Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73results about How to "Does not affect subsequent processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

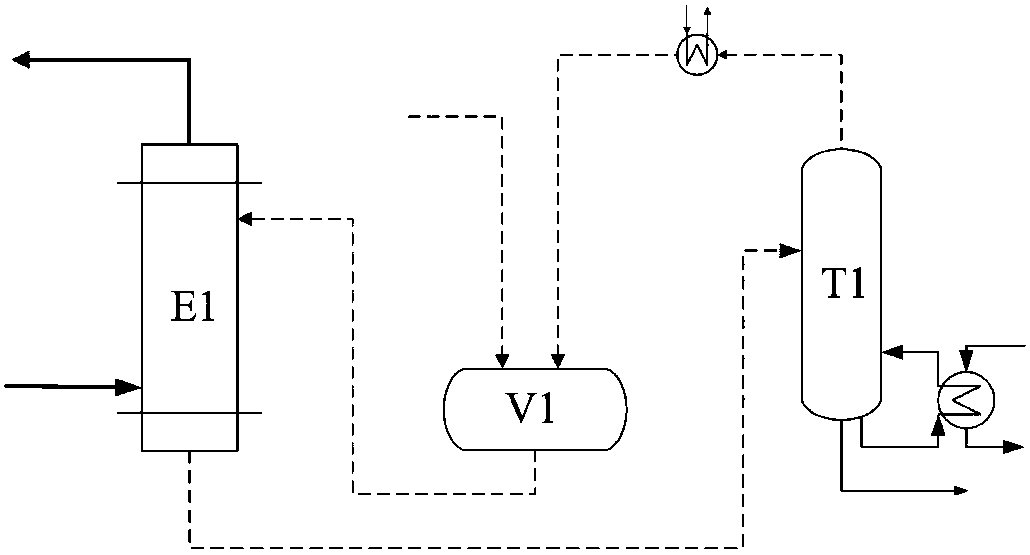

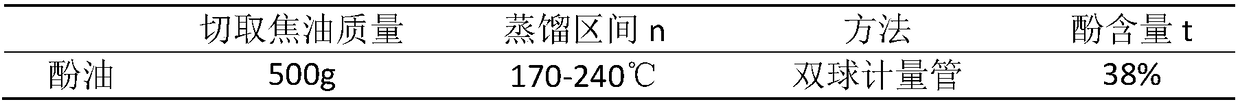

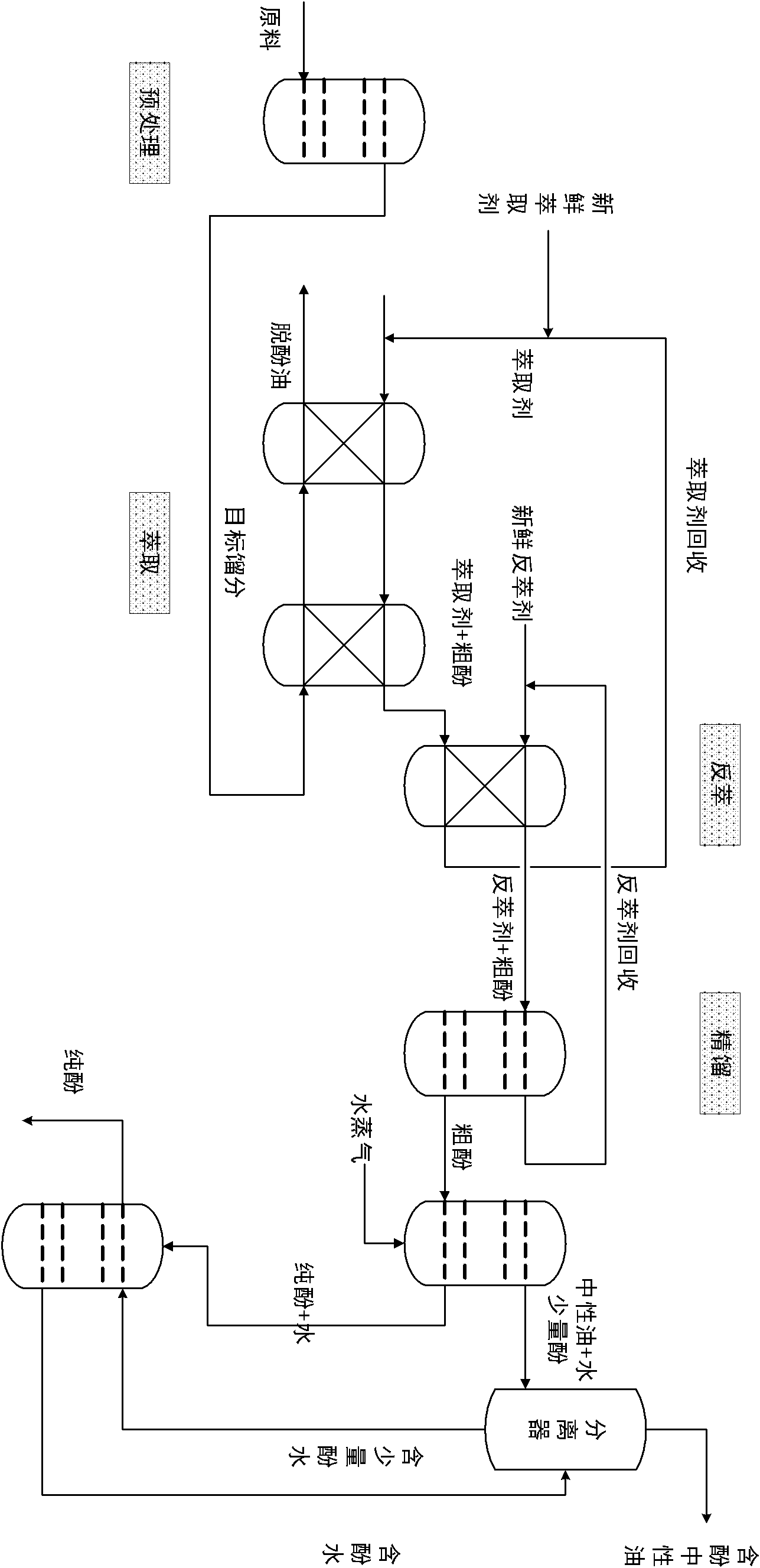

Method of extracting phenolic compound from coal liquefied oil or coal tar

ActiveCN102219649AHigh extraction rateHigh purityOrganic chemistryOrganic compound preparationWater vaporCoal chemical industry

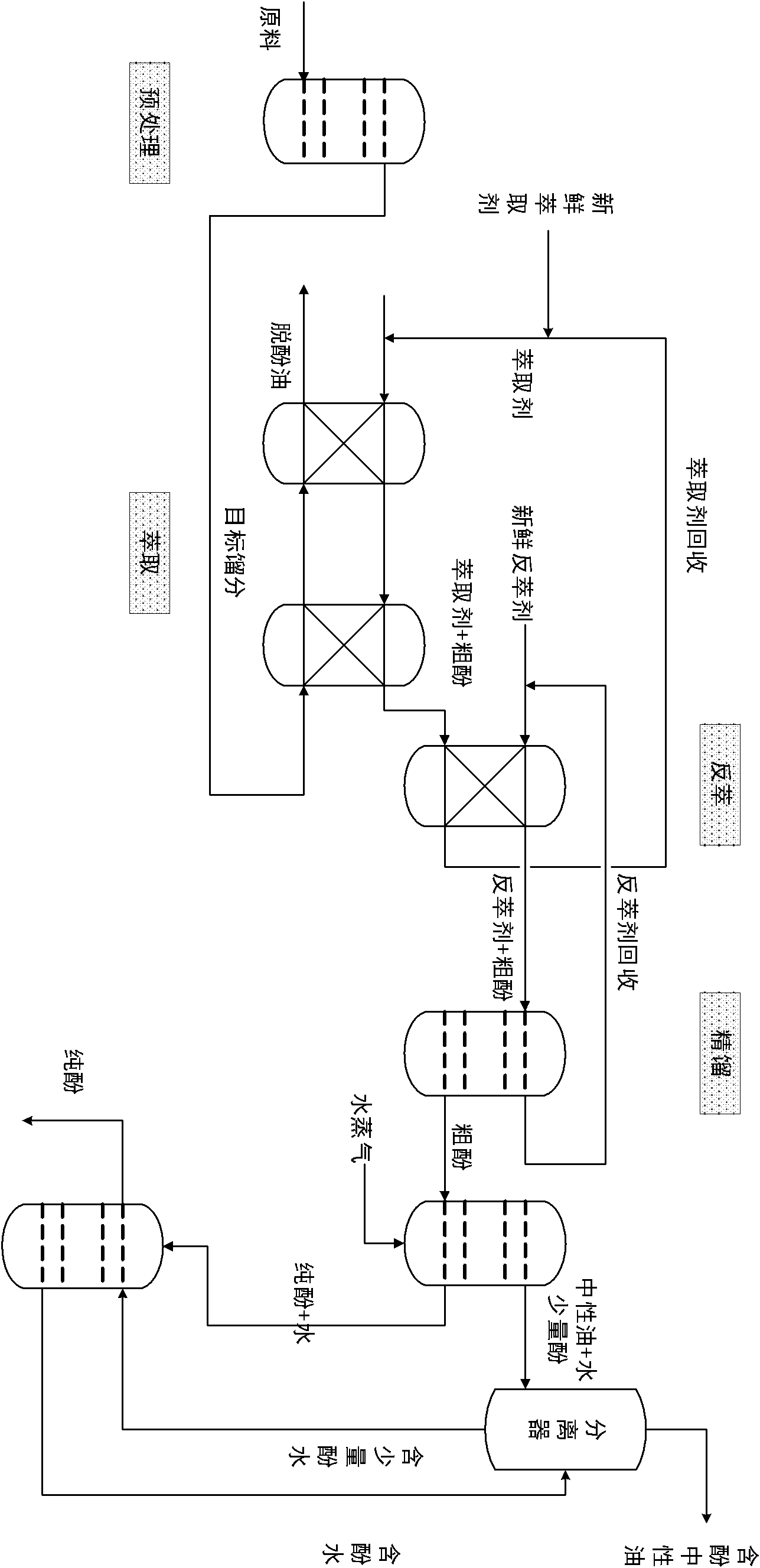

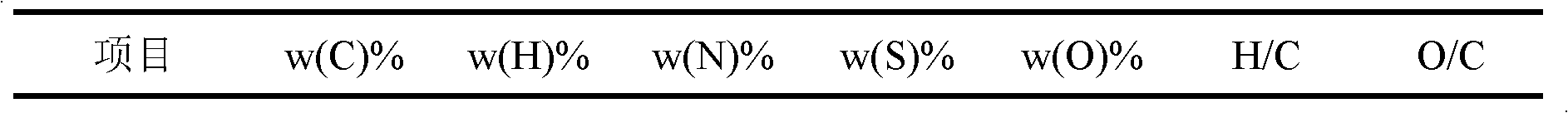

The invention relates to the field of coal chemical industry, and more specifically relates to a method of extracting phenolic compounds from coal liquefied oil or coal tar. The method comprises the following steps: 1) distilling coal liquefied oil or coal tar and cutting to obtain fractions at a temperature of 260 DEG C; 2) mixing an extractant with the obtained fractions and layering the extractant; 3) separating and collecting the extractant layer which contains phenolic compounds; 4) carrying out multistage back extraction on the phenolic compounds so as to obtain a stripping agent-phenol solution and an extractant; 5) separating the stripping agent-phenol solution by rectification, recovering the stripping agent for cyclic utilization, and carrying out separation to obtain crude phenols; 6) removing entrained neutral oil in phenolic compounds by water vapour so as to obtain crude phenol products. The method of extracting phenolic compounds from coal liquefied oil or coal tar provided in the invention avoids the usage of soda acid, exerts no influence on subsequent treating processes, and guarantees high recovery rate and purity of phenols.

Owner:CCTEG CHINA COAL RES INST

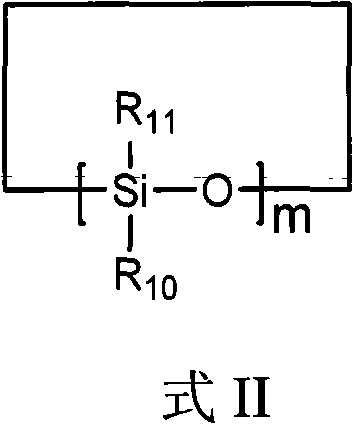

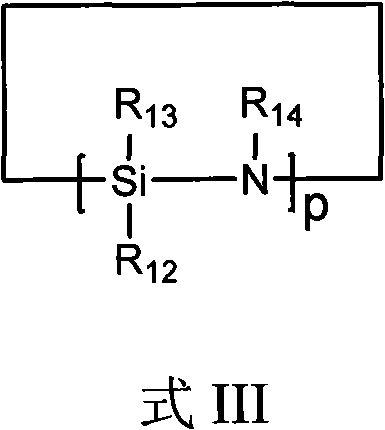

Mold release agent and preparation method and application thereof

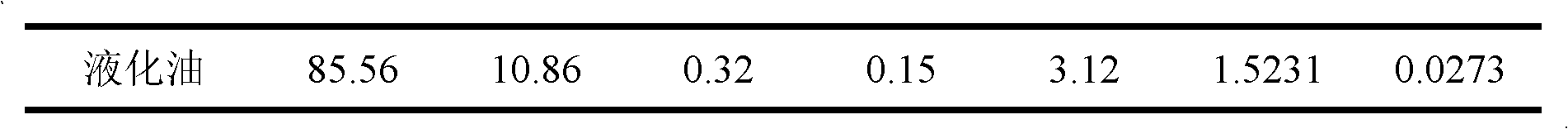

The invention provides a mold release agent, which contains the following components: a silicon-hydrogen bond-containing polysiloxane compound, a cross-linking agent, a catalyst and a solvent, wherein the cross-linking agent is a silicon compound containing Si-OH groups and / or a silicon compound which can form the Si-OH groups through hydrolyzation. The mold release agent is a semi-permanent mold release agent, and has the advantages of rapid low-temperature solidification, less mold release agent transfer, less wax deposition, convenient construction, low cost and the like; the produced product has uniform openings; and the mold release agent particularly achieves major breakthrough in the field of producing polyurethane foam products. The invention also provides a method for preparing the mold release agent, and application of the mold release agent in producing polyurethane foam products, epoxy resin products, glass fiber reinforced epoxy resin products, rubber products, unsaturated polyester products and other polyurethane products.

Owner:HENKEL CORP

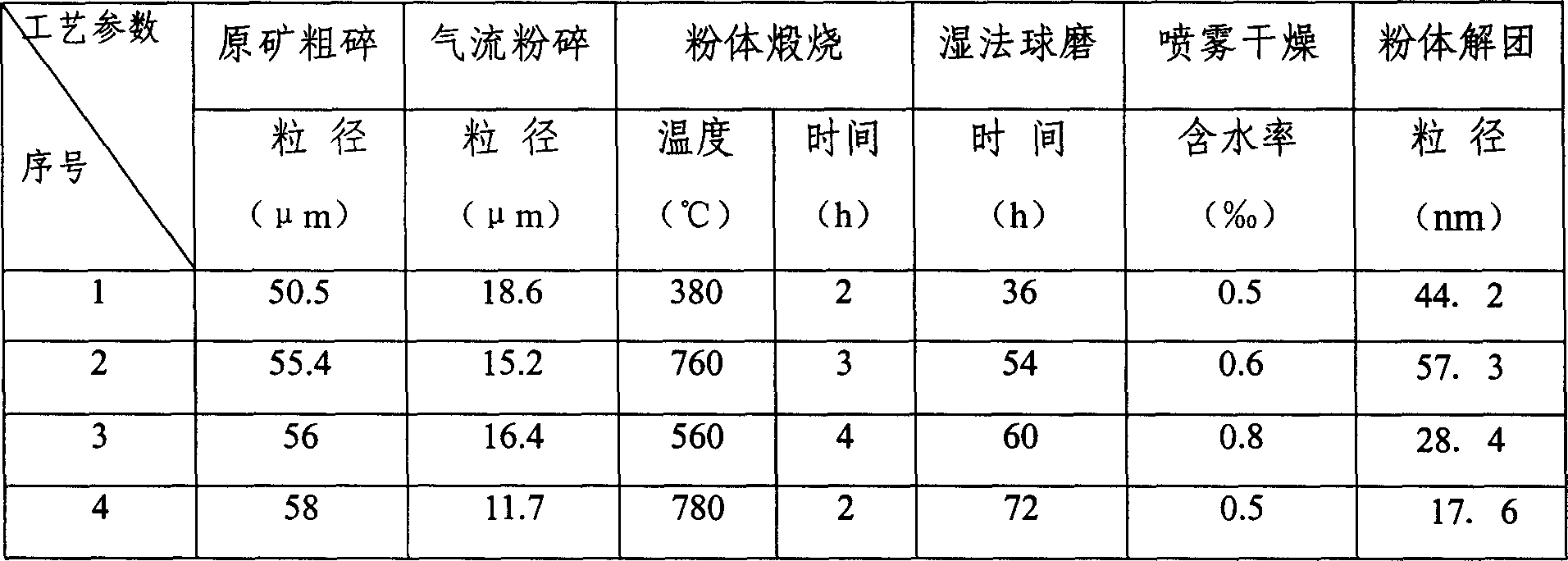

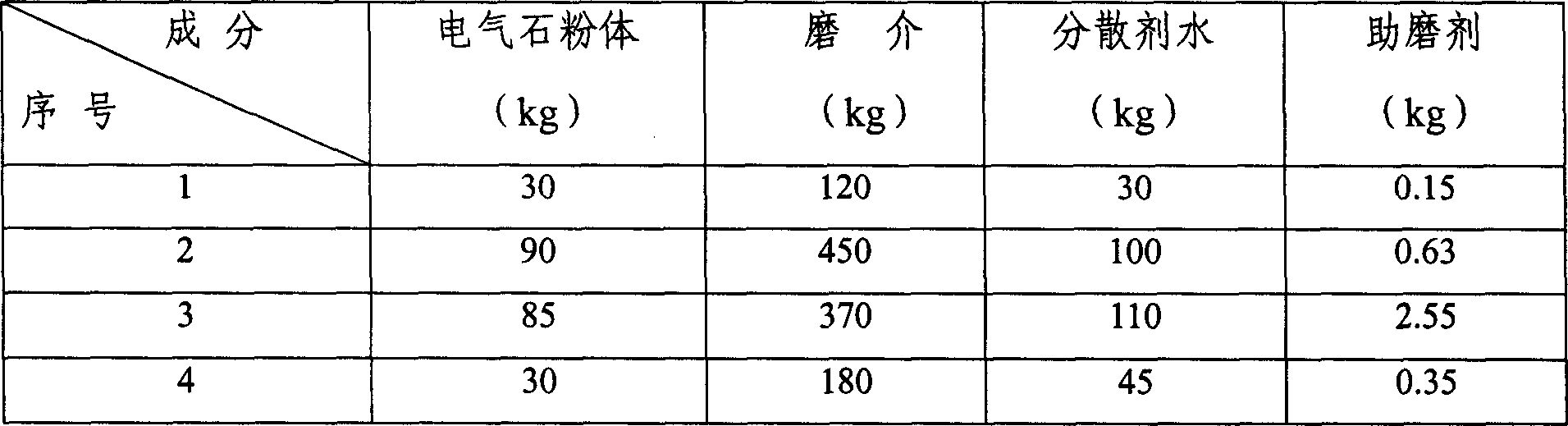

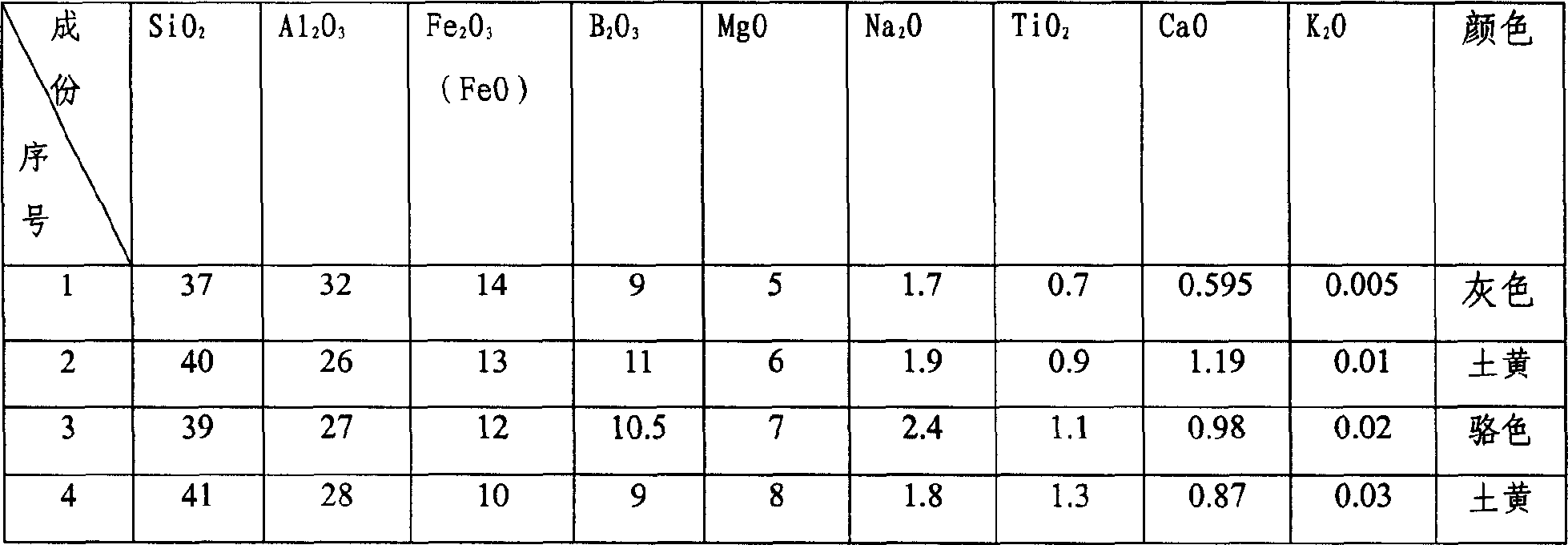

Method for preparing nanometer ultra-fine tourmaline powder

InactiveCN1557558AReduce reunionSmall particle sizeHeat treatmentsDrying solid materials with heatUltra fineGenerating capacity

The present invention relates to production of non-metal mineral powder, and is especially the preparation process of nano superfine tourmaline powder. The technological process includes the steps of: coarse crushing ore, airflow crushing, post-treatment, wet ball milling, spray drying, eliminating agglomeration of powder, and packing. The main technological prameters include calcining temperature of initially crushed powder in air of 300-800 deg.c, calcining time of 2-4 hr to obtain tourmaline powder in different colors, and ball milling period of 36-72 hr. Compared with available technology, the present invention has obviously reduced agglomeration of tourmaline powder, raised crushing efficiency, powder size reduced to 15-60 nm, obviously raised negative ion generating capacity, various color of the powder and wide application range.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

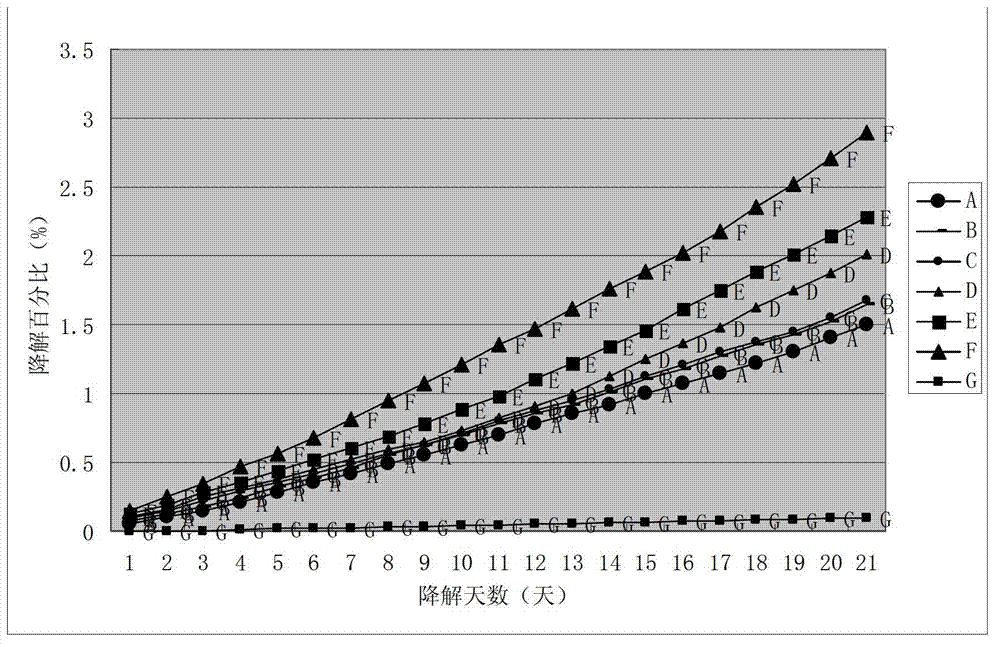

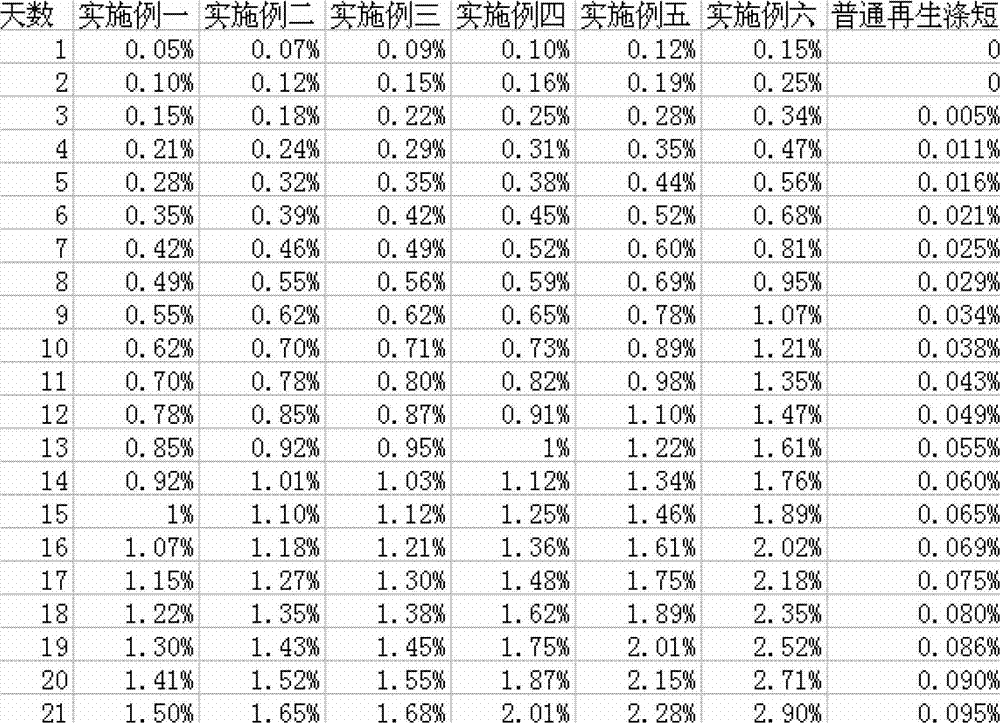

Preparation method of biodegradable regenerated polyester staple fibers

ActiveCN102828276APrevent volatilizationBalanced moistureFilament forming substance formingArtificial filament heat treatmentPolyesterPolymer science

The invention discloses a preparation method of biodegradable regenerated polyester staple fibers, which is characterized by comprising the steps of drying spinning materials by a vacuum drum, mixing with biodegradable master batch dried by a master batch drying system at the feed inlet of a screw extruder; preparing primary fibers after mixing and fusing by the screw extruder and extruding by a spinneret plate; cooling primary fibers by an annular blowing device; successively carrying out winding, falling, bundling and time balancing on the primary fibers in a constant temperature and constant-humidity room; stretching the primary fibers in oil bath and stream respectively; performing curling, relaxation heat setting, cutting and packaging to obtain biodegradable regenerated polyester staple fibers, wherein physical properties and mechanical properties of the biodegradable regenerated polyester staple fibers produced by the method do not change, and therefore, the subsequent processing and usage are not influenced; after being used, the fibers can be decomposed into inert humus, carbon dioxide and water in a microorganism-enriching environments such as refuse landfill or composting site, thereby returning to nature and achieving real biodegradation.

Owner:福建鑫华股份有限公司

Production method for graphite film

ActiveCN104015468AThe fracture is clean and tidyRegular shapeLamination ancillary operationsLaminationCarbonizationWork in process

The invention discloses a production method for a graphite film. The production method comprises the following steps of (1) winding; (2) low-temperature carbonization; (3) high-temperature graphitization; (4) unwinding and taking-up, namely respectively rolling a semi-finished product of an artificial graphite film and flexible graphite paper; (5) rolling, namely pressing the artificial graphite film semi-finished product on a release film or a protection film; and (6) winding and packaging. The winding working procedure comprises the following steps of a, performing half-breakage type die cutting on a macromolecular film at intervals being 0.2-5m by a dotted line cutter to form cut dotted lines; b, coiling a graphite barrel core with a high-temperature resistant elastic material; c, attaching the macromolecular film with the cut dotted lines to the flexible graphite paper to obtain integrated macromolecular film and flexible graphite paper, and coiling the integrated macromolecular film and flexible graphite paper on the graphite barrel core on the basis of the step b; d, after the integrated macromolecular film and flexible graphite paper which is coiled in the step c reaches a specific thickness, fastening the integrated macromolecular film and flexible graphite paper through a carbon rope.

Owner:李鹏

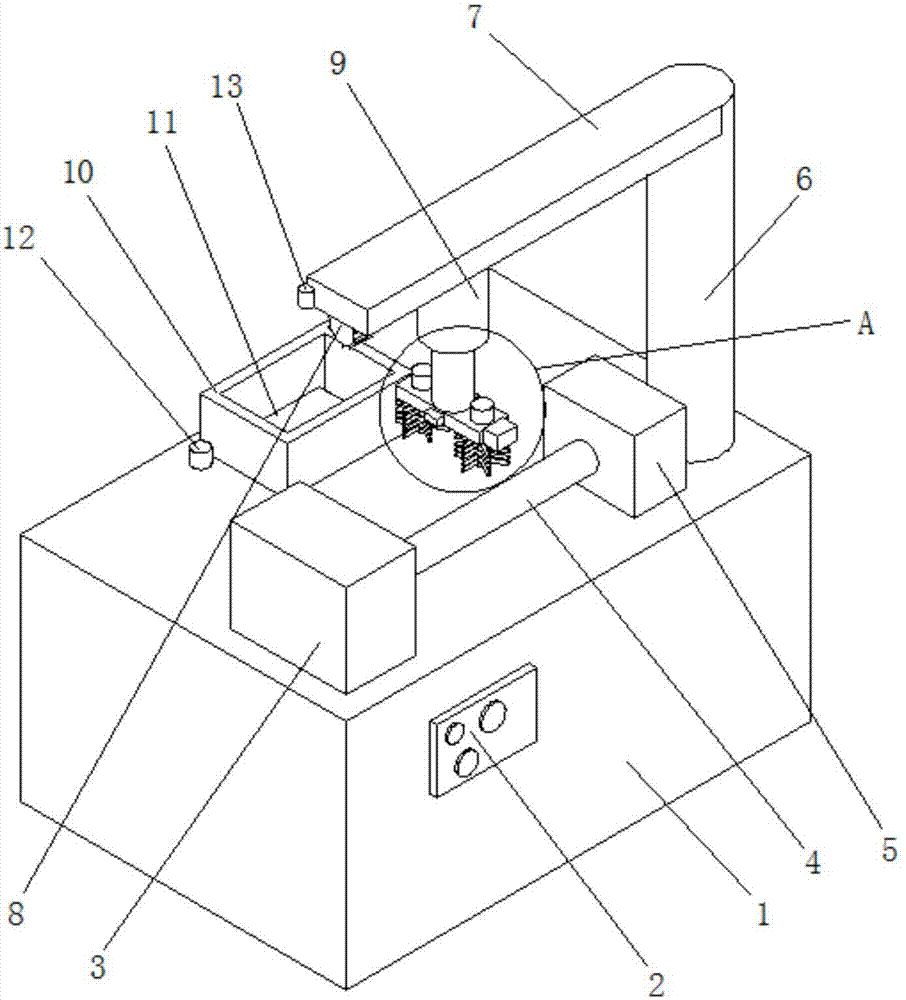

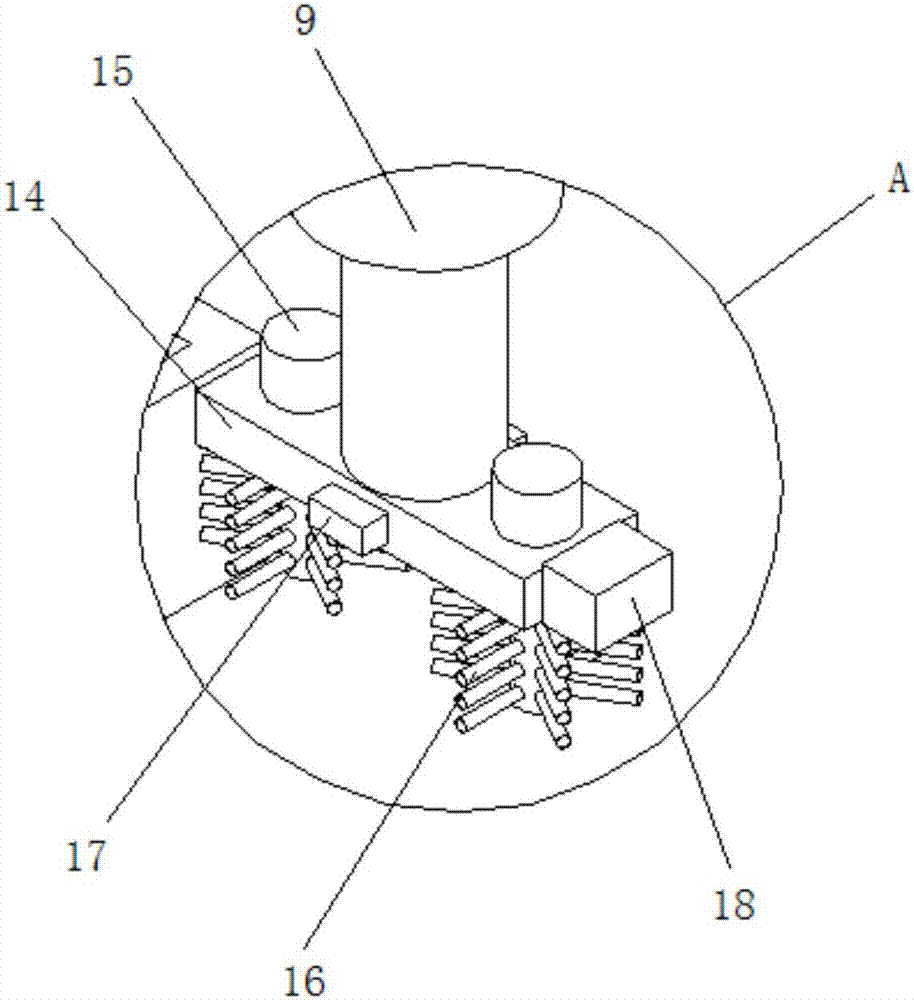

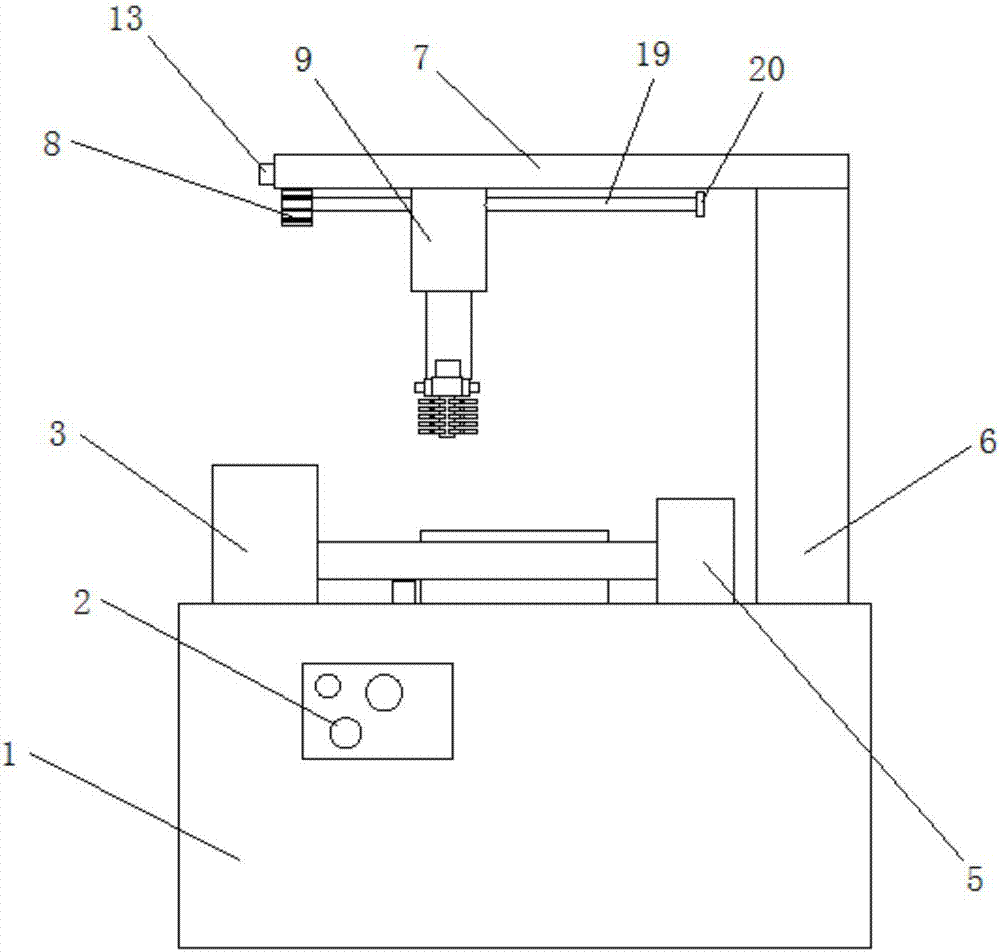

Numerical control lathe provided with lead screw guiding rail cleaning brushes

PendingCN107234480AEasy to fall intoOptimize locationMaintainance and safety accessoriesNumerical controlEngineering

The invention discloses a numerical control lathe provided with lead screw guiding rail cleaning brushes. The numerical control lathe comprises a main body; a PLC is arranged on the side surface of the main body; the input end of PLC is electrically connected with the output end of an externally-arranged power supply; the upper surface of the main body is provided with a spindle box and a tailstock; a lead screw guiding rail is arranged between the spindle box and the tailstock which are arranged on the upper surface of the main body; a motor is arranged inside the main body; an output shaft of the motor penetrates out of the upper surface of the main body and is connected with a rotating column; a mounting plate is arranged at the top end of the rotating column; and a driving motor is arranged on the lower surface of the mounting plate. According to the numerical control lathe provided with the lead screw guiding rail cleaning brushes, the cleaning effect is improved, iron filings generated in the production process can be cleaned up, subsequent machining is not affected, and the working efficiency is improved; second electromagnets can make the cleaning steel brushes to produce magnetism to attract the iron filings on the lead screw guiding rail, so that cleaning is more convenient and complete; and an electric telescopic rod can drive a cleaning device to rise and fall, and the automation degree is increased.

Owner:杭州富阳正成机械设备厂

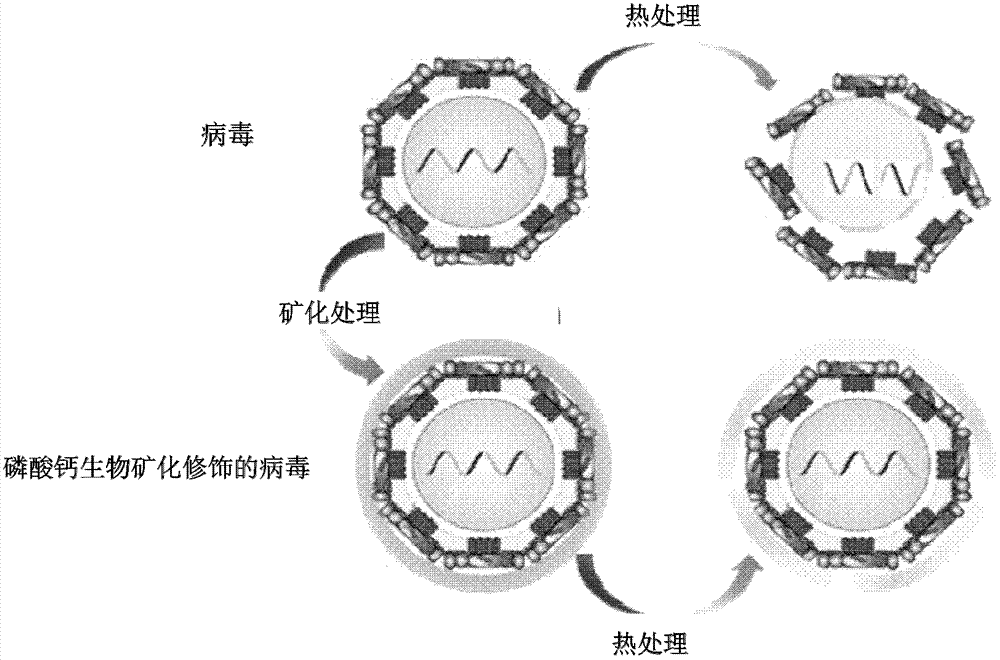

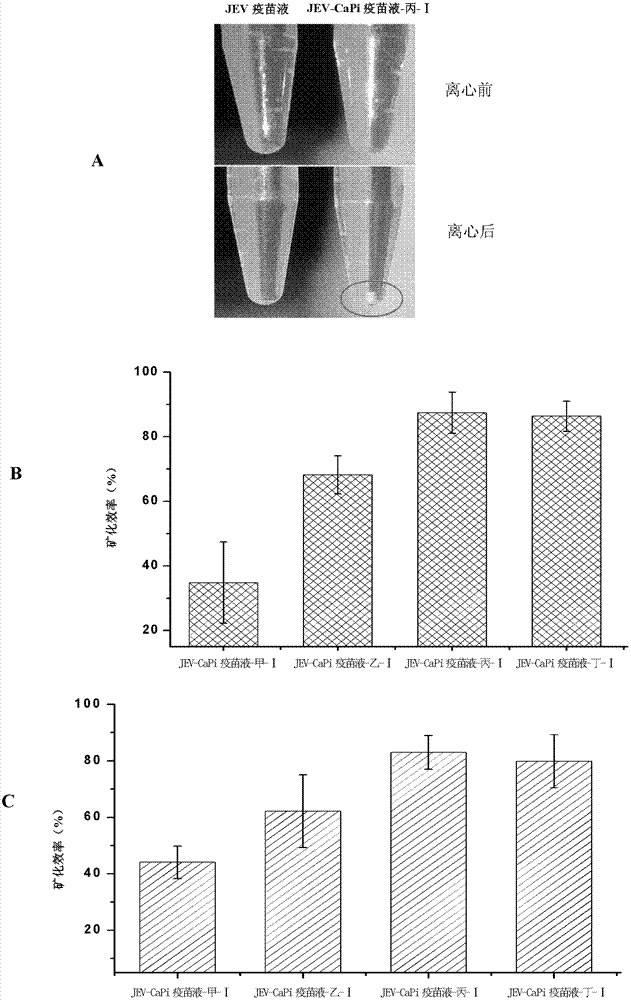

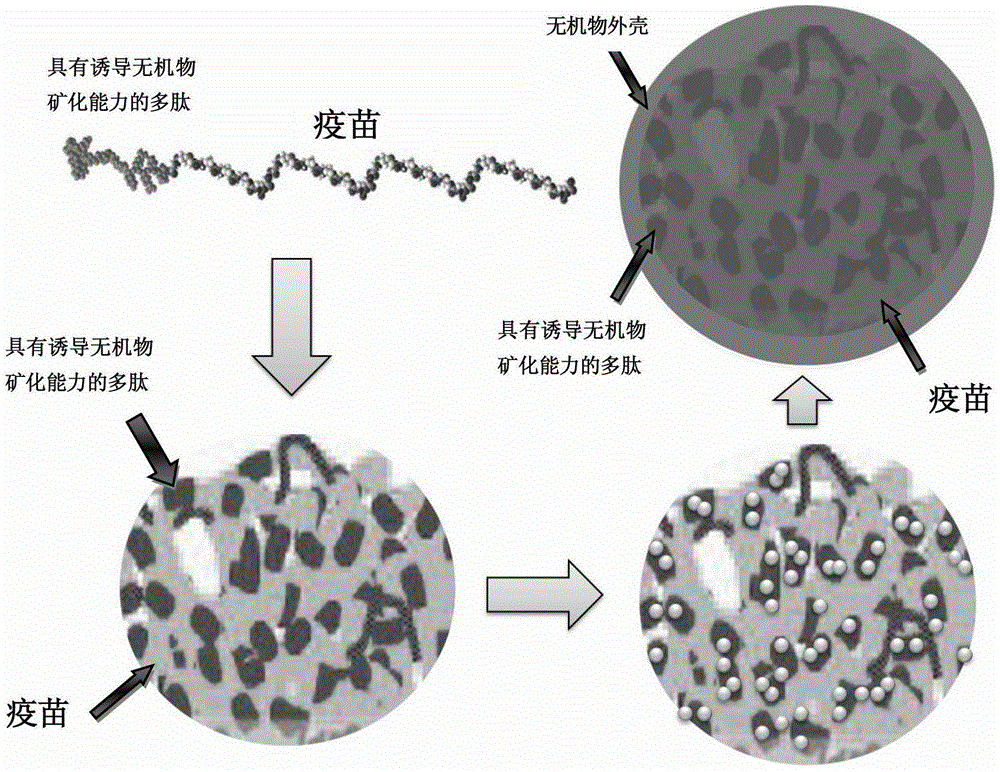

Method for preparing thermal-stability vaccine

ActiveCN102784390AImprove securityImprove effectivenessViral antigen ingredientsInorganic non-active ingredientsCalcium biphosphateVaccine Production

The invention discloses a method for preparing thermal-stability vaccine and particularly relates to a method for preparing thermal-stability vaccine based on calcium phosphate mineralization. The invention provides a method for preparing calcium phosphate coated viruses. The method comprises the following steps that (1) compounds with Ca<2+> ions are added into virus liquid, an initial system is obtained, and PO4<3-> ions are contained in the virus liquid; (3) the initial system is subjected to incubation; and (3) precipitation is centrifugally collected, and the calcium phosphate coated viruses are obtained. The method has the advantages that through virus surface mineralization modification, the problem of heat inactivation phenomenon in the vaccine transportation and storage process can be effectively solved, and the financial expenditure of the attenuated live vaccine is obviously reduced. The method can be widely applied to thermal-stability vaccine production and preparation.

Owner:MICROBE EPIDEMIC DISEASE INST OF PLA MILITARY MEDICAL ACAD OF SCI

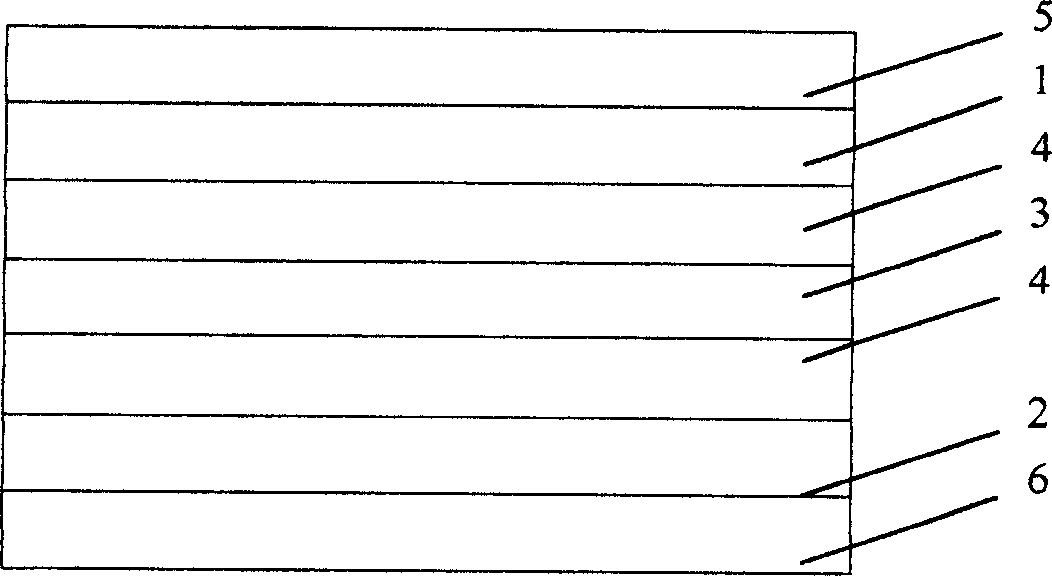

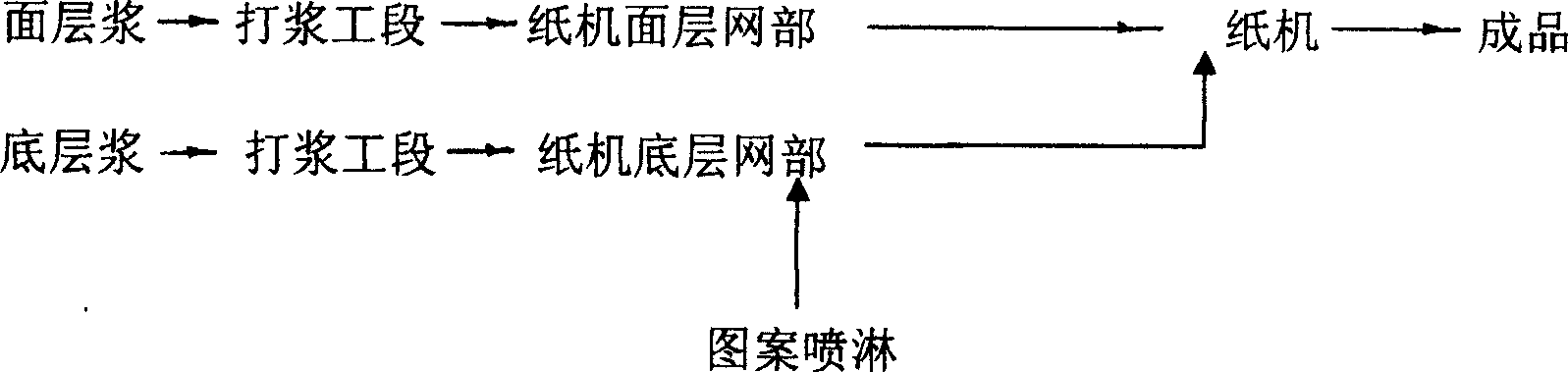

Anti-forge coating white cardboard and producing method thereof

ActiveCN1752340AIncrease the difficulty of counterfeitingRich choicePaper coatingLuminescent/fluorescent substance additionCardboardComputer science

Owner:ZHUHAI S E Z HONGTA RENHENG PAPER

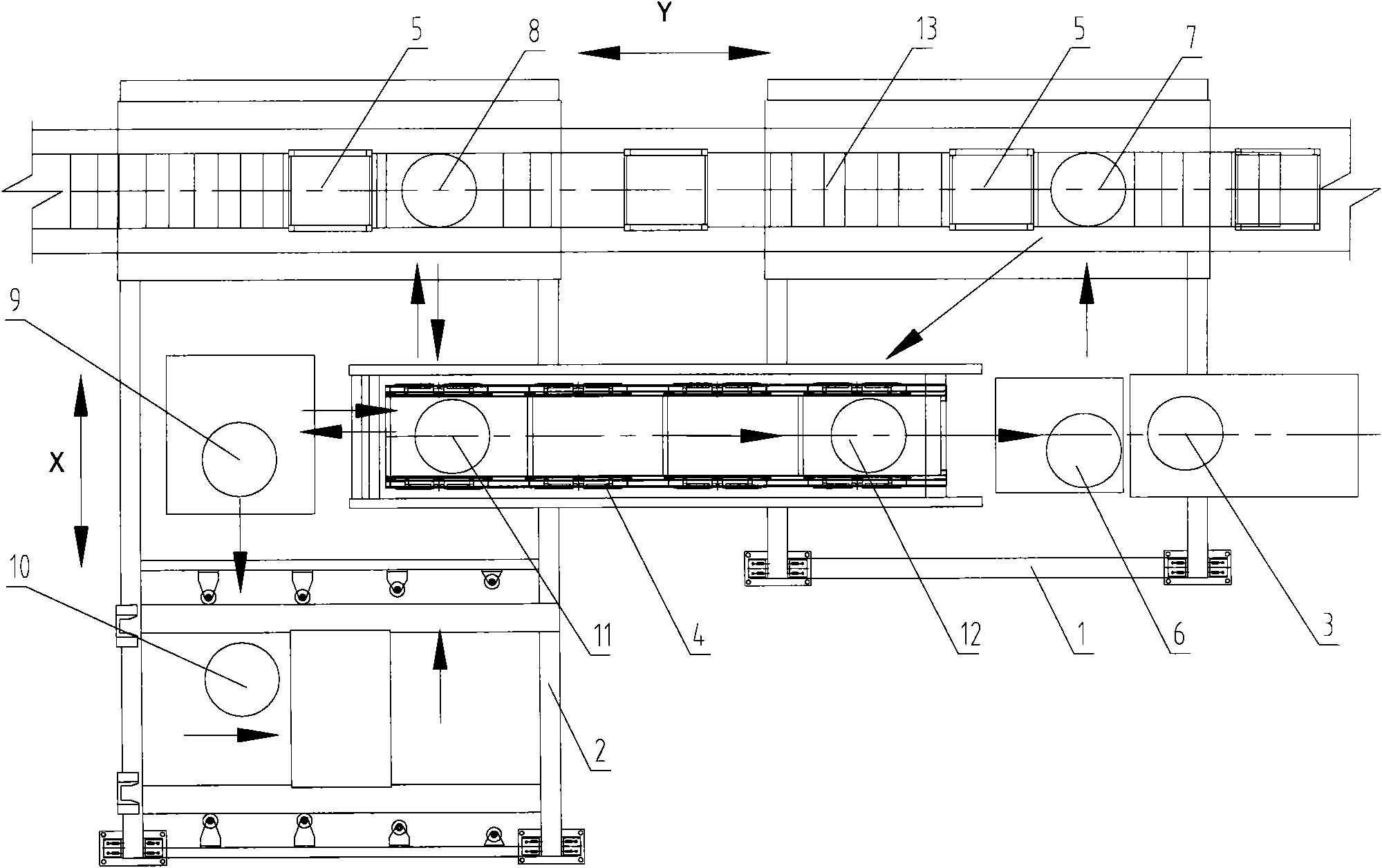

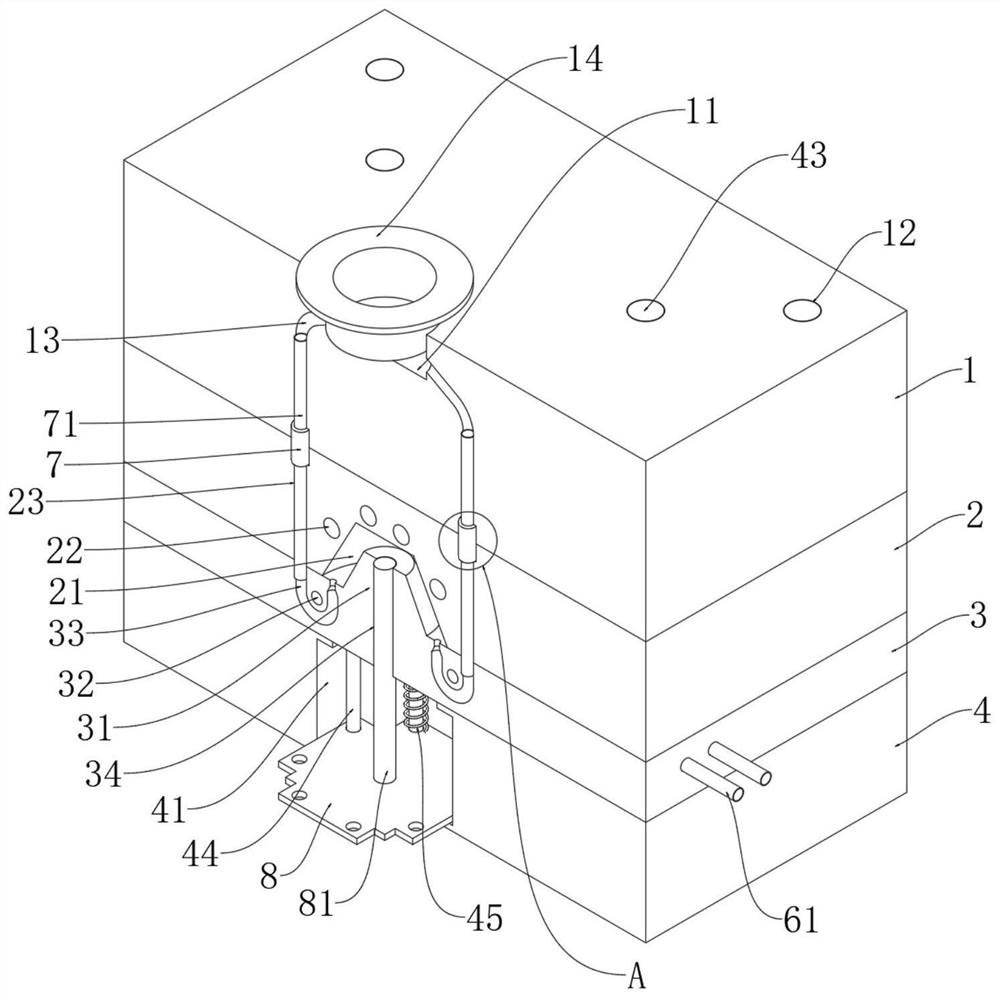

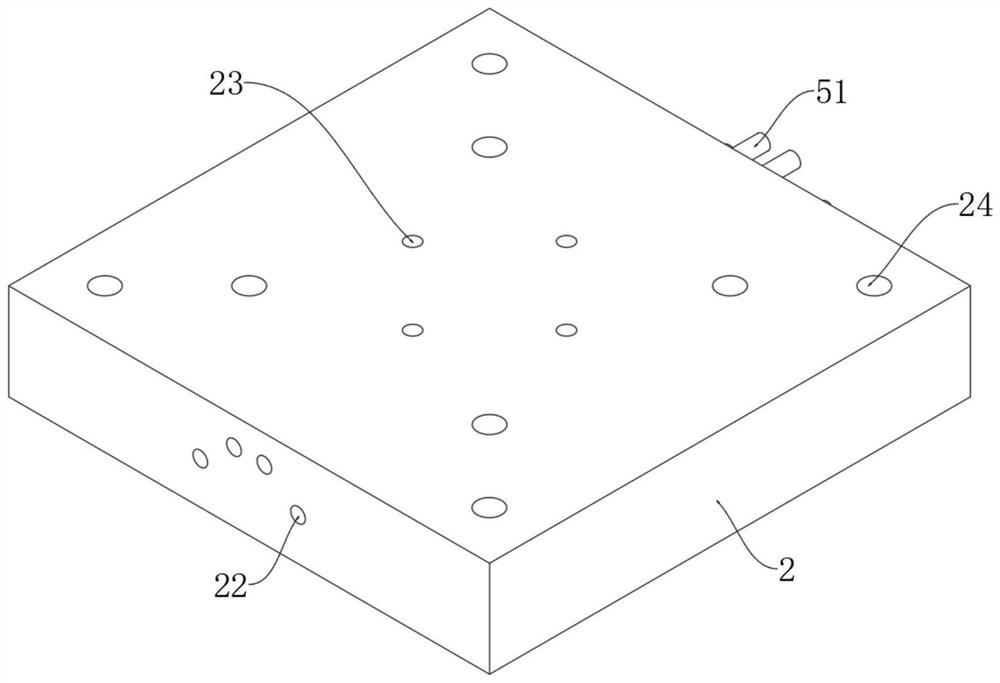

Multi-component small powder automatic packaging palletizing method

InactiveCN101537888ASave materialReduce manufacturing costWrapper twisting/gatheringSolid materialElectronic control systemControl system

The invention relates to a multi-component small powder automatic packaging palletizing method, belonging to a small powder scale automatic weighing batching apparatus. The method changes the overall processes of putting plastic bag into a charging basket, taking out pockets, closing bag mouths, palletizing the pockets into a storing vehicle before mixing former rubber, during matching various small powders according to the formulation into the full mechanical automation. The method is implemented by the following devices: a bag machine 14, a plastic bag clamping unit 4, a special pocket 5, a clamping unit actuating device 20, a transmitting bag and opening bag mouth device 15, a putting bag device, a taking bag device, a heat seal capper 18, a stack device, a pocket positioning device 21, an empty pocket positioning device 33, a pneumatic control system, an electronic control system and an PLC program control system.

Owner:BEIJING UNITED FOUND TECH

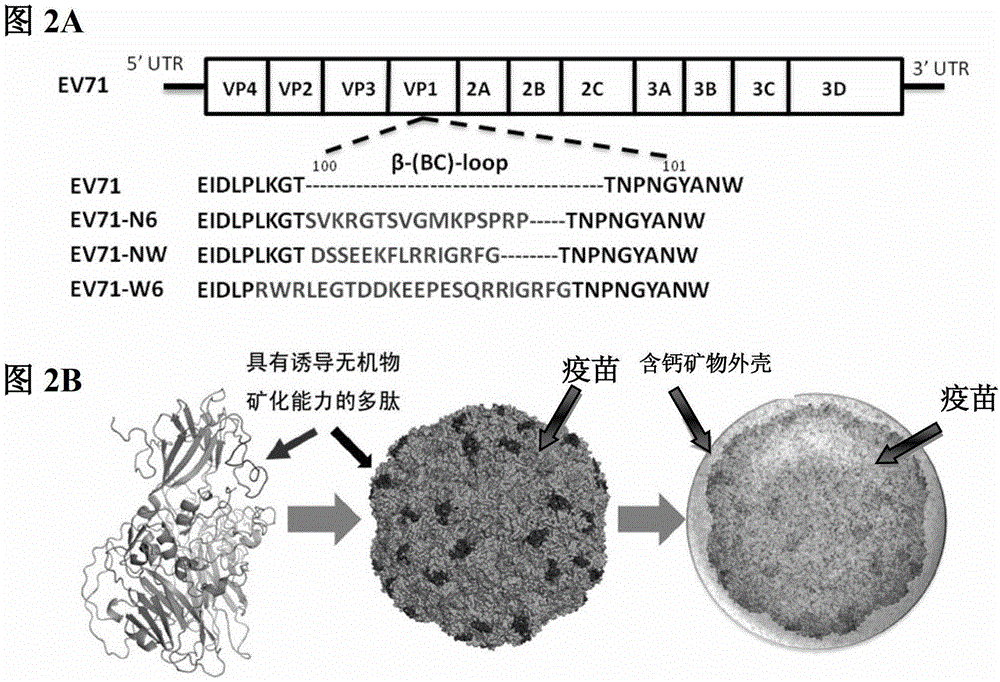

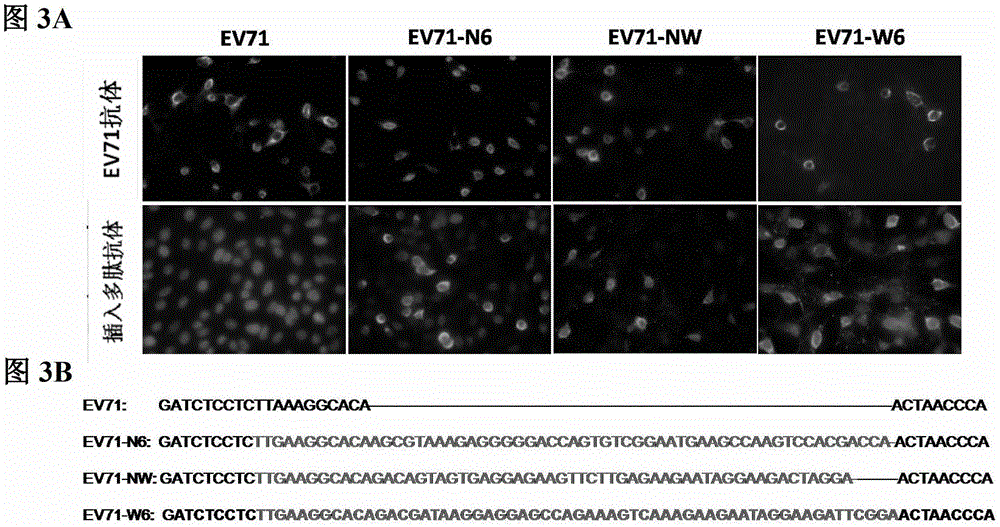

Genetic engineering heat stable vaccine and preparation method thereof

InactiveCN104096235AKeep aliveGet rid of dependenceViral antigen ingredientsPharmaceutical delivery mechanismEscherichia coliCalcium biphosphate

The invention discloses a method for preparing a heat stable vaccine, particularly relates to a method for preparing the heat stable vaccine by the combined use of genetic engineering and biomimetic mineralization technology, and provides a method for introduction of polypeptides with inorganic mineralization induction ability on vaccine surface by use of gene engineering technology. The method is as follows: (1) constructing a vaccine gene clone; (2) inserting a polypeptide nucleic acid sequence into the vaccine gene clone to obtain a recombinant clone; and (3) expressing the recombinant clone in cells or in Escherichia coli to obtain a vaccine with the self-mineralization ability. The invention also provides a method for preparing and calcium mineralization of the vaccine with the self-mineralization ability. The method for preparing and calcium mineralization of the vaccine with the self-mineralization ability is as follows: (1) adding Ca<2 +> ions into a vaccine liquid with acid radicals, and (2) incubating the system to obtain a calcium phosphate coated vaccine. Through vaccine mineralization, thermal inactivation phenomena in vaccine transportation and storage can be effectively solved, the vaccine fiscal expenditure can be significantly reduced, and the method can be well used in production of a new heat stable vaccine.

Owner:ZHEJIANG UNIV +1

Wood softening processing fluid for mould-proof and insect-proof crafts and preparation method of wood softening processing fluid

InactiveCN106313243ALow viscosityImprove solubilityWood treatment detailsWood impregnation detailsChemistryPolyvinyl alcohol

The invention discloses wood softening processing fluid for mould-proof and insect-proof crafts. The wood softening processing fluid is prepared from, by weight, 5-10 parts of poly(ethylene glycol), 4-6 parts of glacial acetic acid, 0.5-1 part of alum, 2-4 parts of hydrogen peroxide with the mass fraction ranging from 20% to 30%, 1-2 parts of polyvinyl alcohol, 2-4 parts of folium artemisiae argyi, 2-4 parts of cortex meliae, 1-1.5 parts of leaves of bunge pricklyash, 0.3-0.5 part of sodium dodecylbenzene sulfonate, 0.1-0.15 part of carboxymethyl chitosan, 0.1-0.15 part of tea saponin, 0.1-0.15 part of tall oil, 0.01-0.015 part of ethylparaben and 60-80 parts of water. The wood softening processing fluid is good in softening processing performance, wood is high in strength and tenacity and is not likely to rebound, subsequent processing is not influenced, dried and formed finished products are high in size stability, are not likely to crack or deform, and are good in mould-proof and insect-proof effect, wide in application range, capable of saving energy and environment-friendly.

Owner:FUNAN FANGLIU ARTS & CRAFTS CO LTD

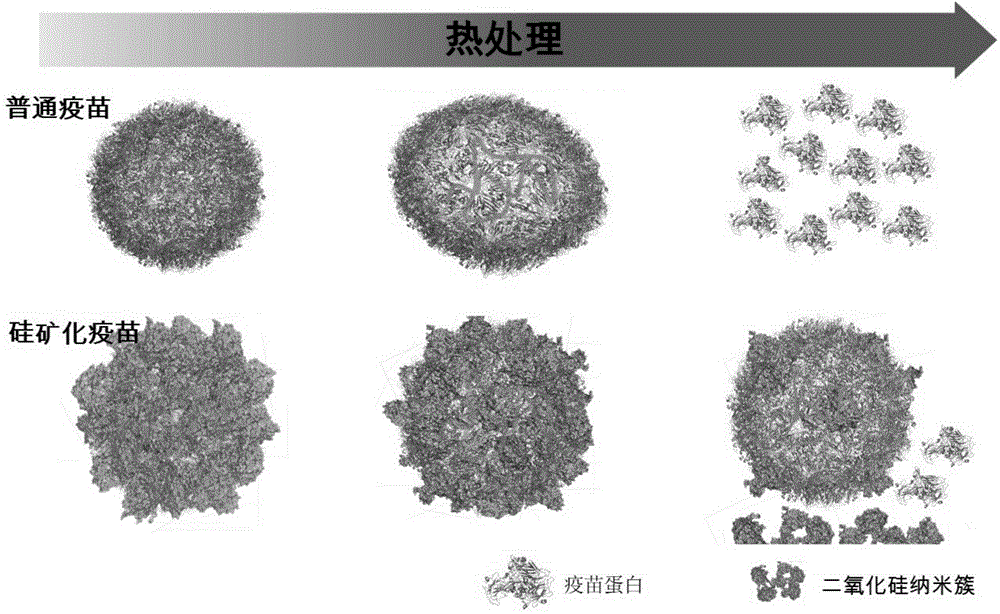

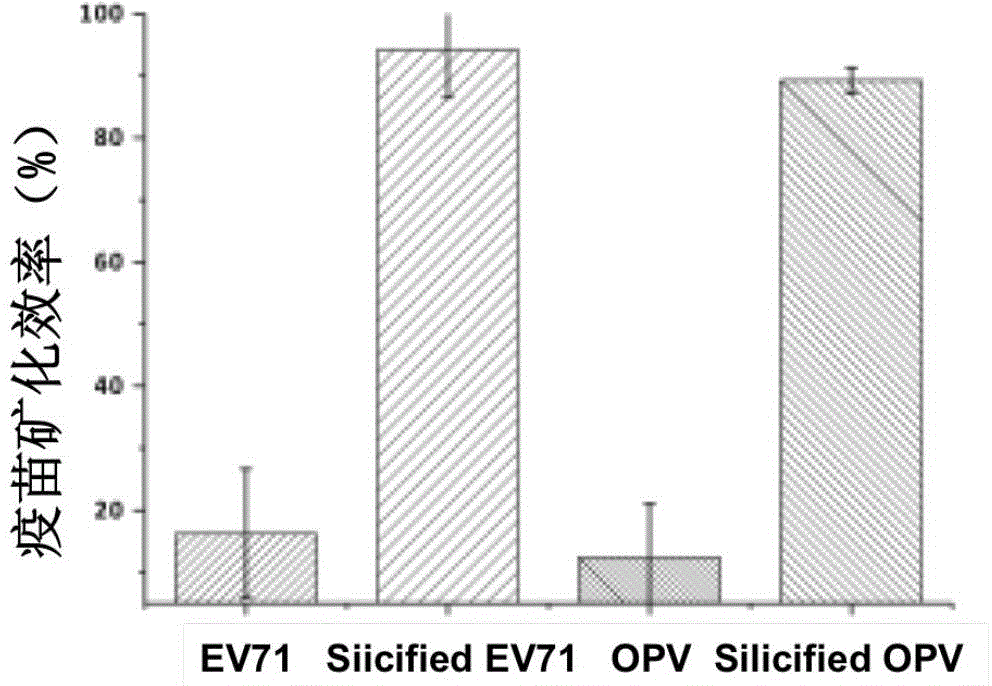

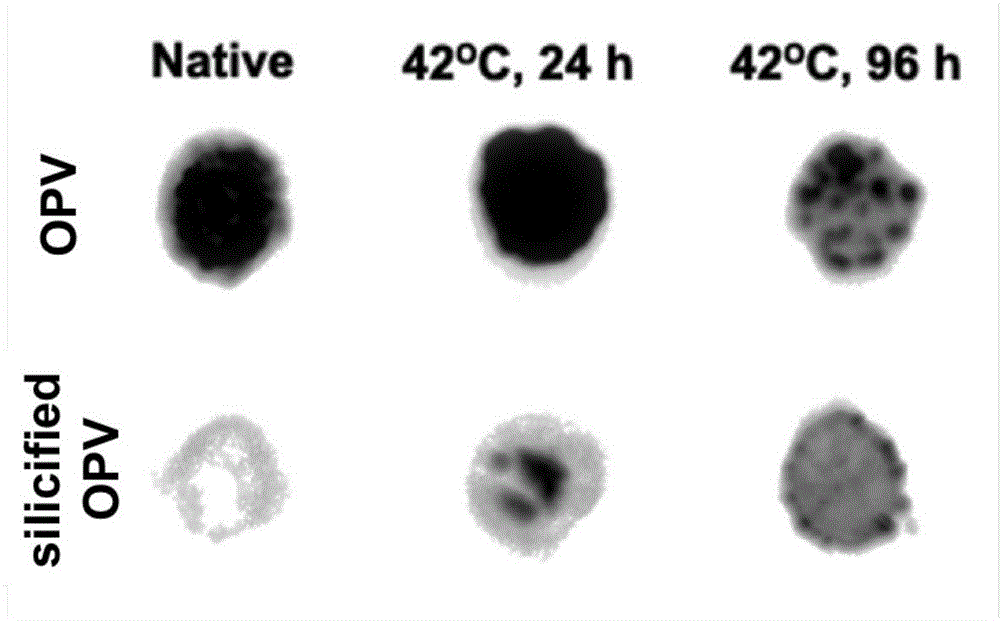

Thermostable vaccine with silica on surface and preparation method therefor

InactiveCN105267970AImprove thermal stabilityImproving immunogenicityAntiviralsMacromolecular non-active ingredientsHydrogenMedicine

The invention discloses a thermostable vaccine with silica on a surface, a preparation method and applications, and especially relates to introduction of a series of uncontinuous amorphous silica with a nanostructure on a surface of a vaccine in a specific manner based on in-situ bionic silicon mineralization. The provided thermostable vaccine is characterized in that uncontinuous amorphous hydrated state silica with a nanostructure exists on the surface of the vaccine. Because amorphous silica can exist stably, a lot of surrounding water molecules can be tied on the surface of the surface through hydrogen bonds to form a protective hydration layer, and therefore a relatively stable microenvironment is provided for the vaccine inside. Experiments show that the silica mineral is effective at the aspect of vaccine protection, the room temperature storage time is prolonged by nearly 10 times, financial expense for vaccine refrigeration is lowered greatly. The preparation method has wide application prospects in development and preparation of a novel thermostable vaccine, and heat inactivation phenomena of vaccines can be solved efficiently in transportation and storage.

Owner:ZHEJIANG UNIV +1

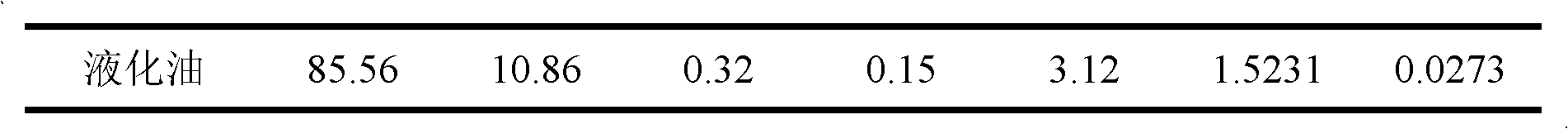

Method for extracting phenolic compounds from coal tar by utilizing ethanolamine

InactiveCN108484368AHigh extraction rateHigh purityOrganic chemistryOrganic compound preparationPhenolCoal tar

The invention relates to a method for extracting phenolic compounds from coal tar by utilizing ethanolamine. The specific steps are as follows: (1) distilling coal tar or coal liquefied oil, and cutting a fraction at 170 to 230 DEG C; (2) mixing an extracting agent with the phenolic oil fraction, and performing layering; (3) separating and collecting a phenolic oil lower layer containing the phenolic compounds; (4) subjecting a phenolic oil upper layer to a multi-stage extraction, and mixing the extracted phenol oil layer with the phenol oil lower layer; (5) separating the extracting agent-phenol solution by rectification, recycling the extracting agent for cyclic utilization, and separating to obtain crude phenol. Compared with the prior art (an alkaline washing method), the method for extracting phenolic compounds from coal tar, provided by the invention, avoids the use of acid-bases, and is beneficial to environmental protection, and the extracting agent can be recycled, thereby saving raw materials; and most importantly, the method can achieve the same extraction rate and purity as those of the alkaline washing method.

Owner:QINGDAO UNIV OF SCI & TECH

Method of extracting phenolic compound from coal liquefied oil or coal tar

ActiveCN102219649BHigh extraction rateHigh purityOrganic chemistryOrganic compound preparationPhysical chemistryProcess engineering

The invention relates to the field of coal chemical industry, and more specifically relates to a method of extracting phenolic compounds from coal liquefied oil or coal tar. The method comprises the following steps: 1) distilling coal liquefied oil or coal tar and cutting to obtain fractions at a temperature of 260 DEG C; 2) mixing an extractant with the obtained fractions and layering the extractant; 3) separating and collecting the extractant layer which contains phenolic compounds; 4) carrying out multistage back extraction on the phenolic compounds so as to obtain a stripping agent-phenol solution and an extractant; 5) separating the stripping agent-phenol solution by rectification, recovering the stripping agent for cyclic utilization, and carrying out separation to obtain crude phenols; 6) removing entrained neutral oil in phenolic compounds by water vapour so as to obtain crude phenol products. The method of extracting phenolic compounds from coal liquefied oil or coal tar provided in the invention avoids the usage of soda acid, exerts no influence on subsequent treating processes, and guarantees high recovery rate and purity of phenols.

Owner:CCTEG CHINA COAL RES INST

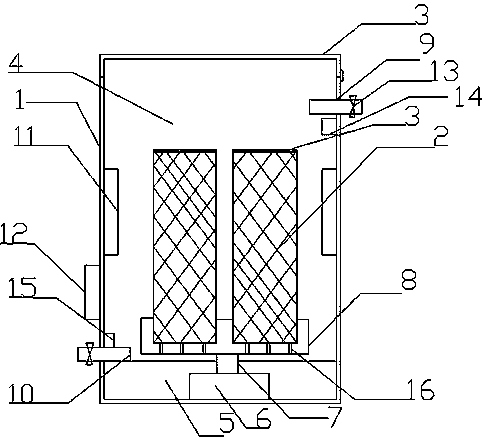

Rice cleaning and soaking device

InactiveCN108906760AQuick washWash thoroughlyDrying solid materials without heatCleaning using liquidsEngineering

The invention provides a rice cleaning and soaking device. The rice cleaning and soaking device comprises an outer barrel and an inner barrel, wherein the inner barrel is placed in the outer barrel; barrel covers are separately arranged on the inner barrel and the outer barrel; the side wall of the inner barrel is latticed; a water storage chamber is formed between the inner barrel and the outer barrel; a motor chamber is formed in the bottom of the outer barrel; a motor is arranged in the motor chamber; a rotating shaft is arranged above the motor chamber and is connected with the motor; a placement groove is formed in the bottom of the outer barrel; the placement groove is connected with the upper end of the rotating shaft; the inner barrel is placed on the placement groove; a water inlet is formed in the right upper portion of the outer barrel; a water outlet is formed in the left lower portion of the outer barrel; dryers are arranged on two sides of the inner wall of the outer barrel; a controller is arranged on the left side of the outer wall of the outer barrel; and the dryers are connected with the controller. The device can clean, soak and dry rice, is simple in structure and high in efficiency, and is suitable for production.

Owner:ANHUI JIAGUDOU FOOD CO LTD

Wood softening treatment fluid for polyglutamic acid-aloe vera gel artworks and preparation method of wood softening treatment fluid

InactiveCN106313245AImprove toughnessImprove rigidityWood treatment detailsWood impregnation detailsPolyvinyl alcoholPolyethylene glycol

The invention discloses wood softening treatment fluid for polyglutamic acid-aloe vera gel artworks. The wood softening treatment fluid is prepared from the following raw materials of, by weight, 0.5-1 part of aloe vera gel, 0.1-0.15 part of polyglutamic acid, 0.3-0.5 part of lanonol polyoxyethylene ether, 5-10 parts of polyethylene glycol, 4-6 parts of glacial acetic acid, 0.5-1 part of alum, 2-4 parts of hydrogen peroxide with the mass fraction of 20-30%, 1-2 parts of polyvinyl alcohol, 0.05-0.1 part of benzyl cinnamate, 0.01 part of ethylparaben, 0.1-0.15 part of sodium benzoate and 50-60 parts of water. The wood softening treatment fluid has the beneficial effects that the softening and processing performance is good, the strength and toughness of wood are high, bounce is not likely to happen, follow-up treatment is not influenced, a dried finished product is high in size stability, not likely to crack and deform and not likely to mildew and rot, the hand feeling is smooth and fine, the application range is wide, and energy saving and environment protection are achieved.

Owner:FUNAN YONGXING ARTS & CRAFTS

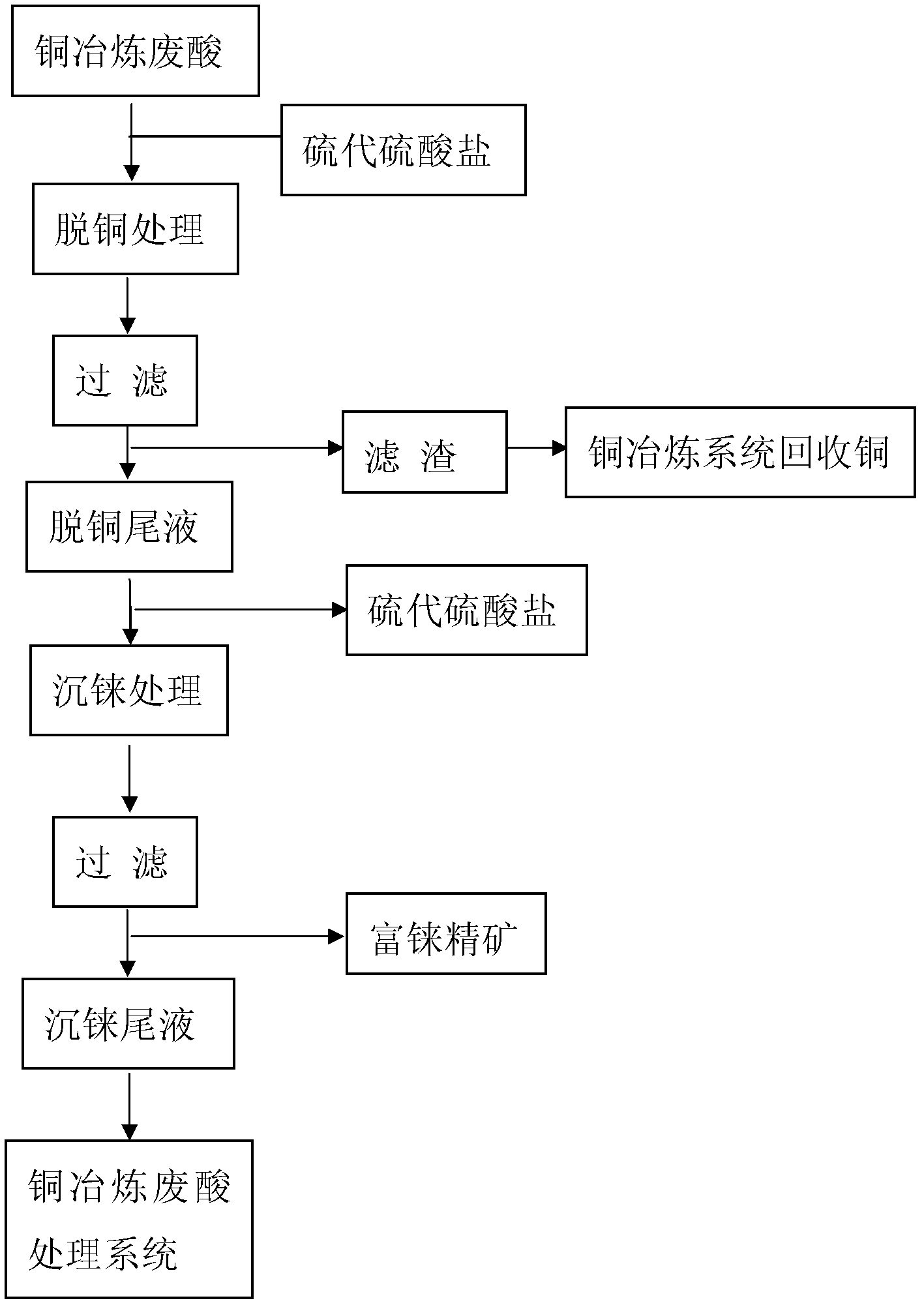

Method for recycling rhenium from copper smelting waste acid

ActiveCN102628110BGood decopper effectGood economic valueProcess efficiency improvementRheniumPre treatment

The invention provides a method for recycling rhenium from copper smelting waste acid. The method comprises the following steps of: adding thiosulfate into the copper smelting waste acid, filtering after a reaction is finished, and taking the filter residues as rhenium-rich concentrates. According to the method for recycling rhenium, provided by the invention, the rhenium is recycled from the waste acid by using thiosulfate, so that the recycling rate is high, and the economic value is obvious. An optimized implementation manner is as follows: under a high copper condition (copper concentration is 0.2-50 g / L), the characteristic of a strong binding capacity between the thiosulfate and copper ions is used, and the operations of removing copper and extracting rhenium are carried out step by step; copper removal pretreatment is carried out on the waste acid, so that the copper is recycled; the rhenium is precipitated in the liquid after copper removal, so that the rhenium-rich concentrates are generated, therefore the purpose of comprehensively recycling copper and rhenium is achieved, the recycling rate is high, the economic value is obvious, and other heavy metals are rarely separated out or slightly separated out in the whole treatment process; and especially, the separate-out quantity of arsenic is very low, so that the subsequent treatment of the waste acid is not affected.

Owner:YANGGU XIANGGUANG COPPER

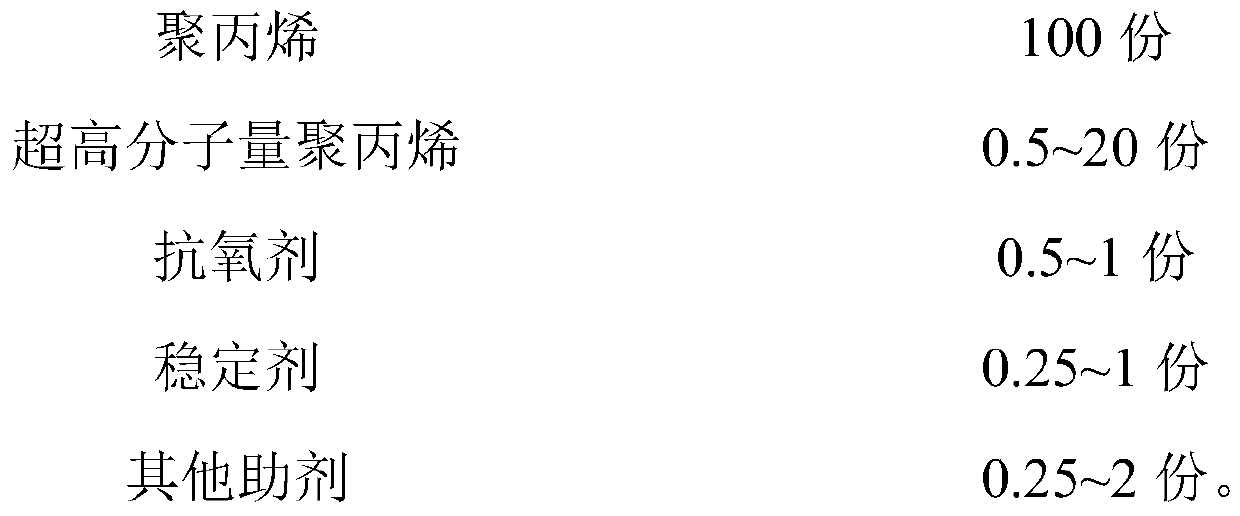

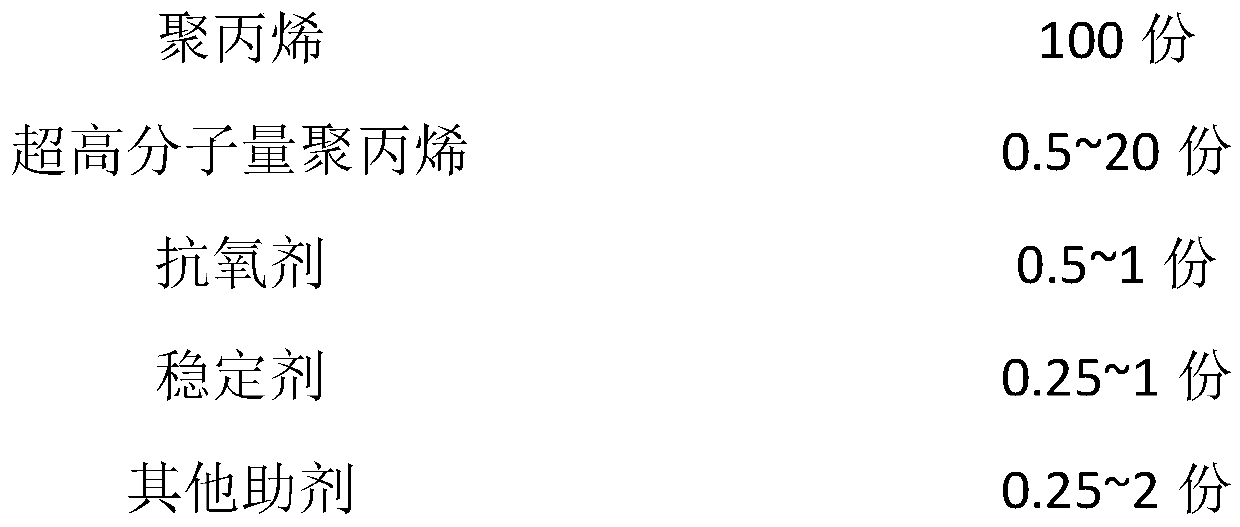

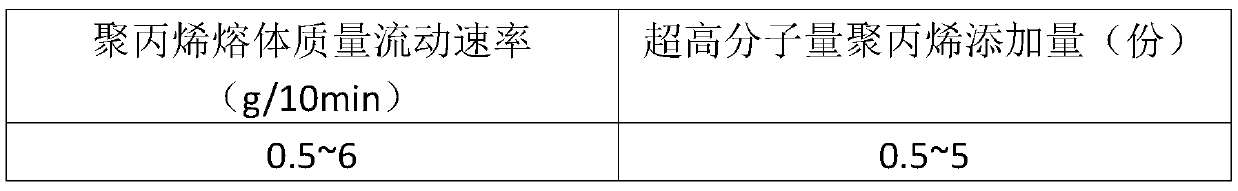

Blended ultrahigh molecular weight polypropylene/polypropylene alloy and preparation method thereof

The invention relates to the field of polymer materials, and concretely relates to a blended ultrahigh molecular weight polypropylene / polypropylene alloy and a preparation method thereof. The principle of similar compatibility is used, ultrahigh molecular weight polypropylene and polypropylene have similar molecular chain segments, and the common polypropylene has excellent processability, so a small amount of the ultrahigh molecular weight polypropylene and polypropylene are subjected to melt blending extrusion to prepare the ultrahigh molecular weight polypropylene / polypropylene alloy, thereby the crosslinking problem generated in the production of high-melt-strength polypropylene by a reactive extrusion method is avoided, and the melt strength of the polypropylene material is enhancedto a certain extent. The method is simple and low in cost, the polypropylene melt strength is remarkably improved, and the prepared alloy is excellent in processability.

Owner:山东清河化工科技有限公司

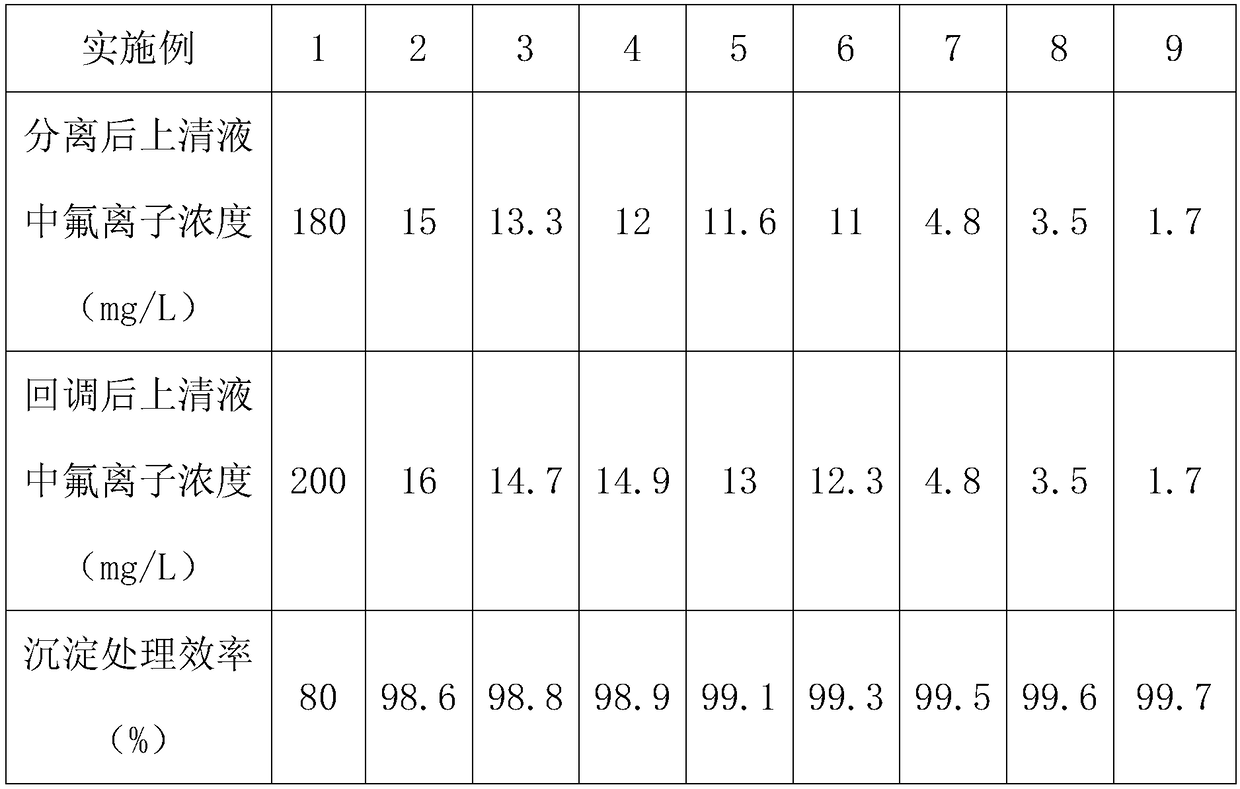

Treatment method of fluorine-containing wastewater

InactiveCN109502826ADoes not affect subsequent processingWater contaminantsMultistage water/sewage treatmentWastewaterAlum

The invention discloses a treatment method of fluorine-containing wastewater. The treatment method comprises the following steps: A, collecting the fluorine-containing wastewater as raw water, addinga lime water solution into the raw water until the pH value is adjusted to be 8-9, and reacting for 20 minutes; B, adding alum into a mixed solution in the step A according to the addition amount of 0.3-0.4g of the alum per liter of the raw water, adjusting the pH value to 10-11, and reacting for 5min; C, adding 10-20ppm of a polyacrylamide solution into a mixed solution in the step B, and reacting for 5min. The fluoride ion concentration of a supernatant is lower than 5mg / L, the national industrial wastewater discharge standard is met, the sedimentation speed is high, and the defluoridation rate is high.

Owner:FOSHAN COMWIN LIGHT & ELECTRICITY

Method for preparing nanometer ultra-fine tourmaline powder

InactiveCN1265887CReduce reunionSmall particle sizeHeat treatmentsDrying solid materials with heatUltra fineGenerating capacity

The present invention relates to production of non-metal mineral powder, and is especially the preparation process of nano superfine tourmaline powder. The technological process includes the steps of: coarse crushing ore, airflow crushing, post-treatment, wet ball milling, spray drying, eliminating agglomeration of powder, and packing. The main technological prameters include calcining temperature of initially crushed powder in air of 300-800 deg.c, calcining time of 2-4 hr to obtain tourmaline powder in different colors, and ball milling period of 36-72 hr. Compared with available technology, the present invention has obviously reduced agglomeration of tourmaline powder, raised crushing efficiency, powder size reduced to 15-60 nm, obviously raised negative ion generating capacity, various color of the powder and wide application range.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

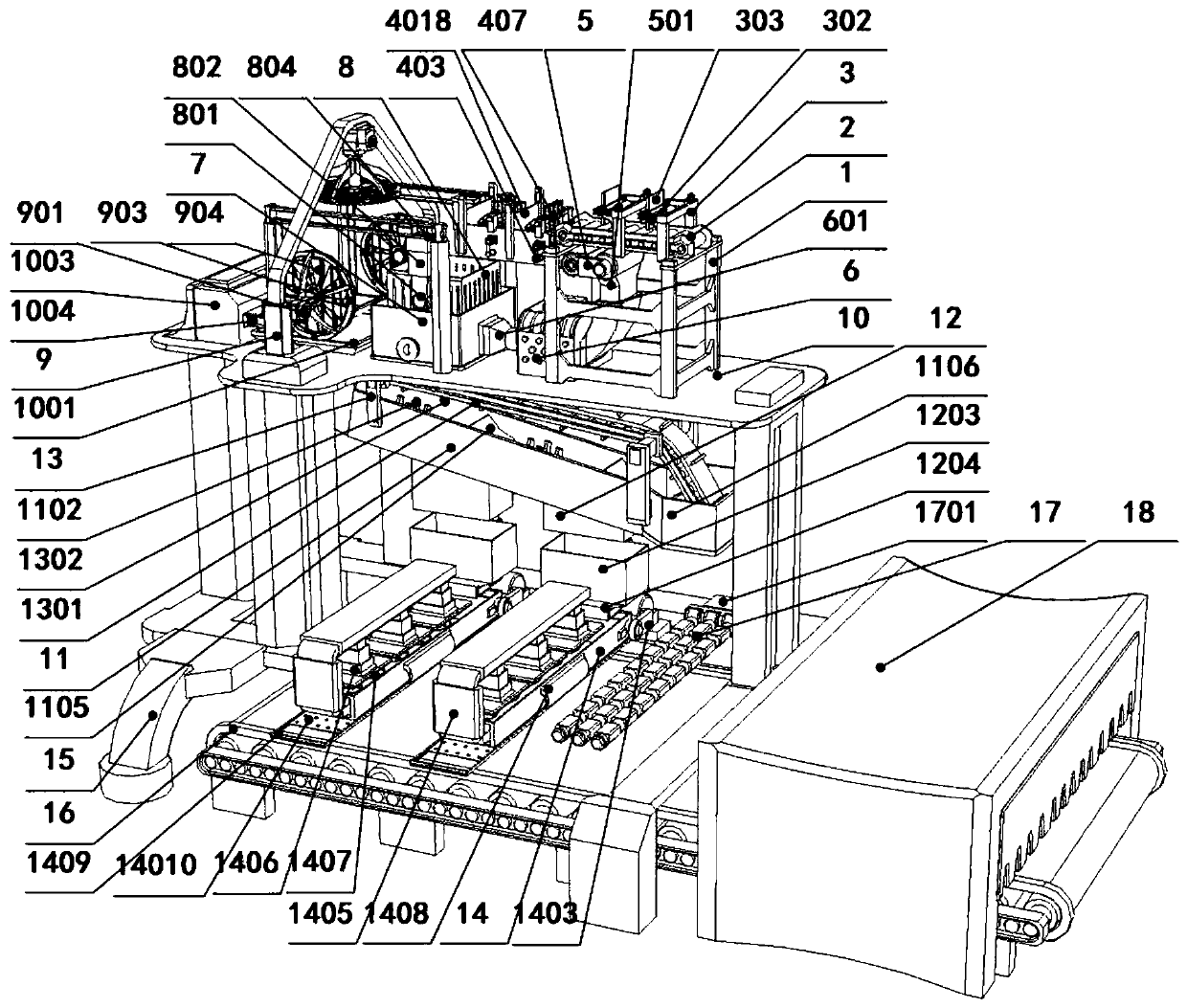

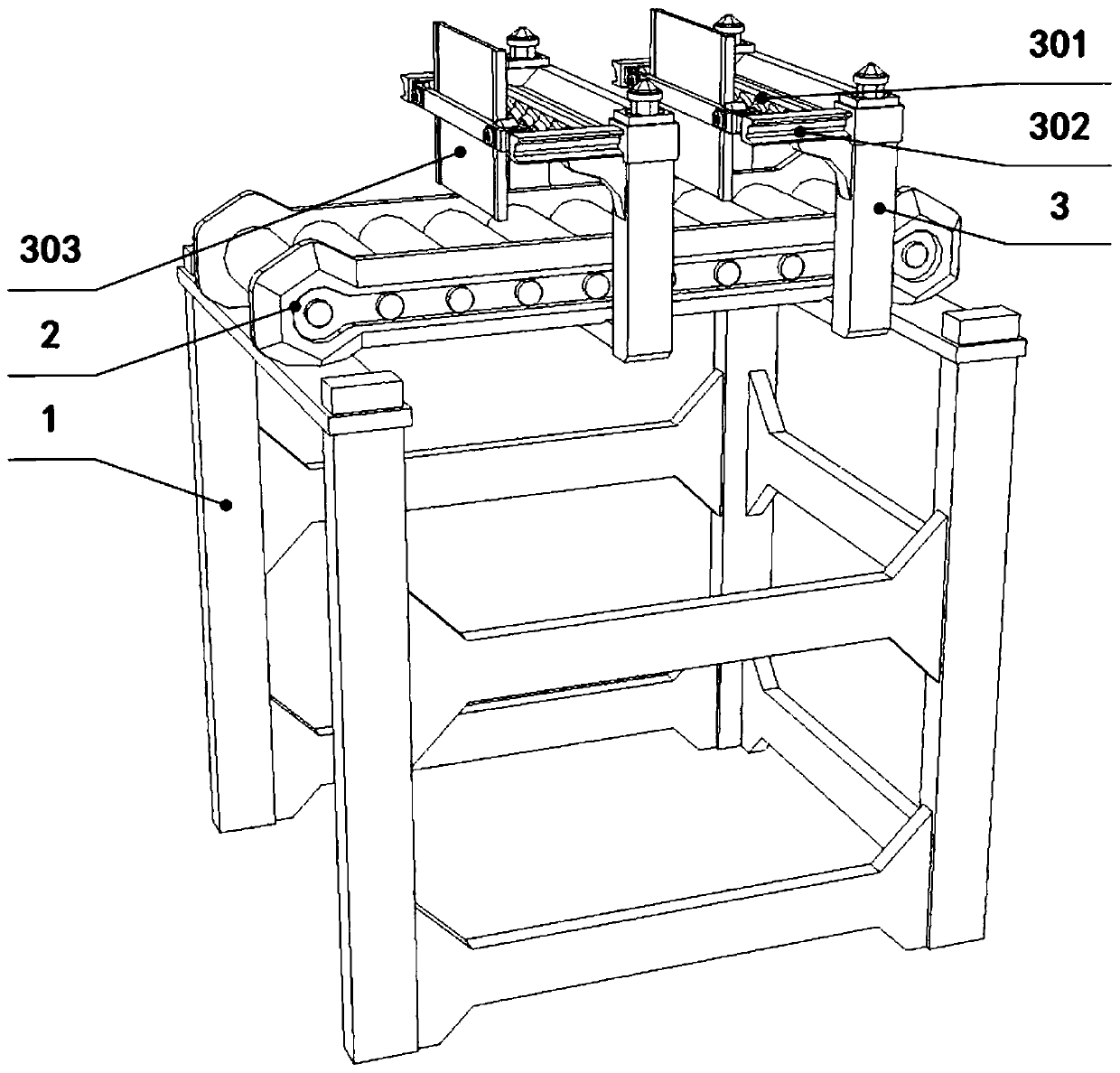

Deep processing equipment for dried potatoes

InactiveCN109938307AEffective deep processingNo human intervention requiredVegetable peelingFood treatmentEngineeringDeep processing

The invention relates to deep processing equipment for dried potatoes. The Equipment includes a first worktable, a roller conveyor, cleaning systems, a peeling system, a sterilization and air-drying system, a second worktable, a weighing system, cutting systems, a third worktable, a conveying caterpillar track and an oven; the roller conveyor is arranged on the first worktable, the two cleaning systems are arranged on the roller conveyor, the peeling system is connected with the cleaning system, the weighing system is located on the lower portion of the second worktable, the two cutting systems are arranged on the lower portion of the weighing system, and the conveying caterpillar track is located on the lower portion of the cutting system. All steps of potato processing can be performed by the equipment, through the equipment, the potatoes can be sequentially cleaned, peeled, steamed, sterilized, air-dried, classified according to the size of potatoes, weighed, and then quantitativelycut into strips or slices, spices are then added, drying is performed, the potatoes can be effectively and deeply processed without manual intervention, the work efficiency is high, the production cost is low, and the equipment can be widely applied and popularized.

Owner:储会春

Fresh keeping agent for fresh dendrobium twigs as well as preparation method and use method of fresh keeping agent

InactiveCN105052896AEasy to useInhibition of germinationDead plant preservationPullulanAdditive ingredient

The invention discloses a fresh keeping agent for fresh dendrobium twigs as well as a preparation method and a use method of the fresh keeping agent. The fresh keeping agent comprises, in percentage by weight, 1%-4% of food-grade pullulan, 0.1%-2% of food-grade chitosan oligosaccharide, 0.1%-2% of food-grade mannan oligosaccharide, 0.5%-2.5% of food-grade glycerin and the balance of water. The picked fresh dendrobium twigs are subjected to preliminary finishing, immersed in the fresh keeping agent for 30-60 seconds and taken out to be aired; or cuts of the fresh twigs are immersed in the fresh keeping agent for 30-60 seconds, then, the fresh keeping agent is sprayed on the fresh twigs at 360 degrees, the fresh twigs are aired, the fresh twigs treated with the fresh keeping agent are directly put in a shady, cool and dry place for storage or put in the shady, cool and dry place for storage after being subjected to vacuum package or put at the temperature ranging from 4 DEG C to 12 DEG C for cold storage. The raw materials used for the fresh keeping agent are all food-grade, the fresh keeping agent doesn't contain a preservative and is safe, non-toxic, cheap and easy to obtain; the treated fresh twigs can be preserved for one year to one and a half year, and the water loss is smaller than 1%; the germination rate is very low, characteristics and nutritional ingredients of the fresh dendrobium twigs can be kept, and follow-up processing is not affected.

Owner:BAOSHAN COMPREHENSIVE INSPECTION CENT OF QUALITY & TECHNICAL SUPERVISION

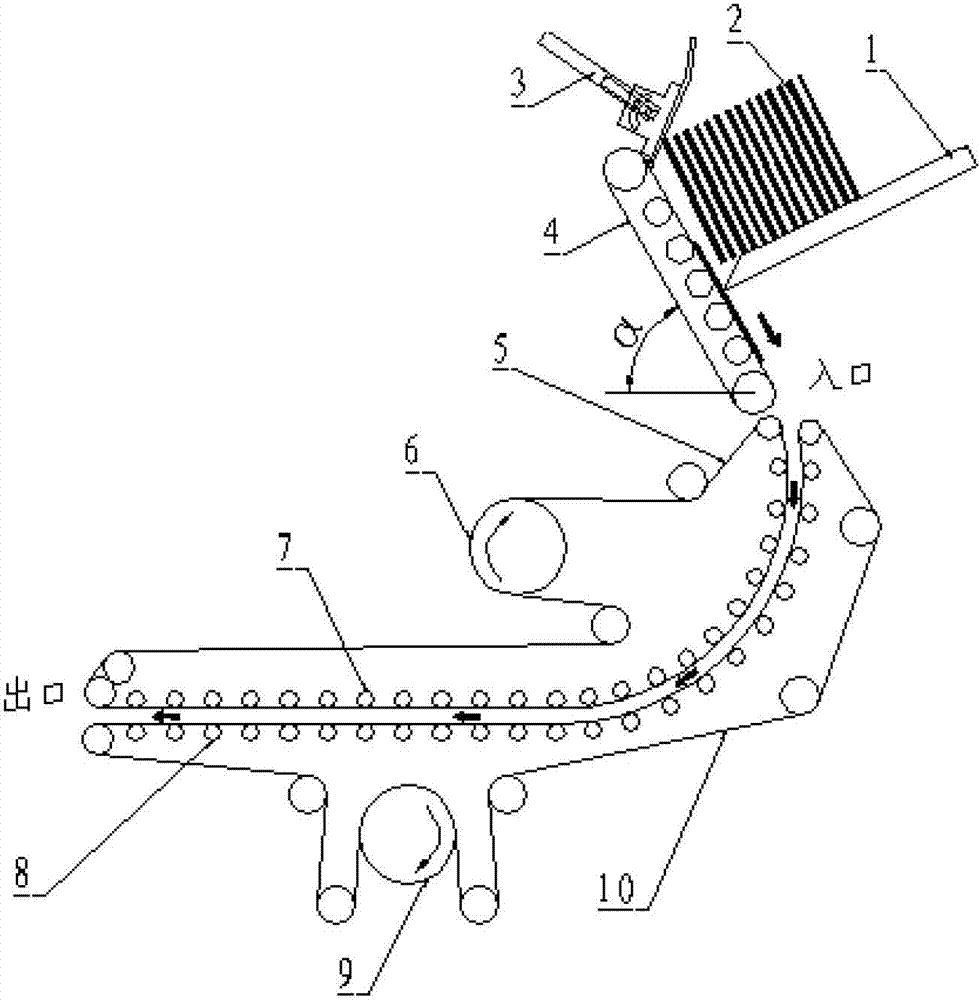

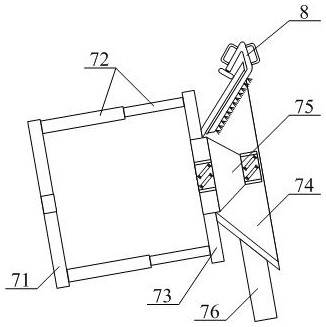

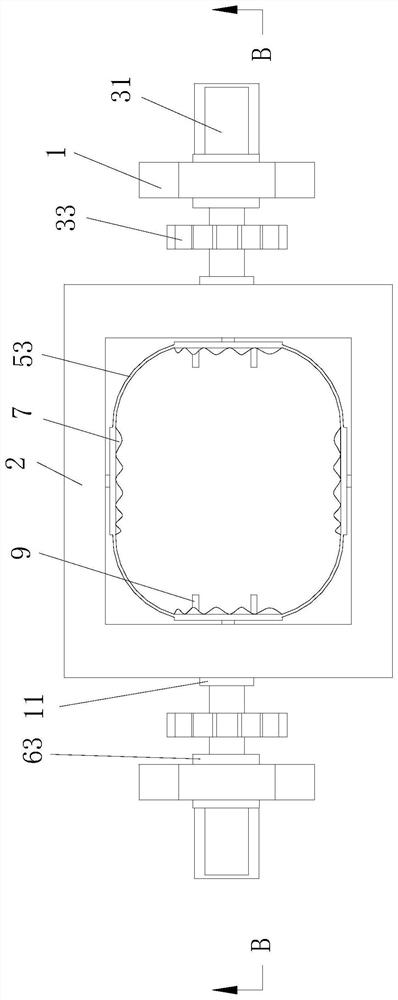

Paper feeder and working method thereof

ActiveCN102730465AQuality improvementEasy to operateArticle deliveryPulp and paper industryAngle alpha

The invention provides a paper feeder. The paper feeder is characterized by comprising a paper feeding device with an inclined angle alpha and an overturn conveying device, wherein the paper feeding device is arranged at an inlet of the overturn conveying device. The working method comprises the following steps of: adjusting the distance between an inclined paper feeding knife and an inclined sending belt; downwards stacking printing surfaces of printing paper pile at the paper feeding knife and a paper support frame at the front part of equipment; moving the sending belt to transport a single printing product fell on the sending belt to the inlet of the overturn conveying device; feeding the printing products with the downward printing surfaces between an upper pressure belt and a lower pressure belt, and operating the printing products while being clamped by the upper pressure belt and the lower pressure belt, thereby gradually realizing upturning the printing surfaces after the printing products pass through whole transportation path and achieve to an outlet; and conveying the printing products between the upper pressure belt and the lower pressure belt. By the device and the method, an operator can safely stack the printing products outside the equipment, and can conveniently operate; the quality of the printing products can be improved through overturning paper feeding, and the qualified rate of the products can be improved; and the printing products are naturally turned for 180 DEG in the transporting process, and the subsequent processing is not affected.

Owner:MASTERWORK GROUP CO LTD

Drilling device for coal mine underground gas extraction

InactiveCN111927355AEasy to collectEasy to navigateConstructionsDerricks/mastsHydraulic cylinderVehicle frame

The invention provides a drilling device for coal mine underground gas extraction. The drilling device comprises a drilling vehicle frame, a drilling vehicle crawler belt, a lug plate, an installationseat, a support column, a top installation plate, a telescopic mud collection frame structure, a mud cleaning frame structure, a moving pipe, a sliding installation plate, a drilling motor, a rotarydrill rod, a drill bit, an installation groove, an adjusting cylinder, a cockpit, a mud filtering settling box structure, a connecting hose, a hydraulic cylinder, a hydraulic pump station and oil inlet and outlet pipe. The drilling device has the beneficial effects that due to the arrangement of a collecting cover and a mud outlet pipe, when the equipment is used for drilling, the collecting coveris attached to the lower part of a rock wall and positioned at the drilling position, and mud flows downwards into the inner side of the collecting cover along the drilling position and is dischargedthrough the mud outlet pipe, so that the mud is collected and guided, the problem that mud falls down to the outer side of the equipment, and workers cannot clean the equipment conveniently is prevented, and the equipment cleaning effect is improved.

Owner:韩若愚

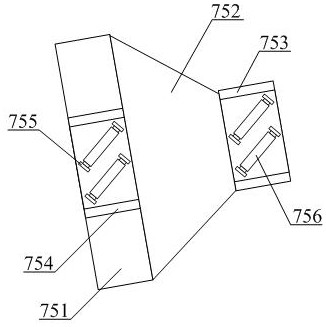

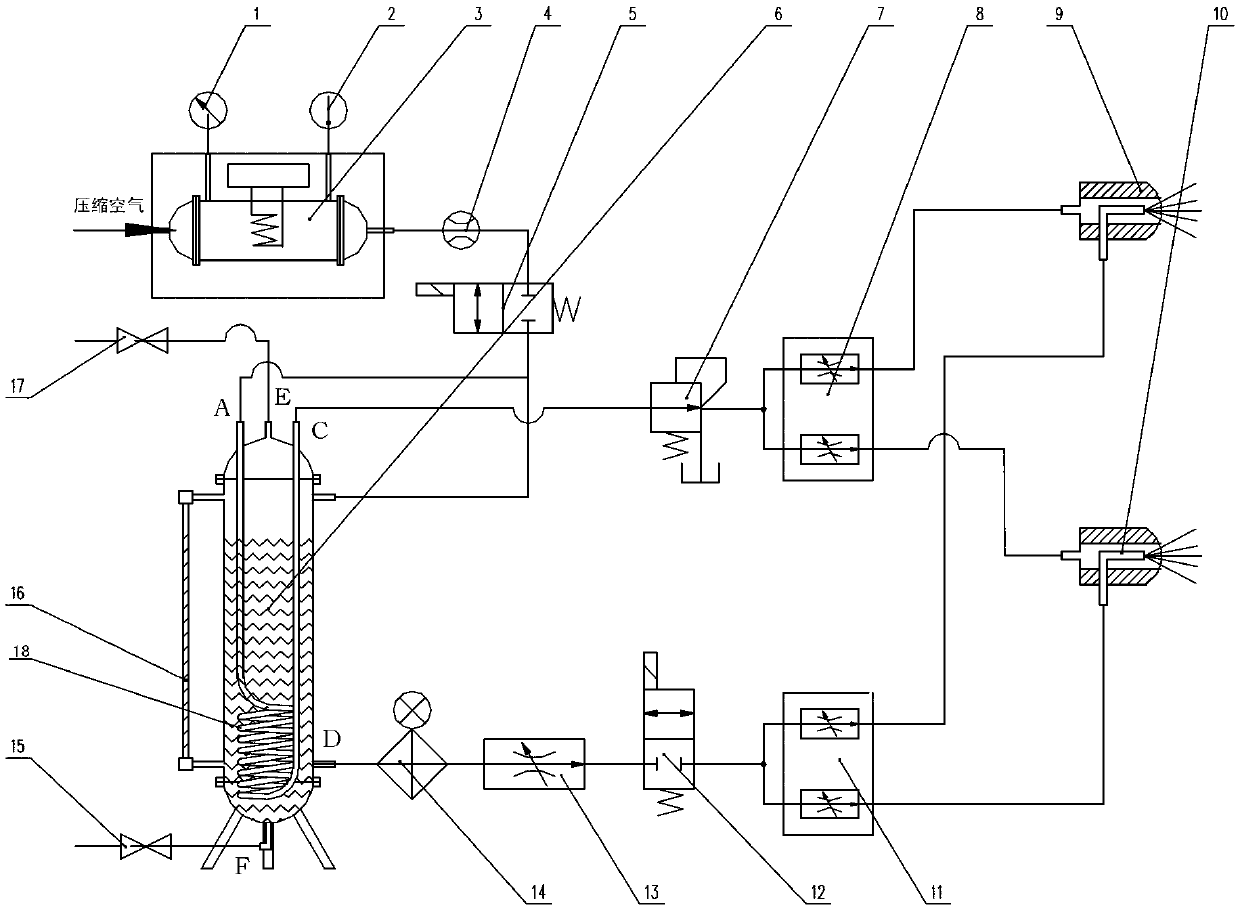

Wood sawing cooling medium refrigeration and atomization cooling system

The invention discloses a wood cooling medium refrigeration and atomization cooling system. The wood cooling medium refrigeration and atomization cooling system comprises a refrigerating device, a pressure-proof liquid medium storage tank, a pressure regulating device and a liquid balance adjusting device, wherein the refrigerating device is used for refrigerating external compressed gas and outputting the compressed gas in two paths; the pressure-proof liquid medium storage tank is used for storing a liquid medium, a refrigerating coil is arranged in a cold flow storage tank, one path of the refrigerating gas output by the refrigerating device is introduced into the refrigerating coil to refrigerate the liquid medium and is respectively input to spraying nozzles through a dividing valve, and the other path of the refrigerating gas is introduced into the pressure-proof liquid medium storage tank and is used for discharging the refrigerated liquid medium out of the pressure-proof liquid medium storage tank; the pressure regulating device is arranged on a gas path pipeline, and is used for lowering the pressure of the gas paths to ensure that the pressure of a liquid path and the gas paths at a nozzle confluence part is balanced, so that the liquid cooling medium can be sprayed out; and the liquid balance adjusting device is used for performing balance adjustment on the liquid medium discharged from the cold flow storage tank and then inputting the liquid medium to each spraying nozzle. By adopting the wood cooling medium refrigeration and atomization cooling system, the problems that a saw blade is heated and deformed, the service life of the saw blade is shortened, the sawing force is increased, the sawing surface quality is reduced and the like during sawing processing of the conventional precious woods or reconstructed bamboo lumbers can be solved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

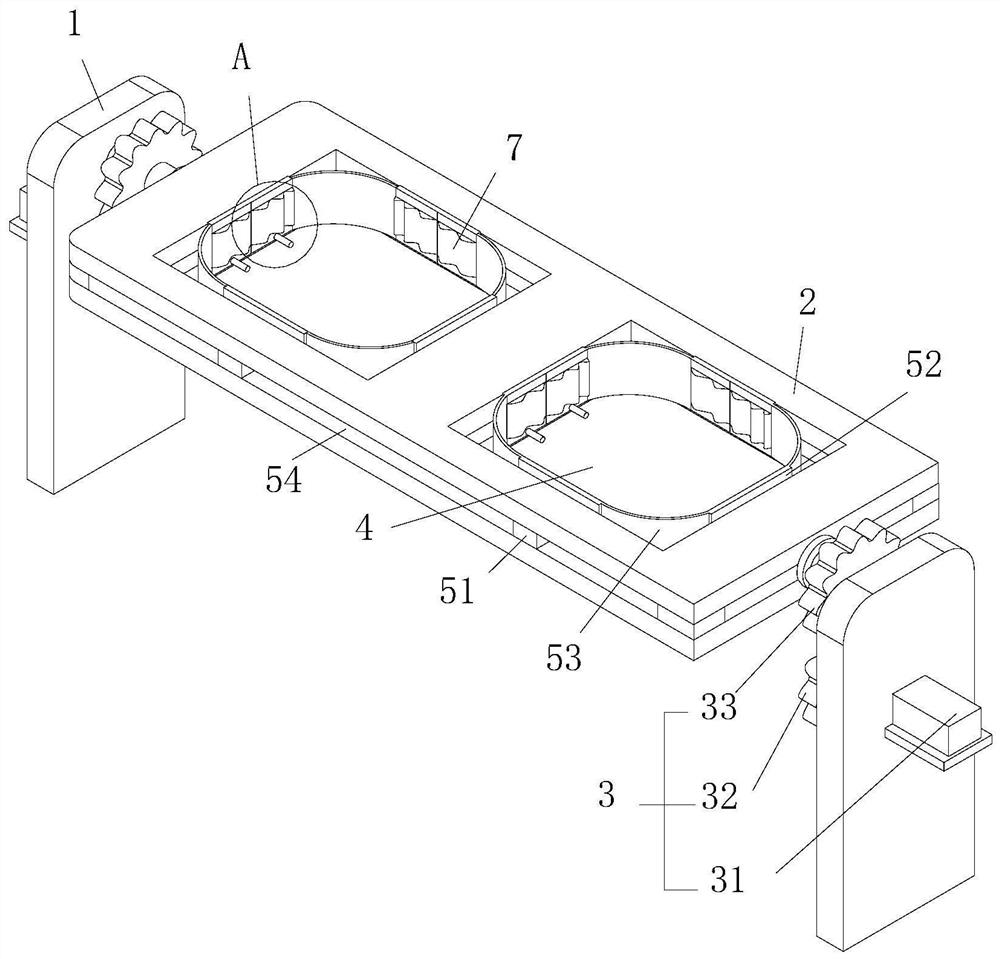

Machining mechanism for automobile cylinder covers

InactiveCN113263207AImprove processing efficiencyReduce the problem of increased processing timeLarge fixed membersMilling equipment detailsStructural engineeringMachine tool

The invention relates to a machining mechanism for automobile cylinder covers. The machining mechanism comprises machine frames, a machining tool and machining grooves, the machine frames are symmetrically distributed on the two sides of the machining tool, the multiple machining grooves are formed in the machining tool and are used for containing the cylinder covers to be machined, driving mechanisms are arranged between the machining tool and the machine frames, clamping mechanisms are arranged on the machining tool, and a lifting mechanism is further arranged on the lower surface of the machining tool. According to the machining mechanism, one or two machining grooves are formed in the machining tool, the multiple clamping mechanisms are arranged above the machining grooves, the cylinder covers needing to be machined are placed in the machining grooves, then the clamping mechanisms are started to clamp the cylinder covers, milling is carried out on the upper end surfaces of the cylinder covers by utilizing an arranged milling device, after milling of the upper end surfaces is completed, the clamping mechanisms do not need to be loosened, the driving mechanisms are directly used for driving the machining tool to turn over by 180 degrees, the lower end surfaces are made to face upwards, milling is carried out again, and therefore the problem that the machining efficiency is low due to repeated clamping can be effectively solved.

Owner:常州美通备品车辆配件有限公司

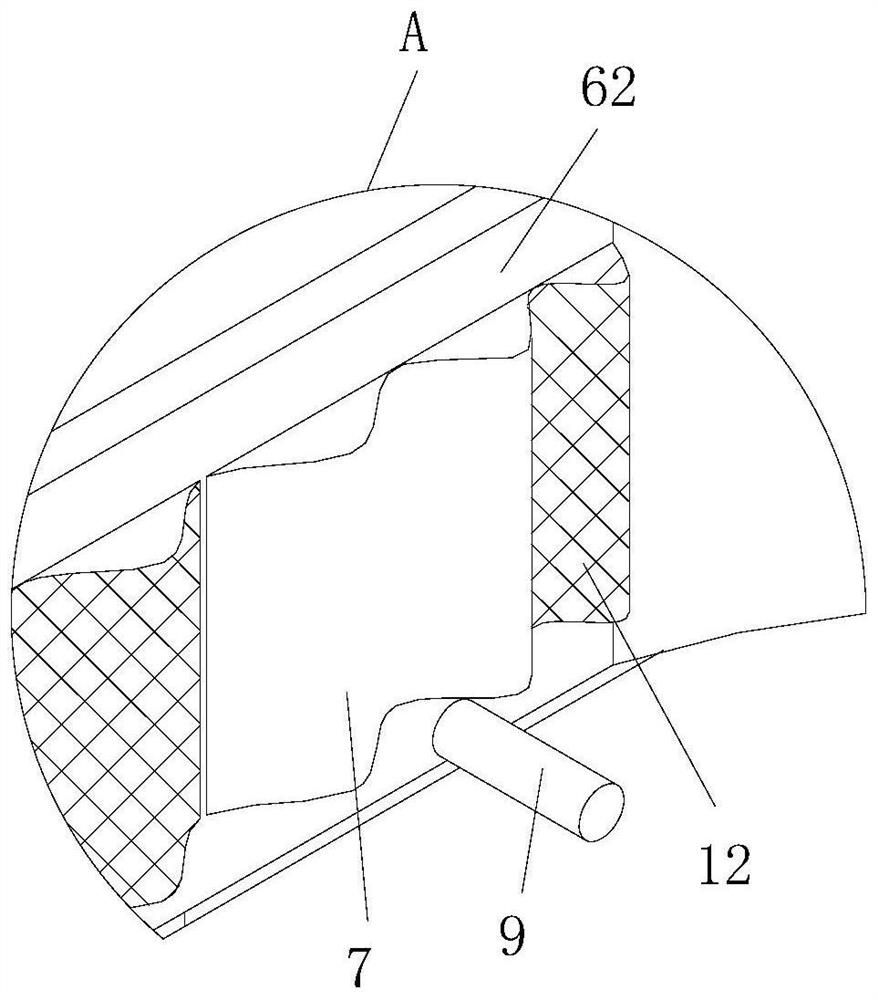

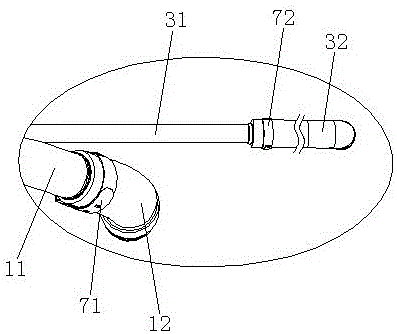

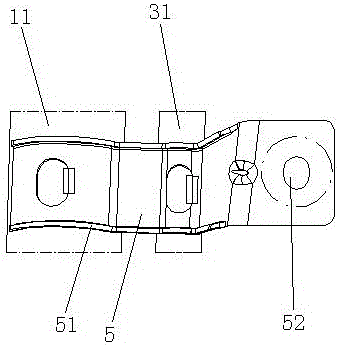

Multi-runner automobile part injection mold and machining method

ActiveCN113172841AReduce difficultyReduce fluidity ejectionDomestic articlesMultiple injectionEngineering

The invention discloses a multi-runner automobile part injection mold. The multi-runner automobile part injection mold comprises an injection plate, a concave mold plate, a convex mold plate and a demolding plate, all of which are sequentially attached to one another. An injection cavity is formed in the middle of the side, away from the concave mold plate, of the injection plate, an injection connecting pipe communicating with the injection cavity is inserted into the injection plate, and multiple injection runners are symmetrically formed in the cavity wall of the injection cavity. The invention further discloses a multi-runner automobile part injection molding machining method. The multi-runner automobile part injection molding machining method comprises the following steps of melt injection, multi-runner filling, double-temperature cooling and forming and demolding. The injection molding speed is increased through simultaneous injection molding of the multiple runners, the demolding difficulty is reduced through high-low-temperature partitioned cooling, the fluidity of molten plastic during demolding is reduced, overflowing is avoided, the re-hot-melting speed of the plastic is increased, and the injection molding efficiency is improved; and through reverse injection molding of the convex mold bent runners, the end face is located on the narrow edge of formed plastic, the flatness of large-area inner and outer surfaces is kept, and the quality of injection molded products is improved.

Owner:青岛方正精密模塑有限公司

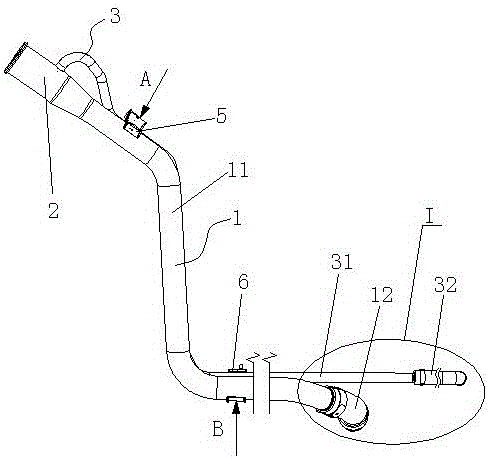

Oil filling pipe with double-side zinc-plating structure and processing method thereof

ActiveCN106004417ASimple structureGuaranteed StrengthCorrosion preventionPipe protection against corrosion/incrustationFluorocarbonZinc

The invention discloses an oil filling pipe with a double-side zinc-plating structure. The oil filling pipe comprises an oil filling pipe body, wherein the oil filling pipe body is formed by connecting and fixing an oil filling steel pipe and an oil filling rubber pipe; one end, far away from the oil filling rubber pipe, of the oil filling steel pipe is provided with an oil filling opening; connecting threads are formed in the oil filling opening; a fluorocarbon resin rubber layer is arranged in the opening position of the oil filling opening; a ventilation pipe is connected onto the oil filling opening; the ventilation pipe is formed by connecting and fixing a ventilation steel pipe and a ventilation rubber pipe; the zinc-plating layers are respectively arranged on the inner and outer surfaces of the oil filling steel pipe and the ventilation steel pipe. According to a processing method of the oil filling pipe, firstly, the zinc plating is performed at the two sides of the steel plate to prepare the zinc-plating layers; then, winding welding is performed to make the steel plate into the zinc-plating pipe; the zinc-plating pipe is finally processed into the oil filling pipe. The processing method is simple; the effective zinc-plating layers can be formed both on the inner and outer surfaces of the oil filling pipe, and the manufactured oil filling pipe has a simple structure and a long service life.

Owner:NINGBO SHUNJIANG AUTO PARTS MFG

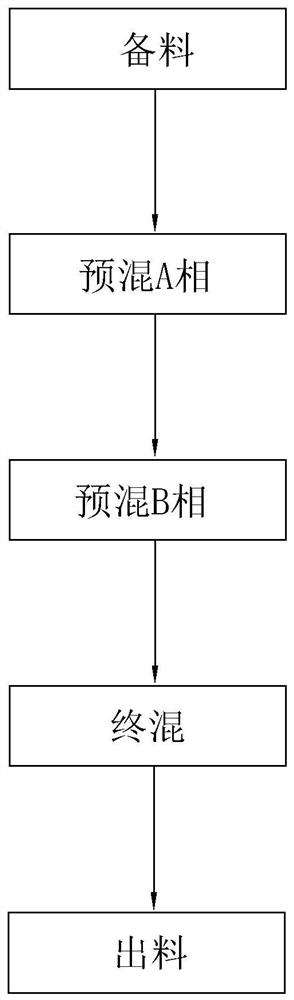

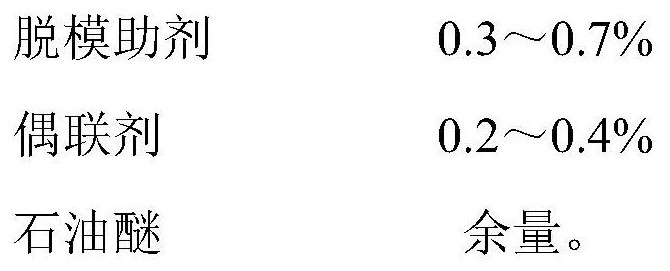

A kind of release agent for rubber molding industry and preparation method thereof

ActiveCN110281433BSolve the way outDoes not affect subsequent processingPolymer scienceEthyl acetate

Owner:SHANGHAI XINPING FINE CHEM CO LTD

Peculiar-smell-free raw cotton fiber capable of keeping natural whiteness and preparation method thereof

ActiveCN112111968ANo smellDoes not affect subsequent processingDry-cleaning apparatus for textilesVegetable materialCotton fibrePulp and paper industry

The invention provides a peculiar-smell-free raw cotton fiber capable of keeping natural whiteness and a preparation method thereof. The smell grade of the raw cotton fiber is greater than or equal tograde 4, the whiteness of the fiber is 60-65, the content of sugar in the fiber is less than or equal to 50[mu]g / g, and the pH value of the fiber is 5-7. According to the peculiar-smell-free raw cotton fiber capable of keeping natural whiteness, polysaccharide is degraded through an acid method to remove the peculiar smell of the cotton fiber, besides, natural pigment and natural wax in the cotton fiber are reserved, the prepared raw cotton fiber not only reserves natural style and appearance of the cotton fiber, but also has no peculiar smell, and subsequent processing of the raw cotton fiber is not affected. The preparation process and the technical route of the peculiar-smell-free raw cotton fiber capable of keeping natural whiteness are simple, can be achieved on existing industrial continuous production equipment, and are high in efficiency, appropriate in cost and convenient to apply and popularize.

Owner:ZHONGDI HOME TEXTILES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com