Gcr15 material surface strengthening treatment technology and device

A technology for surface strengthening and processing equipment, applied in metal material coating process, lighting and heating equipment, ion implantation plating, etc. Increased hardness and improved thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention combined with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

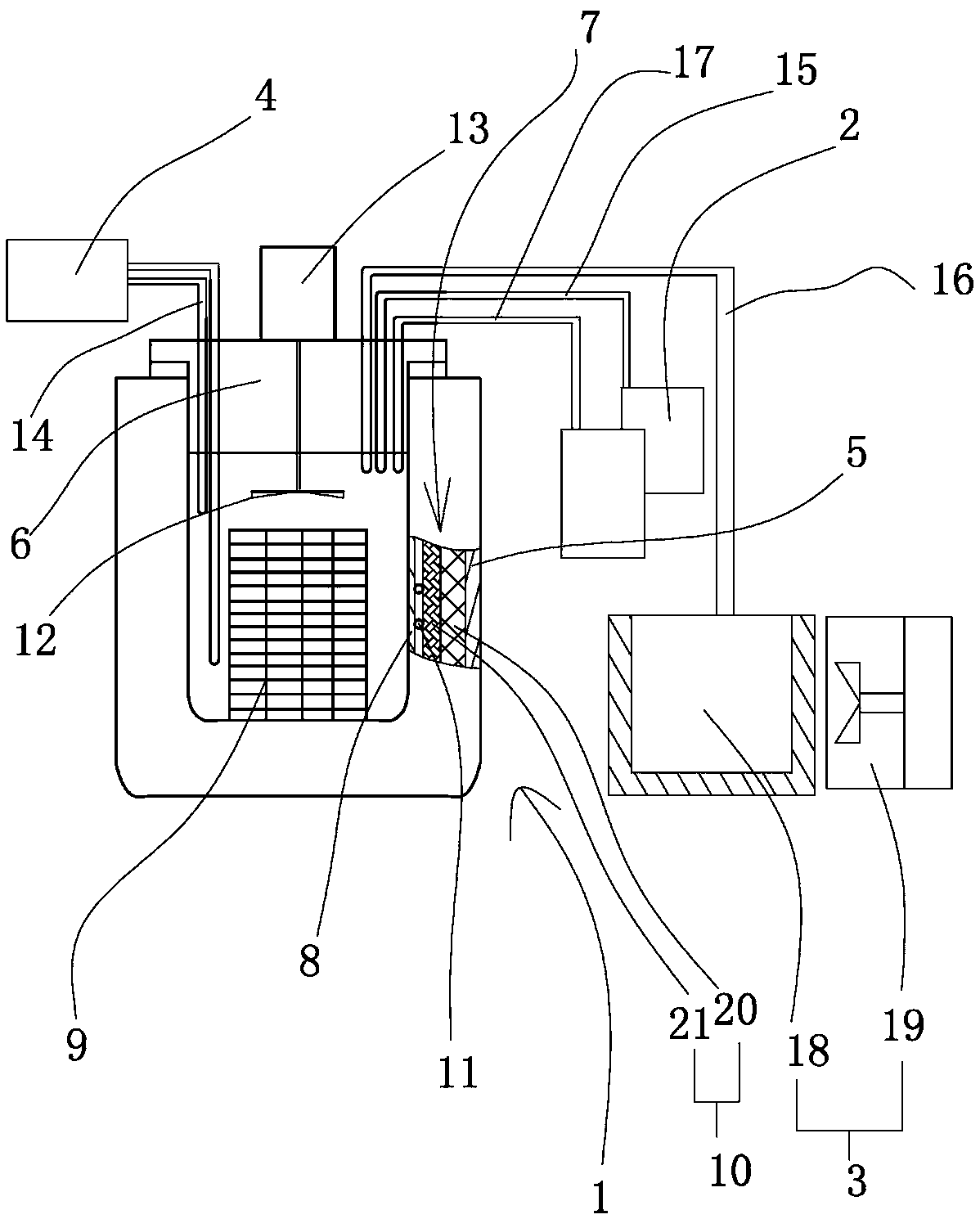

[0032] In order to facilitate the description, first of all, for the surface strengthening treatment equipment of Gcr15 material, such as figure 1 As shown, in order to solve the technical problem, the present invention makes a Gcr15 material surface strengthening treatment equipment, which is specifically composed of a pit furnace 1, a gas supply device 2 and a cooling device 3. The pit furnace 1 consists of a control panel 4, The furnace shell 5 is composed of a furnace cover 6 arranged on the top of the furnace shell 5. The furnace shell 5 is composed of a furnace 7, a furnace pot 8 and a grid-shaped material basket 9 arranged from the outside to the inside. The furnace 7 is filled with insulation Heating element 11 is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com