Blended ultrahigh molecular weight polypropylene/polypropylene alloy and preparation method thereof

An ultra-high molecular weight, polypropylene technology, applied in the field of polymer materials, can solve the problems of difficult control of molding processing, cross-linking after molecular chain breaking, etc., and achieve the effect of excellent processing performance, low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

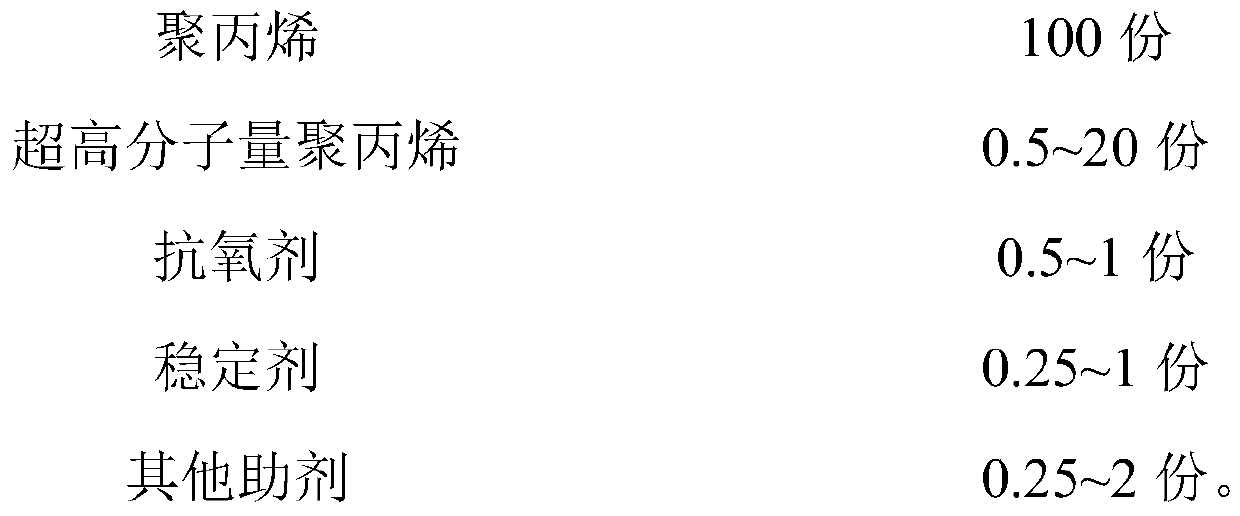

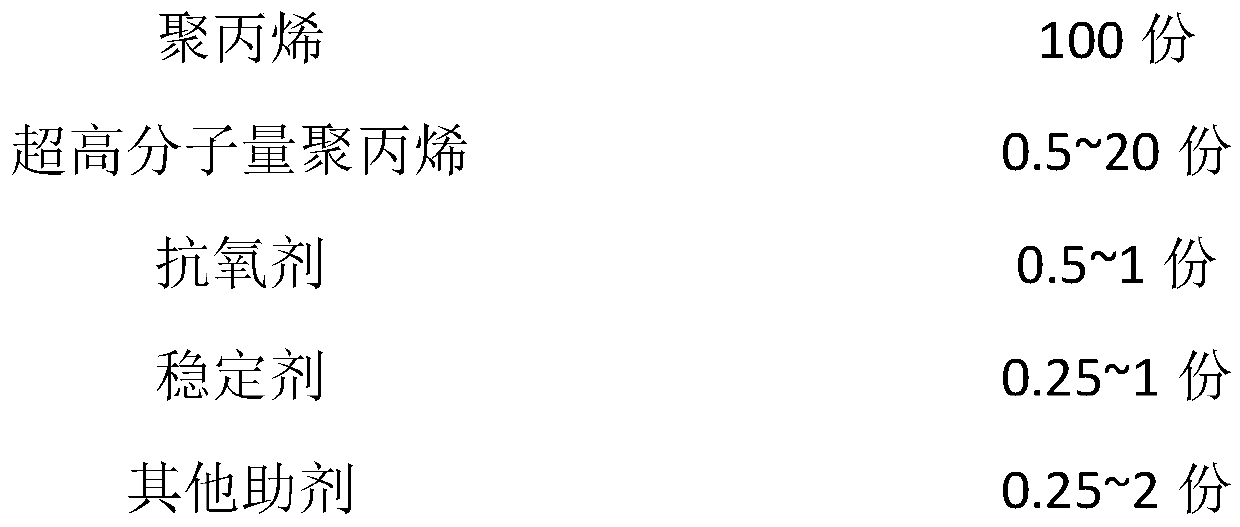

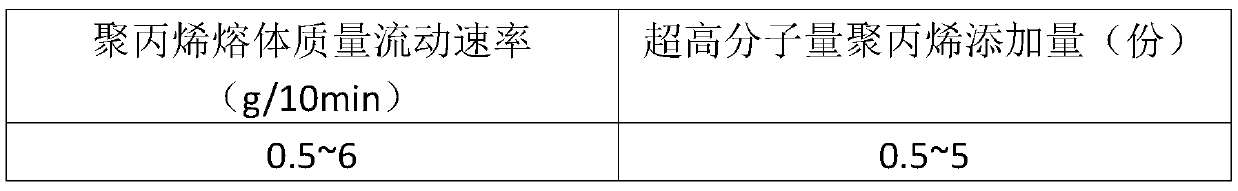

Method used

Image

Examples

Embodiment 1

[0024] S1: An antioxidant compounded with 100 parts of isotactic polypropylene (melt mass flow rate 0.5-6g / 10min), 1 part of ultra-high molecular weight polypropylene, 0.5 part of 1010 type antioxidant and 0.375 part of 168 type antioxidant Add 0.25 parts of zinc stearate and 0.5 parts of liquid paraffin into a high-speed mixer and stir evenly. Adjust the speed of the high-speed mixer to 800-1200r / min, the mixing temperature to 60-80°C, and the mixing time to 10-20min. get the premix;

[0025] S2: The premix is melted, kneaded, homogenized, extruded, and granulated through the screw extruder. The length-to-diameter ratio of the screw extruder is 36:1-50:1, and the temperature in the first zone is set to 120 ~140°C, the temperature from the second zone to the fourth zone is 160~200°C, the temperature from the fifth zone to the eighth zone is 210~230°C, the speed of the screw extruder is 200~350r / min, and the obtained The product is a blended ultra-high molecular weight polyp...

Embodiment 2

[0027] S1: An antioxidant compounded with 100 parts of isotactic polypropylene (melt mass flow rate 6-15g / 10min), 3 parts of ultra-high molecular weight polypropylene, 0.5 part of 1010 type antioxidant and 0.375 part of 168 type antioxidant Add 0.5 parts of zinc stearate and 0.5 parts of liquid paraffin into a high-speed mixer and stir evenly. Adjust the speed of the high-speed mixer to 800-1200r / min, the mixing temperature to 60-80°C, and the mixing time to 10-20min. get the premix;

[0028] S2: The premix is melted, kneaded, homogenized, extruded, and granulated through the screw extruder. The length-to-diameter ratio of the screw extruder is 36:1-50:1, and the temperature in the first zone is set to 120 ~140°C, the temperature from the second zone to the fourth zone is 160~200°C, the temperature from the fifth zone to the eighth zone is 210~230°C, the speed of the screw extruder is 200~350r / min, and the obtained The product is a blended ultra-high molecular weight polypr...

Embodiment 3

[0030] S1: An antioxidant compounded with 100 parts of isotactic polypropylene (melt mass flow rate 15-30g / 10min), 5 parts of ultra-high molecular weight polypropylene, 0.5 part of 1010 type antioxidant and 0.375 part of 168 type antioxidant Add 0.75 parts of zinc stearate and 1 part of liquid paraffin into a high-speed mixer and stir evenly. Adjust the speed of the high-speed mixer to 800-1200r / min, the mixing temperature to 60-80°C, and the mixing time to 10-20min. get the premix;

[0031] S2: The premix is melted, kneaded, homogenized, extruded, and granulated through the screw extruder. The length-to-diameter ratio of the screw extruder is 36:1-50:1, and the temperature in the first zone is set to 120 ~140°C, the temperature from the second zone to the fourth zone is 160~200°C, the temperature from the fifth zone to the eighth zone is 210~230°C, the speed of the screw extruder is 200~350r / min, and the obtained The product is a blended ultra-high molecular weight polypro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com