Method for slenderizing and permanently shaping uncolored wool

An uncolored and woolen technology, which is applied in the direction of textiles and papermaking, textile material treatment, textile material continuous treatment, etc., can solve the problems of large wool damage, low production efficiency, and weak luster, and achieves improved level dyeing, The effect of high production efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

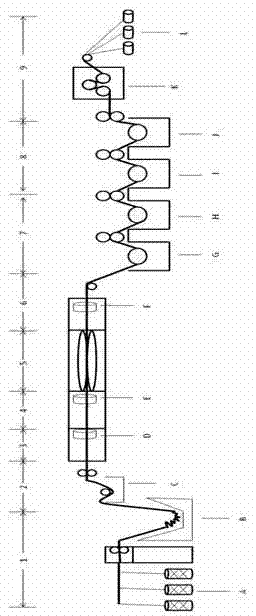

Image

Examples

Embodiment 1

[0023] Method of stretching, thinning and permanently setting unpigmented 21.6um wool to 18.2um wool

[0024](1) Carding: merging, drafting and carding 11 uncolored wool slivers each weighing 24g / m on the carding machine A, the drafting ratio is 3.8 to obtain a wool sliver weighing 75g / m, and Stored in the storage device B, the fineness of the wool in the wool strips used in this process is 21.6um; (2) Pretreatment: the transmission wheel guides the wool strips in the storage device B at a speed of 4.5m / min into the wool strips containing wool stretching In the pretreatment tank C of the thinning pretreatment liquid, the specific composition and weight percentage of the wool stretching thinning pretreatment liquid in the tank are: sodium pyrosulfite: 4.0%, and the penetrating agent FR-M produced by BASF: 0.7%, and the rest is water. After the wool strip is fully wetted, it is passed through the pressure-feeding roll; (3) Twisting: the wool strip after the liquid enters the twi...

Embodiment 2

[0027] Method of stretching, thinning and permanently setting unpigmented 18.6um wool to 16.2um wool

[0028] (1) Carding: merging, drafting and carding 11 uncolored wool slivers each weighing 24g / m on the carding machine A, the drafting ratio is 3.9 to obtain wool slivers weighing 73g / m, and Stored in storage device B, the fineness of wool in the wool sliver used in this process is 18.6um; (2) Pretreatment: The transmission wheel guides the wool sliver in storage device B into the wool sliver containing wool stretching at a speed of 4.5m / min. In the pretreatment tank C of the thinning pretreatment liquid, the specific composition and weight percentage of the wool stretching thinning pretreatment liquid in the tank are: sodium pyrosulfite: 4.0%, and the penetrating agent FR-M produced by BASF: 0.7%, and the rest is water. After the wool strip is fully wetted, it is passed through the pressure-feeding roll; (3) Twisting: the wool strip after the liquid enters the twisting zone ...

Embodiment 3

[0031] Method of stretching, thinning and permanently setting unpigmented 16.6um wool to 14.2um wool

[0032] (1) Carding: merging, drafting and carding 11 uncolored wool slivers each weighing 24g / m on the carding machine A, with a draft ratio of 4.0, to obtain wool slivers weighing 70g / m, and Stored in storage device B, the fineness of wool in the wool sliver used in this process is 16.6um; (2) Pretreatment: The transmission wheel guides the wool sliver in storage device B into the wool sliver containing wool stretching at a speed of 4.5m / min. In the pretreatment tank C of the thinning pretreatment liquid, the specific composition and weight percentage of the wool stretching thinning pretreatment liquid in the tank are: sodium metabisulfite: 4.0%, and the penetrating agent produced by BASF Company is FR-M: 0.7%, the rest is water, after the wool sliver is fully wetted, it is passed through the pressure-feeding roller; (3) Twisting: the wool sliver enters the twisting zone wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com