Method for resource utilization of prepreg leftover residues

A technology for corner waste and prepreg, which is applied in recycling technology, plastic recycling, mechanical material recycling, etc., can solve problems such as environmental pollution, harm to human health, and large multi-layer circuit boards, so as to solve environmental pollution problems and realize recycling. The effect of utilization and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

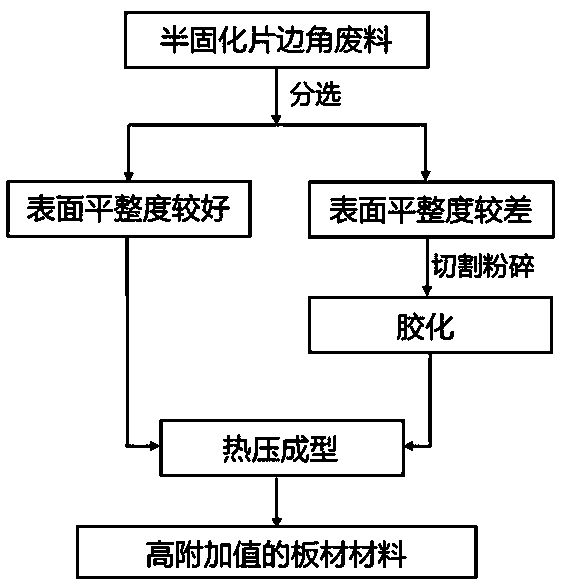

[0024] Embodiment 1: a kind of method for resource utilization of prepreg scraps, such as figure 1 As shown, it includes the following steps:

[0025] S1. Screening and classification: Sorting the semi-solidified corner scraps generated during the production process of printed circuit boards by combining mechanical and manual methods, screening and classifying them into corner scraps with good surface flatness and poor surface flatness;

[0026] S2. Cutting and crushing: cutting and crushing the semi-solidified corner waste with poor surface flatness with a mechanical crusher, and crushing it into particles with a particle size of 1-2mm or flakes with good surface flatness;

[0027] S3. Gelling treatment: the pulverized granules or flake waste are gelled with an adhesive resin glue, the mass fraction of the adhesive in the semi-cured granules or sheets is 30%, and the gelation time 2min;

[0028] S4. Thermocompression molding: perform one-time thermocompression molding on th...

Embodiment 2

[0033] Embodiment 2: a kind of method for resource utilization of prepreg scraps, such as figure 1 As shown, it includes the following steps:

[0034] S1. Screening and classification: Sorting the semi-solidified corner scraps generated during the production process of printed circuit boards by combining mechanical and manual methods, screening and classifying them into corner scraps with good surface flatness and poor surface flatness;

[0035] S2. Cutting and crushing: cutting and crushing the semi-solidified corner waste with poor surface flatness with a mechanical crusher, and crushing it into particles with a particle size of 1-2mm or flakes with good surface flatness;

[0036] S3. Gelling treatment: the crushed granules or flake waste are gelled with an adhesive resin glue, the mass fraction of the adhesive in the semi-cured granules or sheets is 70%, and the gelation time 10min;

[0037] S4. Thermocompression molding: perform one-time thermocompression molding on the ...

Embodiment 3

[0042] Embodiment 3 A method for resource utilization of prepreg corner waste, such as figure 1 As shown, it includes the following steps:

[0043] S1. Screening and classification: Sorting the semi-solidified corner scraps generated during the production process of printed circuit boards by combining mechanical and manual methods, screening and classifying them into corner scraps with good surface flatness and poor surface flatness;

[0044] S2. Cutting and crushing: cutting and crushing the semi-solidified corner waste with poor surface flatness with a mechanical crusher, and crushing it into particles with a particle size of 1-2mm or flakes with good surface flatness;

[0045] S3. Gelling treatment: the pulverized granules or flake waste are gelled with an adhesive resin glue, the mass fraction of the adhesive in the semi-cured granules or sheets is 50%, and the gelation time 7min;

[0046] S4. Thermocompression molding: perform one-time thermocompression molding on the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com