Method of extracting phenolic compound from coal liquefied oil or coal tar

A technology of phenolic compounds and coal liquefied oil, applied in the field of coal chemical industry, can solve the problems of unsuitable development of phenol extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

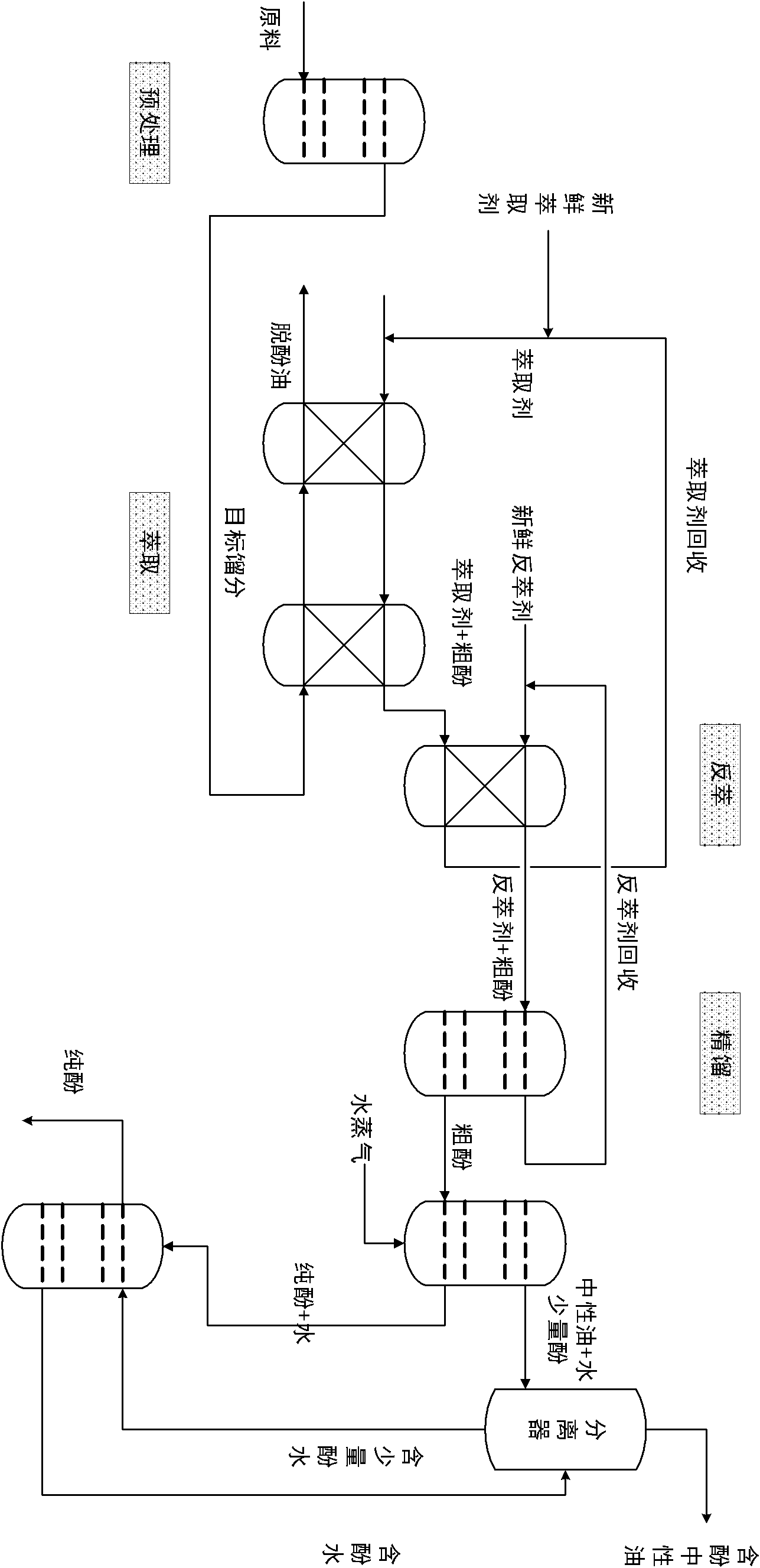

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1, extract phenolic compound from coal direct liquefaction oil

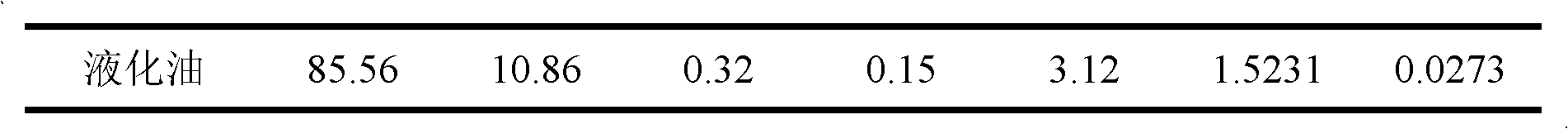

[0031]The raw material to be treated is taken from the liquid product obtained on the 0.1t / d coal direct liquefaction continuous test device, and its elemental analysis results are shown in Table 1.

[0032] Table 1 Elemental analysis results of direct coal liquefaction oil

[0033]

[0034]

[0035] The main phenolic compounds were qualitatively and quantitatively analyzed by means of GC-MS chromatography-mass spectrometry, and their specific compositions are shown in Table 2.

[0036] Table 2 Analysis results of phenolic compounds in direct coal liquefaction oil

[0037]

[0038] The content of phenolic compounds in coal liquefied oil is about 14.5% (IBP~350°C). After the first step of distillation, the target fraction of 160~230°C is cut. This fraction accounts for about 22% of the total raw materials, and phenol Phenolic compounds account for about 56%, of which the lower phenols,...

Embodiment 2

[0041] Embodiment 2, continuous device extracts phenolic compounds from medium and low temperature coal tar

[0042] The raw material is taken from a typical medium-low temperature coal tar produced by a coal chemical enterprise in the west. It has been measured that the water content is about 15%. Atmospheric distillation cuts a fraction at 150-210°C, which accounts for about 18% of the overall raw material. It is measured that the content of phenolic compounds is as high as more than 80%.

[0043] Gas chromatography quantitative analysis was carried out on this fraction section, and the specific results are shown in Table 3.

[0044] Analysis results of phenolic compounds in low temperature coal tar in Table 3

[0045]

[0046]

[0047] The operation process of the continuous device has been described in detail in the above summary of the invention, and the main operating data are listed in Table 4 below.

[0048] Table 4 The main operating data of the continuous pro...

Embodiment 3

[0051] Embodiment 3, extract phenolic compound from medium temperature coal tar

[0052] The raw material is obtained from a semi-coke production enterprise in the Inner Mongolia Autonomous Region. The water content of medium-temperature coal tar is about 5%. It is measured that the content of phenolic compounds reaches more than 57%.

[0053] Carry out gas chromatography quantitative analysis to this cut section, the results are as shown in table 4:

[0054] Table 4 Analysis results of phenolic compounds in medium temperature coal tar

[0055]

[0056]

[0057] The content of phenolic compounds in this fraction is relatively high. The target fraction is extracted by two-stage countercurrent and centrifuged. The mass ratio of ethylene glycol to fraction is 10:1, the average residence time is 50min, and the temperature is about 20°C. After extraction, the extraction rate of phenol can reach 75%, and the entrainment of neutral oil accounts for about 6.2% of the whole ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com