Sealing mechanism for full-automatic chamfering sealing equipment for steel-plastic composite pressure pipe

A technology of steel-plastic composite and sealing equipment, applied in the field of steel-plastic composite pressure pipe processing, can solve the problems of sealing failure, corrosion, low efficiency, etc., and achieve the effect of improving sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

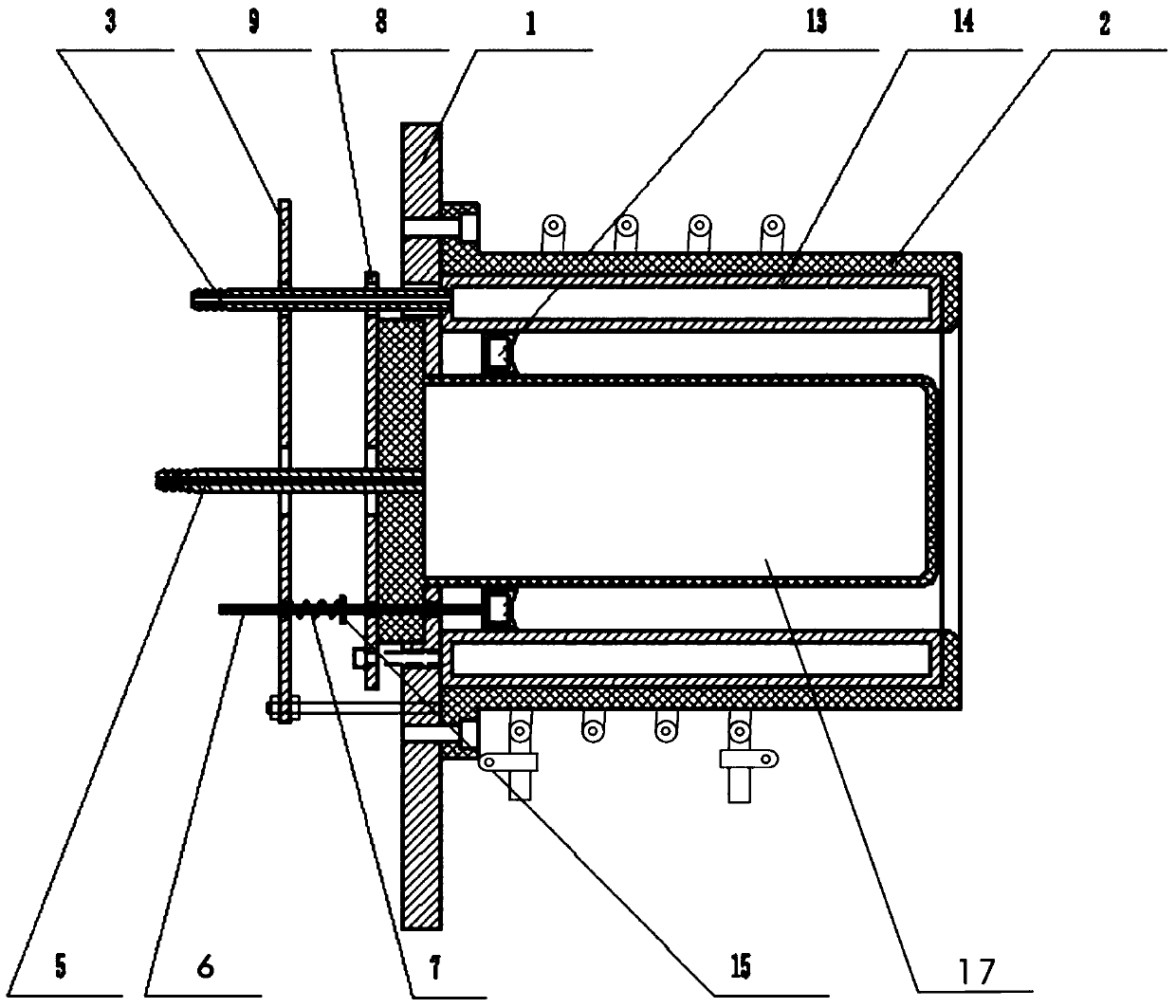

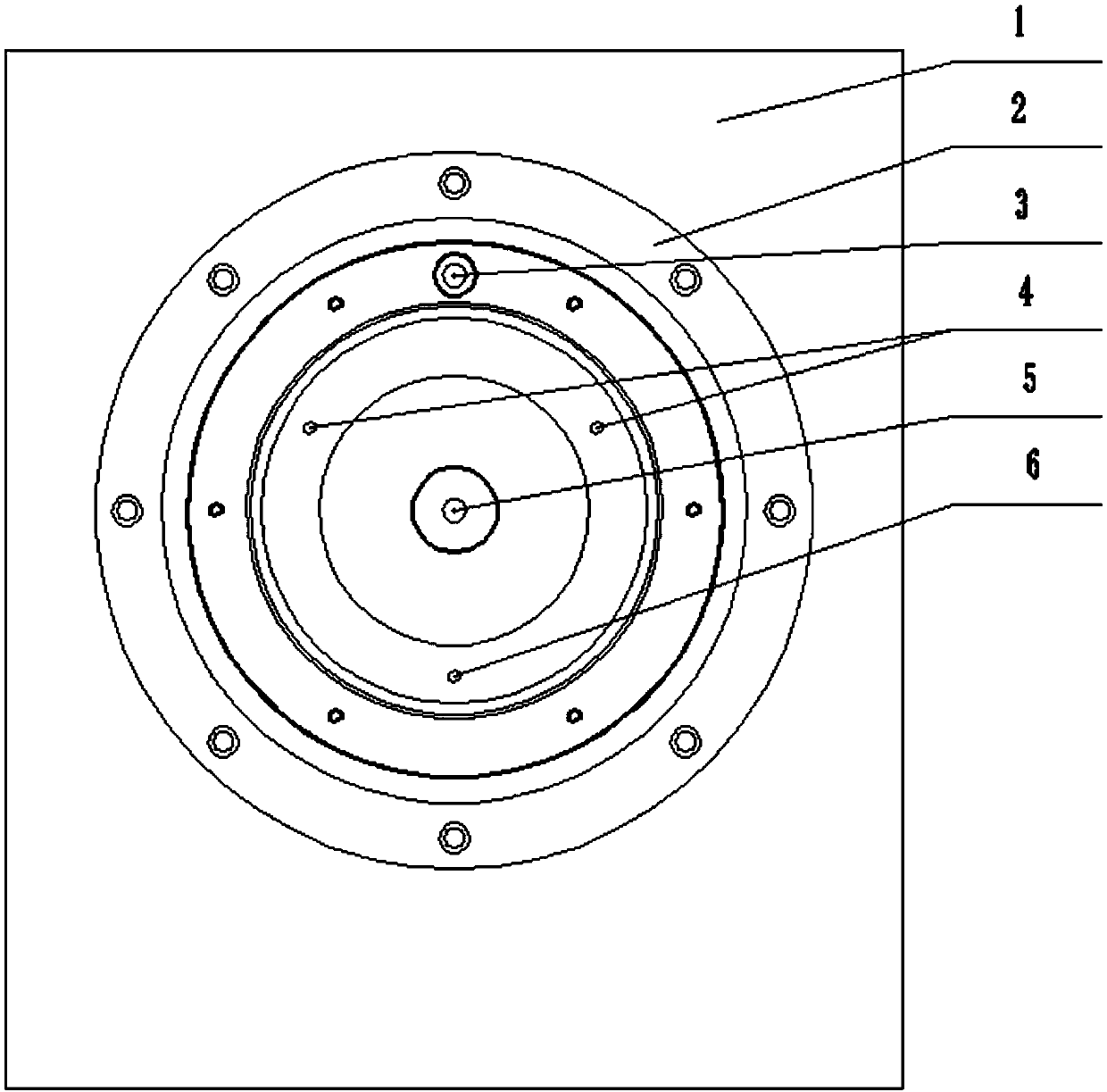

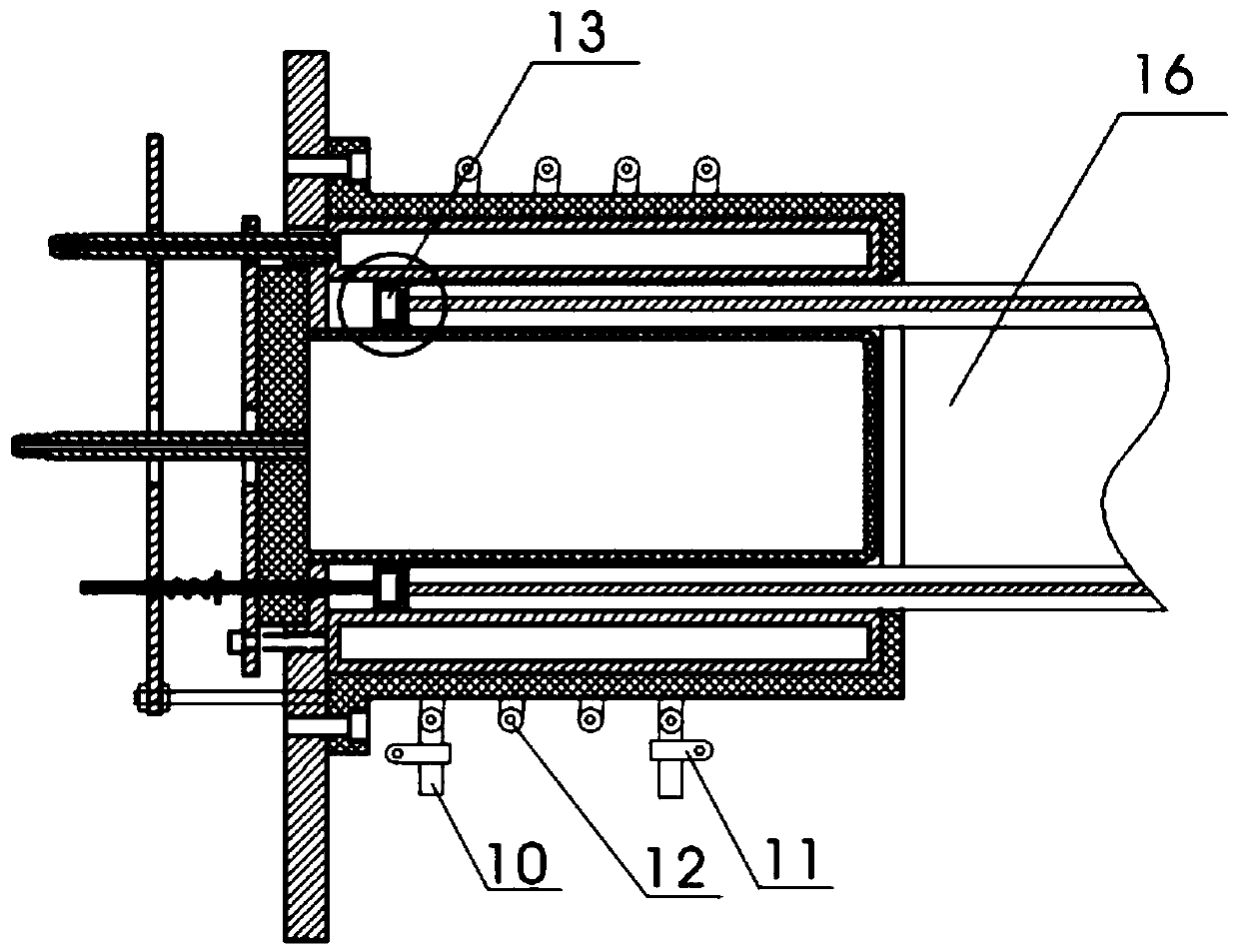

[0025] The invention provides a sealing mechanism for automatic chamfering and sealing equipment for steel-plastic composite pressure pipes, which includes an airbag support plate 1, an outer airbag shell 2, an outer airbag nozzle 3, a cooling water outlet conduit 4, an inner airbag nozzle 5, and a cooling water inlet Conduit 6, spring 7, airbag pressure plate 8, spring pressure plate 9, cooling joint 10, high-frequency power supply joint 11, cable coil 12, cooling forming ring 13, the steel-plastic composite pressure pipe is composed of inner and outer resin and pipe steel pipe layer 19, the pipe The outside of the steel pipe layer 19 is wrapped with resin. The outer airbag housing 2 is screw-fixed on the airbag support plate 1, the airbag support plate 1 and the outer airbag housing 2 are provided with installation openings, and the outside of the outer airbag housing 2 is wrapped with a cable coil 12, the two ends of the cable coil 12 and the height The high frequency power...

Embodiment 2

[0027] This application is mainly used in steel-plastic composite pressure pipes.

[0028]When in use, the steel-plastic composite pressure pipe 16 is delivered to the application through the transmission mechanism, the composite pipe 16 is placed between the inner air bag 17 and the outer air bag 14, the spring seat 15 is integrated with the cooling water inlet conduit 6 and the cooling water outlet conduit 4, When the steel-plastic composite pressure pipe 16 squeezes the cooling forming ring 13, the spring 7 is compressed, and the spring 7 presses the steel-plastic composite pressure pipe 16 and the arc-shaped end of the cooling forming ring 13 tightly against the spring seat 15. The power connector 11 is connected to a high-frequency power supply. When sealing, the high-frequency power supply supplies power to the cable coil 12 outside the outer air bag 14. The cable coil 12 generates a 360° uniform magnetic field. The steel pipe layer 19 of the steel-plastic composite press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com