A Method for Reducing Power Consumption of Transparent Conductive Oxide Thin Film Devices Using Microstructure Regulation

An oxide thin film, transparent and conductive technology, which is applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of limiting the application range of TCO thin film, affecting the stability of devices, and affecting the stability of TCO thin film. Achieve the effect of reducing Joule heat, reducing power consumption and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

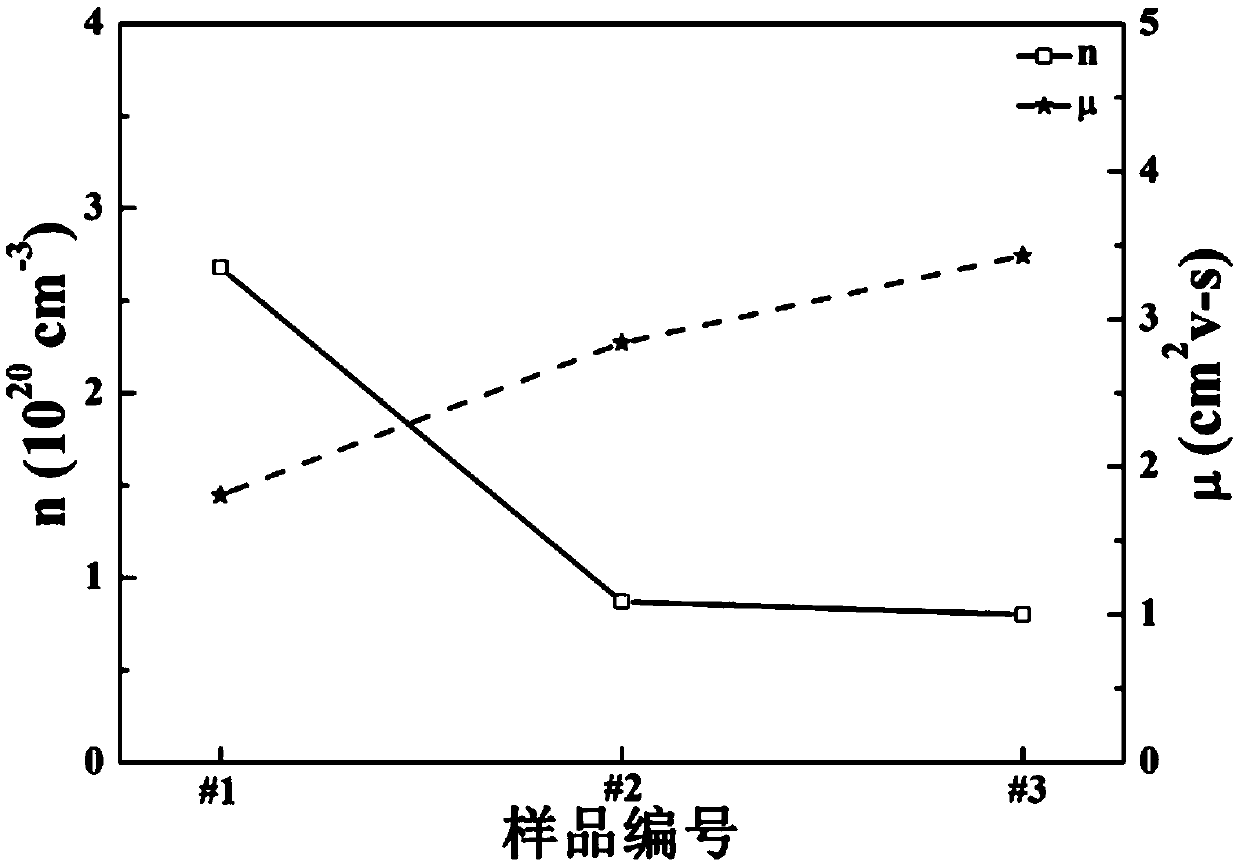

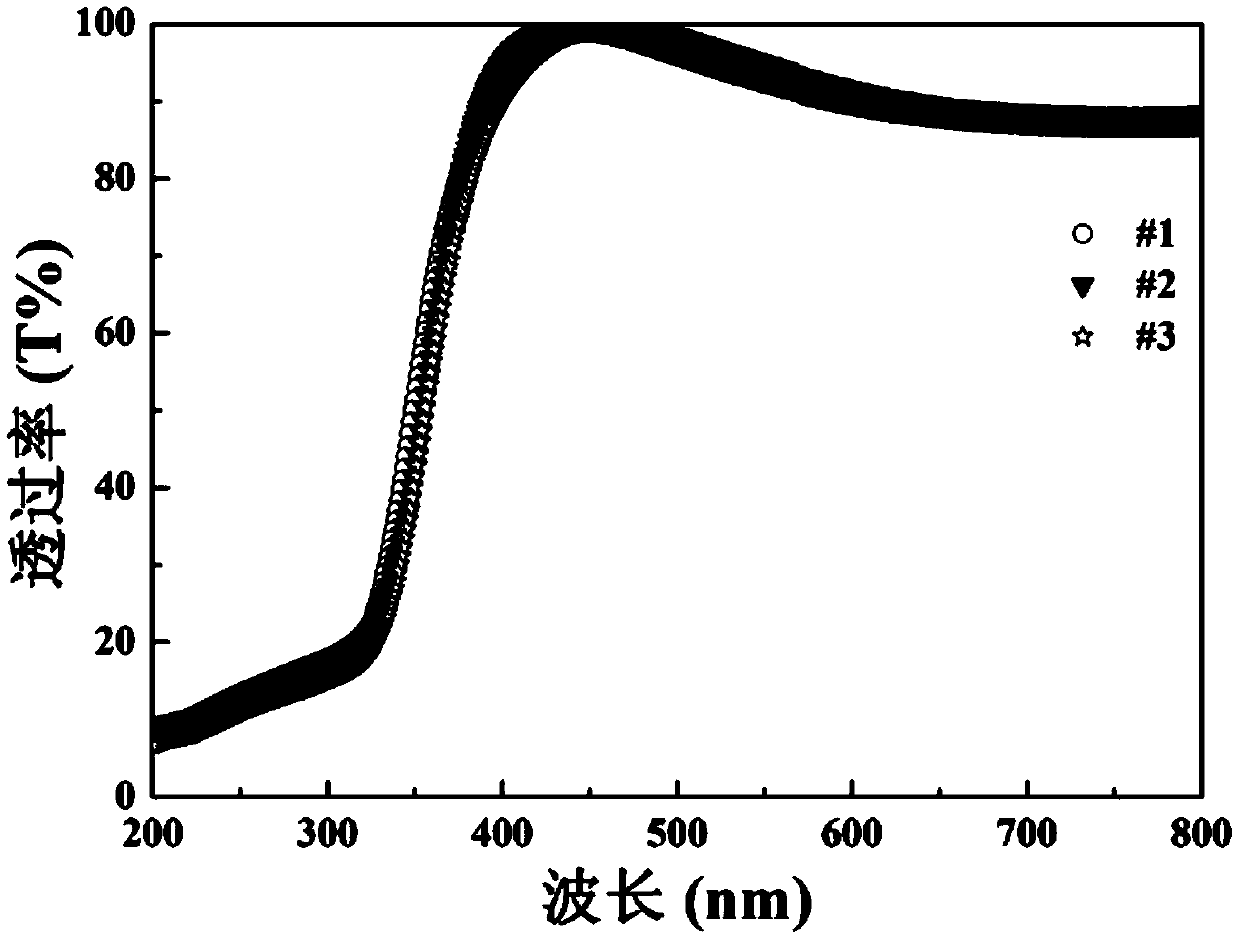

Embodiment 1

[0026] The specific steps of this embodiment are as follows:

[0027] S100 Substrate pretreatment.

[0028] In this embodiment, the substrate is made of quartz glass whose length and width are both 2 cm.

[0029] This step is specifically as follows: sequentially using acetone, absolute ethanol, and deionized water to ultrasonically clean the quartz glass, and then using high-purity nitrogen to dry the quartz glass to obtain a pretreated clean substrate.

[0030] S200 uses magnetron sputtering coating method to prepare TCO film on the substrate.

[0031] This step is specifically:

[0032] The S210 target is installed on the base of the magnetron sputtering coating equipment, and the pretreated clean substrate is glued to the base of the magnetron sputtering coating equipment with conductive adhesive. In this embodiment, the target material is AZO target material from Beijing Zhongnuo New Materials Co., Ltd., the purity of which is 99.999%, and the doping ratio of Al in ZnO...

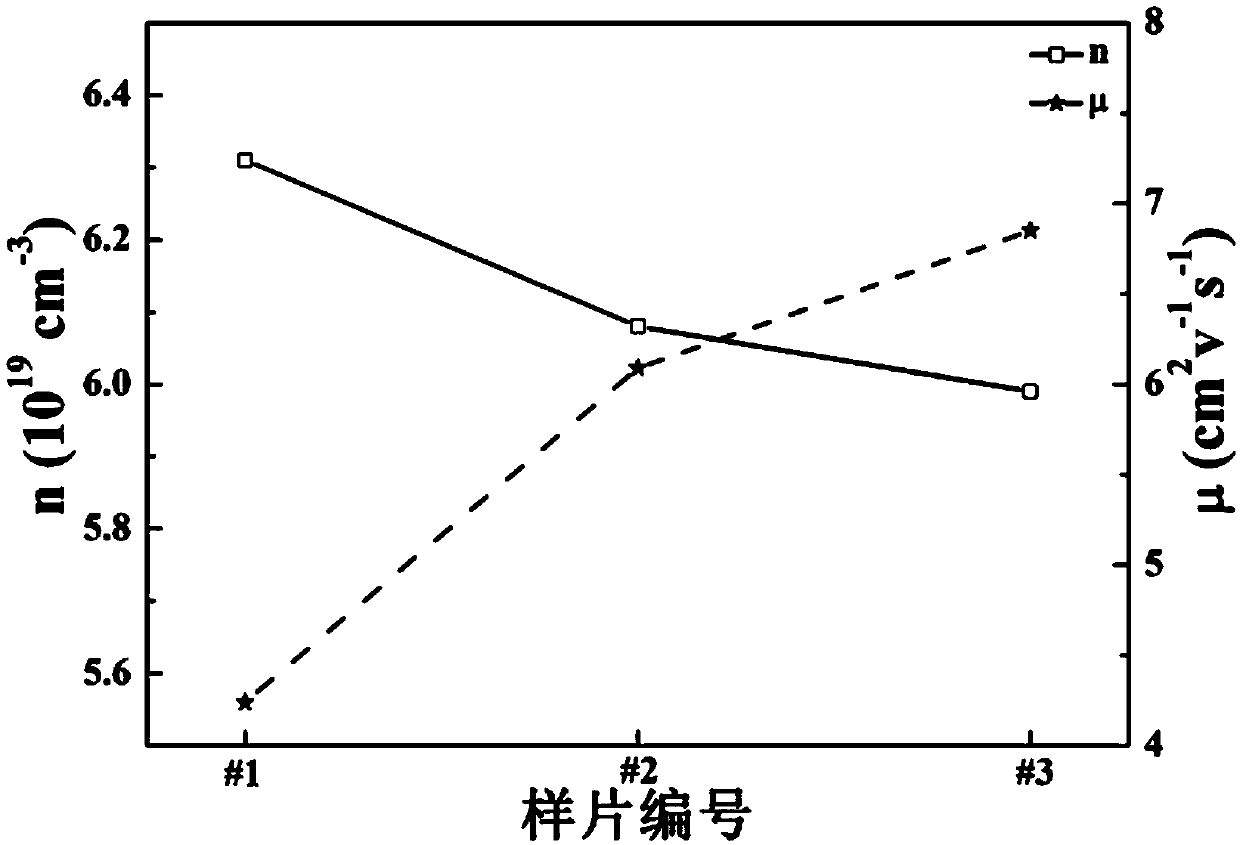

Embodiment 2

[0054] The specific steps of this embodiment are as follows:

[0055] S100 Substrate pretreatment.

[0056] This step is specifically the same as that of Embodiment 1, and will not be repeated here.

[0057] S200 uses the magnetron sputtering coating method to prepare TCO thin film samples on the substrate.

[0058] This step is specifically:

[0059] The S210 target is installed on the base of the magnetron sputtering coating equipment, and the pretreated clean substrate is glued to the base of the magnetron sputtering coating equipment with conductive adhesive. In this example, the target material is the FTO target material of Beijing Zhongnuo New Materials Co., Ltd., its purity is 99.999%, and F is in SnO 2 The doping ratio in is 5 at.%.

[0060] S220 Close the chamber of the magnetron sputtering coating equipment, turn on the mechanical pump and the molecular pump, and evacuate the chamber until the air pressure in the chamber is lower than 4.0×10 -4 Pa.

[0061] S23...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com