Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Easy thermoforming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyester compositions for calendering

Polyester compositions that provide a higher throughput in calendering processes may be prepared from a polyester having crystallization half time of at least 5 minutes, an inherent viscosity of about 0.55 to about 0.75 dL / g, a branching monomer, and a release additive. The polyester compositions show a combination of excellent melt strength with good shear response that permits higher calendering line speeds before melt fracture occurs. Also disclosed are processes for film or sheet by calendering the above compositions and the film or sheet produced therefrom. The polyester compositions, film, or sheet also may include plasticizers and / or flame retardants to increase their flexibility and enable their use in commercial applications requiring flame resistance. The film and sheet have excellent appearance and can be used in a wide range of decorative and packaging applications.

Owner:EASTMAN CHEM CO

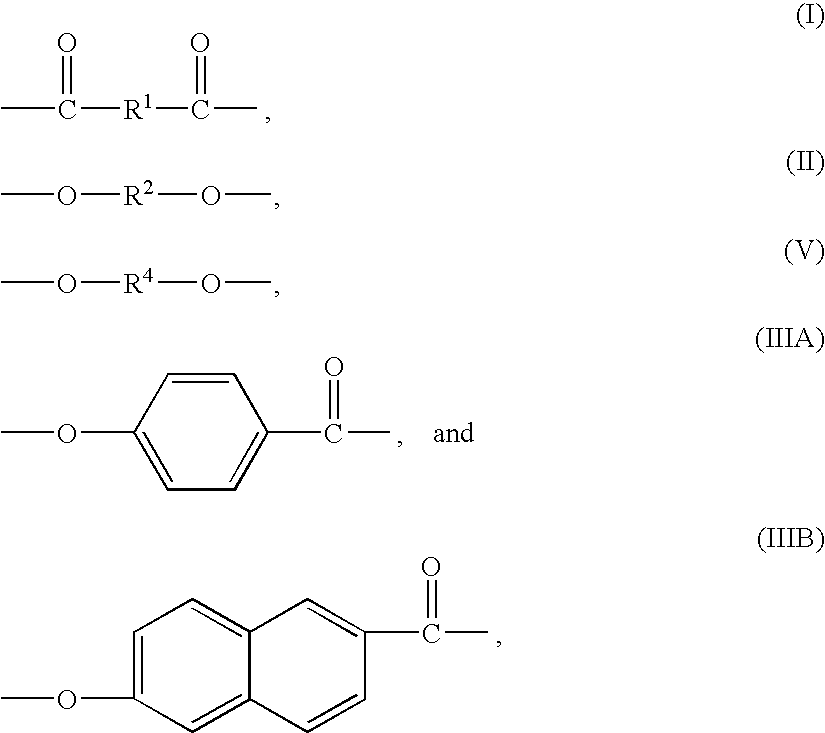

Liquid crystalline polymers, processes for their manufacture, and articles thereof

InactiveUS7105106B2Improve barrier propertiesImprove abilitiesLiquid crystal compositionsSynthetic resin layered productsPolyesterLiquid crystalline

Thermotropic liquid crystalline polymers are produced by the reaction of a polyester made from an aromatic dicarboxylic acid and a diol, one or more hydroxycarboxylic acids, a stoichiometric excess of an aromatic diol, and a carboxylic acid anhydride. Also disclosed are novel liquid crystalline polymers that may be produced by this process. These liquid crystalline polymers are useful as molding resins and shaped articles thereof are produced. In particular, the articles include films, sheets, containers and portions thereof comprising these LCPs.

Owner:PERFORMANCE MATERIALS NA INC

Polyester compositions for calendering

Polyester compositions that provide a higher throughput in calendering processes may be prepared from a polyester having crystallization half time of at least 5 minutes, an inherent viscosity of about 0.55 to about 0.75 dL / g, a branching monomer, and a release additive. The polyester compositions show a combination of excellent melt strength with good shear response that permits higher calendering line speeds before melt fracture occurs. Also disclosed are processes for film or sheet by calendering the above compositions and the film or sheet produced therefrom. The polyester compositions, film, or sheet also may include plasticizers and / or flame retardants to increase their flexibility and enable their use in commercial applications requiring flame resistance. The film and sheet have excellent appearance and can be used in a wide range of decorative and packaging applications.

Owner:EASTMAN CHEM CO

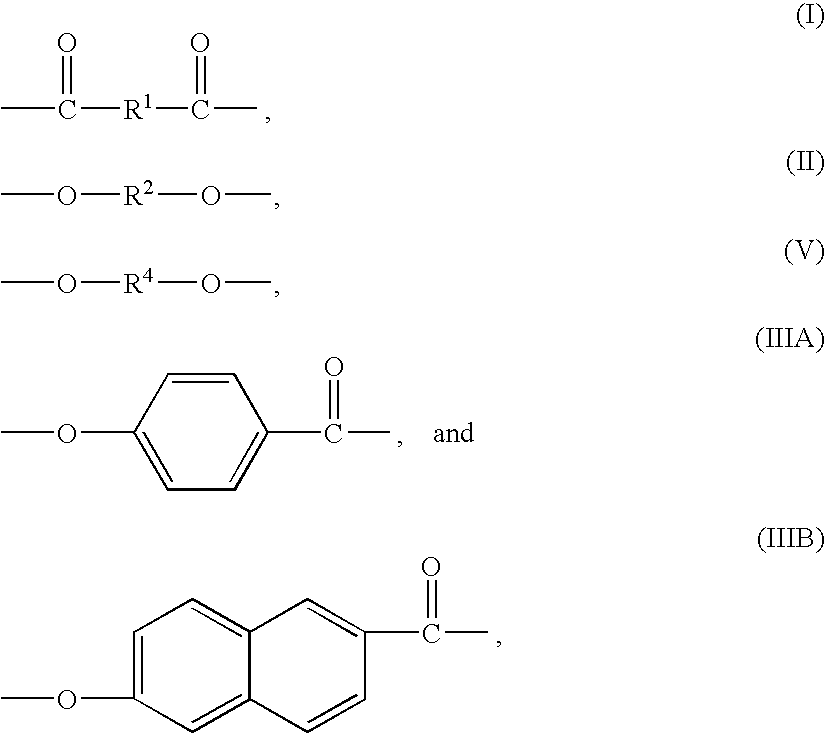

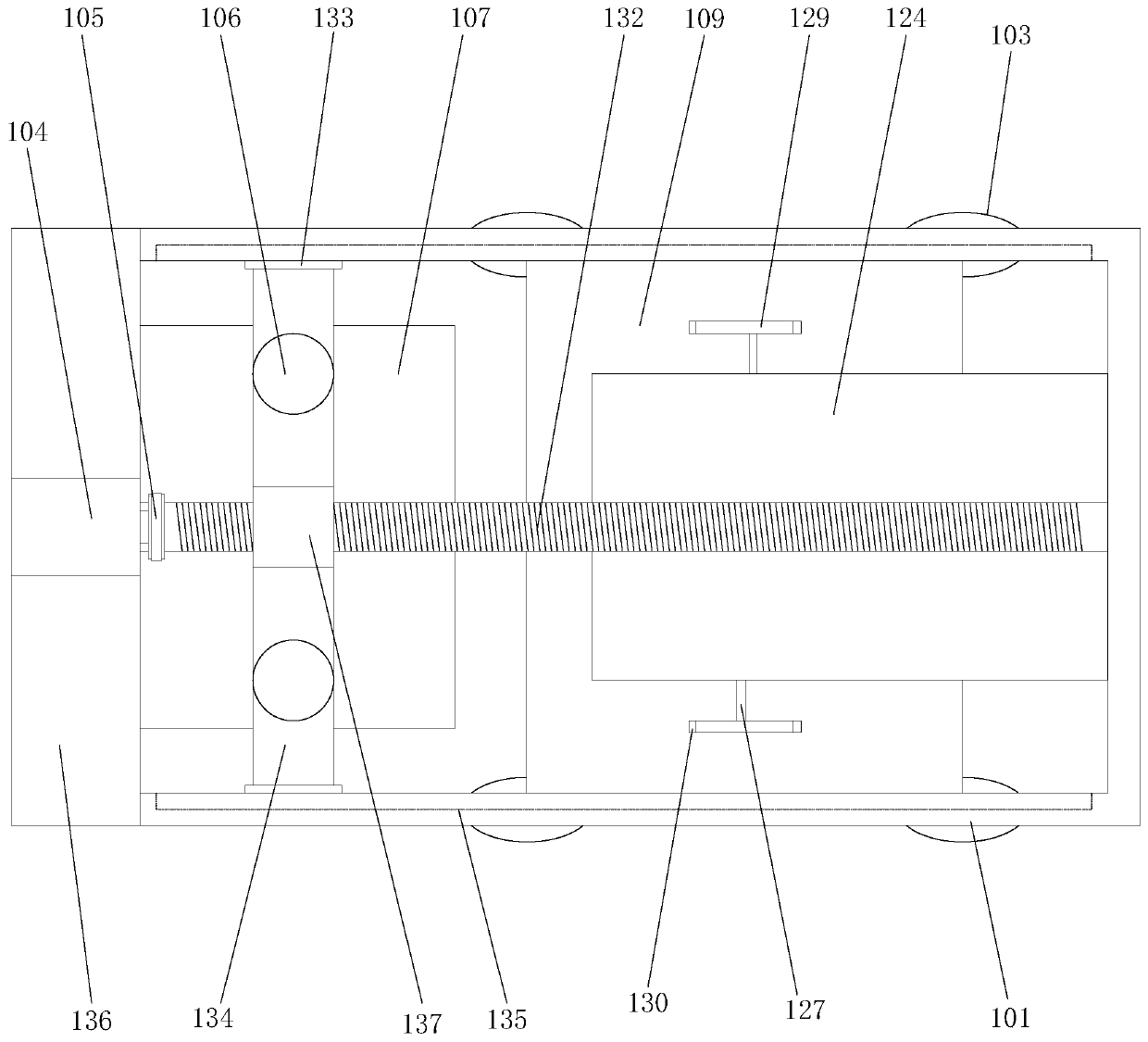

Processing system and technology for natural fibrous composite felt used for automotive trim plate core layer

The invention discloses a processing system and technology for natural fibrous composite felt used for an automotive trim plate core layer. The system comprises a fiber net generating device. The fiber net generating device is connected with a drying oven through a bottom curtain, the bottom curtain is provided with a driving structure, fiber nets which come out of the drying oven pass through a hot pressing device and extends to a winding device, a cloth guide roller used for winding the fiber nets to be in a S shape and a supporting conveying roller are arranged in the drying oven, the hot pressing device is a pair of heating and compressing rotary rollers, the fiber net generating device comprises an opening device, a carding device and a net paving device, and the opening device, the carding device and the net paving device are connected in sequence. The processing system and technology for the natural fibrous composite felt used for the automotive trim plate core layer are low in cost, high in performance, environmentally friendly and capable of greatly improving the strength and tenacity of the natural fibrous composite felt, and the natural fibrous composite felt can be used as base materials of various automobile trim plates with high strength requirements.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +2

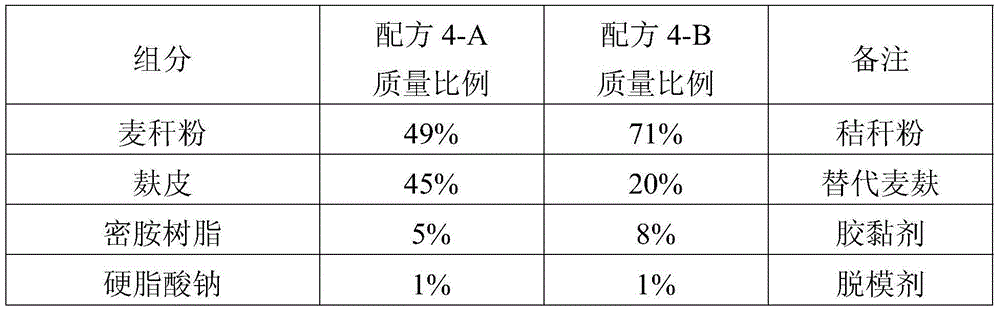

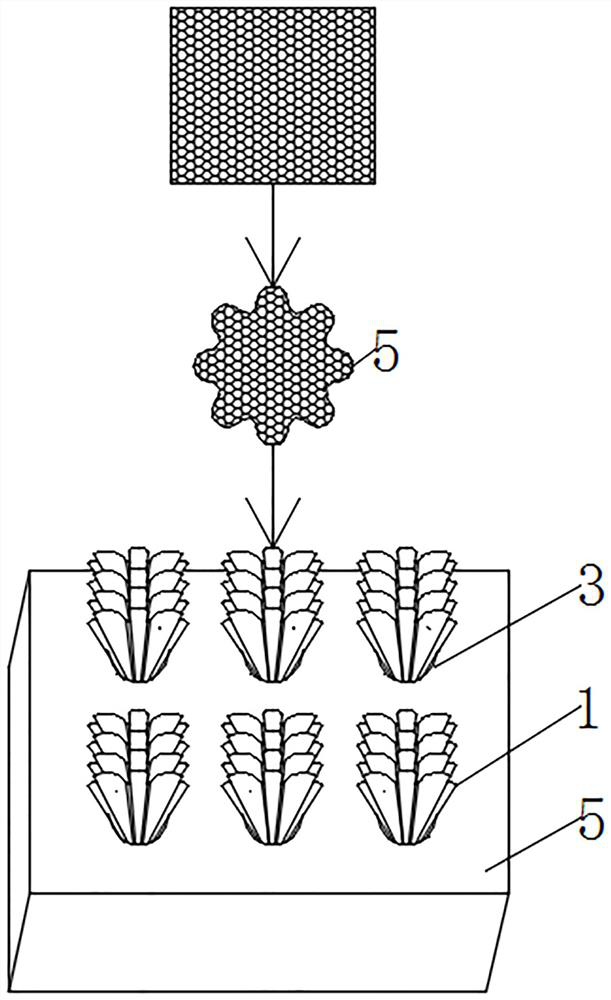

Degradable bio-based seedling raising pot, production method thereof, regulation method in degradation period and application of degradable bio-based seedling raising pot

InactiveCN105613100AImprove liquidityImprove gelatinizationCultivating equipmentsRoot systemAdhesive

The invention discloses a degradable bio-based seedling raising pot, a production method thereof, a regulation method in a degradation period and an application of the degradable bio-based seedling raising pot. The degradable bio-based seedling raising pot is produced from straw powder, wheat bran and an adhesive through dry-method hot pressing after mixing. The degradable bio-based seedling raising pot can keep certain strength in a seedling raising process and is relatively complete in appearance, after seedlings and the pot are transplanted to a field simultaneously, the pot can crack and disintegrate rapidly, and plant root extension is facilitated.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

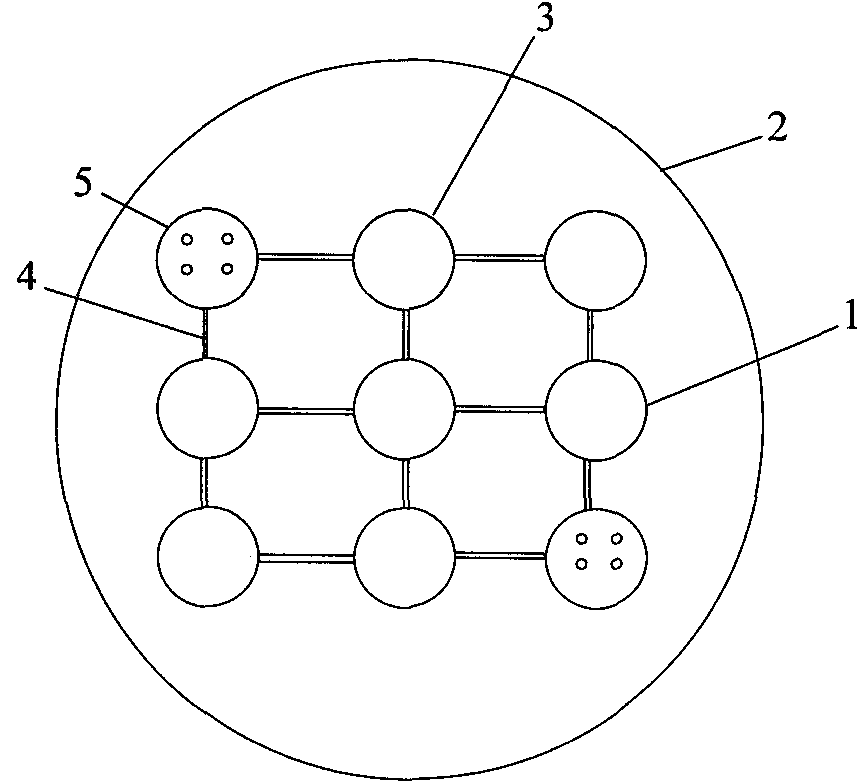

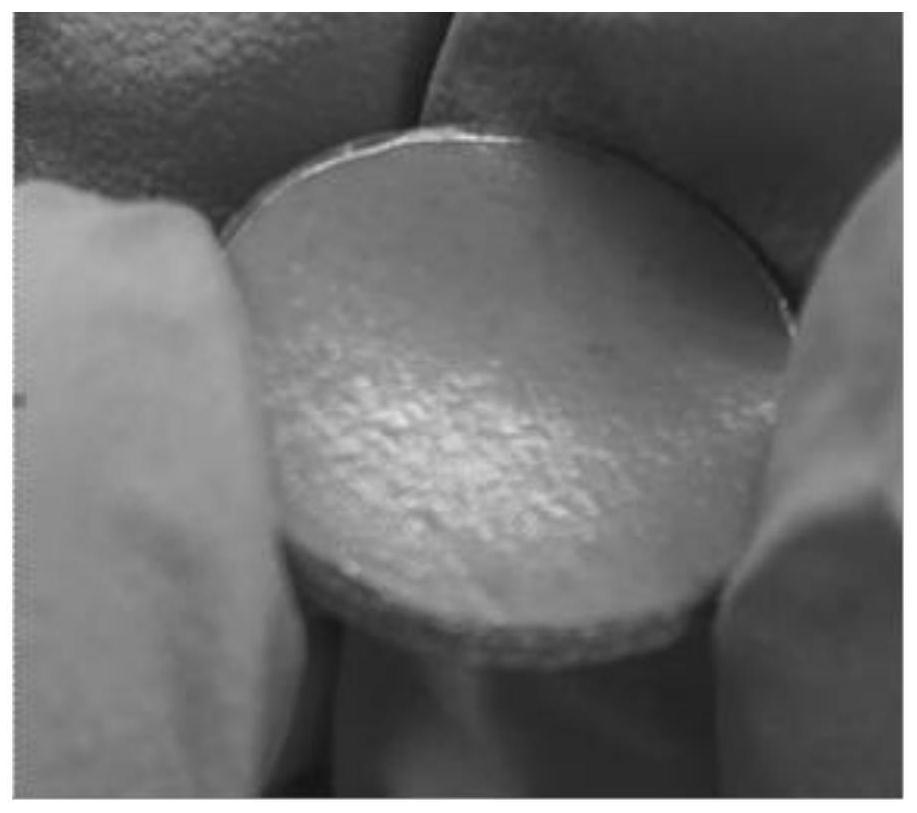

Method for preparing wafer-level uniform-dimension glass microcavity by positive pressure thermal forming

ActiveCN101905859ANot easy to expandLow costPrecision positioning equipmentSoldering apparatusPhysical chemistrySilicon

The invention discloses a method for preparing a wafer-level uniform-dimension glass microcavity by positive pressure thermal forming. The method comprises the following steps of: etching an array consisting of microgrooves on a silicon wafer, and etching microchannels connecting the microgrooves, wherein the minimum groove width of the microgrooves is 5 times more than the runner width; and putting a proper amount of thermal outgassing agent into at least one microgroove, correspondingly bonding the plurality of microgrooves to form a sealed cavity by using a glass wafer, heating to soften the glass, making the thermal outgassing agent heated to release gases to generate positive pressure, acting the positive pressure on the softened glass corresponding to the plurality of microgrooves which are connected through the microchannels so as to form a spherical microcavity with uniform dimension, and cooling the microcavity. By connecting the same microgrooves through the microchannel, the inside air pressure of the microgrooves is substantially consistent, and the formed glass microcavity has uniform dimension. When the dimension of the microgrooves is far greater than that of the microchannel, the microchannels with smaller radius hardly expand due to higher additional pressure. Therefore, the glass corresponding to the microchannels can keep smooth.

Owner:SOUTHEAST UNIV

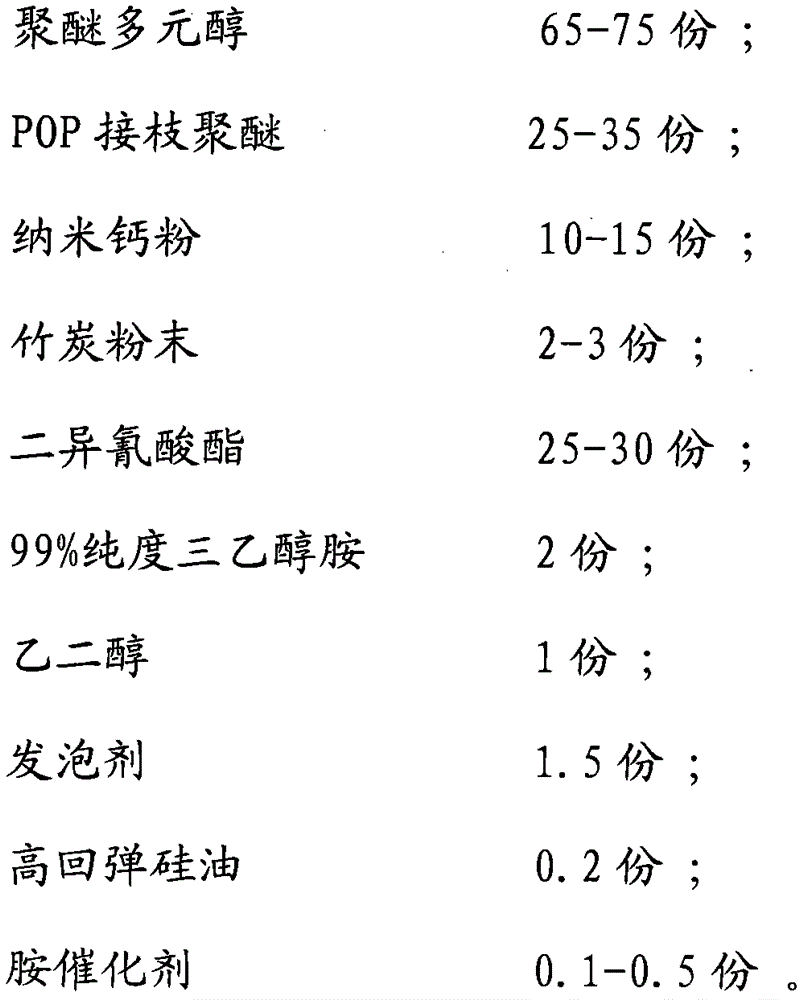

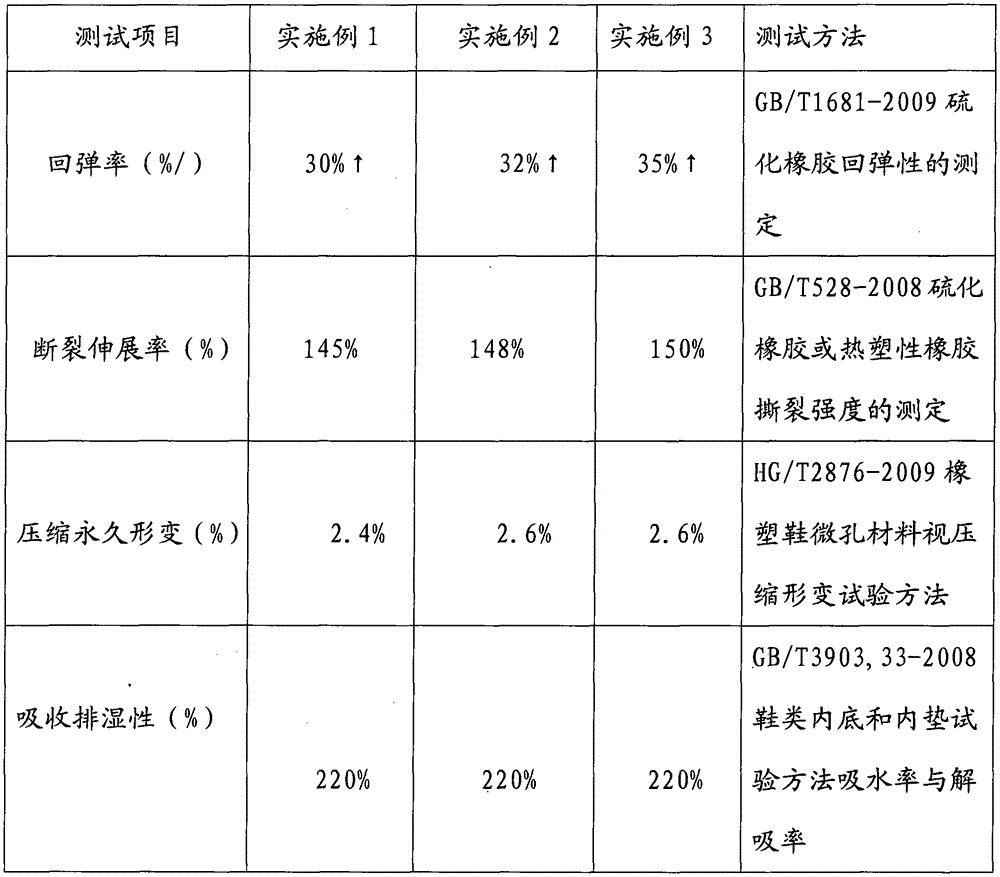

PU-integral skin carbon-containing foam for making shoe pads, and preparation method thereof

InactiveCN104987485AGuaranteed resistance to compression setGood resistance to compression setInsolesFoaming agentPolyol

Owner:RUIAN BOXIN SYNTHETIC MATERIAL

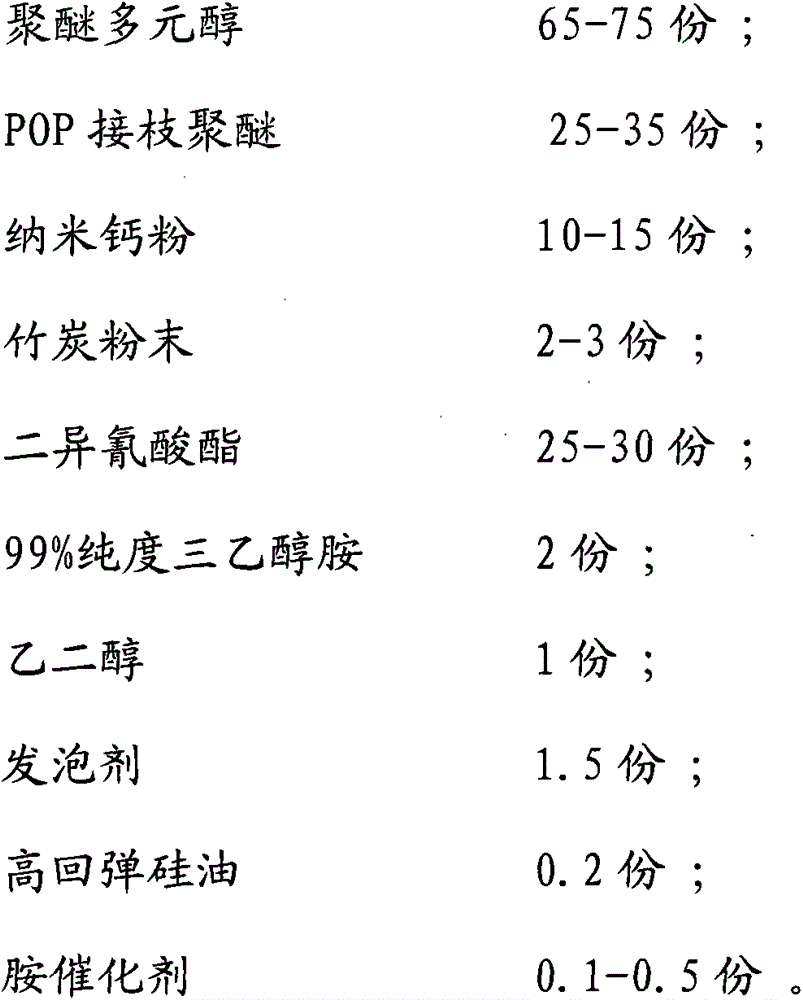

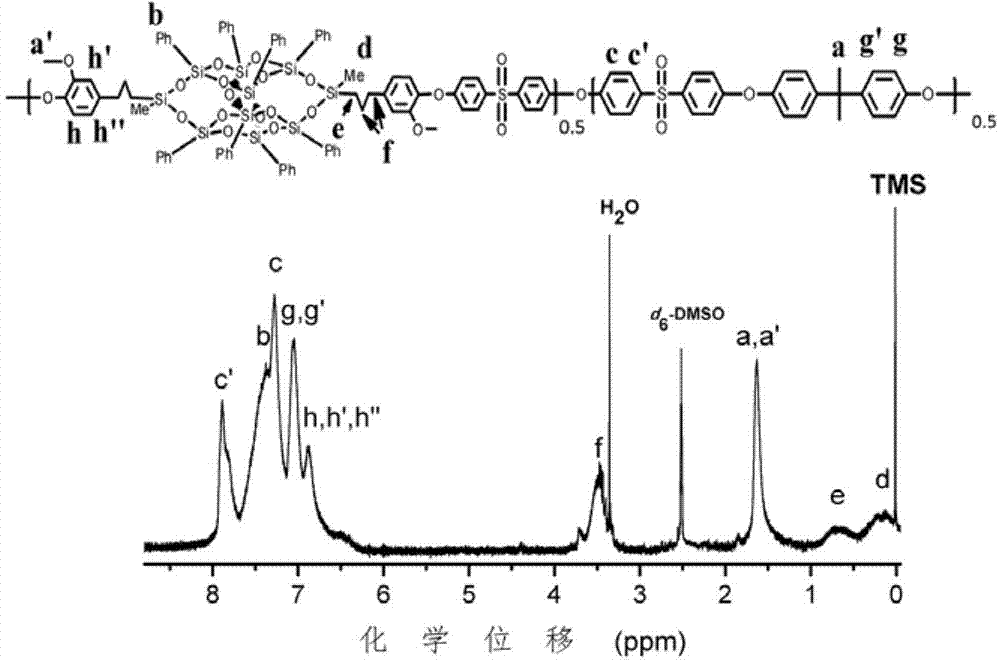

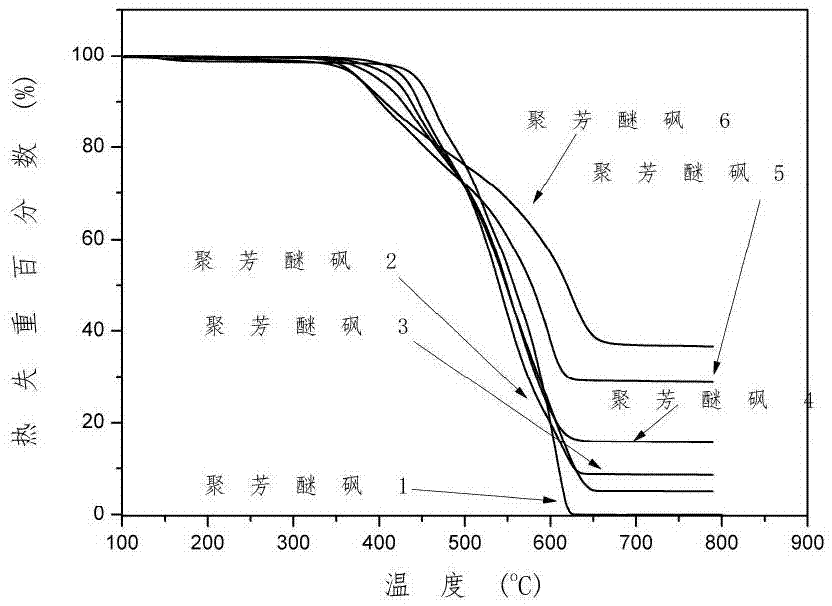

Polyarylether sulphone resin with main chain containing cage-type silsesquioxane double-deck structure and preparation method thereof

The invention discloses polyarylether sulphone resin with a main chain containing a cage-type silsesquioxane double-deck structure and a preparation method thereof, and belongs to the technical field of high polymer chemistry. The polyarylether sulphone resin is prepared by taking 3,13-bis(2-methoxy-4-propyl phenol) octaphenyl cage-type silsesquioxane, bisphenol and dichlorodiphenyl sulphone as reactants, taking sulfolane as a solvent and taking potassium carbonate as a salt forming agent through heating to 150-170 DEG C, and carrying out a water-carrying salifying reaction for 2-4 h; then, respectively heating to 180-190 DEG C, 200-210 DEG C and 210-220 DEG C to react 2-4 h; discharging obtained materials to deionized water, crushing the obtained object, and respectively washing the obtained product 3-5 times by using water and ethanol, so that the polyarylether sulphone resin with the main chain containing the cage-type organic silsesquioxane double-deck structure is obtained. The polyarylether sulphone resin disclosed by the invention is simple in synthetic route, and easily-obtained in raw materials; because the prepared polyarylether sulphone random copolymer resin has excellent heat resistance, low dielectric properties and hydrophobicity, therefore, the polyarylether sulphone resin has a good industrial application prospect.

Owner:JILIN UNIV

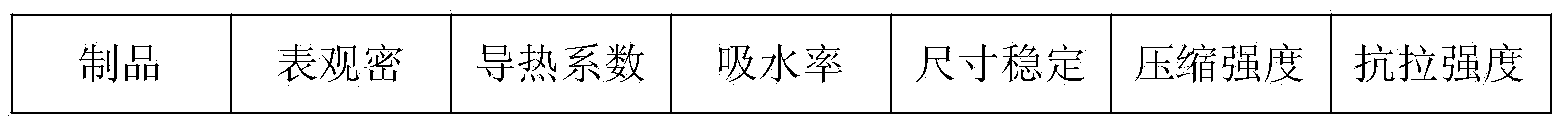

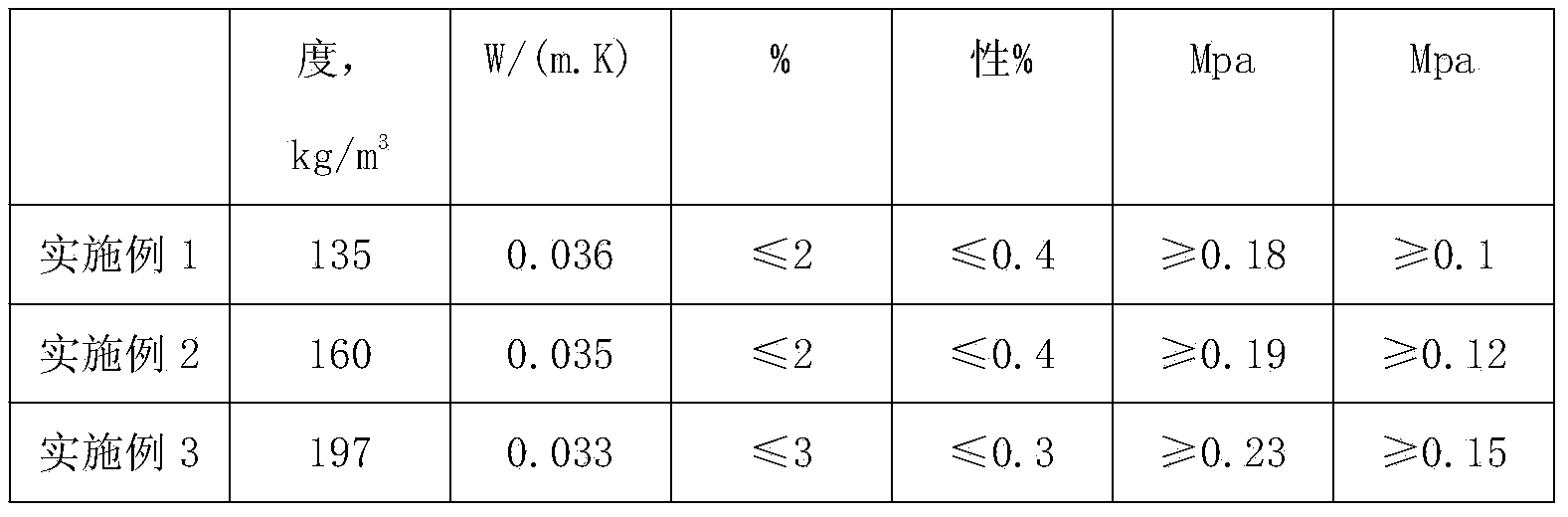

Thermosetting composite resin foam insulation board and preparation method thereof

The invention discloses a thermosetting composite resin foam insulation board and a preparation method thereof. The insulation board is prepared from the following raw materials in parts by weight: 100 parts of pre-foamed and cured EPS (Expandable Polystyrene) particles, 50-2000 parts of fire-proof hybridized adhesive and 5-500 parts of curing agent. The thermosetting composite resin foam insulation board disclosed by the invention achieves the level A2. The thermosetting composite resin foam insulation board prepared by the fire-proof hybridized adhesive has the advantages that the firing surface is carbonized in case of fire, no vertical and horizontal fire spread exists, the self-extinguishing is achieved apart from the fire, no smoldering is generated, no ember dripping and no toxicity are generated, the amount of flue gas is low and the safety is guaranteed, so that level-A2 fire prevention can be truly achieved. The fire-proof hybridized adhesive disclosed by the invention has the advantages of high bonding strength and high toughness and is conductive to the latter thermoforming of particles, and the fire rating of the homogeneous mixed foam insulation board is ensured.

Owner:哈尔滨工业大学空间钢结构幕墙有限公司

Preparation method of high-strength formaldehyde-free wood fiber board, fiber board and application

PendingCN113146789APromote decompositionSpeed up hydrolysisDomestic articlesFlat articlesFiberSulfite salt

The invention belongs to the technical field of artificial boards, and particularly relates to a preparation method of a high-strength formaldehyde-free wood fiber board, the fiber board and application. The preparation method comprises the following steps of S1, wood pretreatment, wherein after poplar waste is crushed, two-step dipping with a mixed solution of potassium hydroxide and sodium sulfite and a calcium chloride solution, high-temperature treatment and drying for later use are carried out; S2, pre-pressing and forming; and S3, hot pressing for board forming. The mixed solution of potassium hydroxide and sodium sulfite is used for treating cellulose in wood waste residues, decomposition and hydrolysis of hemicellulose, lignin and the like are accelerated, TEMPO is used for oxidizing the cellulose, the oxidation degree is improved, calcium ions and cellulose nanofibers are crosslinked, the self viscosity is improved, and hot pressing forming of the fiber board is facilitated.

Owner:NANJING FORESTRY UNIV

Polarized angle hot bending protective film and preparation method thereof

The invention discloses polarized angle hot bending protective film and a preparation method thereof. The polarized angle hot bending protective film comprises a PMMA protective layer, a silicone protective layer, an HC coating, an anti-blue-ray coating, a PET substrate layer, a TPU colloid layer, a silica gel release layer and a release film layer which fit one another in sequence from top to bottom, wherein the polarized angle of the PET substrate layer is 30-48 degrees; PET film is subjected to polarization angle die-cut molding reasonably, and the polarization direction of the PET film isin accordance with the polarization direction of a screen, thereby better fitting an unlocking mode, reducing the adverse effects on the unlocking sensitivity, facilitating smooth unlocking of fingerprint under the screen, and enhancing the user experience; TPU is applied to form the TPU colloid layer, so that the polarized angle hot bending protective film is flat adsorbed on the surface of a to-be-bonded object better, and the polarized angle hot bending protective film has an automatic exhausting function, has softness, is easier to hot press and form, does not rebound, can be adsorbed on the surface of a 3D curved screen better, has a good buffering effect, has an explosion-proof effect, has high practicability, and is conducive to widespread popularization and application.

Owner:东莞市鑫博仕新材料有限公司

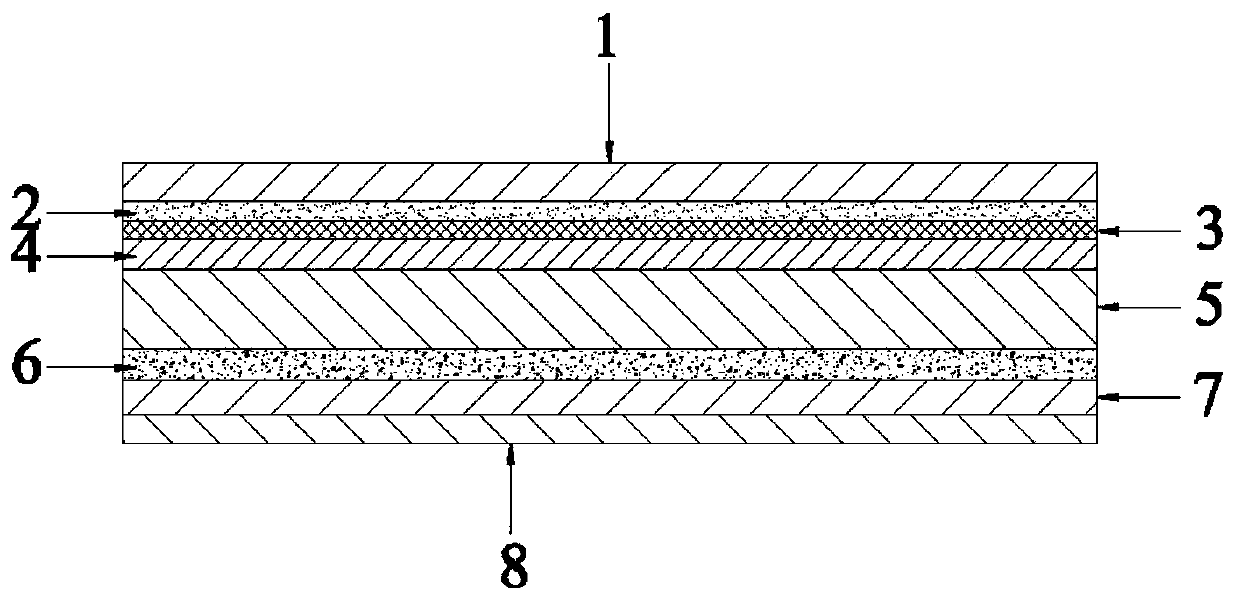

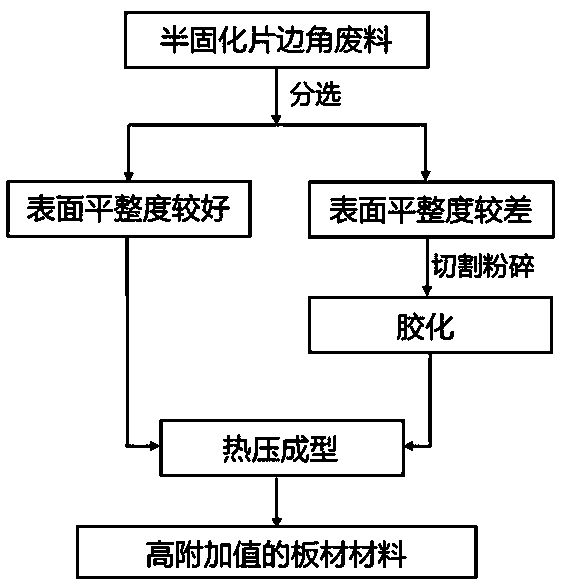

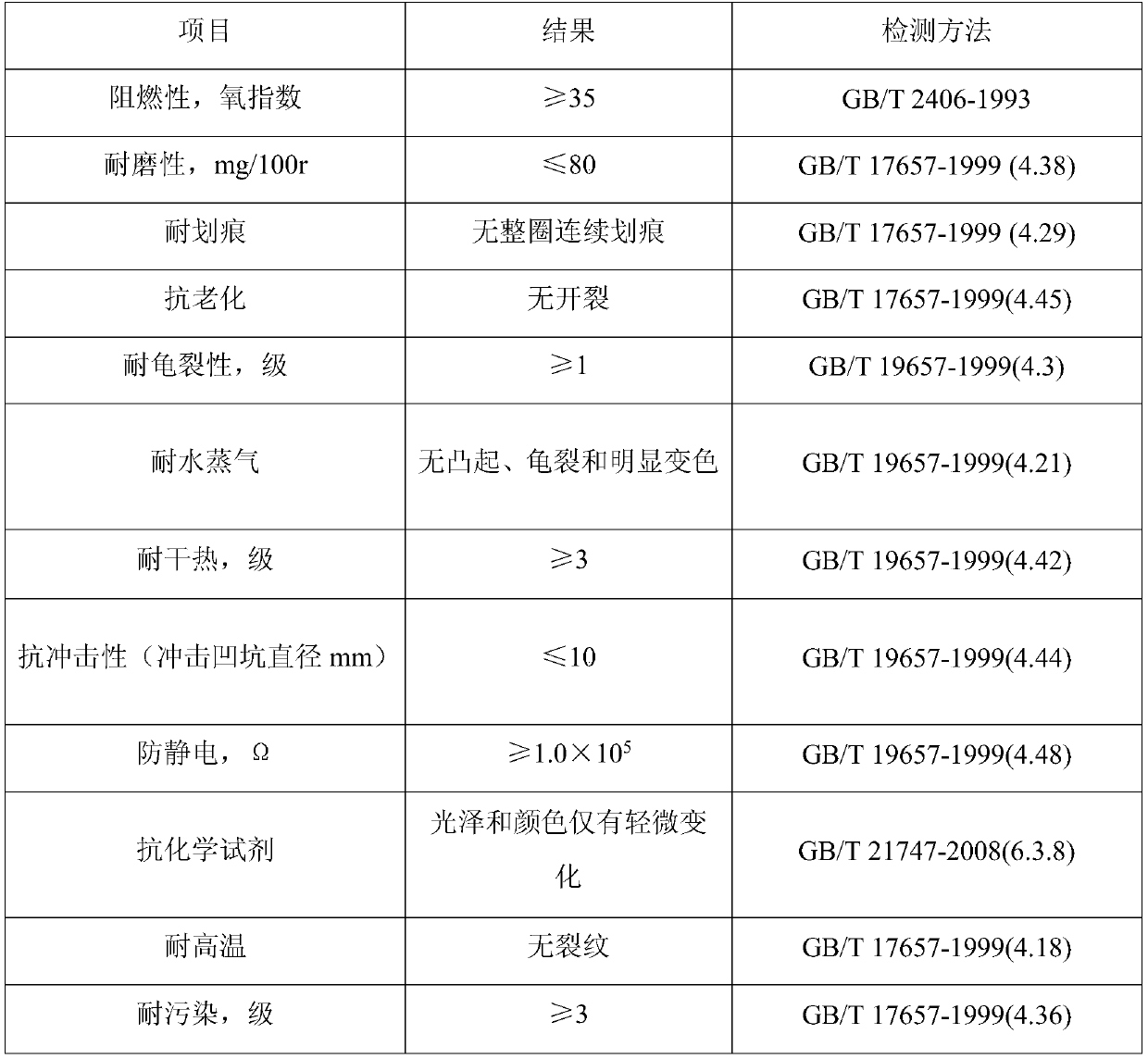

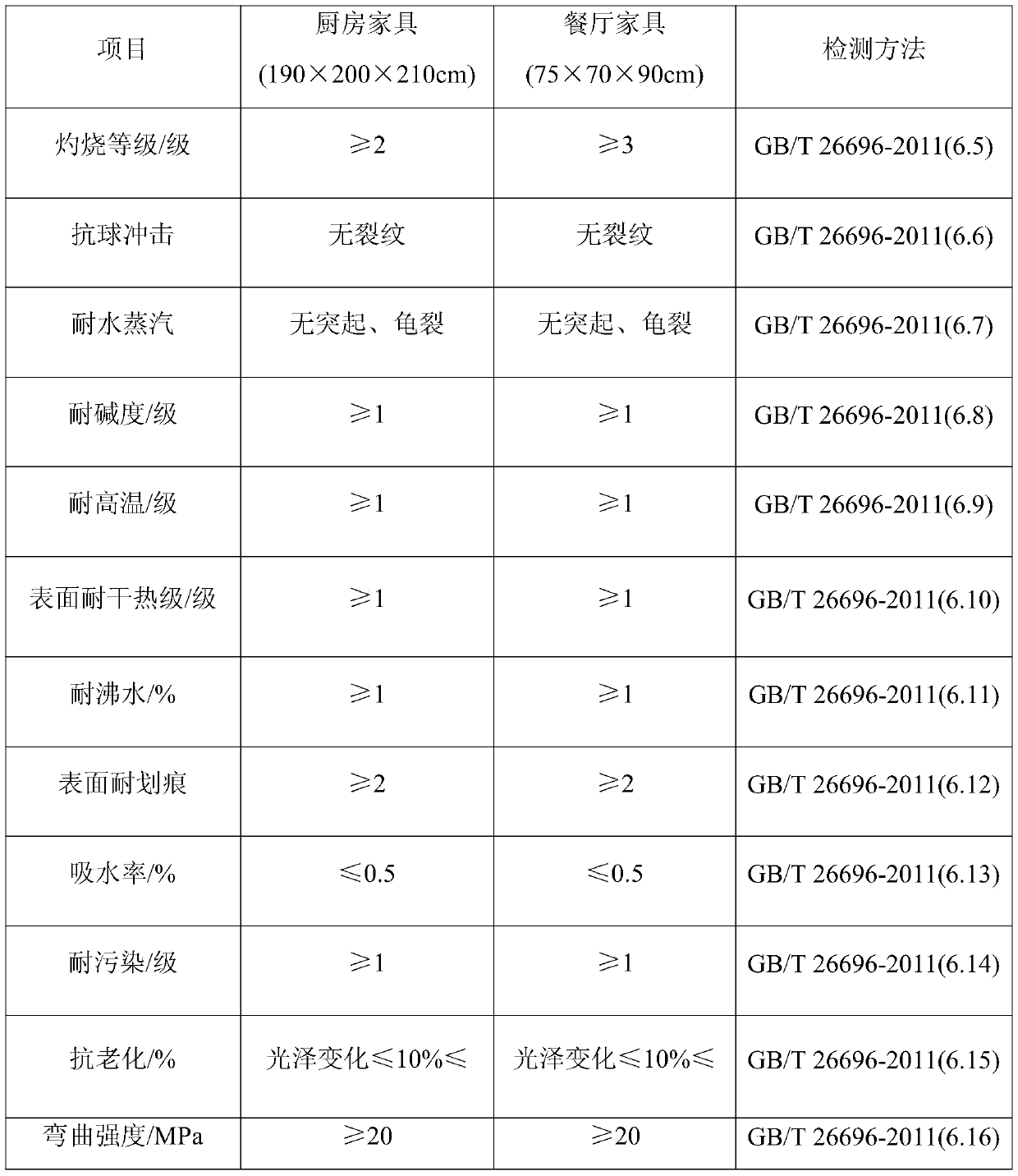

Method for resource utilization of prepreg leftover residues

ActiveCN110625852ASolve pollutionAchieve recyclingPlastic recyclingMechanical material recoveryResource utilizationEngineering

The invention discloses a method for resource utilization of prepreg leftover residues. The method comprises screening and classification, cutting and smashing, gelling processing, thermal press shaping and testing processing. The method disclosed by the invention has the beneficial effects that the prepreg leftover residues are of fixed sources and a huge amount and belong to a typical type of solid waste; through resource processing of the residues, environmental pollution problems can be solved to a great extent; the leftover residues can be recycled; cost expenditures of production enterprises are saved; industrial chain crossing with other industries can be realized; and downstream industrial development can be better promoted.

Owner:四川英创力电子科技股份有限公司 +1

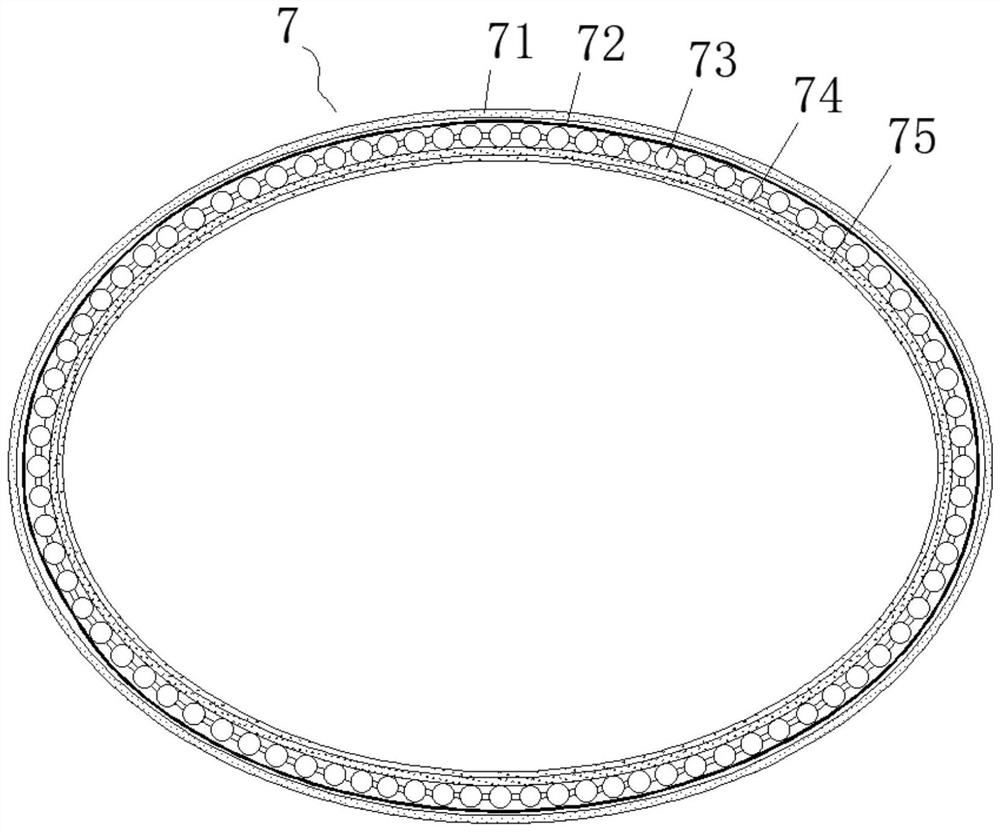

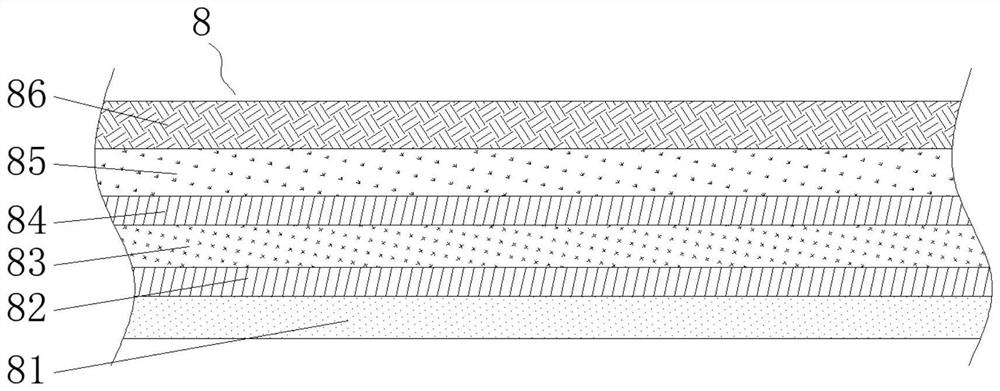

Antibacterial swim ring for children

The invention mainly relates to the technical field of a macromolecular material, and discloses an antibacterial swim ring for children. The swim ring is made from a PVC resin, chlorinated paraffin, gas phase white carbon black, nanometer titanium dioxide, antibacterial zeolite, a stabilizer and aminophylline. The raw materials are simple, and the swim ring is safe and non-toxic, is antibacterialand antiskid, and can keep the children's skin healthy, and the operationality and security of the swim ring are improved. Chlorinated paraffin and graphene which is a stabilizer are added to the PVCresin to raise the heat-resistant temperature and to improve the ductility of the PVC resin, so that the PVC resin is easy for heating moulding, and the strength of the swim ring is improved. Antibacterial zeolite and aminophylline are added for adsorbing and king pathogens and resisting to bacteria and skid, wherein aminophylline can promote mixing and crosslinking of zeolite and the PVC resin, so that the stability and durability of the swim ring are improved. Hydrophobic gas phase white carbon black and nanometer titanium dioxide are added to increase the strength and improve the durabilityof the swim ring, can effectively resist skid, reduce hydrophily, allow rapid drying, and inhibit pathogen propagation.

Owner:刘辉

Cutting machine

InactiveCN107081798APrecise control of descent heightReduce the temperatureMetal working apparatusElectric machineryEngineering

The invention discloses a cutting machine, which belongs to the technical field of electric machinery. The cutting machine includes a frame, on which a workbench, a cutting mechanism and an automatic lifting mechanism are arranged, the cutting mechanism is arranged above the workbench, and the automatic lifting mechanism is connected with the cutting mechanism through a connecting rod. The lifting cylinder in the automatic lifting mechanism is connected with the cutting mechanism, the air source is turned on, and the lifting cylinder drives the cutting mechanism to move downward along the guide rails on the first support rod and the second support rod in the automatic lifting mechanism. A vertical scale is set on the workbench, a camera is set on the automatic lifting mechanism, and a control device is also set on the workbench. Both the camera and the pressure regulating valve of the lifting cylinder are electrically connected to the control device; Touch screen for cutting depth. The cutting machine of the invention can not only effectively control the cutting depth, but also greatly reduce the vibration of the cutting knife during the working process of the cutting machine, and improve the cutting precision.

Owner:柳州市昌泉贸易有限公司

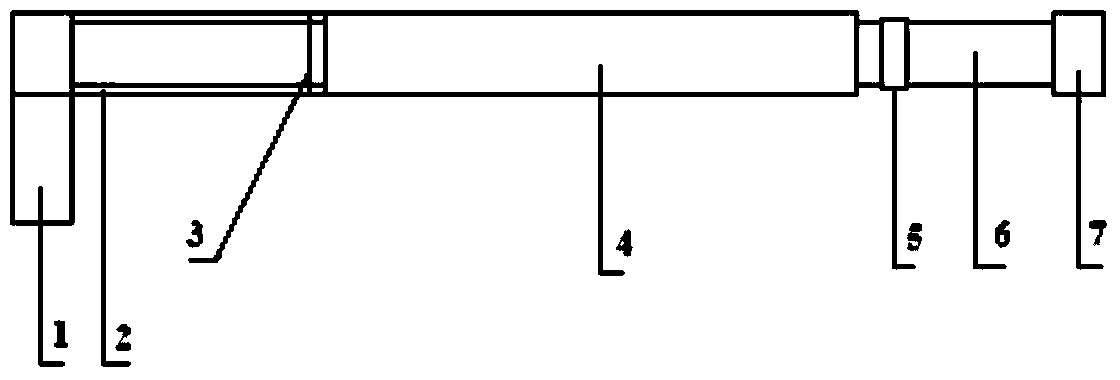

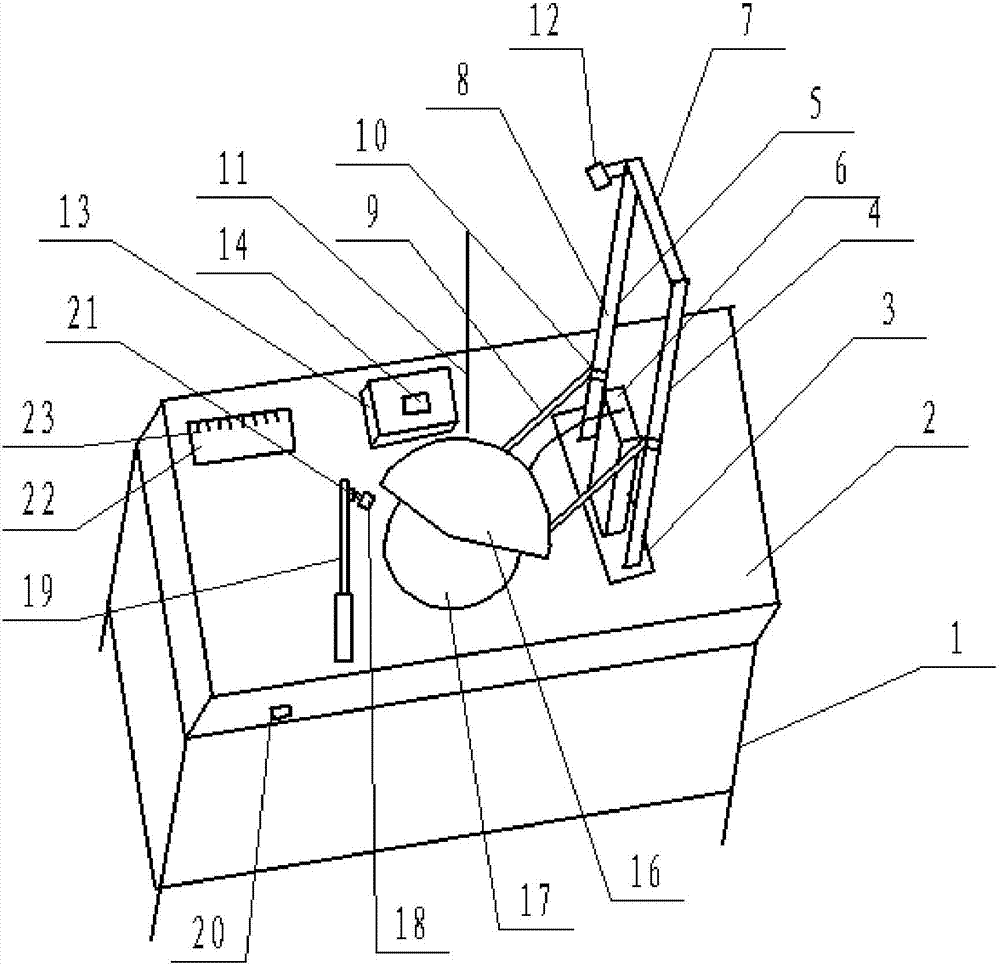

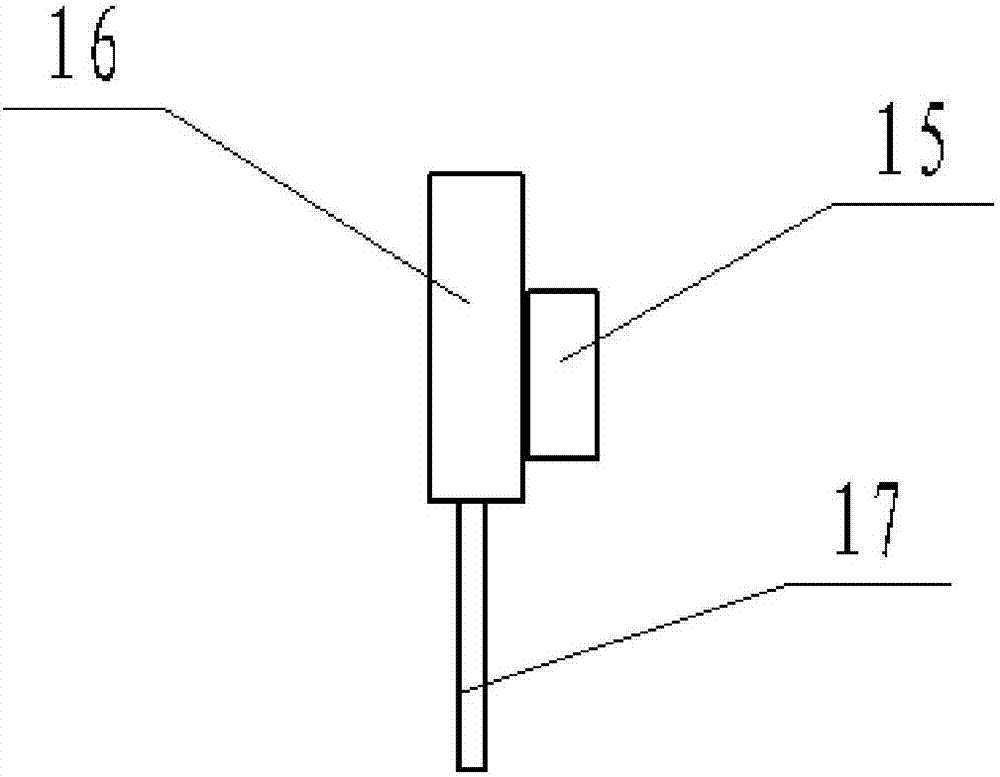

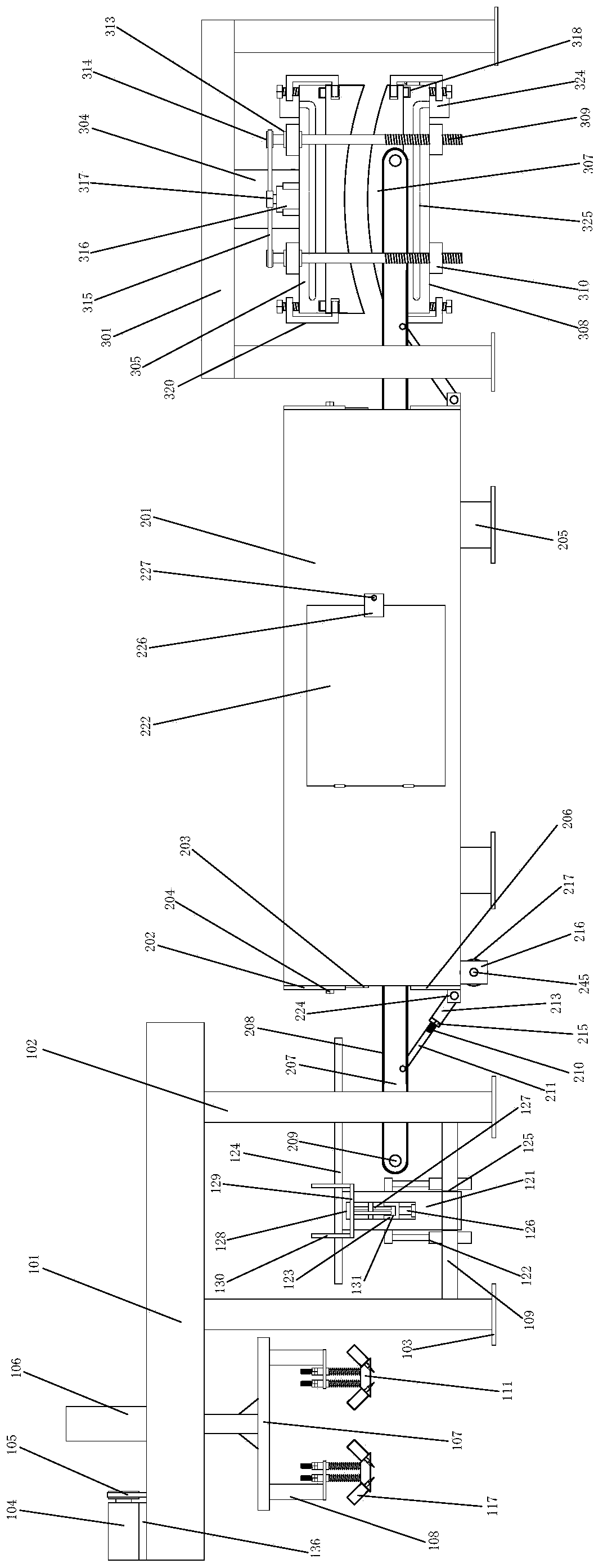

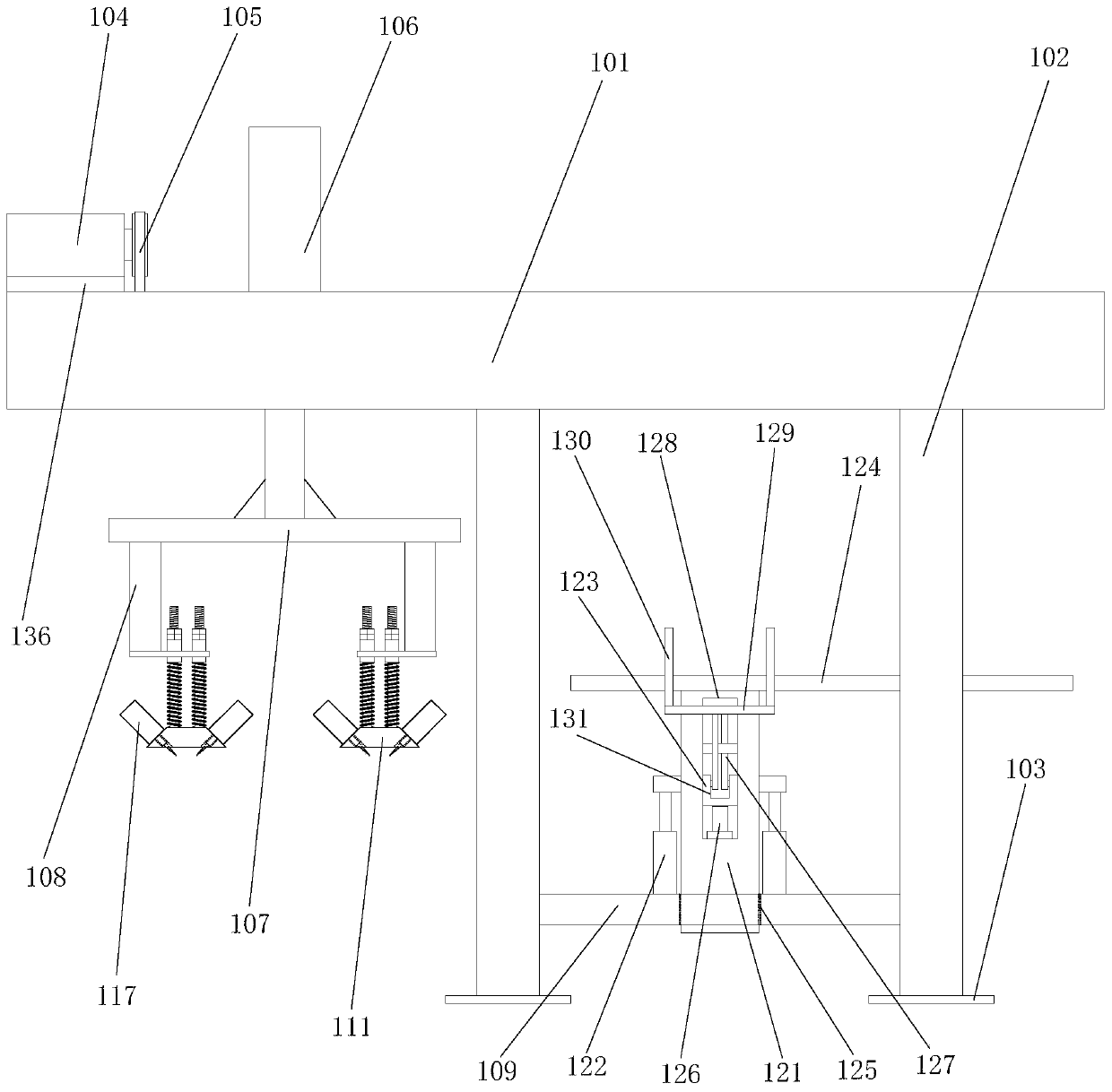

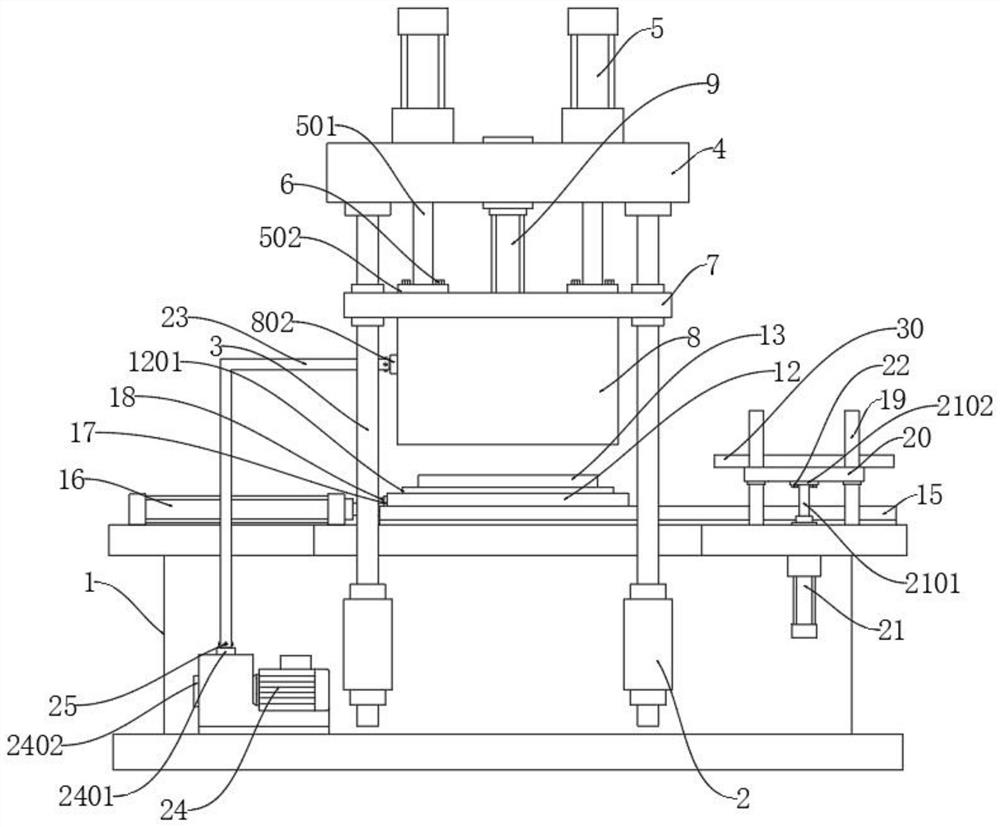

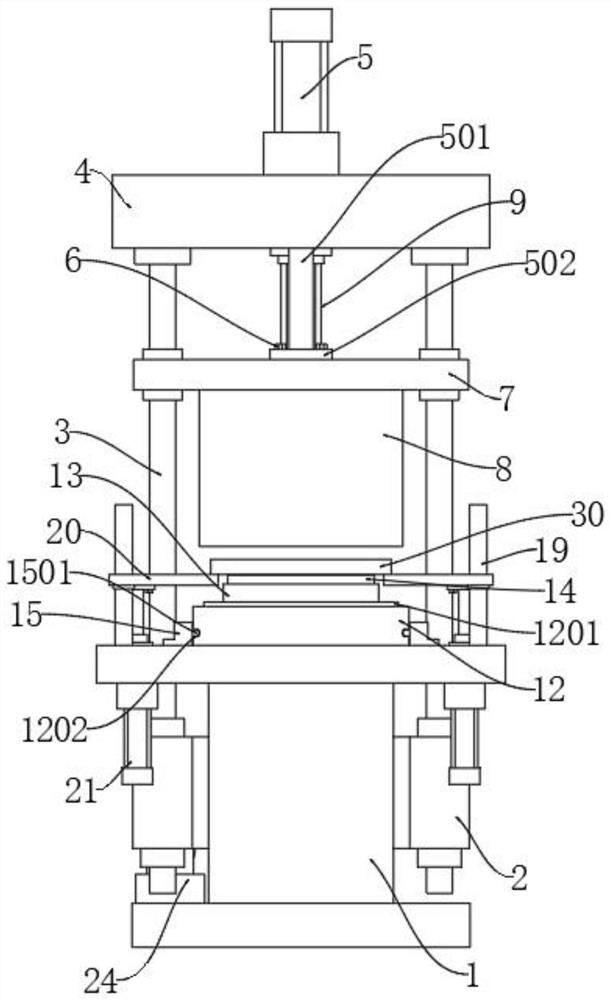

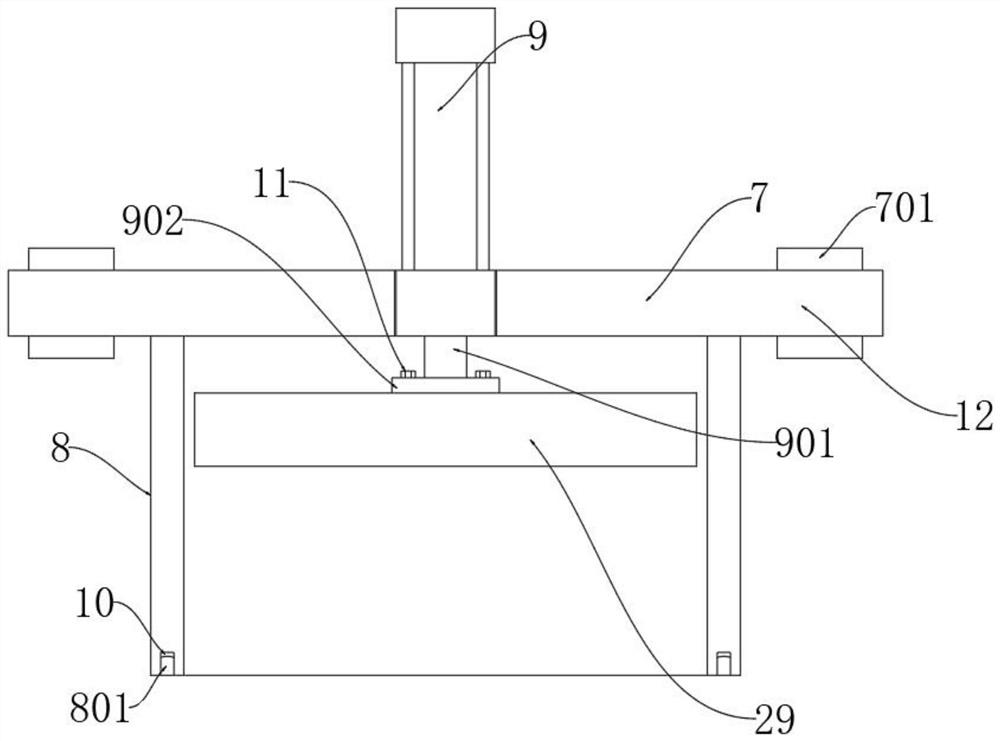

Assembly line type hot press molding system

The invention discloses an assembly line type hot press molding system, which comprises a lining feeding device, a tunnel type heating device and hot press molding equipment, wherein the tunnel type heating device comprises a long-strip-shaped shell, a conveying driving motor and two outer side conveying chain mechanisms; the lining feeding device is arranged on the left side of the tunnel type heating device; and the hot press molding equipment is arranged on the right side of the tunnel type heating device. According to the assembly line type hot press molding system, the left ends of the two outer side conveying chain mechanisms can be in butt joint with the lining feeding device, and the right ends of the two outer side conveying chain mechanisms can be in butt joint with the hot pressmolding equipment, so that an automobile roof lining on a material placement plate is automatically fed to a heating tunnel for heating and softening, and then the heated and softened automobile rooflining is automatically fed to the hot press molding equipment; accurate feeding of the left side of the tunnel type heating device can be facilitated through the lining feeding device; the hot pressmolding equipment can be used for conducting hot press molding on the to-be-processed lining.

Owner:盐城科普尔科技发展有限公司

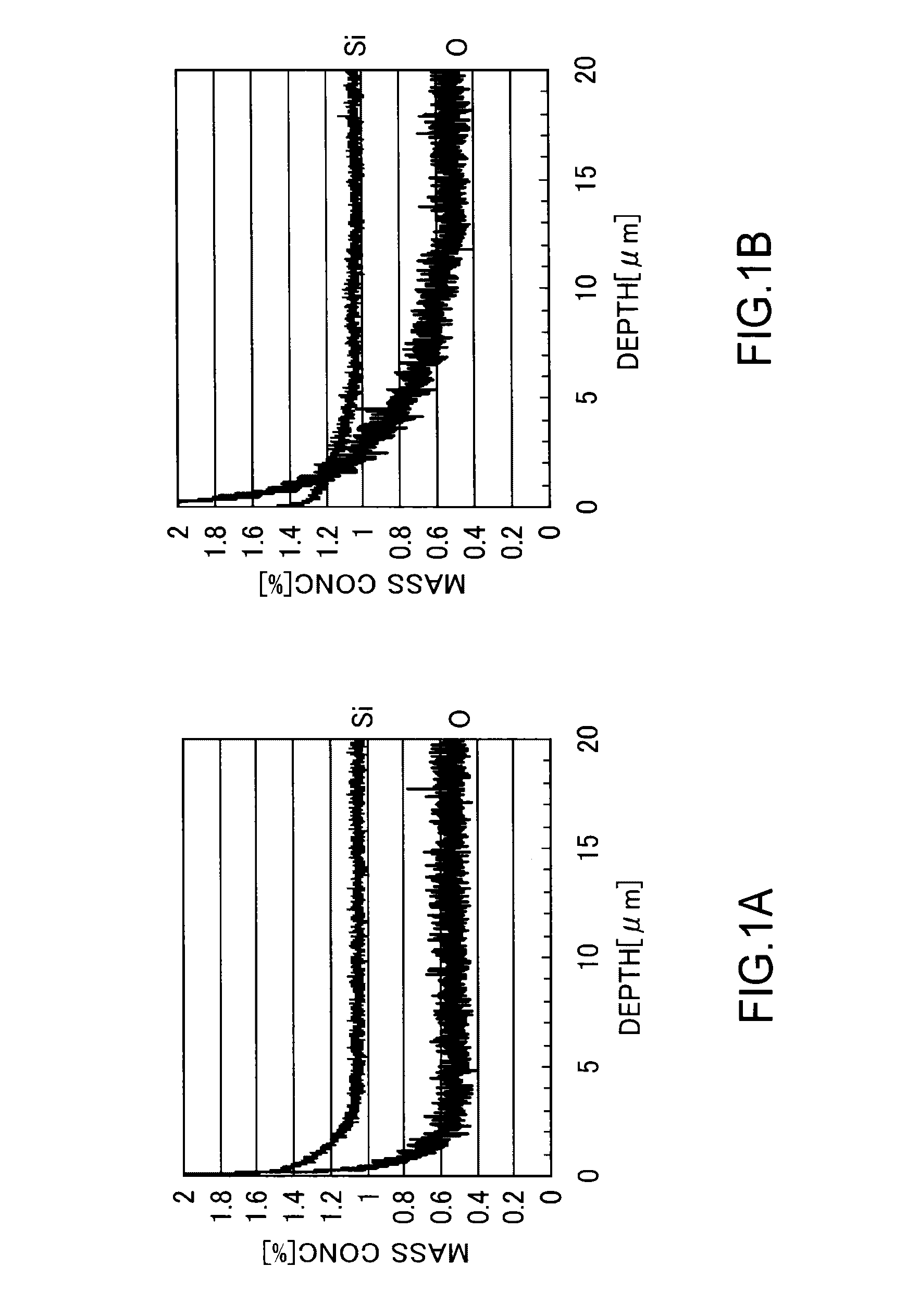

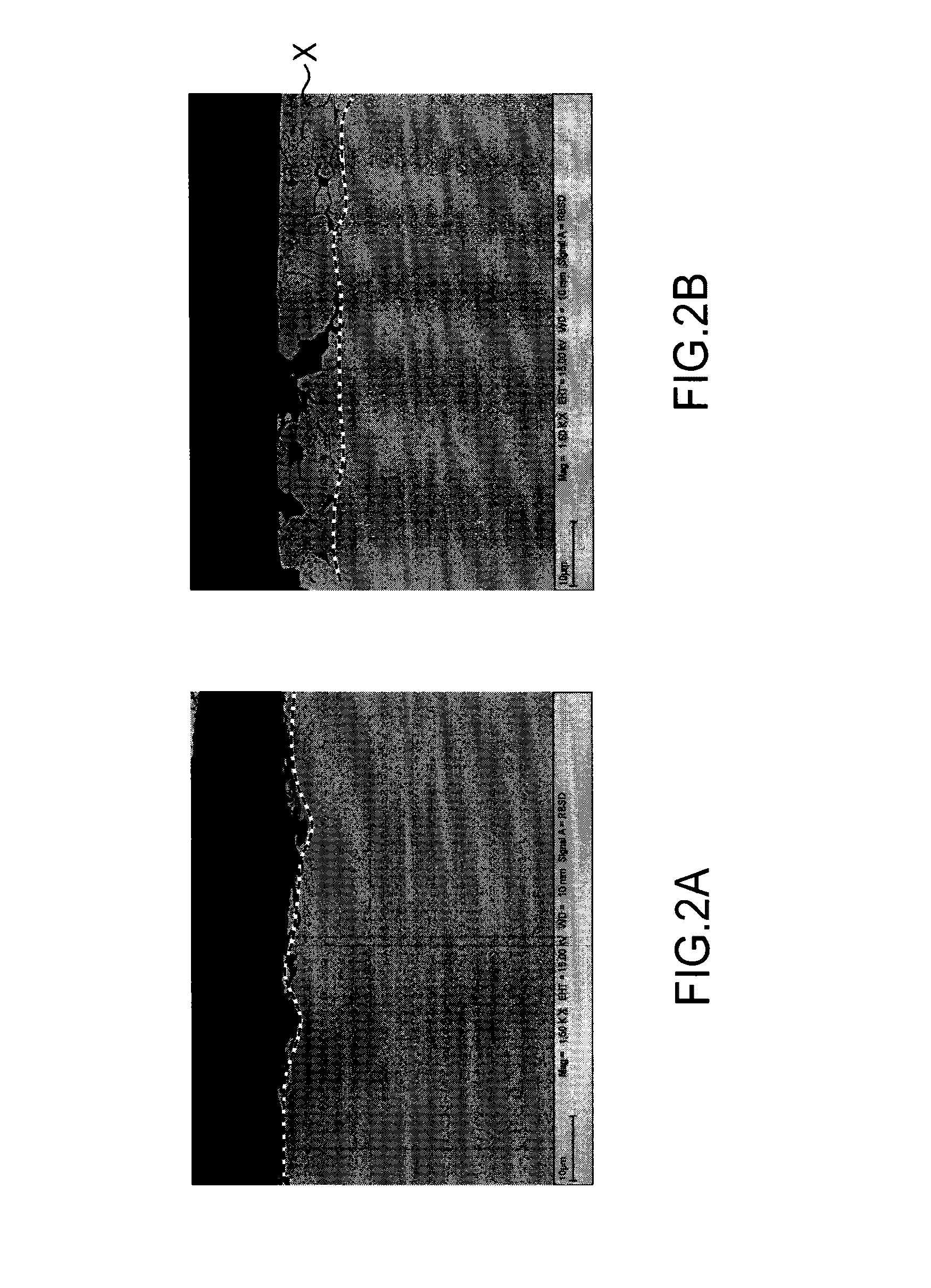

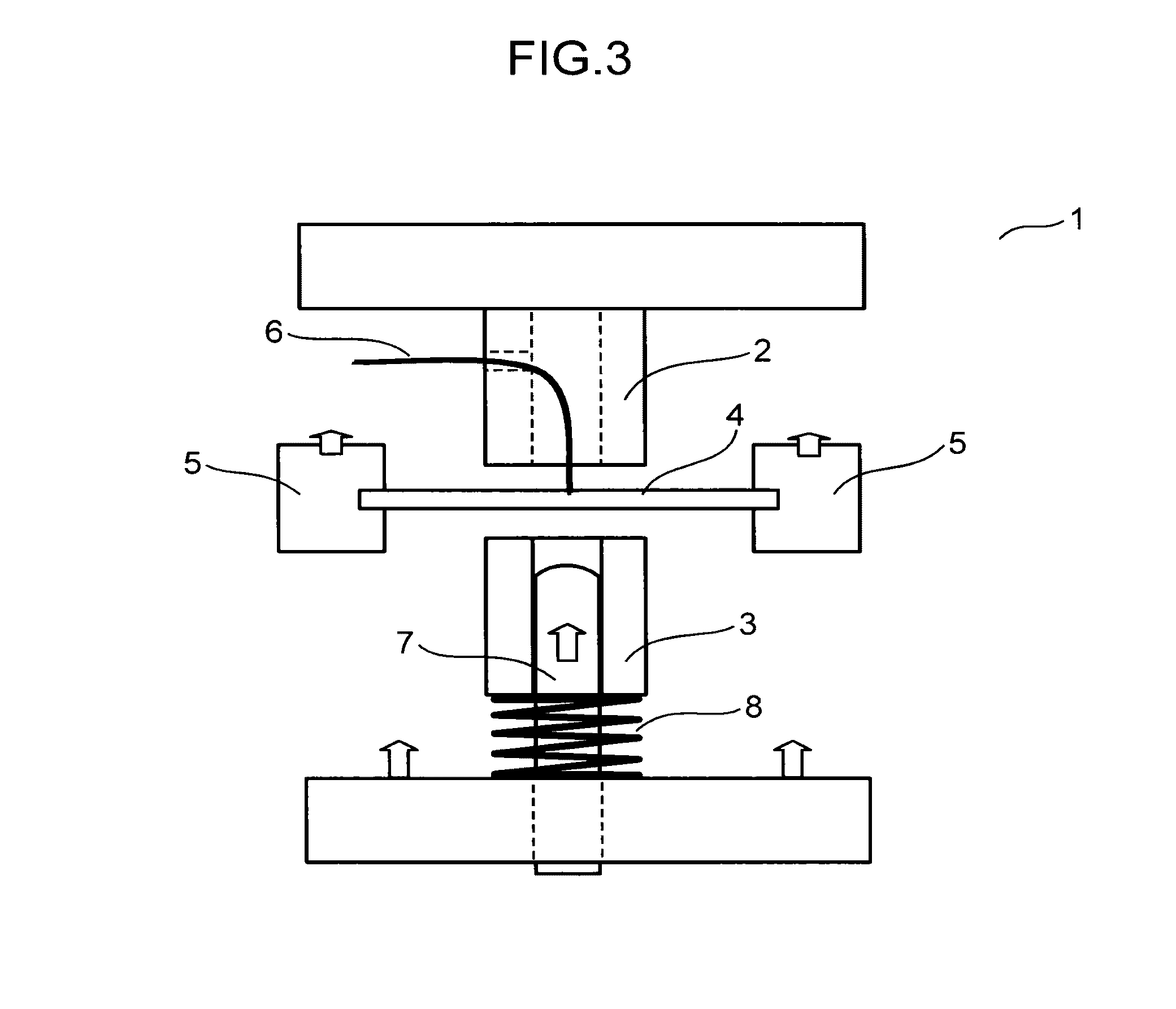

Steel plate for hot forming and manufacturing method of hot press formed steel member

InactiveUS20160319403A1Suppression scaleEasy thermoformingSolid state diffusion coatingFurnace typesNarrow rangeOxygen

Provided is a method for manufacturing a steel member through hot press forming using a steel sheet that contains a comparatively large amount of Si. The method allows hot press forming to be carried out satisfactorily by stably and reliably suppressing shedding / peeling of oxide scale during hot press forming, even without restricting hot press forming conditions to a narrow range. The steel sheet includes, in mass ratio, C: 0.15% to 0.35%, Si: 1.0% to 3.0%, Mn: 1.0% to 3.0%, Al: more than 0% up to 0.10%, Ti: ([N]×48 / 14) % to 0.10% (where [N] denotes the amount of N in the steel sheet), B: 5 ppm to 50 ppm, P: more than 0% to less than 0.015%, S: more than 0% up to 0.010%, and N: more than 0% up to 0.010%, the balance being iron and unavoidable impurities. The average oxygen concentration from an outermost surface of the steel sheet down to a depth of 10 μm in a sheet thickness direction is 0.70 mass % or higher.

Owner:KOBE STEEL LTD

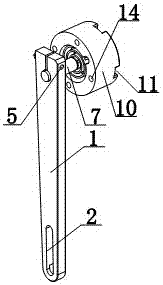

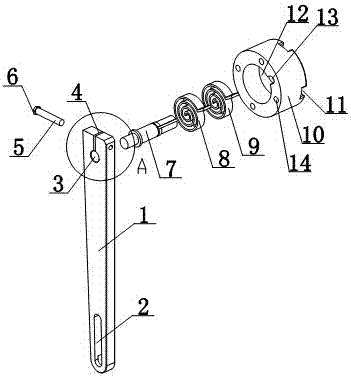

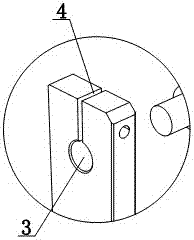

Spiral spring forming mounting mechanism

The invention discloses a plane scroll spring forming installation mechanism, which comprises a mounting plate, an installation hole is arranged at the upper end of the installation plate, an adjustment groove is arranged at the upper end of the installation plate, and the adjustment groove communicates with the installation hole; a set column is arranged at the installation hole , the end of the set column is provided with a mounting seat, the mounting seat is provided with an opening, the inner side wall of the mounting seat is provided with a card slot, the card slot communicates with the opening, and the opening is provided with a first molding piece and a second molding piece, the first The forming piece and the second forming piece are scroll-shaped; one end of the set column is set with a fixed ring, the other end of the set column is set with a buckle ring, and the end of the set column is provided with a slot, the first form piece and the second form piece The inner end of the first forming piece and the outer end of the second forming piece are clamped in the slotting position. The invention facilitates the heating and forming of the plane scroll spring and facilitates the processing of the plane scroll spring.

Owner:刘军

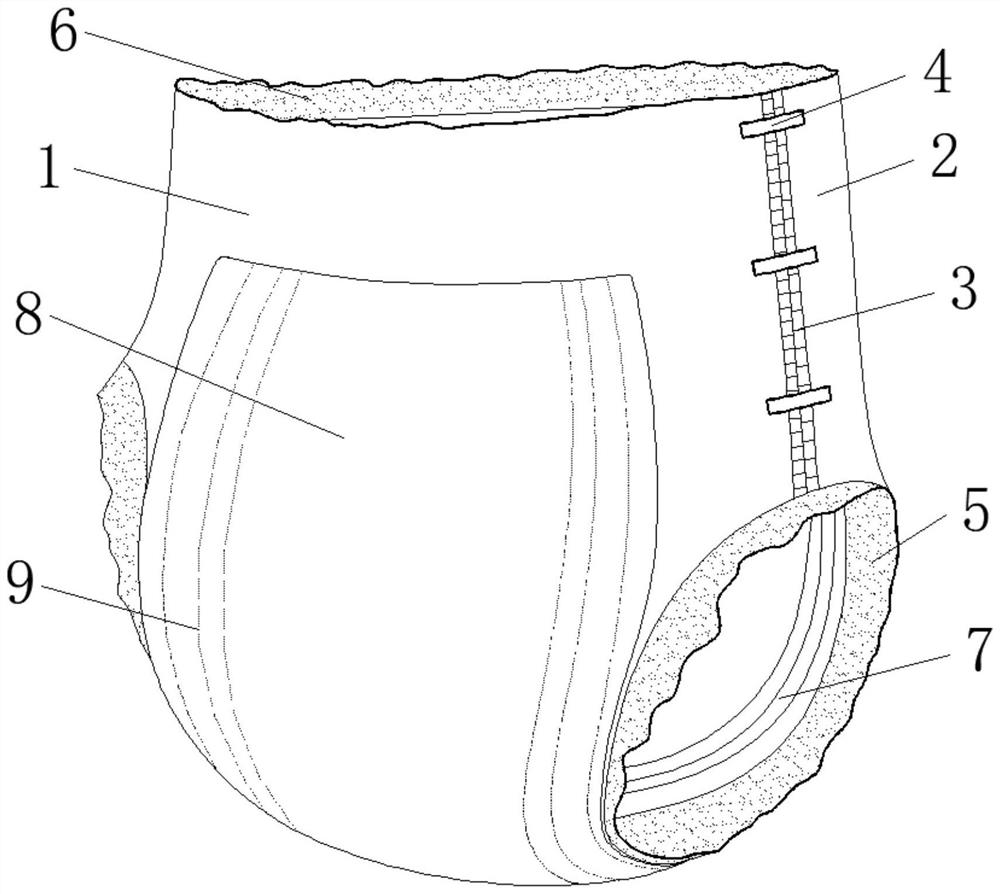

Infantile pull-up diaper and production process therefor

InactiveCN113041035AGuaranteed fit and comfortPrevent accidental dropAbsorbent padsBaby linensEngineeringPhysical therapy

The invention discloses an infantile pull-up diaper and a production process therefor. The infantile pull-up diaper comprises a front waistline region, a back waistline region, a thigh opening and a core layer, wherein the back waistline region is arranged at the tail end of the front waistline region, the core layer is arranged between the front waistline region and the back waistline region, a tear belt is arranged between the top of the front waistline region and the top of the back waistline region, a tearable adhesive tape is arranged at the outer side of the tear belt, the thigh opening is formed in the bottom of the front waistline region, a lumbar region enclosing port is formed in the top end of the front waistline region, a clinging belt is arranged at the inner side of the thigh opening, a discoloring belt is fixed to the brink of the core layer, and one end of the tearable adhesive tape is correspondingly fixed to the outer side part of the front waistline region or back waistline region. According to the infantile pull-up diaper and the production process therefor, the clinging and comfort of the pull-up diaper during wearing can be guaranteed, accidental falling-off can be avoided, relief of pressure to the legs and waist of an infant is facilitated, and meanwhile, the production efficiency of the pull-up diaper is guaranteed.

Owner:龙弟力

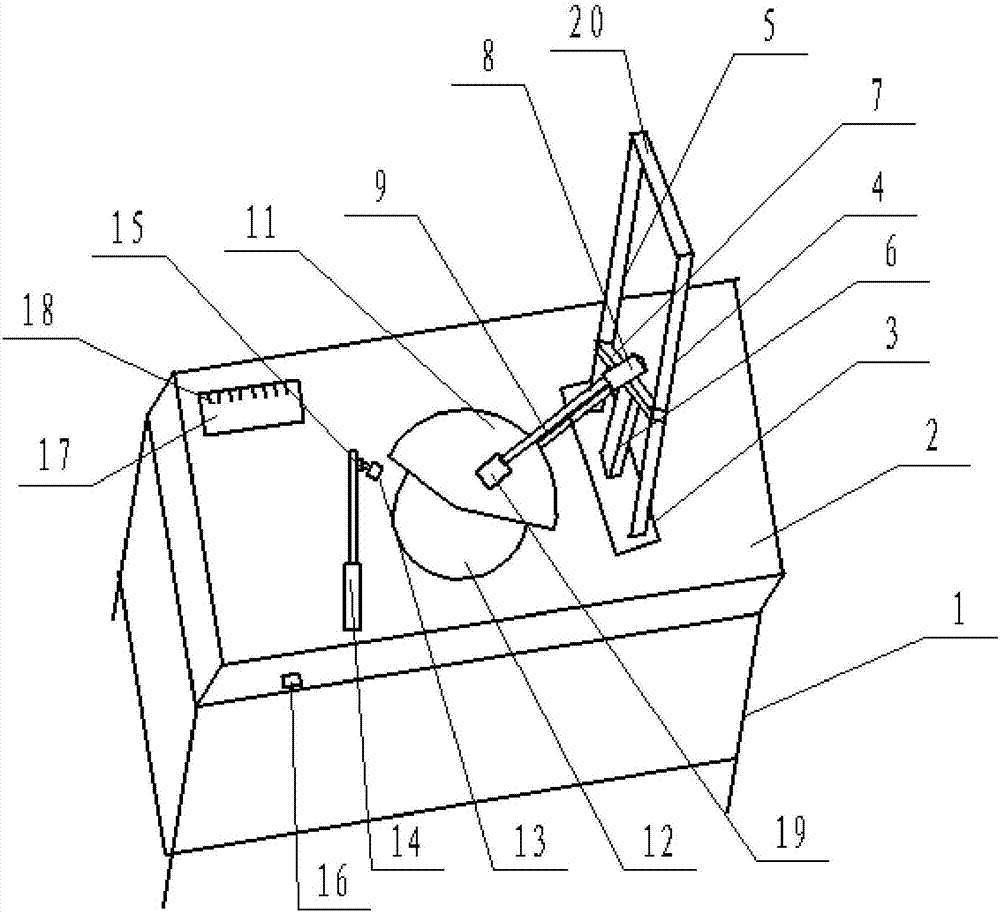

High-strength deformation-resistant carbon fiber bulletproof composite plate and forming process thereof

PendingCN113251867AImprove production and processing efficiencyEasy loadingLaminationLamination apparatusFiberCarbon fibers

The invention discloses a high-strength deformation-resistant carbon fiber bulletproof composite plate and a forming process thereof, and relates to the technical field of carbon fiber bulletproof composite plate structures. The problem that an existing high-strength deformation-resistant carbon fiber bulletproof composite plate forming device cannot well and quickly machine and form a carbon fiber bulletproof composite plate is solved. Limiting mounting bases are mounted on the two sides of a forming device table correspondingly, supporting rods are arranged at the upper ends of the limiting mounting bases, a mounting fixing base is mounted above the supporting rods, an electric air cylinder is mounted above the mounting fixing base, a movable limiting base is mounted below the electric air cylinder, a first air cylinder is installed above the movable limiting base, a sealing box is arranged below the movable limiting base, a movable supporting seat is installed above the forming device table, a limiting rod is arranged at the upper end of one side of the forming device table, a supporting seat is installed on one side of the limiting rod, and a second air cylinder is arranged at the lower end of the forming device table.

Owner:许瑞俊

Cutting machine capable of achieving positioning and damping

InactiveCN107116267AEasy to useImprove cutting accuracyMetal sawing devicesMetal sawing accessoriesEngineeringSlide plate

The invention discloses a cutting machine capable of positioning and damping, which belongs to the technical field of electric machinery. The cutting machine that can be positioned and shock-absorbed includes a frame, on which a workbench is provided, a cutting mechanism and an adjustment and positioning mechanism are arranged on the workbench, the cutting mechanism is located above the workbench, and the adjustment and positioning mechanism is connected with the cutting mechanism. Institutional connections. The slide plate on the adjusting and positioning mechanism is connected with the worm gear lifter, and the height of the cutting knife can be adjusted; and the clamping arm on the adjusting and positioning mechanism is connected with the cutting mechanism, and the clamping arm is formed into a pair by the reciprocating motion of the piston rod in the hydraulic cylinder. Clamping positioning of the cutting mechanism. Shock-absorbing material is also embedded within the cutting mechanism. The present invention can not only adjust the height of the cutting knife according to the thickness of different cutting materials, and is flexible to use, but also flexibly clamps and positions the cutting mechanism after the height is adjusted. The shock-absorbing material embedded in the cutting knife mounting body further improves the cutting precision of the cutting machine of the present invention.

Owner:柳州市昌泉贸易有限公司

Method for producing methacrylate ester resin forms

The invention provides: (1) a method for manufacturing methacrylate resin molded body, which is characterized in that a methacrylate resin paste containing polymerization initiator 100 to 5,000 ppm, alkyl sulfhydrate 500 to 3,500 ppm and terpenoid 50 to 150 ppm is injected into an element and polymerized; (2) a method for manufacturing methacrylate resin secondary molded body, which is characterized in that the slab-shaped methacrylate resin molded body obtained by the manufacture method recorded in (1) is subjected to thermoforming; (3) a methacrylate resin molded body, which is characterized in being formed by injecting methacrylate resin paste containing polymerization initiator 100 to 5,000 ppm, alkyl sulfhydrate 500 to 3,500 ppm and terpenoid 50 to 150 ppm and polymerized; and (4) a methacrylate resin paste containing polymerization initiator 100 to 5,000 ppm, alkyl sulfhydrate 500 to 3,500 ppm and terpenoid 50 to 150 ppm.

Owner:SUMITOMO CHEM CO LTD

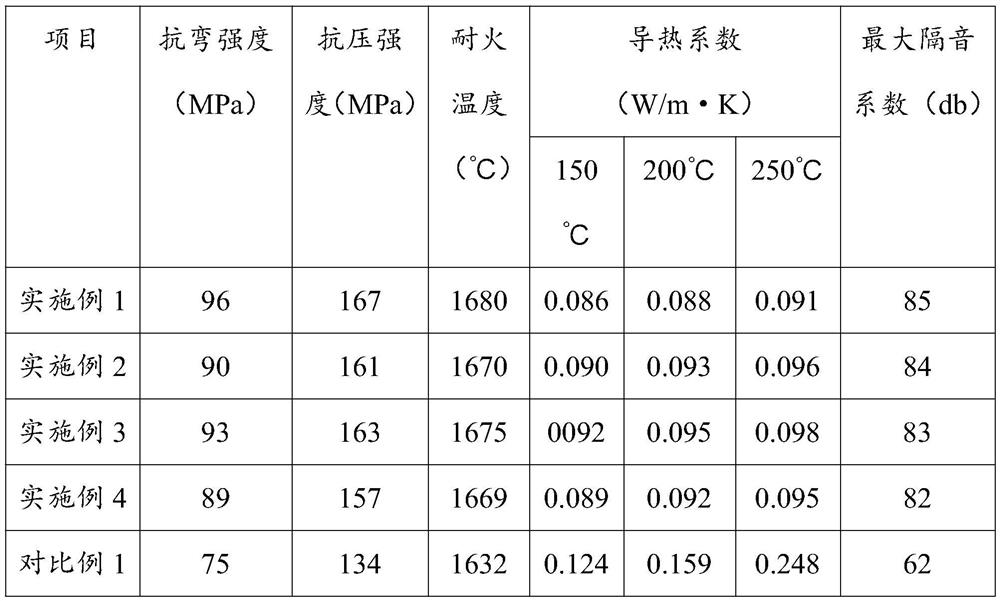

A kind of building material with high sound insulation epoxy resin

Owner:SHENZHEN ZHIBEN BUILDING ENERGY SAVING MATERIALS CO LTD

Manufacturing method of glue filler

InactiveCN114316840AImprove board speedNot stickyNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesive glueProcess engineering

The invention relates to a manufacturing method of a glue filler. The manufacturing method specifically comprises the following steps: (1) weighing the following raw materials in percentage by weight: 65-75% of mineral substances, 15-25% of wood flour and 10% of a thickening agent; and 2) mixing the raw materials, uniformly stirring with a stirrer, and bagging. The adhesive has the advantages that the adhesive can replace flour, and the adhesive applying requirement for plywood production can be met in the adhesive mixing link; in the plate arranging link, the ecological flour is better than traditional flour, the plate arranging speed is increased, gluing plates are not prone to adhesion, operation of workers is facilitated, and the working efficiency is improved. In the cold pressing process, pre-pressing forming is easy, the pre-pressing effect is good, and the pre-pressing time is short. In the hot pressing process, the bonding strength of the plywood can be enhanced, hot pressing forming is good, and glue failure is not prone to occurring.

Owner:胡心怡

A kind of y-doped pseudo-ternary semiconductor refrigeration material and its preparation method

ActiveCN108878634BPromote growthObvious lamellar structureThermoelectric device manufacture/treatmentThermoelectric device junction materialsPhysical chemistrySemiconductor

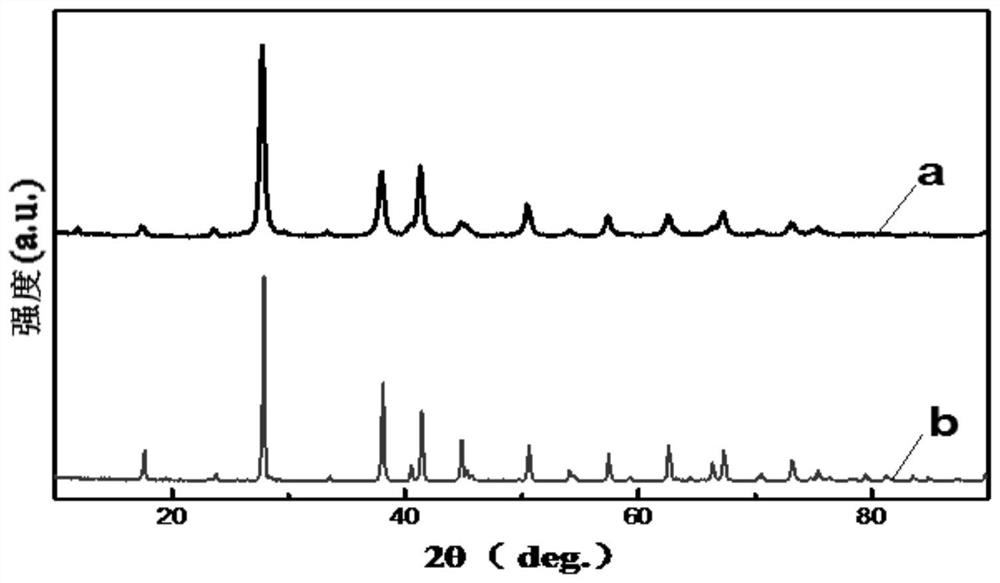

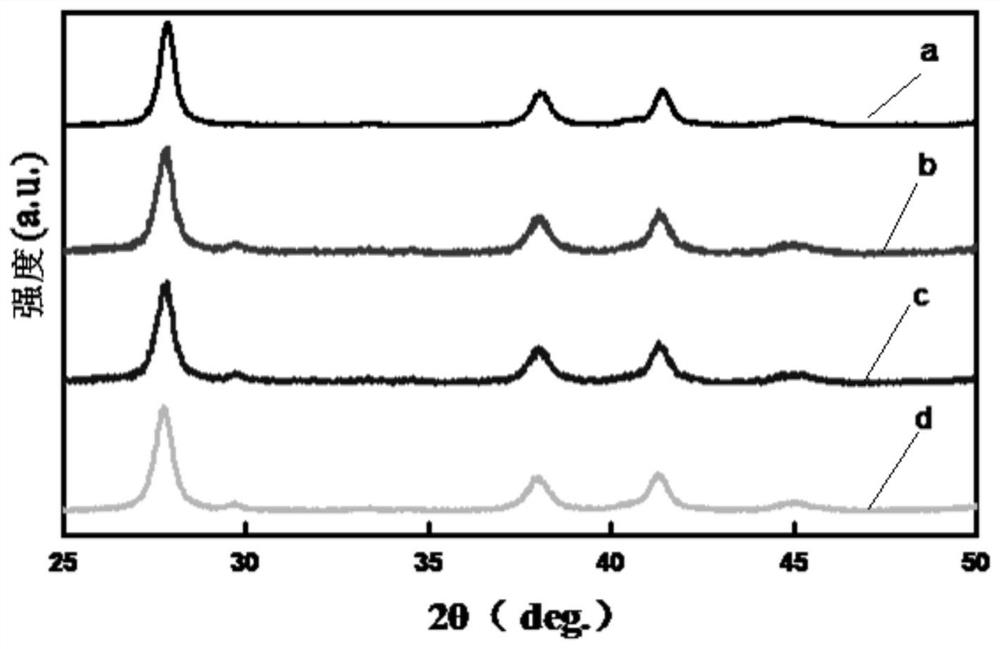

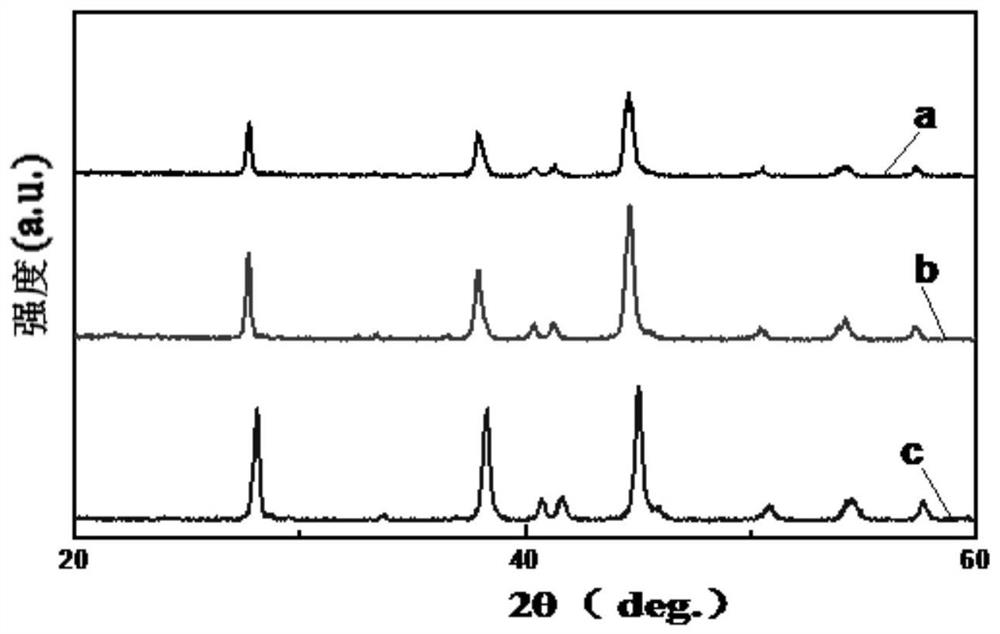

A Y-doped pseudo-ternary semiconductor refrigeration material and a preparation method thereof, relating to a semiconductor refrigeration material and a preparation method thereof. The purpose is to solve the existing Bi 2 Te 3 The semiconductor-based cooling material is prone to splitting during the cutting process. The molecular formula of the Y-doped pseudo-ternary semiconductor refrigeration material is: (Bi 2 Te 3 ) (1‑2x) (Sb 2 Te 3 ) x (Bi 2 Se 3 ) x ‑Y, x in the molecular formula is 0.04~0.06. Preparation: Weigh yttrium powder, tellurium powder, bismuth powder, antimony powder and selenium powder as raw materials; the raw materials are mechanically alloyed, the sample is sintered in vacuum at high temperature, and finally hot-pressed. The mechanical properties of the Y-doped pseudo-ternary semiconductor refrigeration material prepared by the invention are greatly improved, and the problem of easy splitting is solved. The Y-doped concentration is 1% and the ZT value of the material at 300K when the Y-doped concentration is 1% and is hot-pressed at 200°C 0.73. The invention is suitable for preparing semiconductor refrigeration materials.

Owner:HARBIN NORMAL UNIVERSITY

Moisture barrier material

PendingUS20200317959A1Speed up application processSafer to applyNatural rubber adhesivesFilm/foil adhesivesMoisture barrierComposite material

Owner:NITTO INC +1

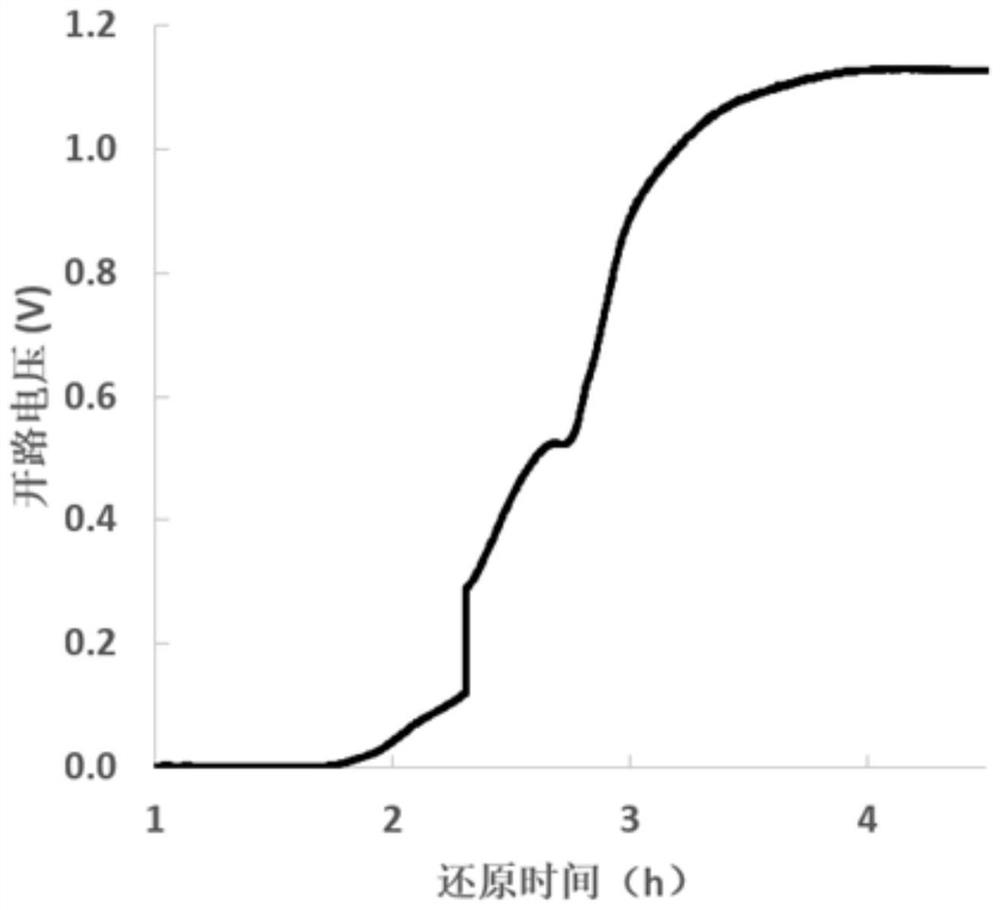

Composite reagent for tape casting, fuel cell and preparation method of fuel cell

PendingCN114267843AReduce the differenceEasy thermoformingCell electrodesElectrical batteryMaterials science

The invention provides a composite reagent for tape casting, a fuel cell and a preparation method of the fuel cell. The reagent comprises a composite solvent, a composite liquid binder and a composite plasticizer, the universal reagent for composite tape casting is obtained, the difference of raw material powder in different structures can be weakened when a fuel cell is prepared, the shaping, lubricity and ductility of a tape casting blank are optimized at the same time through the synergistic effect, and the service life of the fuel cell is prolonged. Hot press molding is easier between the tape casting layers, and the film has higher self-adaptability to oxides and metal powder, and is suitable for tape casting to prepare each structure of a fuel cell; a half cell containing an anode and an electrolyte of a fuel cell is prepared by adopting the reagent for tape casting, and a cathode is prepared by adopting a pyrolysis spraying mode, so that the preparation process of the fuel cell is simplified, the firing time of part of key components is prolonged, and the production cost is reduced. And the limitation that a conventional cathode cannot be prepared by sintering a battery support body mainly made of stainless steel or containing metal components in a high-temperature oxidizing atmosphere is avoided.

Owner:湖北赛傲氢能科技有限公司

ABS board machining method and equipment

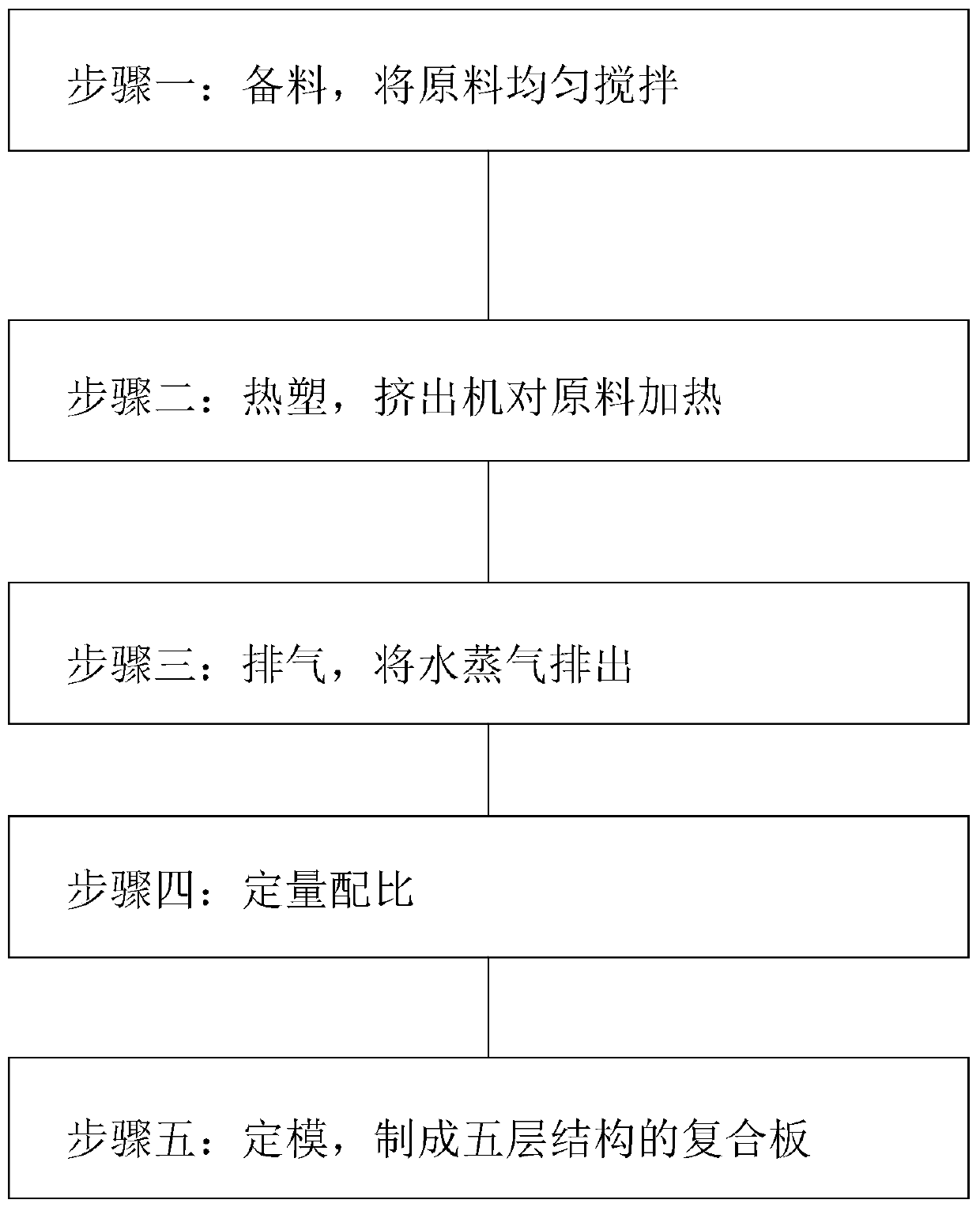

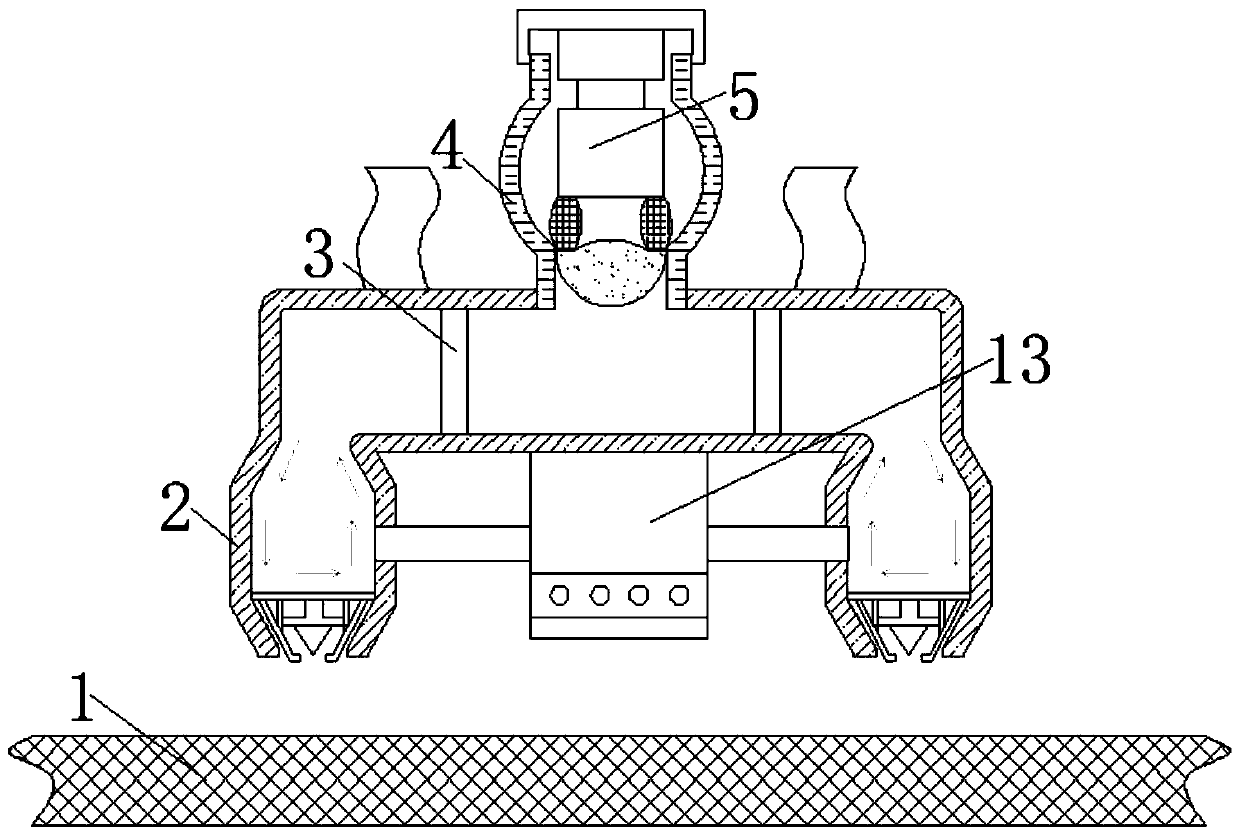

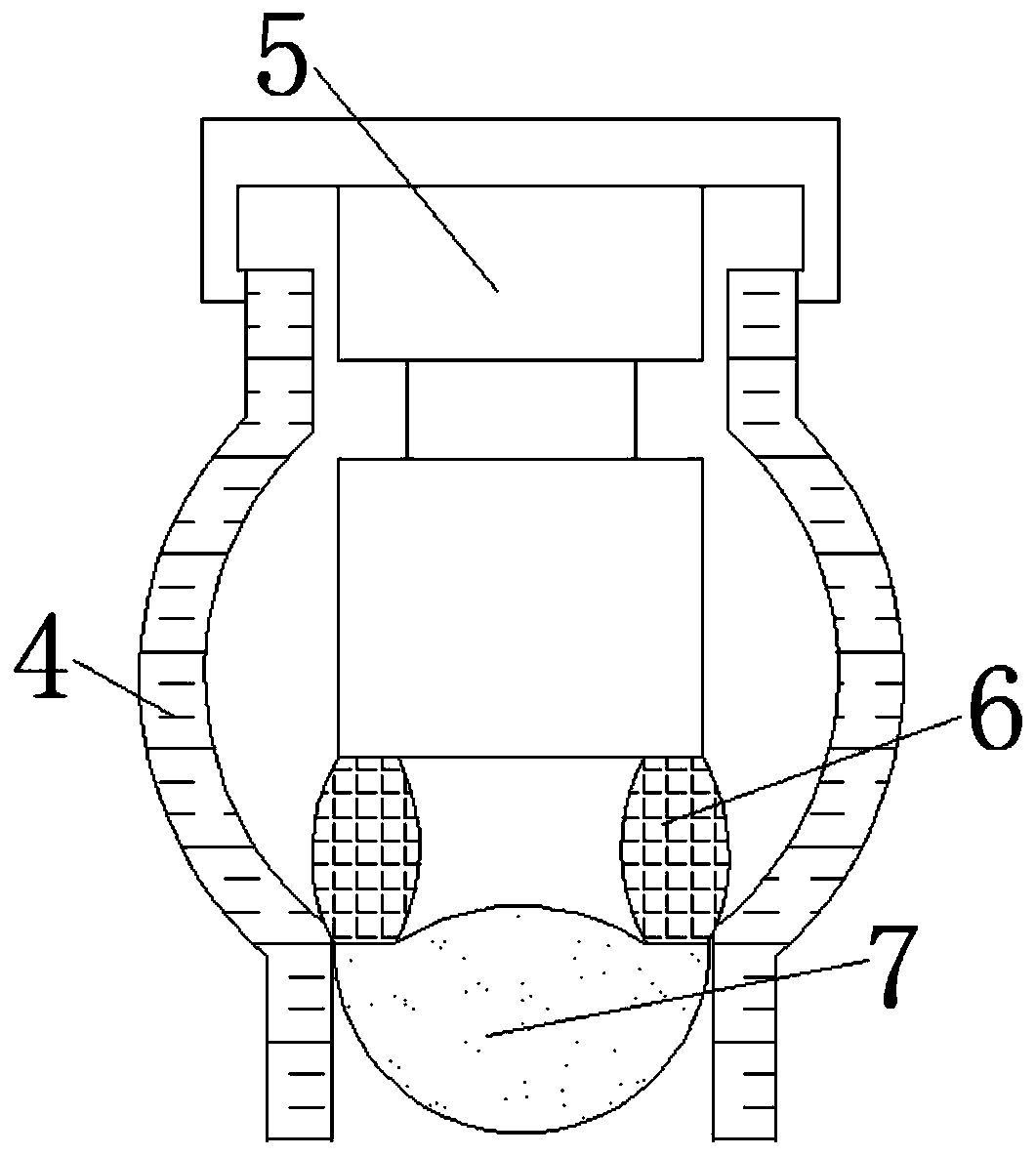

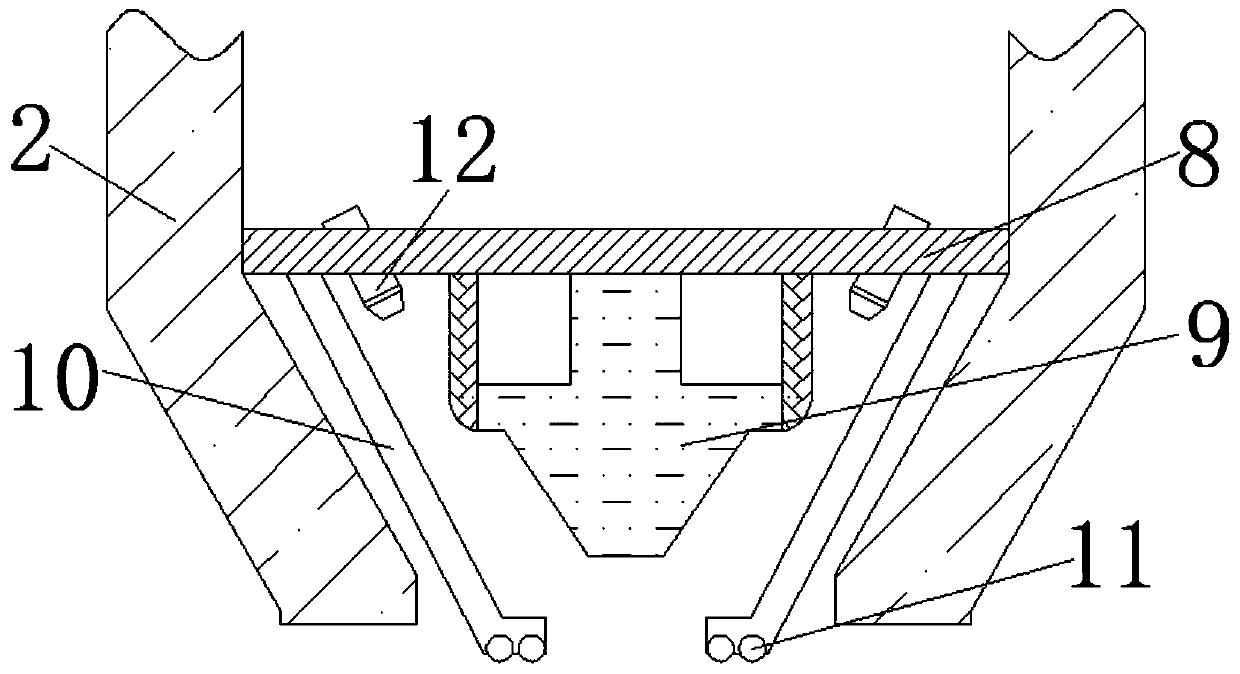

ActiveCN110421816AGood optical performanceImprove aestheticsSynthetic resin layered productsGlass/slag layered productsWater vaporEngineering

The invention discloses an ABS board machining method and equipment. The method comprises the following steps of 1, preparing materials, specifically injecting ABS raw materials, ASA raw materials, PMMA raw materials and sound insulation raw materials into four stirring machines, starting the stirring machines, and uniformly stirring the raw materials; 2, heating plastic, specifically heating theraw materials through an extruding machine; 3, exhausting air, specifically discharging water vapor in the raw materials after hot melting from an air exhaust hole of a material barrel; 4, quantifying, specifically quantitatively extruding the ABS raw materials, the ASA raw materials, the PMMA raw materials and the sound insulation raw materials; and 5, molding, specifically injecting the raw materials into five corresponding mold cavities in a mold to producing a composite board with five layers of structures. According to the technical scheme, the proportion of different raw materials can bequantified, ABS boards with different functions can be machined and produced, and the production efficiency of the ABS boards is improved.

Owner:浙江达尔美塑胶有限公司

Negative pressure principle based flat setting device for canvas production

ActiveCN111074463AWill not be voidEasy activityHeating/cooling textile fabricsTextile treatment by spraying/projectingCompression moldingEngineering

The invention relates to the technical field of canvas production, and discloses a negative pressure principle based flat setting device for canvas production. The device comprises an operation platform, a shell is arranged above the operation platform, an adsorption plate is fixedly installed at the upper end inside the shell, a negative pressure shell is fixedly installed on the upper surface ofthe shell, and a hydraulic rod is fixedly installed at the upper end of the negative pressure shell. Through the cooperative use of a seal plate, a negative pressure suction head, a heating block, afinishing ball and an atomization pipe, water in the shell can be atomized out, and the atomized water is sprayed on a canvas, so that fiber tissues are expanded, loose and stretched when the heatingblock and the finishing ball are used for finishing wrinkles on the canvas; by virtue of the lubricating effect of water molecules, fiber internal macromolecules are easy to move, hot compression molding is facilitated, and finally the purpose of heat setting is achieved; and the use is facilitated, the canvas is not cancelled, and the environment and resources are protected.

Owner:诸城市金泽园工贸有限公司

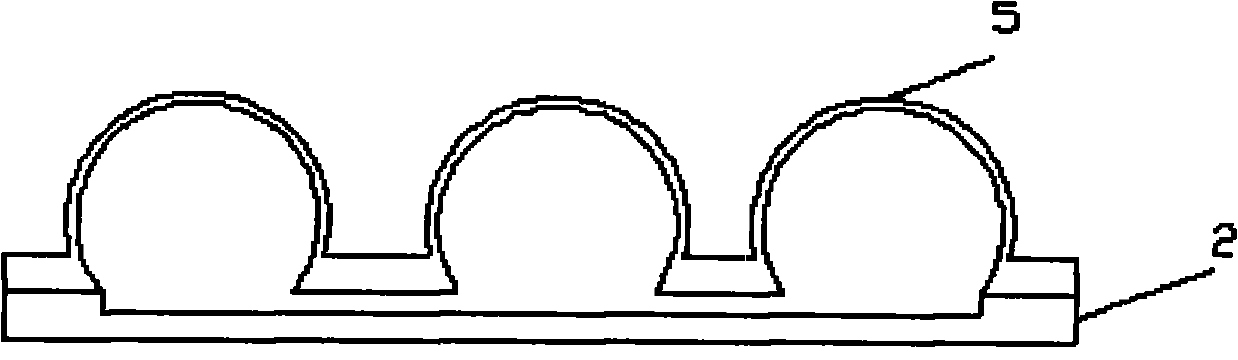

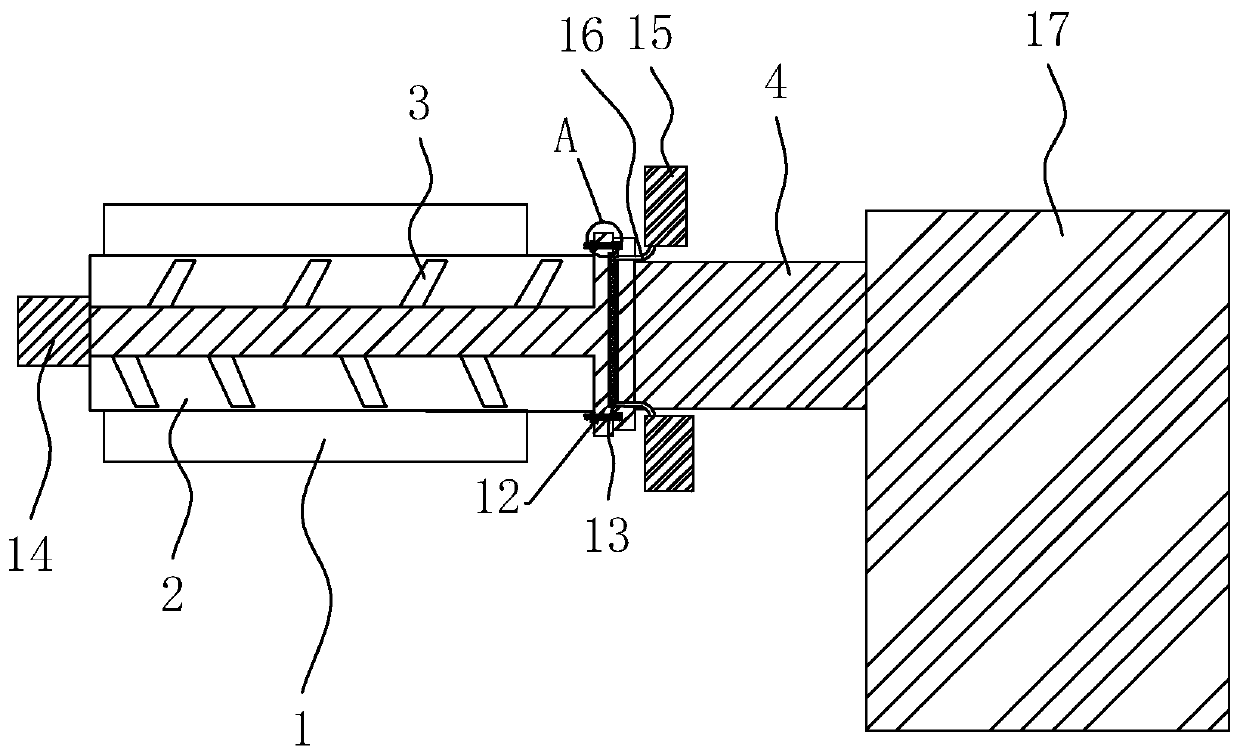

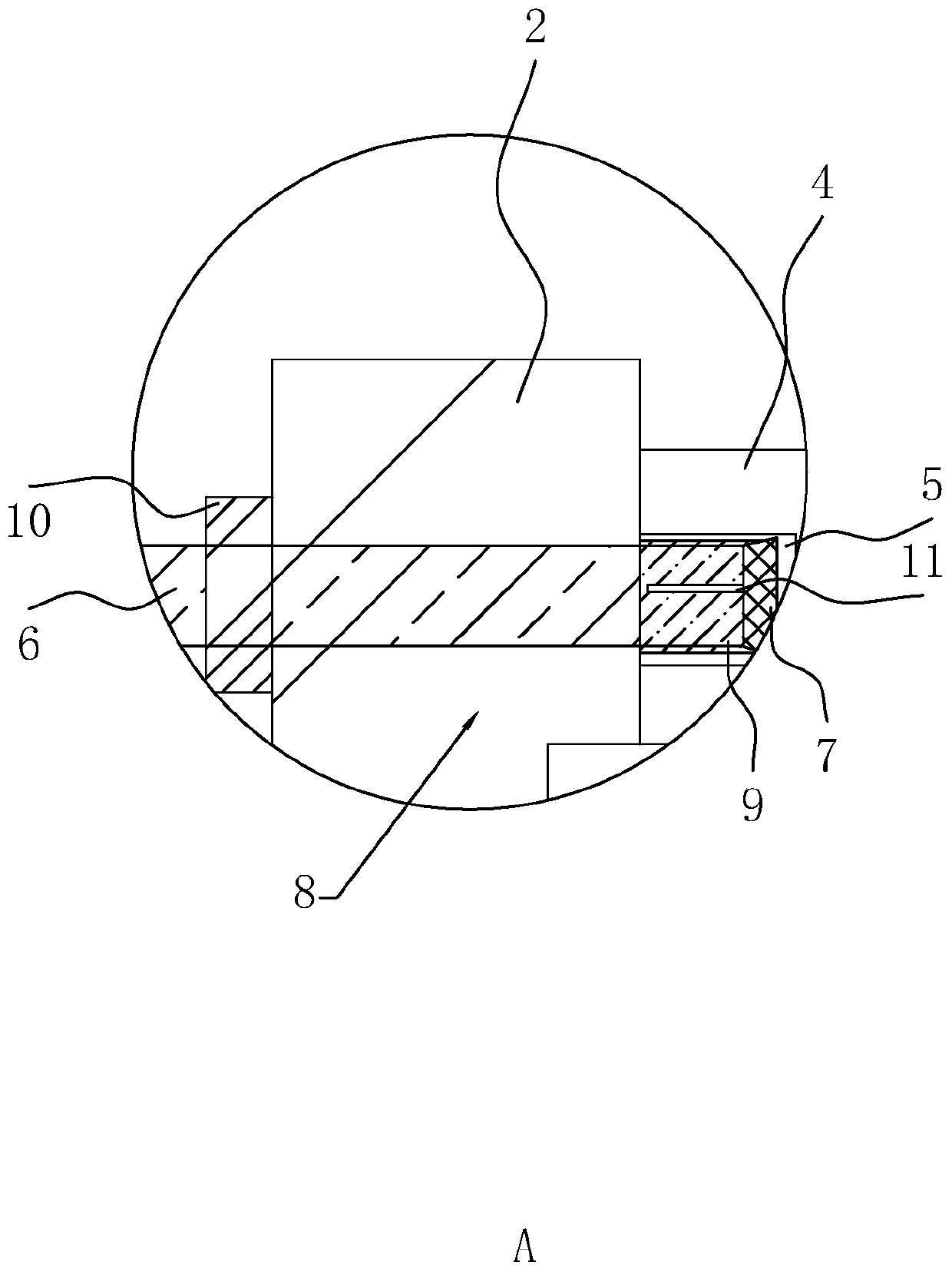

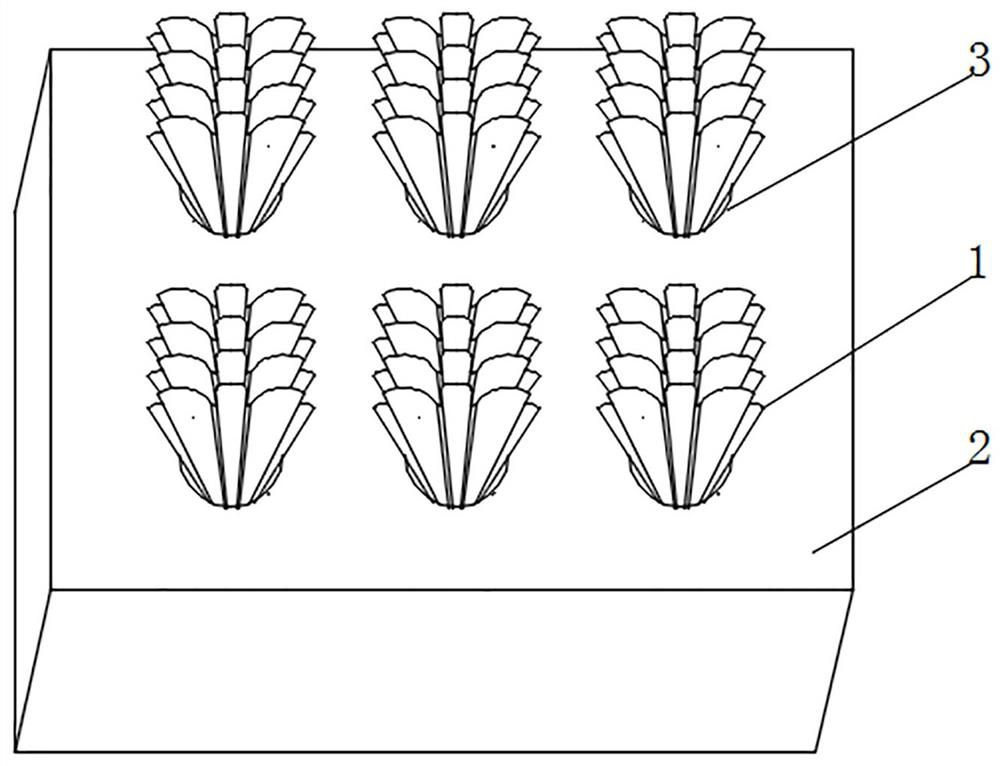

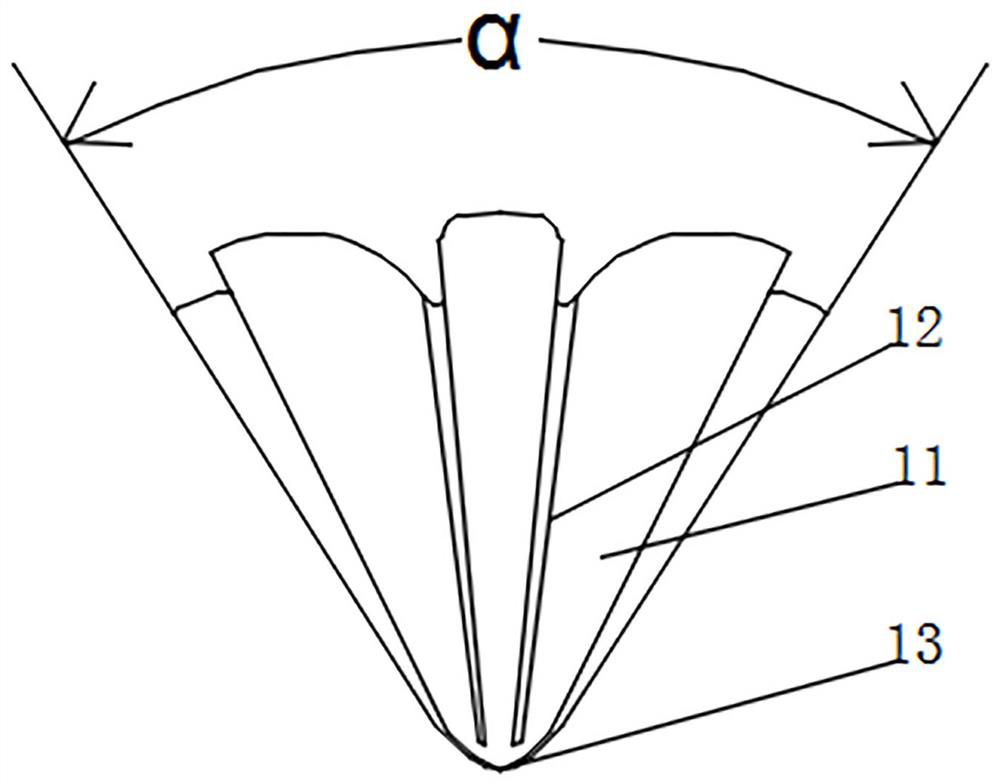

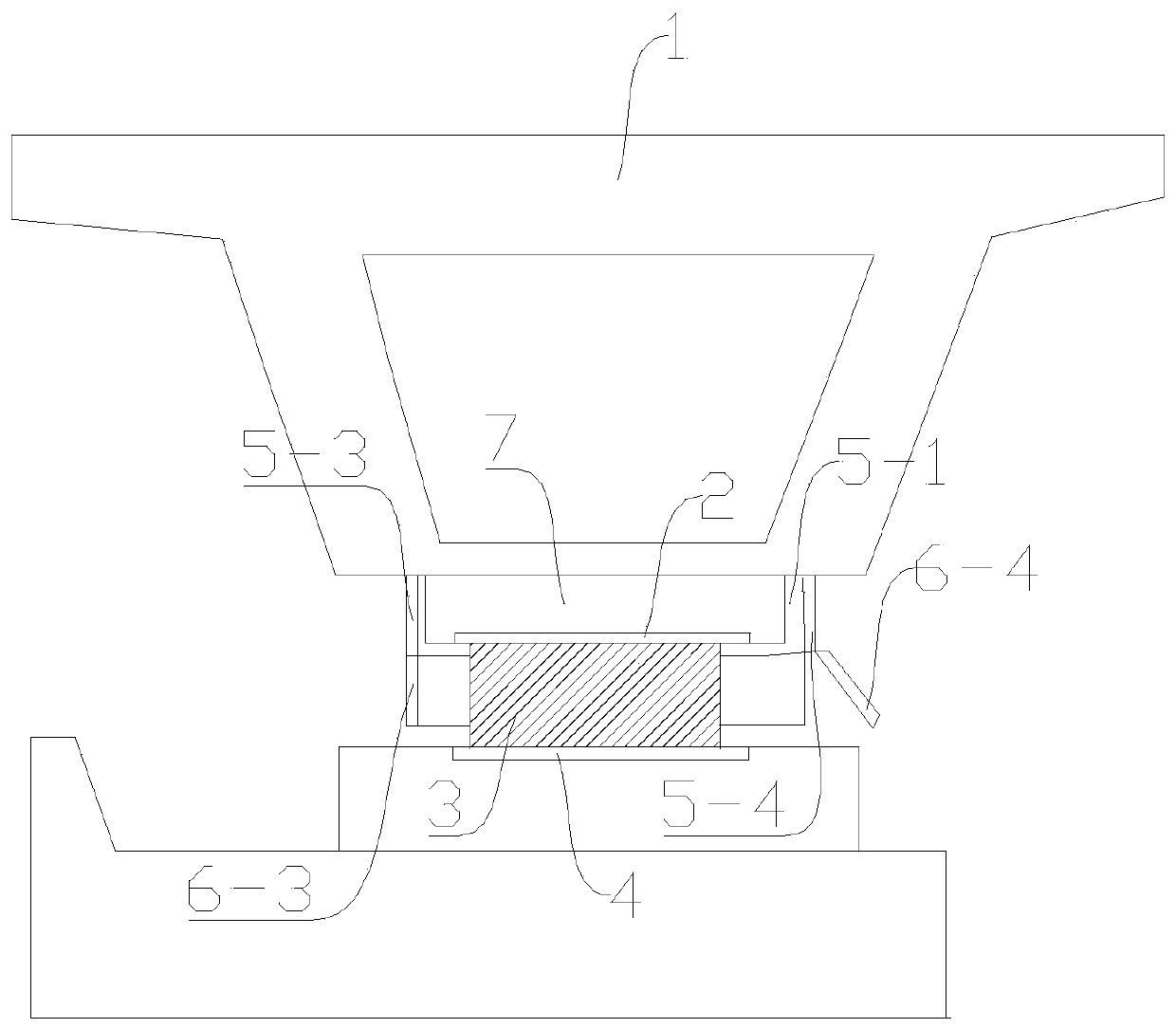

Preparation technology of mesh plug type patch

A preparation process of a mesh plug type patch belongs to the technical field of hernia repair patches, and in particular relates to a preparation process of a mesh plug type patch. It is characterized in that it includes the following steps: step 1, cutting the petal-shaped polypropylene mesh: cutting the polypropylene mesh into petal-shaped polypropylene mesh; step 2, processing the hot-pressing forming device: the hot-pressing forming device includes a base, the base The fixing holes are arranged on the base; the fixing holes are arranged vertically and horizontally on the base, and a shaping device is movably arranged on the fixing hole; 3. Heating and shaping: heating at 120°C-180°C for 90min-150min to set the shape; step 4, cooling and moulding: after cooling to 20°C-35°C, take out; step 5, sterilization of the packaged product: sterilize with ethylene oxide . The invention has the positive effects of simple process, low labor intensity and low scrap rate.

Owner:日照天一生物医疗科技有限公司

Novel road bridge beam supporting seat dustproof structure

PendingCN110184905AAdaptableGood weather resistanceBridge structural detailsTest efficiencyArchitectural engineering

The invention discloses a novel road bridge beam supporting seat dustproof structure, including a beam body, an upper cushion stone and an upper steel plate located below the beam body, a supporting seat located below the upper steel plate, a fixed side plate enclosing the upper cushion stone and the upper steel plate, a movable side plate located below the fixed side plate and enclosing the supporting seat, and a lower steel plate located below the supporting seat, and the upper edge of the movable side plate is hinged to the lower edge of the fixed side plate. According to the novel road bridge beam supporting seat dustproof structure, manufacture of the fixed side plate and the movable side plate by perspex is adopted, durability is good, and the structure is not prone to aging; and corrosion of the steel plate of the bridge beam supporting seat caused by seepage of water is prevented effectively, the influence of dust on a sliding surface of the supporting seat is prevented, agingof the supporting seat is slowed, and the life of the supporting seat is prolonged. The state of the supporting seat is tested visually without the need of using other methods, testing efficiency is improved, a supporting seat maintenance operation is not hindered, a replacement operation of the supporting seat during later maintenance is convenient, and long-time benefits are obvious.

Owner:江苏京沪高速公路有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com