Polarized angle hot bending protective film and preparation method thereof

A protective film and angle technology, which is applied in the field of polarized angle hot bending protective film and its preparation, can solve the problems of affecting the sensitivity and accuracy of fingerprint unlocking under the screen, affecting the effect of sticking, and affecting the user experience. Widely promote the application, reduce adverse effects, and improve the effect of user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

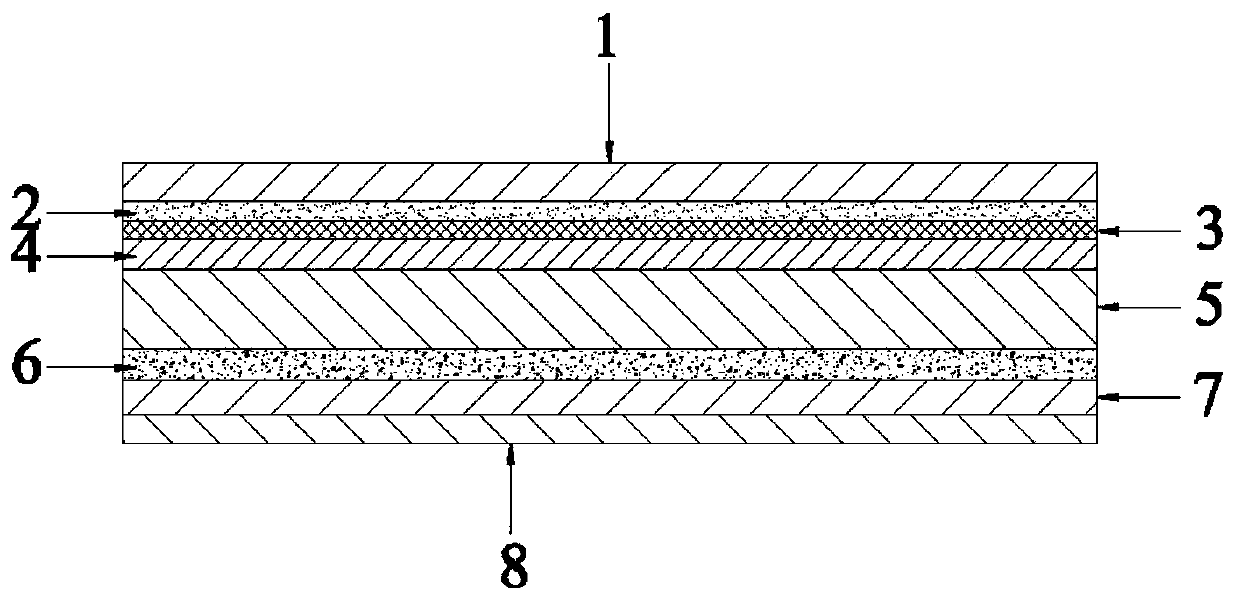

[0024] Example: see figure 1 , an embodiment of the present invention provides a thermal bending protective film with a polarization angle, which includes a PMMA protective layer 1, a silica gel protective layer 2, an HC coating 3, an anti-blue light coating 4, a PET substrate layer 5, and a TPU colloidal layer 6 , silica gel release layer 7 and release film layer 8, the PMMA protective layer 1, silica gel protective layer 2, HC coating 3, anti-blue light coating 4, PET substrate layer 5, TPU colloid layer 6, silica gel release The layer 7 and the release film layer 8 are laminated sequentially from top to bottom, and the polarization angle a of the PET substrate layer 5 is 30-48 degrees. Usually the light emitted by the screen of the mobile phone is polarized at 45 degrees, therefore, the polarization angle a is preferably 45 degrees.

[0025] The thickness of the PMMA protective layer 1 is 20-60 microns, preferably 30 microns. The thickness of the silica gel protective lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com