Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Does not affect heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature decarburization-preventing coating material used for spring steel

ActiveCN102453794AAlleviate the problem of high temperature decarburizationImproved decarburization sensitivitySpring steelHot Temperature

The invention relates to a coating material used for heat treatment technology before rolling a billet of spring steel. The coating materials is directly sprayed onto the billet at the temperature below 500 DEG C and has good blocking property, a dense microcrystal glass layer is formed on the surface of the billet at a high temperature section, mutual diffusion of carbon and nitrogen can be effectively blocked; meanwhile, ingredients in the coating can obviously reduce high temperature activity of carbon atoms in steel, improve decarburization sensibility of the steel and effectively alleviate high temperature decarburization problem of the spring steel, and the dense microcrystal glass layer can naturally strip off in a subsequent cooling process. The coating can effectively prevent decarburization problem of the spring steel in a heat treatment process at the temperature of 950-1150 DEG C, self-stripping capability is high, the coating is safe and convenient to use, heating is not influenced, cost is low, and no pollution is produced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

High-temperature protective coating for nickel base alloy steel

ActiveCN104017397ASolve the problem of difficult descalingReduced diffusion rateCoatingsSodium carboxymethylcelluloseAluminium

The invention relates to a high-temperature protective coating for a hot-rolling heat pretreatment process of nickel base alloy steel. The coating powder comprises the following components: 20%-40% of Al2O3, 10%-30% of SiO2, 10%-20% of MgO, 10%-20% of TiO2, 5%-15% of CuO, 5%-15% of Y2O3, 0%-1% of Na2O and 0%-1% of K2O, wherein Al2O3 and SiO2 are from one or two of Kyanite and aluminum ash, and TiO2 is from rutile ore. A binder in the coating is mixed from one or more selected from sodium silicate, potassium silicate and silica sol, and a dispersant is carboxymethyl cellulose. For usage, the powder and water are mixed and milled into a slurry according to the weight ratio of 2:1; the slurry is added with the binder accounting for 5-10 wt.% of the slurry, and the dispersant accounting 1-2 wt.% of the slurry; the mixture is well mixed and milled to size of 200-600 mesh to obtain the coating. The coating can be directly sprayed on billet below 800 DEG C, and can effectively solve the problem of hard descaling in heat treatment of nickel base alloy at 1200-1350 DEG C.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

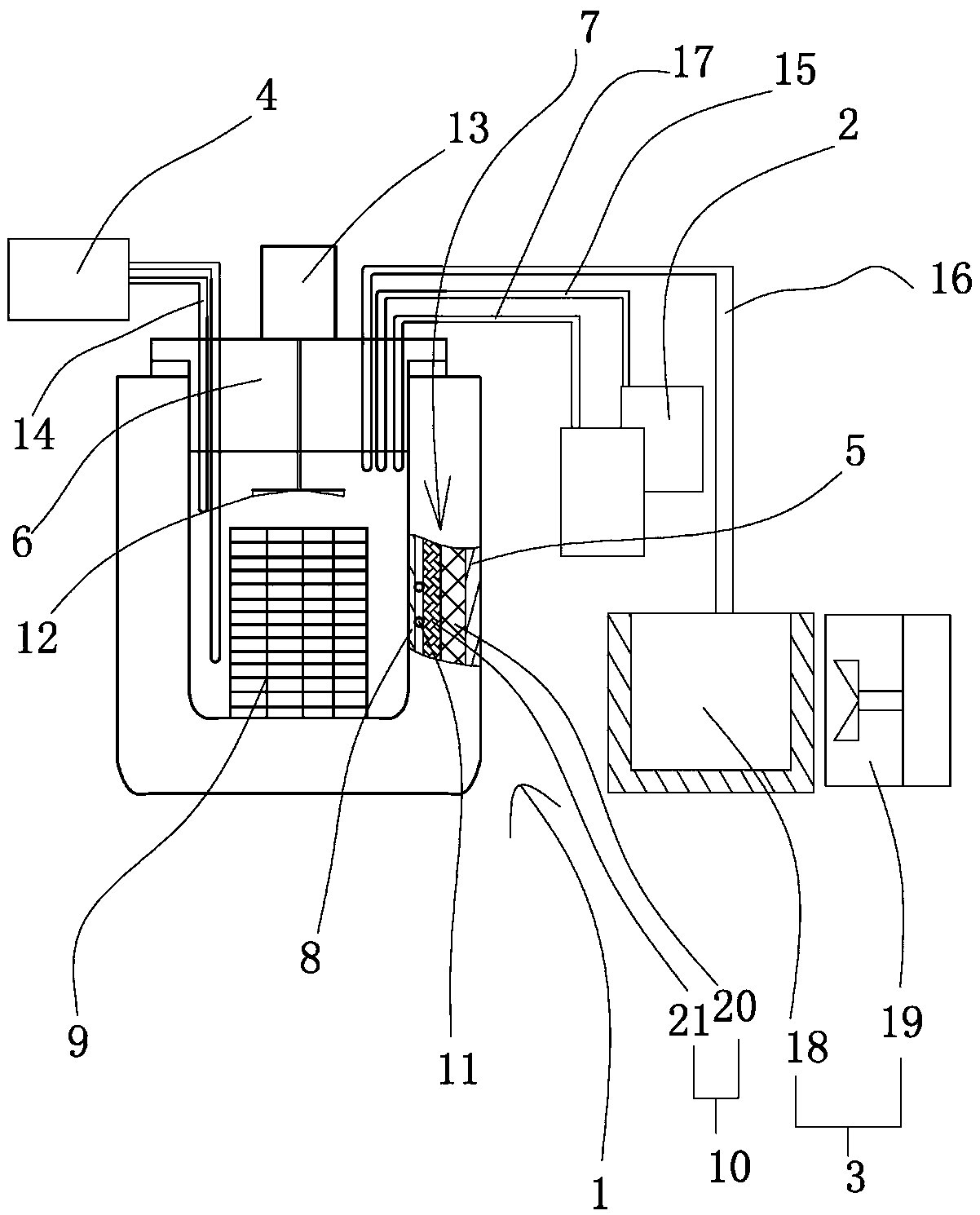

Multi-functional water heating machine and work method thereof

InactiveCN102966998ASmall footprintStrong mobilityLighting and heating apparatusElectric heating systemHeat sinkWater pipe

The invention relates to the heating field, in particular to a multi-functional water heating machine and a work method thereof. The multi-functional water heating machine comprises a water storage tank, a water pump, a heater, a first water pipe, a heat radiator, a second water pipe, a third water pipe, a mattress, a fourth water pipe and a circuit board, wherein a water filling port is formed at the top of the water storage tank; the water pump and the heater are respectively connected with the circuit board; the third water pipe is arranged in the mattress; the water storage tank and the heater are respectively connected with the water pump; the heater is connected with the heat radiator; and the heat radiator and the third water pipe are respectively connected with the second water pipe. The work method comprises the following steps: in heating, radiating heat by the heat radiator so as to heat a room; heating the room through the heat radiation of the third water pipe; and delivering water evaporating in the water storage tank to the room through the water filling port so as to increase the humidity of the room. The multi-functional water heating machine provided by the invention has multiple functions, and can be used for indoor heating, bedding heating as well as room humidity maintaining.

Owner:吕学广

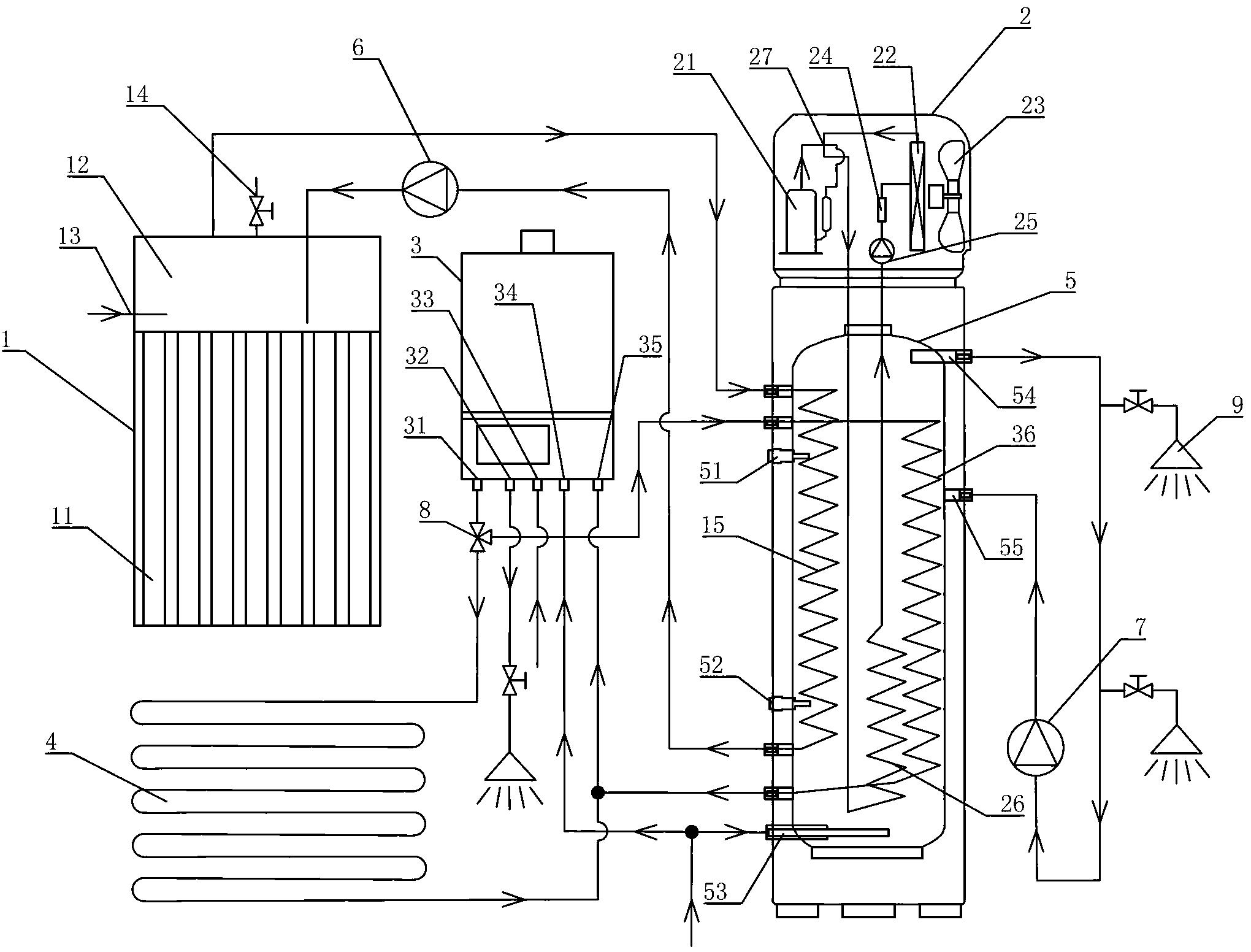

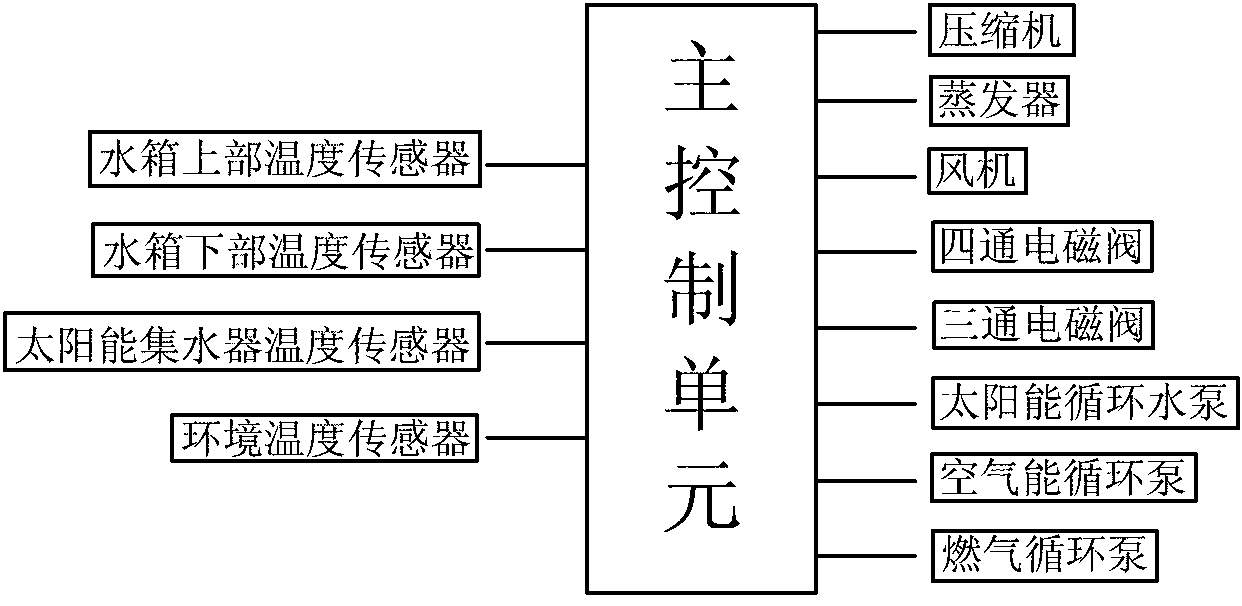

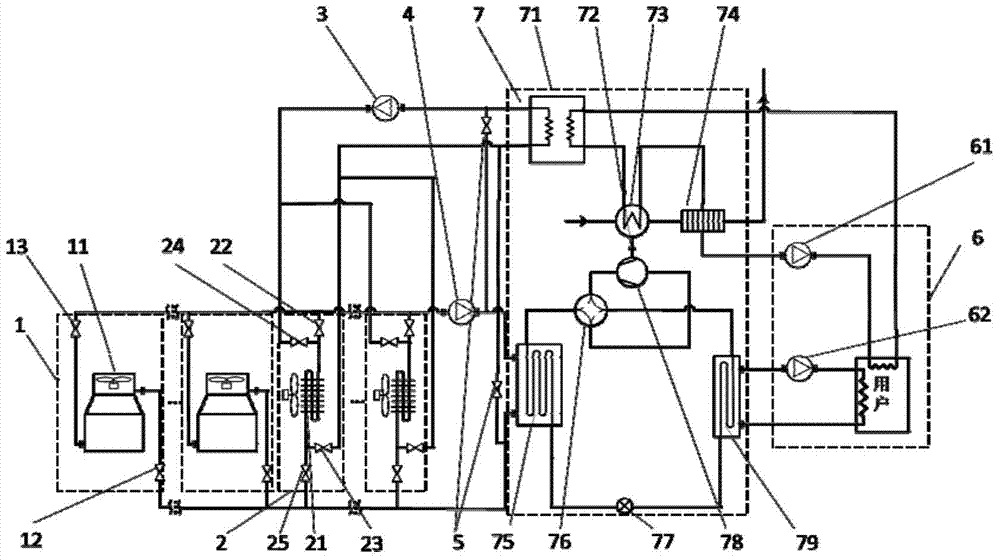

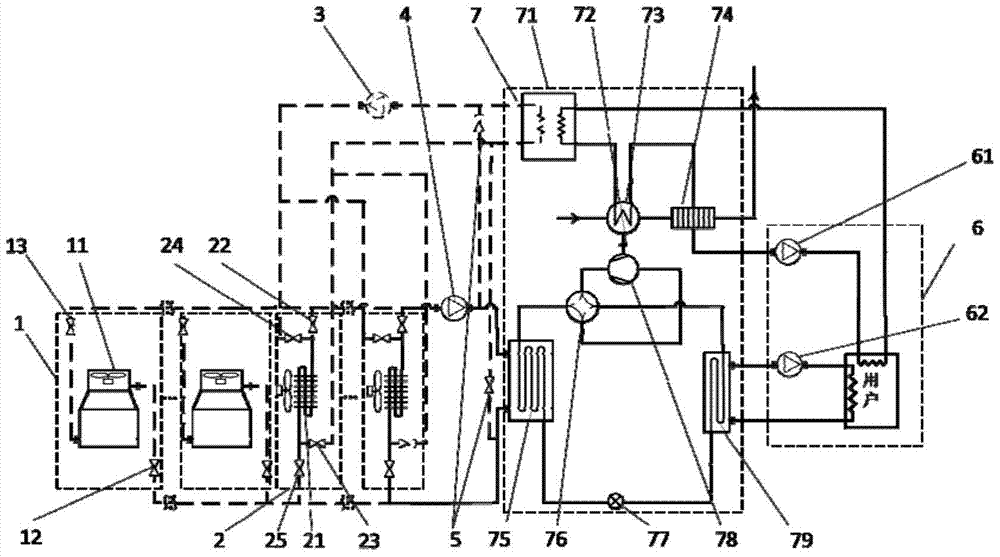

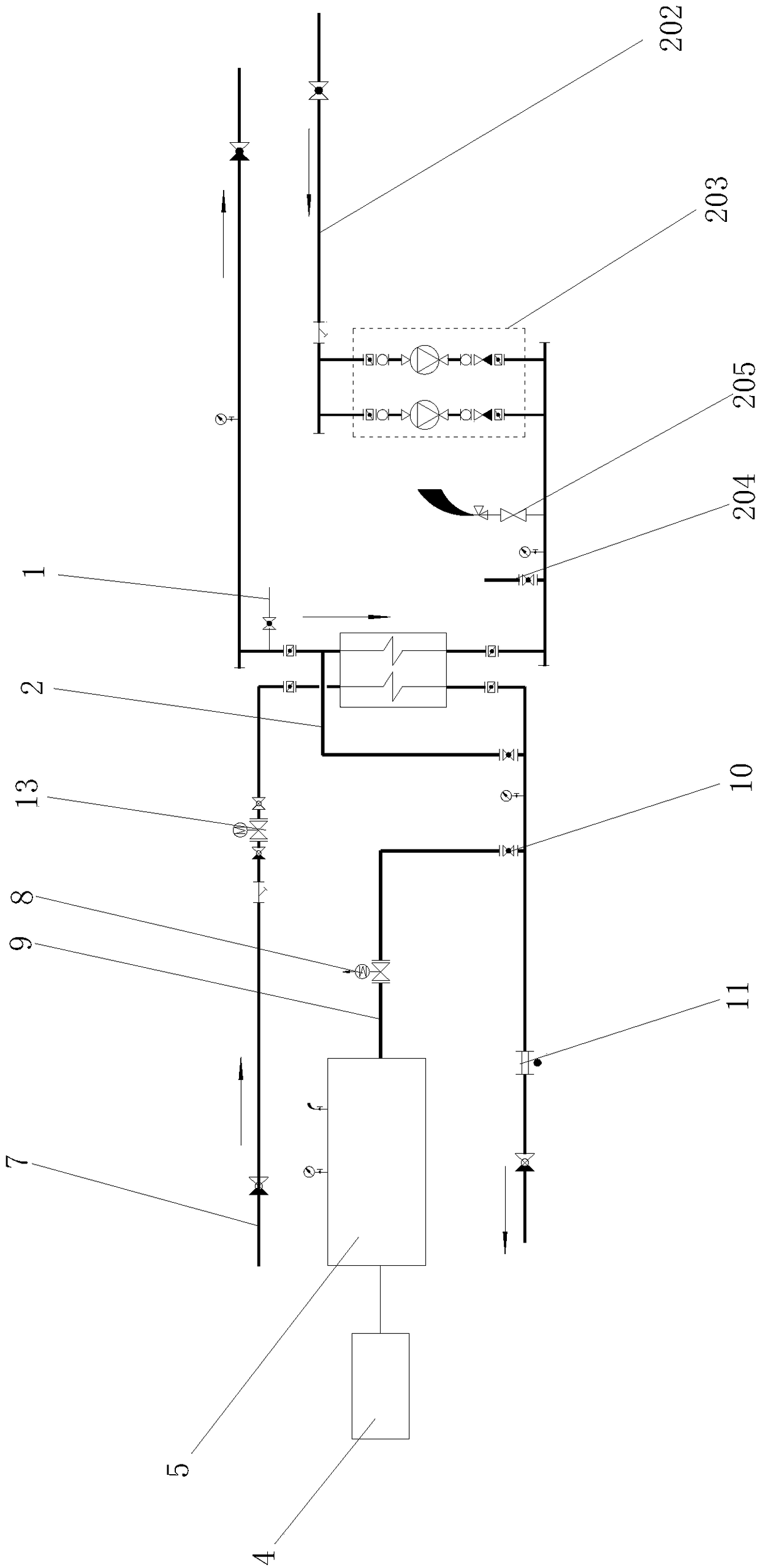

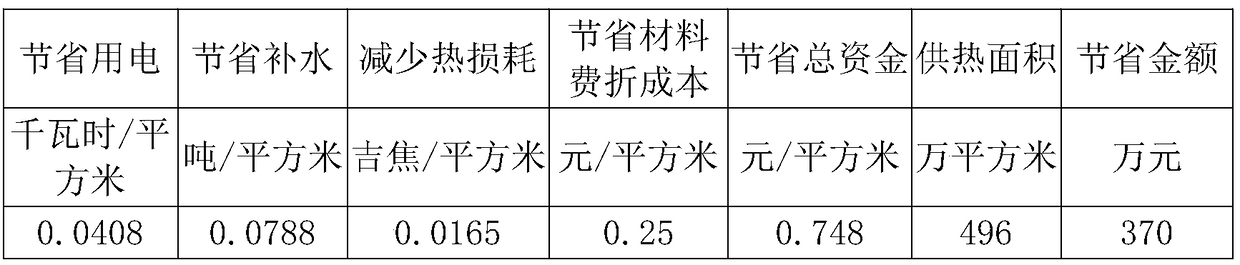

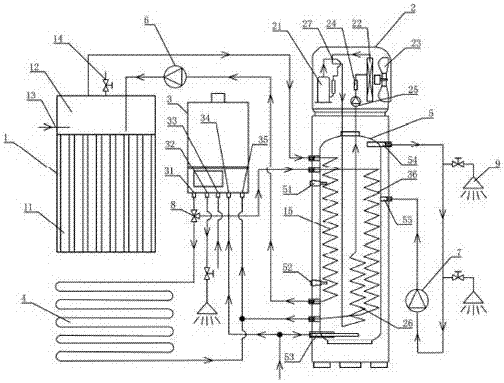

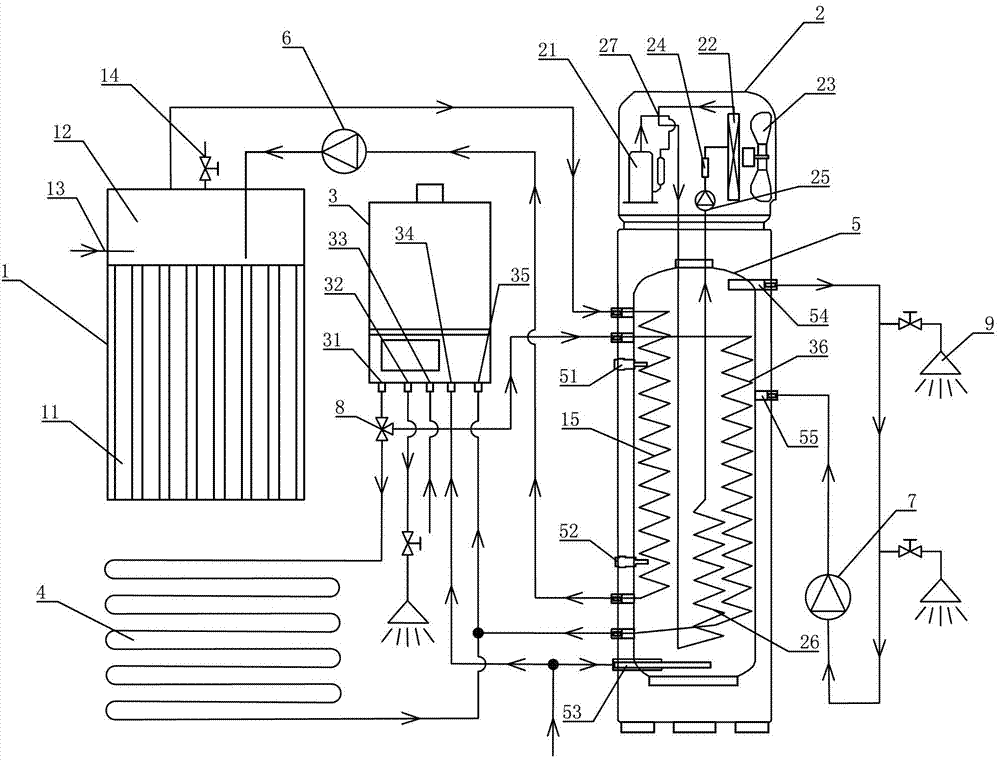

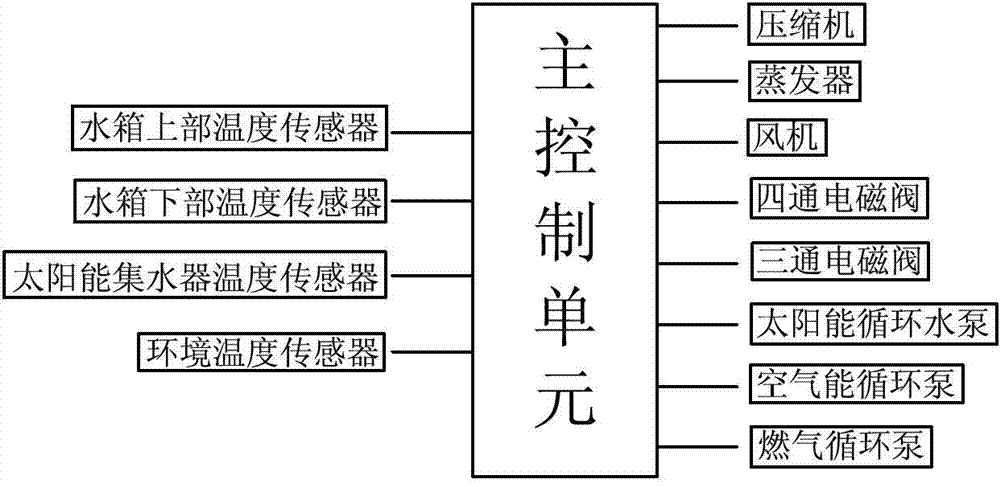

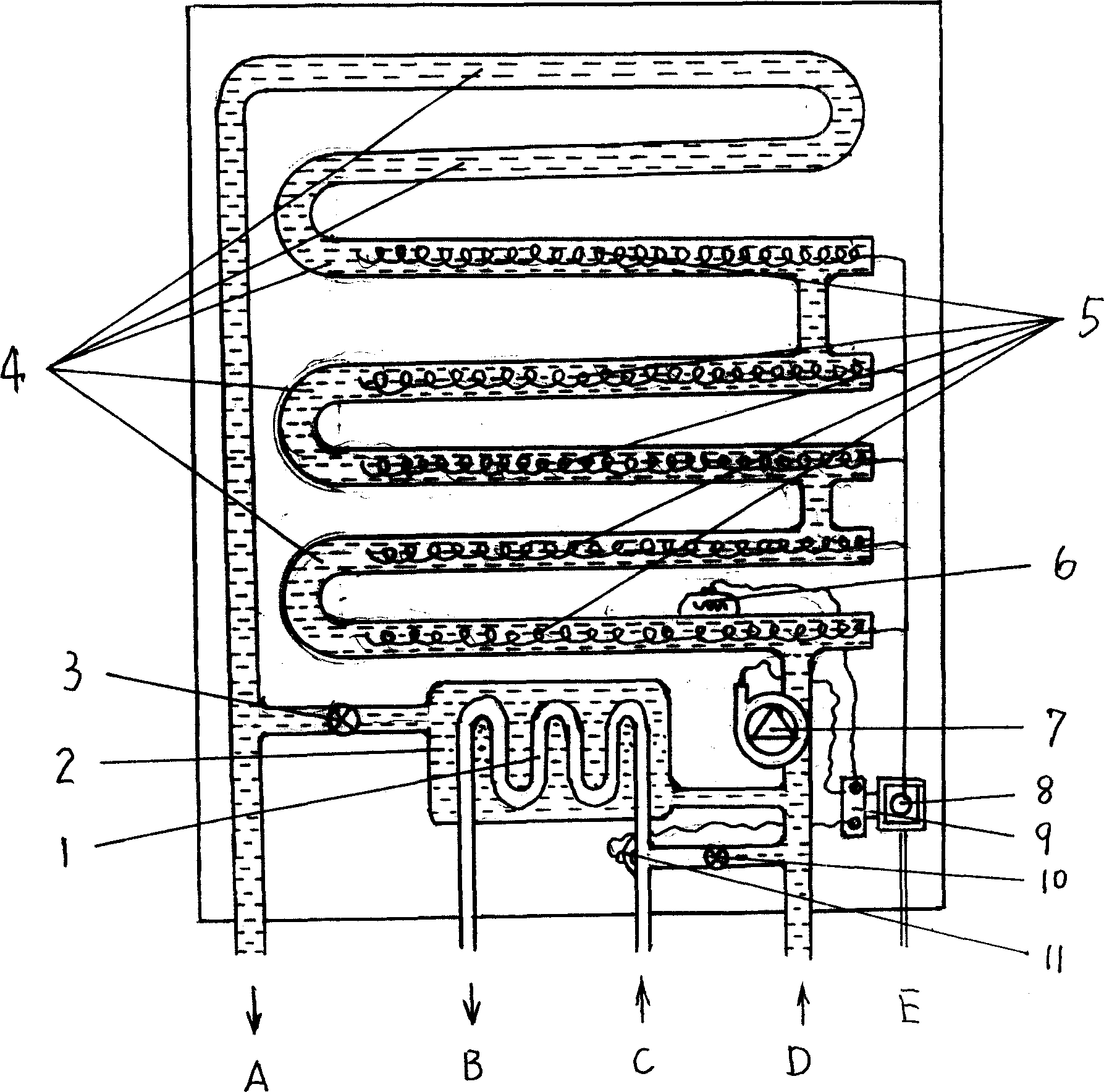

Multi-energy integrated water heating system

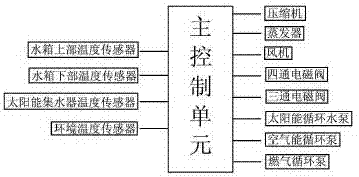

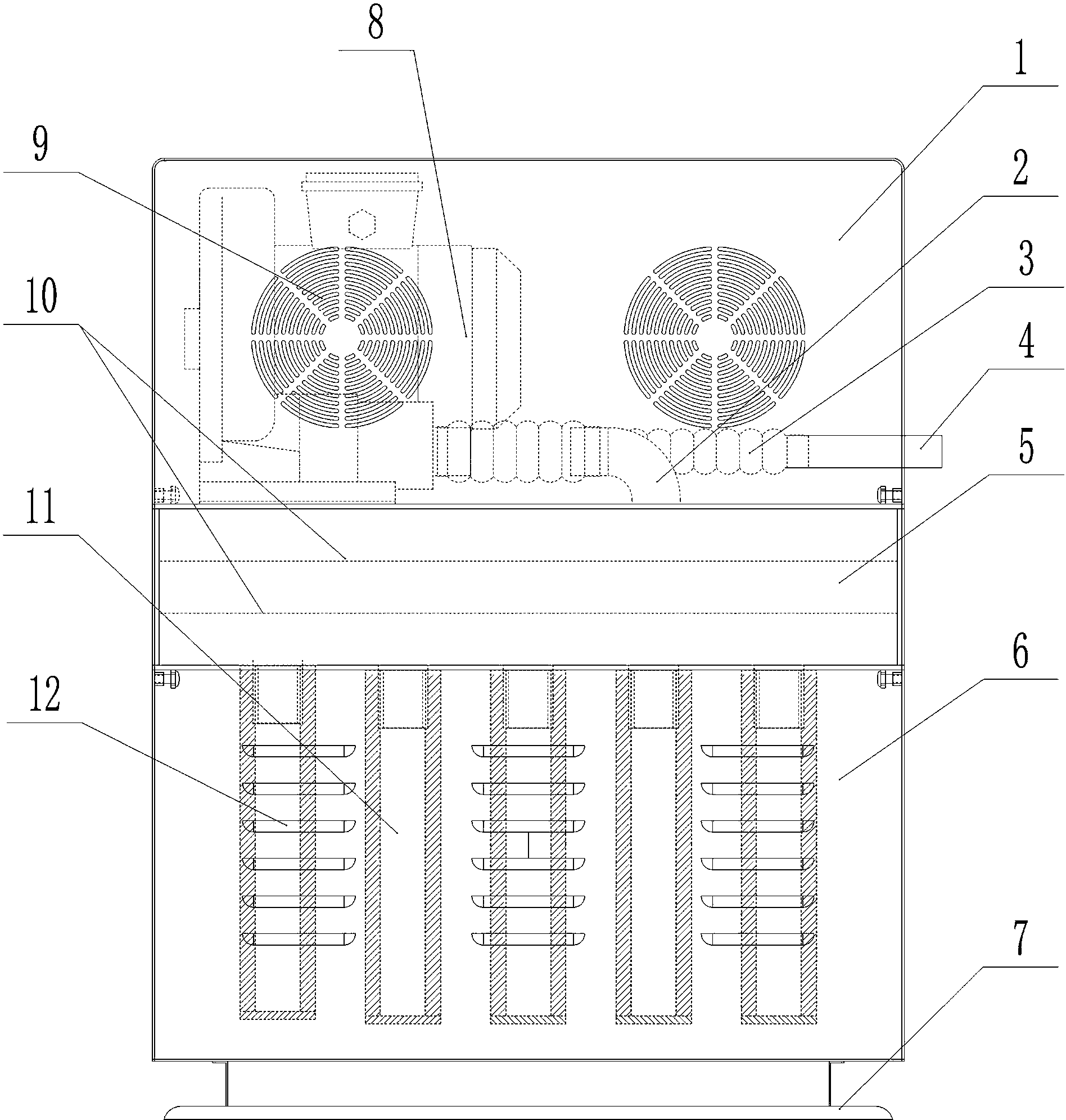

ActiveCN103017245ADoes not affect heatingImprove energy utilizationFluid heatersSolar heat devicesSolar waterCirculator pump

The invention discloses a multi-energy integrated water heating system, which comprises a solar heating device, a wall-hung gas boiler heating device, an air energy heating device, a water tank and a master control unit. A solar heat exchange pipe coil is connected with a water inlet pipe and a water outlet pipe of a solar water collector to form a water circulation loop. A wall-hung boiler heat exchange pipe coil is connected with a water inlet pipe and a water outlet pipe of the wall-hung gas boiler heating device to form a water circulation loop. The solar heat exchange pipe coil, the wall-hung boiler heat exchange pipe coil and a condenser of the air energy heating device are arranged in the water tank. The output end of the master control unit is electrically connected with a solar circulating water pump, an air energy circulating pump and a gas circulating pump. According to the system, the advantages of a solar water heater, an air energy heat pump water heater and a wall-hung gas boiler water heater are integrated, and the shortcomings of the solar water heater, the air energy heat pump water heater and the wall-hung gas boiler water heater are overcome, so that the system is efficient and energy-saving under the condition of ensuring the use of hot water; and in addition, the wall-hung gas boiler heating device is connected with a floor heating heat exchange system, so that the utilization rate of energy is increased.

Owner:法罗力热能设备(中国)有限公司

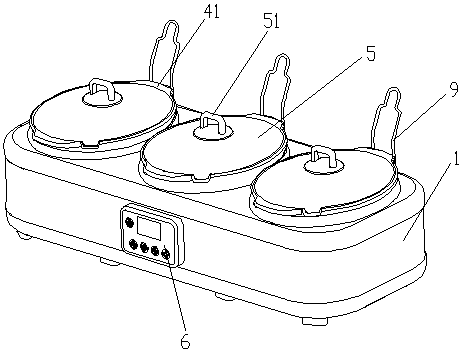

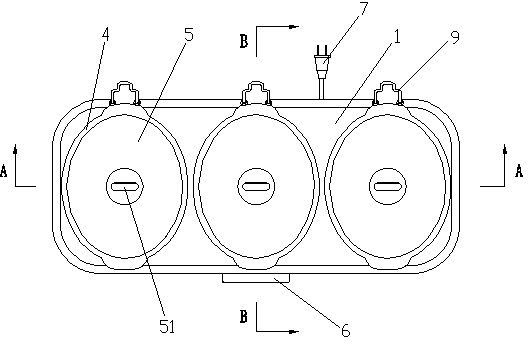

Slow stew pot with computer control panel

The invention discloses a slow stew pot with a computer control panel. The slow stew pot with the computer control panel comprises a pot shell body provided with a power line, wherein the computer control panel is arranged on the pot shell body, the computer control panel and the power line form an electricity loop, and at least two pot cavities are formed in the cooker shell body in parallel. A pot aluminum liner is assembled in each cooker cavity, a heat-insulating ring is formed between each cooker aluminum liner and the cooker shell body, a pot ceramic liner is assembled in each pot aluminum liner, and the outer circumferential surface and the bottom wall of each pot ceramic liner and the inner circumferential surface and the upper bottom surface of each pot aluminum liner are respectively provided with a heating cavity which wraps the pot ceramic liner and takes air as a heat conductive medium. A heating element is installed on each pot aluminum liner. The computer control panel is electrically connected with the heating elements. A pot cover which is matched with each pot ceramic liner is assembled in the position of an opening of each pot ceramic liner. The slow stew pot with the computer control panel can stew different kinds of food simultaneously. The computer control panel can switch pot liners which are controlled by the computer control panel and can conveniently and accurately control the stewing temperature and the stewing time, and therefore cooking is made to be easier.

Owner:宁波江东晟利工业产品设计有限公司 +2

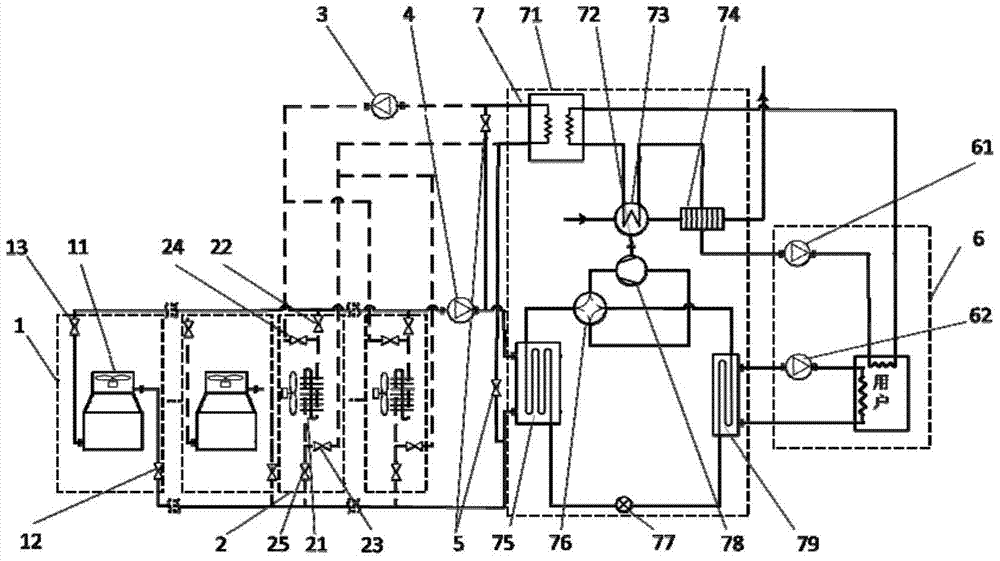

An air source flexible gas heat pump unit and its operating method

ActiveCN105318601BGuaranteed uptimeDoes not affect heatingMechanical apparatusFluid circulation arrangementCooling towerLiquid medium

An air source flexible gas heat pump unit and an operation method thereof belong to the field of heat pumps. The system includes an outdoor unit, a gas heat pump unit, and a user unit. The outdoor unit includes at least two sets of air-cooled heat exchangers, only one less set of cooling towers, valves, the second liquid pump and the first liquid pump; the gas heat pump unit includes two parts: a gas engine and a heat pump unit, and the gas engine includes waste heat heat exchange heat exchanger, engine, flue gas heat recovery heat exchanger, the heat pump part includes a first heat exchanger, a compressor, a second heat exchanger, a four-way valve and a throttle valve, and both the first heat exchanger and the second heat exchanger It is a liquid medium heat exchanger, and the two parts are connected through the linkage shaft between the engine and the compressor; the invention can solve the problems of low operating efficiency of traditional air-cooled gas heat pumps in summer and inability to obtain heat efficiently in winter, and has a great impact on reducing energy consumption and pollution emissions play a huge role.

Owner:TSINGHUA UNIV

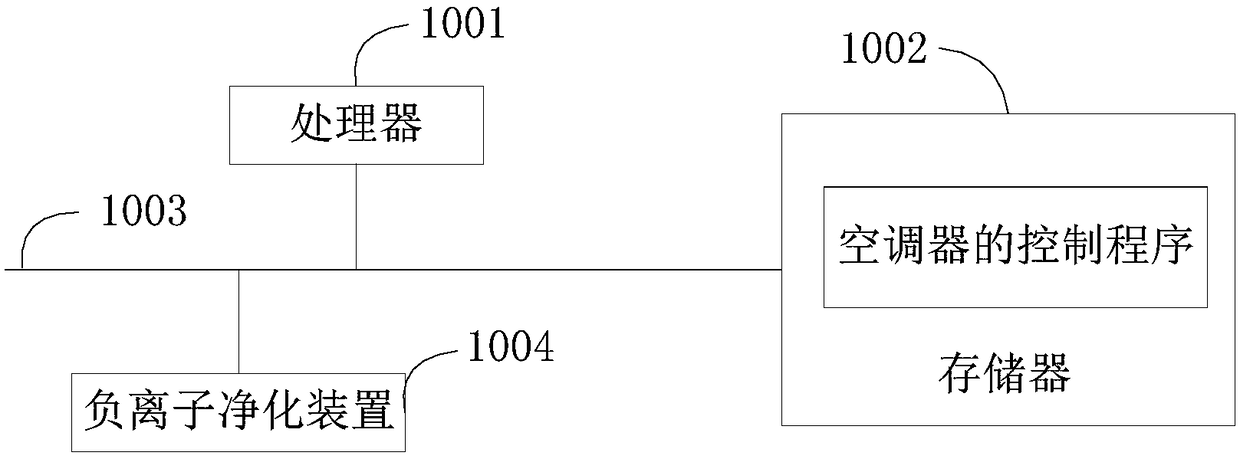

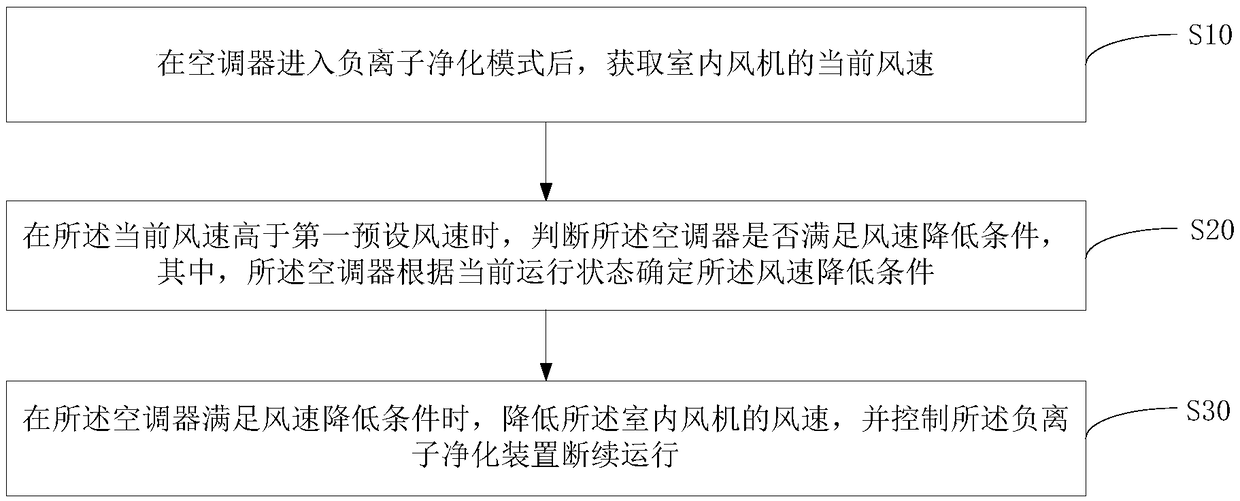

Air conditioner and control method thereof and computer readable storage medium

ActiveCN109084425ADoes not affect refrigerationDoes not affect heatingMechanical apparatusEfficient regulation technologiesWind speedComputer engineering

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Steam pulse washing device and method

PendingCN109186319AShorten cleaning timeEasy to operateFlush cleaningProcess engineeringHeating efficiency

The invention discloses a steam pulse washing device. The steam pulse washing device comprises a first washing device body, a second washing device body and a plate heat exchanger; the first washing device body is connected with the plate heat exchanger; the plate heat exchanger is connected with the second washing device body; and a flushing pipe is connected between the first washing device bodyand the second washing device body. The invention further provides a washing method of the steam pulse washing device. Limescale and impurities adhering to a heat exchange plate can be removed in time under the condition of not dismounting the plate heat exchanger, the circulating heat efficiency of a heat exchange unit is improved, and the blocking removal cost is reduced.

Owner:HUADIAN ENERGY COMPANY LIMITED

Multi-layer ceramic-wood composite heating floor tile and preparing method and laying method thereof

PendingCN111058593AEasy to installHeating up fastLighting and heating apparatusElectric heating systemComposite materialCeramic tiles

The invention discloses a multi-layer ceramic-wood composite heating floor tile which comprises a ceramic tile layer. A wood layer is arranged on the back face of the ceramic tile layer. A heating layer is arranged between the ceramic tile layer and the wood layer. The heating layer comprises a heating chip and a positive and negative electrode connector led out of the heating chip. A wire outletslot is formed in the back face of the wood layer. The heating floor tile is easy and rapid to install and maintain and is installed in the same way as an ordinary floor rapidly and easily, floor heating is realized after the floor tile is laid, and the floor tile is an independent unit and can be replaced conveniently and rapidly.

Owner:JIANGSU D VEO FURNITURE MFG

Green gold glaze ceramic and preparation method thereof

ActiveCN113387578AImprove liquidityGood film formingCeramic materials productionVitrificationTemperature control

The invention relates to a green gold glaze ceramic which comprises a green body and a green gold glaze material, the green gold glaze material is arranged on the surface of the green body, the green gold glaze material comprises calcite, potassium feldspar, black wool soil, aluminum ore, plant ash, albite, quartz and agate, and the glaze material has good fluidity and film-forming property, is reduced in temperature sensitivity, is not sensitive to small-range temperature fluctuation, and low in vitrification temperature and can complte vitrification at 1230 DEG C, stable temperature rise can be realized during firing molding, temperature rise speed is slow, temperature control by adopting a mixed carbon paste cover scattering method is adopted to guarantee stable temperature rise speed, and the problems of high temperature requirement and difficult firing during firing of the green gold glaze ceramic can be solved.

Owner:河南弘宝汝瓷坊有限公司

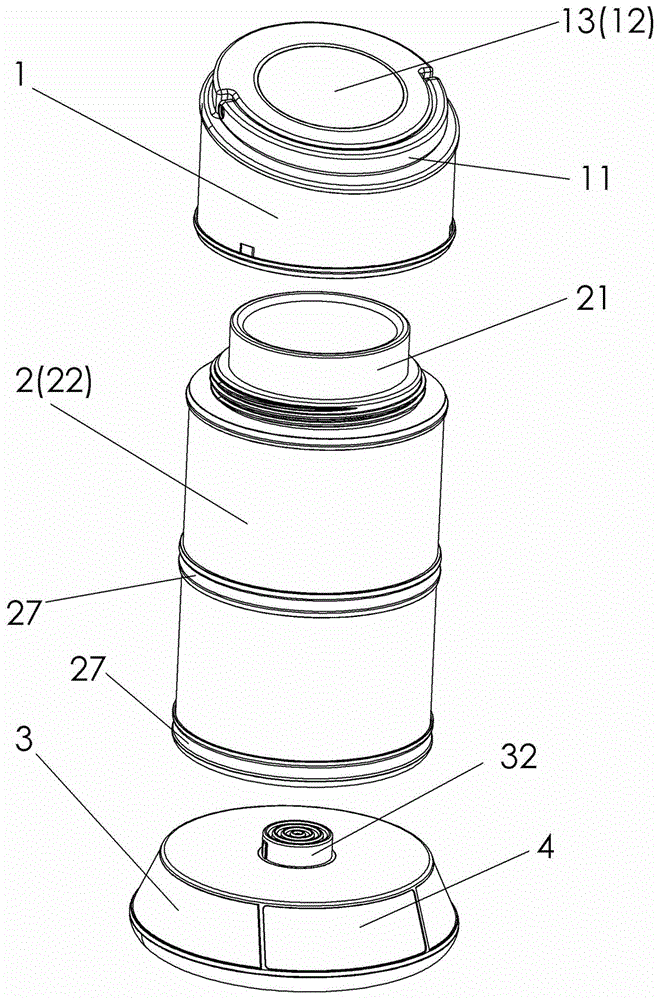

Quick-heating type health care kettle

InactiveCN105919399AIncrease the heating surfaceEvenly heatedCooking-vessel lids/coversWarming devicesFood materialMechanical engineering

The invention relates to a health care kettle, in particular to a quick-heating type health care kettle. The quick-heating type health care kettle comprises a kettle body, and the kettle body comprises a ceramic inner container and a shell. The ceramic inner container comprises a bottom wall and a side wall. A bottom wall heating body is arranged on the outer side wall of the bottom wall. A side wall heating body is arranged on the outer side wall of the side wall and extends spirally on the outer side wall of the side wall. The quick-heating type health care kettle has the advantages that the health care kettle is lightweight and portable; food materials in the ceramic inner container are prevented from directly contacting with the bottom wall heating body and the side wall heating body, so that sanitation is guaranteed, and food tastes good; heating speed is increased, cooking time is saved, and production cost is further reduced.

Owner:佛山市顺德区龙江镇旗龙电器有限公司

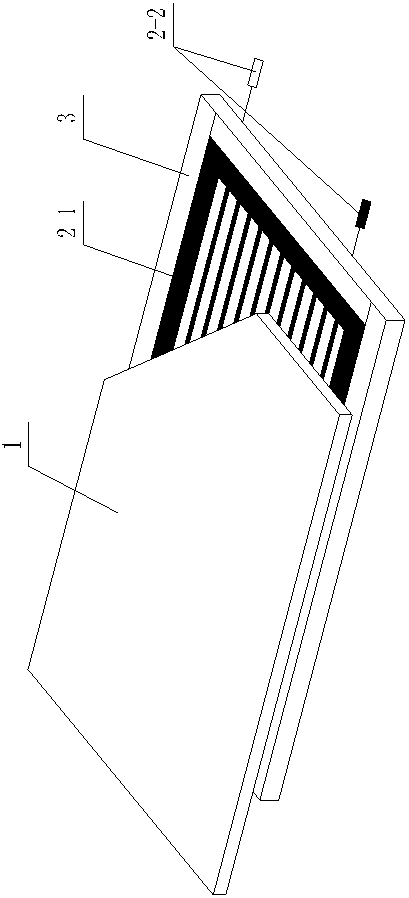

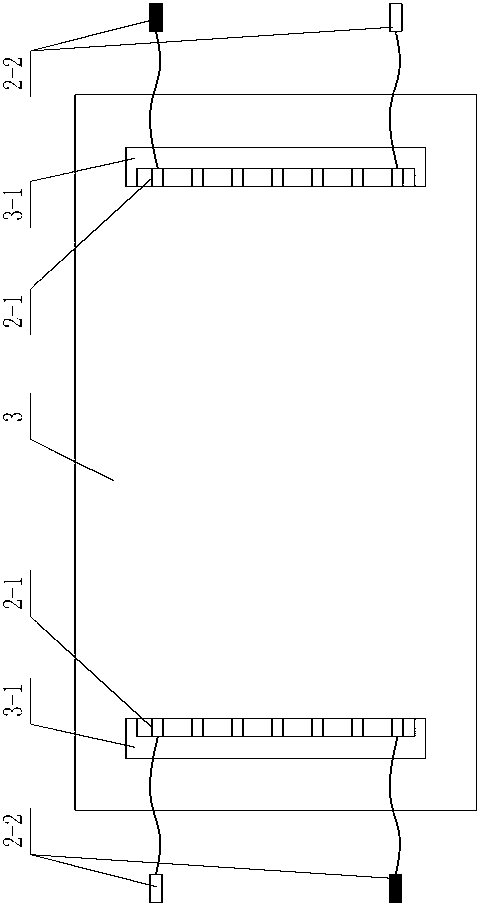

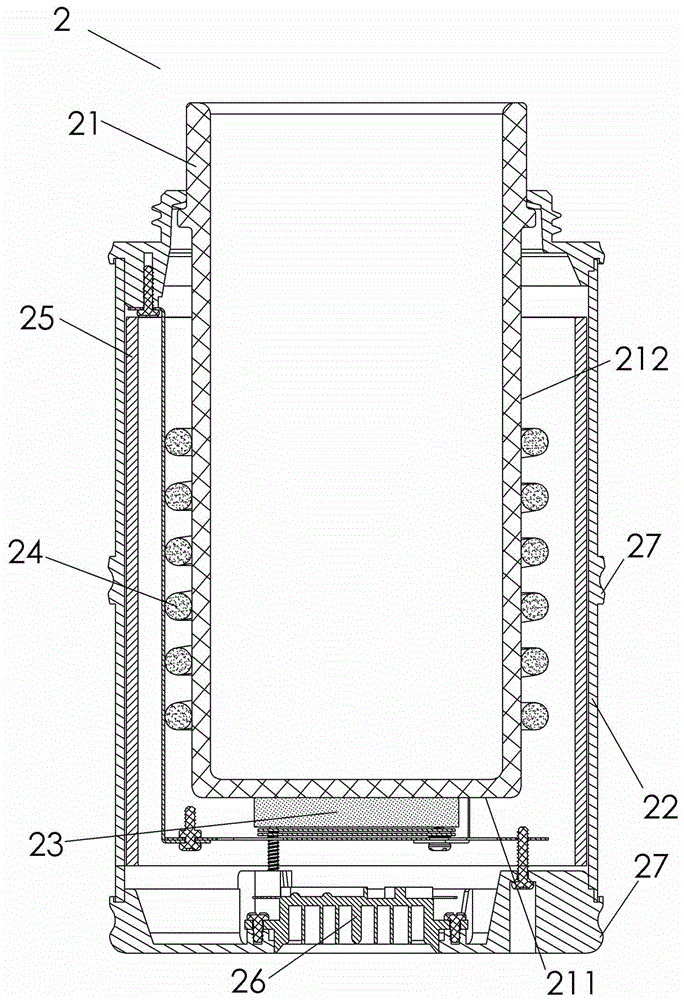

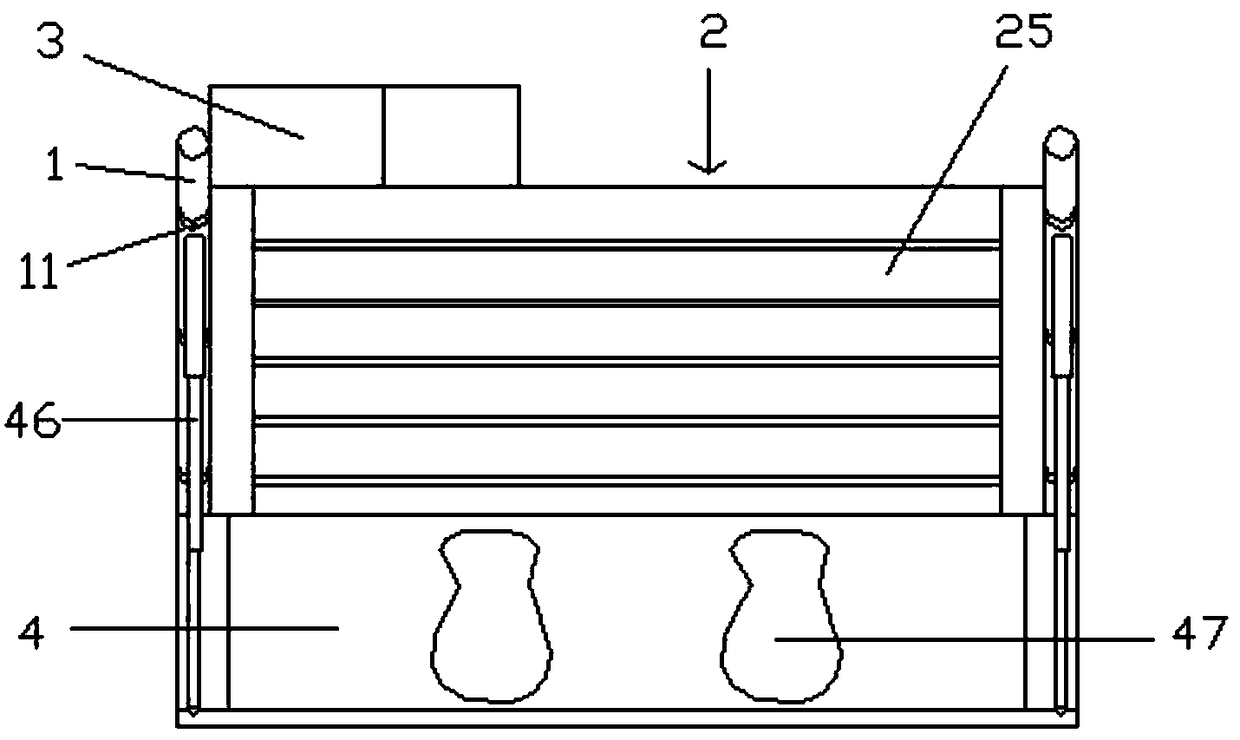

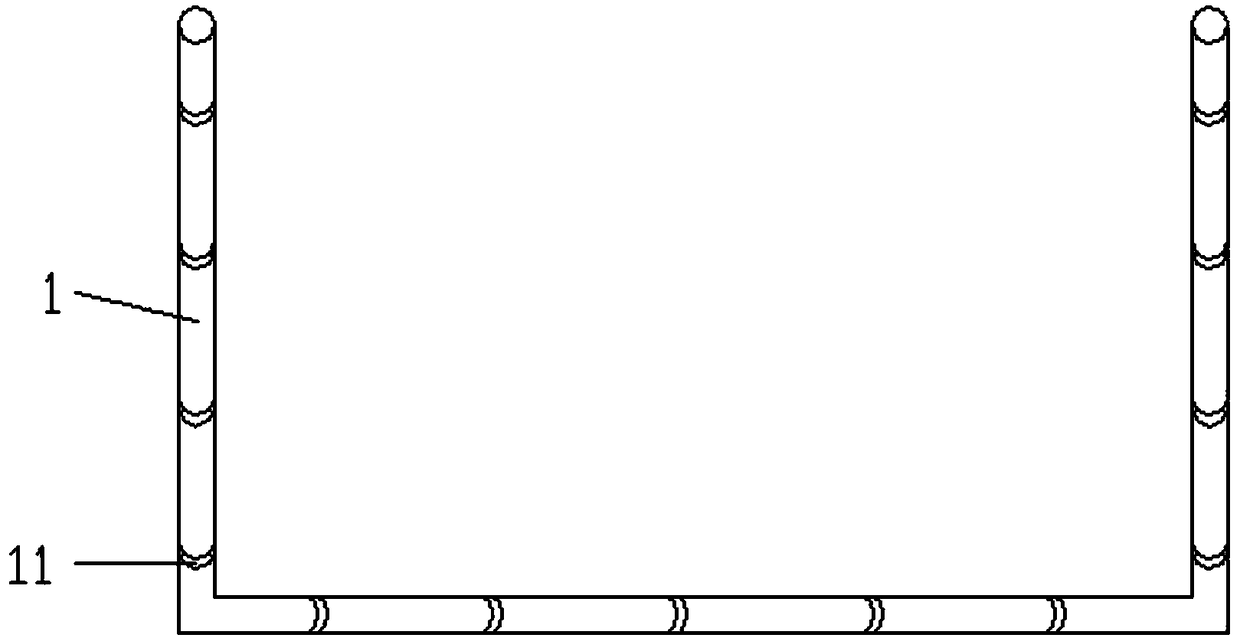

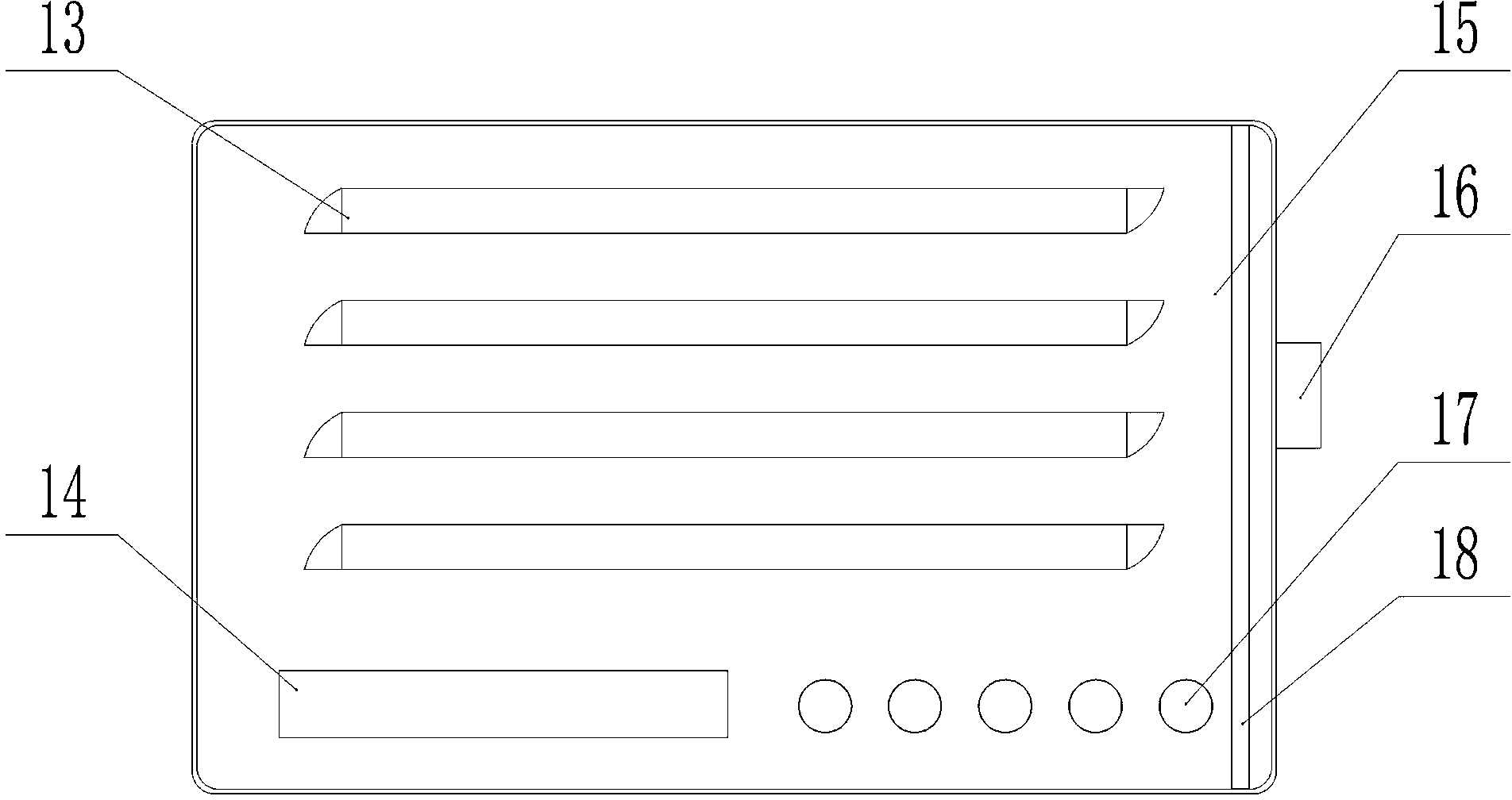

Intelligent electric heater for office

InactiveCN108426292AMeet heating needsSimple structureHeating fuelLighting and heating apparatusElectricityEngineering

The invention discloses an intelligent electric heater for an office. The intelligent electric heater for the office comprises a controller, a wire conduit, a heating vertical plate and a touch display screen. The wire conduit is in a U shape; a wire communicating with an external power supply is arranged in the wire conduit; a main switch connected with the controller is arranged on the wire; thecontroller is arranged above the wire conduit; the heating vertical plate is arranged between two movable ends of the wire conduit, and comprises a heating inner plate, a first heat reflecting material layer, a first electric heating wire layer and a heat radiating device sequentially arranged from inside to outside; the first electric heating wire layer comprises a first heating rod and a plurality of first heating wires; the heat radiating device is of a blind window structure as a whole, and comprises multiple cooling fins and a synchronous rotation motor; and the touch display screen is arranged adjacent to the controller and is electrically connected with the controller. The intelligent electric heater is simple in structure, reasonable in design, and capable of meeting the warming demands of office personnel, and has the beneficial effects of good automation effect, high intelligent degree, energy conservation and environment protection, and the like.

Owner:成都市坤盛电子科技有限公司

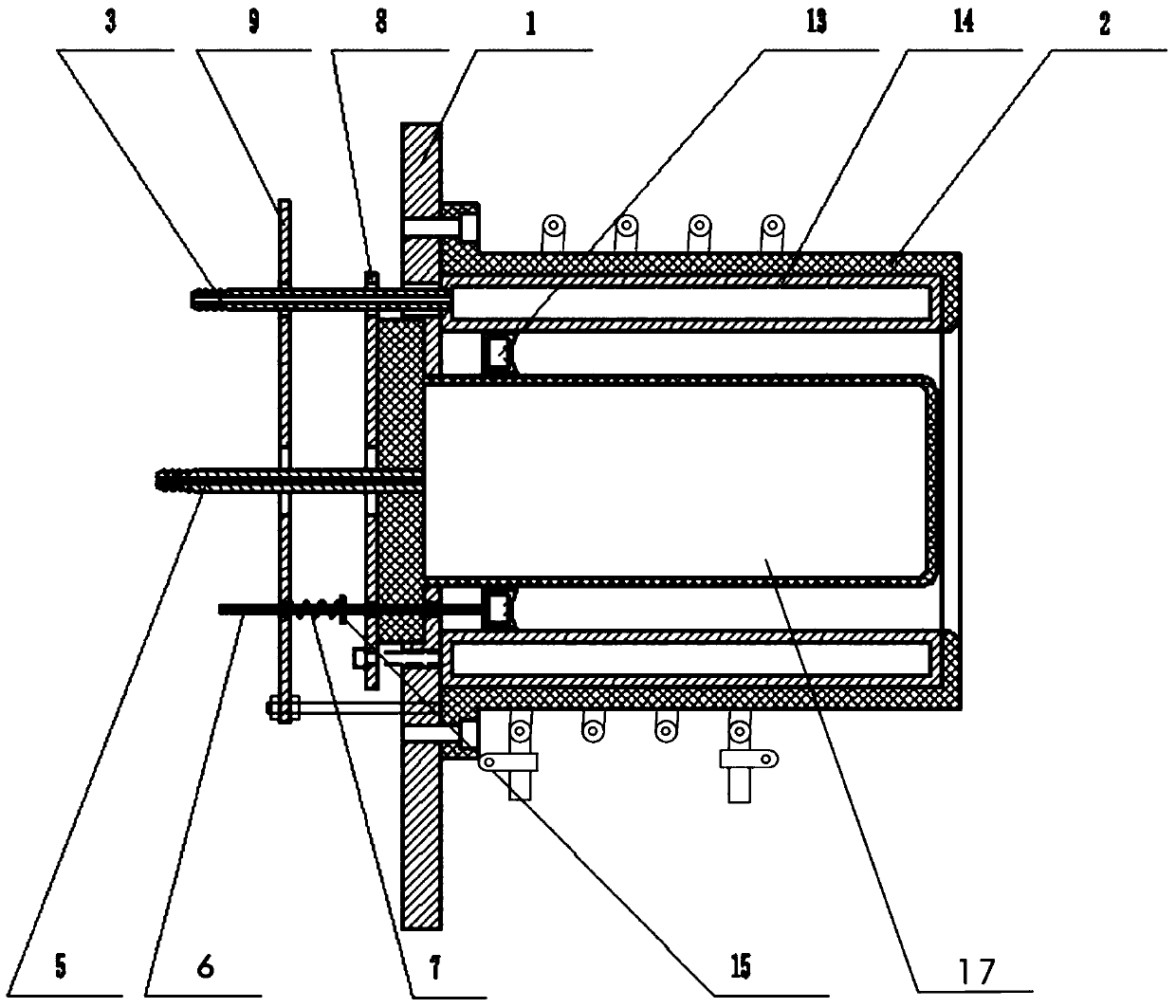

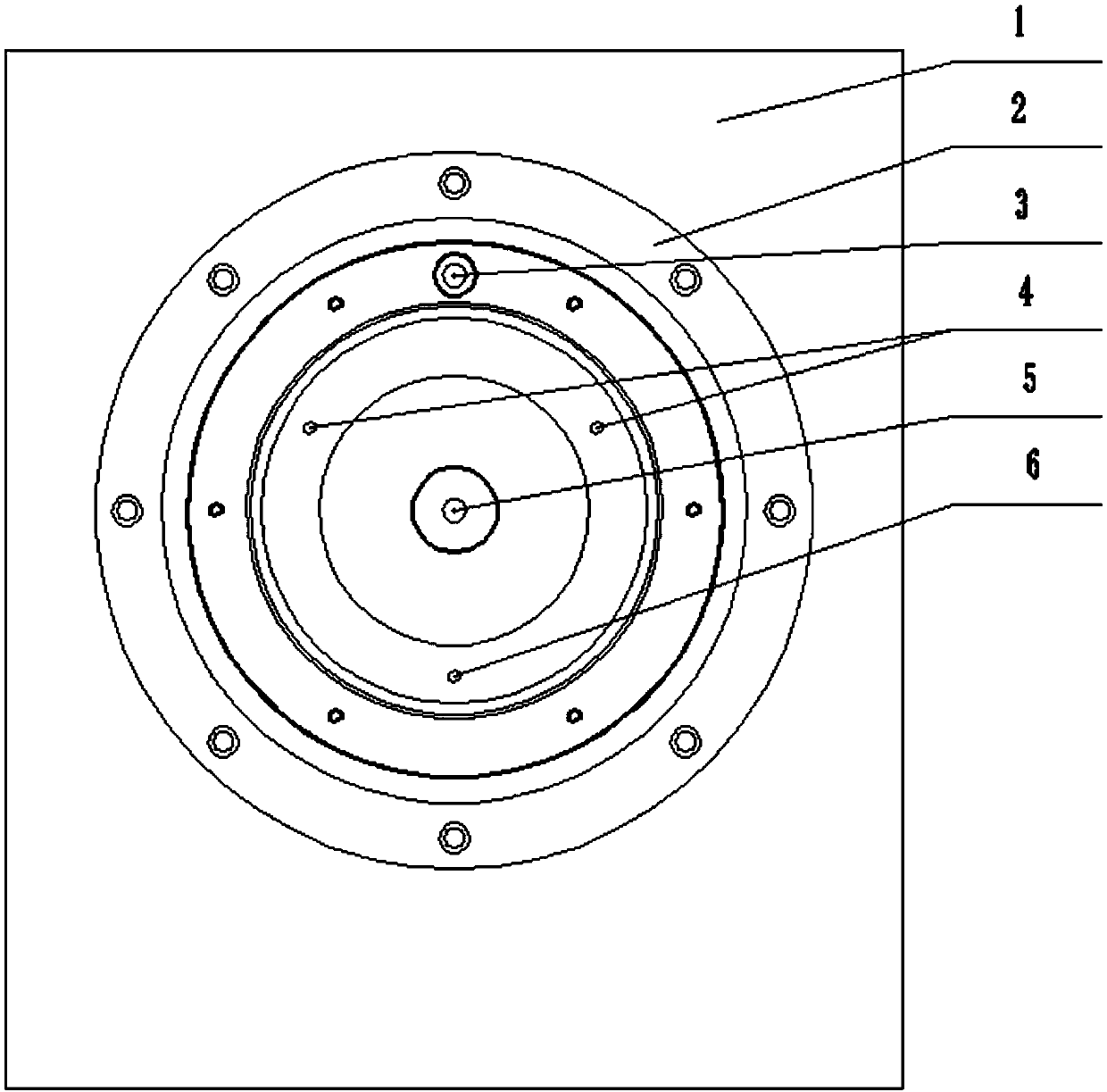

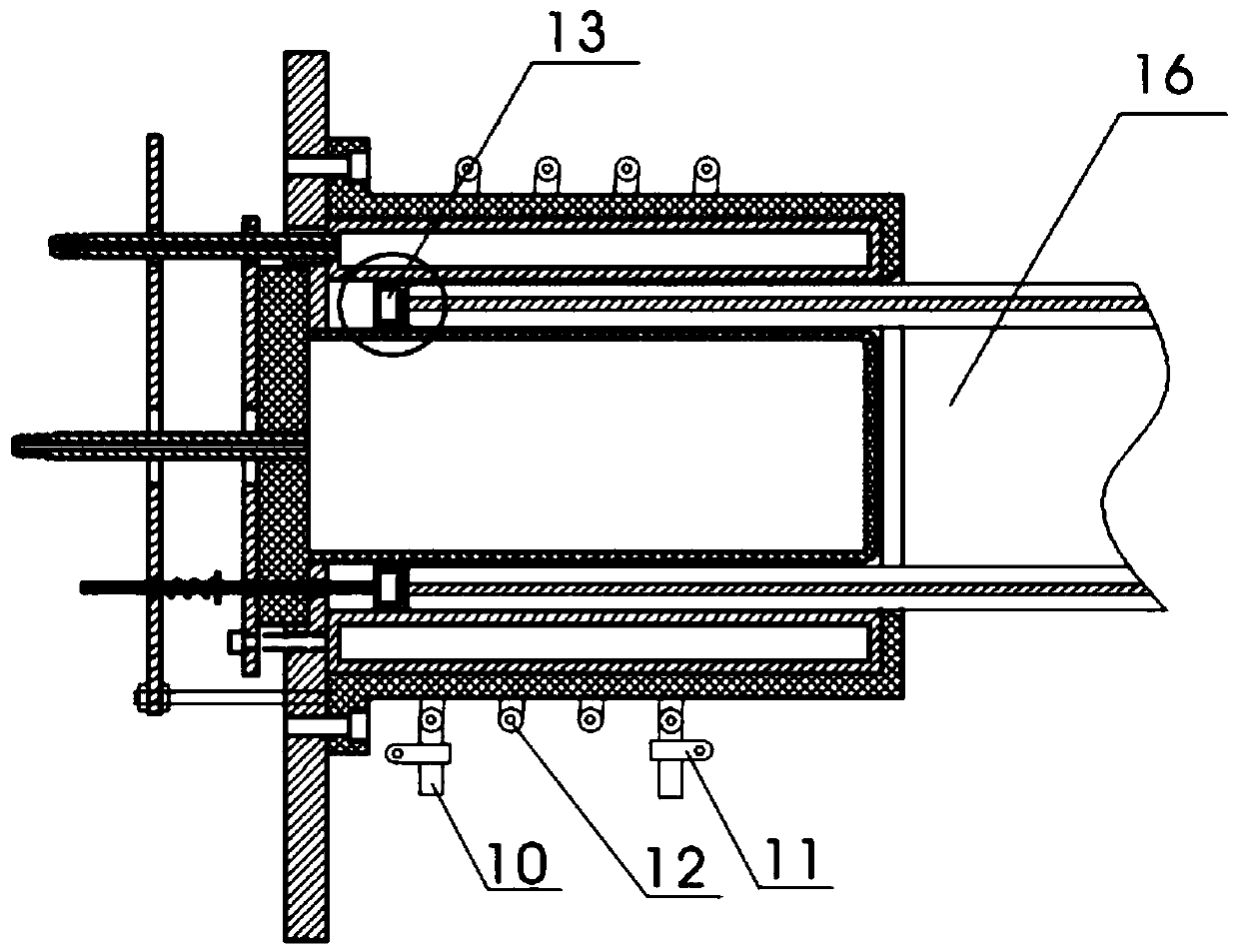

Sealing mechanism for full-automatic chamfering sealing equipment for steel-plastic composite pressure pipe

The invention provides a sealing mechanism for full-automatic chamfering sealing equipment for a steel-plastic composite pressure pipe. The sealing mechanism comprises an air bag supporting plate, anouter air bag casing, an outer air bag nozzle and the like; the outer air bag casing is spirally fixed to the air bag supporting plate; mounting openings are formed in the air bag supporting plate andthe outer air bag casing; the outer side of the outer air bag casing is coated with a cable coil; high-frequency power connectors are arranged in the positions, close to the tips, of two ends of thecable coil; the cable coil adopts the hollow structure; and cooling connectors are arranged at the tips of the cable coil. By the aid of the sealing mechanism, the end surfaces of the pipe are sealedin such a manner that melted inner-layer and outer-layer resin of the pipe is extruded to the end openings of the pipe by the aid of inner and outer air bags, the sealed part and the inner-layer and outer-layer resin of the pipe are melted into a whole, and the exposure phenomenon of the steel pipe layer can be avoided. The problem of oxidation corrosion of the steel-plastic composite pressure pipe during placement is avoided, meanwhile, the condition of failure of seals of the end openings due to ejection of the steel pipe layer during use of the steel-plastic composite pressure pipe is avoided, and the sealing performance of the steel-plastic composite pressure pipe is improved.

Owner:TIANJIN JUNXING PIPE GRP CO LTD

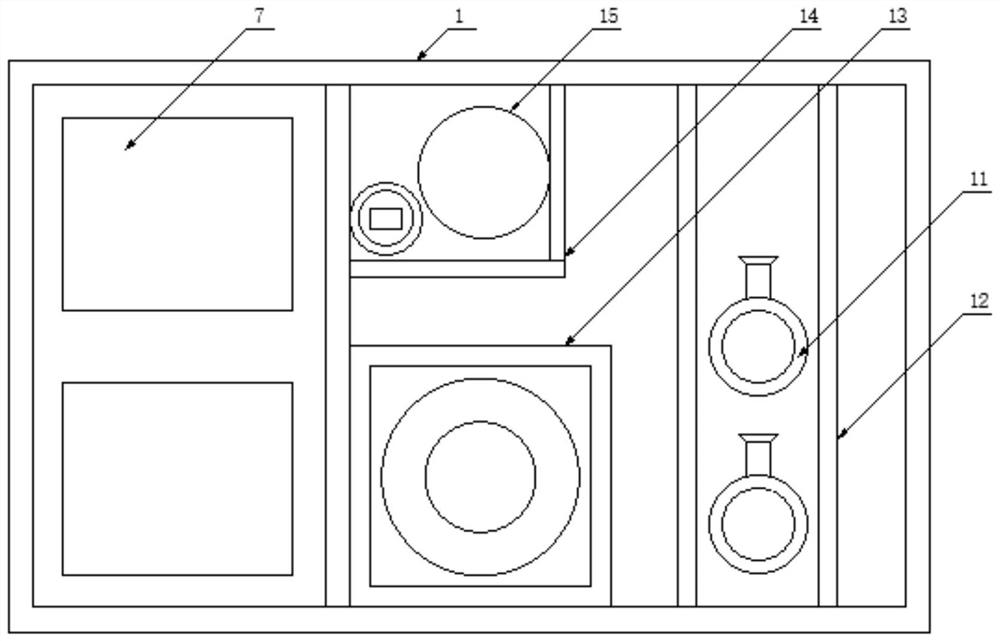

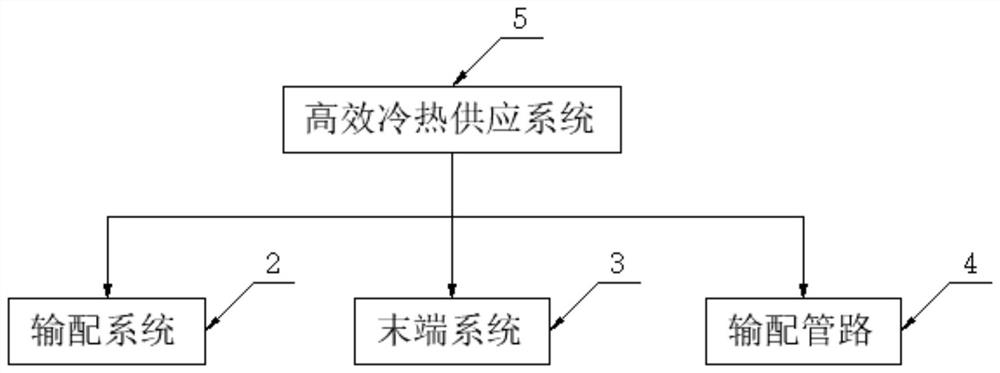

Modular power integrated unit

PendingCN112097303AWide range of applicationsEasy constructionLighting and heating apparatusSpace heating and ventilation detailsDistribution systemAutomatic control

The invention discloses a modular power integrated unit in the technical field of cold and heat supply. The unit comprises an efficient cold and heat supply system, wherein the efficient cold and heatsupply system comprises a hot and cold source, a transmission and distribution system, a tail end system and a transmission and distribution pipeline, the transmission and distribution system comprises a modular power integrated unit body, the modular power integrated unit body is in electric output connection to a transmission and distribution function unit, an auxiliary heating and heat loss balancing function unit and an automatic control unit, the hot and cold source is an air source heat pump, the air source heat pump is installed on the roof of a building, an application range is wide,the modular power integrated unit is not limited by regions, and is suitable for newly-built and rebuilt residential communities, the problem that an air source heat pump in a region is poor in heating effect is effectively solved, construction is convenient and flexible, different numbers of modules can be arranged for different single building scales, influence on the community environment spaceis small, only a single module can be cut off and maintained in a maintaining process, and heating of all buildings cannot be affected.

Owner:徐州达希能源技术有限公司

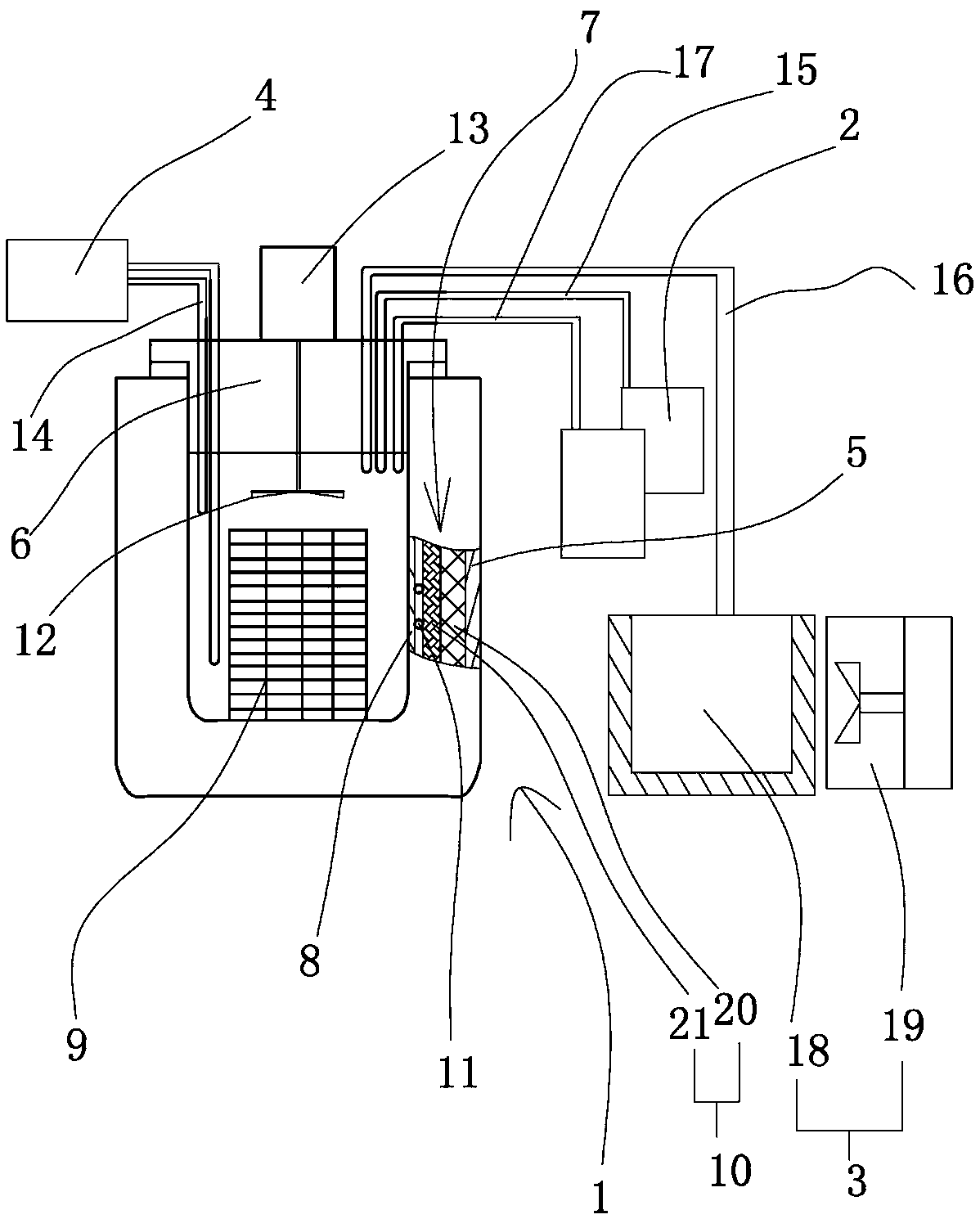

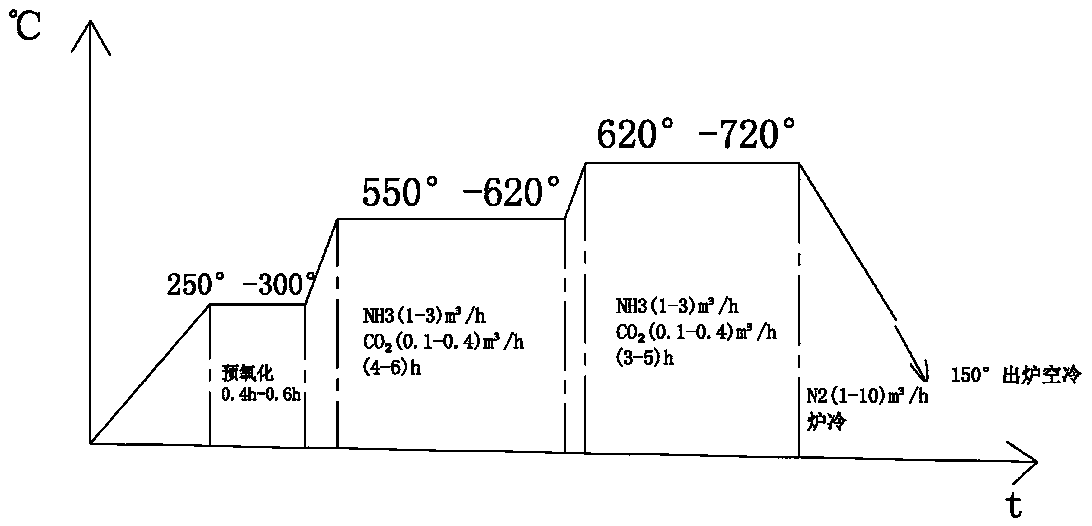

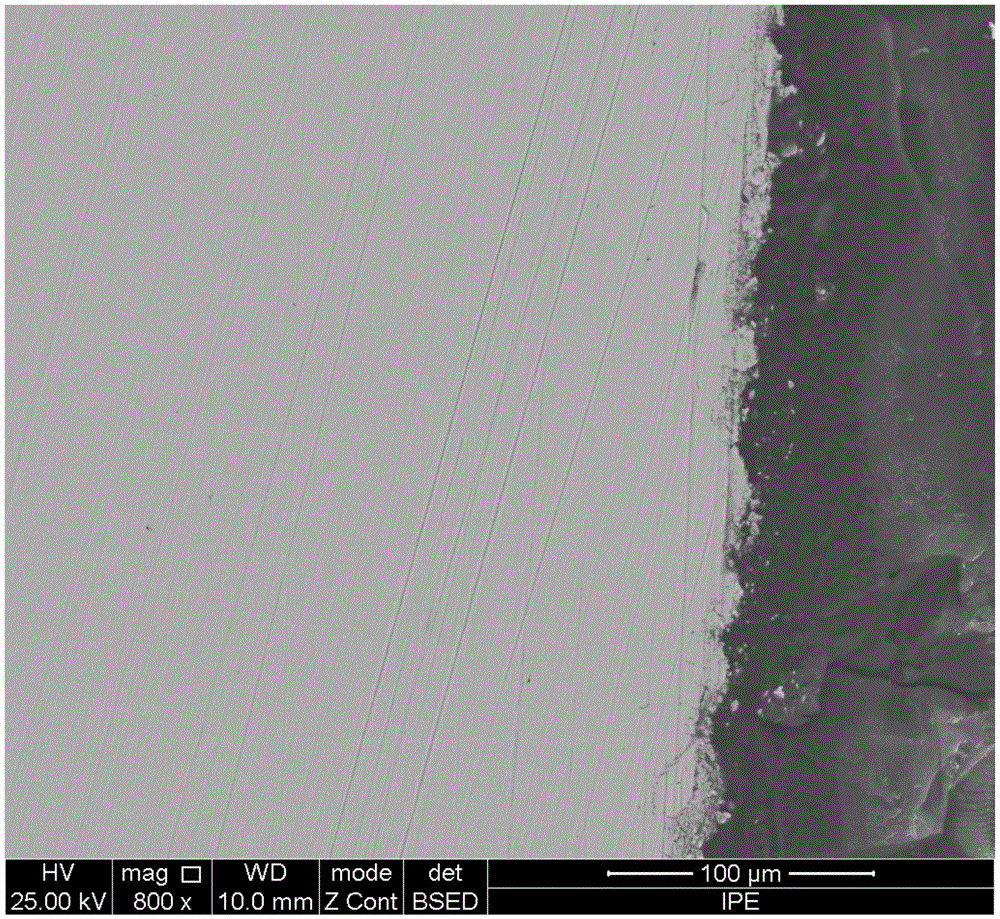

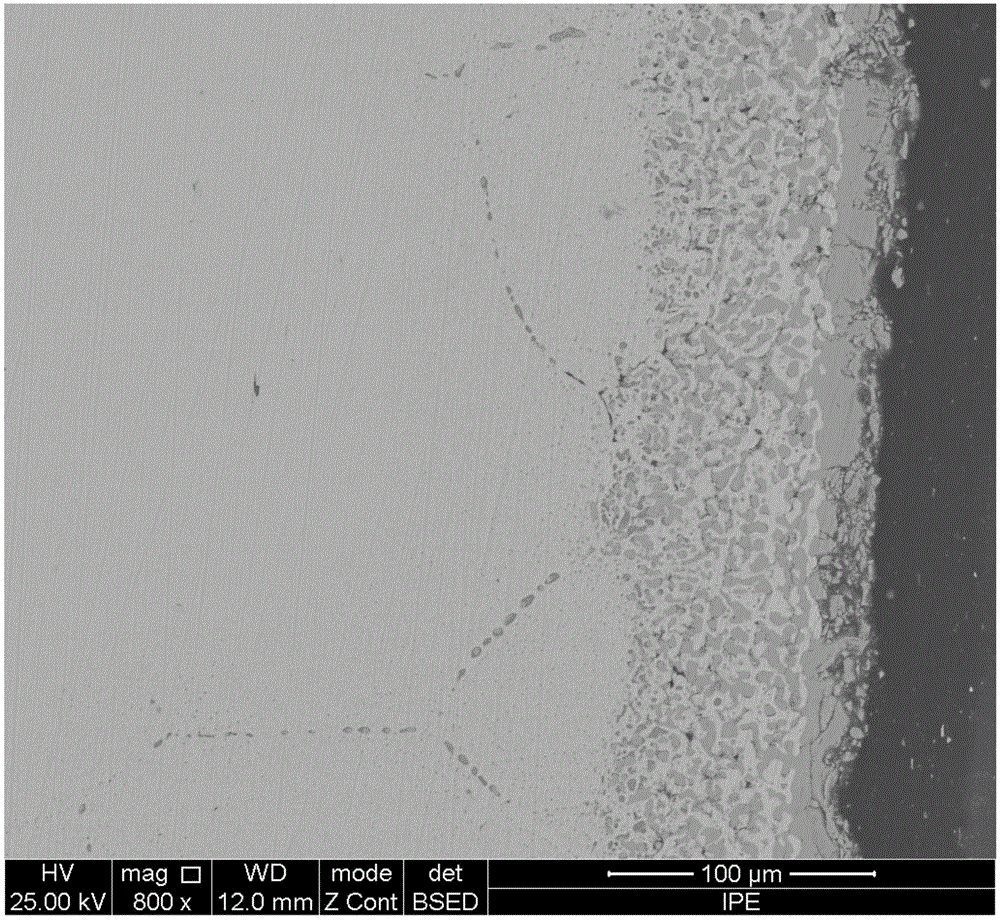

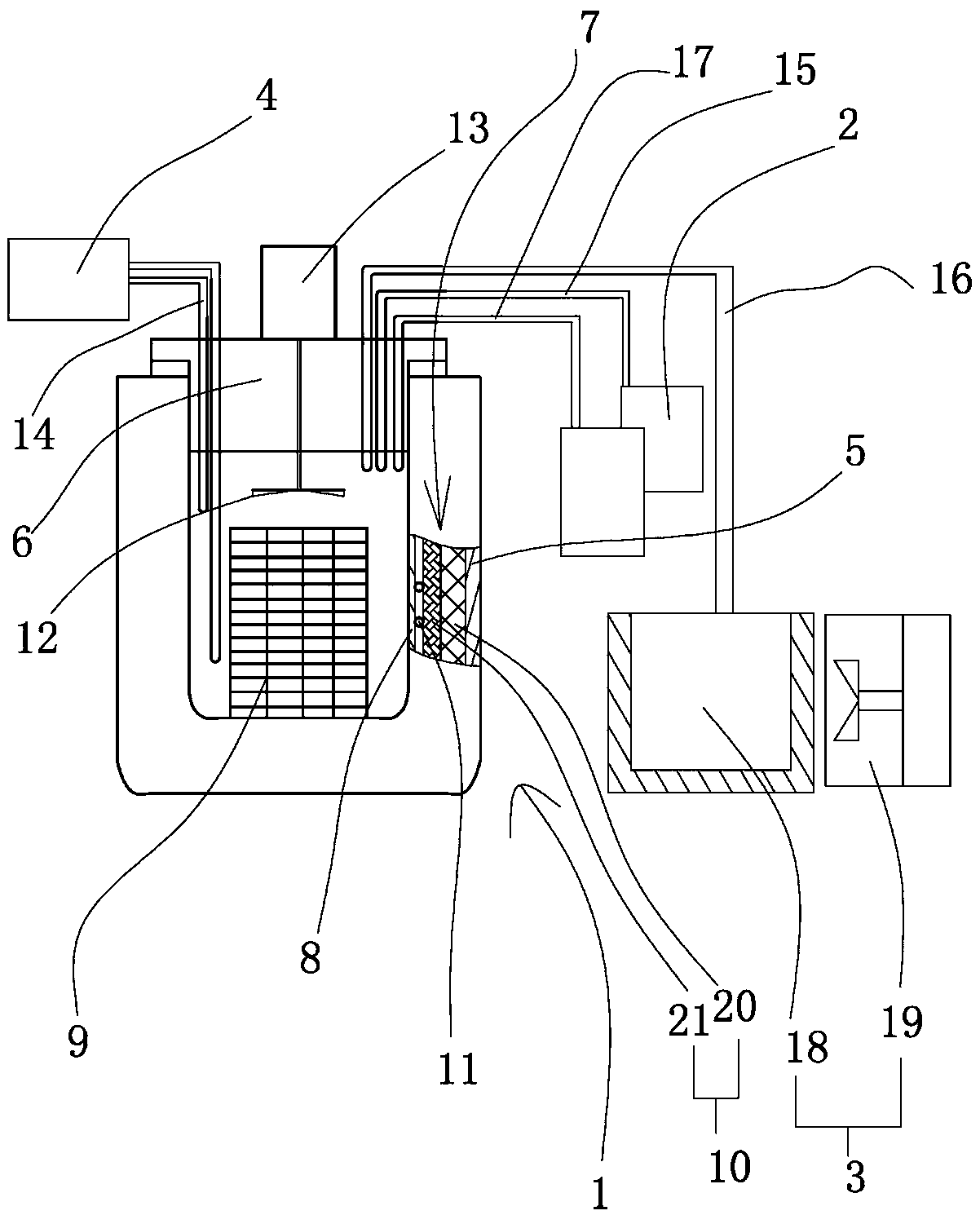

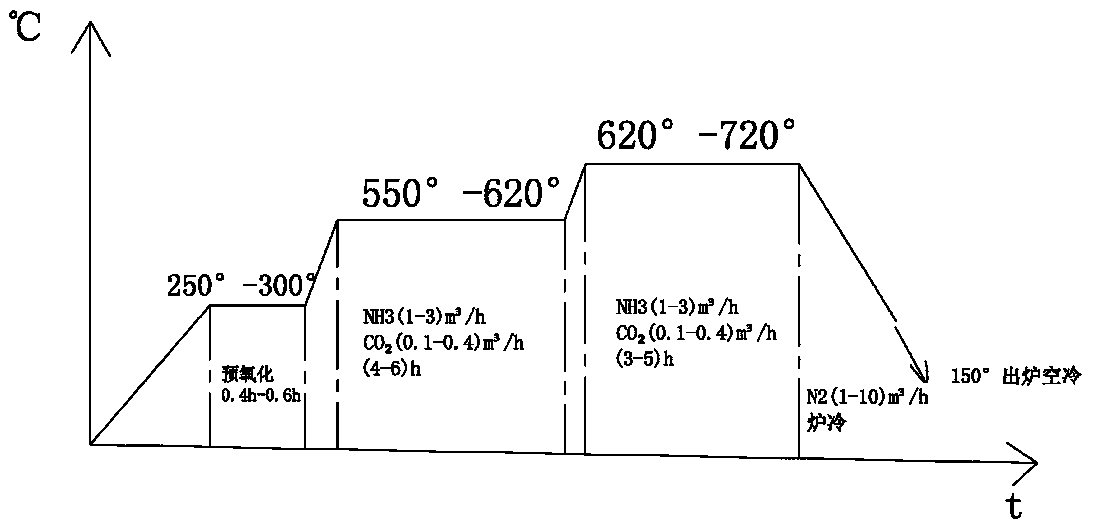

Gcr15 material surface strengthening treatment technology and device

ActiveCN107806763AAccurate dataAccurate temperatureVacuum evaporation coatingSputtering coatingInsulation layerNitrogen

The invention provides a Gcr15 material surface strengthening treatment technology and device and belongs to the technical field of metal surface treatment. The problem that the surface anti-fatigue performance of an existing Gcr15 material part surface is poor is solved. The Gcr15 material surface strengthening treatment device is composed of a well type furnace, a gas supply device and a coolingdevice. The well type furnace is composed of a control panel, a furnace shell, and a furnace cover arranged on the top of the furnace shell. A hearth, a furnace tank and a material basket are arranged in the furnace shell. The hearth is filled with a heat preservation and heat insulation layer, and a heating element is installed on the inner wall of the heat preservation and heat insulation layer. Multiple thermocouples with the end portions stretching in the furnace tank are arranged on the furnace cover. The furnace cover is provided with an ammonia pipe, a nitrogen pipe and a dioxide carbon pipe. The Gcr15 material surface strengthening treatment technology includes the steps that cleaning drying is conducted on a Gcr15 material through argon ion sputtering for 30 min, drying is conducted, then the Gcr15 material is put into the well type furnace to be heated to 250 DEG C to 300 DEG C, then temperature is increased continuously, and when the temperature is increased to 480 DEG C to500 DEG C, ammonia and carbon dioxide are led in. By means of the Gcr15 material surface strengthening treatment technology and device, the surface wear resistance and the anti-fatigue strength of the Gcr15 material can be improved.

Owner:TAIZHOU YONGNING BEARING MFG

High-temperature decarburization-preventing coating material used for spring steel

ActiveCN102453794BAlleviate the problem of high temperature decarburizationImproved decarburization sensitivityNitrogenOxygen

The invention relates to a coating material used for heat treatment technology before rolling a billet of spring steel. The coating materials is directly sprayed onto the billet at the temperature below 500 DEG C and has good blocking property, a dense microcrystal glass layer is formed on the surface of the billet at a high temperature section, mutual diffusion of carbon and nitrogen can be effectively blocked; meanwhile, ingredients in the coating can obviously reduce high temperature activity of carbon atoms in steel, improve decarburization sensibility of the steel and effectively alleviate high temperature decarburization problem of the spring steel, and the dense microcrystal glass layer can naturally strip off in a subsequent cooling process. The coating can effectively prevent decarburization problem of the spring steel in a heat treatment process at the temperature of 950-1150 DEG C, self-stripping capability is high, the coating is safe and convenient to use, heating is not influenced, cost is low, and no pollution is produced.

Owner:上海钫淦新材料科技有限公司

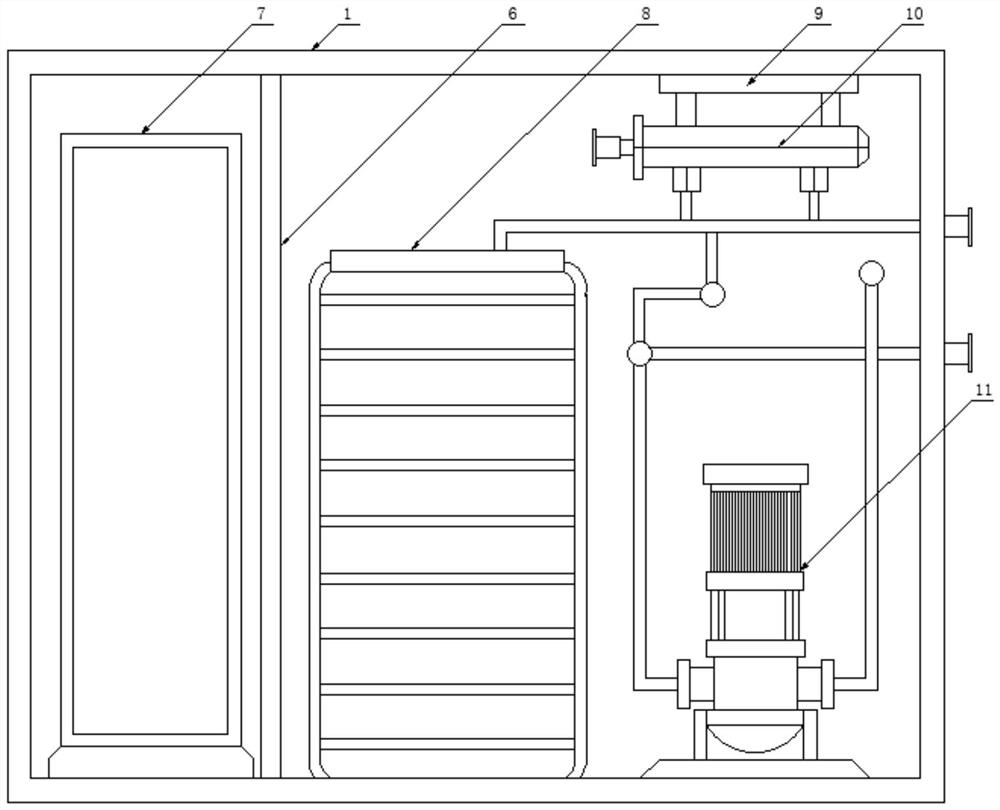

Multi-energy integrated hot water system

InactiveCN106979547ADoes not affect heatingImprove energy utilizationSolar heating energyLighting and heating apparatusSolar waterEngineering

The invention discloses a multi-energy integrated hot water system comprising a solar heating device, a fuel gas wall-hanging stove heating device, an air energy heating device, a water tank and a main control unit. A solar heat exchange coil pipe is connected with a water inlet pipe and a water outlet pipe of a solar water collector to form a water circulation loop. A wall-hanging stove heat exchange coil pipe is connected with a water inlet pipe and a water outlet pipe of the fuel gas wall-hanging stove heating device to form a water circulation loop. Condensers of the solar heat exchange coil pipe, the wall-hanging stove heat exchange coil pipe and the air energy heating device are arranged in the water tank. The output end of the main control unit is electrically connected with a solar circulation water pump, an air energy circulation pump and a fuel gas circulation pump. According to the device, by integrating the advantages and making up the defects of a solar water heater, an air energy heat pump water heater and a fuel gas wall-hanging stove water heater, under the condition that water is provided to be used, high efficiency and energy saving are achieved; and meanwhile the fuel gas wall-hanging stove heating device is connected with an underfloor heat exchange system, so that the utilization rate of energy is improved.

Owner:安徽新富地建设工程有限公司

Environment-friendly treatment process for blow-in flue gas of zinc sulfide concentrate fluidized roaster

InactiveCN106110797AReduce pollutionDoes not affect heatingHuman health protectionGas treatmentCooling towerAtmospheric pollution

The invention relates to an environment-friendly treatment process for flue gas generated by a zinc sulfide concentrate fluidized roaster in the heating blow-in process. The process includes the following steps that the flue gas generated through heating blow-in of the zinc sulfide concentrate fluidized roaster enters a waste heat boiler, and after a cyclone dust collector recycles heat and removes dust, the flue gas is conveyed to a purification first-class efficient washer and a gas cooling tower for dust removal and cooling through an electric dust collector bypass flue gas pipe via a blow-in draught fan; after the flue gas is conveyed to a tail gas absorption tower for absorption of lampblack and SO2 through a sub-pipeline, the blow-in flue gas is exhausted through a tail gas chimney after reaching the standard, and atmosphere pollution is avoided and greatly reduced.

Owner:南丹县南方有色金属有限责任公司

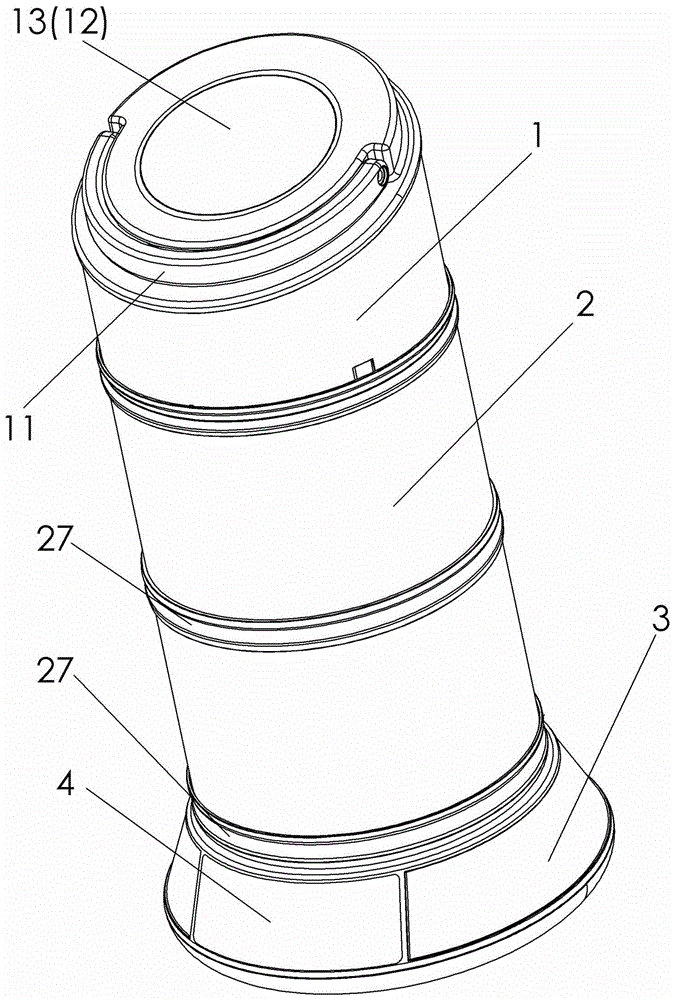

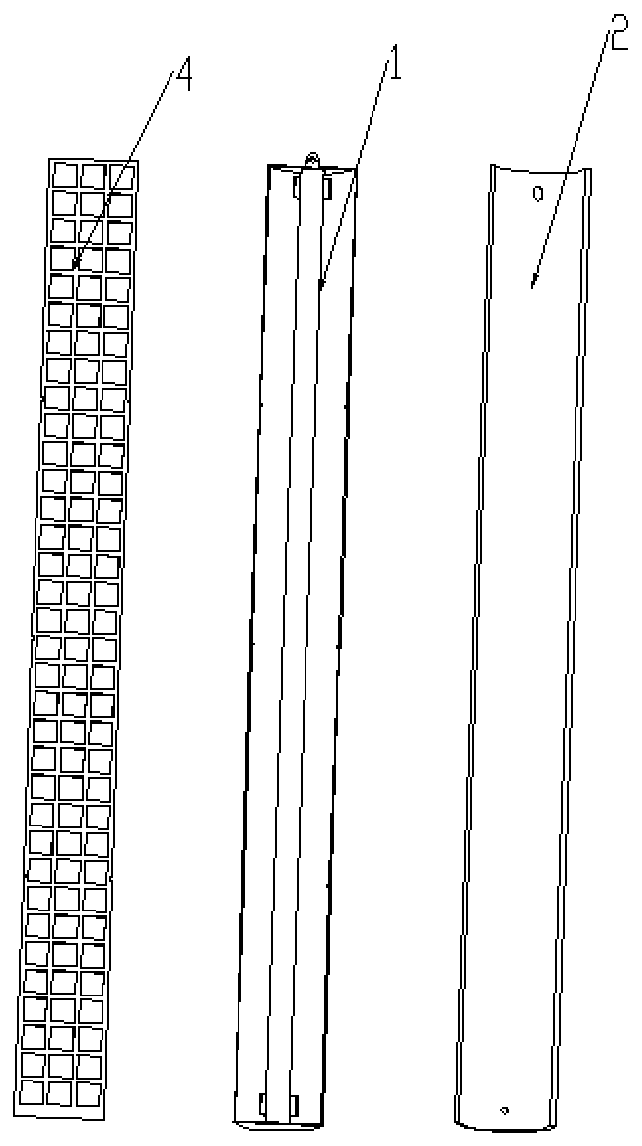

Split-type air purifier

InactiveCN104110742AImprove applicabilityImprove purityLighting and heating apparatusSpace heating and ventilation detailsUser needsAir purifiers

The invention discloses a split-type air purifier. The split-type air purifier is characterized by comprising an outdoor unit and an indoor unit, wherein the outdoor unit comprises a shell assembly, a filter element assembly, a purification assembly and a power assembly; the filter element assembly is arranged in front of the air inlet of the outdoor unit; a sterilization assembly is arranged in he indoor unit; the outdoor unit is communicated with the indoor unit through a ventilation pipeline, and the outdoor unit is used for exhausting the sucked outdoor air into a room through the indoor unit after passing through the filter element assembly and the purification assembly; the shell assembly of the outdoor unit is divided into an upper box body, a middle box body and a lower box body. The split-type air purifier disclosed by the invention integrates a composite filter element technology, a carbon absorption technology, a photocatalytic degradation technology and an ultraviolet sterilization technology, adopts a novel filter element, and is higher in filter accuracy, better in purification effect, higher in applicability, and wider in application range; with the adoption of an inner and outer air exchange mode, air purity and air quality are improved, and the environmental pollution generated by the running of the equipment is also reduced; the split-type air purifier can be designed according to user needs and an air quantity can be adjusted.

Owner:GUILIN GUANGTUO ENVIRONMENTAL PROTECTION EQUIP

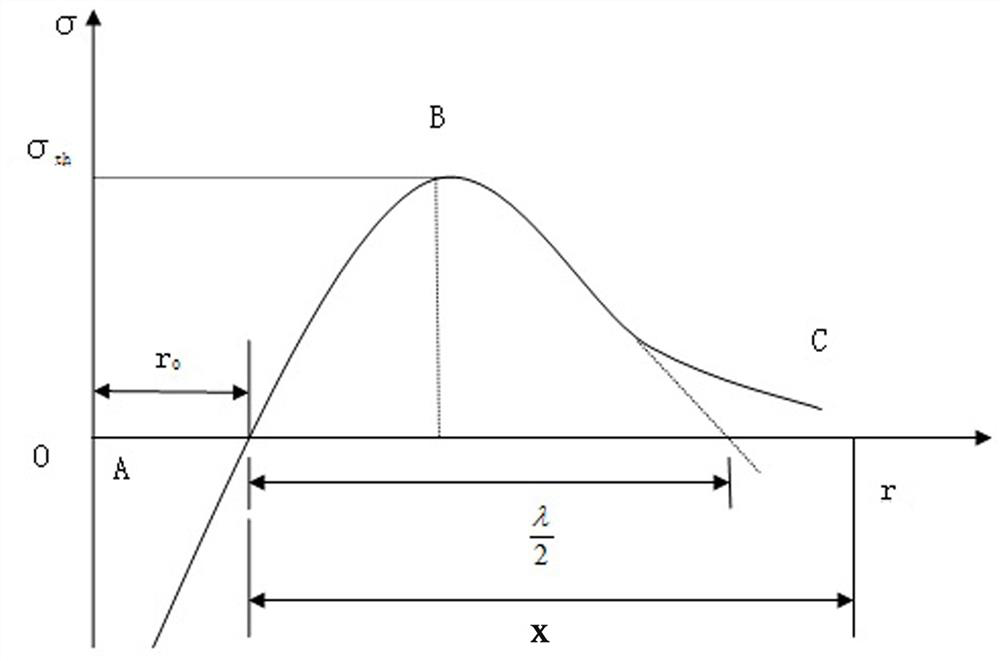

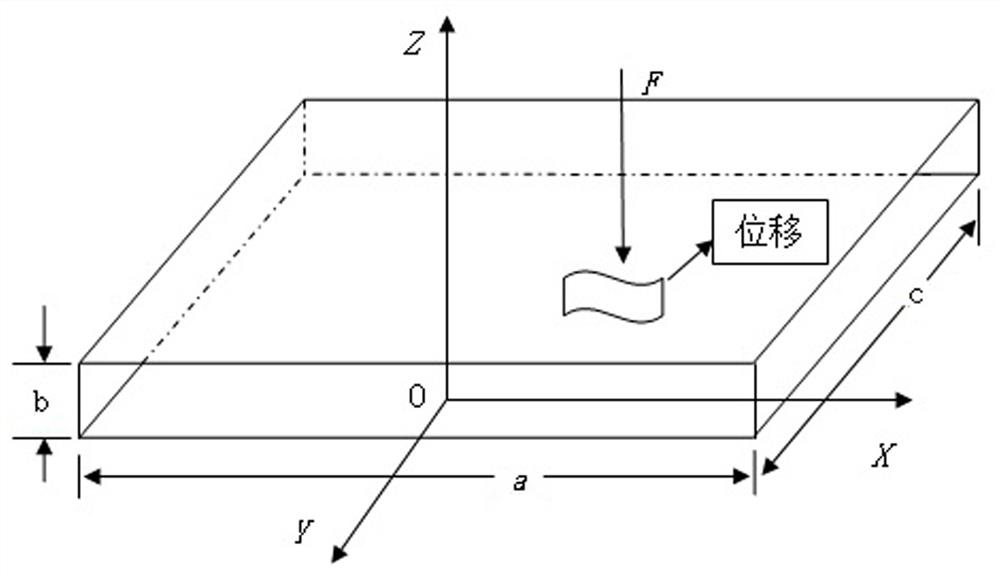

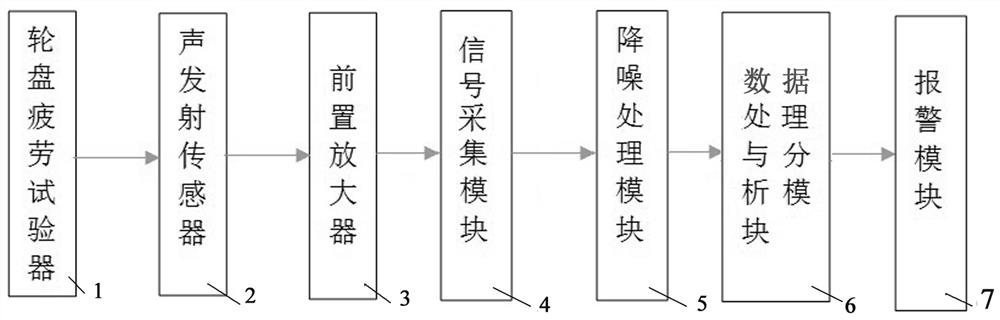

An acoustic emission crack monitoring method and system

ActiveCN113252794BDoes not affect normal operationSolving the World's Problems of Online MonitoringMaterial analysis using acoustic emission techniquesProcessing detected response signalAcoustic emissionEngineering

Owner:SHENYANG POLYTECHNIC UNIV

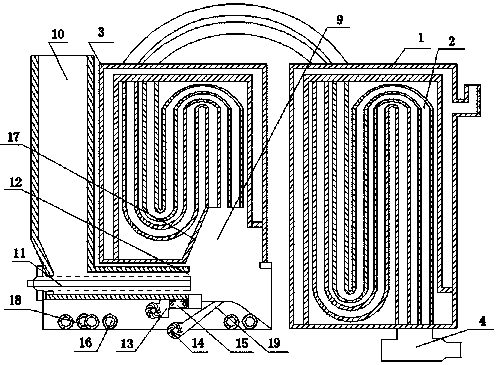

A multi-energy integrated hot water system

ActiveCN103017245BDoes not affect heatingImprove energy utilizationFluid heatersSolar heat devicesSolar waterEngineering

The invention discloses a multi-energy integrated water heating system, which comprises a solar heating device, a wall-hung gas boiler heating device, an air energy heating device, a water tank and a master control unit. A solar heat exchange pipe coil is connected with a water inlet pipe and a water outlet pipe of a solar water collector to form a water circulation loop. A wall-hung boiler heat exchange pipe coil is connected with a water inlet pipe and a water outlet pipe of the wall-hung gas boiler heating device to form a water circulation loop. The solar heat exchange pipe coil, the wall-hung boiler heat exchange pipe coil and a condenser of the air energy heating device are arranged in the water tank. The output end of the master control unit is electrically connected with a solar circulating water pump, an air energy circulating pump and a gas circulating pump. According to the system, the advantages of a solar water heater, an air energy heat pump water heater and a wall-hung gas boiler water heater are integrated, and the shortcomings of the solar water heater, the air energy heat pump water heater and the wall-hung gas boiler water heater are overcome, so that the system is efficient and energy-saving under the condition of ensuring the use of hot water; and in addition, the wall-hung gas boiler heating device is connected with a floor heating heat exchange system, so that the utilization rate of energy is increased.

Owner:法罗力热能设备(中国)有限公司

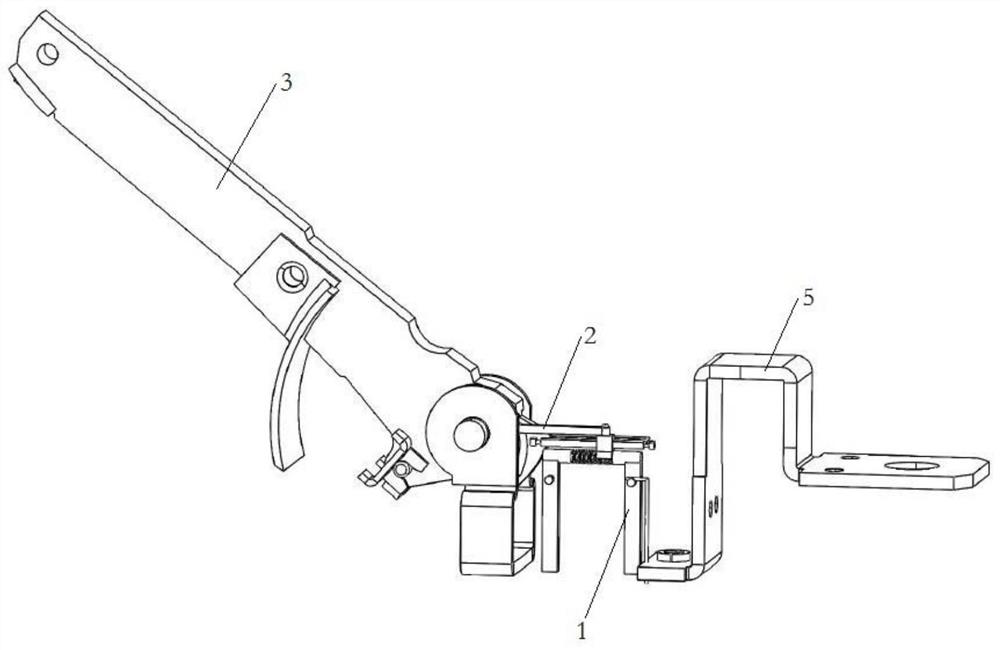

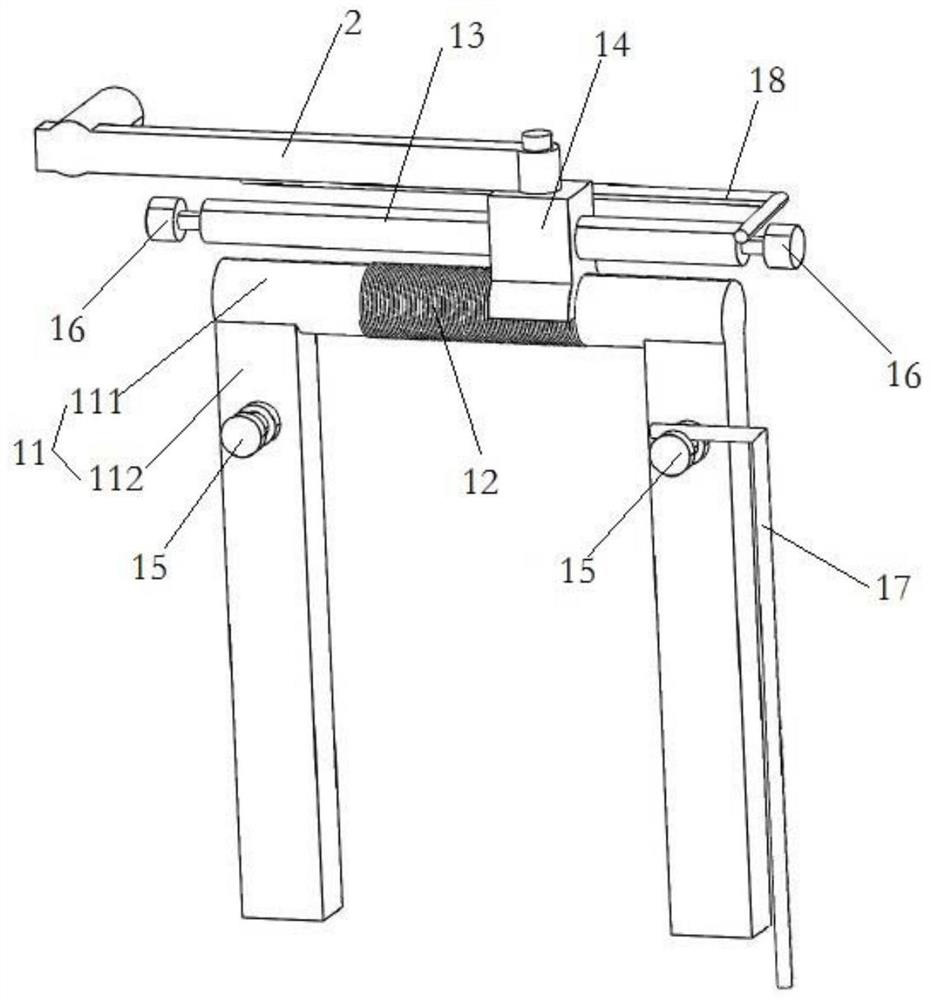

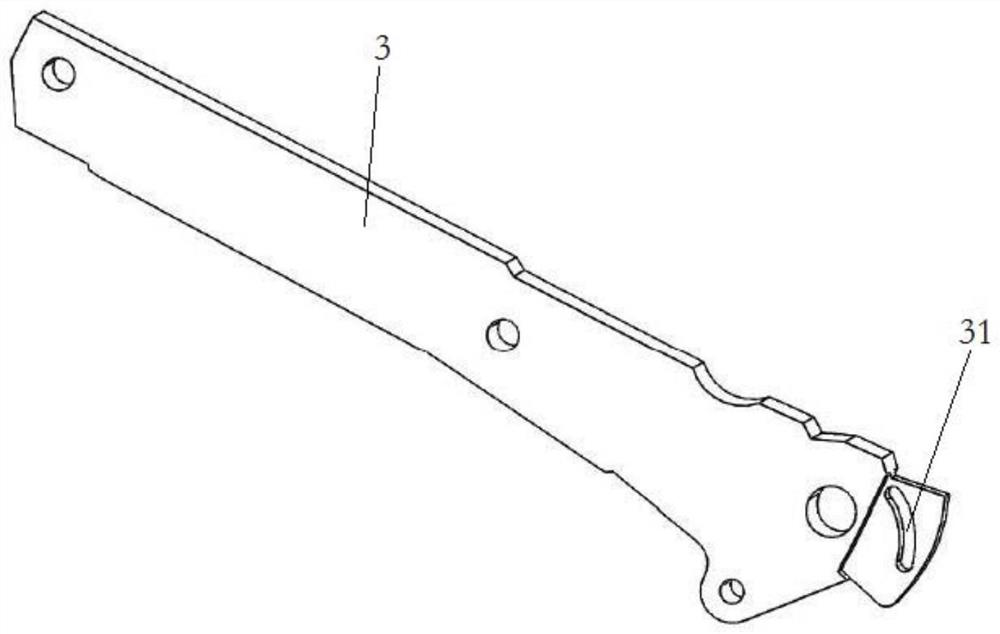

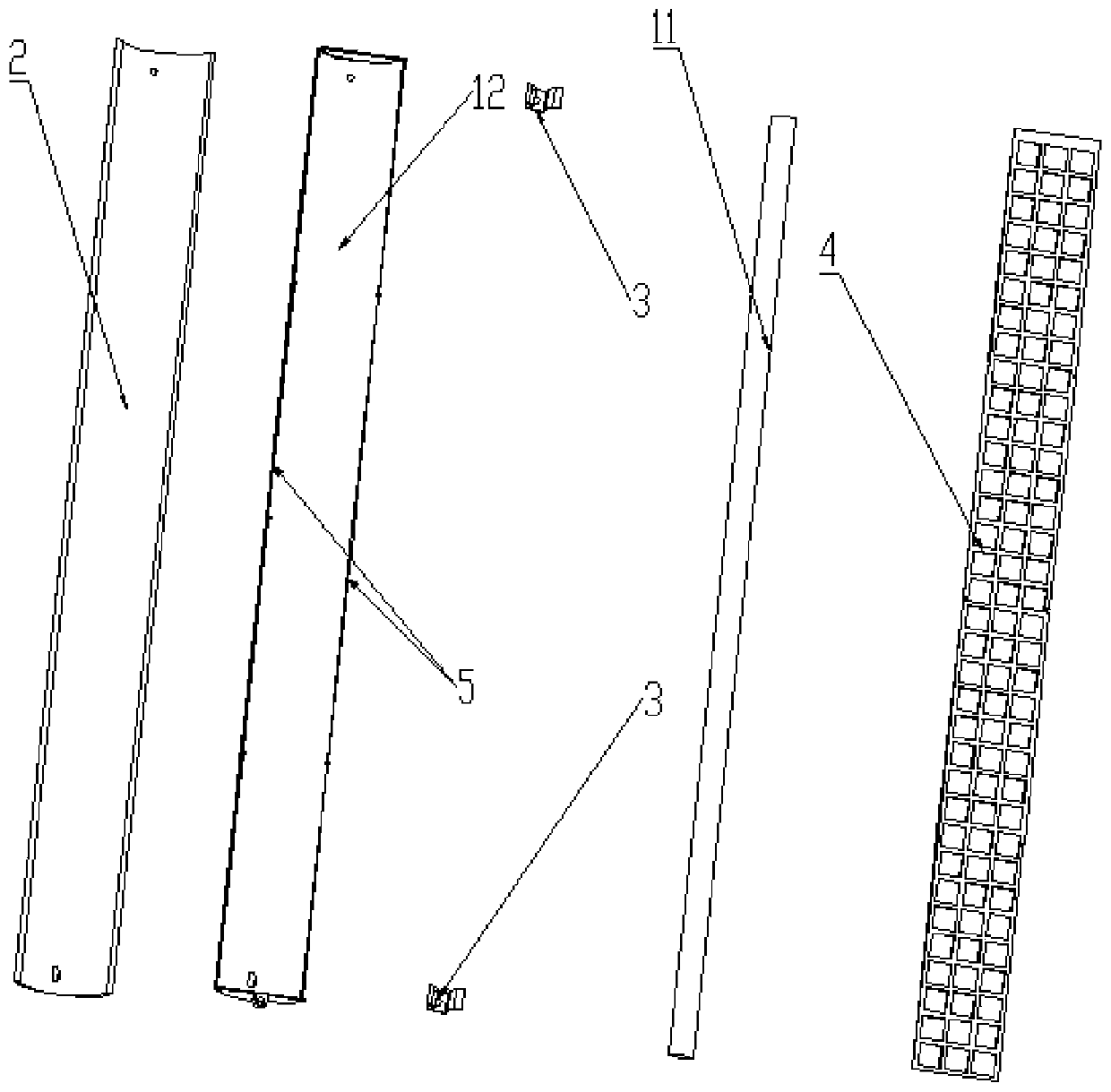

Current limiting structure and circuit breaker

PendingCN112713067AReduce volumeIncrease arc voltageProtective switch operating/release mechanismsAdjustment of protective switch conditionsCurrent limitingElectrical connection

Owner:ZHEJIANG TENGEN ELECTRIC

Defrosting device and air conditioner comprising same

PendingCN109813016ADoes not affect heatingImprove defrosting efficiencyCorrosion preventionRefrigeration componentsProcess engineeringComfort levels

The invention provides a defrosting device and an air conditioner comprising the same and relates to the technical field of refrigerating and heating equipment. The defrosting device and the air conditioner comprising the same aim at achieving the effects that the defrosting efficiency is improved, heat can be supplied into a room normally while defrosting is conducted, and the defrosting device can be applied to an outdoor unit heat exchanger. The defrosting device comprises a heating assembly and a thermally-insulating structure. The heating assembly is arranged on a to-be-frosted structure.The thermally-insulating structure is arranged on the side, away from the to-be-frosted structure, of the heating assembly. Heating is conducted through the heating assembly arranged on the to-be-frosted structure to directly defrost the to-be-frosted structure; and in the defrosting process, normal heat supply of the air conditioner is not affected, and the comfort level inside the room is maintained. Meanwhile, by means of the thermally-insulating structure, heat exchange formed between the outdoor low-temperature air and the heating assembly is isolated; hot losses of the heating assemblyare reduced; the work efficiency of the heating assembly is improved; and furthermore, the defrosting efficiency of the outdoor heat exchanger is improved.

Owner:GREE ELECTRIC APPLIANCES INC

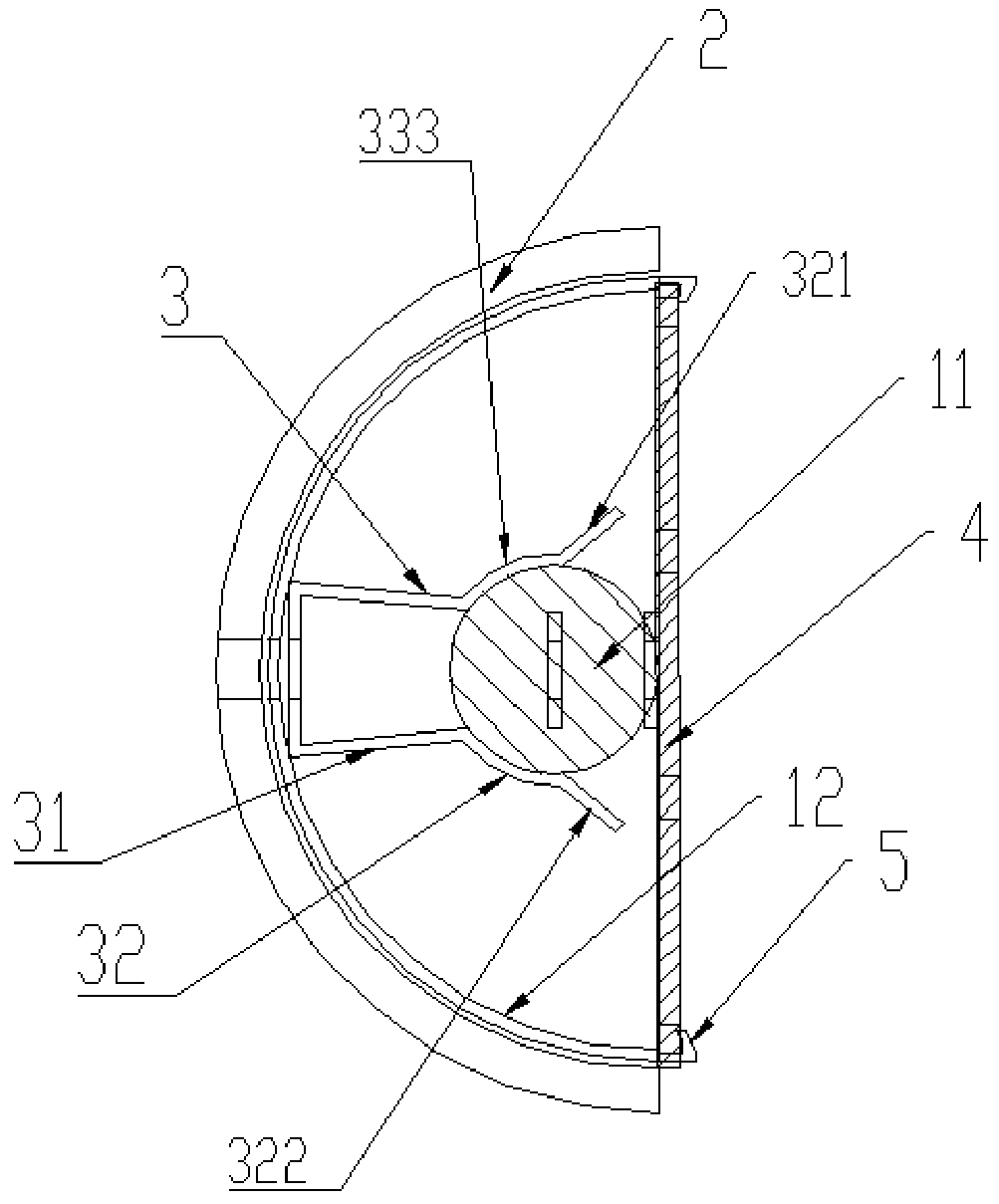

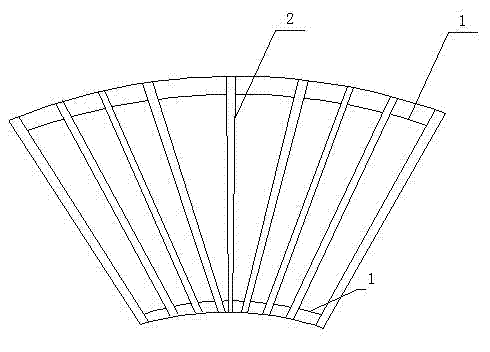

Fan-shaped radiator

InactiveCN102954714ANice appearanceDoes not affect heatingStationary conduit assembliesEngineeringHeat supply

The invention provides a fan-shaped radiator which comprises two arc-shaped header pipes and a plurality of straight pipes. The two header pipes are respectively arranged at the upper part and the lower part of the radiator; both ends of the straight pipes are connected with the upper and lower header pipes; the upper arc-shaped header pipe is longer than the lower arc-shaped header pipe; the space between the header pipes and the straight pipes are fan-shaped; and the straight pipes are arranged in two lines and are connected atto two sides of the header pipes. The fan-shaped radiator provided by the invention is beautiful attractive and elegant in appearance and does not affect heat supply.

Owner:WUXI HONGSHENG ALUMINUM IND

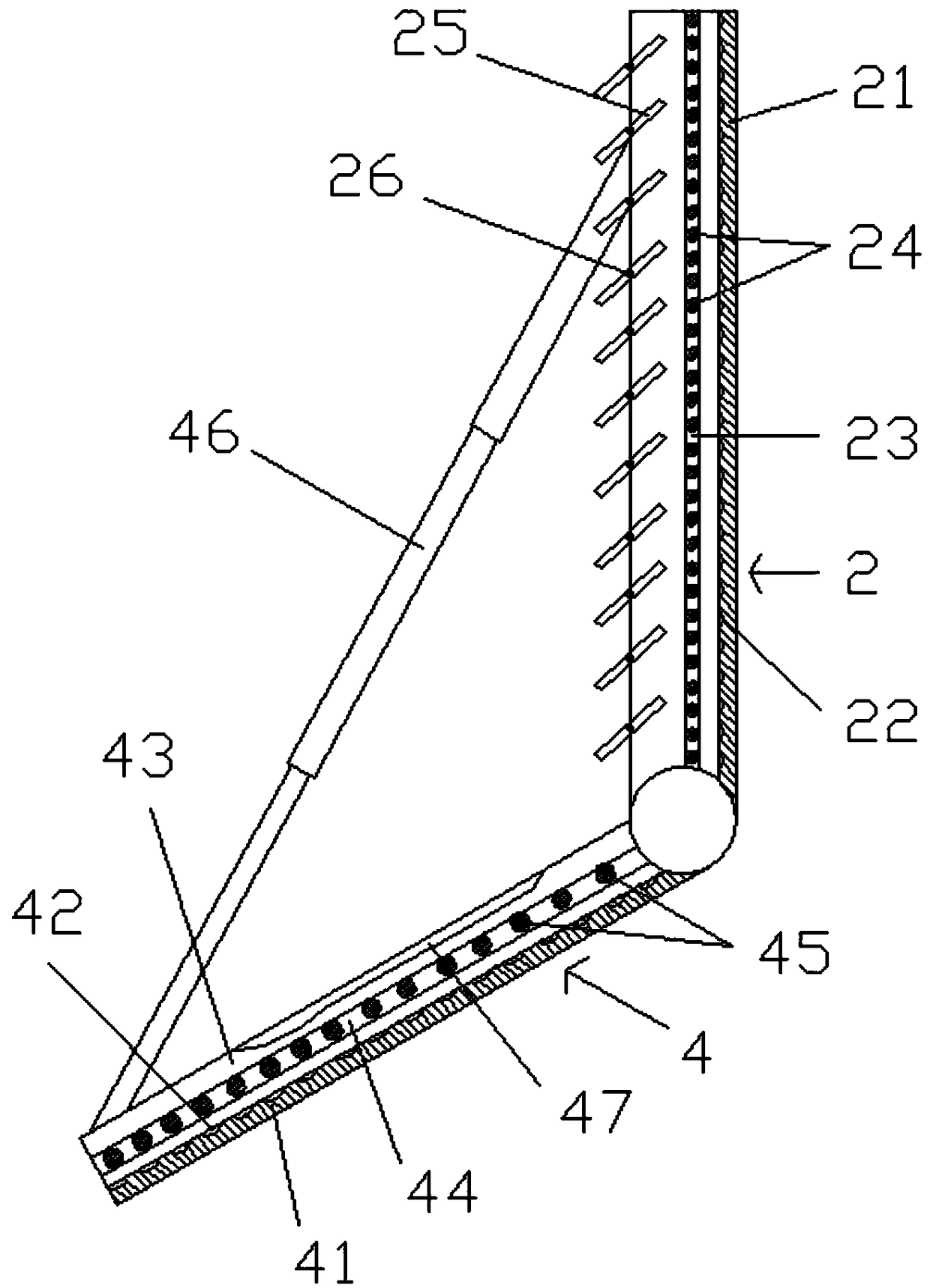

Biomass fuel environmental-friendly energy-saving furnace

InactiveCN108645035ABurn fullyGuarantee the need for secondary combustionFluid heatersSolid fuel combustionThermal energyProcess engineering

Provided is a biomass fuel environmental-friendly energy-saving furnace. At present, a large number of boilers use biomass fuel for heating, a large amount of heat is lost and runs into the air in vain by using boiler flues, a large amount of heat is wasted, and the air and the environment are polluted. The biomass fuel environmental-friendly energy-saving furnace comprises a waste heat recovery accumulator body (1) with a circulating water pipe. A group of smoke guiding pipes (2) is arranged in the waste heat recovery accumulator body, the smoke guiding pipes are connected with a boiler (3),and the other ends of the smoke guiding pipes are connected with a smoke guiding machine (4). The biomass fuel environmental-friendly energy-saving furnace is used for the biomass fuel boiler.

Owner:SUZHOU BOHAN ENVIRONMENTAL PROTECTION TECH

A High Temperature Protective Coating for Nickel-based Alloy Steel

ActiveCN104017397BSolve the problem of difficult descalingReduced diffusion rateCoatingsPotassiumSlurry

The invention relates to a high-temperature protective coating used in the heat treatment process before hot rolling of nickel-based alloy steel. The coating powder part includes the following components: Al 2 o 3 20%-40%, SiO 2 10%-30%, MgO10%-20%, TiO 2 10%-20%, CuO5%-15%, Y 2 O35%-15%, Na 2 O0%-1%, K 2 O0%-1%, where Al 2 o 3 and SiO 2 Derived from one or both of kyanite and aluminum ash; TiO 2 Originated from rutile ore. The binder in the paint is formed by mixing one or more of sodium water glass, potassium water glass, and silica sol; the dispersant is carboxymethyl cellulose. When using, first mix the powder and water in a weight ratio of 2:1 to form a slurry, add a binder, the binder accounts for 5%-10% of the slurry, add a dispersant, and the dispersant accounts for the slurry The mass ratio is 1%-2%. After mixing, ball mill to a particle size of 200-600 mesh to get the coating. It can be sprayed directly under the steel billet below 800 °C, which can effectively solve the difficult removal of nickel-based alloy steel caused by heat treatment at 1200-1350 °C. scale problem.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A kind of gcr15 material surface strengthening treatment process and equipment

ActiveCN107806763BAccurate dataAccurate temperatureVacuum evaporation coatingSputtering coatingInsulation layerNitrogen

The invention provides a Gcr15 material surface strengthening treatment technology and device and belongs to the technical field of metal surface treatment. The problem that the surface anti-fatigue performance of an existing Gcr15 material part surface is poor is solved. The Gcr15 material surface strengthening treatment device is composed of a well type furnace, a gas supply device and a coolingdevice. The well type furnace is composed of a control panel, a furnace shell, and a furnace cover arranged on the top of the furnace shell. A hearth, a furnace tank and a material basket are arranged in the furnace shell. The hearth is filled with a heat preservation and heat insulation layer, and a heating element is installed on the inner wall of the heat preservation and heat insulation layer. Multiple thermocouples with the end portions stretching in the furnace tank are arranged on the furnace cover. The furnace cover is provided with an ammonia pipe, a nitrogen pipe and a dioxide carbon pipe. The Gcr15 material surface strengthening treatment technology includes the steps that cleaning drying is conducted on a Gcr15 material through argon ion sputtering for 30 min, drying is conducted, then the Gcr15 material is put into the well type furnace to be heated to 250 DEG C to 300 DEG C, then temperature is increased continuously, and when the temperature is increased to 480 DEG C to500 DEG C, ammonia and carbon dioxide are led in. By means of the Gcr15 material surface strengthening treatment technology and device, the surface wear resistance and the anti-fatigue strength of the Gcr15 material can be improved.

Owner:TAIZHOU YONGNING BEARING MFG

Instant-heating type electric heating boiler

InactiveCN1967084ADoes not affect heatingWater heatersHot-water central heatingElectricityAutomatic control

An electric quick heating boiler features in the electric heater inside each pipe of the heat exchanger, with quicker flowing speed of the water and bigger exchanging area to improve heating efficiency, small circulation of the hygiene heat exchanger and the heating circulating heat exchanger can provide ideal hygiene water, with the computer automatically controlling each operation of the boiler.

Owner:马国实

Exchange method of coking furnace basement gas heating system during overhauling of gas exchanger

ActiveCN105400525AReduce operating intensityNo gas leakCombustible gas coke oven heatingHeating systemGas heating

The invention relates to an exchange method of a coking furnace basement gas heating system during overhauling of a gas exchanger. The exchange is carried out by the use of an electric hydraulic cylinder and comprises the following steps: a chain block is hung by a chain block exchange method and a steel wire rope is stretched tightly; the exhaust gas hydraulic cylinder's two ends and exhaust gas stroke connecting parts are dismantled; the exhaust gas hydraulic cylinder and electric hydraulic cylinder pipelines are connected, and power connection is carried out for no-load test; the hydraulic cylinder position is turned to a position consistent with the exhaust gas stroke position after no-load test is normal, and an adapter between the exhaust gas stroke and the electric hydraulic cylinder is connected; the chain block is slowly loosened, and change of stroke is paid attention to during the loosening period; and according to exchange need, the electric hydraulic cylinder is used for exchange. According to the method, the electric hydraulic cylinder is adopted during the overhauling of the exchanger to replace a chain block, and exchange can be operated only by pressing a button. Exchange time is close to exchange time by the use of the exchanger. Thus, operating intensity of people can be greatly reduced, and requirements of coking furnace heating system are met. Heating is not affected, and gas leakage will not be caused.

Owner:BENGANG STEEL PLATES

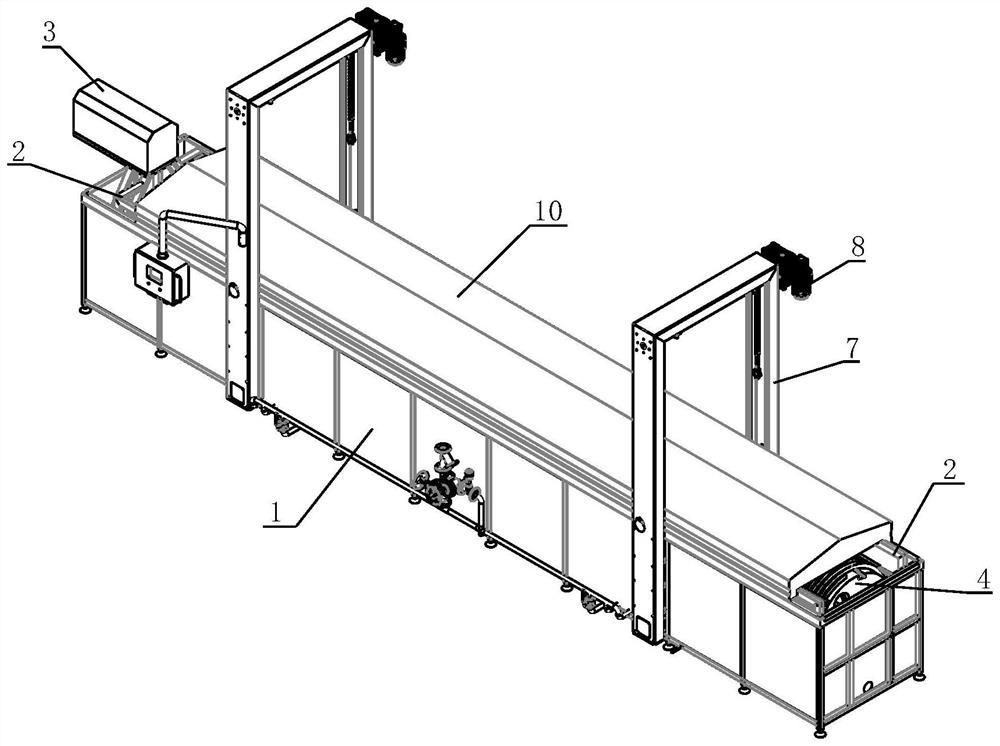

Spiral water boiling machine

PendingCN114128822ANo manual traction requiredImprove labor safetyFood shapingWater boilMechanical engineering

The invention belongs to the technical field of food processing equipment, and particularly relates to a spiral poaching machine which comprises an outer box body, a roller mounting frame is arranged in the outer box body, a roller driven by a power mechanism is rotatably mounted on the roller mounting frame, a spiral guide blade is arranged outside the roller, and the spiral guide blade is rotatably mounted on the roller mounting frame. The inner edge of the spiral guide blade is close to the outer peripheral surface of the roller; a track extending parallel to the axial direction of the roller is arranged on the peripheral face of the roller, a traction guide wheel is arranged in the track, and the top of the traction guide wheel is located in a gap between adjacent blades of the spiral guide blades. According to the spiral boiling machine provided by the invention, the traction guide wheel drags sausage to be wound on the roller along the spiral guide blade, manual traction is not needed, the production safety is greatly improved, and the roller can be lifted, so that the roller can be conveniently cleaned and kept clean and sanitary.

Owner:山东省春华机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com