simple mobile phone membrane sticking device. The device comprises a supporting plate, one side of the supporting plate is connected with a warping plate, clamping strips are fixedly connectedto the two sides of the top of the supporting plate, and notches are formed in the sides, opposite to each other, of the two clamping strips; movable grooves communicated with the notches are formedin the tops of the clamping strips, movable shafts are inserted into the movable grooves, and pressing pieces are fixedly connected to the bottom ends of the movable shafts. According to the device, an adhesive ring on a roller shaft is placed on a mobile phone screen, then a sticky membrane is plugged in the notches between the two clamping strips, the supporting plate is pulled, the sticky membrane is pushed, and at the time, the sticky membrane is closely attached to the rear side of the adhesive ring; after one portion of the adhesive ring is cleaned, the sticky membrane is in an inclinedstate, and an adhesive layer of the sticky membrane just adheres to the screen.

Owner:嘉兴市建美轻体建材有限公司

A simple mobile phone film sticker

ActiveCN109229616BAvoid easy stainingEasy to stainCleaning using toolsPackaging protectionClassical mechanicsEngineering

The invention relates to the technical field of mobile phone film sticking devices, in particular to a simple mobile phone film sticking device. The technical problem to be solved by the present invention is that it is inconvenient to carry out cleaning and film sticking at the same time in the existing mobile phone film sticking device. In order to solve the above technical problems, the present invention provides a simple mobile phone film applicator, which includes a support plate, a seesaw is connected to one side of the support plate, and clip bars are fixedly connected to both sides of the top of the support plate, and The opposite sides of the two clips are provided with notches, and the top of the clips is provided with a moving groove communicating with the notch, and a moving shaft is inserted in the moving groove, and the bottom end of the moving shaft is fixedly connected with a Tablet. In this invention, the adhesive ring on the roller is placed on the screen of the mobile phone, the film is inserted into the notch between the two clips, the supporting plate is pulled, and the film is pushed. At this time, the film is closely behind the adhesive ring. After one place of the adhesive ring is cleaned, the adhesive layer of the adhesive film is just glued on because the adhesive film is in a tilted state.

Owner:嘉兴市建美轻体建材有限公司

Method for slenderizing and permanently shaping uncolored wool

ActiveCN103361925BGood level dyeingThe process is simple and fastSucessive textile treatmentsLiquid/gas/vapor fibres/slivers/rovings treatmentCardingPulp and paper industry

The invention discloses a method for slenderizing and permanently shaping uncolored wool. The method adopts the scheme comprising the following steps of carding, preprocessing, twisting, slenderizing, shaping, untwisting, oxidizing, washing, drying and winding the uncolored wool with the fineness of 14.5 to 27.5mum in the form of wool tops to obtain the permanently shaped wool with the fineness of 12.5 to 22.5mum. The method has the advantages of simple process and high production efficiency, the obtained slenderized wool has silky luster and hand feeling, the fineness, the dispersion rate and the short-haired rate of the wool are equivalent to those of ordinary wool with the same fineness, and the fiber strength of the wool is improved by 20% in comparison with that of the ordinary wool with the same fineness.

Owner:SHANDONG NANSHAN TEXTILE GARMENT

A biological modification process of lactic acid fiber with good spinnability

ActiveCN105256401BGood hygroscopicityEasy to stainBiochemical fibre treatmentFibre typesPolymer scienceFermentation

The invention discloses a biomodification method of lactic acid fiber with good spinnability, which is prepared by the following method: adding various raw materials into a high-speed mixer, and dispersing at high speed to obtain a modified polylactic acid mixture; uniformly mixing The modified polylactic acid mixture is melt blended and extruded through a twin-screw extruder to obtain a modified polylactic acid masterbatch, and vacuum dried; the modified polylactic acid functional masterbatch chips and vacuum dried ordinary polylactic acid chips are put into high-speed mixing The mixture is evenly mixed in the machine, and the mixture is spun on a melt spinning machine through circular spinneret holes to obtain modified polylactic acid fibers, and then undergoes microbial modification and strictly controls the fermentation parameters. Different from ordinary constant temperature fermentation, certain instantaneous heat treatment is adopted. The purpose of shortening the fermentation time and obtaining an unexpected modification effect can be achieved.

Owner:浙江逸蓓新材料科技有限公司

A kind of stone surface protective nano coating and its manufacturing process

ActiveCN104761939BPrevent diseaseHigh fullnessAntifouling/underwater paintsPaints with biocidesContaminationN-Butyl acetate

The invention discloses a stone surface protective nano-coating, which comprises the following formula (parts by weight): 24-26 nanometer silicon dioxide; 24-26 butanol; 4.5-5.5 butyl acetate; 4.5; ethyl carbamate 2.5~3.5; methyl methacrylate 1.5~2.5; acrylic acid 14.5~15.5; butyl acrylate 5.5~6.5; hydroxyethyl acrylate 6.5~7.5; Ethylene glycol monobutyl ether 3.5~4.5. The invention also discloses a process for preparing the stone surface protective nano coating. The coating can be applied to the surface protection of various stone products such as building interior and exterior walls, stone floors, stone guardrails, and stone countertops. At room temperature, it can penetrate deeply into the surface of the stone, forming a dense, transparent, hard protective film on the surface of the stone, preventing various diseases of the stone, and improving the fullness, color saturation, texture, permeability and surface of the stone itself. Hardness and has the ability of easy cleaning and stain resistance.

Owner:CHONGQING XINGYU POLYMER PAINT

Reactive dyeing method for pearl viscose fibers

The invention provides a reactive dyeing method for pearl viscose fibers. The reactive dyeing method mainly comprises the following steps of: dyeing, wherein reactive dyes, sodium carbonate and sodium sulfate are added in water to form dye liquor, pearl viscose fiber fabric is put into the dye liquor after the dye liquor is heated to be at a temperature ranging from 50 DEG C to 60 DEG C, the liquor ratio equals to (25-30):1, the pH of the dye liquor equals to 6 to 7.5, and then the dye liquor is heated continually to reach a temperature ranging from 70 DEG C to 100 DEG C and is kept at the temperature for 80 minutes to 100 minutes, thereby dyeing the fabric; washing the dyed fabric till the fabric is neutral; and drying the fabric. According to the dyeing method, the composition and component proportion of the dye liquor are optimized, the parameters of the dyeing process are adjusted, the dyeing is easy, and the dye-uptake and color fastness of the pearl viscose fibers are improved.

Owner:TAICANG RONGWEN SYNTHETIC FIBER

A kind of water-based emulsion antirust liquid and preparation method thereof

ActiveCN103710709BSuitable for long and short term rust preventionPromote sheddingWater basedHazardous substance

The invention discloses a water-based emulsion-type antirust liquid and a preparation method thereof. The water-based emulsion-type antirust liquid is prepared from 12-15 parts by weight of urethane acrylate, 4-5 parts by weight of dodecenylsuccinic acid, 1-2 parts by weight of monoethanolamine, 0.9-1.4 parts by weight of sodium molybdate, 1.5-3 parts by weight of polyoxyethylene octylphenol ether, 1-2 parts by weight of hydroquinone, 3-4 parts by weight of ditetradecane alcohol ester, 1-2 parts by weight of ethylenediaminetetraacetic acid disodium salt, 4-5 parts by weight of an assistant and 300 parts by weight of water. The polymer monomer forms a stable emulsion under the action of a chelating agent and a nonionic surfactant and the emulsion forms a film on the metal surface, does not fall off easily, resists oxidation, is not polluted easily and can be cleaned easily. The water-based emulsion-type antirust liquid contains less harmful substances, has a low cost and is suitable for long / short-period rust prevention of metal products and machinery parts.

Owner:盐城新汇村镇建设发展有限公司

Natural bamboo fiber shirt fabric and manufacture method thereof

InactiveCN103046200BReduce cohesionEasy to stainBiochemical fibre treatmentBleaching apparatusYarnAntibiosis

The invention provides natural bamboo fiber shirt fabric which has silky gloss, good feel and drapability, and is rich in graceful feeling, antibiosis, moisture-adsorption and ventilating. Warps and wefts of the fabric are both natural fiber / bamboo viscose blended yarns, the blending ratio of the warps and the wefts is 1:1, the warp density is 512 / 10cm, and the weft density is 338.5 / 10cm. A manufacture method of the natural bamboo fiber shirt fabric comprises the following steps: a, blending: opening picking, carding cotton, drawing out, roving and spun yarn; b, drum yarn dying: tube loosening, pretreatment, dying, dehydration and drying, wherein the pretreatment comprises bleaching and enzyme treatment; during bleaching: soda ash is 1-3g / L, hydrogen peroxide is 1-2g / L, the temperature is 95 DEG C, the time is 35-45min; and during the enzyme treatment, HontonezymePA is 1-1.5g / L, pH value is 4.5-5.5, the bath ratio is 1:15, and the time is 25-35min; and during dying, the drum yarn density is 0.33-0.35g / cm<3>, and MegafixB type reactive dying is adopted; c, weaving: winding, warp pulp connection, drawing in or warp tying and weaving; and d, after treatment: singeing, desizing, sizing and preshrinking.

Owner:JIANGSU YDTEX GRP LTD

Preparation method and application of modified polyester stretch yarn with special-shaped section

ActiveCN103334174BGood moisture wicking effectImprove comfortFibre typesFilament/thread formingYarnFiber

The invention relates to the technical field of spinning and provides a preparation method of a modified polyester stretch yarn with a special-shaped section so as to solve the problem that polyester fiber cannot meet the requirements on excellent moisture absorption and sweat releasing properties. The preparation method comprises the following steps of: preparing alkali-soluble master batches; mixing the alkali-soluble master batches, barium sulfate subjected to surface treatment by a modifier and a dispersing agent at high speed, and pelleting the mixture by using a double-screw extruder to prepare barium sulfate-alkali-soluble master batches; and performing blended spinning on the barium sulfate-alkali-soluble master batches and polyethylene glycol terephthalate to obtain the modified polyester stretch yarn with the special-shape section. In a production process, the using efficiency of a machine platform is high and the end breakage rate is low, so the production speed of the modified polyester stretch yarn is increased, the processing cost is reduced, and the modified polyester stretch yarn can be applied to development of various high-grade fabrics.

Owner:ZHEJIANG HENGYI HIGH TECH MATERIAL

Composite door structure and method of forming a composite door structure

InactiveUS20070119114A1Improve thermal performanceImprove impact resistanceStrutsAdhesivesFiberEngineering

A method of forming a composite door is disclosed. The method comprises: mixing together a thermoplastic polymer with an organic fibrous material in a ratio such that the organic fibrous material constitutes 40 to 60 percent by weight of the mixture; extruding the mixture under heat and pressure to create a thin sheet form; cutting the sheet to a predetermined size; removing material from at least one surface of the sheet to create a homogeneous appearance devoid of obvious fibrous particles; thermoforming the sheet to impart to the at least one surface an exterior three dimensional door surface to create a thin door facing; and assembling two of the thermoformed thin door facings, a peripheral frame and a core material into a door.

Owner:CCB RE HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com