Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Does not affect optical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

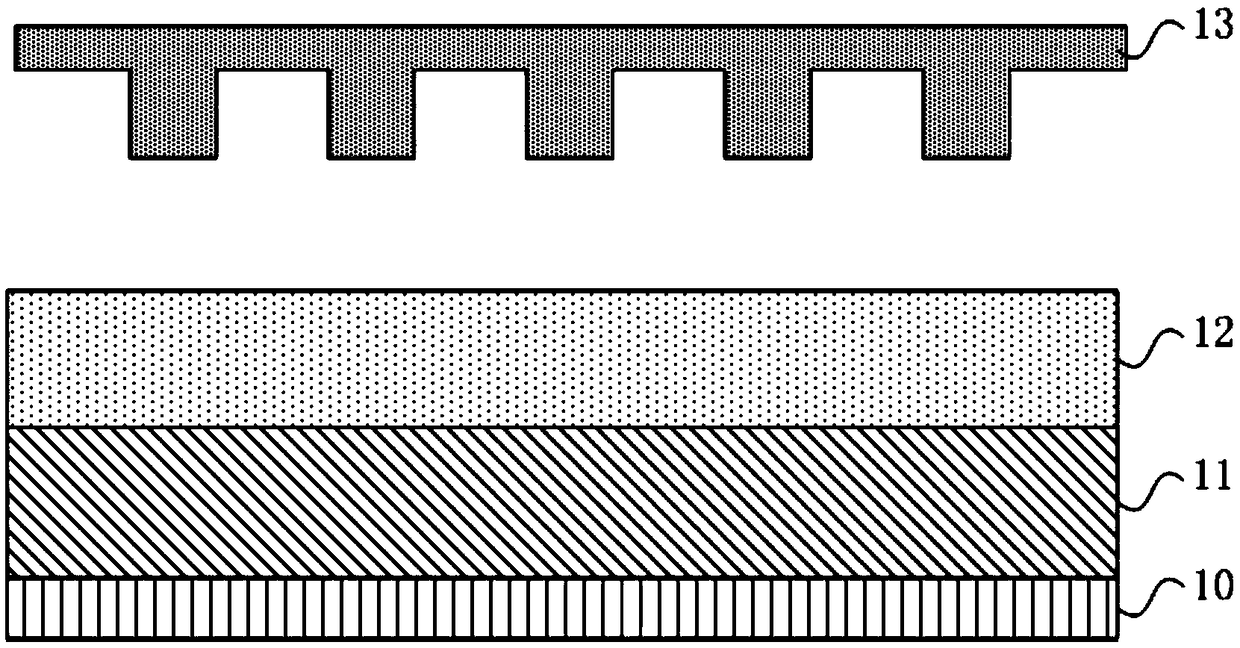

Preparation method of nanometer metal grating and nanometer metal grating

ActiveCN107479121AEasy to etchSolve the problem that etching cannot be carried outPhotomechanical apparatusPolarising elementsState of artOxygen

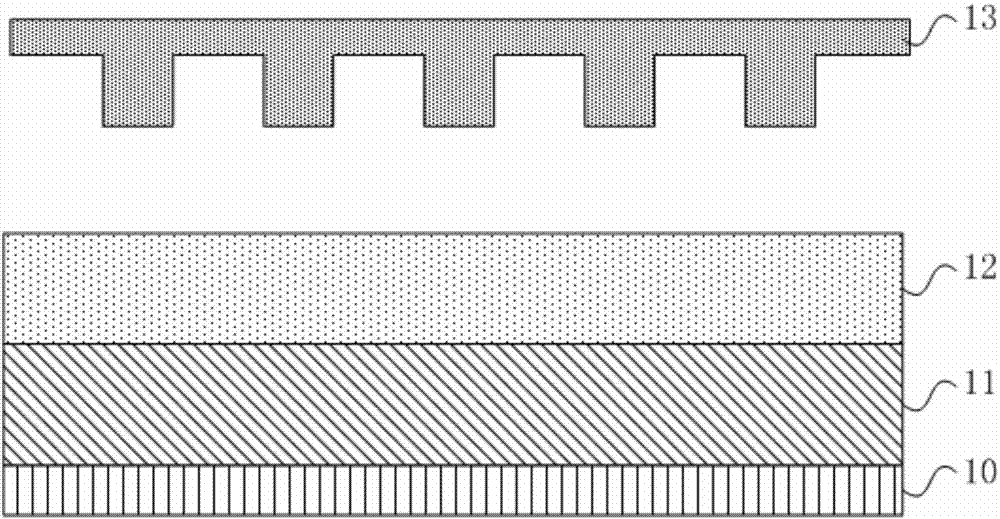

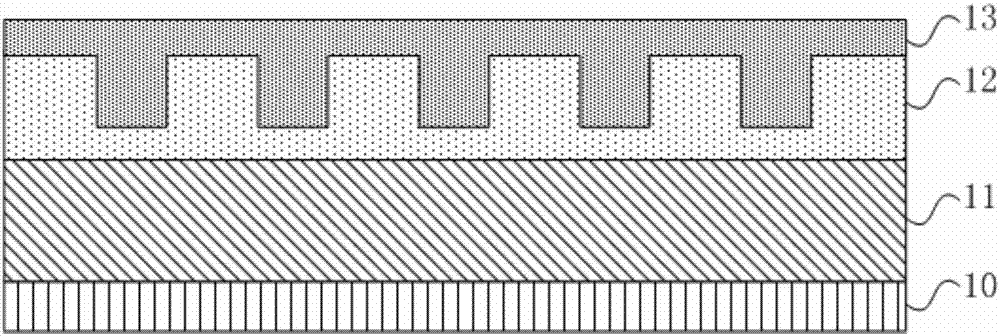

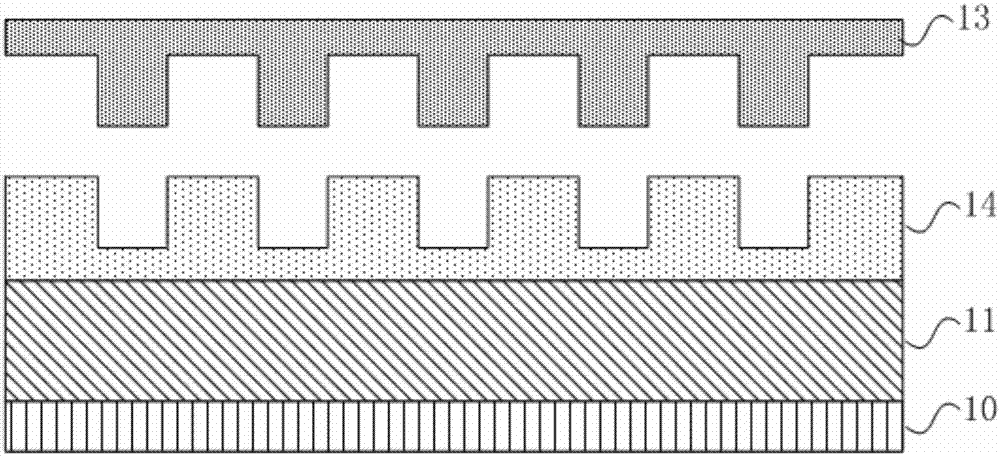

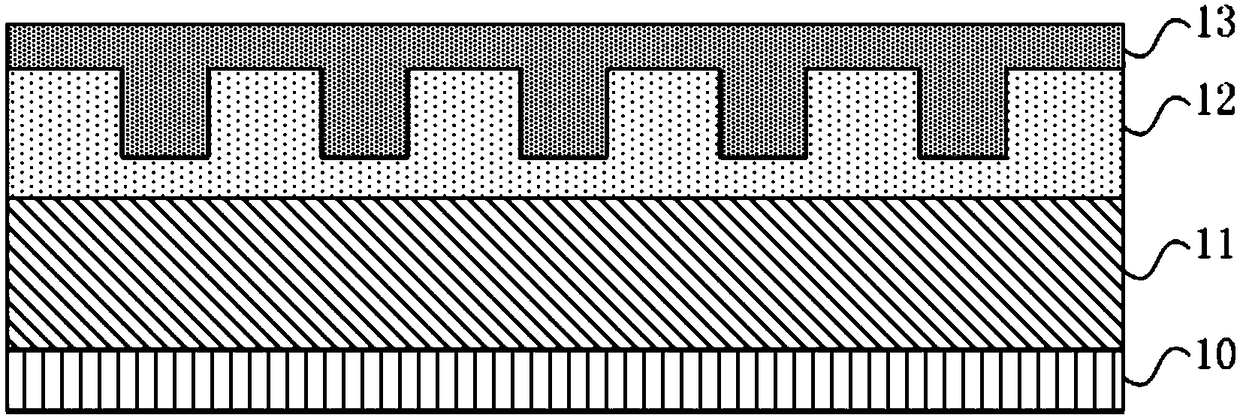

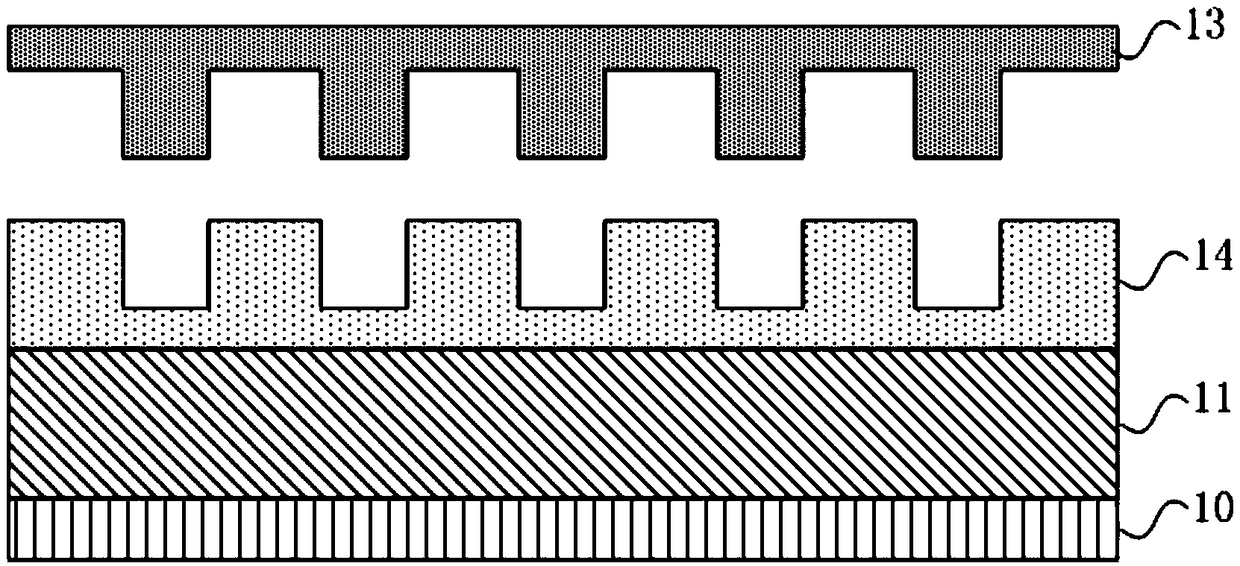

The invention provides a preparation method of a nanometer metal grating and a nanometer metal grating. The method includes providing a substrate on which a metal layer is arranged; forming an impression glue layer on the metal layer; impressing the impression glue layer with an impression template with a grating period pattern; solidifying a impression glue layer, removing the impression template after the solidification, forming the impression glue with the grating period pattern, and remaining the impression glue at the bottom of the grating period pattern; removing the residual impression glue by means of oxygen ashing, exposing the metal layer at the bottom of the grating period pattern, and forming a metal oxide film on the surface of the exposed metal layer; removing the impression glue with the grating period pattern; and taking the metal oxide film as a mask layer, and patterning the metal layer to form a nanometer metal grating. The method is advantageous in that the problem that the metal layer in the prior art cannot be etched after the oxidation is solved; and the metal oxide film is taken as the mark layer for the subsequent technology, and can be used as a nanometer metal grating protective layer.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

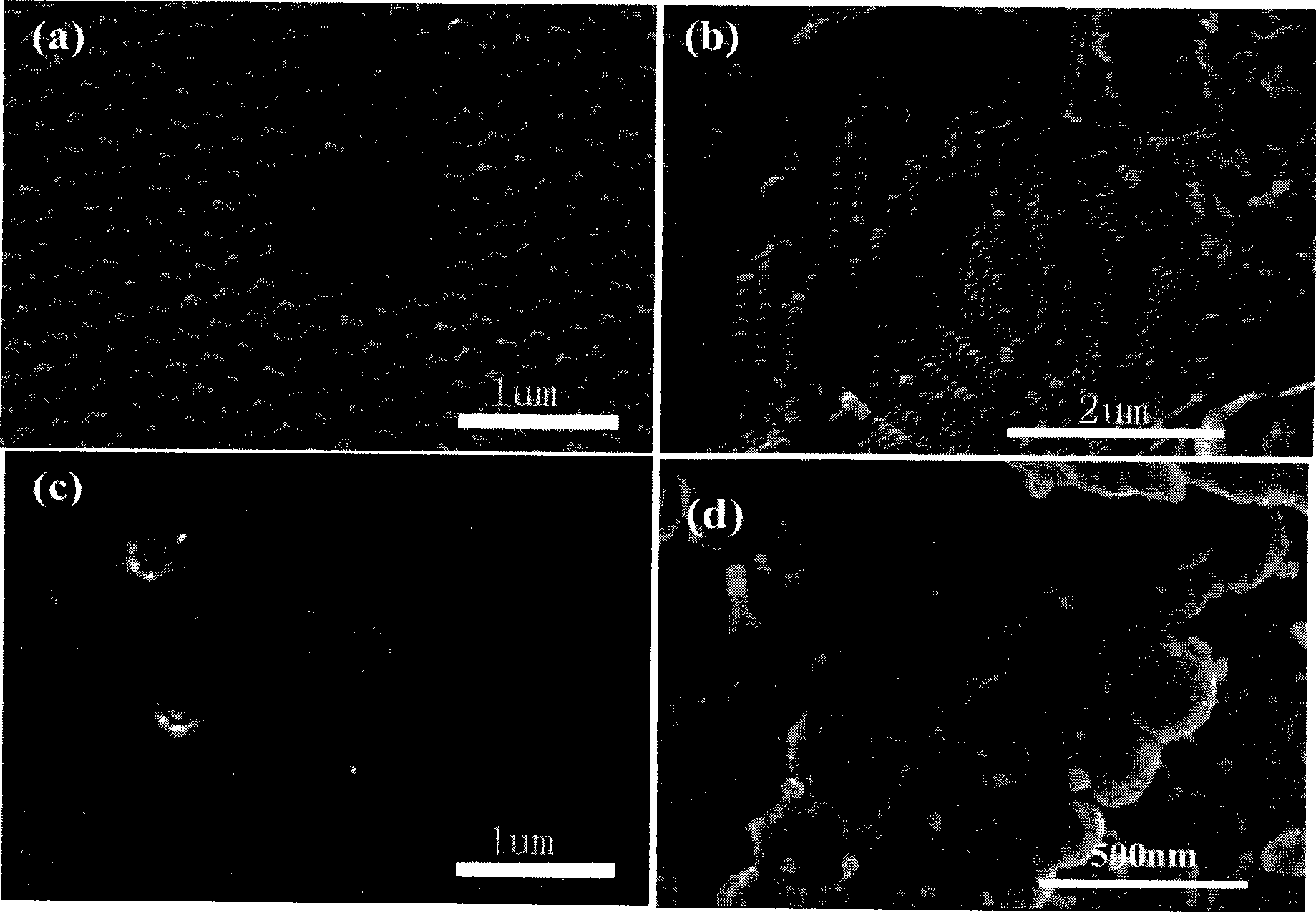

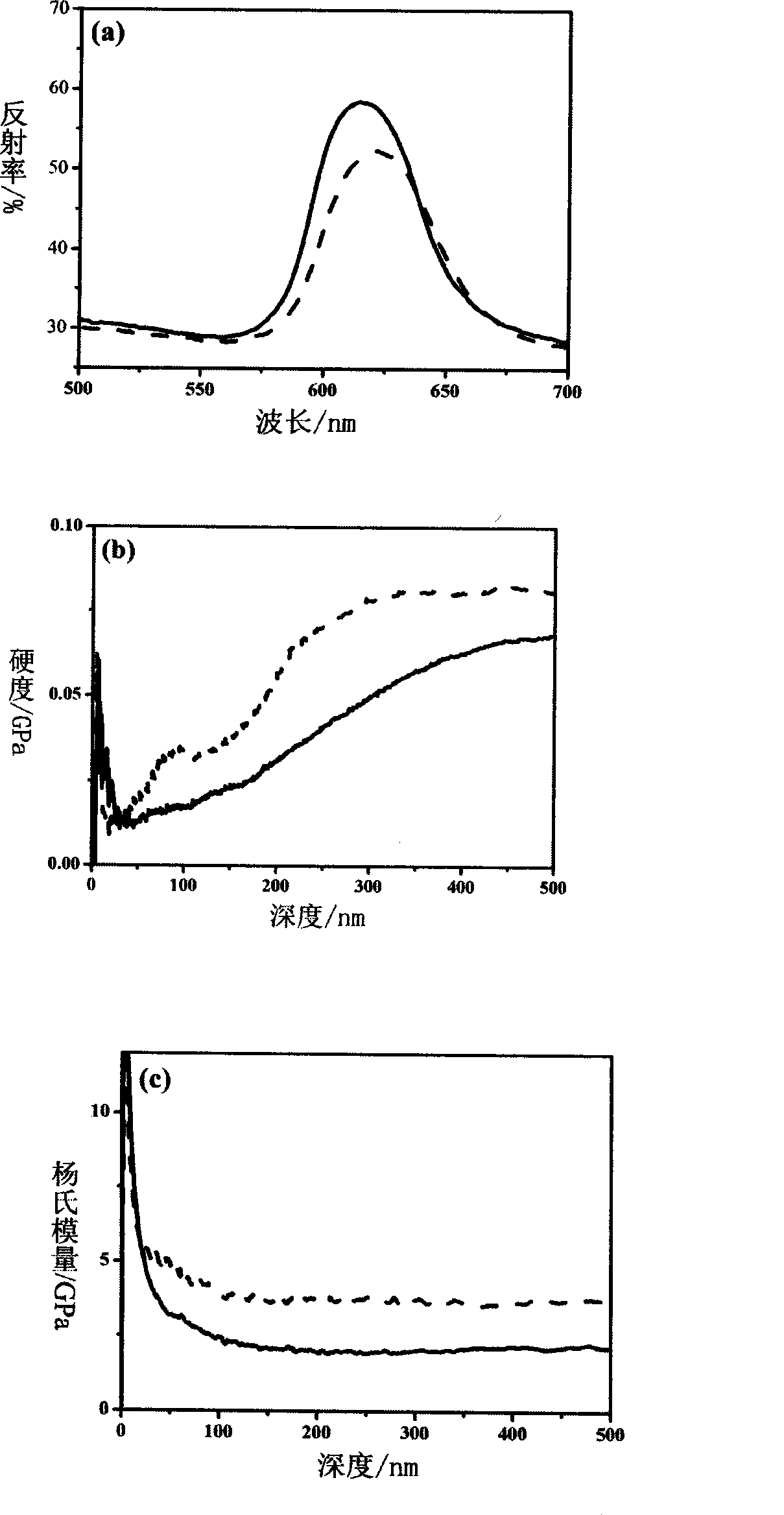

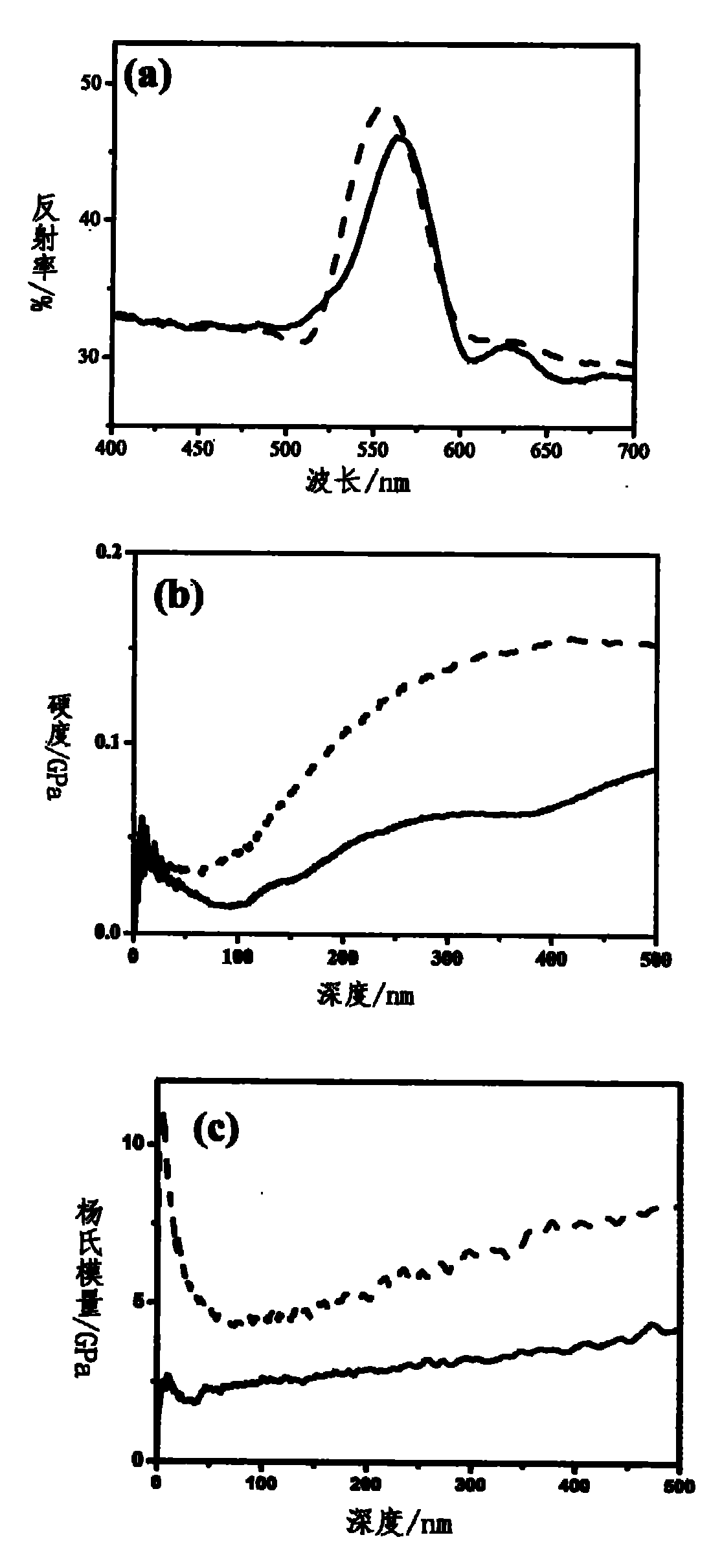

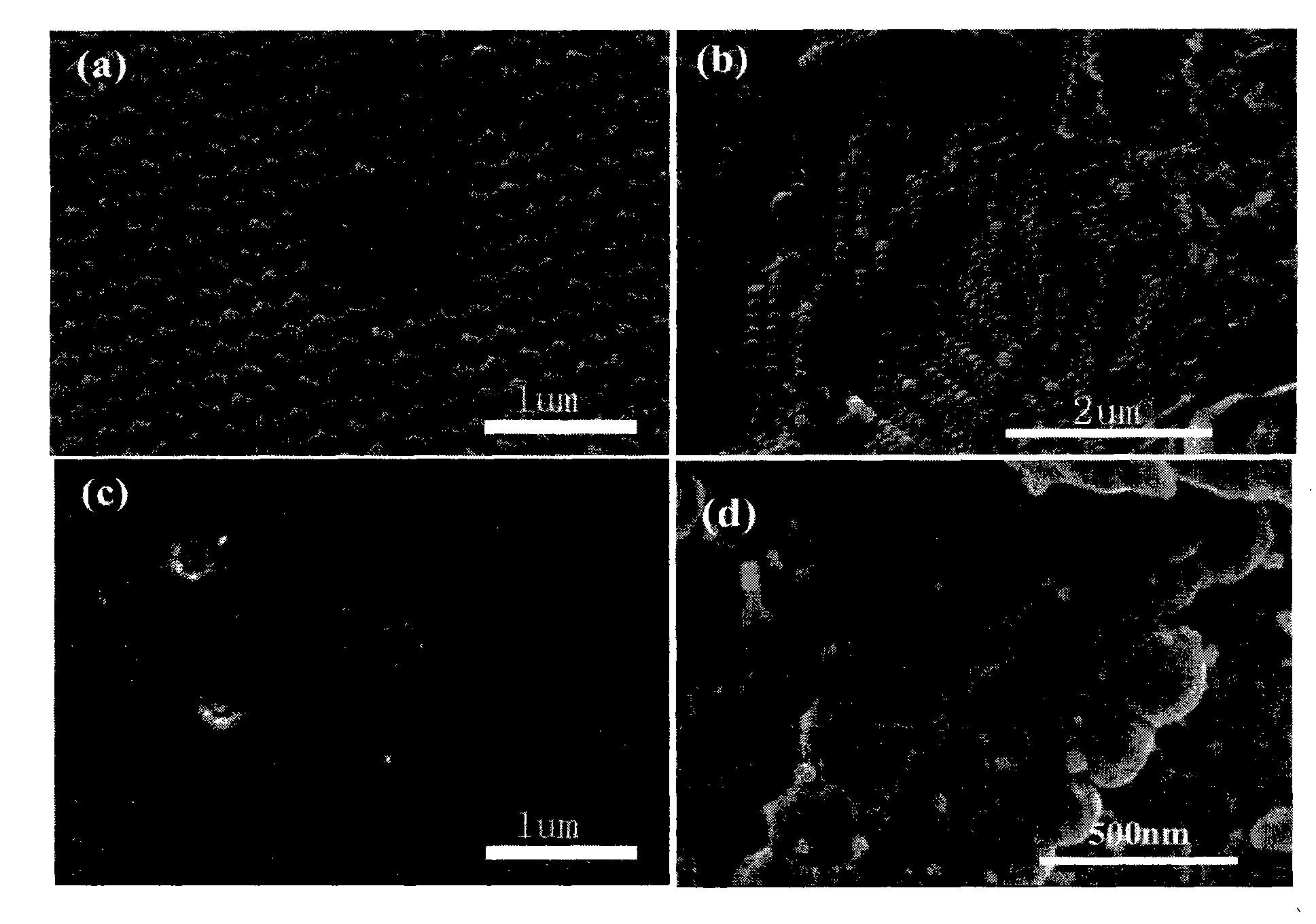

Method for producing photon crystal film for improving mechanical strength and solvent resistance

ActiveCN101369029AHigh mechanical strengthGood solvent resistanceAfter-treatment detailsOptical elementsUltraviolet lightsYoung's modulus

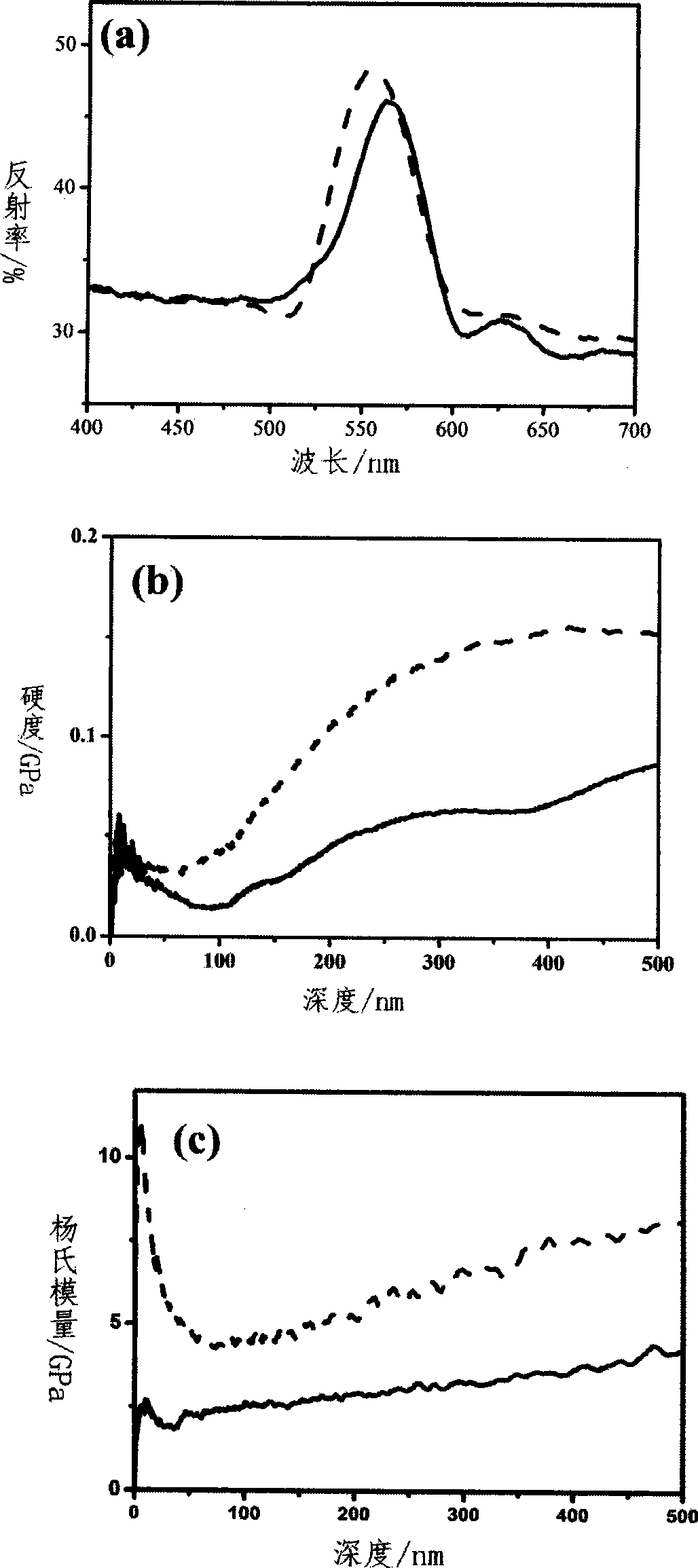

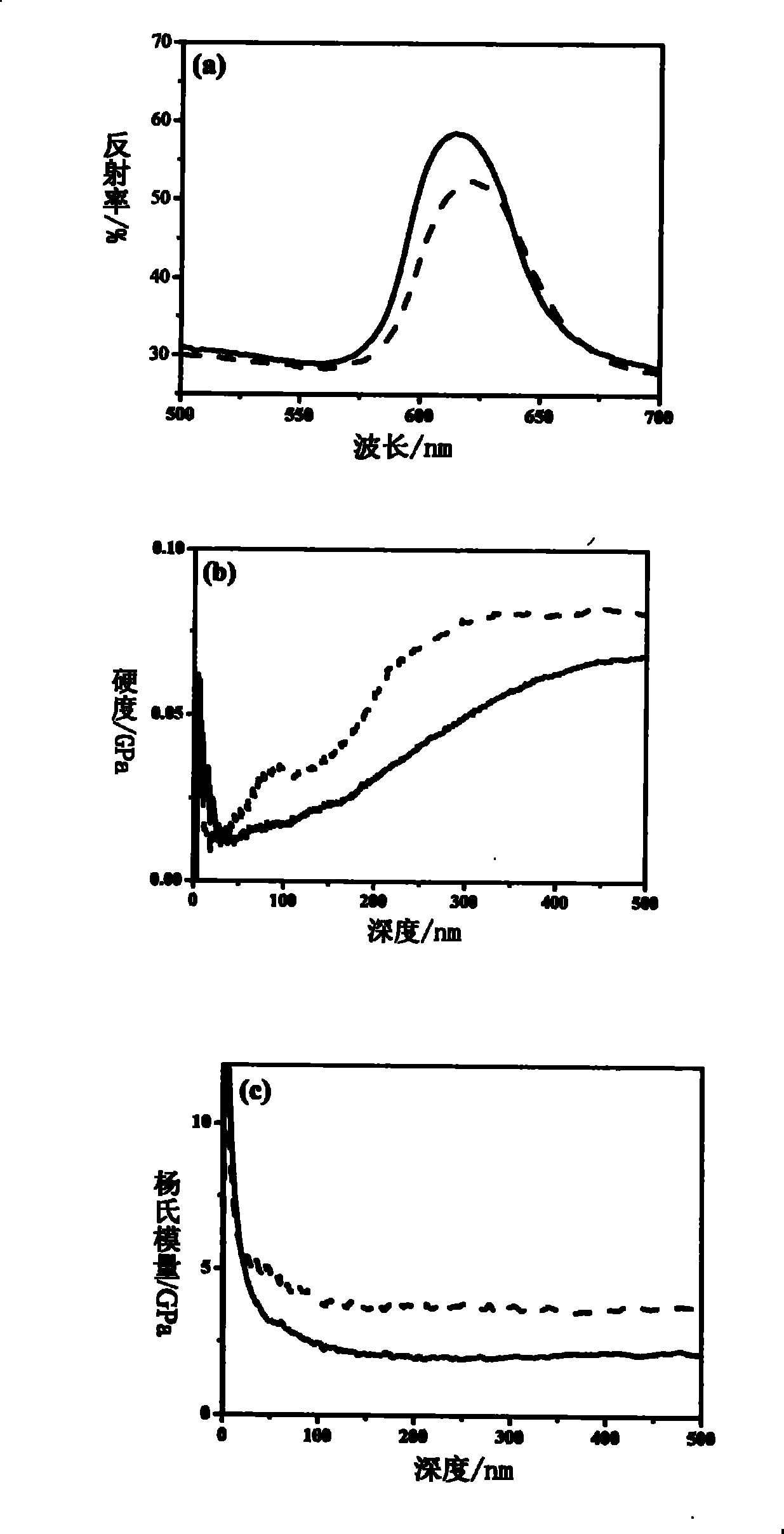

The invention relates to a preparing photon crystal film method, wherein, the mechanical intension and the solvent resistance of the photon crystal film can be improved. In the method, the polymer monomer solution which is adulterated with photoinitiator and cross linker can evenly permeate into interspaces of the photon crystal film with an opal type structure, and then the film can be irradiated by ultraviolet light to make the polymer monomer polymerized; after the polymer monomer is polymerized, the emulsion particle bulbs in the photon crystal film with a opal type structure can be jointed firmly, a polymer macromolecule net can be formed among the emulsion particle bulbs, the performance of the phone crystal can be enhanced through utilizing the net structure which is formed by the polymer macromolecule chains, therefore, the mechanical performance of the photon crystal film can be enhanced. Taking the rigidity of the film and Young modulus for example, the polymer monomer solution can permeate in the interspaces of the photon crystal film with an opal type structure, through the processing of photo-cross linking, the mechanical property of the rigidity of the photon crystal film, the Young modulus and the like and the solvent resistance can be improved greatly, and the initial mechanical property can not be essentially effected.

Owner:INST OF CHEM CHINESE ACAD OF SCI

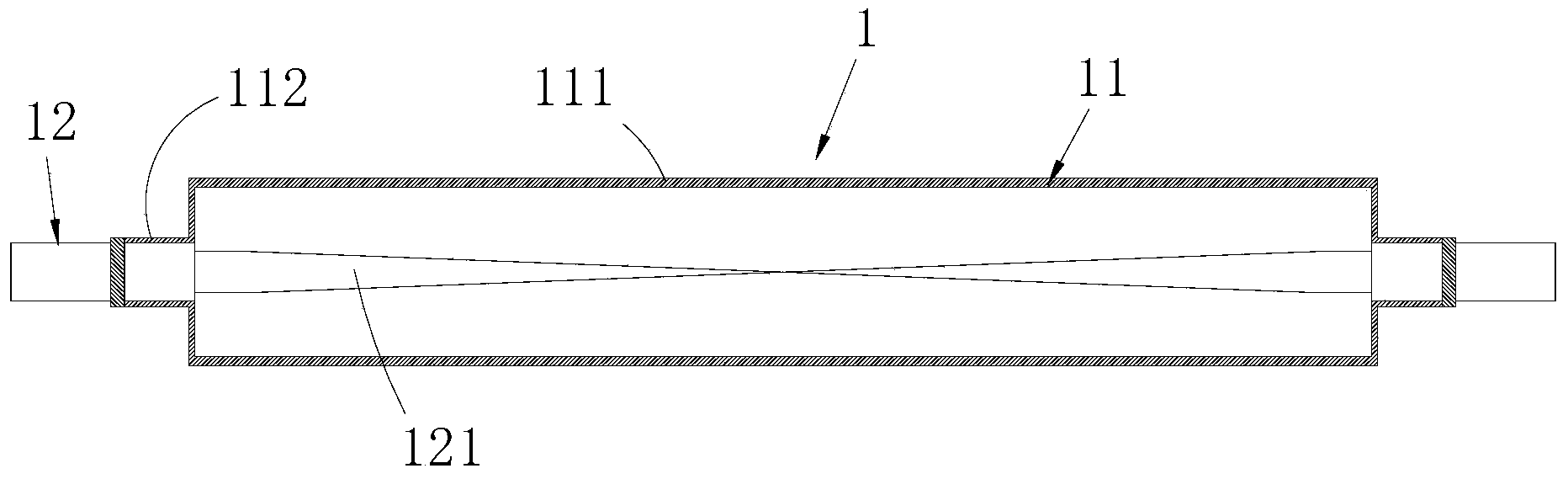

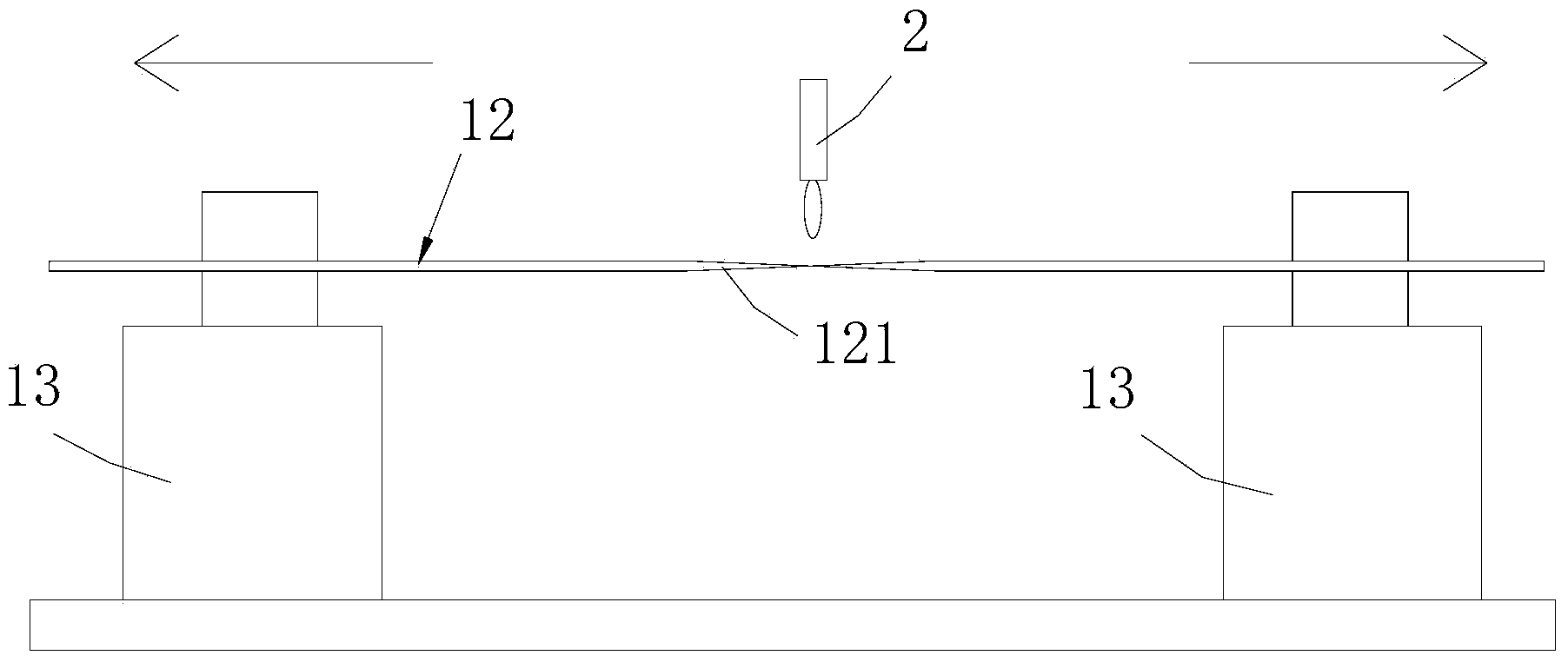

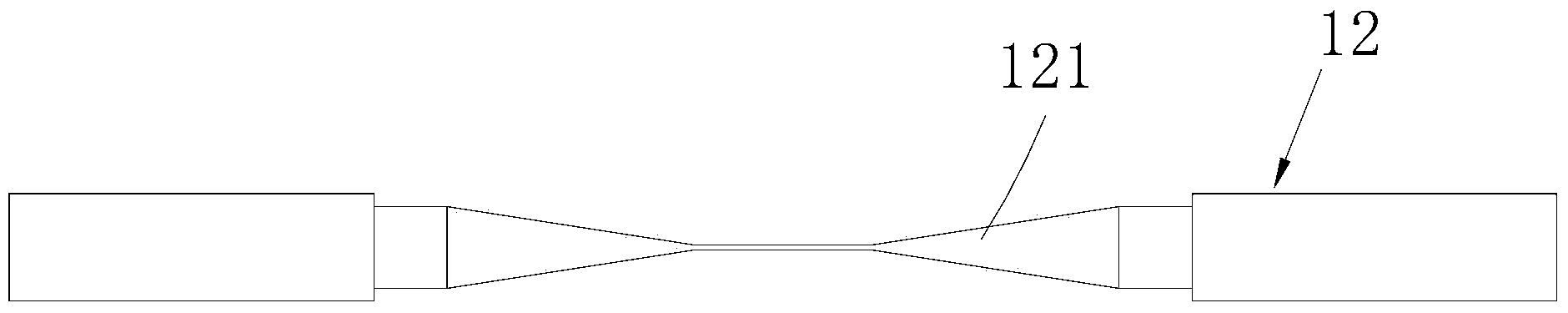

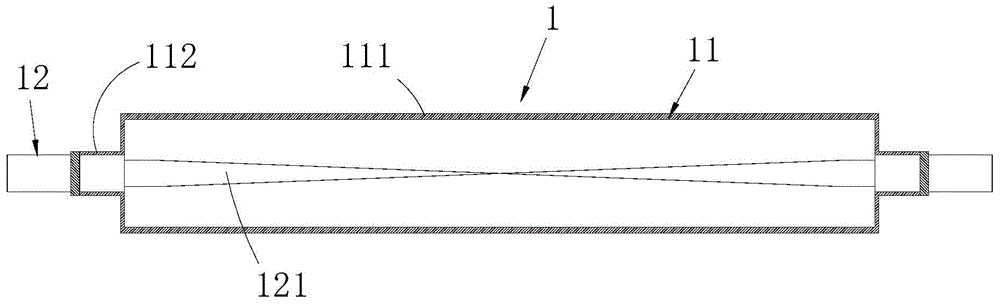

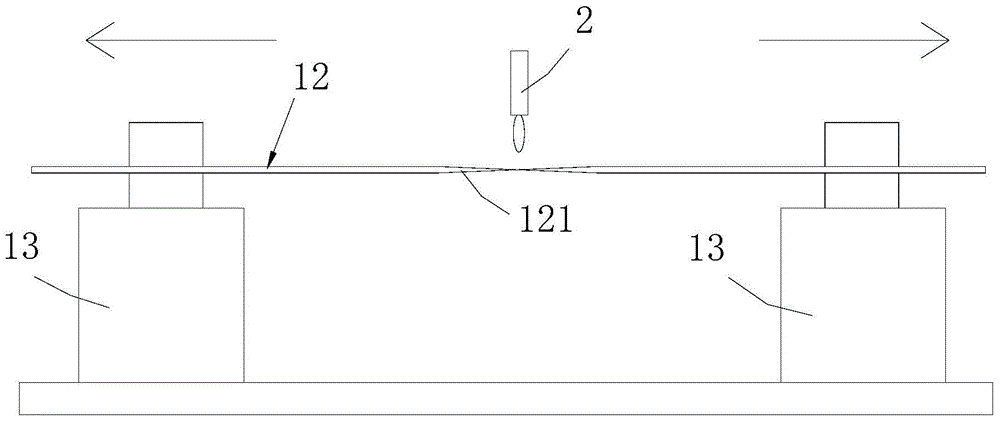

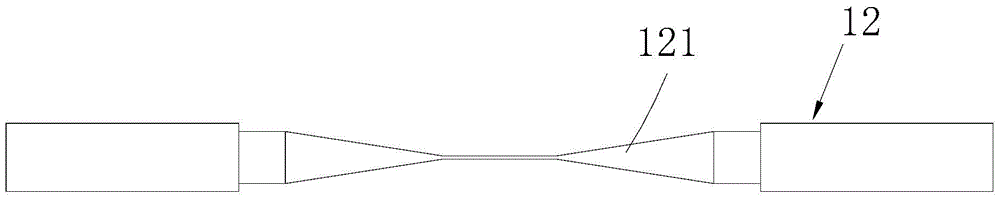

Micro-nano optical fiber micro experiment structure, manufacturing method thereof and measuring instrument

ActiveCN103983435AWill not polluteAvoid contactCladded optical fibreTesting optical propertiesMicro nanoMeasuring instrument

The invention relates to the technical field of micro-nano optical fiber, and discloses a micro-nano optical fiber micro experiment structure, manufacturing method of the structure and measuring instrument. The micro experiment structure comprises monomode optical fiber and a capillary glass straight pipe, and ports are formed in the two ends of the capillary glass straight pipe; the middle of the monomode optical fiber is provided with drawing-made micro-nano optical fiber, the monomode optical fiber is arranged in the capillary glass straight pipe in a penetrated mode, and is fixedly connected with the capillary glass straight pipe, and the whole micro-nano optical fiber is arranged in the capillary glass straight pipe and is arranged in a suspended mode. Because the whole micro-nano optical fiber is arranged in the capillary glass straight pipe and is arranged in a suspended mode, under the protection of the capillary glass straight pipe, the micro-nano optical fiber is protected from being polluted, outside dust and vapor are avoided from making contact with the micro-nano optical fiber, optical nature of the micro-nano optical fiber will not be affected, the optical performance of the micro-nano optical fiber will not degrade rapidly along with time, the micro-nano optical fiber is easy to process, long-term and stable practical application of the micro-nano optical fiber can be achieved, and the micro-nano optical fiber is easy to compile with other optical fiber devices.

Owner:THE HONG KONG POLYTECHNIC UNIV SHENZHEN RES INST

Electronic component cleaning agent

ActiveCN102816659AIntegrity does not affectDoes not affect optical propertiesSurface-active non-soap compounds and soap mixture detergentsLiquid-crystal displayOrganic base

The invention provides an electronic component cleaning agent which comprises the following ingredients in percentage by mass: 50-75% of magnetic water, 2-14% of organic base, 15-35% of surfactant and 0.1-1.0% of chelator. The electronic component cleaning agent provided by the invention is low in cost, wide in raw material sources and high in cleaning capability. can effectively remove pollution of metal ions, can not damage the integrity of an electronic component, can not influence the current-illumination characteristic, electromagnetic characteristic, permeability, surface physical characteristic and other properties of the electronic component, and is environment-friendly and pollution-free. Thus, the electronic component cleaning agent can be widely used for cleaning in the manufacturing processes of electronic components, integrated circuits, PCBs (printed circuit board), liquid crystal displays and the like, and has a wide application range.

Owner:HENGYANG HONDAWEI ENVIRONMENTAL TECH CO LTD

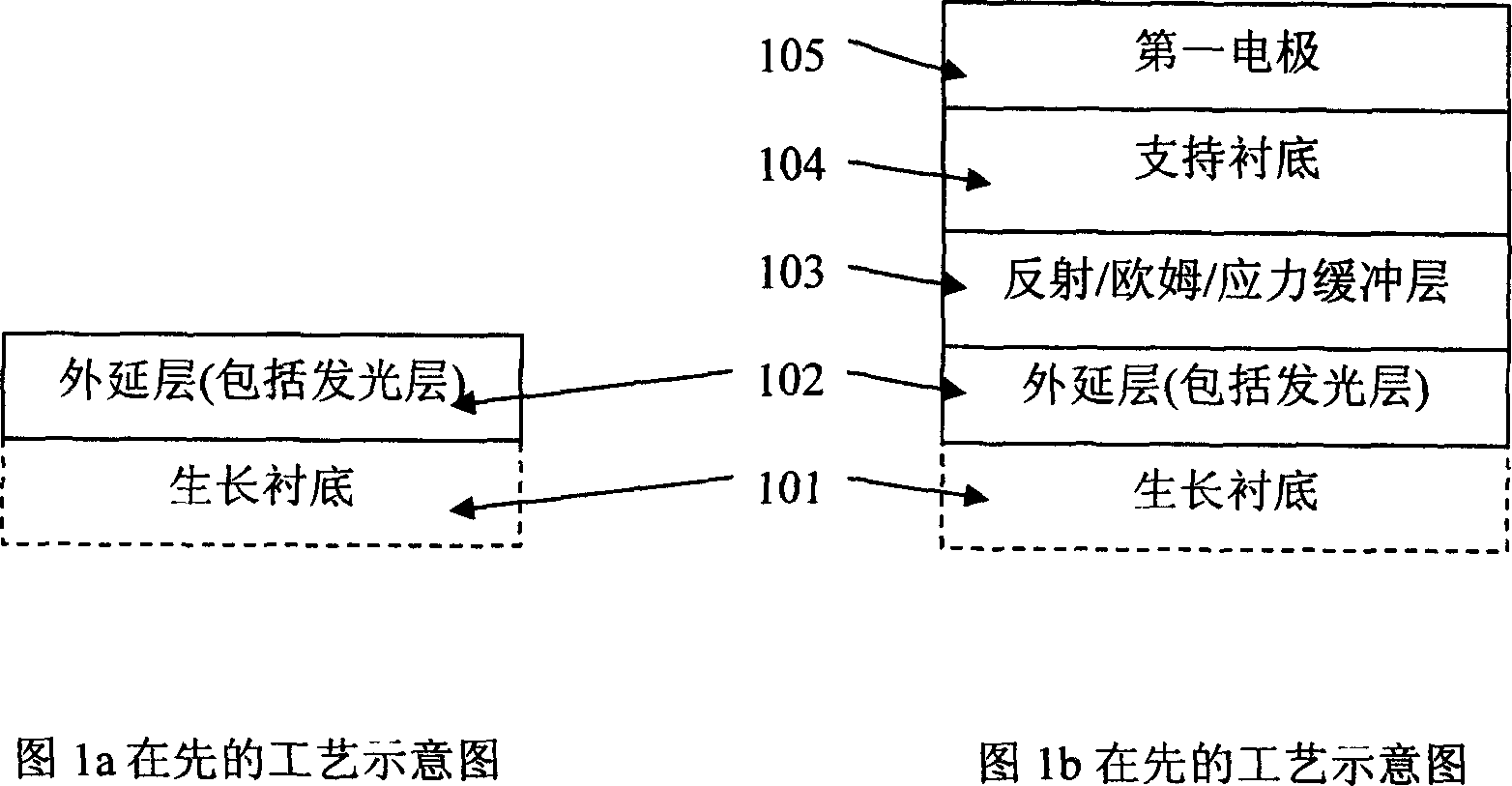

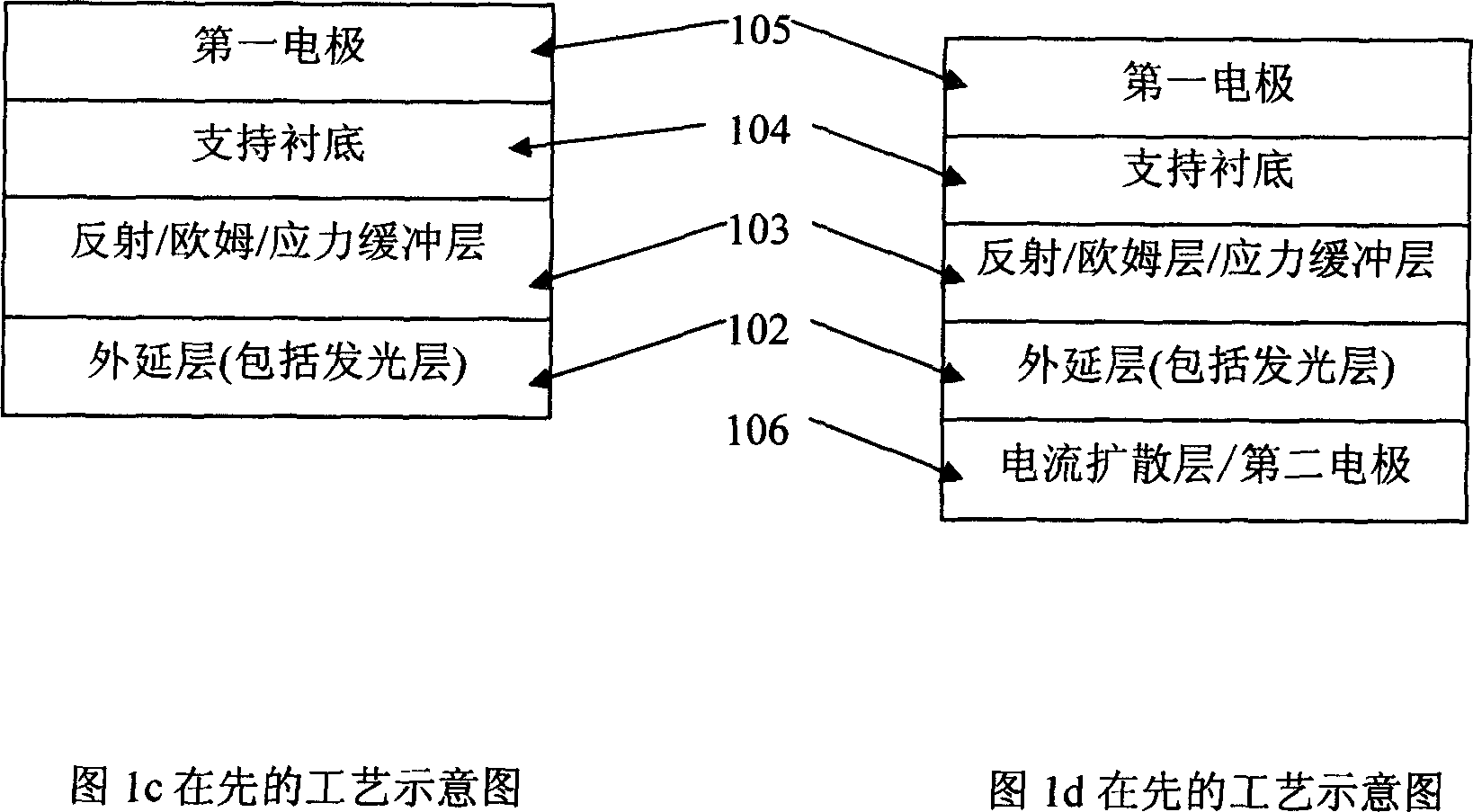

Batch manufacturing method for vertical structural semiconductive chip or device

InactiveCN1812145ADoes not affect quality propertiesDoes not affect optical propertiesSemiconductor devicesSemiconductor chipEngineering

This invention discloses the high luminance semiconductor chip or device (concludes AlGaInP base LED) of vertical structure and low-cost high-output batch production method. The process of producing vertical structure AlGaInP base LED conclude: first, develop first style restricting layer on the developing substrate. Then, stack up reflecting / ohm / stress buffer layer on the first style restricting layer; bond electricity-conductive supporting substrate on the reflecting / ohm / stress buffer layer. The bonding side of electricity-conductive substrate and reflecting / ohm / stress buffer layer can has etched texture structure to reduce the stress of heat mismatching. First electrode stacks on the other side of electricity-conductive supporting substrate. When peeling off developing substrate, the first style restricting layer uncovers. There are developing illuminant layer, second style restricting layer, electric-current diffused layer and second electrode on the uncovered first style restricting layer.

Owner:ZHEJIANG INVENLUX TECH

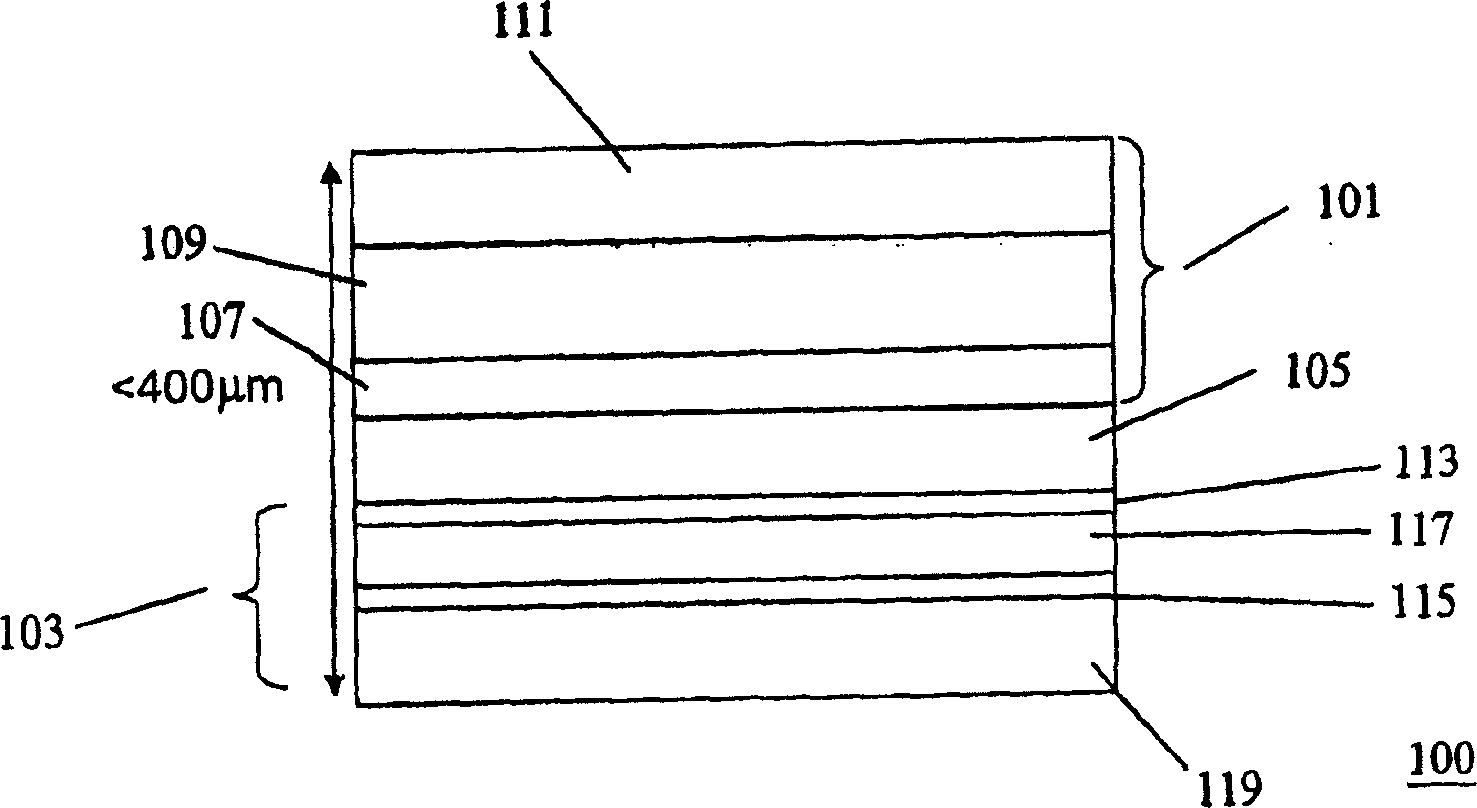

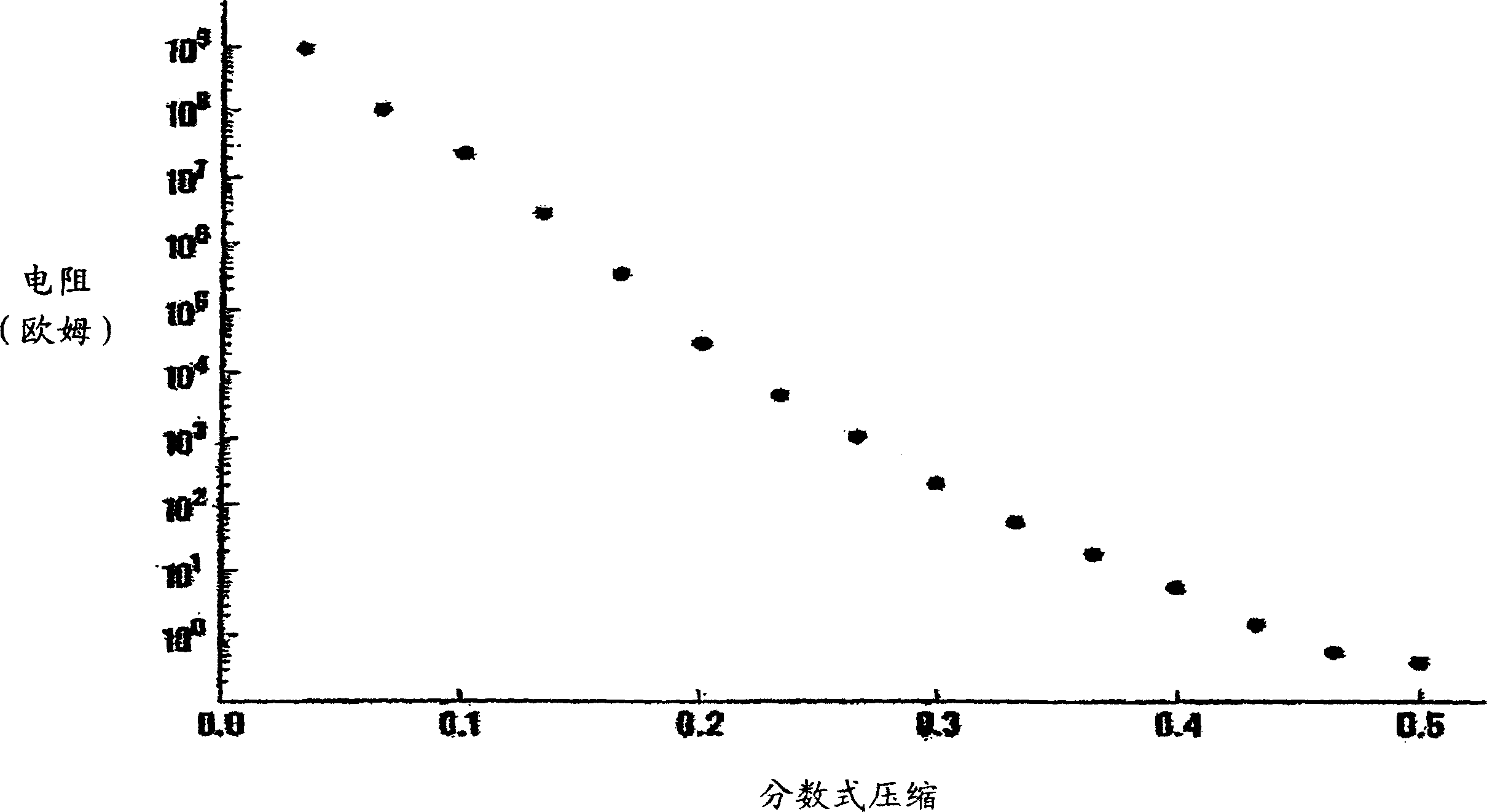

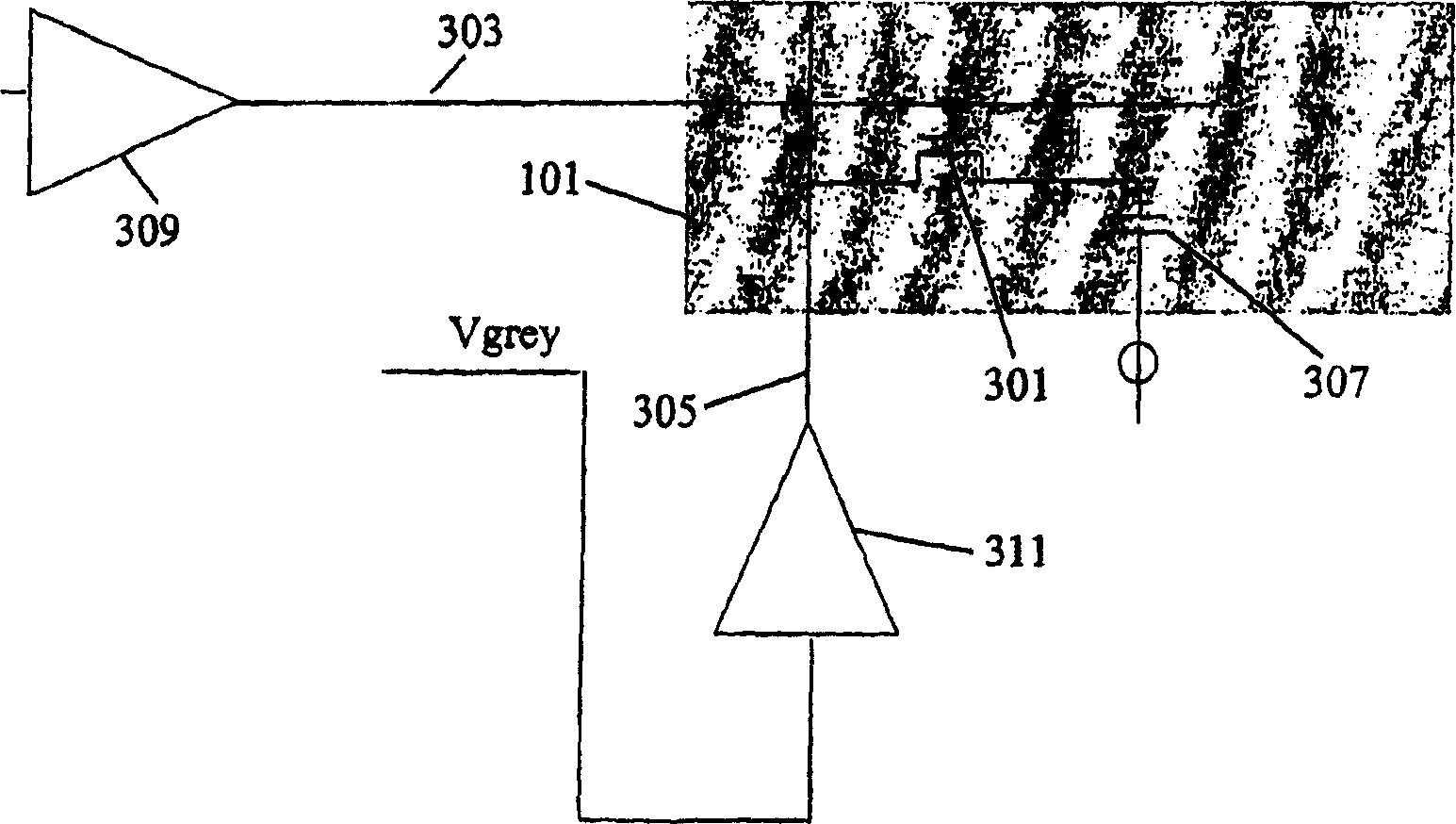

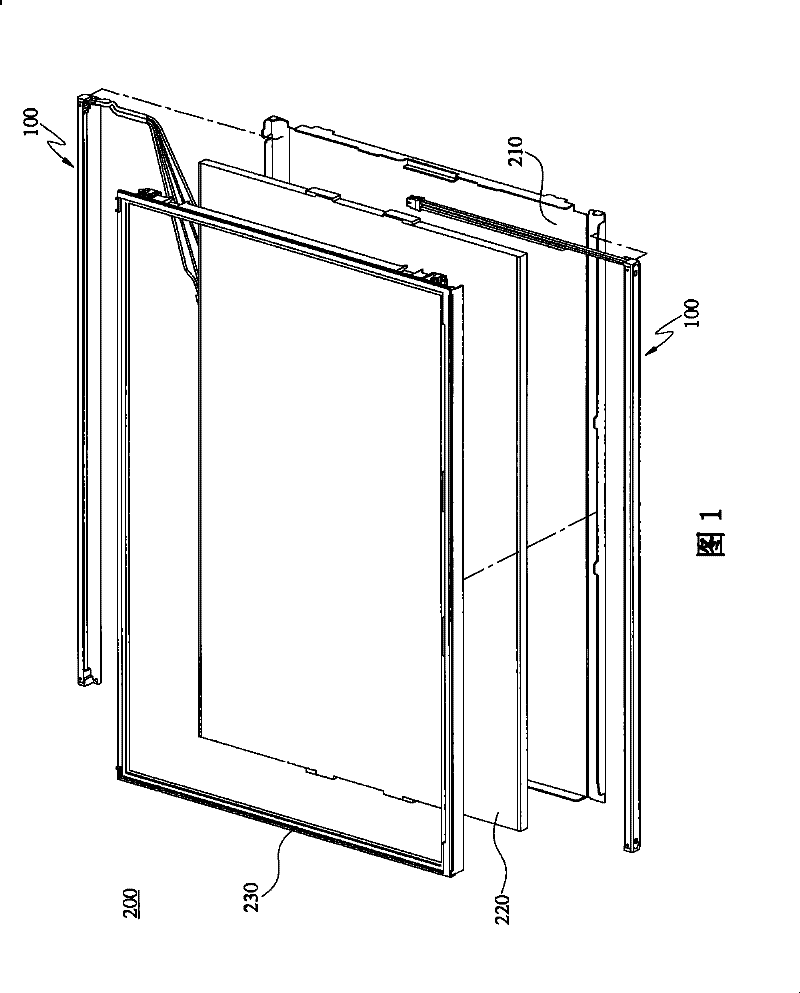

Touch sensitive display for a portable device

InactiveCN1826576ADoes not affect optical propertiesReduce sensitivityStatic indicating devicesGraph readingElectrical conductorActive matrix

A portable device is provided having a touch sensitive display (100) comprising an active matrix display element (101) and a touch sensitive element (103). The touch sensitive element (103) is disposed on the viewer distal side of the active matrix display element (101) thereby not affecting the display properties. The touch sensitive element (103) comprises a first and second conductive layer (113, 115) each having a plurality of conductors. The conductive layers (113, 115) sandwich a pressure sensitive layer (117) which modifies an electrical conductivity between two conductors of the two conductive layers (113, 115) in response to a pressure point resulting from an applied pressure. Thus, accurate position detection is achieved. The conductors may be aligned with the active matrix and the requirement for calibration may be obviated.

Owner:SAMSUNG ELECTRONICS CO LTD

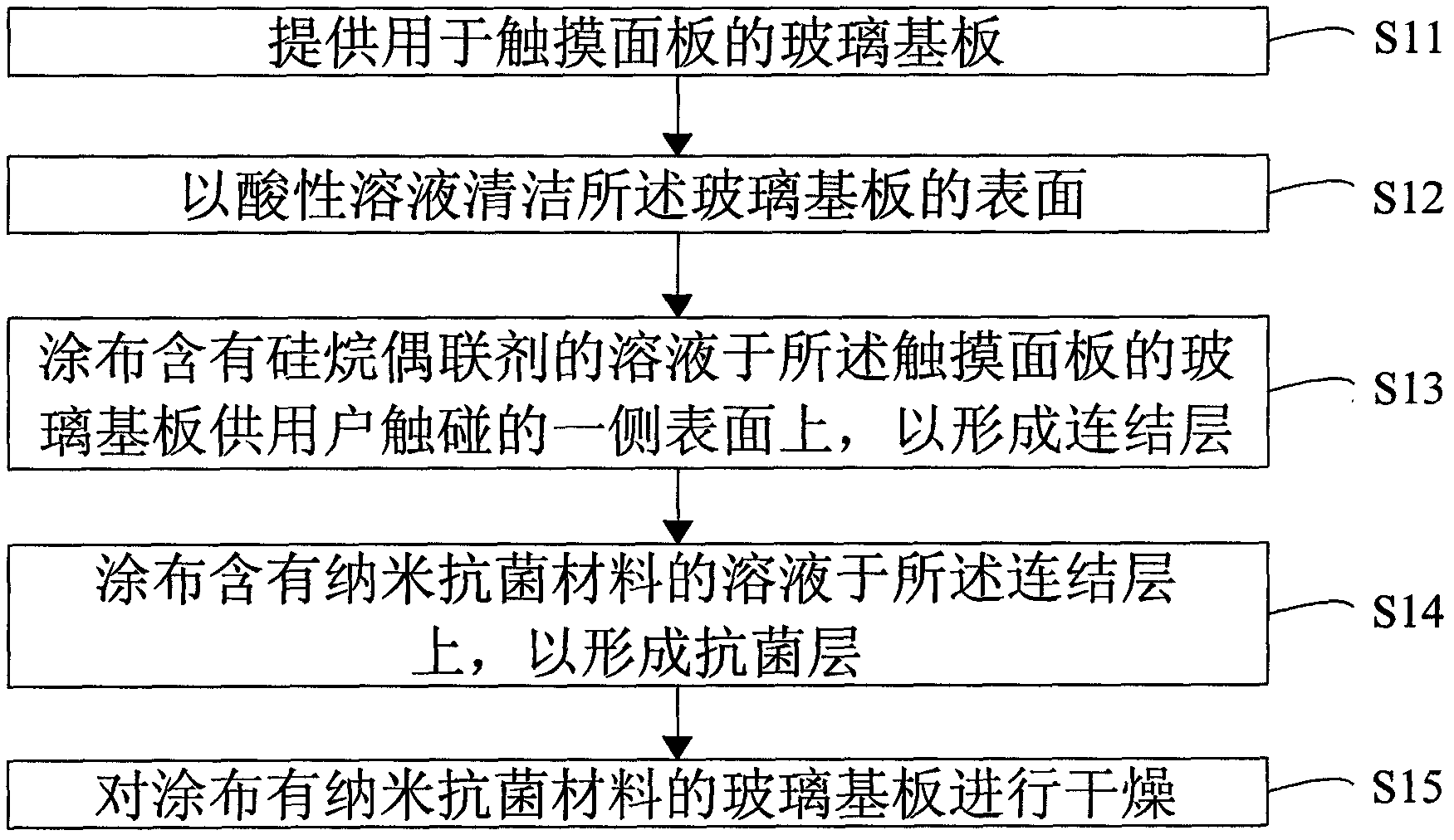

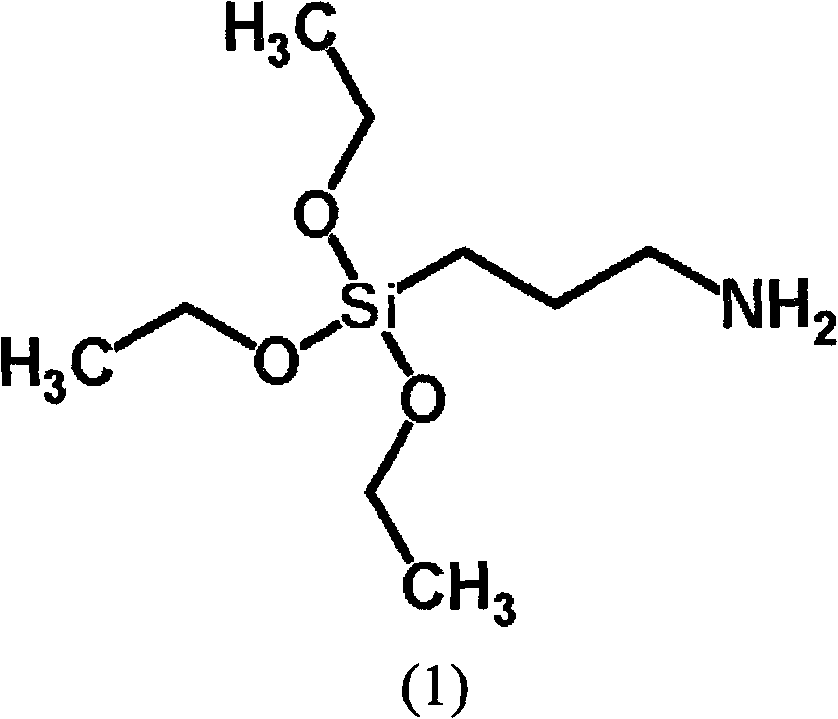

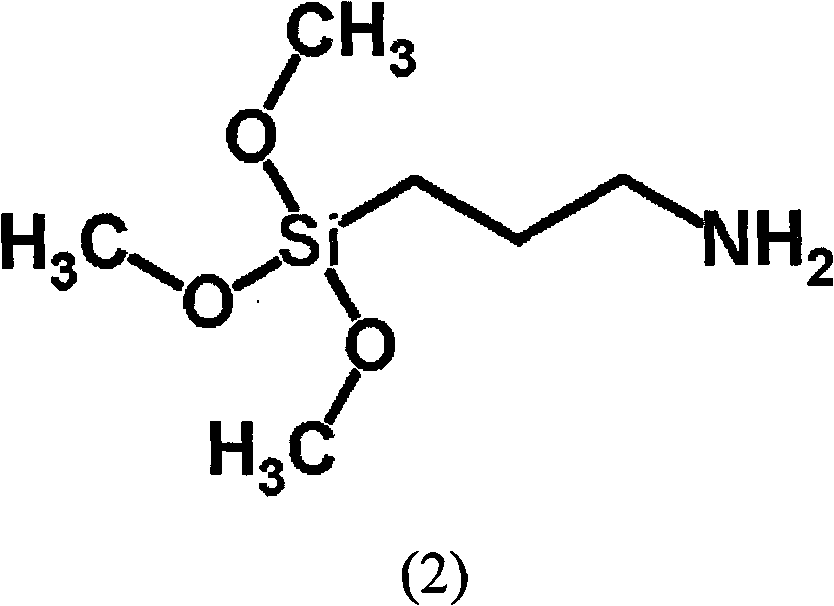

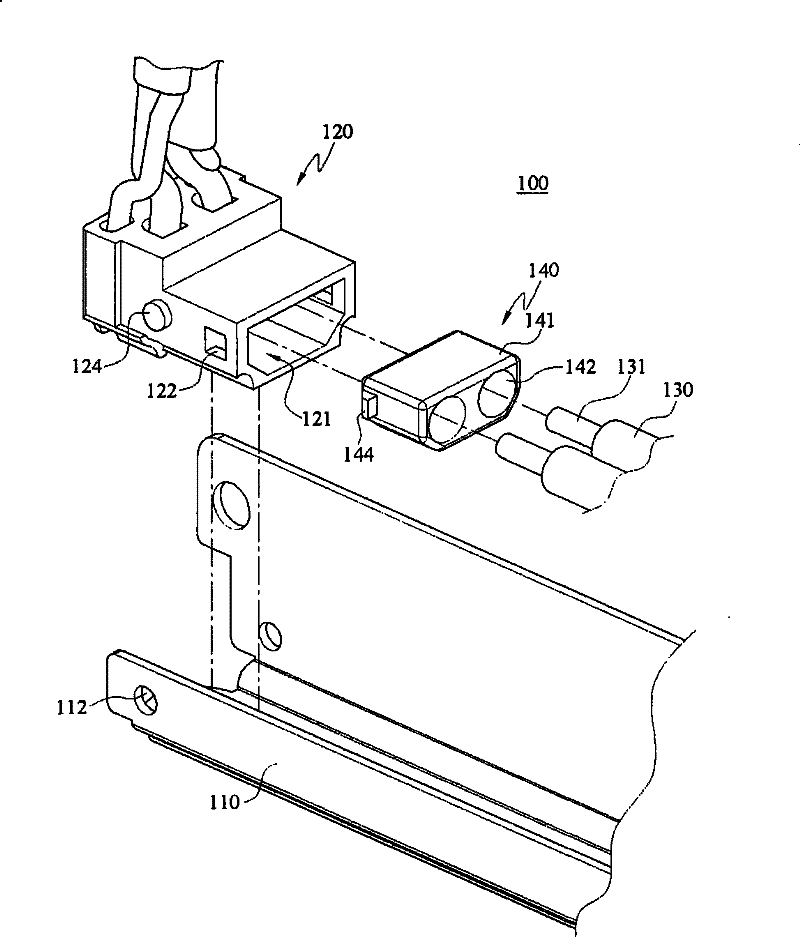

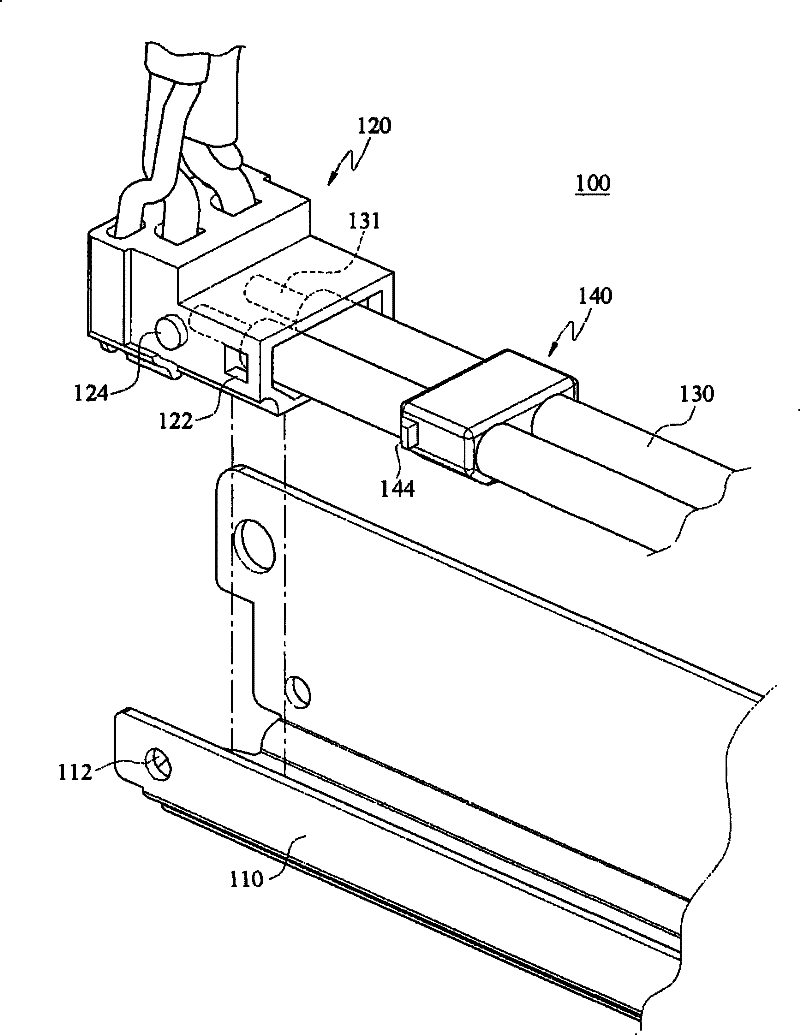

Antibacterial touch panel and manufacturing method thereof

InactiveCN103172275ADoes not affect volumeDoes not affect optical propertiesInput/output processes for data processingMolecular levelEngineering

The invention discloses an antibacterial touch panel and a manufacturing method thereof. The manufacturing method comprises the following steps of: forming a connecting layer by using a silane coupling agent, connecting the connecting layer to a glass substrate of a touch panel in a chemical crosslinking manner, and manufacturing an antibacterial layer from a nano antibacterial material. Because the total thickness of the antibacterial layer and the connecting layer on the touch panel is of molecular level, the size and the optical characteristics of the product cannot be influenced.

Owner:FUGANG ELECTRONICS DONGGUAN +1

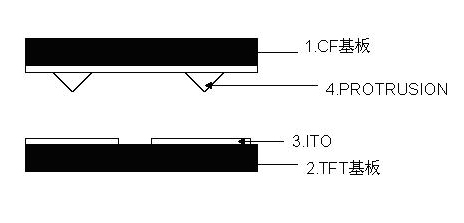

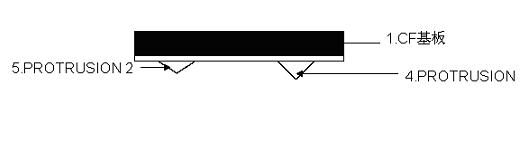

Method for improving chromatic aberration of liquid crystal display (LCD)

InactiveCN101943826AIncrease chromatic aberrationReduce overheadNon-linear opticsOptical propertyChromatic aberration

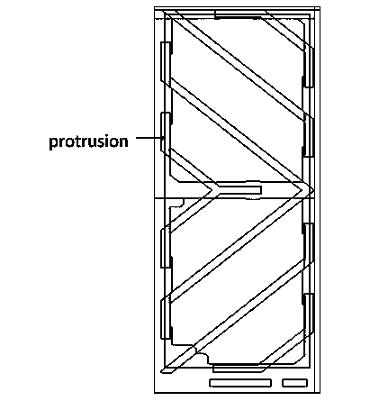

The invention relates to a method for improving the chromatic aberration of a liquid crystal display (LCD). The method is characterized in that adjacent protrusions or slits in each sub-pixel are not equal. In the invention, the heeling conditions of liquid crystal molecules under driving voltage are increased through improving the protrusions on a CF substrate of a VA mode LCD to realize more domain displays, which is beneficial to the improvement of the chromatic aberration without influencing other optical characteristics and increasing manufacture procedures. Compared with other domain realization modes, the invention does not increase the pay expenses in the aspect of driving.

Owner:NANJING CEC PANDA LCD TECH

Efficient and environmental-protection liquid crystal display screen cleaning agent

InactiveCN107354018ALow costExtensive sources of raw materialsInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsIonEnvironmental resistance

The present invention discloses an efficient and environmental-protection liquid crystal display screen cleaning agent, which comprises the following raw materials by weight: 36-44 parts of fatty alcohol polyoxyethylene ether, 18-25 parts of metasilicate, 16-20 parts of glycerol, 8-14 parts of amine alkali, 15-35 parts of a surfactant, 6-9 parts of a chelating agent, and 50-75 parts of deionized water. Compared to the liquid crystal display screen cleaning agent in the prior art, the liquid crystal display screen cleaning agent of the present invention has advantages of low cost, wide raw material source, strong cleaning capability, less consumption, effective metal ion pollution removing, environmental protection and no pollution, cannot damage the integrity of the liquid crystal display screen, and cannot not affect the photoelectric property, the electromagnetic property, the permeability, the device surface physical properties and other performances.

Owner:HEFEI HUIKE PRECISION DIE CO LTD

Sulfonated long chain alpha-olefin copolymer and its prepn and use

The present invention discloses one kind of sulfonated long chain alpha-olefin copolymer and its preparation process and use. The preparation process includes the following steps: 1. adding triisobutyl aluminum, diphenyl dimethoxy silane, spherical polypropylene catalyst, long chain alpha-olefin and styrene into n-heptane solvent to polymerize styrene-long chain alpha-olefin copolymer; and 2. dissolving the styrene-long chain alpha-olefin copolymer in o-dichlorobenzene through heating and stirring, and dropping concentrated sulfuric acid slowly to sulfonate and obtain sulfonated long chain alpha-olefin copolymer. The preparation process is simple and low in production cost, and the sulfonated long chain alpha-olefin copolymer may be used in preparing agricultural film with excellent surface hydrophilicity, long service life and other advantages.

Owner:ZHEJIANG UNIV

Hydrophilic long-chain alpha-olefin branched copolymer and preparation method and usage thereof

The invention discloses a hydrophilicity long chain alpha-olefin graft copolymer and preparing method and use thereof. The preparing method includes steps: 1) adding water-free and oxygen-free long chain alpha-olefin, triisobutyl aluminum, diphenyl dimethoxyl silicon and spheric polypropylene catalyst in turn to plastic test tube with magnetic force stirring device under inertia gas protection; after polymerizing, transferring the mixture to refrigerator and obtaining poly(long chain alpha-olefin); 2) adding the poly(long chain alpha-olefin) to three-mouth flask with magnetic force stirring device and nitrogen inlet, adding toluene as solvent, heating and stirring to sufficient dissolve, ventilating nitrogen, adding maleic anhydride and organic peroxide initiator, reacting and obtaining hydrophilicity long chain alpha-olefin graft copolymer. Advantages of the invention are: technique is simple, operation is convenient, polyethylene film basal body is not influenced, processing method id simple, cost is low, hydrophilicity of film surface is good and life of fogdrop resistant is long.

Owner:ZHEJIANG UNIV

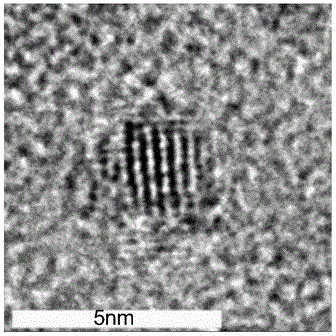

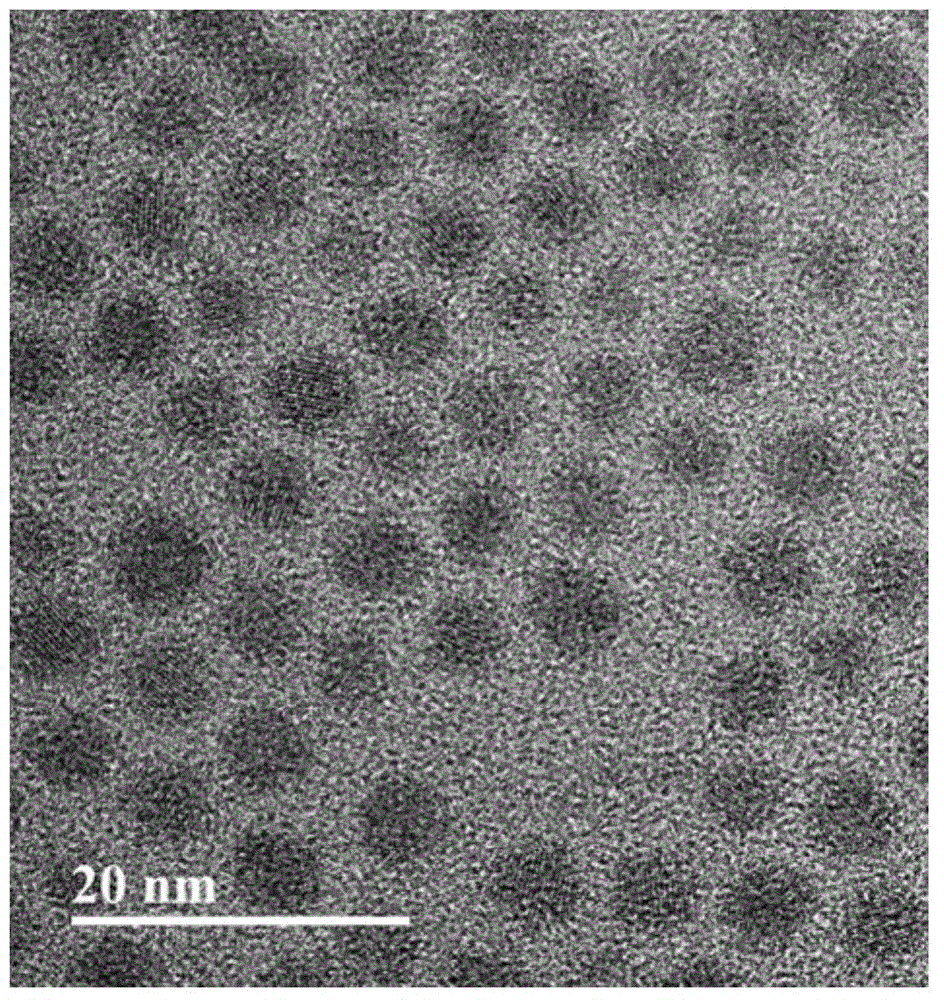

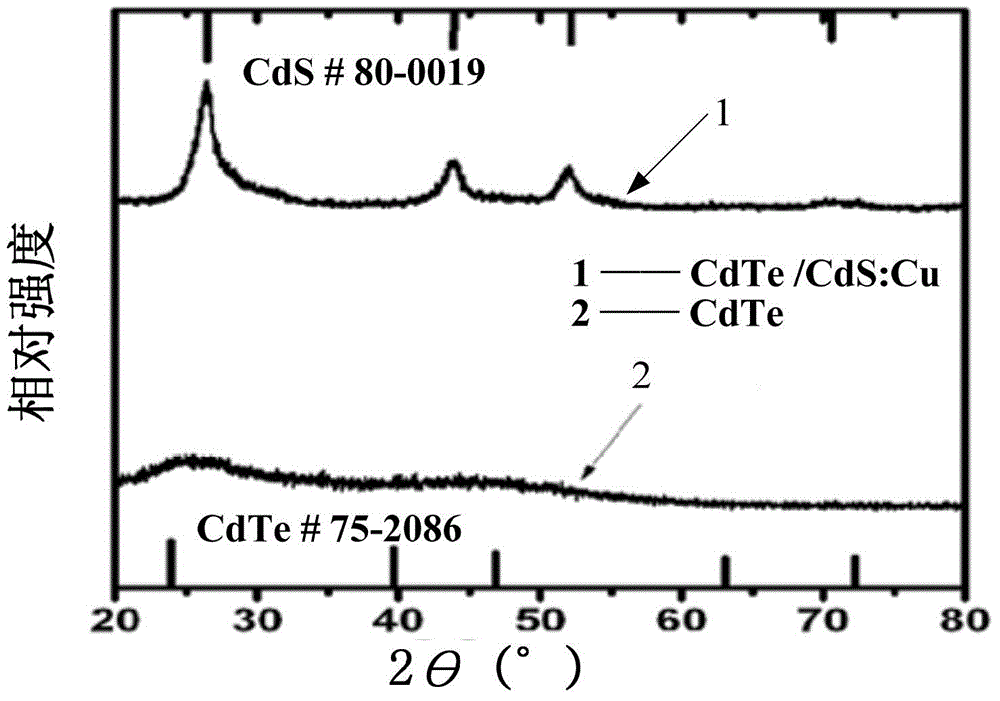

Fluorescence coded microspheres based on long-life composite quantum dots and preparation method thereof

ActiveCN105018068AGood biocompatibilityHigh biosecurityLuminescent compositionsMicroballoon preparationMicrosphereFluorescence

The invention provides fluorescence coded microspheres based on long-life composite quantum dots and a preparation method thereof. The fluorescence coded microspheres based on long-life composite quantum dots comprise agarose microspheres, first quantum dots and second quantum dots; the first quantum dots and the second quantum dots are combined with the agarose microspheres by virtue of chemical bonds; each first quantum dot has a core-shell structure which takes cadmium telluride as a core and cadmium sulfide doped with copper ions as a shell; the doping molar fraction of the copper ions in the cadmium sulfide doped with the copper ions is 0.5%-2%, the size of the core is 1.8nm-2.2nm, the thickness of the shell is 2nm-4nm, the emission wavelength range of the first quantum dots is 700nm-910nm, and the fluorescent life is 0.8-1.2 microseconds; and the emission wavelength range of the second quantum dots is 700nm-820nm, and the fluorescent life is 100-220 nanoseconds. The invention further provides a preparation method of the fluorescence coded microspheres based on the long-life composite quantum dots.

Owner:SHENZHEN INST OF ADVANCED TECH

Micro-nano optical fiber micro-experimental structure and its manufacturing method and measuring instrument

ActiveCN103983435BWill not polluteAvoid contactCladded optical fibreTesting optical propertiesMicro nanoWater vapor

The invention relates to the technical field of micro-nano optical fiber, and discloses a micro-nano optical fiber micro experiment structure, manufacturing method of the structure and measuring instrument. The micro experiment structure comprises monomode optical fiber and a capillary glass straight pipe, and ports are formed in the two ends of the capillary glass straight pipe; the middle of the monomode optical fiber is provided with drawing-made micro-nano optical fiber, the monomode optical fiber is arranged in the capillary glass straight pipe in a penetrated mode, and is fixedly connected with the capillary glass straight pipe, and the whole micro-nano optical fiber is arranged in the capillary glass straight pipe and is arranged in a suspended mode. Because the whole micro-nano optical fiber is arranged in the capillary glass straight pipe and is arranged in a suspended mode, under the protection of the capillary glass straight pipe, the micro-nano optical fiber is protected from being polluted, outside dust and vapor are avoided from making contact with the micro-nano optical fiber, optical nature of the micro-nano optical fiber will not be affected, the optical performance of the micro-nano optical fiber will not degrade rapidly along with time, the micro-nano optical fiber is easy to process, long-term and stable practical application of the micro-nano optical fiber can be achieved, and the micro-nano optical fiber is easy to compile with other optical fiber devices.

Owner:THE HONG KONG POLYTECHNIC UNIV SHENZHEN RES INST

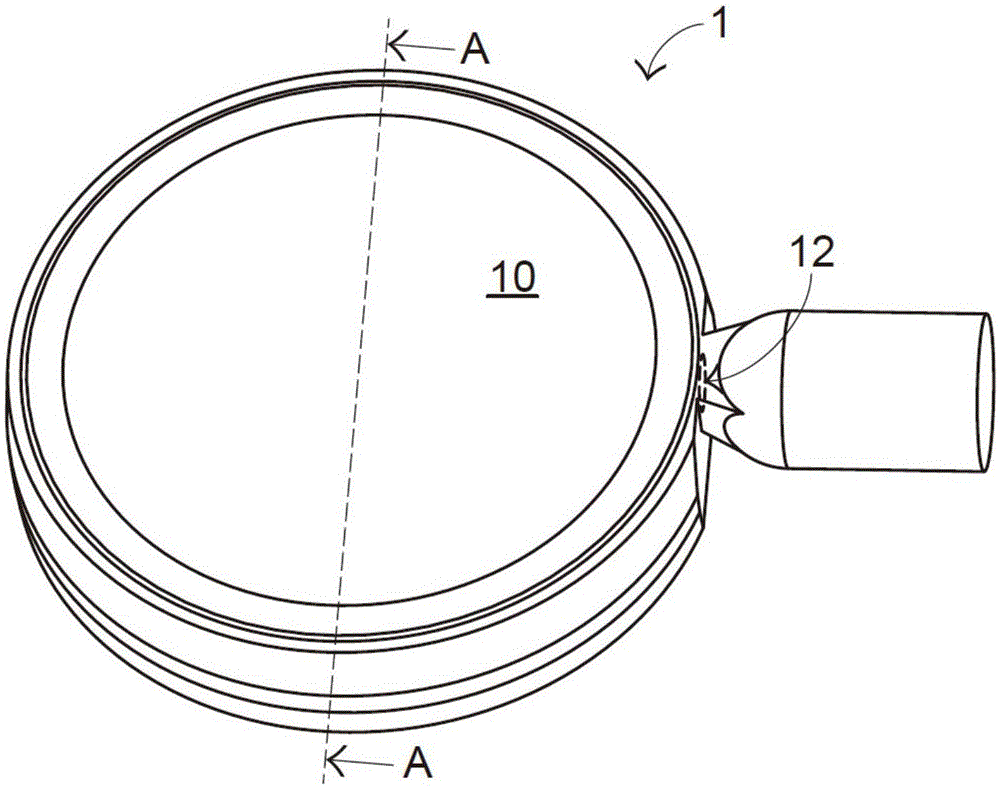

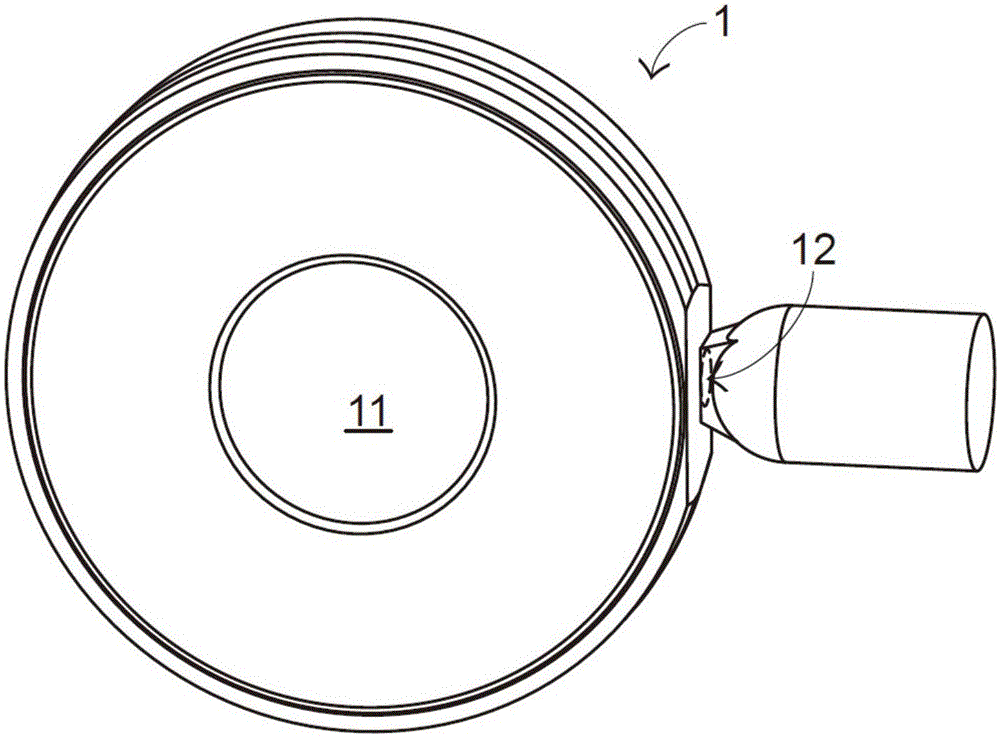

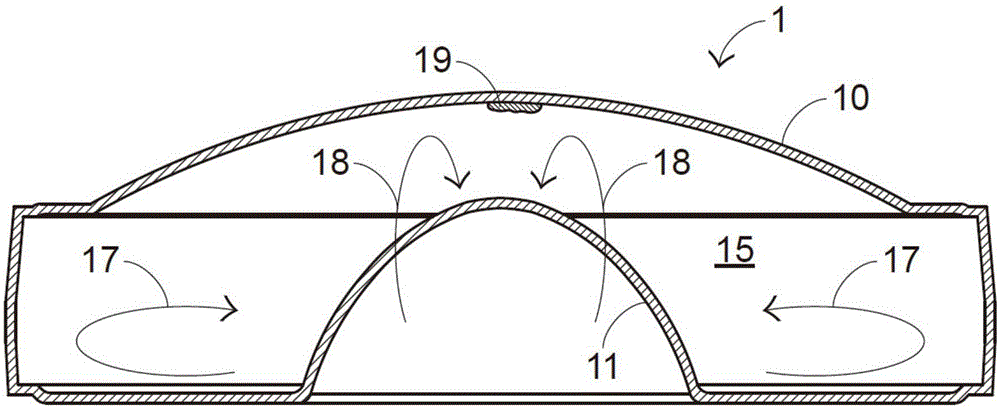

Optical lens and injection molding mold thereof

InactiveCN106514957AImprove yieldIncreased stress intensityOptical articlesLensOptic lensInjection molding machine

The invention provides an optical lens and an injection molding mold thereof. The injection molding mold of the optical lens comprises a disc-shaped mold seat and a nozzle. A mold cavity chamber and a sprue communicating with the mold cavity chamber are defined by the disc-shaped mold seat. The mold cavity chamber comprises an optical effective area center runner and a non-optical effective area circumferential runner. The optical effective area center runner is defined between an upper curved surface and a lower curved surface in the disc-shaped mold seat. The non-optical effective area circumferential runner surrounds and communicates to the optical effective area center runner and communicates with the sprue. A plurality of turbulent flow structures are formed at the positions, on the non-optical effective area circumferential runner, of the disc-shaped mold seat. The nozzle is connected to the disc-shaped mold seat. Melt is injected into the mold cavity chamber through the sprue. The flow speed of the melt on the non-optical effective area circumferential runner is disturbed by the multiple turbulent flow structures, the optical effective area center runner is preferentially filled with the melt, and therefore an optical effective area of the optical lens cannot be generated with defects so as to increase the yield of the optical lens.

Owner:EVERREADY PRECISION IND

Method for producing photon crystal film for improving mechanical strength and solvent resistance

ActiveCN101369029BHigh mechanical strengthGood solvent resistanceAfter-treatment detailsOptical elementsUltraviolet lightsCross linker

The invention relates to a method for preparing a photonic crystal film which can improve the mechanical intension and the solvent resistance. In the method, a polymer monomer solution which is adulterated with photoinitiator and cross linker can evenly permeate into interspaces of the photonic crystal film with an opal type structure, and then the film can be irradiated by ultraviolet light to make the polymer monomer polymerized; after the polymer monomer is polymerized, the emulsion particle bulbs in the photonic crystal film with an opal type structure can be jointed firmly, a polymer macromolecule net can be formed among the emulsion particle bulbs, the performance of the photonic crystal can be enhanced through utilizing the net structure which is formed by the polymer macromoleculechains, therefore, the mechanical performance of the photonic crystal film can be enhanced. Taking the rigidity of the film and Young modulus for example, the polymer monomer solution can permeate inthe interspaces of the photonic crystal film with an opal type structure, through the processing of photo-cross linking, the mechanical property of the rigidity of the photonic crystal film, the Young modulus and the like and the solvent resistance can be improved greatly, and the initial mechanical property can not be essentially affected.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Collection type lens group and production method thereof

InactiveCN101315453AImprove assembly efficiencyExemption Frequency and ContaminationMountingsEngineering

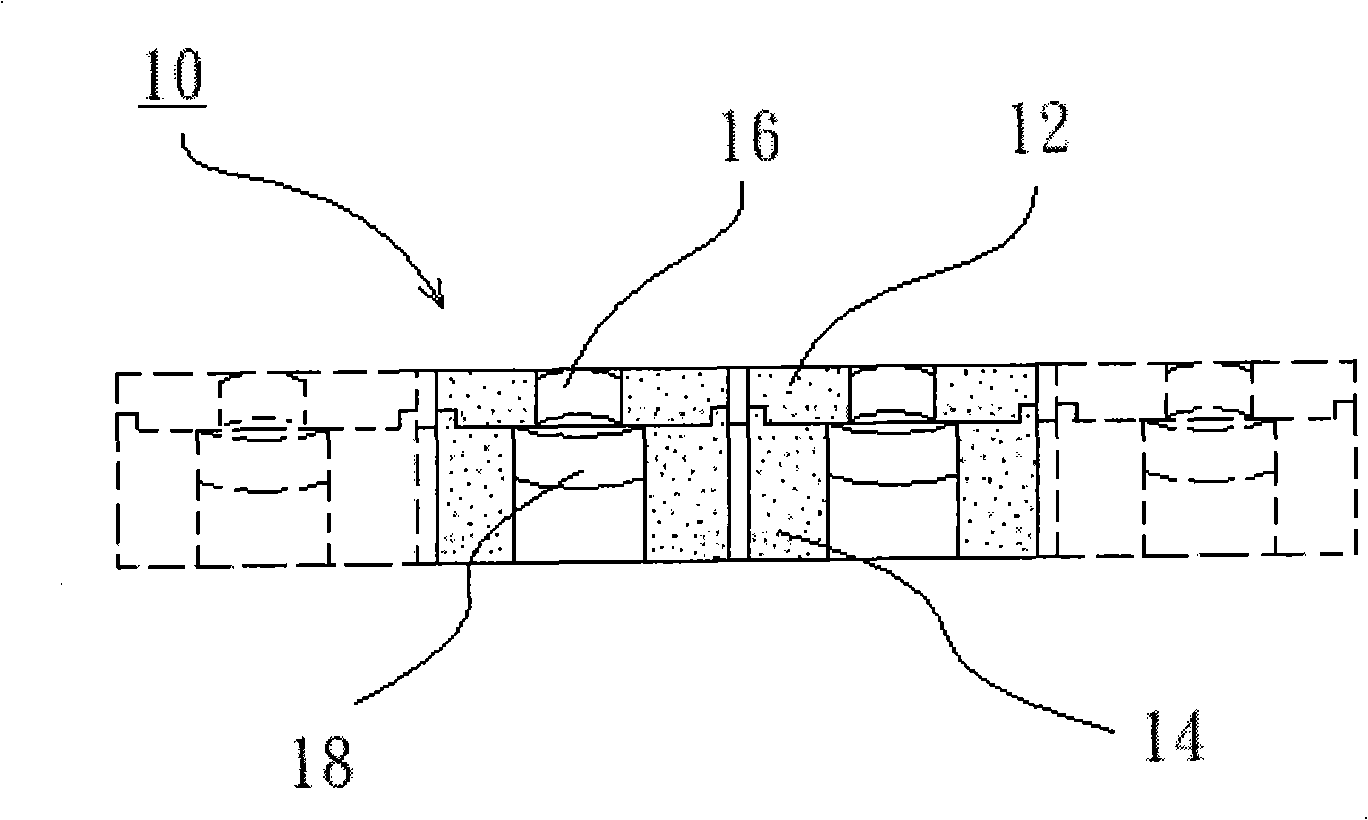

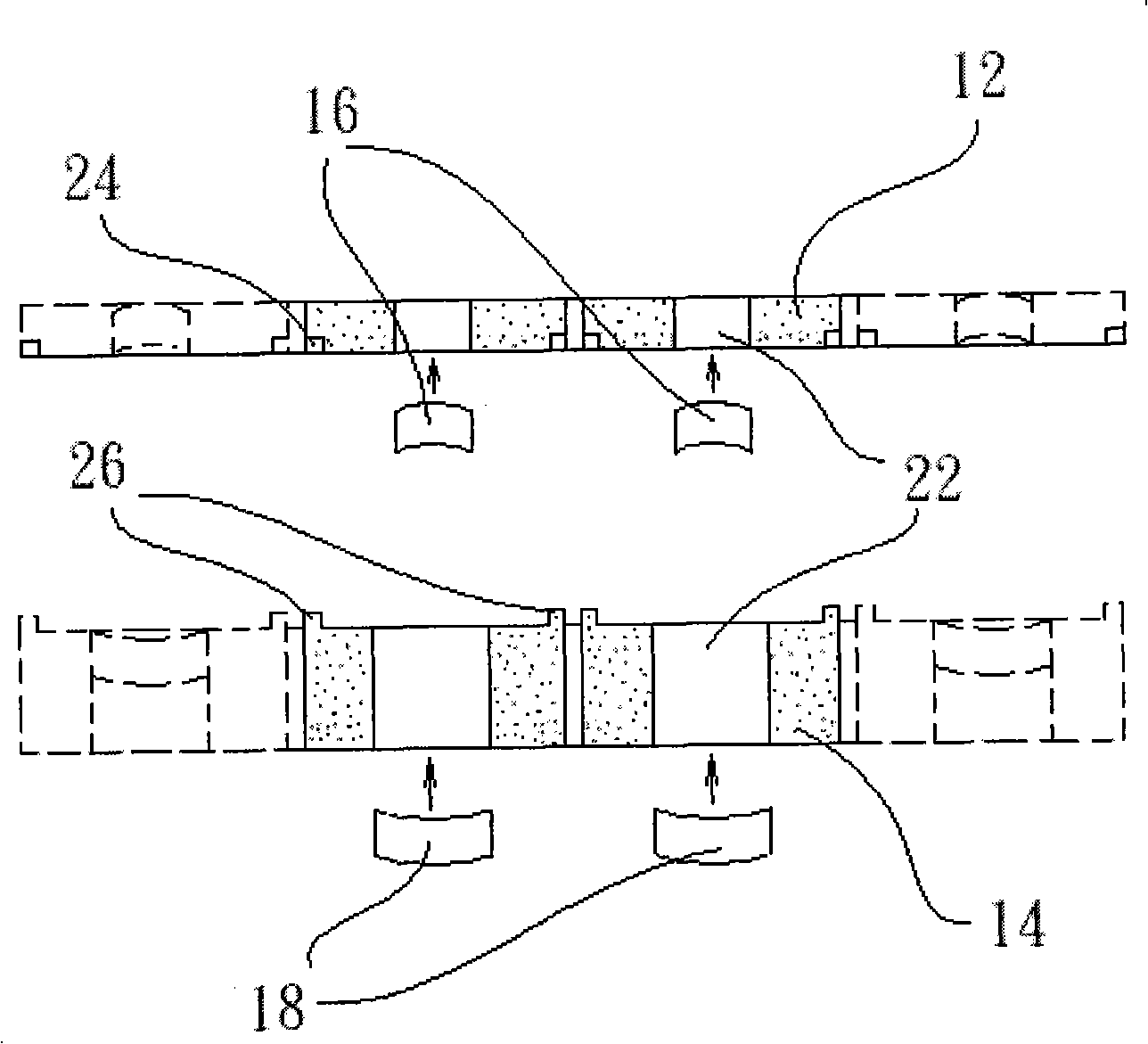

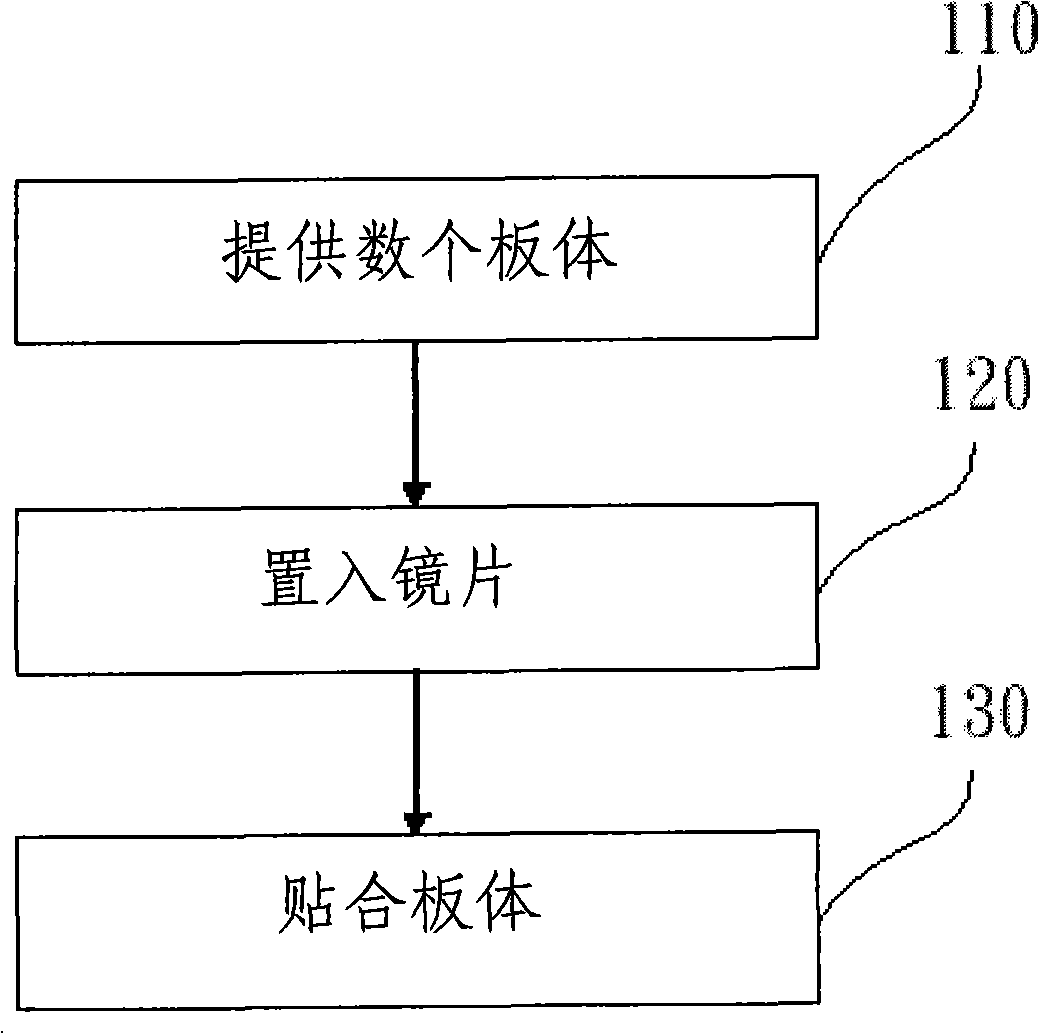

The invention provides an integrated lens group and a manufacturing method thereof. The integrated lens group is composed of a plurality of board bodies which are oppositely adhered; a plurality of hollows are respectively formed on each of the board bodies correspondingly; and one or more lenses are respectively arranged in each hollow. The manufacturing method of the integrated lens group adopts the following steps: a plurality of board bodies with a plurality of hollows are firstly provided, then the lenses are respectively arranged in the hollows of each board body, finally the board bodies are oppositely adhered, so that the peripheral areas of the hollows and the lenses in the hollows can correspondingly form a plurality of lens groups which can be cut and separated.

Owner:ETHER PRECISION

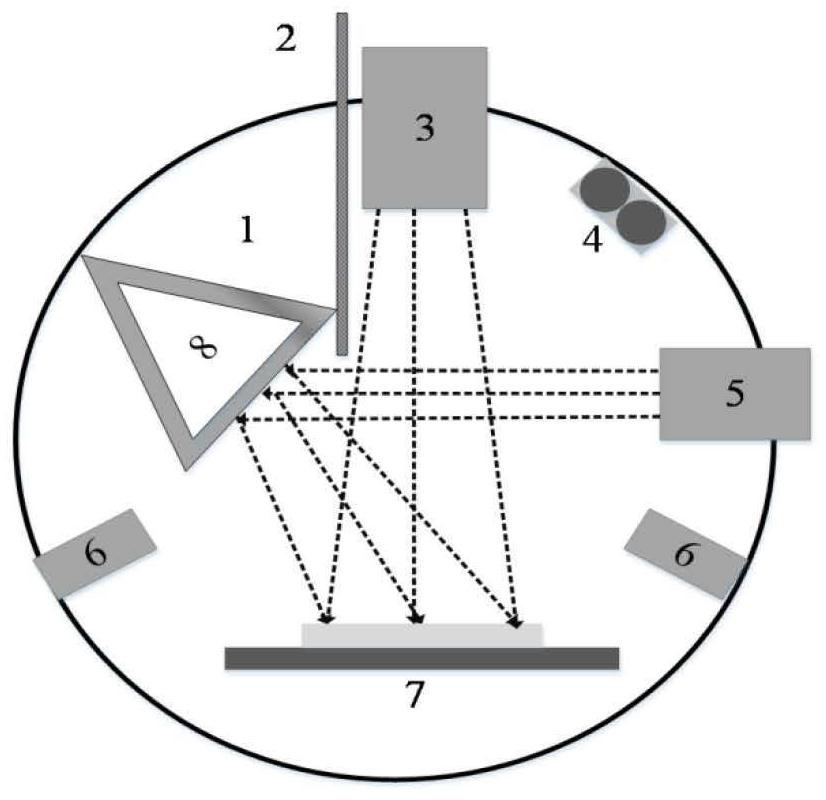

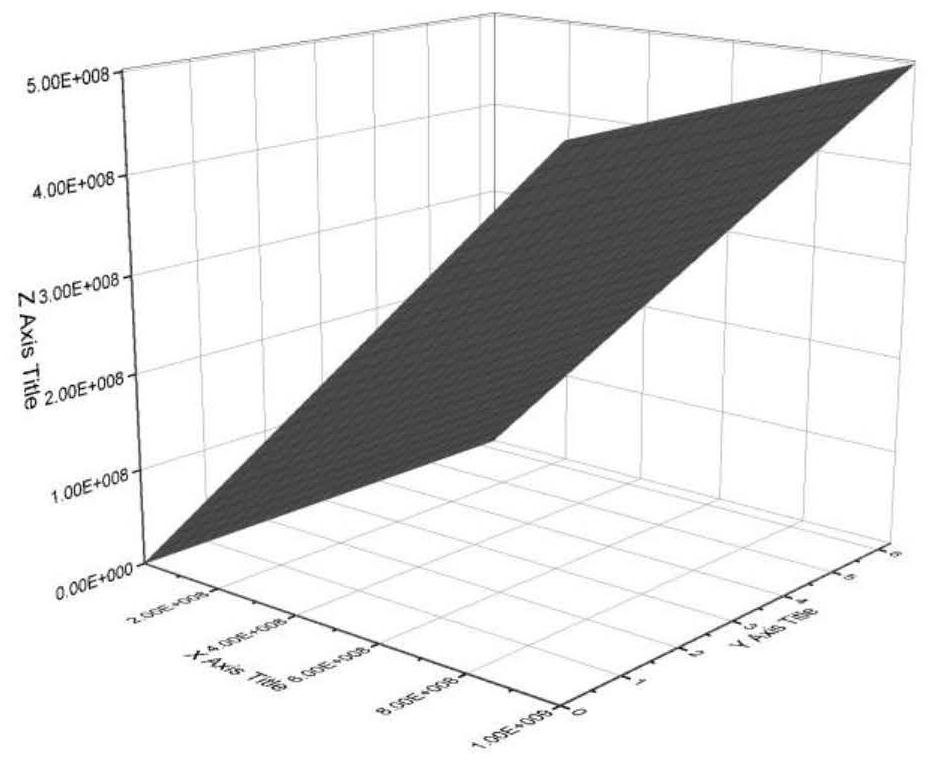

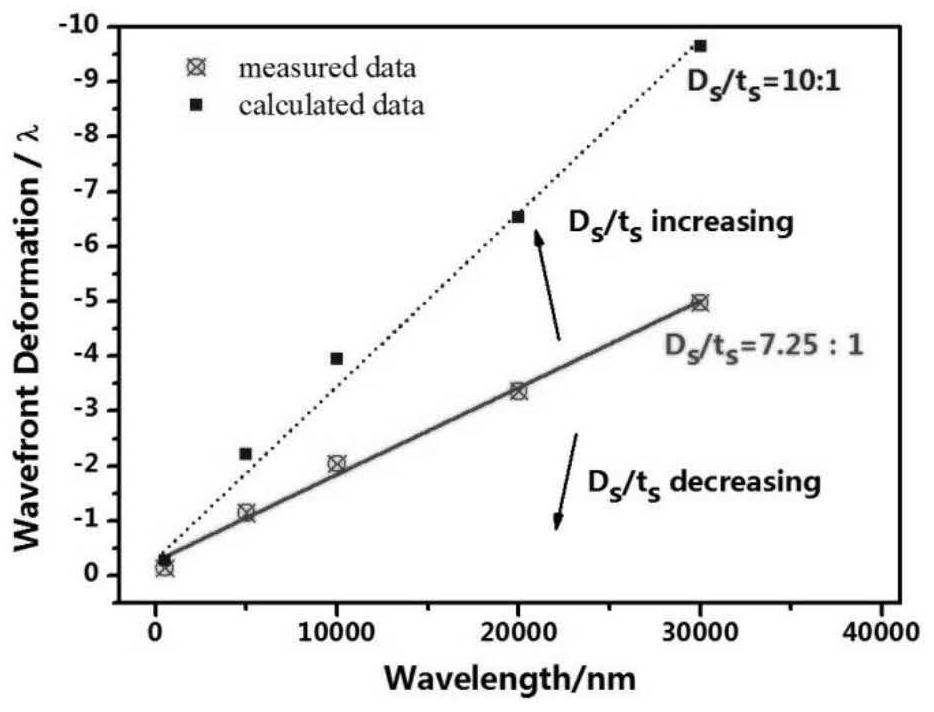

Method for controlling curvature radius of large-curvature optical element

PendingCN113061861AShorten production timeImprove efficiencyVacuum evaporation coatingSputtering coatingThin membraneLinear relationship

The invention discloses a processing method for accurately controlling the curvature radius of a large-curvature optical element based on film stress. The control method is a method combining a traditional optical processing technology and a coating technology, accurate control over the curvature radius of the optical element can be achieved, particularly, a film is plated on the surface of the optical element through the film stress characteristic, the curvature radius of the element can be changed through film stress, and finally, the purpose of accurately controlling the curvature radius of the optical element is achieved. Meanwhile, the processing method has the advantages that optical elements with different curvature radiuses can be accurately controlled by depositing films with different thicknesses according to the linear relation between the film thickness and the strain on the premise that the optical characteristics of the elements are not affected. The production time can be effectively shortened, and the efficiency is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of nanometer metal grating and nanometer metal grating

ActiveCN107479121BNot easy to etchSolve the problem that etching cannot be carried outPhotomechanical apparatusPolarising elementsOxygenNanometre

Disclosed is a method for preparing a nano metal grating (35). The method includes: forming a patterned metal oxide film (34) on a surface of a metal layer (31) by using the characteristic of forming a metal oxide during an oxygen ashing process, and making the nano metal grating (35) by using the patterned metal oxide film (34) as a mask film. First, the method solves the problem that the metal layer (31) cannot be etched after oxidation; and secondly, the metal oxide film (34) is used as a mask film for preparing the nano metal grating (35), and can also be used as a protective layer for the nano metal grating (35).

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

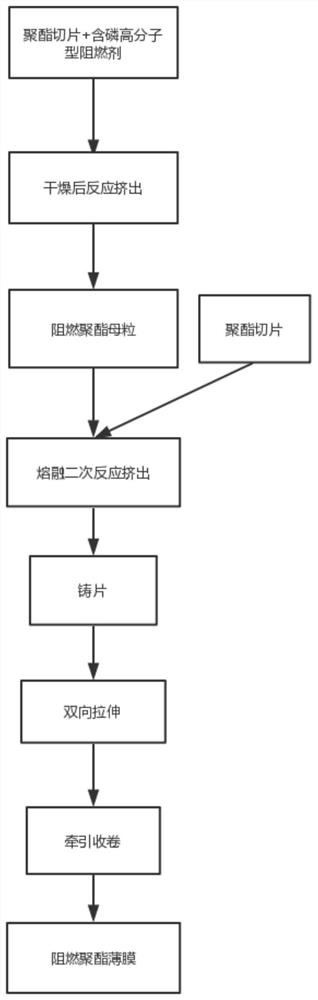

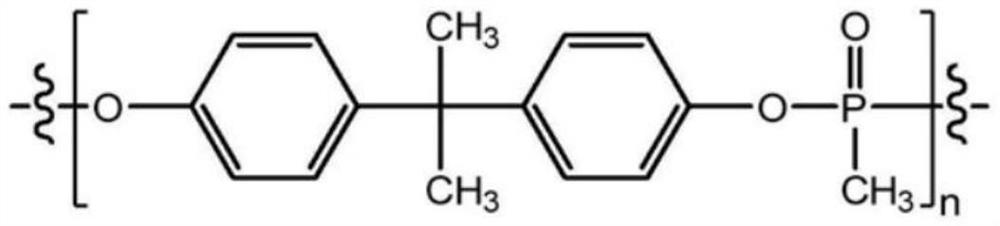

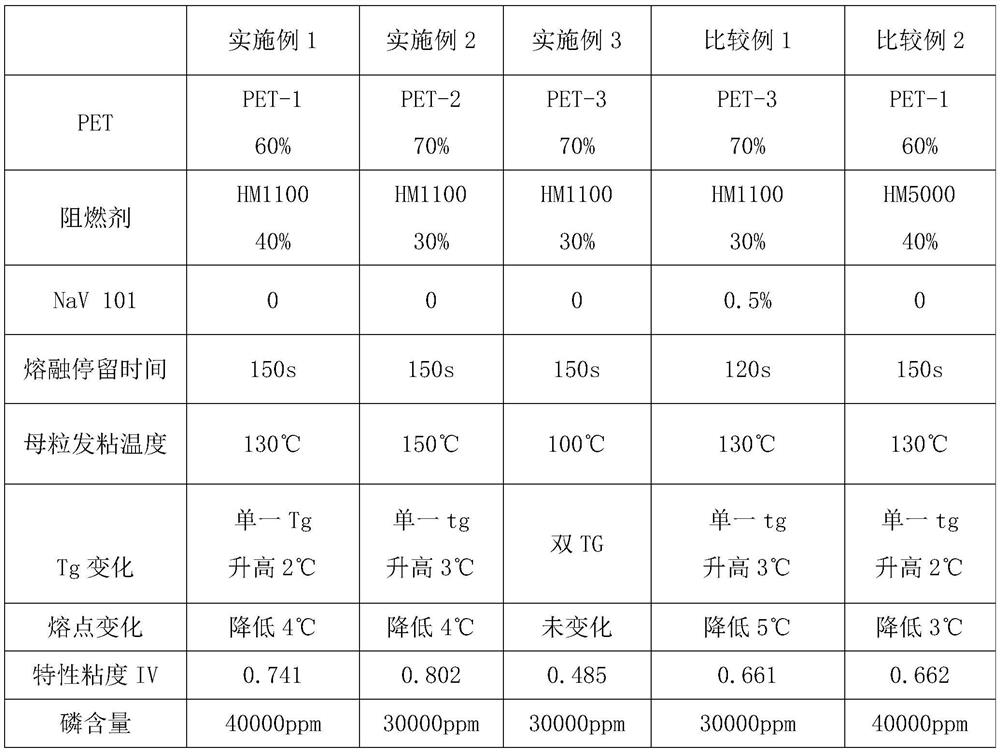

Heat-resistant high-strength halogen-free flame-retardant polyester film and preparation method thereof

The invention discloses a heat-resistant high-strength halogen-free flame-retardant polyester film and a preparation method thereof, and particularly relates to a special flame-retardant polyester master batch prepared by reactive extrusion of a phosphorus-containing macromolecular flame retardant polymer and polyester, and a polyester film with the flame-retardant grade reaching UL94VTM-0 prepared from the raw materials according to different addition proportions. The obtained flame-retardant polyester film has the characteristics of high strength, good heat resistance and no influence on optical properties such as the original product color. The halogen-free flame-retardant polyester film is good in film-forming property and environment-friendly.

Owner:浙江南洋科技有限公司

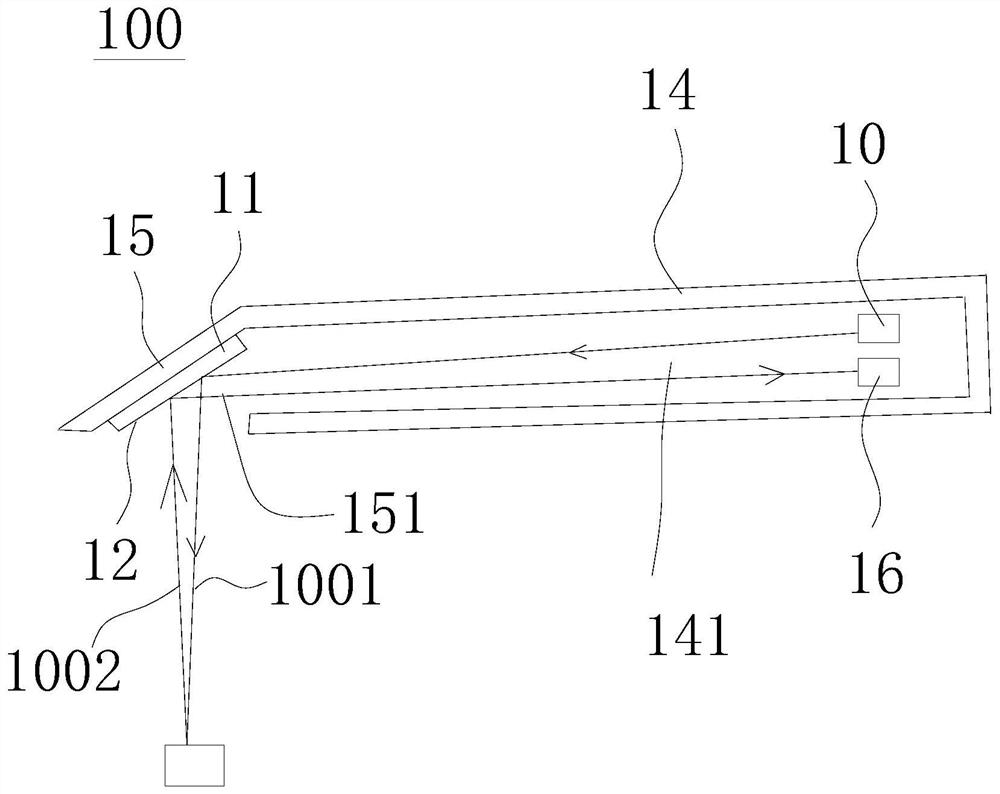

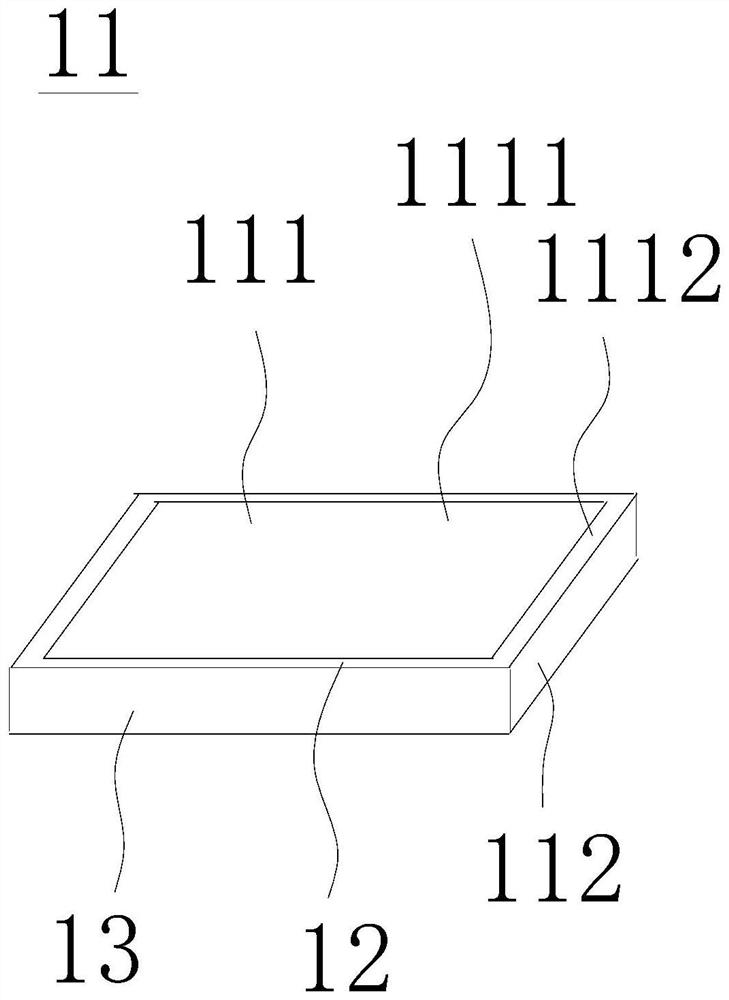

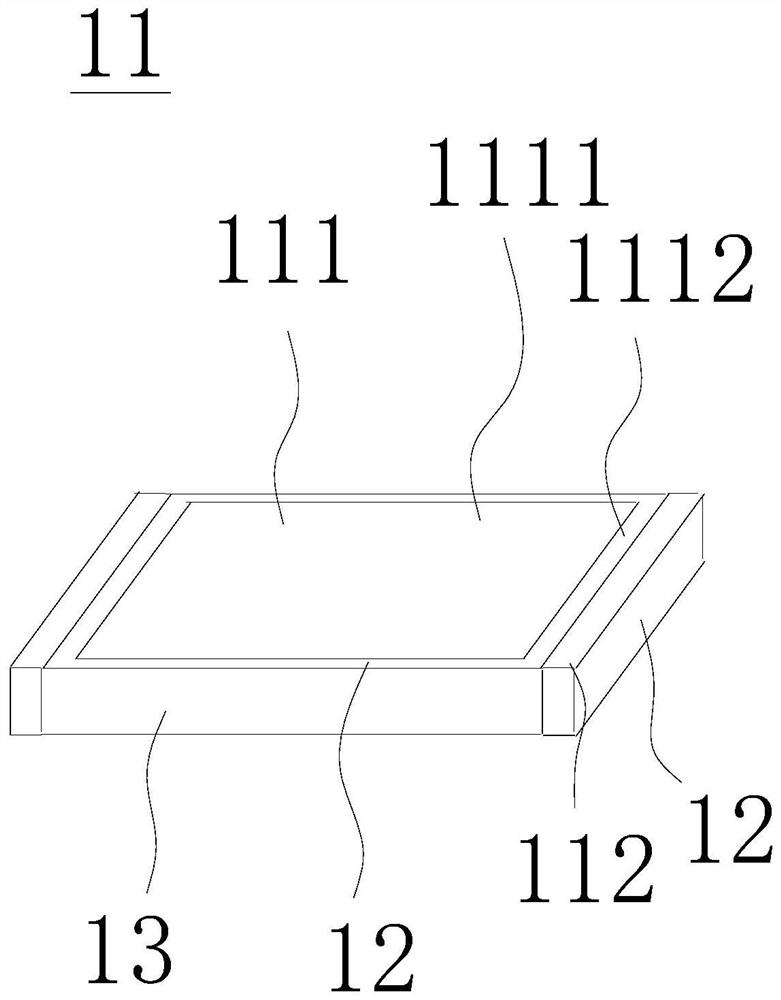

Oral cavity scanner

PendingCN114098617ADoes not affect optical propertiesDoes not affect accuracyEndoscopesSomatoscopeOptical propertyMedicine

An oral cavity scanner for scanning an object includes a main body having a first space, a light source disposed in the first space and configured to emit a first light, an image capturing unit disposed in the first space and configured to capture an image of the object, an optical element disposed in the first space and configured to emit a second light, and a heater disposed in the first space. The optical element is arranged in the first space and provided with a first surface, the first surface is provided with a first area and a second area, the heater is arranged in the second area to heat the optical element, the first light rays can reach the object through the first area to form second light rays, and the second light rays reach the image taking unit from the object through the first area. The heater can save power, the optical characteristics and accuracy of the oral cavity scanner are not affected when the demisting efficiency is improved, the heater is not damaged in the cleaning process, and the optical characteristics and accuracy of the oral cavity scanner are not affected.

Owner:QISDA OPTRONICS (SUZHOU) CO LTD +1

Electronic component cleaning agent

ActiveCN102816659BIntegrity does not affectDoes not affect optical propertiesSurface-active non-soap compounds and soap mixture detergentsOrganic baseActive agent

Owner:HENGYANG HONDAWEI ENVIRONMENTAL TECH CO LTD

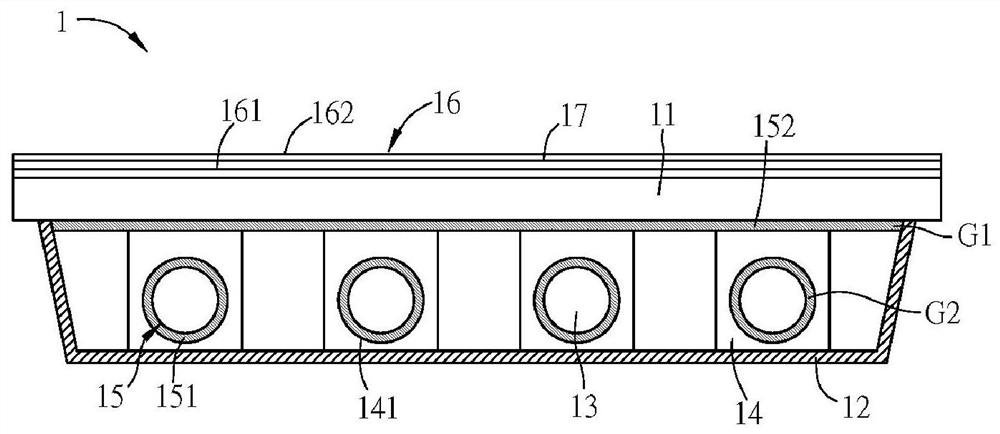

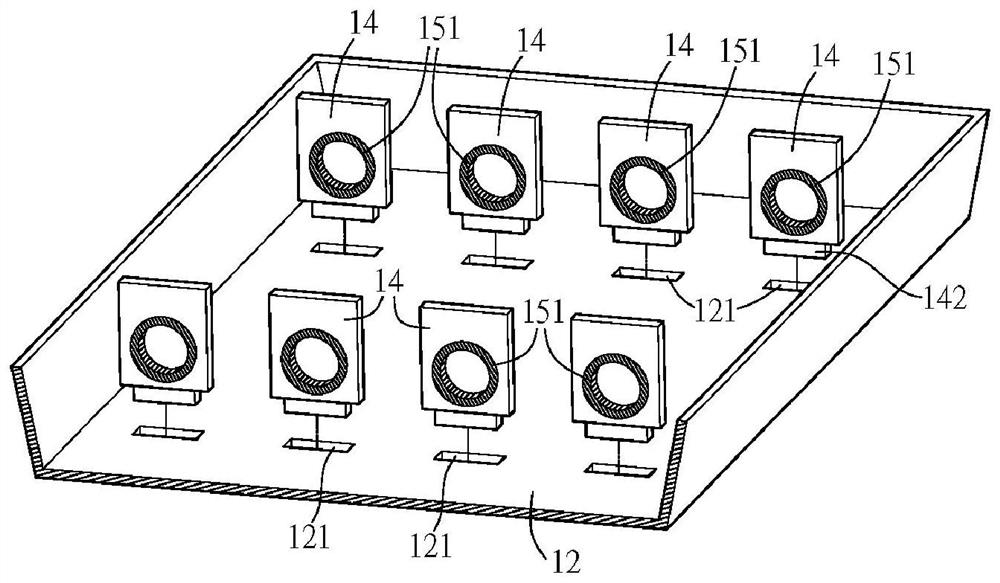

Direct type backlight module and display device

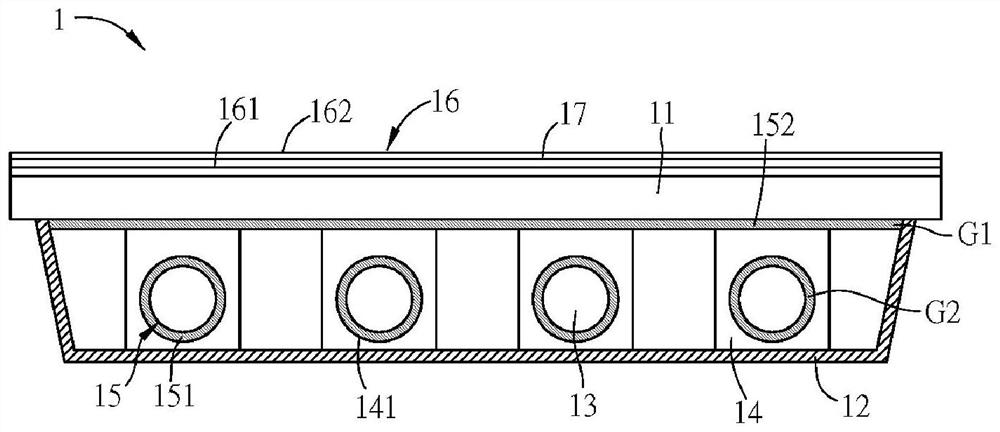

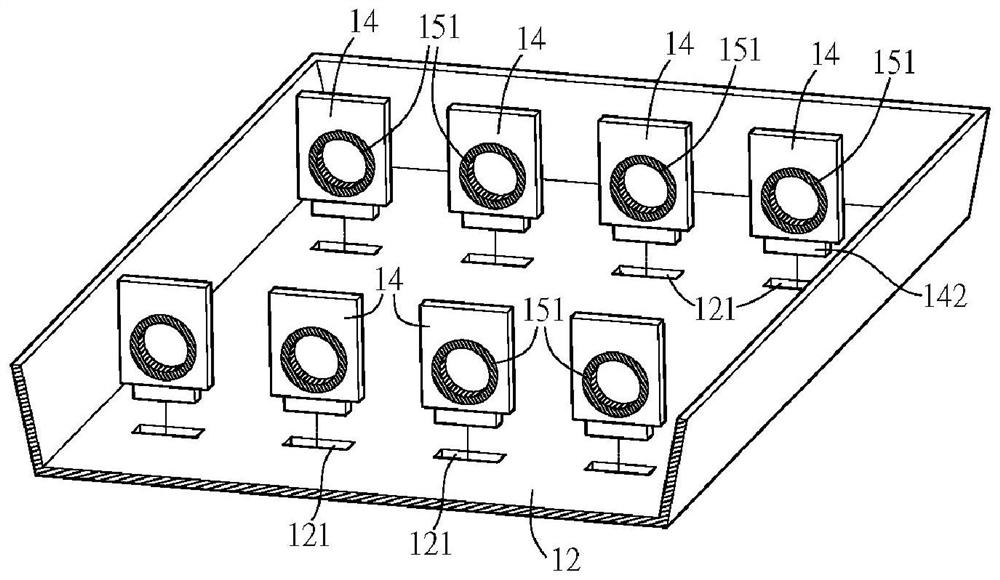

InactiveCN111812891AAvoid deformationDoes not affect optical propertiesNon-linear opticsDisplay deviceEngineering

The invention discloses a direct type backlight module. The direct type backlight module comprises a diffusion plate, a reflection plate and a plurality of light sources. The reflection plate is arranged below the diffusion plate and spaced from the diffusion plate, the reflection plate is provided with a protruding column, and the protruding column is arranged adjacent to the diffusion plate andprovided with an installation part. A light source penetrates through a mounting part; and the protruding column is used for simultaneously supporting the diffusion plate and the light source.

Owner:HKC CORP LTD

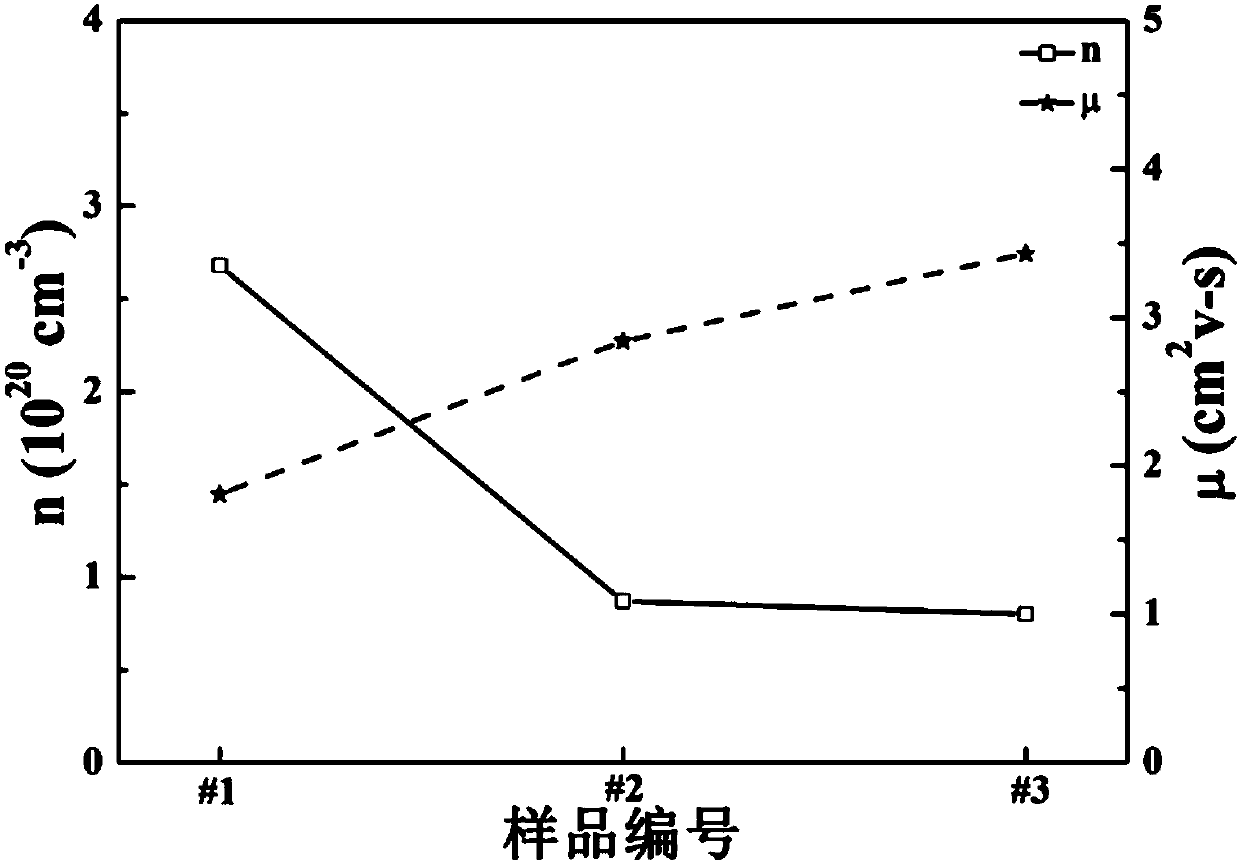

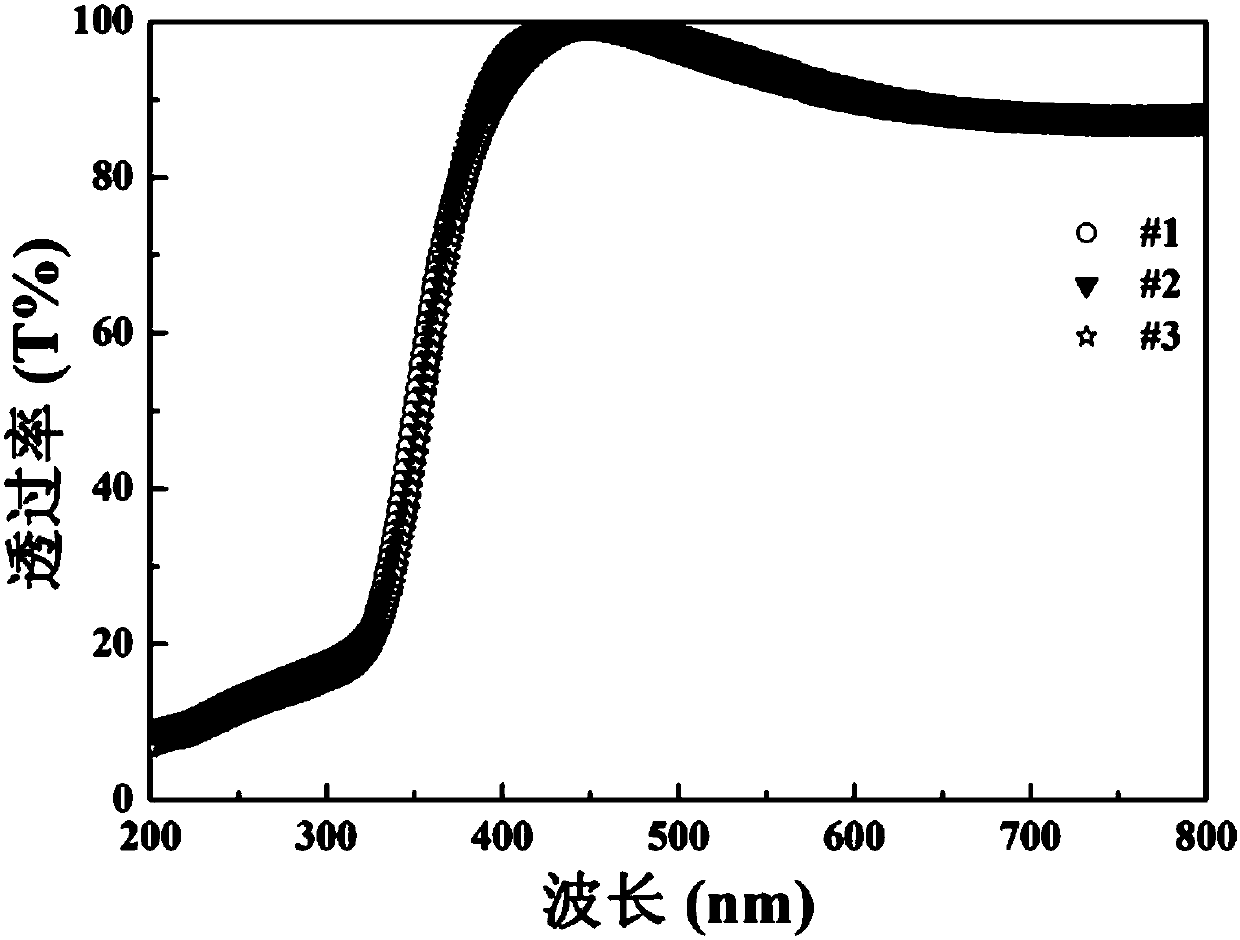

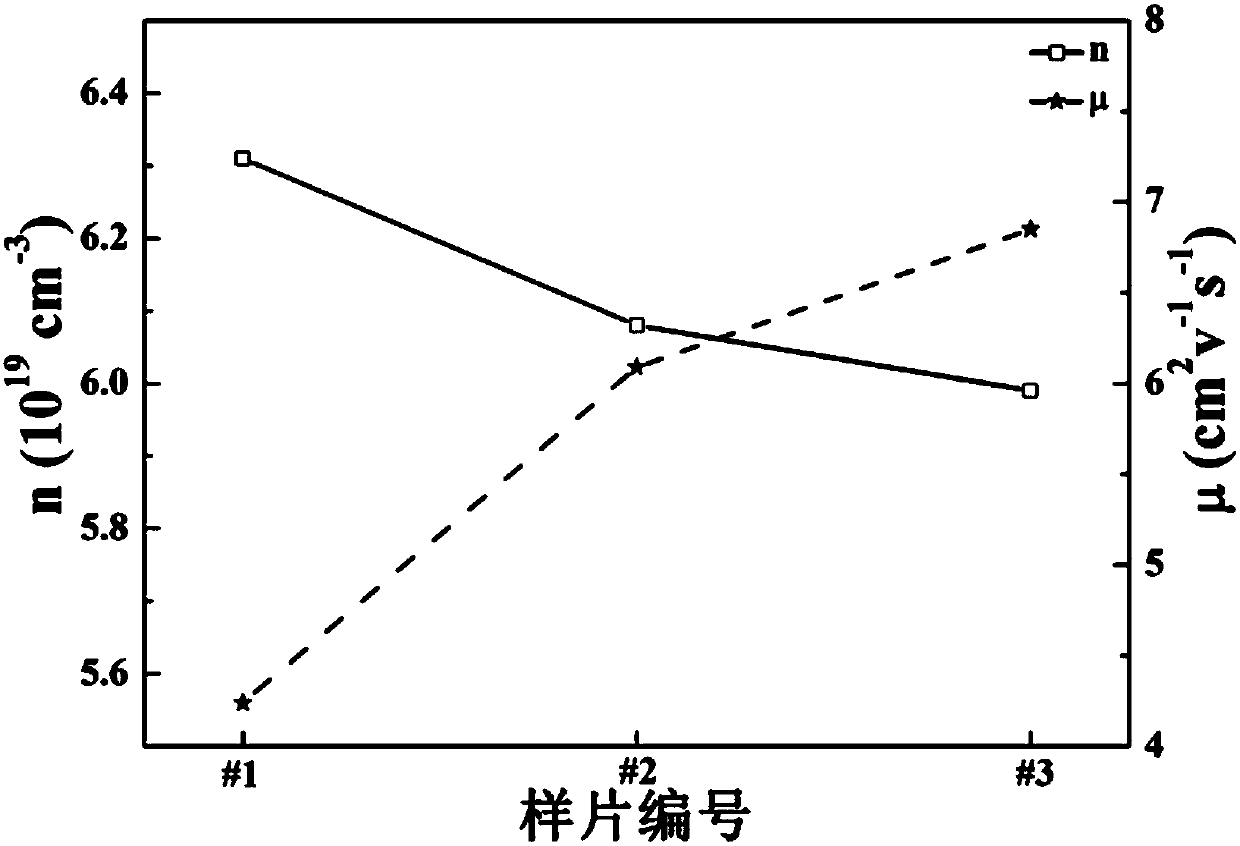

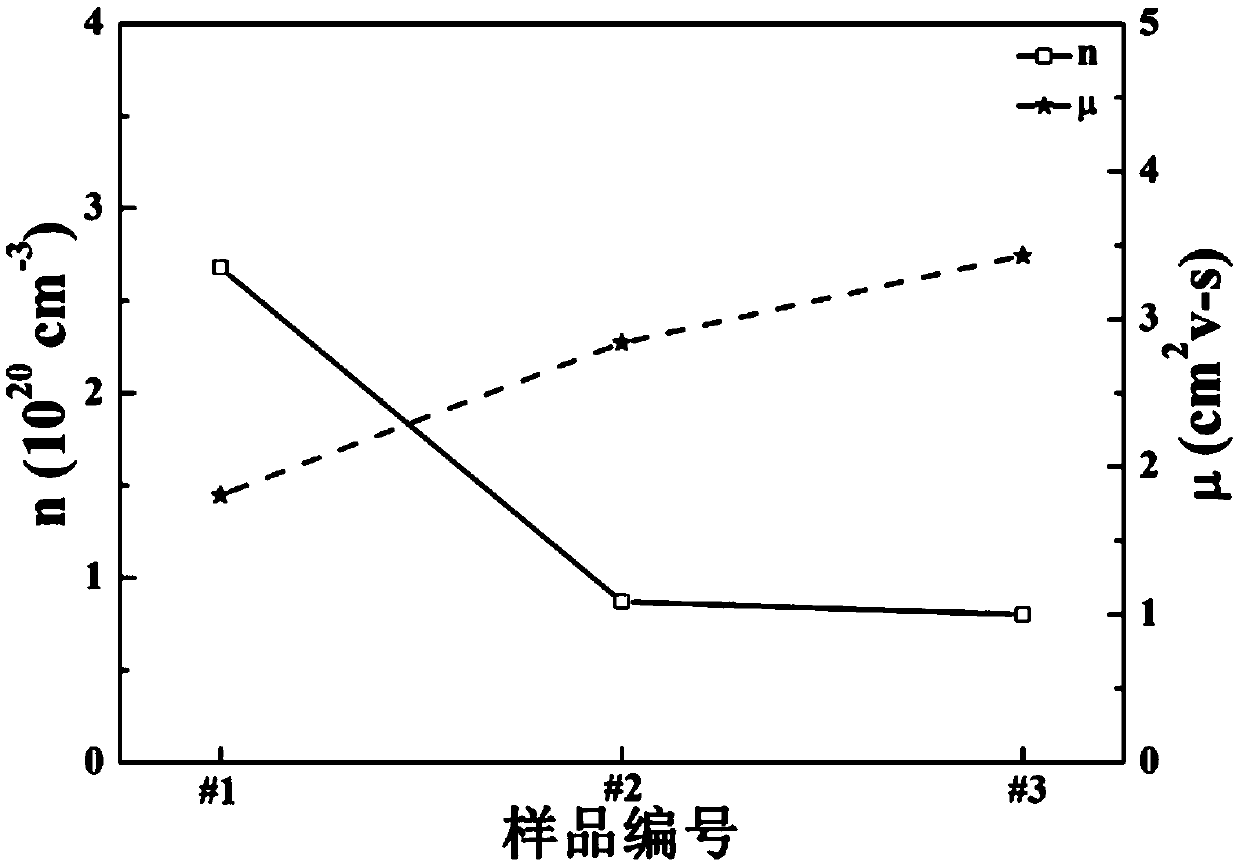

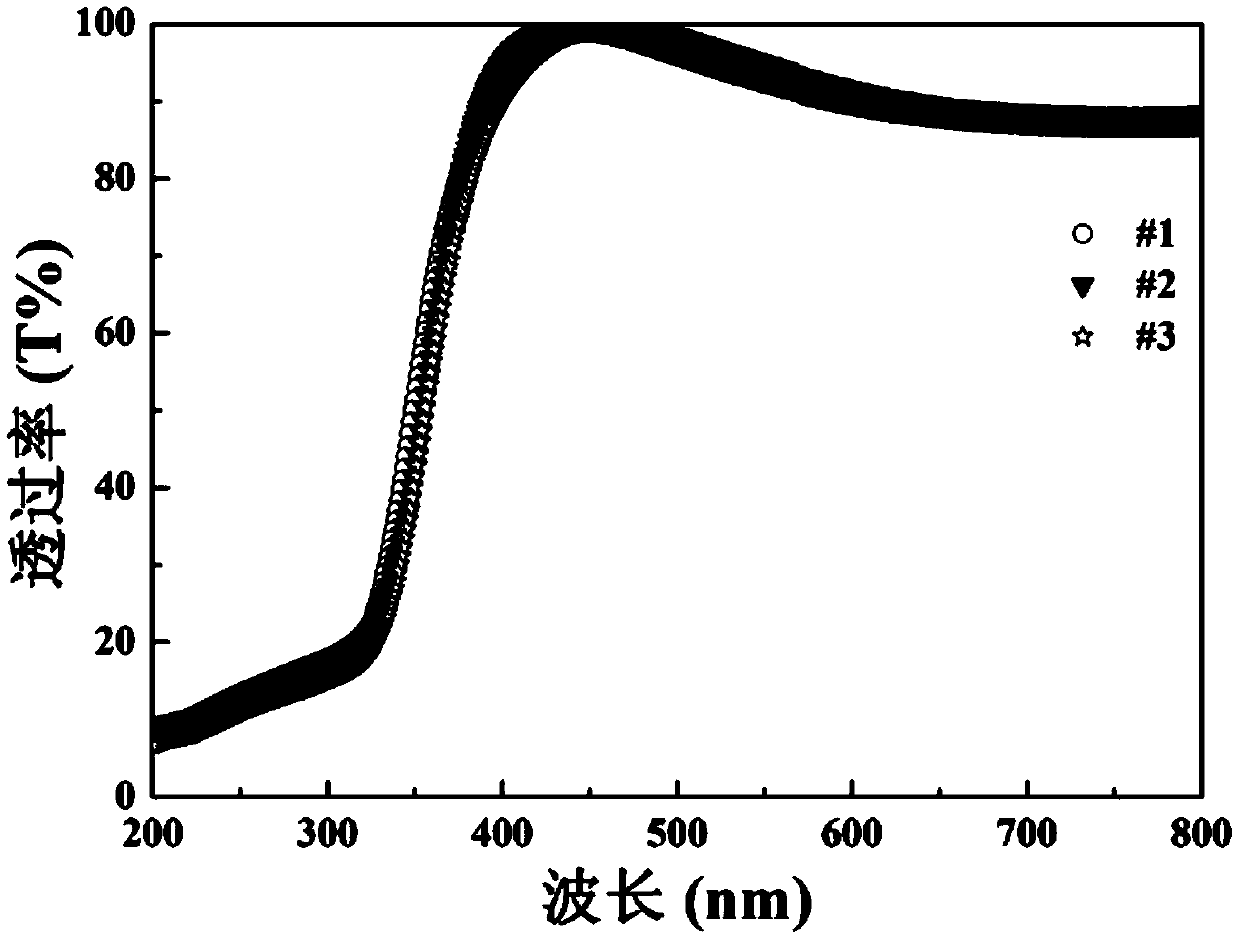

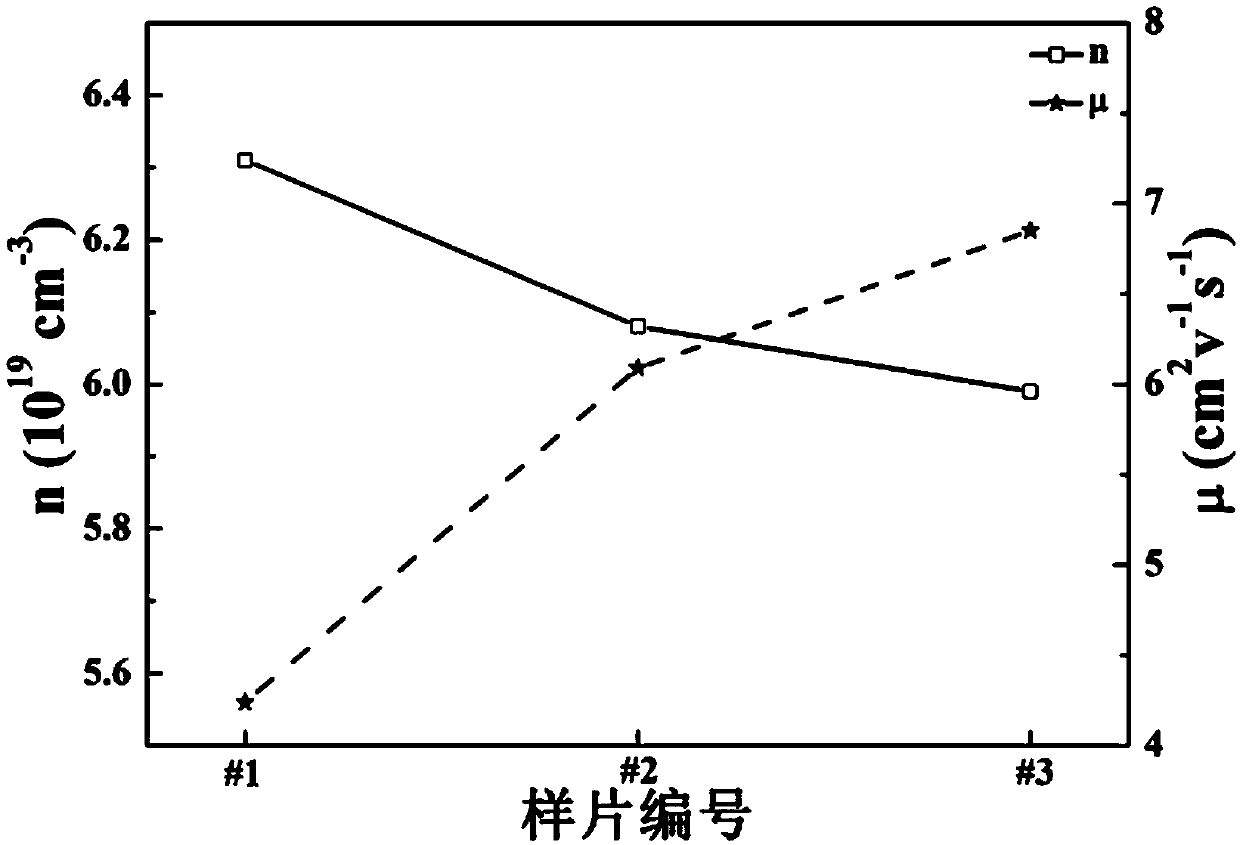

Method for reducing power consumption of transparent and conductive oxide thin film device by using micro structure adjustment and control

ActiveCN107761068AFill in the gapsImproved resistance characteristicsVacuum evaporation coatingSputtering coatingMicro structureJoule

The invention discloses a method for reducing power consumption of a transparent and conductive oxide thin film device by using micro structure adjustment and control. The method comprises a step of treating a transparent and conductive oxide thin film by adopting an SCCO2 method, specifically: adding deionized water into a reaction kettle of SCCO2 equipment; putting the transparent and conductiveoxide thin film into the reaction kettle, but enabling the transparent and conductive oxide thin film to be not in contact with the deionized water, and sealing the reaction kettle; heating the solution in the reaction kettle to 55 to 75 DEG C, pressurizing CO2 to 10 to 13 MPa, then continuously heating the solution to 120 to 150 DEG C, and carrying out thermal reaction for 30 to 90 min. According to the method for reducing the power consumption of the transparent and conductive oxide thin film device by using micro structure adjustment and control, the defects in the transparent and conductive oxide thin film are filled up by a simple and easy-to-control method; on the premise of not affecting the optical characteristic of the transparent and conductive oxide thin film, the electrical property of the transparent and conductive oxide thin film is effectively changed, so that joule heat of the transparent and conductive oxide thin film device, which is generated in a use process, is reduced.

Owner:WUHAN UNIV

A Method for Reducing Power Consumption of Transparent Conductive Oxide Thin Film Devices Using Microstructure Regulation

ActiveCN107761068BDoes not affect optical propertiesChange electrical propertiesVacuum evaporation coatingSputtering coatingOptical propertyJoule

The invention discloses a method for reducing power consumption of a transparent and conductive oxide thin film device by using micro structure adjustment and control. The method comprises a step of treating a transparent and conductive oxide thin film by adopting an SCCO2 method, specifically: adding deionized water into a reaction kettle of SCCO2 equipment; putting the transparent and conductiveoxide thin film into the reaction kettle, but enabling the transparent and conductive oxide thin film to be not in contact with the deionized water, and sealing the reaction kettle; heating the solution in the reaction kettle to 55 to 75 DEG C, pressurizing CO2 to 10 to 13 MPa, then continuously heating the solution to 120 to 150 DEG C, and carrying out thermal reaction for 30 to 90 min. According to the method for reducing the power consumption of the transparent and conductive oxide thin film device by using micro structure adjustment and control, the defects in the transparent and conductive oxide thin film are filled up by a simple and easy-to-control method; on the premise of not affecting the optical characteristic of the transparent and conductive oxide thin film, the electrical property of the transparent and conductive oxide thin film is effectively changed, so that joule heat of the transparent and conductive oxide thin film device, which is generated in a use process, is reduced.

Owner:WUHAN UNIV

Independent parallel optical cable

InactiveCN111796377ASmall thermal deformationComprehensive performance of high flame retardant and low smokeFibre mechanical structuresBuffer (optical fiber)Composite material

The invention relates to the technical field of optical cables. The invention also discloses an independent parallel optical cable. The optical cable comprises an outer sheath. A bearing suspension part is arranged on one side of the outer sheath, and a bearing suspension wire is arranged on the inner side of the bearing suspension part. A reinforcing member is arranged on the inner side of the outer sheath, and an optical fiber is arranged on one side of the reinforcing member. An insulating layer is arranged on the outer surface of the optical fiber, a waterproof layer is arranged on the outer surface of the insulating layer, an inner sheath is arranged on the outer surface of the waterproof layer, and a compression-resistant structure is arranged on the inner side of the inner sheath. The compression-resistant structure comprises an upper pressing block, a lower pressing block, an upper fixing block, a lower fixing block, a piston rod and a buffer spring. The outer surface of the outer sheath is provided with a groove, the outer surface of the outer sheath is provided with a positioning block corresponding to the inner side of the groove, and the outer surface of the positioningblock is provided with a reinforced connecting buckle. The independent parallel optical cable has the advantages that the joint of a connecting wire and a charging pile body can be flexibly adjustedalong with the bending angle, the charging plug is convenient to store and safer, the independent parallel optical cable is more convenient to use at night and convenient to disassemble and overhaul,and a better use prospect is brought.

Owner:SUZHOU DACHENG RUIFENG COMM TECH CO LTD

A lamp group and its insulation protective jacket

InactiveCN101532654BPrevent breakdownAvoid arc phenomenonElongate light sourcesLighting safety devicesEngineeringLight tube

Owner:AU OPTRONICS CORP

Electronic element cleaning agent

InactiveCN107641563ADoes not affect optical propertiesLow costInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsEthylenediamineOrganic base

The invention relates to an electronic element cleaning agent which is composed of the following components in percentage by mass: 50-75% of magnetized water, 2-14% of organic base, 15%-35% of a surfactant and 0.2%-0.4% of an anti-rust agent; the magnetic source adopted by the magnetized water is a neodymium iron boron magnet, the shape of the magnet is in a tile shape, and the intensity of the magnetic field is 2000-12000 gauss; wherein the organic base is one or several kinds of compounds selected from N, N'-dihydroxyethyl ethylenediamine, beta-dihydroxyethyl ethylenediamine, N-(2-hydroxyethyl) ethylenediamine, N, N, N', N' tetrakis(2-hydroxyethyl) ethylenediamine, N-hydroxyethyl propane diamine, trimethyl hydroxyethyl propane diamine and N, N '-di(2-hydroxyethyl)-1,3 propane diamine andthe surfactant is one or several kinds of compounds selected from alkyl polysaccharide glycoside, sodium gluconate, coconut diethanol amide and isomeric alcohol ethoxylates. The invention has the following advantages: the cleaning agent is low in cost, wide in raw material source, high in cleaning capacity and small in use amount, the washed materials are not rusted, the pollution of metal ions can be effectively removed, the cleaning agent is environmental friendly and no pollution is generated.

Owner:NVISION ELECTRICAL APPLIANCE

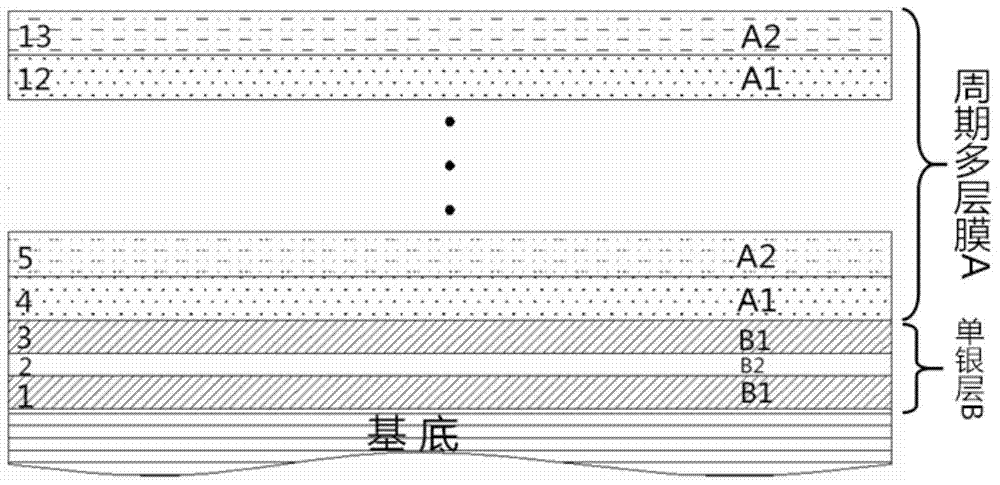

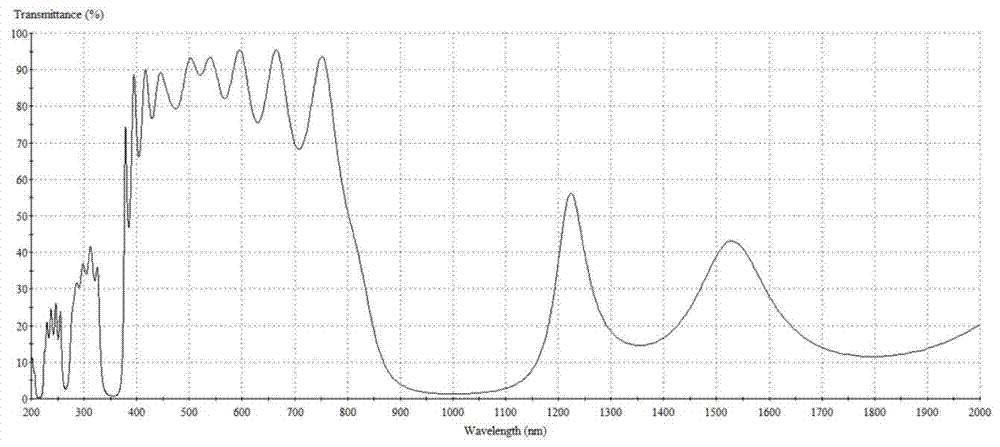

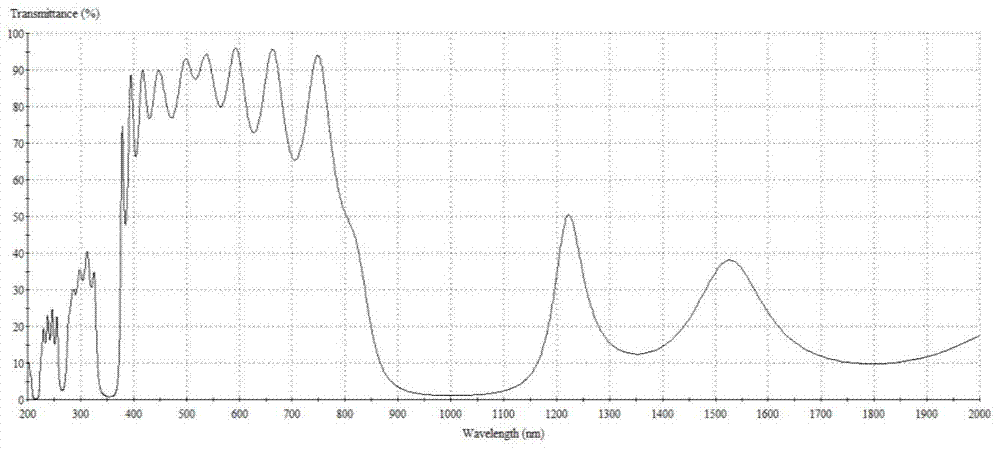

A low-emissivity film

ActiveCN104608434BFacilitate transmissionPlay a blocking roleMetal layered productsLow emissivityUltraviolet

The invention discloses a low-emissivity film. The low-emissivity film comprises a substrate, a single silver layer and a periodical multi-layer film, wherein the single silver layer covers the substrate, is composed of two protective layers and an Ag film, and has the thickness of 29nm-92nm; the thickness of the lower-emissivity film is 1325nm-1575.8nm; the periodical multi-layer film covers the single silver layer and is formed by alternatively overlapping a high-refractive-index material and a low-refractive-index material, and has the thickness of 1275nm-1490nm. For the low-emissivity film disclosed by the invention, the transmission of long-wavelength infrared waves and short-wavelength ultraviolet waves is inhibited by adopting a metal thin silver layer, the transmission of a visible light waveband is intensified by adopting a periodical structure, the transmissivity for visible light is 70-96%, the transmissivity for the ultraviolet wave band is reduced to be 15%, the transmissivity for 780nm-1200nm infrared wave band is reduced to be below 10%, the transmissivity for the 1200-3000 infrared wave band is reduced to be below 25%, the number of layers is obviously reduced, the cost is reduced to a great extent, and the technological process is simplified.

Owner:HUAZHONG UNIV OF SCI & TECH +1

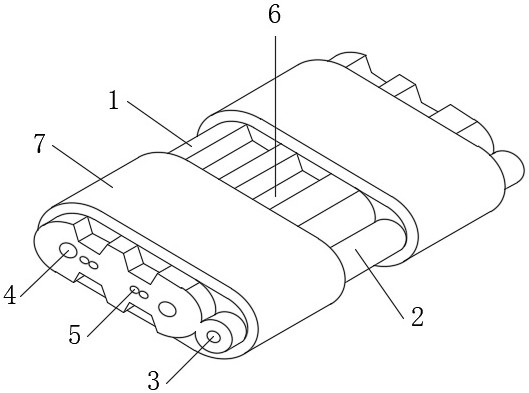

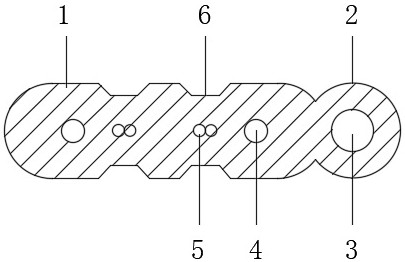

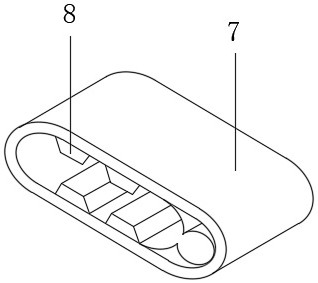

Direct type backlight module and display device

InactiveCN111856816AAvoid deformationDoes not affect optical propertiesNon-linear opticsDisplay deviceEngineering

The invention discloses a direct type backlight module. The direct type backlight module comprises a diffusion plate, a reflecting plate, a plurality of light sources, a plurality of supports and a plurality of buffer pads. The reflecting plate is arranged below the diffusion plate and spaced from the diffusion plate, the light sources are arranged between the diffusion plate and the reflecting plate, and the supports are arranged on the reflecting plate, located between the diffusion plate and the reflecting plate and used for supporting the diffusion plate and the light sources at the same time. Each support is provided with an installation portion, the light sources are directly arranged in the installation portions in a penetrating mode, a first gap is formed between each support and the diffusion plate, and a second gap is formed between each installation portion and the corresponding light source. The buffer pads respectively fill the first gaps and the second gaps.

Owner:HKC CORP LTD

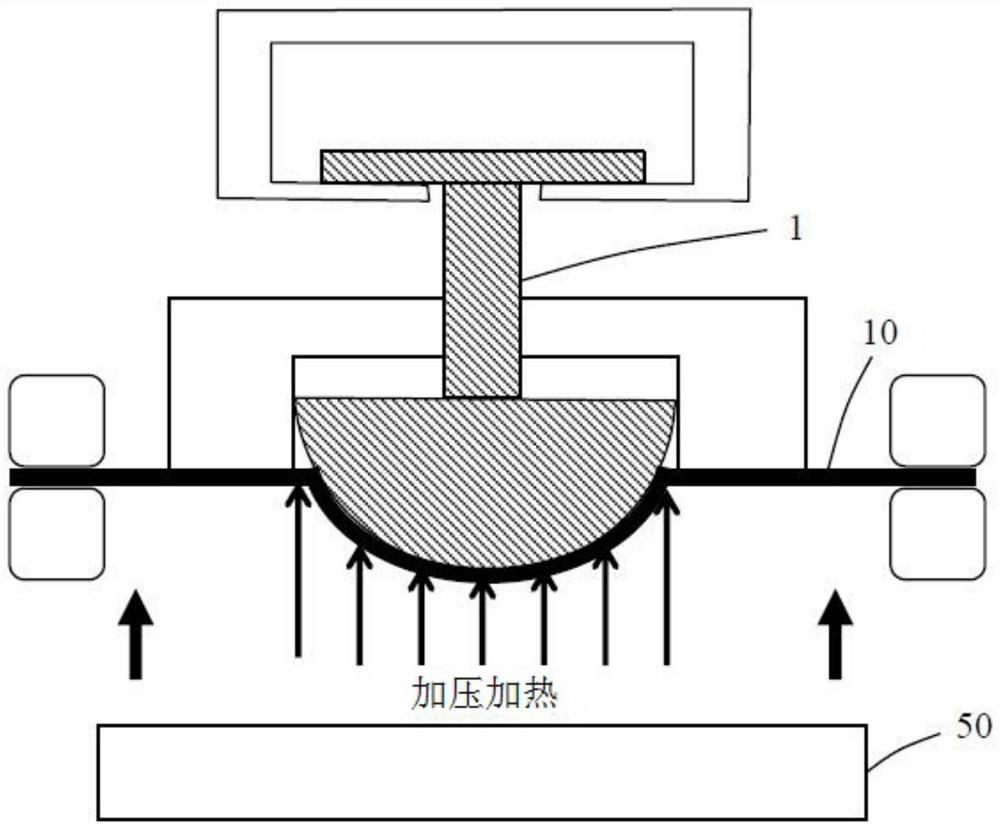

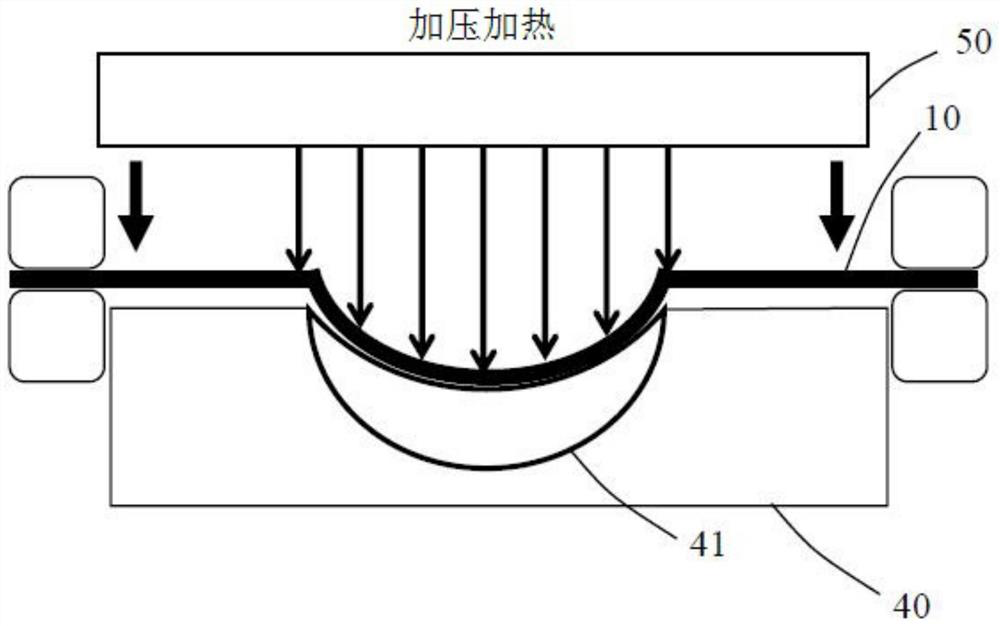

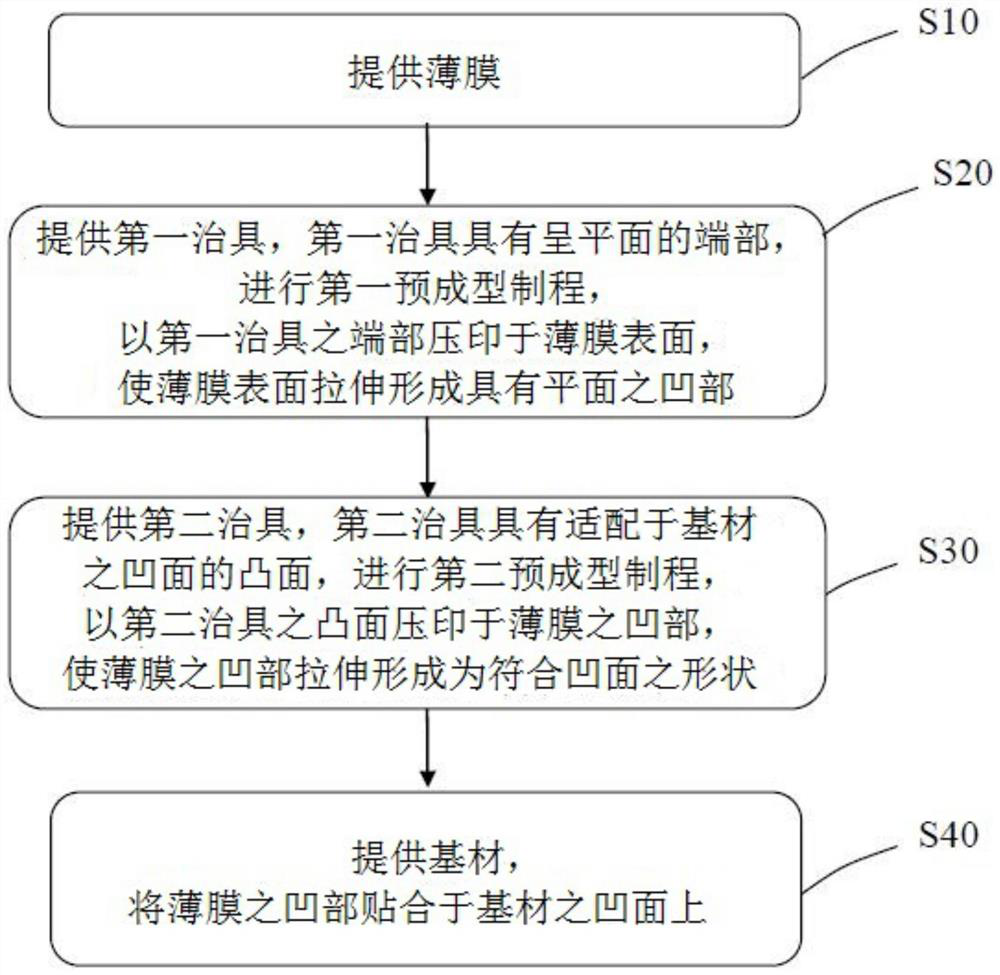

Concave surface attaching method

ActiveCN114734620AReduce total strainDoes not affect optical propertiesDomestic articlesThin membraneConcave surface

The invention relates to a concave surface attaching method, which is suitable for attaching a thin film to a concave surface of a base material, and is provided with a first jig and a second jig, the first jig is provided with a planar end part, the second jig is provided with a convex surface matched with the concave surface, a first pre-forming process is firstly carried out, the end part of the first jig is imprinted on the surface of the thin film, and a second pre-forming process is carried out. A second pre-forming process is carried out, the convex surface of a second jig is embossed on the concave part of the thin film, the concave part of the thin film is stretched to form a shape conforming to the concave surface, and finally, the concave part of the thin film is attached to the concave surface of the base material; according to the invention, two pre-forming processes are added before the laminating process, so that the total dependent variable at the center of the thin film can be greatly reduced.

Owner:INTERFACE TECH CHENGDU CO LTD +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com