Assembly line type hot press molding system

A hot-press forming and flow-through technology, which is applied to household components, household appliances, and other household appliances, can solve the problems of inaccurate positioning, high labor intensity of workers, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

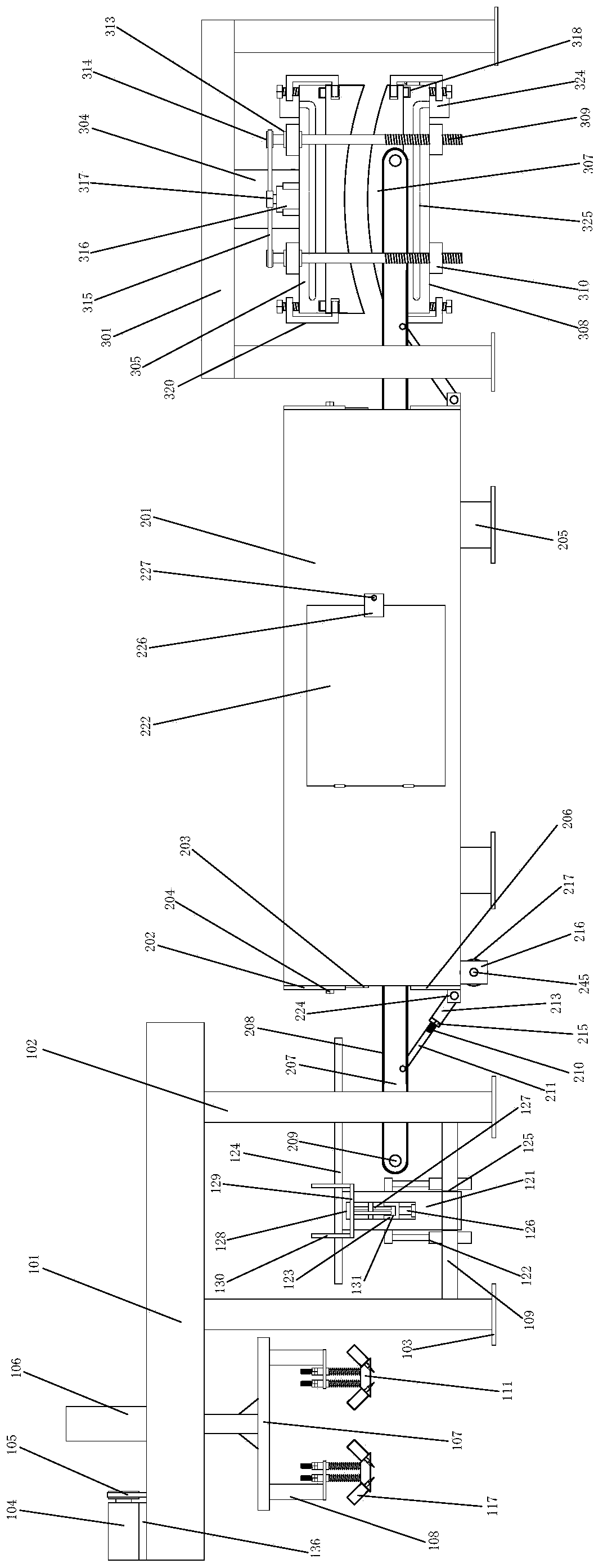

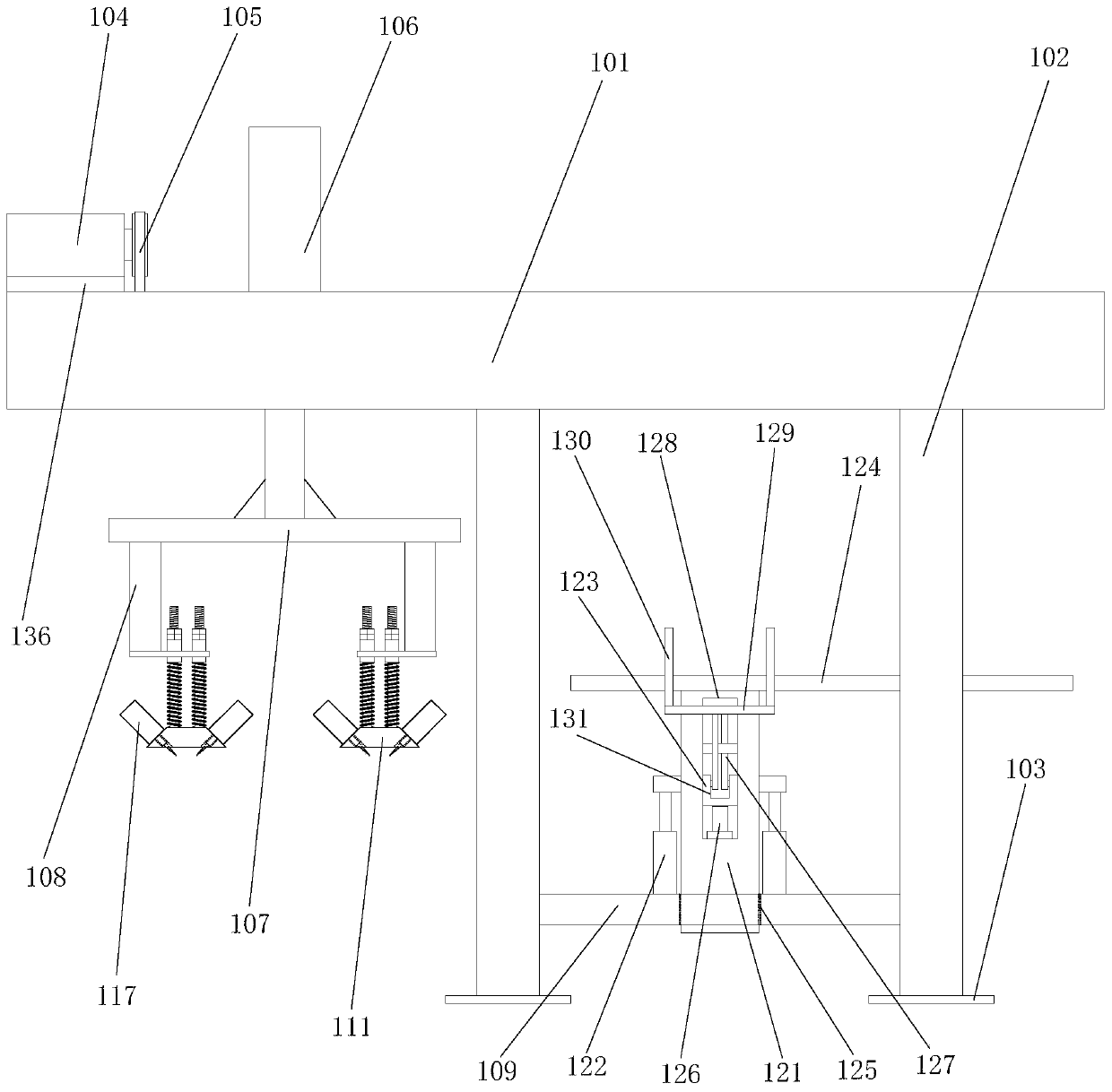

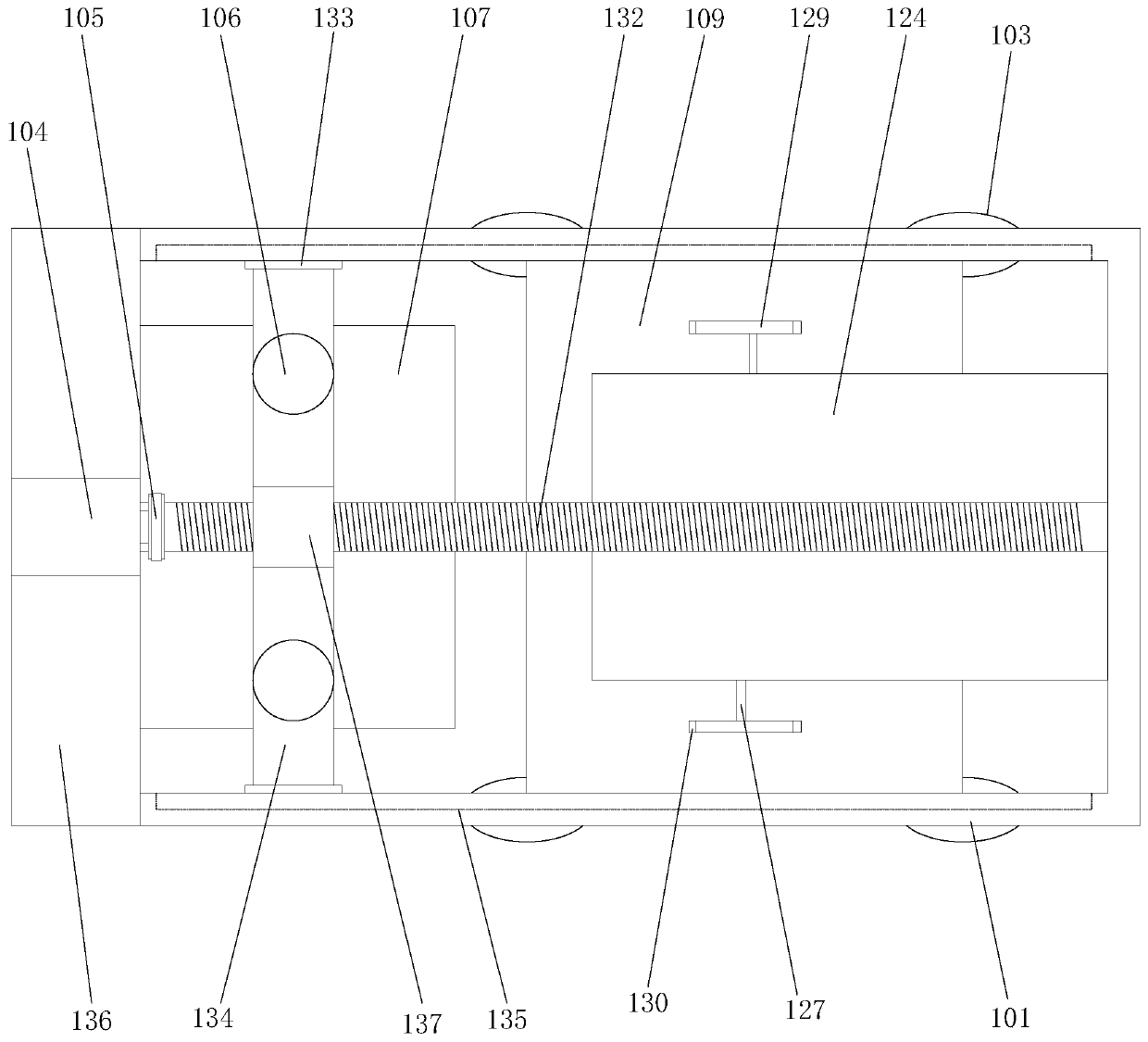

[0042] Such as Figure 1-10 As shown, the flowing water hot press forming system disclosed in the present invention includes: an inner lining feeding device, a tunnel heating device and a hot press forming device;

[0043] The tunnel heating device includes an elongated housing 201, a conveying drive motor 217, and two outer conveying chain mechanisms;

[0044] The bottom of the elongated shell 201 is provided with four shell support feet 205; a heating tunnel 236 is arranged transversely in the elongated shell 201, and an inner conveying chain mechanism is arranged transversely in the heating tunnel 236; an inner conveying chain mechanism It includes two supporting shafts 237 and two strip-shaped side plates 235; the two supporting shafts 237 are respectively installed longitudinally and rotatably at the left and right side tunnel entrances of the heating tunnel 236; the two strip-shaped side plates 235 respectively rotate at both ends Mounted on two supporting shafts 237, and tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com