Preparation method of nanometer metal grating and nanometer metal grating

A kind of nano metal, grating technology, applied in diffraction grating, opto-mechanical equipment, photoengraving process of pattern surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

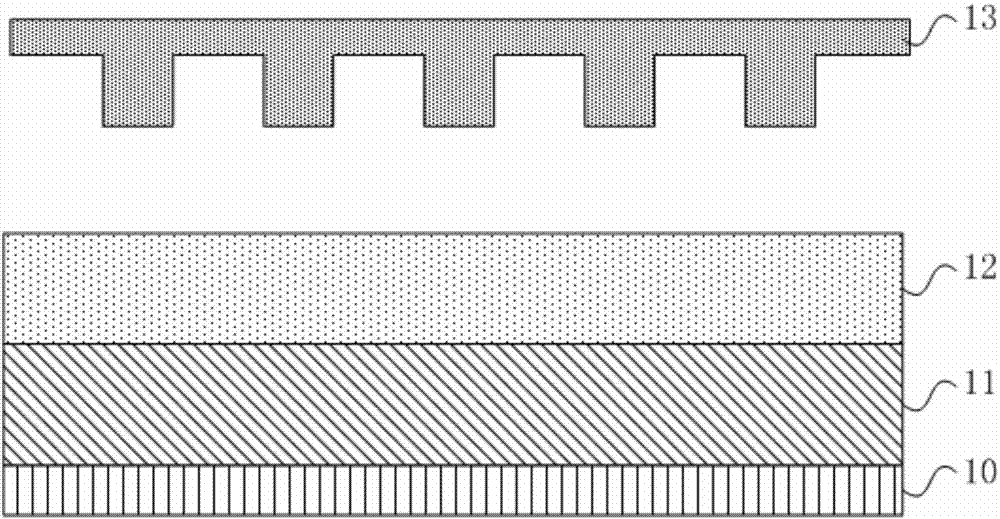

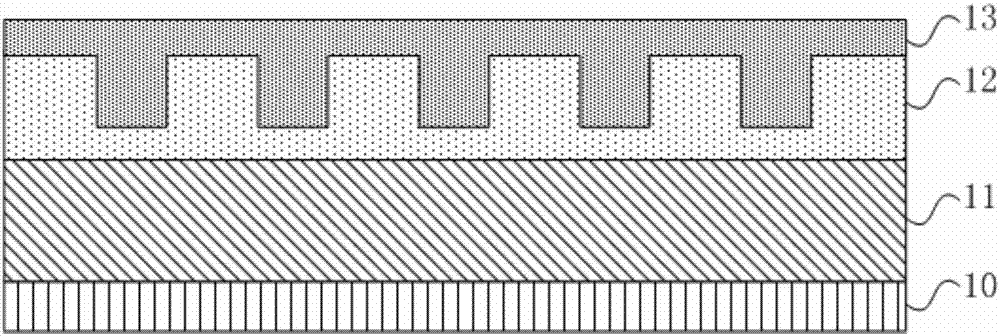

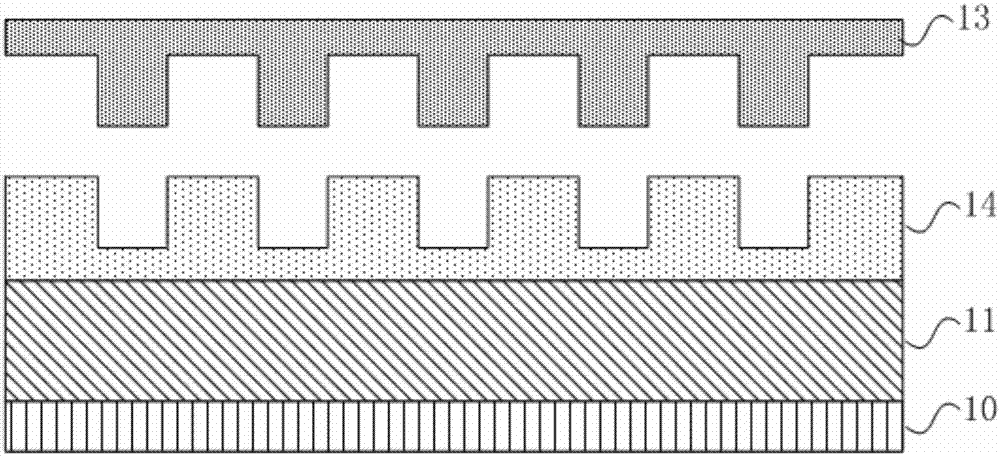

[0028] The preparation method of the nano-metal grating and the specific implementation of the nano-metal grating provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0029] As mentioned in the background technology, after the residual imprinting glue is removed by oxygen ashing, if the process time is longer or the air flow control is inaccurate, oxygen will react with the exposed metal Al on the bottom layer to form a dense metal oxide film , and the metal oxide film is difficult to be etched, resulting in the impossibility of the subsequent etching process and the inability to form the nanometer metal grating. In view of this, the present invention provides a method for preparing a nano-metal grating, which increases the process time in the step of removing the residual imprinting glue, so that oxygen reacts with the exposed metal, and a dense oxide film is formed, and the oxide film is used to The film acts as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com