Polyarylether sulphone resin with main chain containing cage-type silsesquioxane double-deck structure and preparation method thereof

A technology of silsesquioxane and polyaryl ether sulfone, which is applied in the field of polymer chemistry, can solve the problems of cage-type silsesquioxane hybridization, etc., achieve good industrial application prospects, easy to obtain raw materials, and simple synthesis route Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 2Si-OH monomer, bisphenol A, dichlorodiphenyl sulfone and potassium carbonate into a nitrogen-protected container, use sulfolane as a solvent, and use toluene as a water-carrying agent. Raise the temperature to 150°C, and react with water to form a salt for 4 hours. The temperature was raised sequentially to 180, 200 and 220°C for 2 hours each. Discharge in deionized water, pulverize, wash with water and ethanol three times respectively to prepare polyarylether sulfone 1 and polyarylether sulfone 2-6 with cage organosilsesquioxane double deck structure in the main chain. The feed ratio and production rate are shown in Table 1.

[0026] Table 1: The feed ratio and yield of polyarylethersulfone 1-6

[0027]

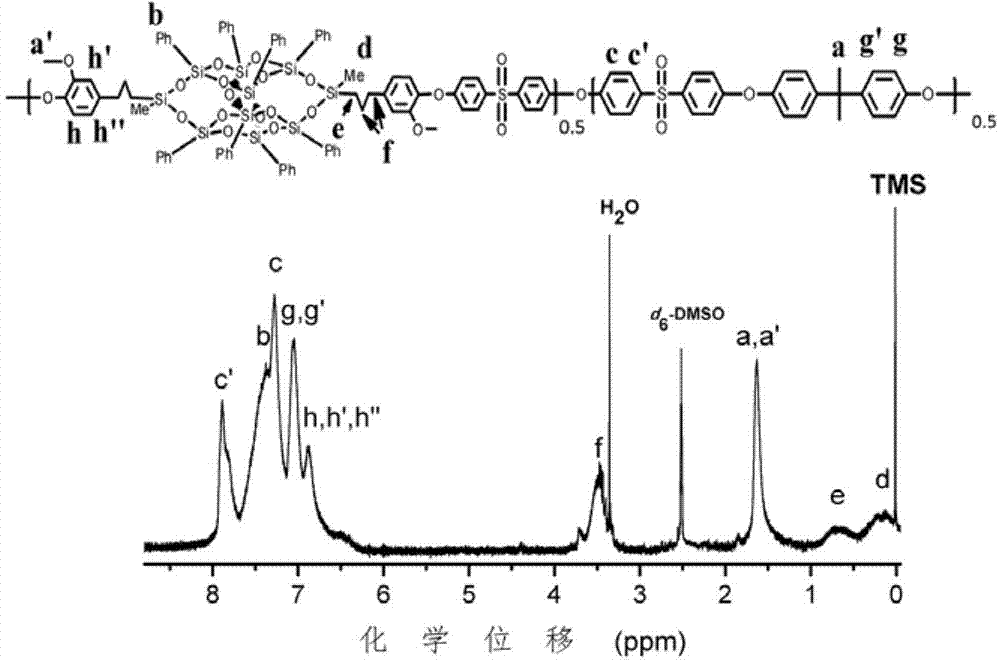

[0028] Bruker Advance510 nuclear magnetic resonance instrument (300MHz) was used to measure the hydrogen nuclear magnetic resonance spectrum of polyarylethersulfone 5 containing cage organosilsesquioxane double deck structure in the main chain, with deuterat...

Embodiment 2

[0045] Polymerization was carried out by changing the feed ratio, and the synthesis process was the same as in Example 1 to prepare polyarylethersulfone 7 and polyarylethersulfone 8-12 with a cage-type silsesquioxane structure in the main chain. The feed ratio and production rate are shown in Table 5.

[0046] Table 5: The feed ratio and yield of polyarylethersulfone 7-12

[0047]

Embodiment 3

[0049] Polymerization was carried out by changing the feed ratio, and the synthesis process was the same as in Example 1 to prepare polyarylethersulfone 13 and polyarylethersulfone 14-18 with a cage-type silsesquioxane structure in the main chain. The feed ratio and production rate are shown in Table 6.

[0050] Table 6: The feed ratio and yield of polyarylethersulfone 13-18

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com