Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Achieve catalytic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-hardness epoxy modified polyurethane composite material and preparation method thereof

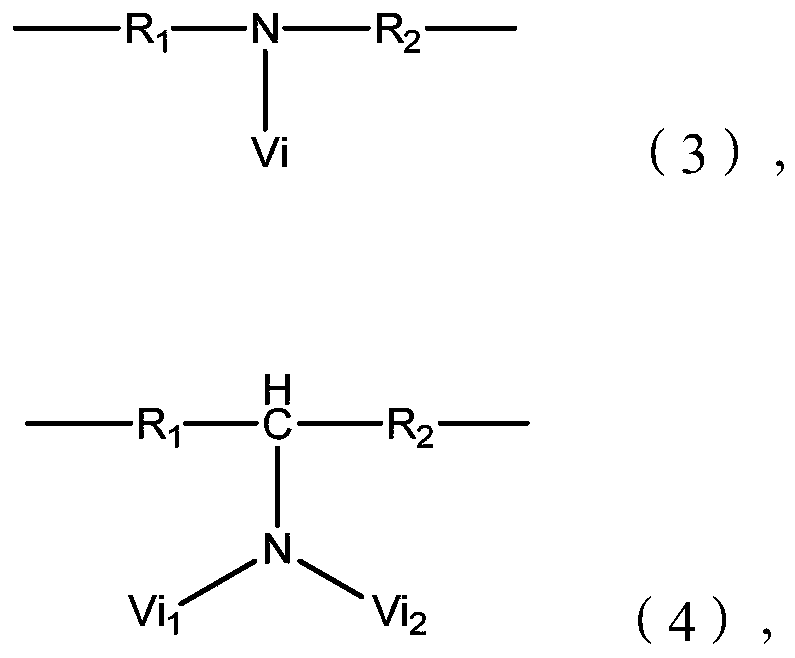

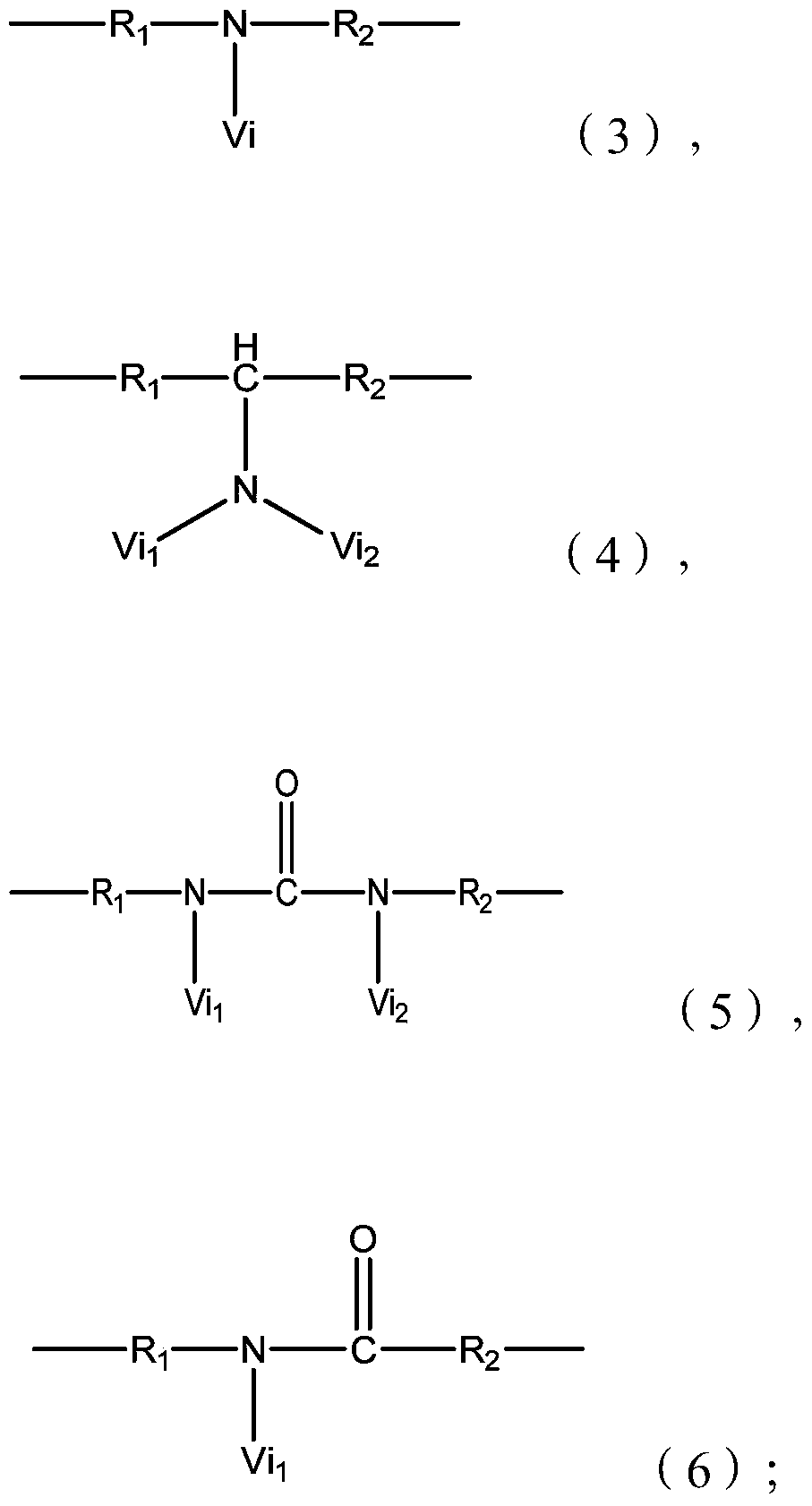

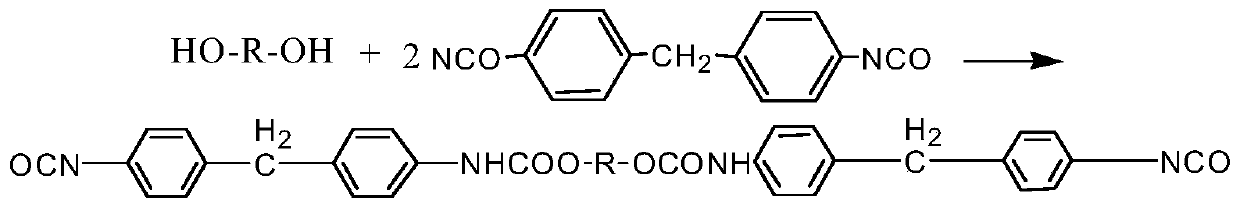

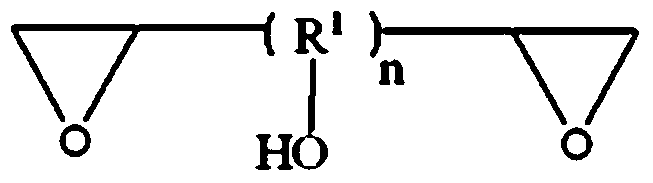

The invention relates to a high-hardness epoxy modified polyurethane composite material, which is prepared by adding a component A and a component B into a vacuumable sealed container and carrying out a mixed reaction by using a prepolymer method, wherein the component A is a mixture of a terminal isocyanate prepolymer and an epoxy resin, and the component B is a mixture of a chain extender and a catalyst. The preparation method comprises: weighing 130-140 parts of the component A and 2.4-15.2 parts of the component B, respectively pre-heating, adding the pre-heated components A and B to a vacuumable sealed container, mixing, carrying out vacuum deaeration while stirring, taking out after the gas bubbles are completely removed, pouring into a corresponding mold, carrying out low temperature curing, demolding, and carrying out heating vulcanization to prepare the high-hardness epoxy modified polyurethane composite material. According to the present invention, the product has advantages of high toughness, prolonged service life in the kettle, controllable reaction speed, low cost, and the like.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

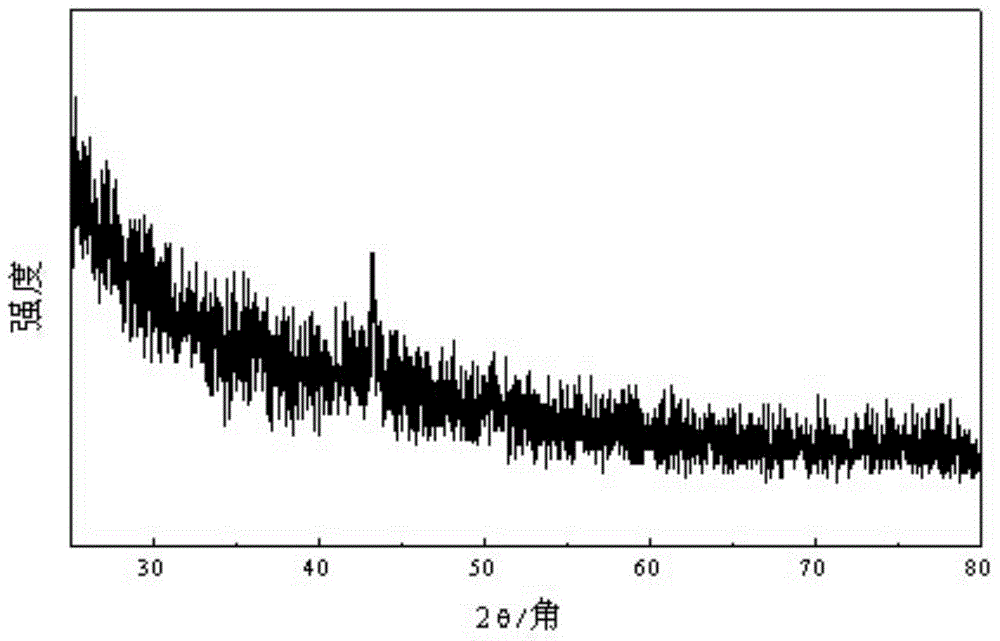

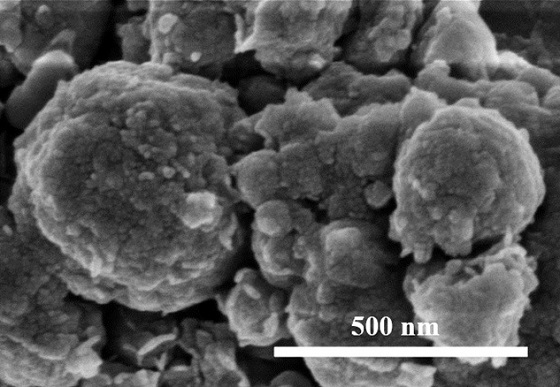

Manganese-based oxide catalyst used for catalytic oxidation of ethanol, and preparation method and application thereof

InactiveCN103055847AAchieve decentralizationAchieve catalytic effectDispersed particle separationCatalyst activation/preparationOxideHydrothermal synthesis

The invention relates to a preparation method for a manganese-based oxide catalyst used for catalytic oxidation of ethanol. The method is a hydrothermal synthesis method and comprises the following steps: (1) mixing a divalent manganese salt and an oxidizing agent, dissolving an obtained mixture in water and adjusting the pH value of an obtained solution to 0 to 2, wherein the mol ratio of divalent manganese in the divalent manganese salt to the oxidizing agent is 0.5 to 2.0; (2) stirring the mixed solution obtained in step (1) at room temperature and subjecting the mixed solution to a reaction at a temperature of 80 to 200 DEG C for 1 to 36 h; (3) washing and drying a product obtained in step (2); and (4) roasting the dried product so as to obtain the manganese-based oxide catalyst used for catalytic oxidation of ethanol. The manganese-based oxide catalyst has high activity in a low temperature range ( lower than 150 DEG C) and is applicable to elimination of ethanol gas which has not been totally consumed at a low temperature working condition section of a motor vehicle and to elimination of indoor ethanol gas.

Owner:佛山中科华洋材料科技有限公司

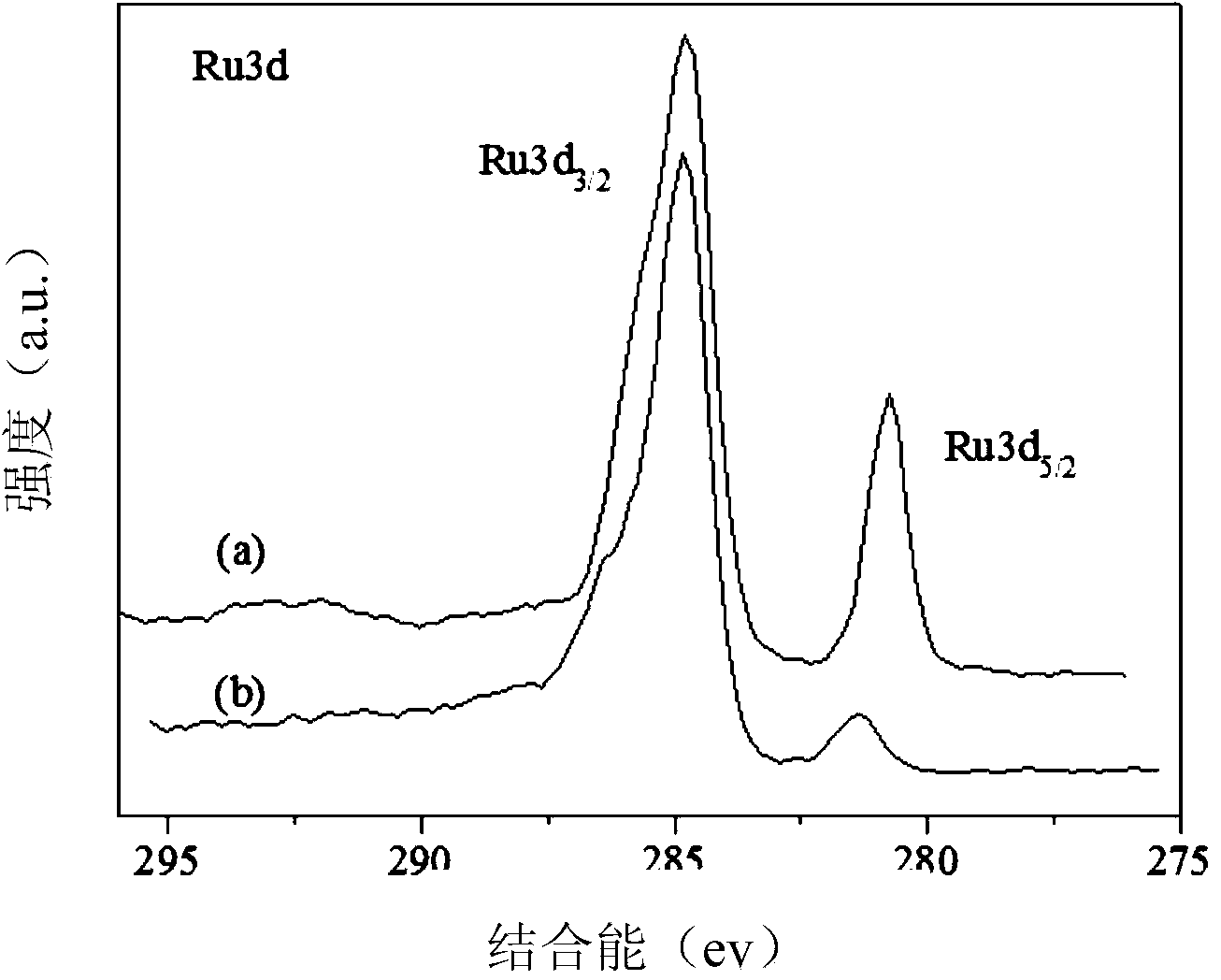

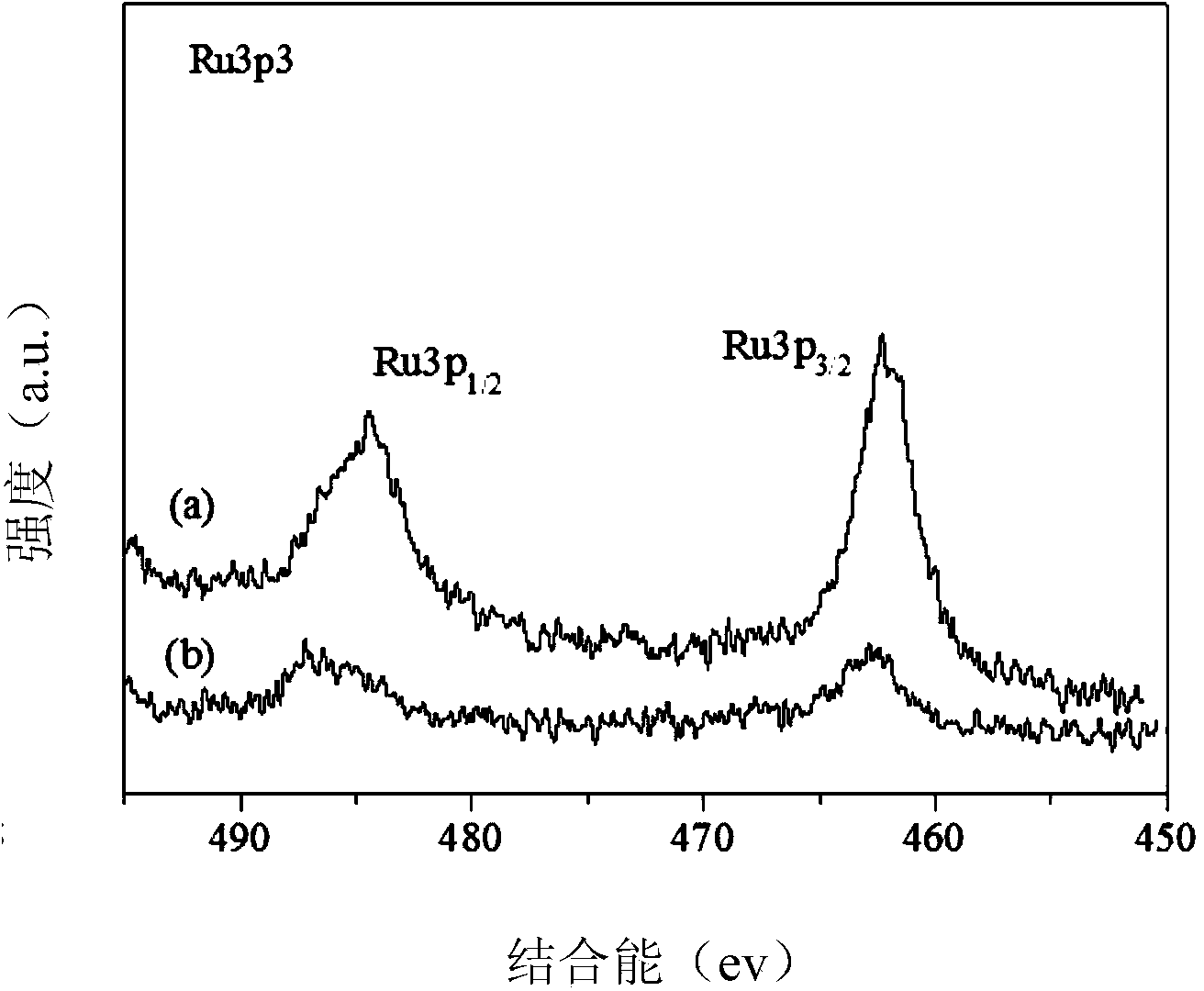

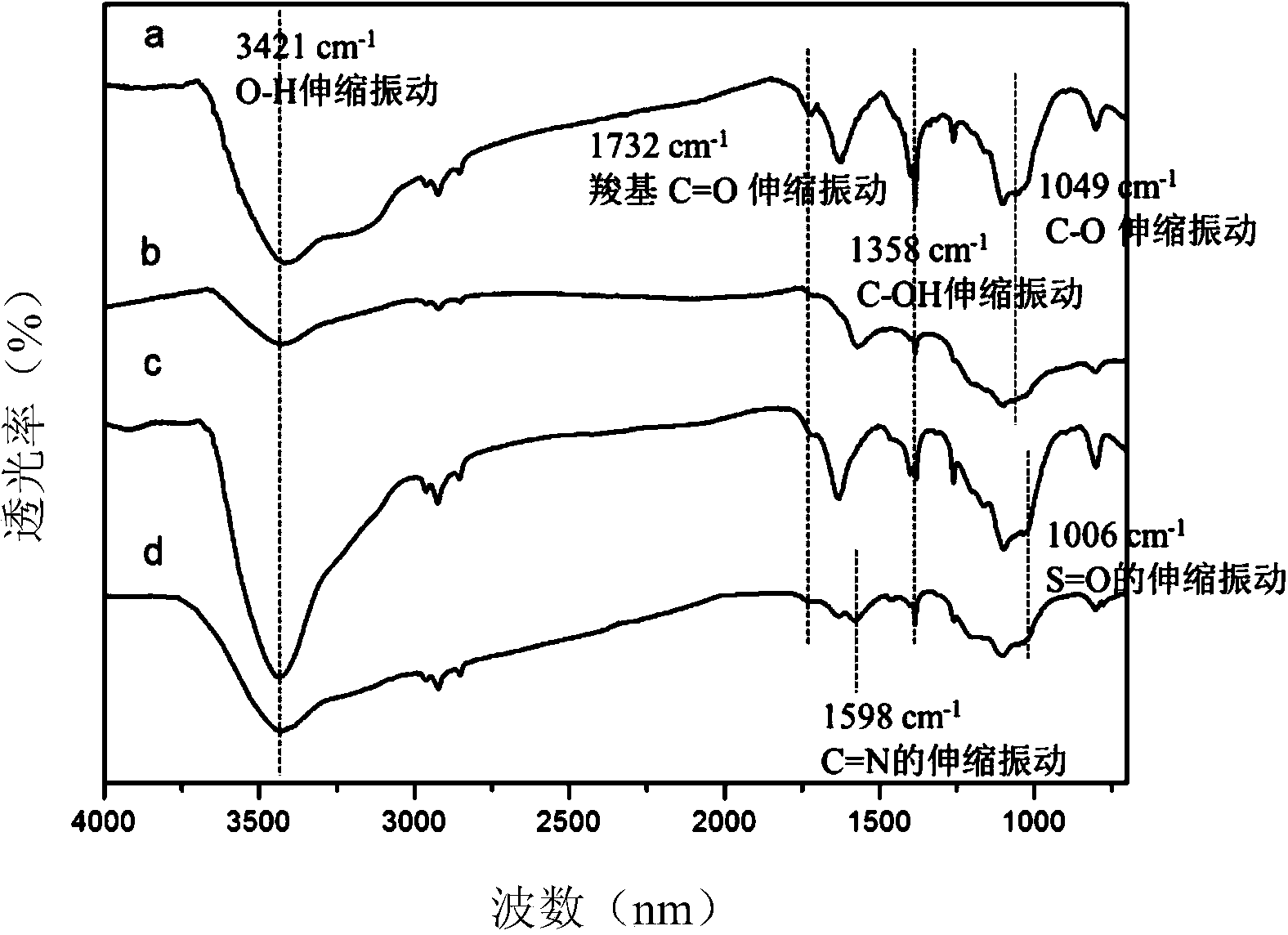

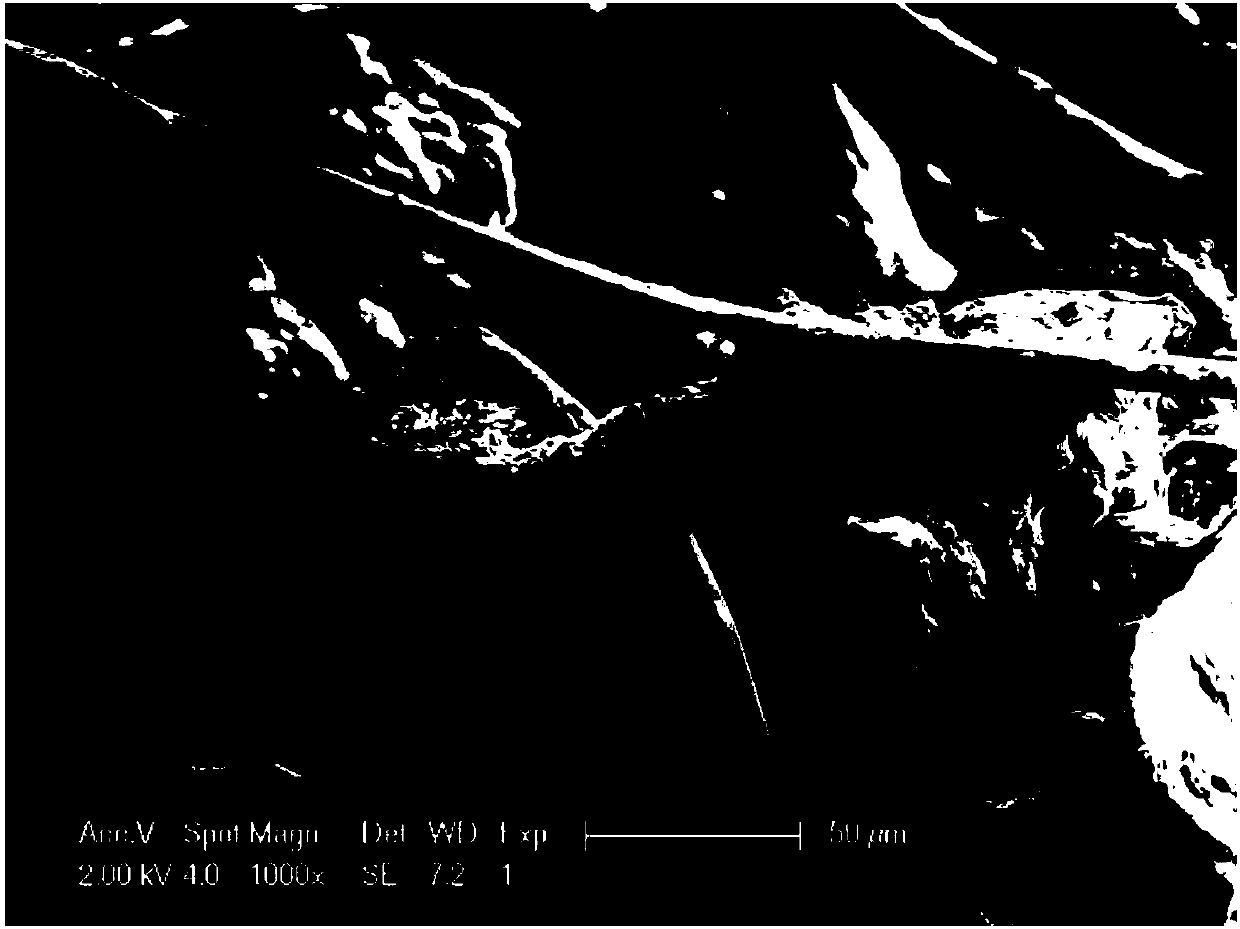

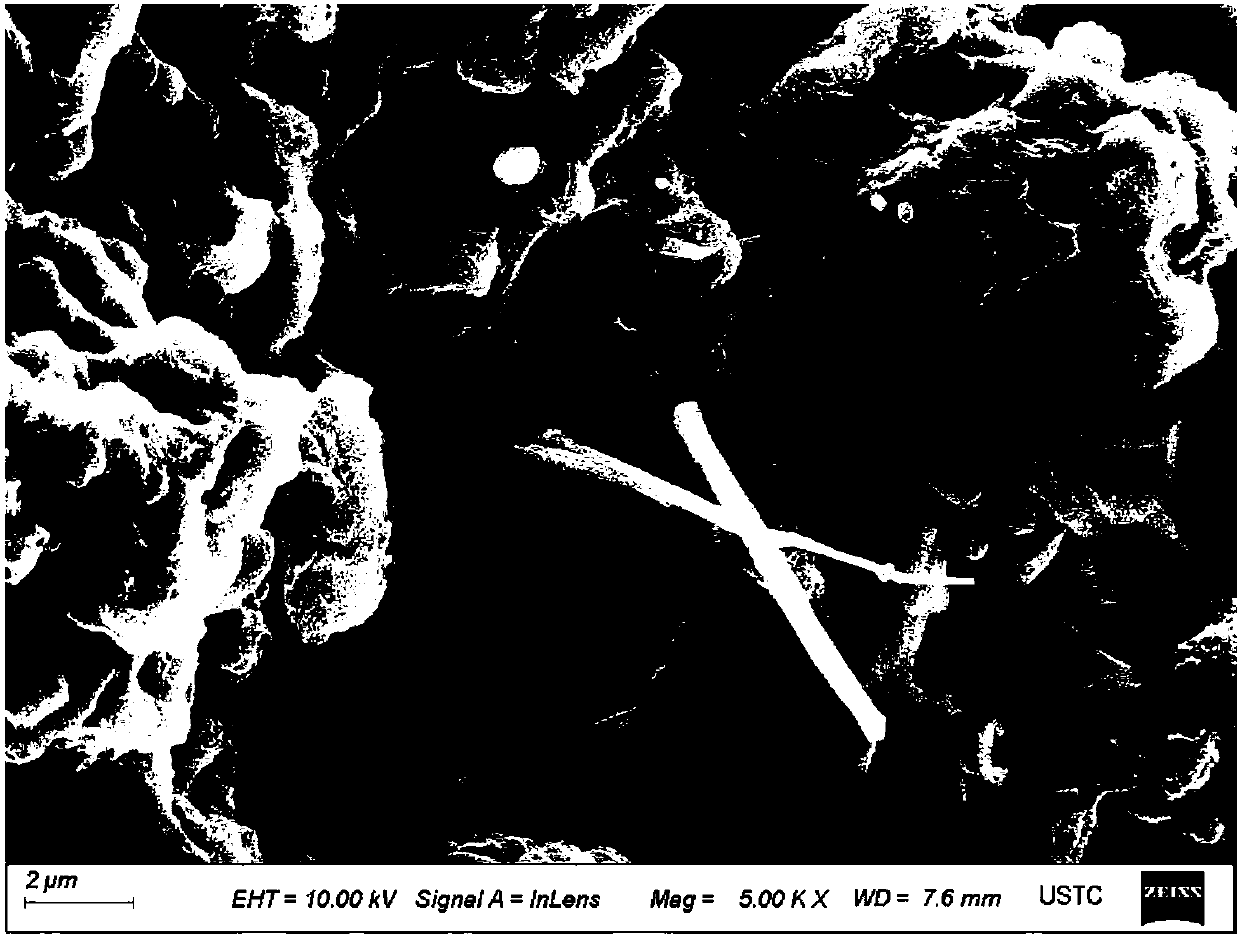

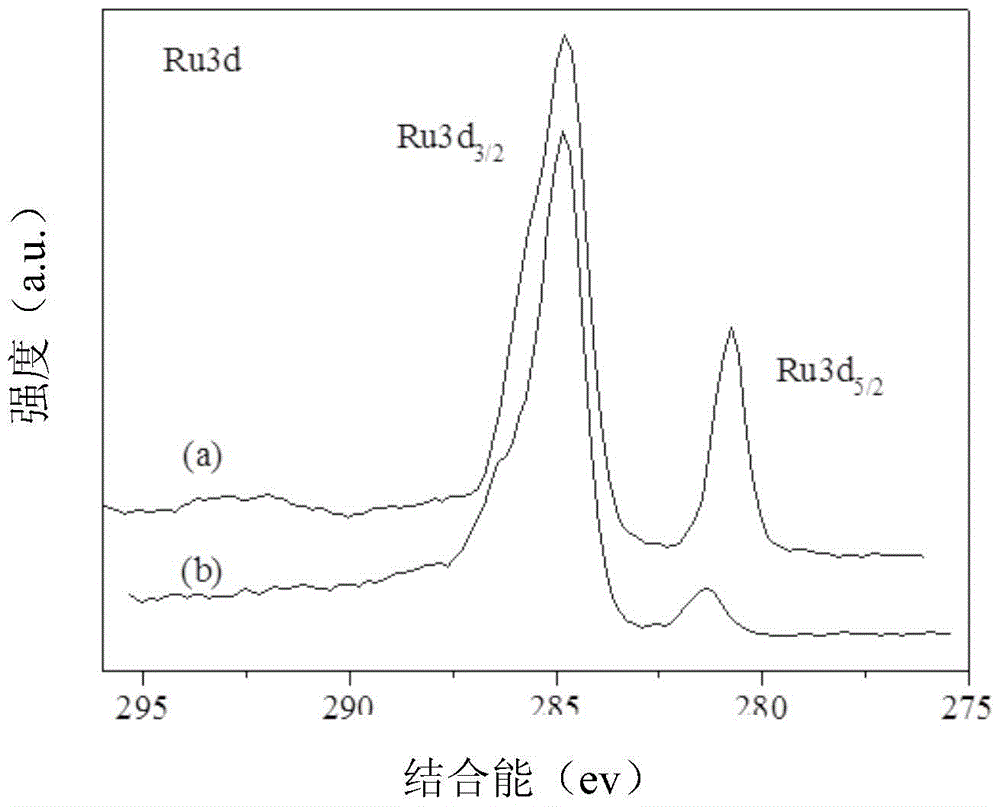

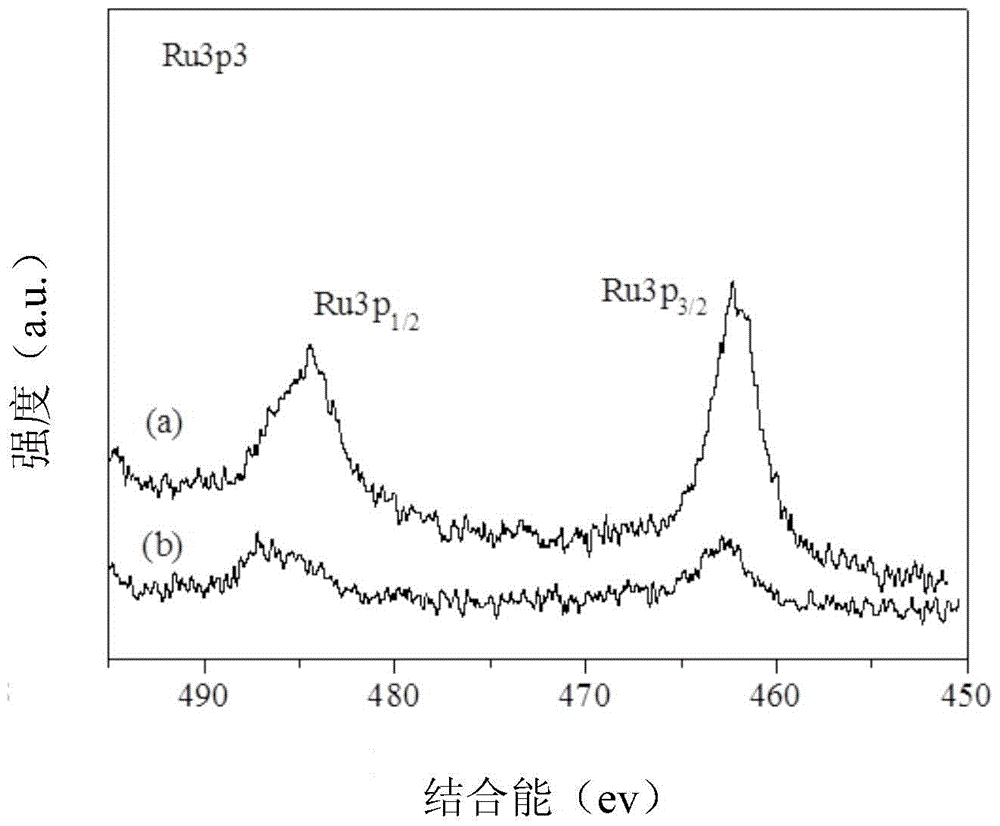

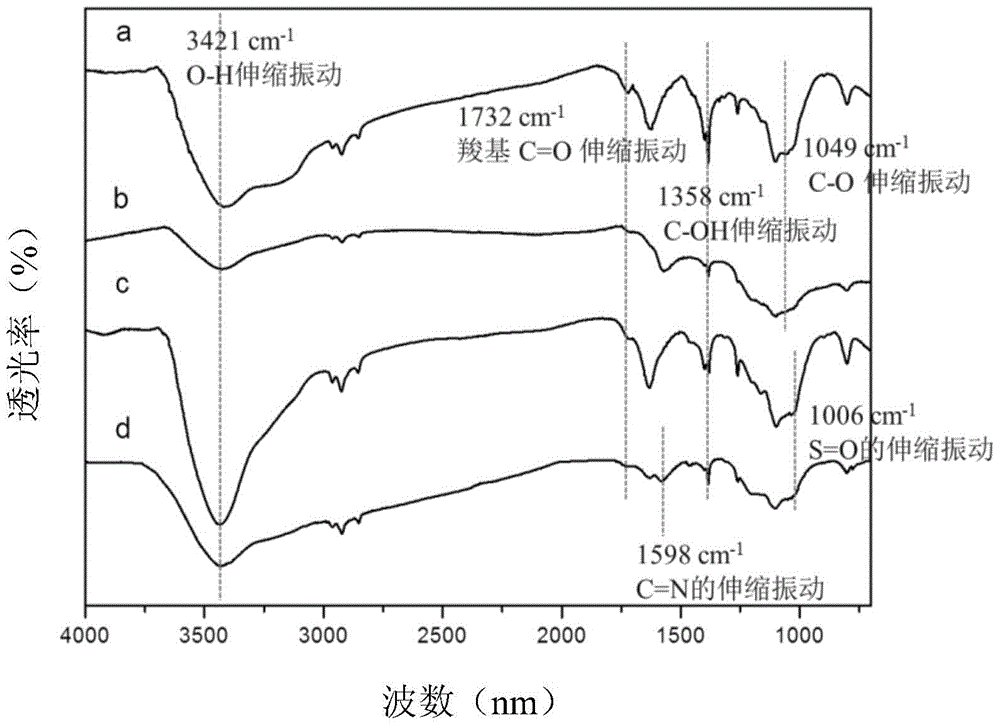

Sulfonated-graphene-based novel Ru(bpy)3<2+> nano heterogeneous catalyst and preparation method thereof

InactiveCN103977835AEliminate the effects of diffusionUnique two-dimensional planar structure of single atomic layerCatalyst carriersOrganic compound preparationPhotoinduced electron transferPtru catalyst

The invention discloses a sulfonated-graphene-based novel Ru(bpy)3<2+> nano heterogeneous catalyst and a preparation method thereof. The nano heterogeneous catalyst comprises a sulfonated graphene matrix and Ru(bpy)3<2+> groups, wherein the sulfonated graphene matrix comprises a graphene matrix and sulfonic groups distributed on the graphene matrix; the Ru(bpy)3<2+> groups are connected onto the sulfonated graphene matrix after being matched with the sulfonic groups, and the active sites of the Ru(bpy)3<2+> groups are dispersed on a two-dimensional plane of the graphene matrix. The preparation process comprises the following steps: carrying out an ion exchange reaction on sulfonated reduction graphene and Ru(bpy)3<2+> to form the nano heterogeneous catalyst. The nano heterogeneous catalyst is high in chemical and heat stability, has catalytic active sites of Ru(bpy)3<2+> with visible-light activity, is high in catalytic activity, can be well dispersed in a reaction system, is easy to recover, is suitable for repeated use, and can be widely applied to a light-induced electron transfer reaction; simultaneously, the preparation process is simple, the raw material is low in cost and easily available, the cost is low and the need of large-scale production is met.

Owner:SHANGHAI NORMAL UNIVERSITY

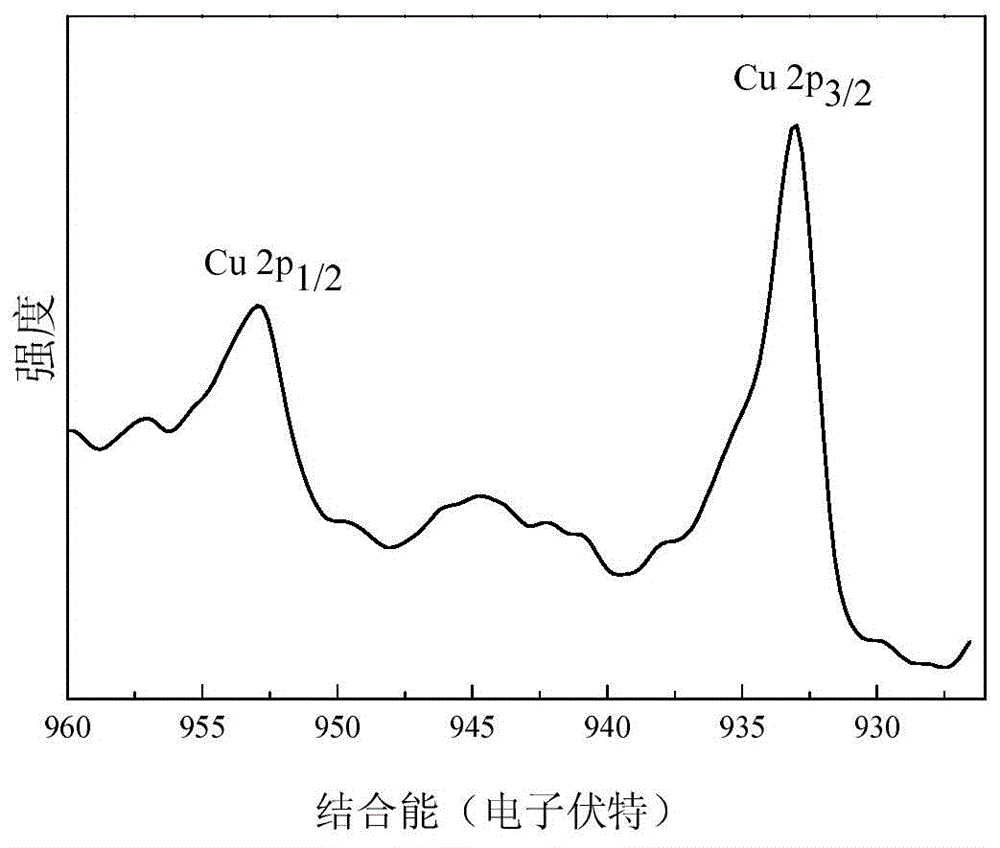

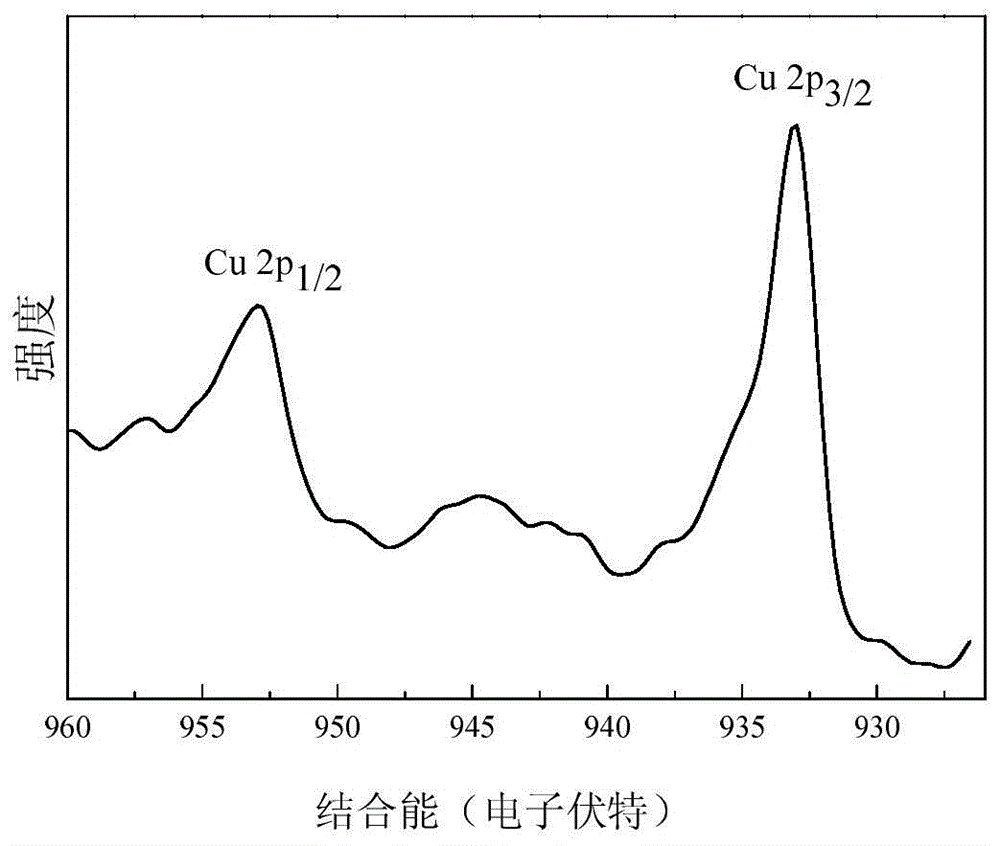

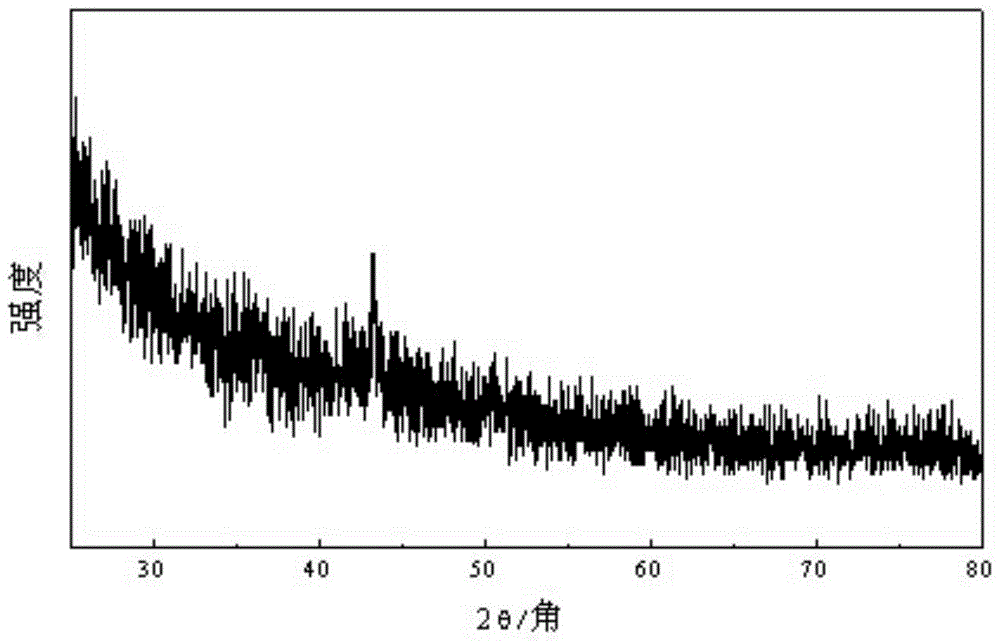

Mesoporous phenolic resin/copper nano particle heterogeneous catalyst, and preparation method and application of catalyst

InactiveCN104624234AEliminate the effects of diffusionUnique ordered two-dimensional hexagonal structureOrganic-compounds/hydrides/coordination-complexes catalystsCarbonyl compound preparation by condensationOrganocatalysisHomogeneous catalysis

The invention discloses a mesoporous phenolic resin / copper nano particle heterogeneous catalyst, and a preparation method and an application of catalyst. With ordered mesoporous phenolic resin as carrier and elementary substance state copper nano particle as catalyst active component, the heterogeneous catalyst has a regular mesoporous structure, as well as has the characteristics of large specific surface area, uniform particle size distribution, even active site distribution and the like; meanwhile, the catalyst has high chemical and thermal stabilities, can be dispersed well in a reaction system, is easy to recover and recycle, and is widely applied to each elementary copper based organic catalytic reaction. Furthermore, the preparation process of the catalyst is simple, the raw materials are cheap and available, the cost is low, and no reducing agent is added during the preparation process, so that the environment-friendly effect is achieved.

Owner:SHANGHAI NORMAL UNIVERSITY

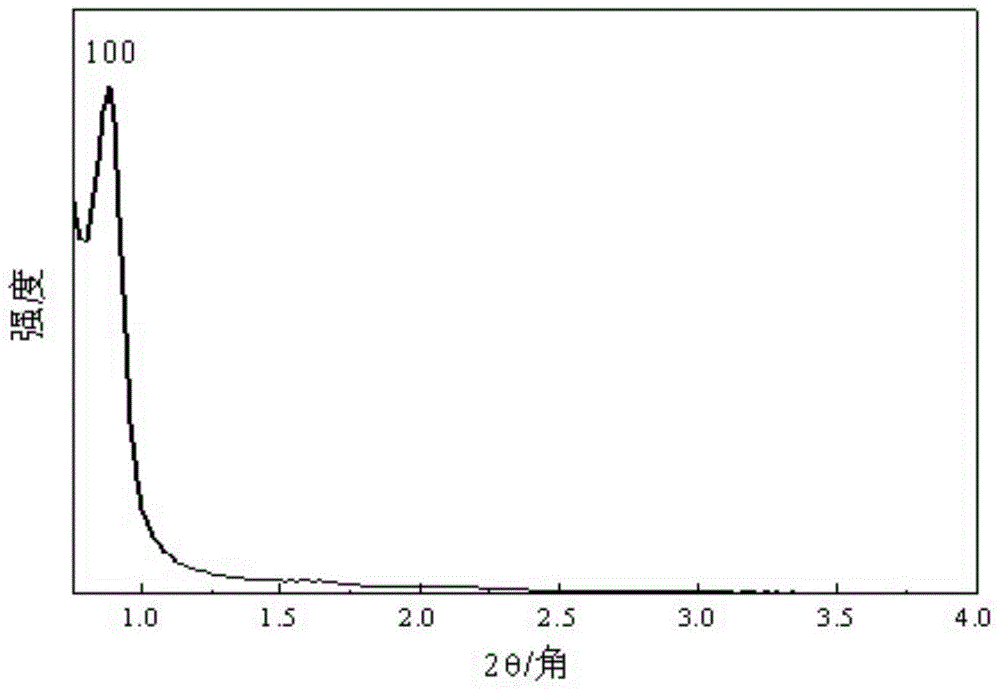

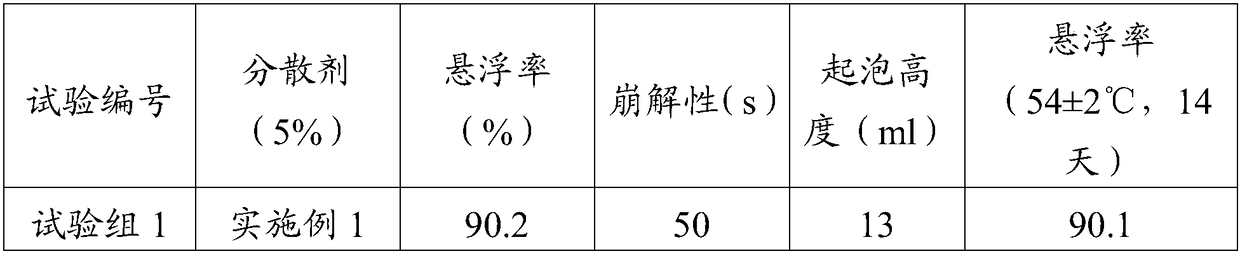

Preparation method and application of naphthalene sulfonate-alkyl naphthalene sulfonate-formaldehyde condensate

InactiveCN109020843AReduce dosageAvoid wastingBiocideSulfonic acids salts preparationSulfonateAlkyl transfer

The invention discloses a preparation method of a naphthalene sulfonate-alkyl naphthalene sulfonate-formaldehyde condensate. The preparation method comprises the following steps: firstly enabling naphthalene and an alkylation reagent to generate a mixed solution of naphthalene and alkyl naphthalene under the catalysis of sulfuric acid; then adding sulfuric acid into the mixed solution of naphthalene and alkyl naphthalene, and performing the sulfonation reaction; and adding formaldehyde, performing the one-pot condensation, and preparing thea naphthalene sulfonate-alkyl naphthalene sulfonate-formaldehyde condensate. By adopting the preparation method, the naphthalenesulfonic acid and alkyl naphthalene sulfonate do not need to be prepared independently, and the operation is simple; the wasteacid does not need to be removed, no acidic waste water is produced, and safety and environmental protection can be realized; and the prepared naphthalene sulfonate-alkyl naphthalene sulfonate-formaldehyde condensate is used as a dispersing agent to be applied to pesticide water dispersion granules or suspension, and has higher suspension rate and better heat storage stability.

Owner:江苏精禾界面科技有限公司

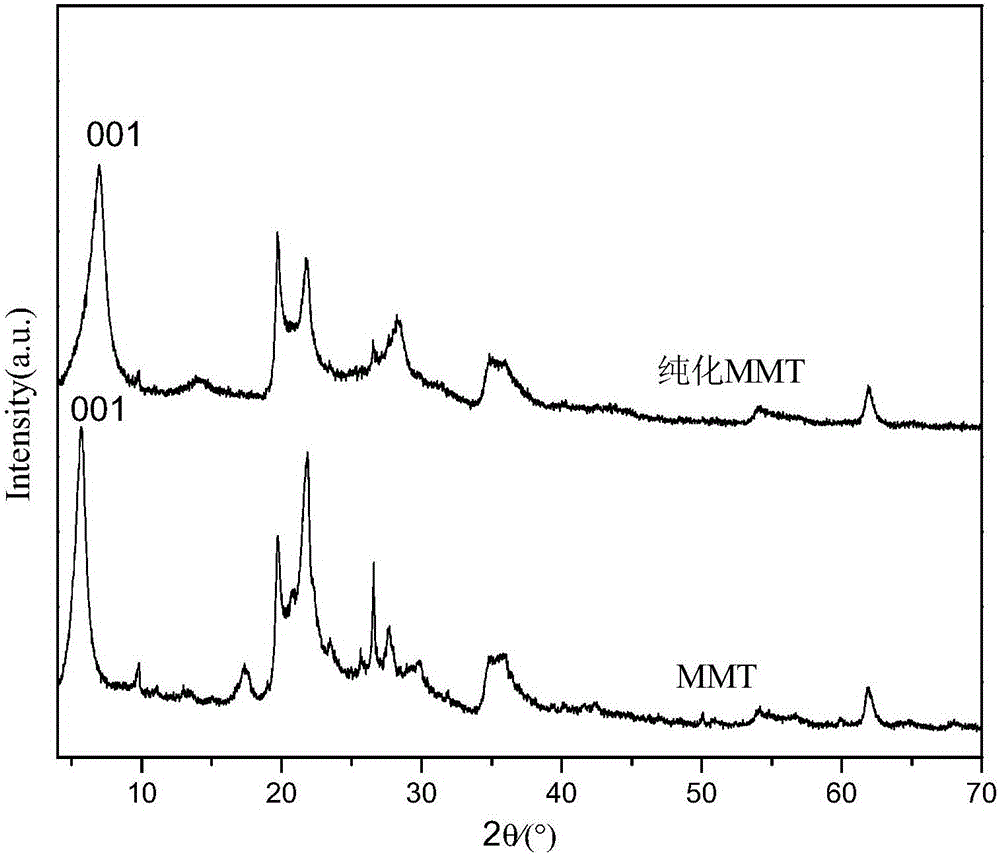

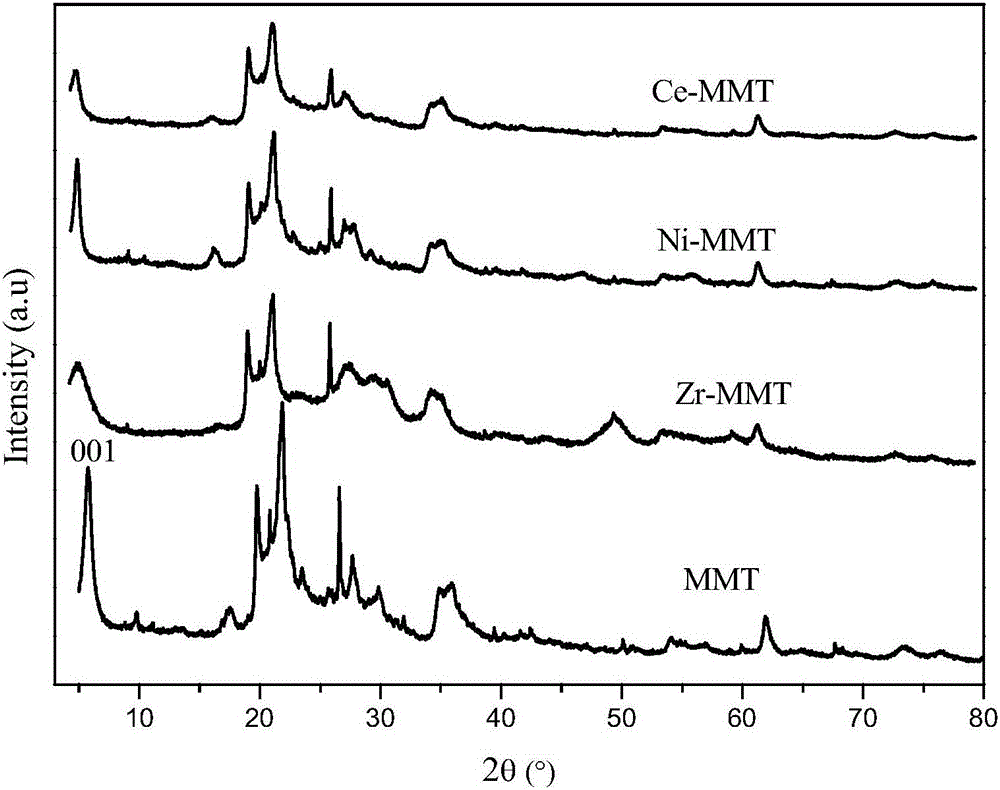

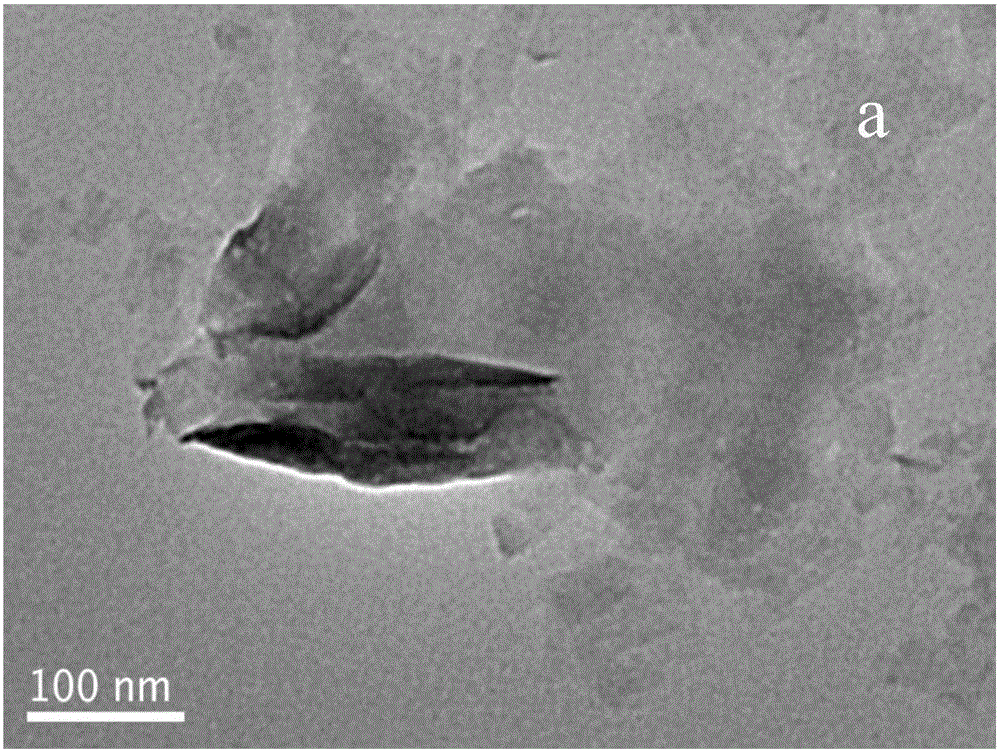

Metal pillared montmorillonite supported gamma-MnO2 low-temperature denitration catalyst and preparation method thereof

ActiveCN106423192AGood priceExpensive, good reactivityGas treatmentDispersed particle separationFlue gasMontmorillonite

The invention belongs to the field of flue gas denitration and provides a metal pillared montmorillonite supported gamma-MnO2 low-temperature denitration catalyst and a preparation method thereof, aiming at low support strength of existing commercial catalysts and the defects of the denitration properties of Mn-based catalysts in the presence of SO2. The catalyst is characterized in that lamellar montmorillonite is taken as a support, is interlayer-pillared by metals with different SO2 resistance and simultaneously supports gamma-MnO2 with higher low-temperature activity. The catalyst and the preparation method have the beneficial effects that superiority combination of gamma-MnO2 and interlayer SO2 resistant metals is achieved by utilizing the large specific surface area of lamellar montmorillonite; the catalyst prepared by adopting the method has high mechanical strength, is unnecessary to be calcined at high temperature, has good low-temperature activity and also has excellent SO2 resistance; besides, adopted montmorillonite is abundant in China, is low in cost, is easy to mold and transport and is an excellent catalyst support which can be actually used.

Owner:CHANGZHOU UNIV

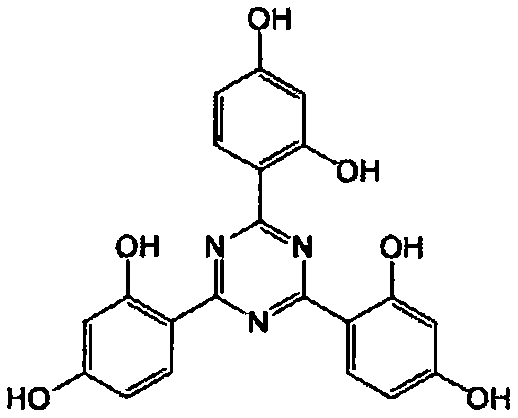

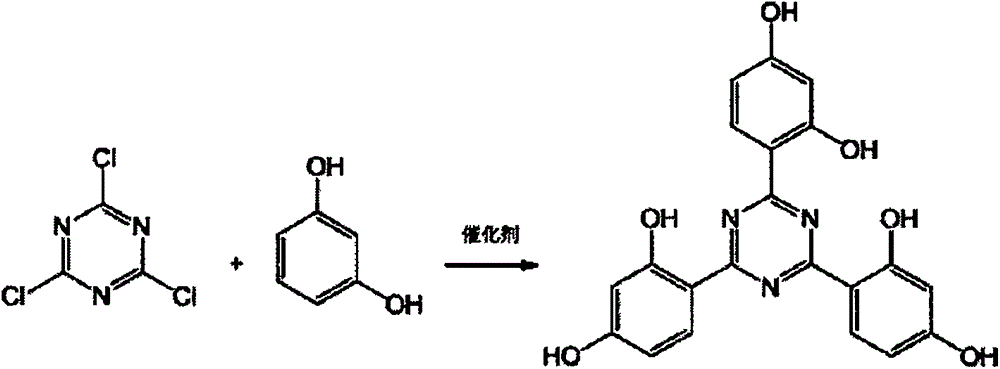

Preparation method of 2,4,6-tri(2',4'-dihydroxyphenyl)-1,3,5-triazine

ActiveCN105218466ASolve pollutionThe reaction steps are simpleOrganic chemistryChemical recyclingSolid acidReaction temperature

The invention discloses a synthetic method of 2,4,6-tri(2',4'-dihydroxyphenyl)-1,3,5-triazine. The method comprises the following steps: cyanuric chloride and resorcinol are taken as raw materials and react in an aprotic or protic solvent at the reaction temperature of 20-100 DEG C under the action of a metal oxide or supported solid acid catalyst, 2,4,6-tri(2',4'-dihydroxyphenyl)-1,3,5-triazine is generated, a reaction mixture is filtered and separated, and the catalyst can be recycled and reused after washing. The method has simple reaction steps and low cost; the adopted catalyst is simple, easy to obtain and stable in activity, environmental pollution caused by use of a traditional Lewis acid catalyst is avoided, and good catalytic effect is realized.

Owner:BEIJING TIANGANG AUX CO LTD

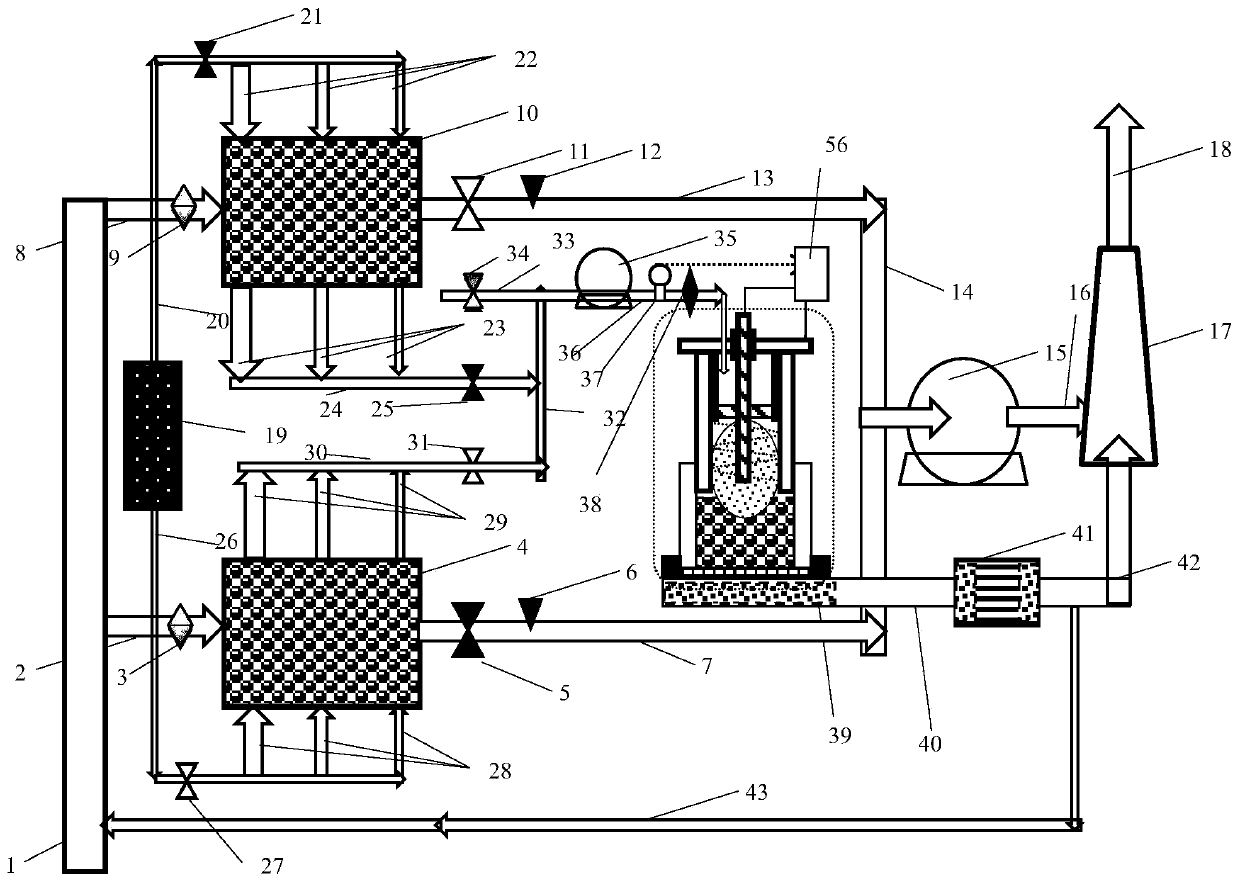

Rotating arc thermal plasma catalytic cracking high-concentration VOC tail gas treatment system and method

PendingCN110508109ASmall scaleLow investment costGas treatmentDispersed particle separationHigh concentrationActivated carbon

The invention relates to a rotating arc thermal plasma catalytic cracking high-concentration VOC tail gas treatment system and method, and the rotating arc thermal plasma catalytic cracking high-concentration VOC tail gas treatment system comprises an activated carbon alternating adsorption device, a hot air alternating desorption device, a rotating arc thermal plasma high-concentration waste gascracking catalytic device, a DBD plasma advanced treatment device and a water spraying device. According to the invention, through the activated carbon alternating adsorption device and the hot air alternating desorption device, and through parallel alternating work, one path realizes that low-concentration (10 mg / m<3>) waste gas is firstly adsorbed and then directly discharged, and the other pathdesorbs the other path of adsorption module with 1% of hot air flow rate, so that the low-concentration waste gas with large air volume is converted into high-concentration waste gas with small air volume for treatment, thereby providing possibility for greatly reducing the scale of plasma equipment and reducing investment cost.

Owner:NANJING SUMAN PLASMA TECH CO LTD

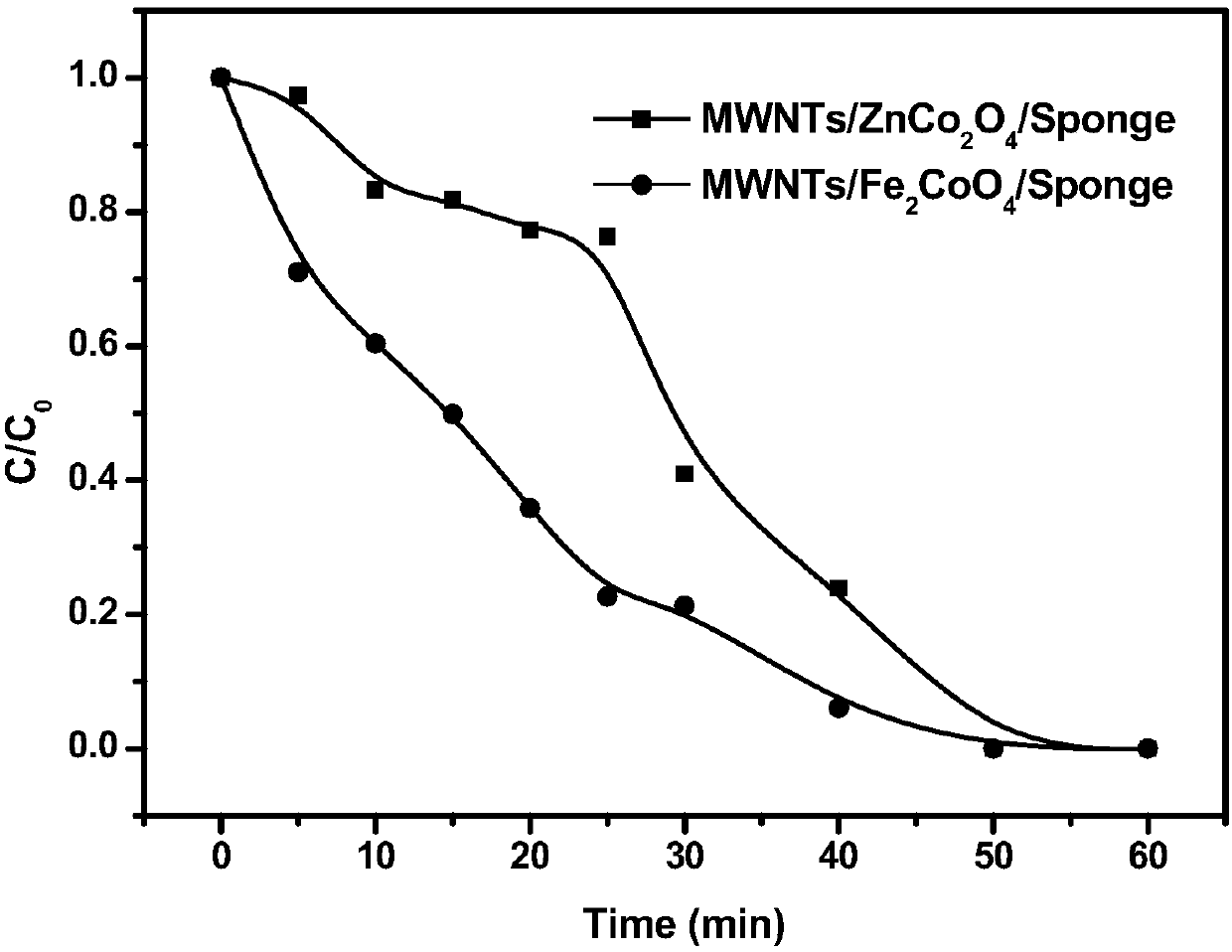

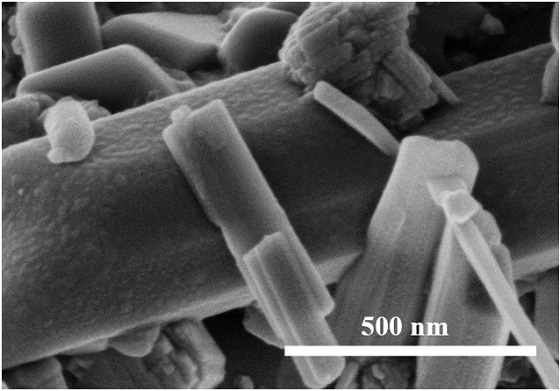

Electrode loading with composite oxide magnetic nanowire and carbon nanotube and its preparation and application

InactiveCN107774264AAchieve catalytic effectImprove catalytic performanceWater contaminantsWater/sewage treatmentCarbon nanotubeCarbon felt

The invention discloses an electrode loading with a composite oxide magnetic nanowire and a carbon nanotube and its preparation and an application. The preparation includes steps of (1), mixing hexadecyl trimethyl ammonium bromide, hexamethylene and n-amyl alcohol evenly; then adding oxalic acid solution; after mixing evenly, adding mixed solution containing transition metal ion and cobalt ion; continuously stirring under the room temperature to obtain microemulsion; (2), centrifugally removing impurities and drying in the air to obtain powder; forging in the air to obtain the transition metal / cobalt composite oxide magnetic nanowire; (3), dissolving the transition metal / cobalt composite oxide magnetic nanowire and sodium dodecyl benzene sulfonate in ethylene glycol; after dispersing evenly, immersing a sponge or carbon felt electrode; taking out the sponge or carbon felt electrode and drying; immersing again; repeating the operation for many times to obtain the electrode. The actual application effect is stable and efficient, the electrode loaded with metal oxide / carbon nanotube can be prepared, and the plasma of organic pollutant can be degraded.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

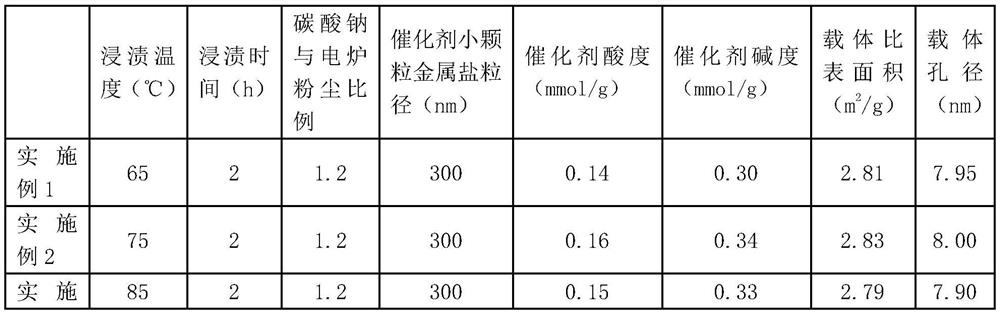

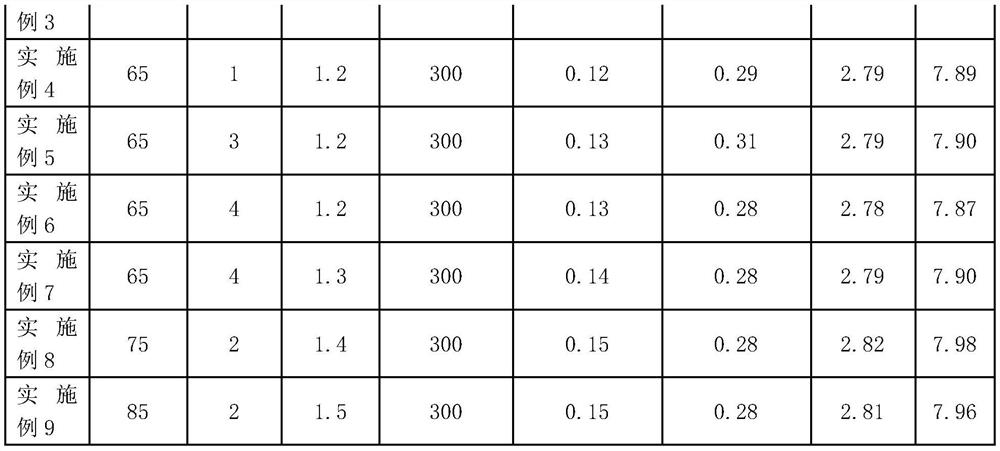

Catalyst and method for preparing biodiesel by using catalyst

ActiveCN113477260AHigh catalytic activityAchieve catalytic effectFatty acid esterificationBiofuelsLiquid productPtru catalyst

The invention discloses a catalyst. A preparation method for the catalyst comprises the following steps: grinding electric furnace dust by using a ball mill, and conducting sieving by using a 75-to-400-mesh sieve; placing the sieved electric furnace dust in a drying oven for drying at a temperature of 75-105 DEG C for 5-48 h so as to obtain pretreated electric furnace dust; and putting the pretreated electric furnace dust and sodium salt solution into a rubber-sealed glass bottle, conducting magnetic stirring in an oil bath pan at 55-105 DEG C for 0.5-5 hours, drying an obtained sample in the drying oven at 75-105 DEG C for 4 hours or more, and conducting sieving with the 75-to-400-mesh sieve to obtain the required sodium-electric furnace dust catalyst. The catalyst has acidity and alkalinity at the same time, and can be automatically separated from a liquid product through standing. The catalyst can be directly used for reaction of low-acid-value oil, the catalytic effect of the catalyst is very good, biodiesel yield is larger than 95%, and the recovery rate of the catalyst is larger than 90%. Moreover, the recycling capability of the catalyst is better, and the yield of biodiesel can still reach 90% or above after 15 times of reactions.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for using catalysts in microwave field

InactiveCN110538571ADoes not affect the distributionAchieve catalytic effectGas treatmentDispersed particle separationMicrowave cavityCombustion

The invention discloses a method of using catalysts in a microwave field. According to the method of the invention, a metal net, solid catalysts and a spot welding machine are employed; the metal netwraps the outer surfaces of the solid catalysts; and the spot welding machine welds the metal net to fix the metal net into a plate-shaped material which then can be directly installed in a microwavecavity of waste gas treatment equipment. According to the invention, a traditional photocatalyst, a traditional thermal catalyst and carriers thereof are packaged in the metal net which is then fixedin the microwave ultraviolet waste gas treatment cavity; since the metal net can reflect microwaves, the catalysts cannot absorb microwave energy and are thus prevented from ignition or combustion; meanwhile, irradiation of ultraviolet light and passing of airflow are not affected, so the selection range of catalysts, carriers and carrier bed materials in the microwave field can be greatly widened, and equipment manufacturing cost is reduced.

Owner:陕西青朗万城环保科技有限公司

Application of a polyurethane catalyst in the synthesis of rigid polyurethane materials

A polyurethane catalyst comprises a sodium compound which is 1-60 wt% of the polyurethane catalyst, and a tertiary amine and / or pyridine compound. The sodium compound and the tertiary amine and / or pyridine compound achieve the synergistic effect; during the catalysis of the polymerization of isocyanate and polyalcohol, the speed of the polymerization reaction is increased; the prepared polyurethane material high tensile strength, elasticity, aging resistance and other physical properties; besides, the catalyst does not contain any heavy metal element at all, is an environment-friendly catalyst, and is particularly applicable to the preparation of rigid polyurethane foamed plastic, a rigid polyurethane elastomer and a composite material thereof, as well as a polyurethane sole material; moreover, compared with the traditional catalyst, the catalyst, provided by the invention, has the advantages that the hydrolysis resistance is good, and the storage stability is obviously improved.

Owner:JIANGSU OSIC PERFORMANCE MATERIALS CO LTD

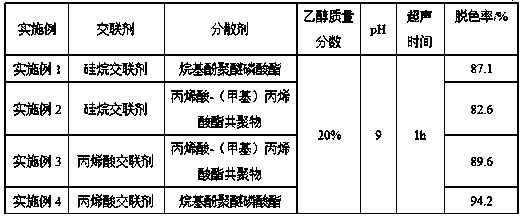

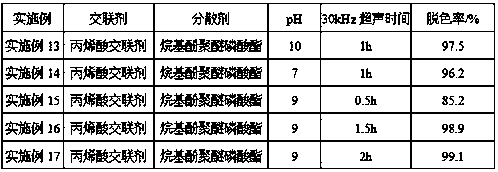

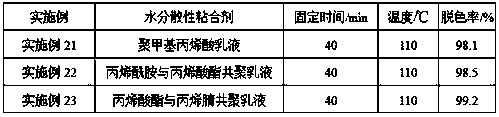

Method for loading nano titanium dioxide on textile, textile loaded with nano titanium dioxide and application thereof

InactiveCN110924138AImprove load fastnessEasy reunionStain/soil resistant fibresBiochemical fibre treatmentAdhesiveAnti bacterial

The invention discloses a method for loading nano titanium dioxide on a textile, the textile loaded with the nano titanium dioxide and an application thereof. The method comprises the following stepsof step S1, preparation of a nano titanium dioxide solution: placing nano titanium dioxide particles, an adjuvant and a solvent in a container for mixing, adjusting the pH to be 5 to 10, ultrasonically dispersing for 2 to 5 minutes at 20 to 40kHz to obtain the uniform nano titanium dioxide solution; step S2, a textile loading process: placing the textile in the nano titanium dioxide solution, andperforming the ultrasonic treatment at the temperature of 60 to 95 DEG C for 0.2 to 2h at 20 to 40kHz; and step S3, blocking, fixing and forming: adding a water-dispersible adhesive to fix for 0.5 to1h, and drying and curing at 80 to 120 DEG C. According to the method of the invention, the manufacturing cost is low, the loading fastness of the nano titanium dioxide particles is high, and the problem of agglomeration of the titanium dioxide particles is solved. According to the textile loaded with the nano titanium dioxide prepared by the method provided by the invention, the catalytic actionbetween the nano titanium dioxide particles, air and water molecules is maximized, and the anti-fouling, anti-bacterial and anti-ultraviolet performance of the textile is improved.

Owner:浙江迈实科技有限公司 +1

Sodium salt-blast furnace dust catalyst and method for preparing biodiesel from sodium salt-blast furnace dust catalyst

ActiveCN113893861AHigh catalytic efficiencyPost-processing is simpleBiofuelsCatalyst activation/preparationNitrogen atmosphereNitrogen gas

The invention discloses a catalyst which is prepared by the following steps: grinding blast furnace dust by using a ball mill, and conducting screening; drying the sieved blast furnace dust at 75-105 DEG C for 5 hours or more to obtain pretreated iron-containing blast furnace dust; and soaking the pretreated blast furnace dust in a sodium salt solution, placing the pretreated blast furnace dust in an oil bath pan, carrying out magnetic stirring at 65 DEG C, drying the obtained sample at 75-105 DEG C for 5 hours or more, sieving the dried sample, and conducting calcining at 500-700 DEG C in a nitrogen atmosphere to obtain the sodium salt-blast furnace dust catalyst. The catalyst can be directly used for reaction of low-acid-value oil, the biodiesel yield is larger than or equal to 95%, the recycling capacity is good, and the biodiesel yield can reach 90% or above after 16 times of recycling.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Sulfonated graphene-based ru(bpy) 3 2+ Nano heterogeneous catalyst and preparation method thereof

InactiveCN103977835BEliminate the effects of diffusionUnique two-dimensional planar structure of single atomic layerCatalyst carriersOrganic compound preparationElectron transfer reactionsIon exchange

The invention discloses a sulfonated-graphene-based novel Ru(bpy)3<2+> nano heterogeneous catalyst and a preparation method thereof. The nano heterogeneous catalyst comprises a sulfonated graphene matrix and Ru(bpy)3<2+> groups, wherein the sulfonated graphene matrix comprises a graphene matrix and sulfonic groups distributed on the graphene matrix; the Ru(bpy)3<2+> groups are connected onto the sulfonated graphene matrix after being matched with the sulfonic groups, and the active sites of the Ru(bpy)3<2+> groups are dispersed on a two-dimensional plane of the graphene matrix. The preparation process comprises the following steps: carrying out an ion exchange reaction on sulfonated reduction graphene and Ru(bpy)3<2+> to form the nano heterogeneous catalyst. The nano heterogeneous catalyst is high in chemical and heat stability, has catalytic active sites of Ru(bpy)3<2+> with visible-light activity, is high in catalytic activity, can be well dispersed in a reaction system, is easy to recover, is suitable for repeated use, and can be widely applied to a light-induced electron transfer reaction; simultaneously, the preparation process is simple, the raw material is low in cost and easily available, the cost is low and the need of large-scale production is met.

Owner:SHANGHAI NORMAL UNIVERSITY

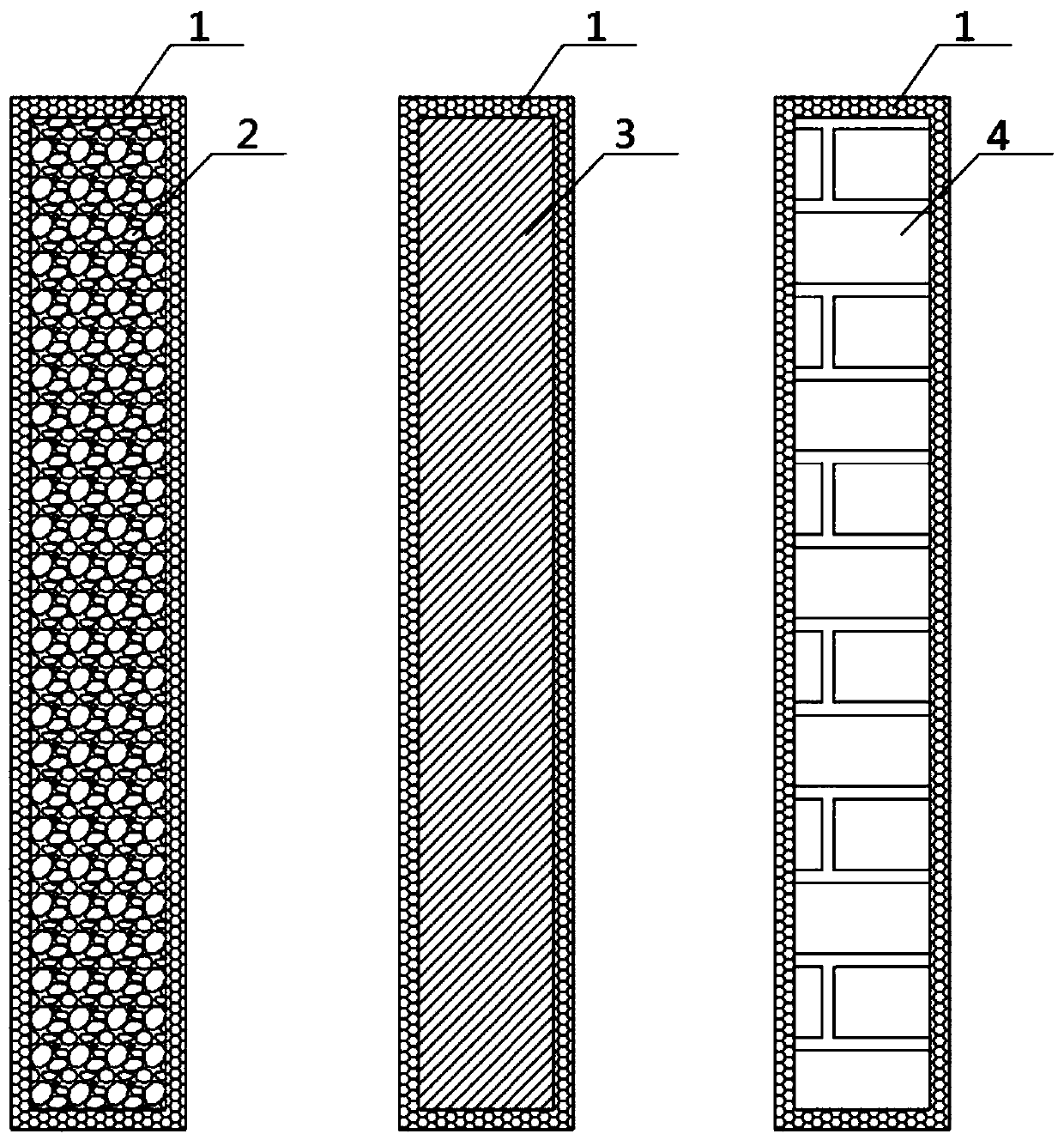

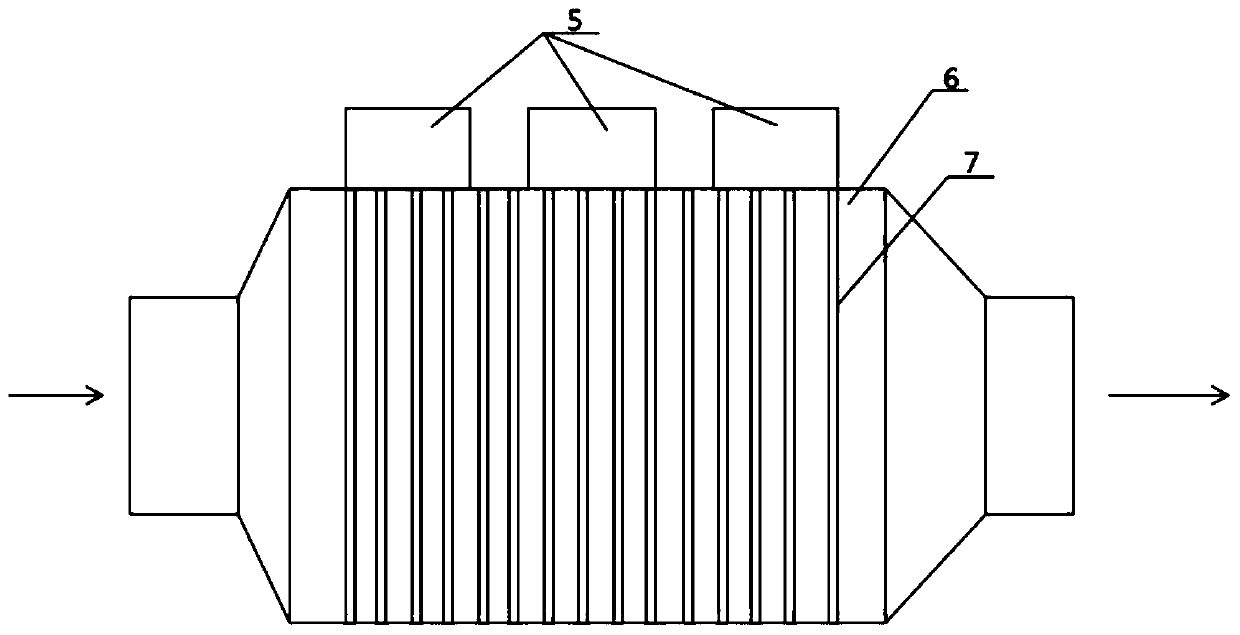

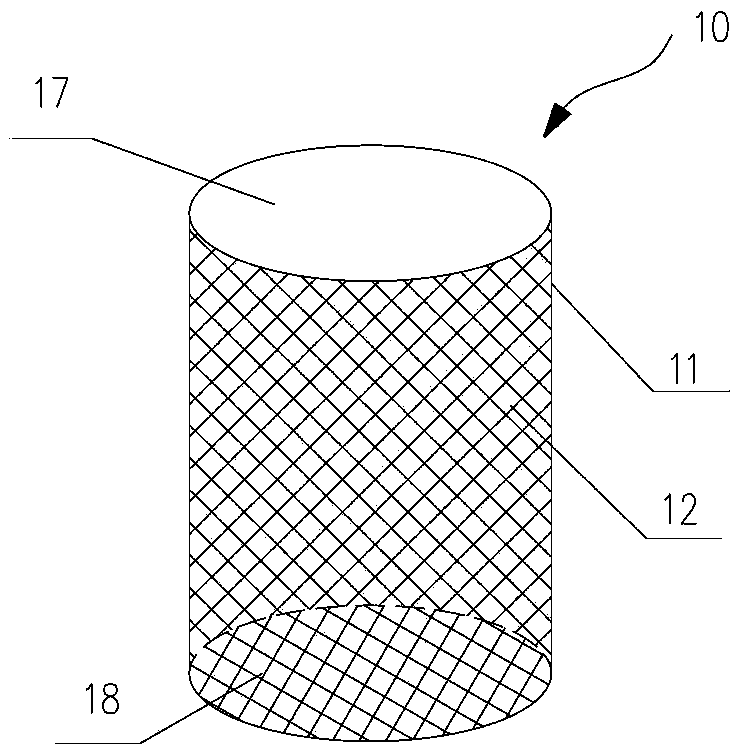

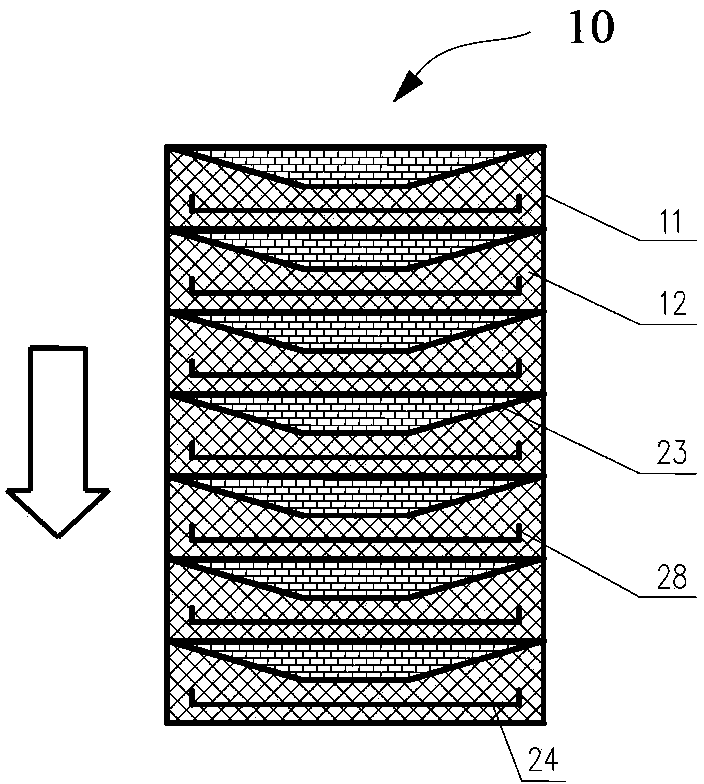

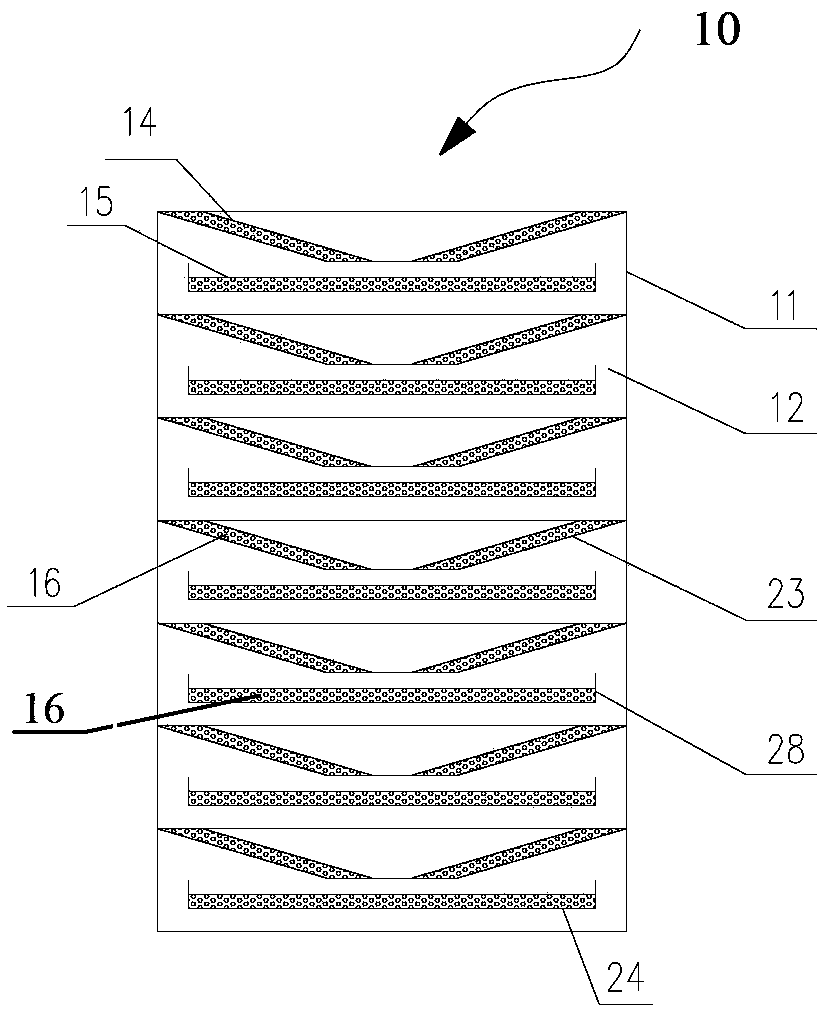

Scale depositing basket

ActiveCN103381349AExtended use timeAchieve catalytic effectChemical/physical processesPetrochemicalEngineering

The invention relates to a scale depositing basket for a fixed bed reactor, belonging to the field of petrochemical plants. The scale depositing basket includes a cylindrical frame, an outer screen mesh mounted on the frame and a plurality of sieve tray groups arranged in the frame, wherein each sieve tray group comprises a spatial sieve tray and a planar sieve tray, and holes are arranged along the vertical center axis of the spatial sieve tray. The scale depositing basket provided in the invention can effectively filter ash scales and other impurities in a liquid feed, mitigates the problem of scaling of impurities on the contact surface of the scale depositing basket and a fixed bed catalyst bed during a reaction, prolongs the working time of the scale depositing basket and lengthens the service time of a catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

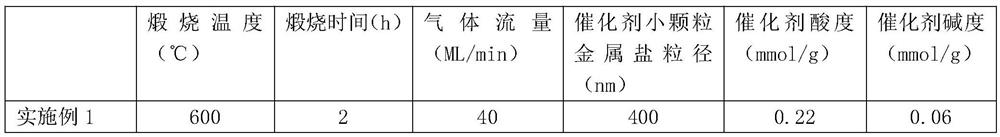

Catalyst and method for preparing biodiesel using the catalyst

ActiveCN112264052BHigh catalytic activityAchieve catalytic effectPhysical/chemical process catalystsFatty acid esterificationLiquid productBiodiesel

The invention discloses a lead-containing catalyst, which is prepared by the following method: the lead-containing blast furnace dust is ground by a ball mill and passed through a 75-400 mesh sieve; the sieved lead-containing blast furnace dust is placed in an oven at 75-105°C Drying for 5‑48 hours to obtain the pretreated lead-containing blast furnace dust; take the pretreated lead-containing blast furnace dust and place it in a high-temperature tubular reaction furnace, and calcinate it in an inert gas at 200-1000°C for 1-24 hours, The gas flow rate is set to 1-40mL / min, and the calcined sample is passed through a 75-400 mesh sieve to obtain the required lead-containing blast furnace dust catalyst. The catalyst is both acidic and basic, and can be automatically separated from the liquid product by standing still. It can be directly used in the reaction of high acid value oil, and the catalytic effect is very good, the yield of biodiesel is >95%, and the recovery rate of catalyst is >90%. Moreover, the recycling ability is better, and the yield of biodiesel can reach more than 80% after 5 reactions.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

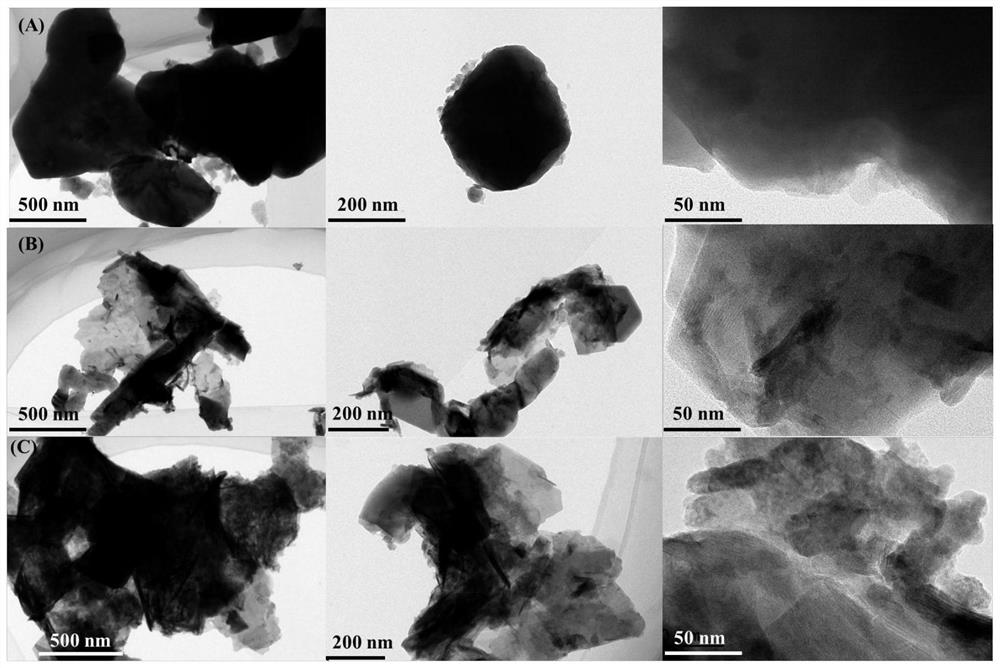

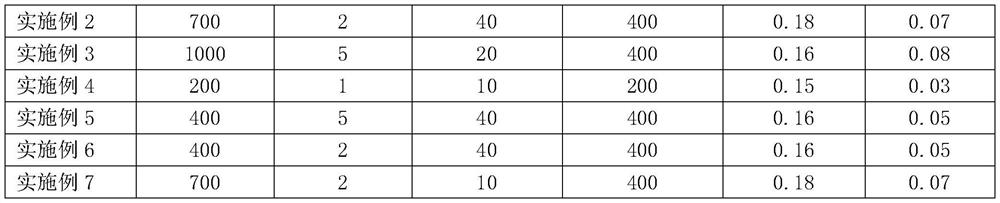

Preparation method of sapo-34/sapo-5 composite molecular sieve

ActiveCN107601523BAchieve catalytic effectGood repeatabilityMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sievePhysical chemistry

The invention provides a preparation method of an SAPO-34 / SAPO-5 composite molecular sieve. The preparation method comprises the following steps: 1, mixing a first phosphorus source, a first silicon source and deionized water uniformly, adding a first aluminum source, adding a first template agent, and performing first hydrothermal crystallization treatment after uniform stirring to obtain a firstcrystallization / crystallized solution; 2, adding a second aluminum source to the first crystallization solution, then adding a second phosphorus source and a second template agent, performing secondhydrothermal crystallization treatment after uniform stirring, and performing filtering to obtain a filter cake; 3, washing, drying and roasting the filter cake sequentially, and naturally cooling aproduct to obtain the SAPO-34 / SAPO-5 molecular sieve. The composite silicoaluminophosphate molecular sieve prepared with the method has pore channel characteristics of SAPO-34 and SAPO-5, and pore channels and acid site distribution of the composite molecular sieve can be adjusted by adjusting preparation conditions.

Owner:XIAN ORIGIN CHEM TECH

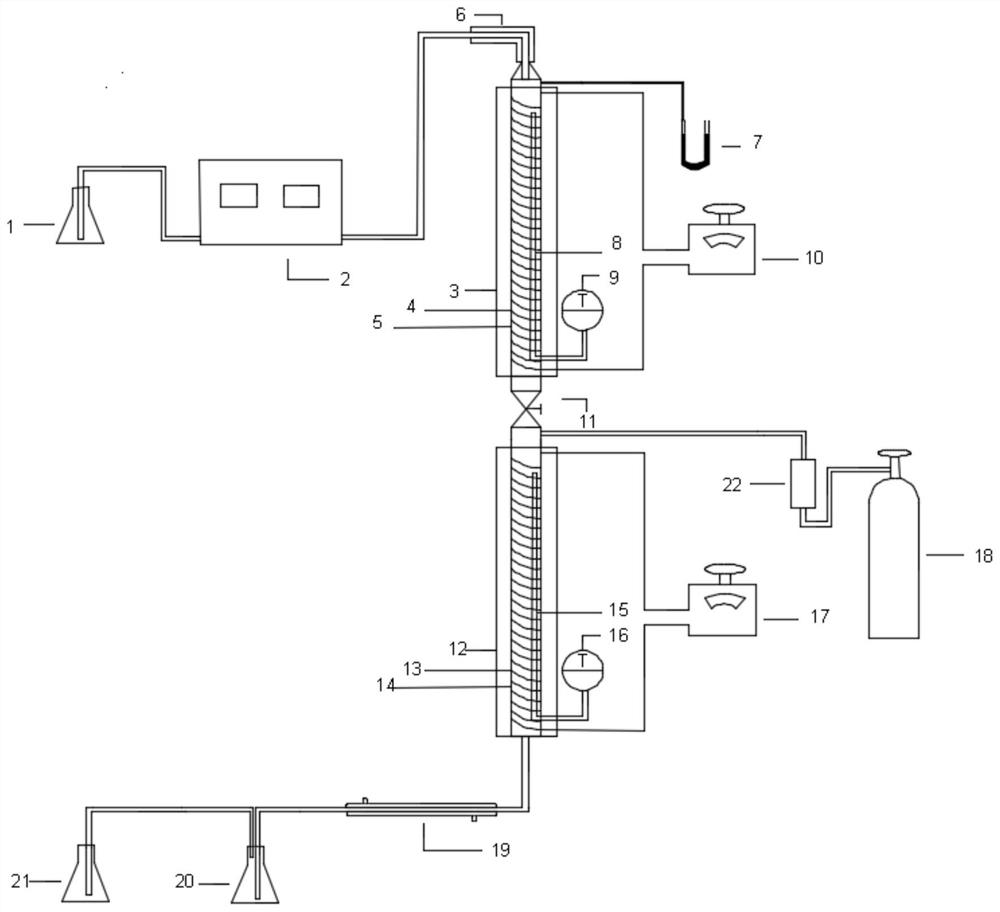

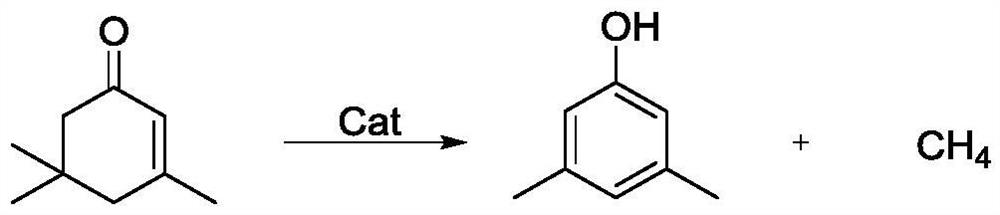

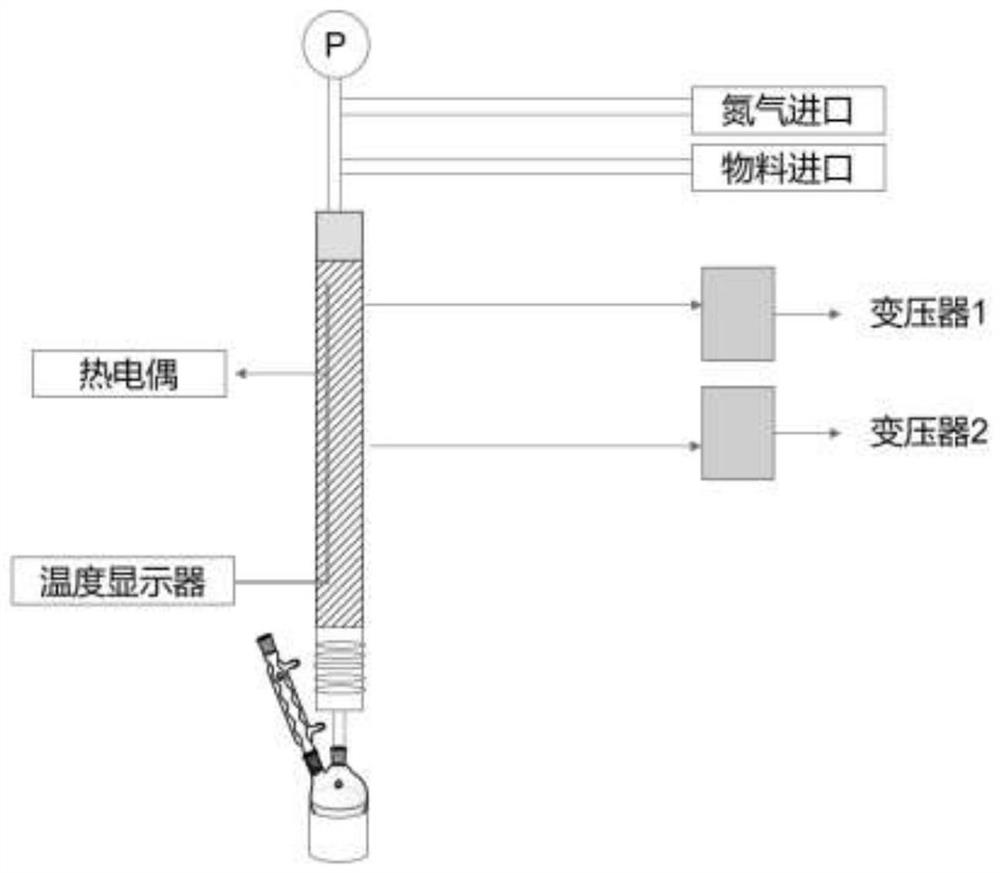

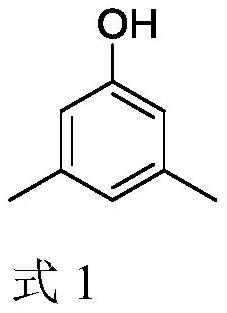

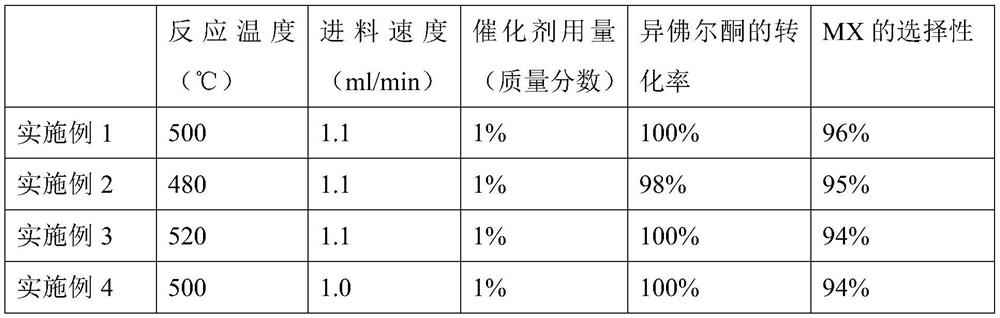

Production method of 3, 5-dimethylphenol and pressure-controlled production device used in production method

ActiveCN112263969ALow reaction temperatureLow reaction pressureOrganic chemistryOrganic compound preparationIsophoronePtru catalyst

The invention discloses a pressure-controlled production device which is a cracking reactor, and an outlet of a raw material container is communicated with a top inlet of a reaction tube I after sequentially passing through a sample injection pump and a preheating tube; a bottom outlet of the reaction tube I is communicated with a top inlet of a reaction tube II after passing through a pressure control valve; a bottom outlet of the reaction tube II is sequentially connected with a product collection bottle and a tail gas absorption bottle after passing through a condensation tube; and a gas bottle for containing inert gas is communicated with a top inlet of the reaction tube II after passing through a rotor flow meter. The invention further provides a method for producing 3, 5-dimethylphenol by using the device, and isophorone is used as a raw material to carry out cracking reaction under the action of a bromine-containing catalyst. According to the invention, the reaction selectivityand conversion rate can be improved.

Owner:ZHEJIANG JINKE CHEM

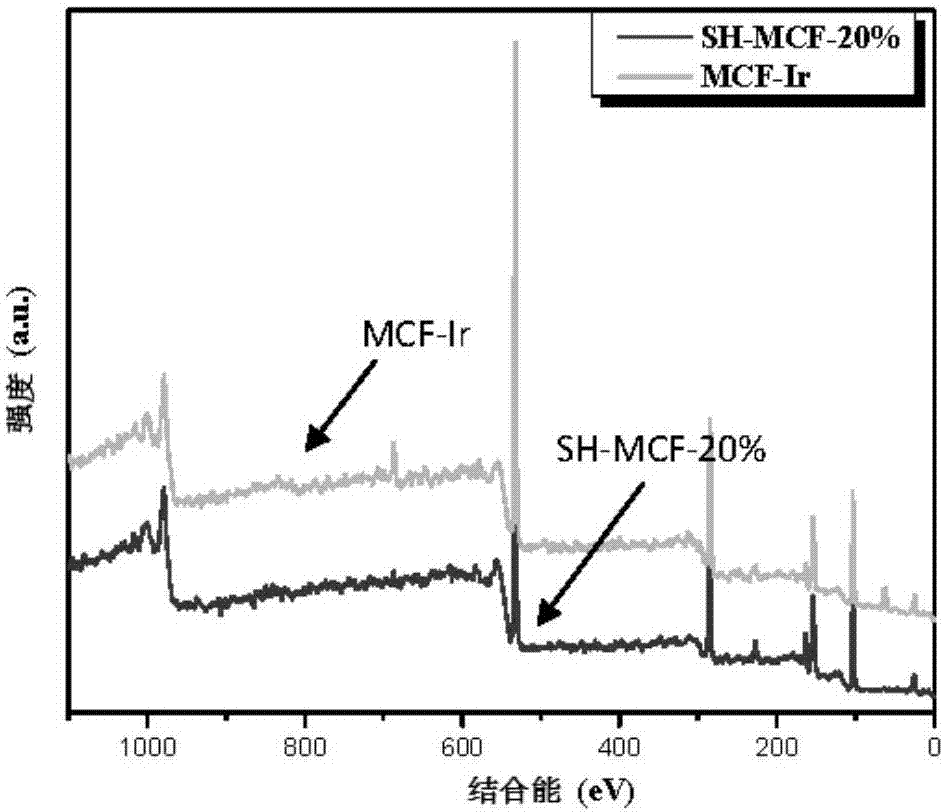

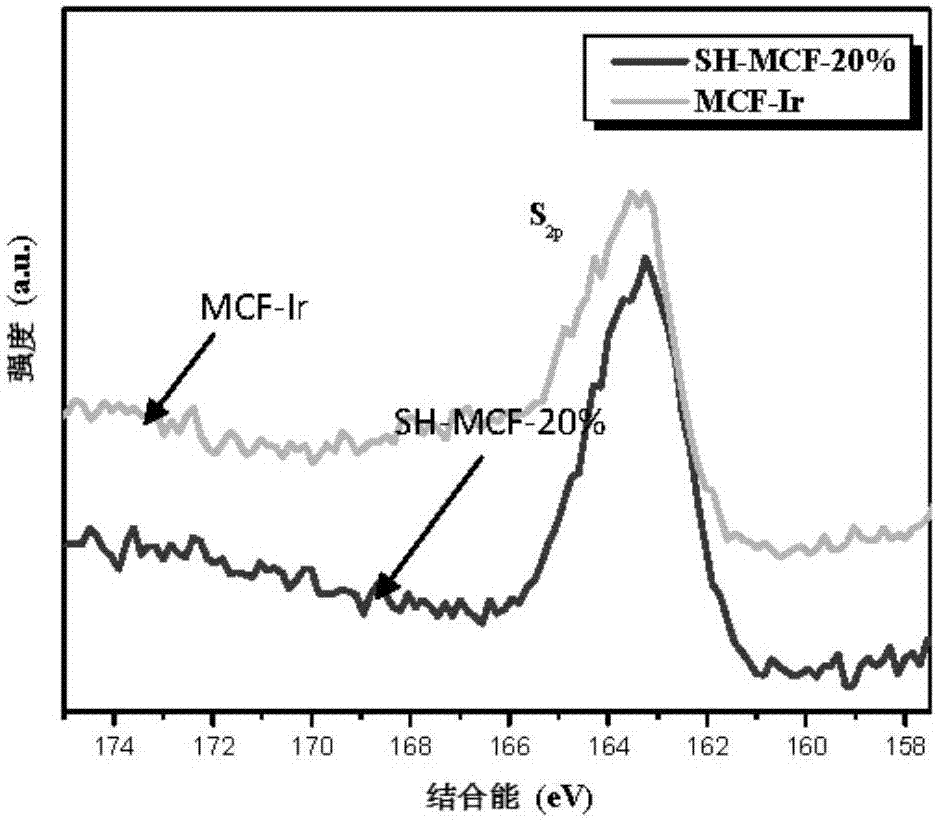

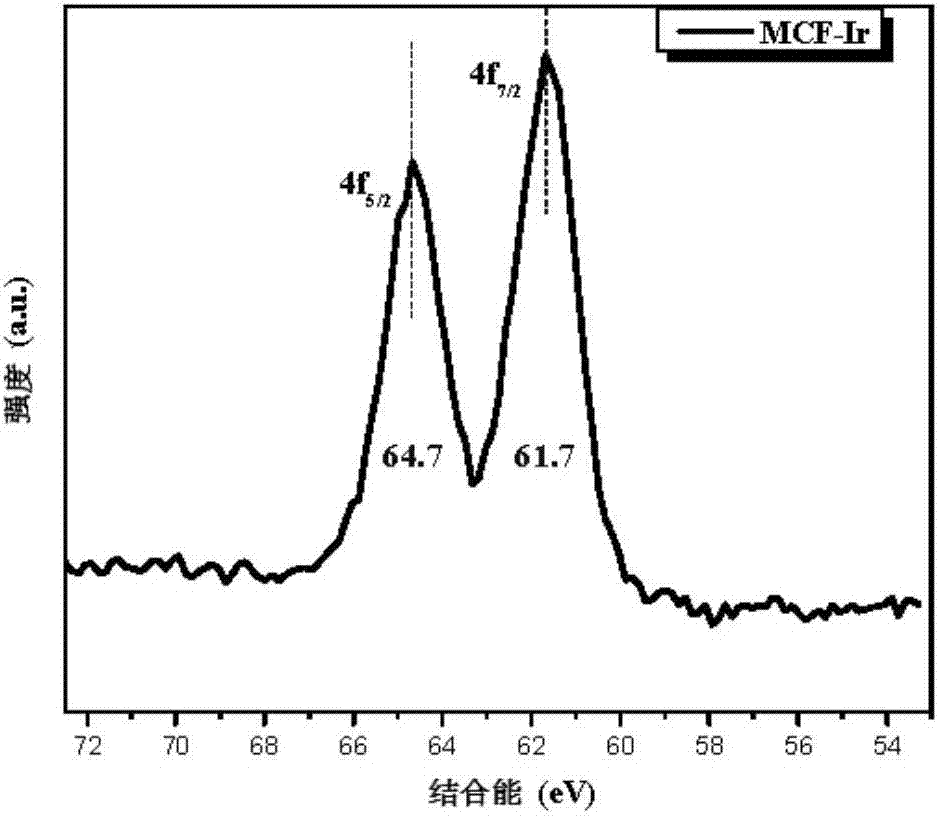

Mesoporous iridium pyridine heterogeneous catalyst, its preparation method and application

InactiveCN105251532BEliminate the effects of diffusionFacilitated DiffusionOrganic-compounds/hydrides/coordination-complexes catalystsIridiumPtru catalyst

The invention discloses a mesoporous iridium pyridine heterogeneous catalyst, its preparation method and application. The mesoporous iridium pyridine heterogeneous catalyst comprises a mercapto-functionalized mesoporous foamed silica matrix and an iridium pyridine catalyst covalently bonded to the matrix, and the active sites of the iridium pyridine catalyst are dispersed in the mesoporous channels of the matrix. Further, the heterogeneous catalyst has a three-dimensional pore structure. The preparation method of the heterogeneous catalyst is mainly realized by the click chemistry method, which can be well dispersed in the reaction system, and grafted Ir3+ active sites are dispersed on the inner wall of the channel, which can contact the substrate independently of each other , can achieve catalytic effect without mutual influence, has good chemical and thermal stability, can eliminate the influence of reaction substrate diffusion, can be widely used in photoinduced electron transfer reactions, and can be reused, and its preparation process is simple, The source of raw materials is extensive, the operation is convenient and controllable, the cost is low, and it is easy to implement on a large scale.

Owner:SHANGHAI NORMAL UNIVERSITY

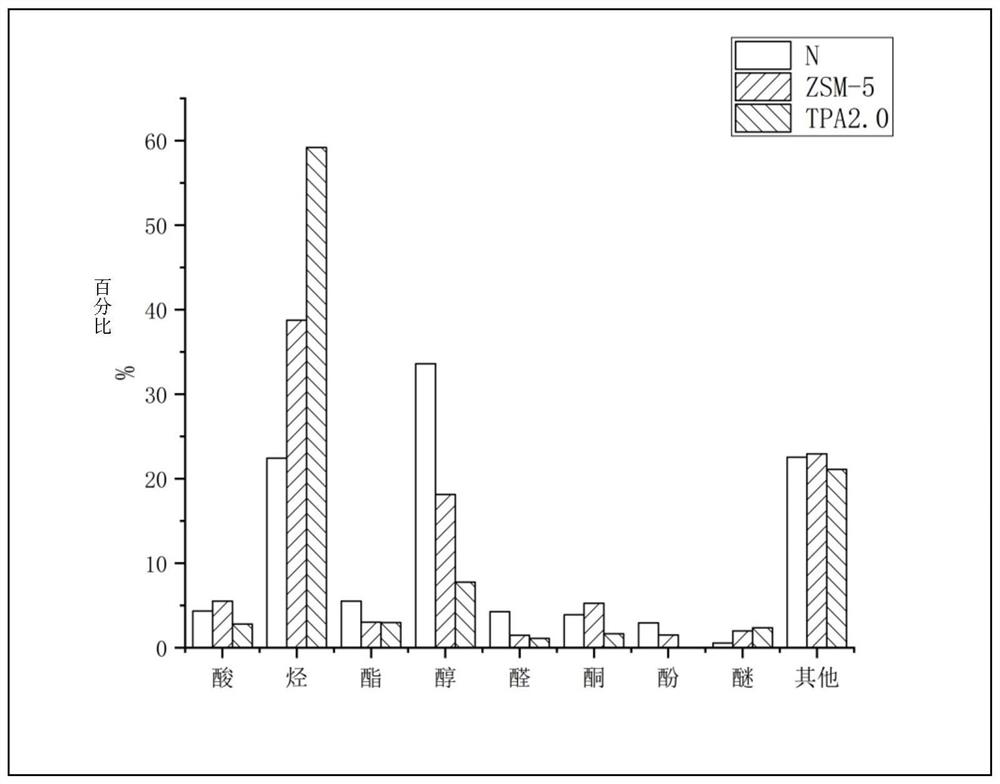

Preparation method of shell-core structure molecular sieve catalyst for biomass pyrolysis reforming upgrading

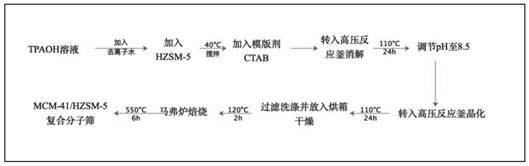

PendingCN112275313AExtended service lifeImprove stabilityMolecular sieve catalystsCatalyst activation/preparationTetrafluoroethyleneMolecular sieve

The invention provides a preparation method of a shell-core structure molecular sieve for biomass pyrolysis oil production, which comprises the following steps of: adding deionized water into a beaker, measuring a TPAOH solution, adding the TPAOH solution into the deionized water, weighing HZSM-5 molecular sieve powder, adding the HZSM-5 molecular sieve powder into the solution, quickly stirring,sufficiently stirring for 1 hour, weighing a template agent CTAB, adding the template agent CTAB into a turbid liquid, sufficiently stirring, fully stirring the turbid liquid, transferring the turbidliquid into a high-pressure reaction kettle with a tetrafluoroethylene lining, placing the reaction kettle in a drying oven, digesting for 24 hours, taking out the reaction kettle, adjusting the pH value to 8.5, transferring the solution back into the high-pressure reaction kettle, crystallizing for 24 hours in the drying oven, filtering and washing the obtained solution containing the crystal grains, drying the filtered crystal grains in the drying oven, putting the dried molecular sieve into a muffle furnace, heating the muffle furnace to 550 DEG C at a heating rate of 10 DEG C / min, and roasting for 2-6 hours to remove the template agent, thereby obtaining the mesoporous-microporous composite molecular sieve with a core-shell structure.

Owner:SOUTHEAST UNIV

Mesoporous phenolic resin/copper nanoparticle heterogeneous catalyst, its preparation method and application

InactiveCN104624234BEliminate the effects of diffusionUnique ordered two-dimensional hexagonal structureOrganic-compounds/hydrides/coordination-complexes catalystsCarbonyl compound preparation by condensationOrganocatalysisHomogeneous catalysis

The invention discloses a mesoporous phenolic resin / copper nano particle heterogeneous catalyst, and a preparation method and an application of catalyst. With ordered mesoporous phenolic resin as carrier and elementary substance state copper nano particle as catalyst active component, the heterogeneous catalyst has a regular mesoporous structure, as well as has the characteristics of large specific surface area, uniform particle size distribution, even active site distribution and the like; meanwhile, the catalyst has high chemical and thermal stabilities, can be dispersed well in a reaction system, is easy to recover and recycle, and is widely applied to each elementary copper based organic catalytic reaction. Furthermore, the preparation process of the catalyst is simple, the raw materials are cheap and available, the cost is low, and no reducing agent is added during the preparation process, so that the environment-friendly effect is achieved.

Owner:SHANGHAI NORMAL UNIVERSITY

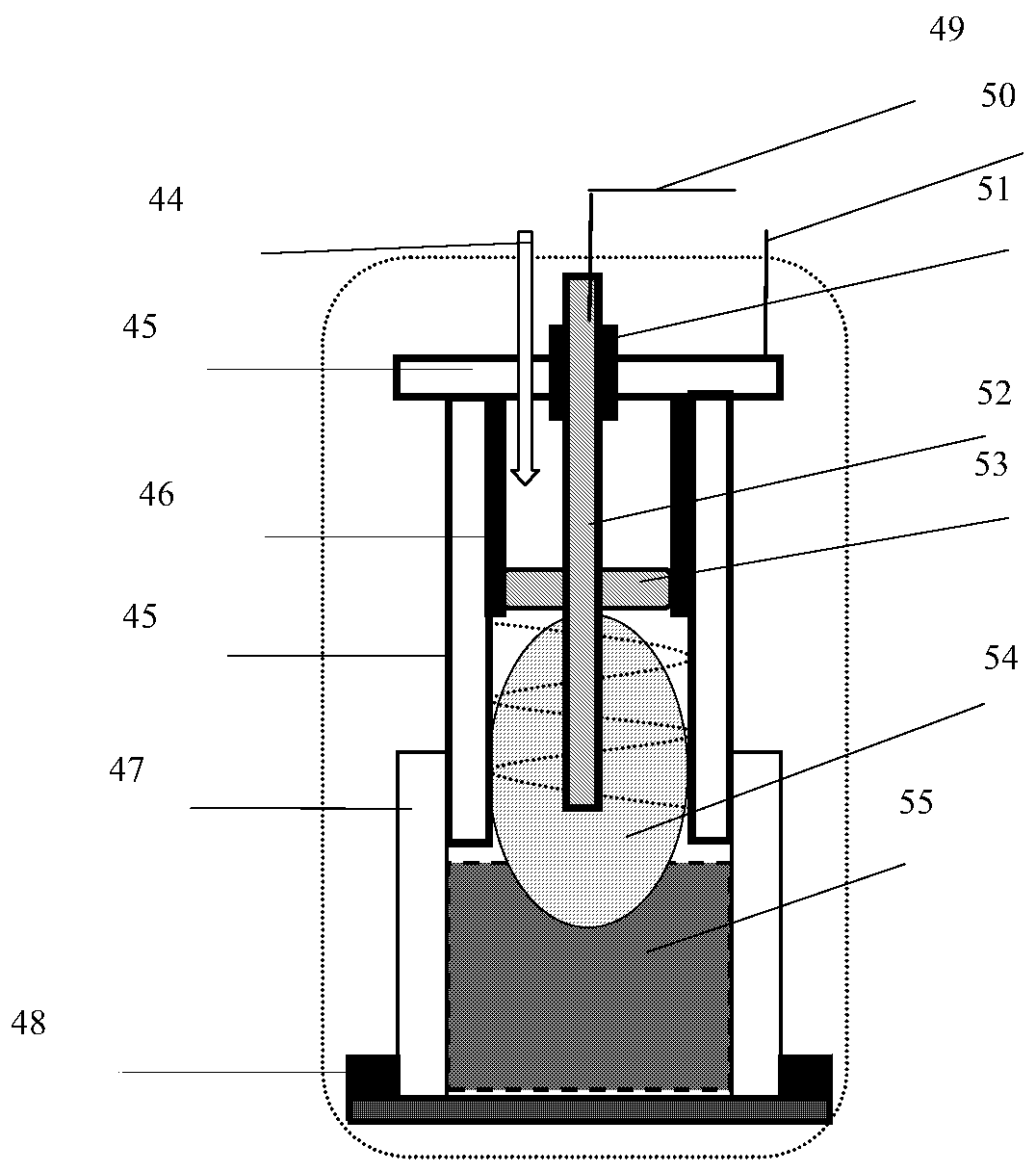

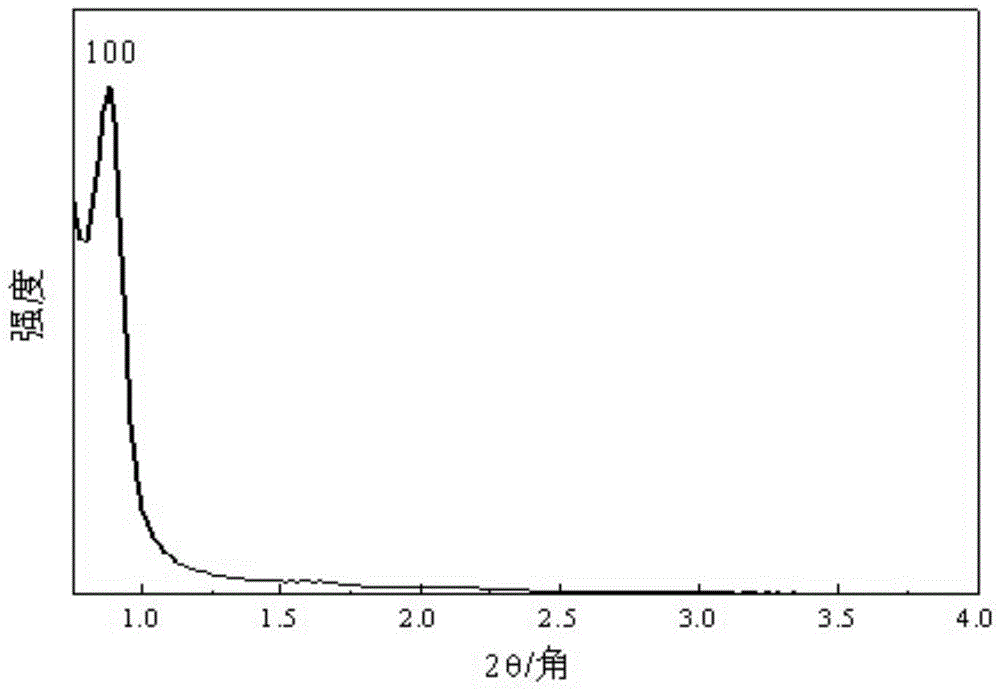

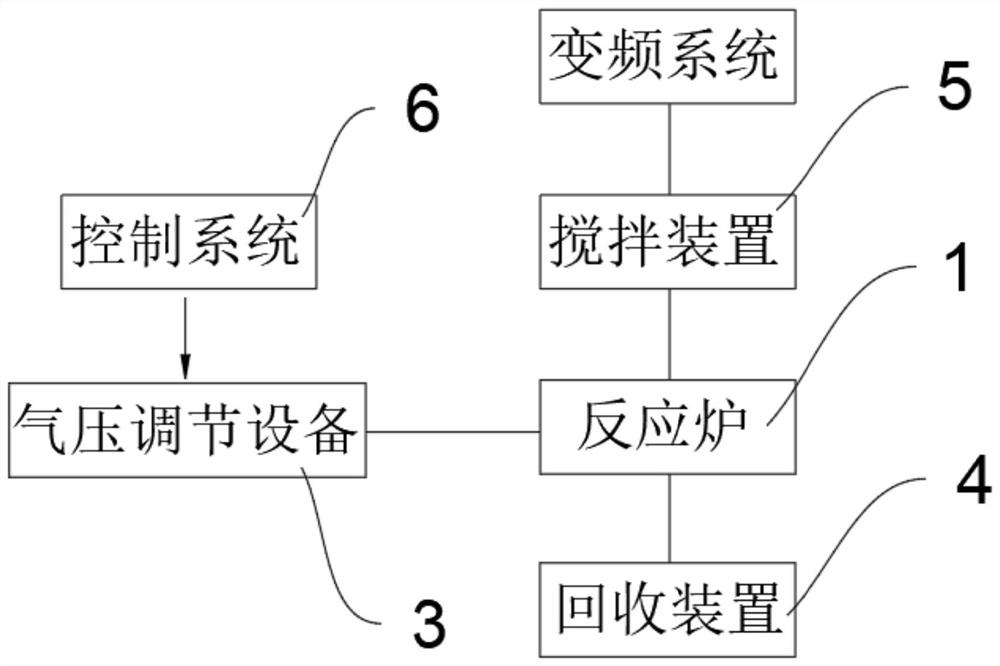

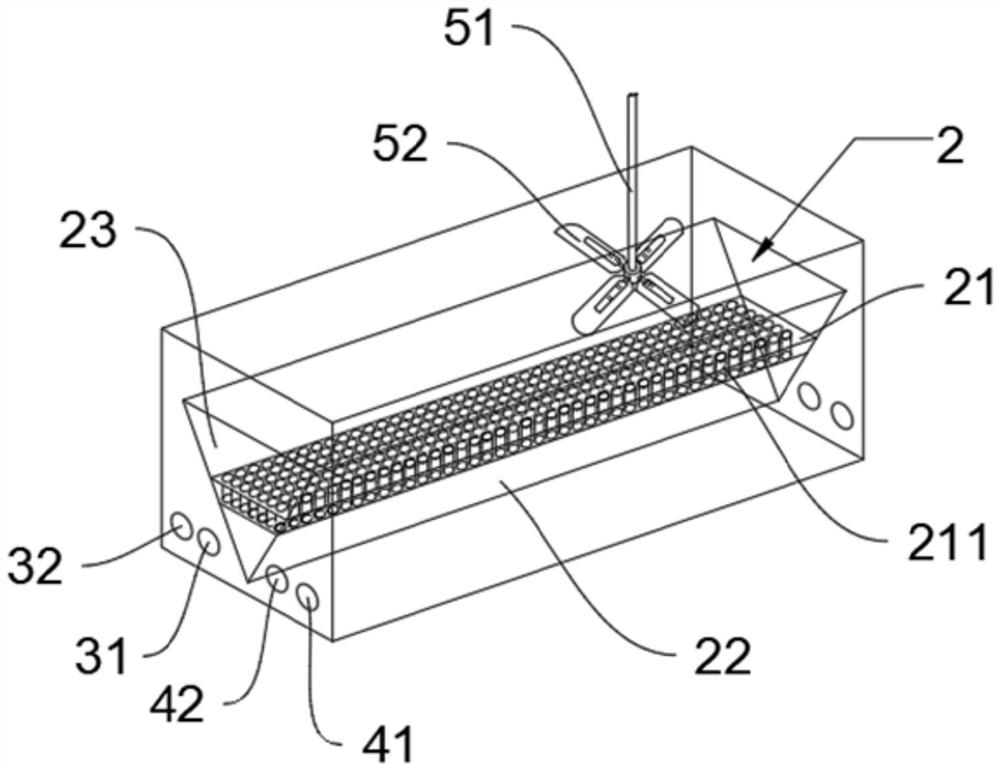

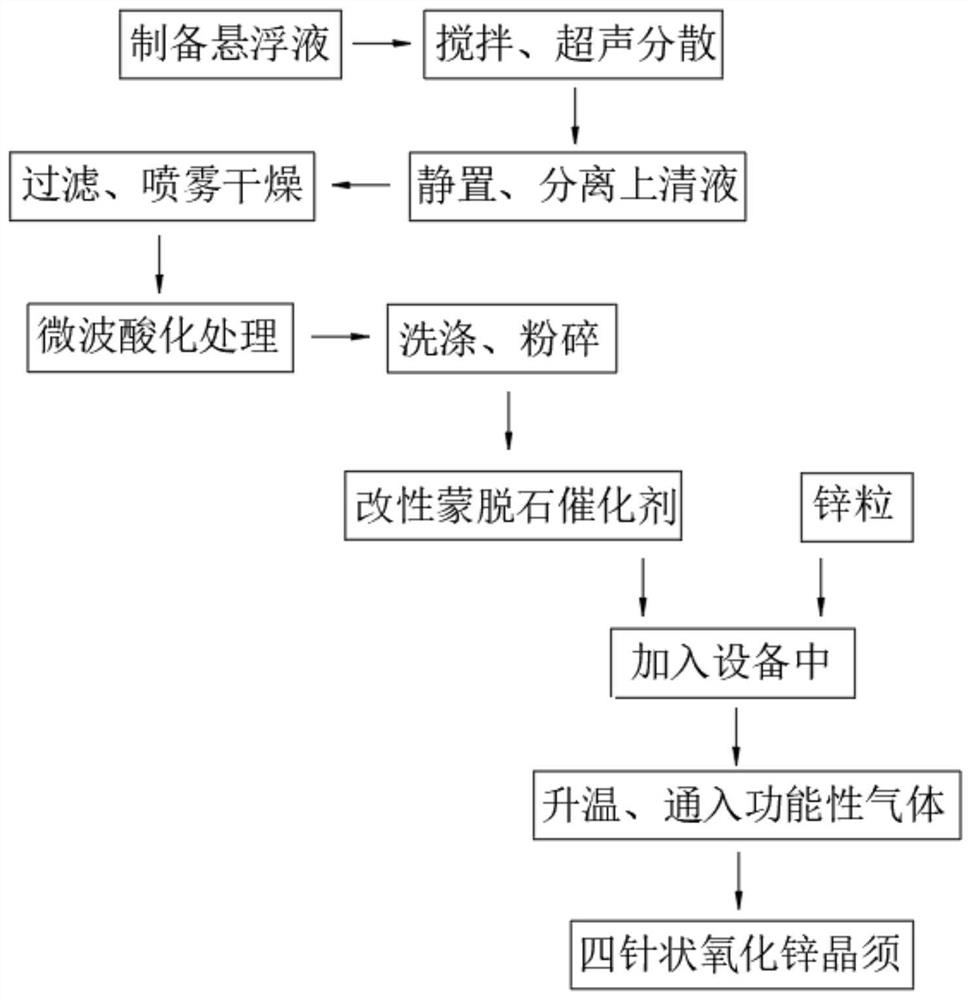

Equipment and method for preparing tetrapod-like zinc oxide whiskers by using modified montmorillonite catalyst

PendingCN112853488ALarge specific surface areaIncrease the areaPolycrystalline material growthPhysical/chemical process catalystsPtru catalystControl system

The invention discloses equipment and a method for preparing tetrapod-like zinc oxide whiskers by using a modified montmorillonite catalyst. The equipment comprises a reaction furnace, air pressure adjusting equipment, a recovery device, a stirring device and a control system, the air pressure adjusting equipment, the recovery device and the stirring device are respectively connected with the reaction furnace, the control system is connected with the air pressure adjusting equipment, and a reactor with an inverted triangular section is arranged in the reaction furnace; and the reactor comprises a partition plate horizontally arranged in the middle of the reactor, the reactor is divided into a raw material bin and a catalyst bin from top to bottom by the partition plate, a plurality of through connecting holes are formed in the partition plate, independent heaters are arranged in the catalyst bin and the raw material bin, and the heaters are electrically connected with a control system. The tetrapod-like zinc oxide whiskers prepared by the technical scheme of the invention have the advantages of high needle forming rate, good whisker growth, uniform and regular tetrapod-like whisker, and uniform whisker size; furnace pressure and stock bin pressure are intelligently controlled; and the production cost is low.

Owner:四川祺又飞新材料科技有限责任公司

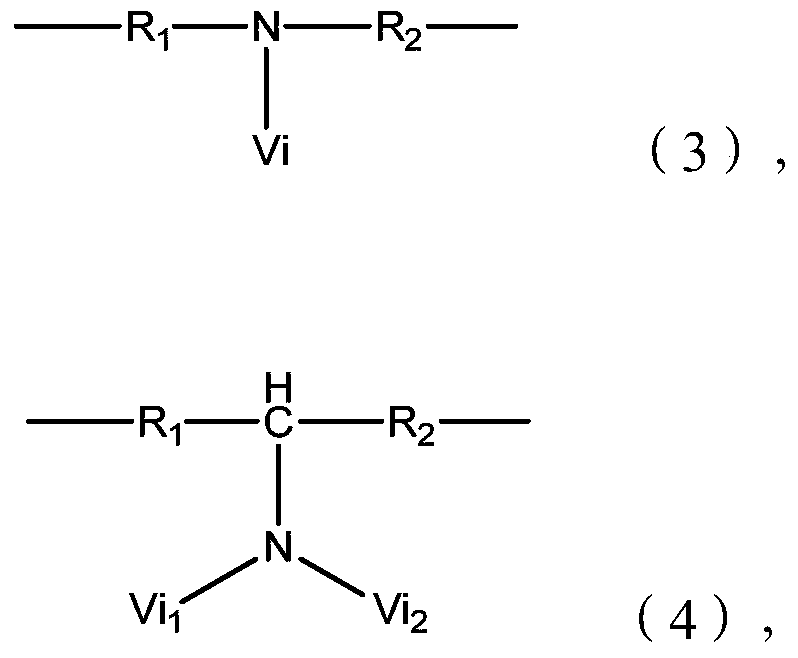

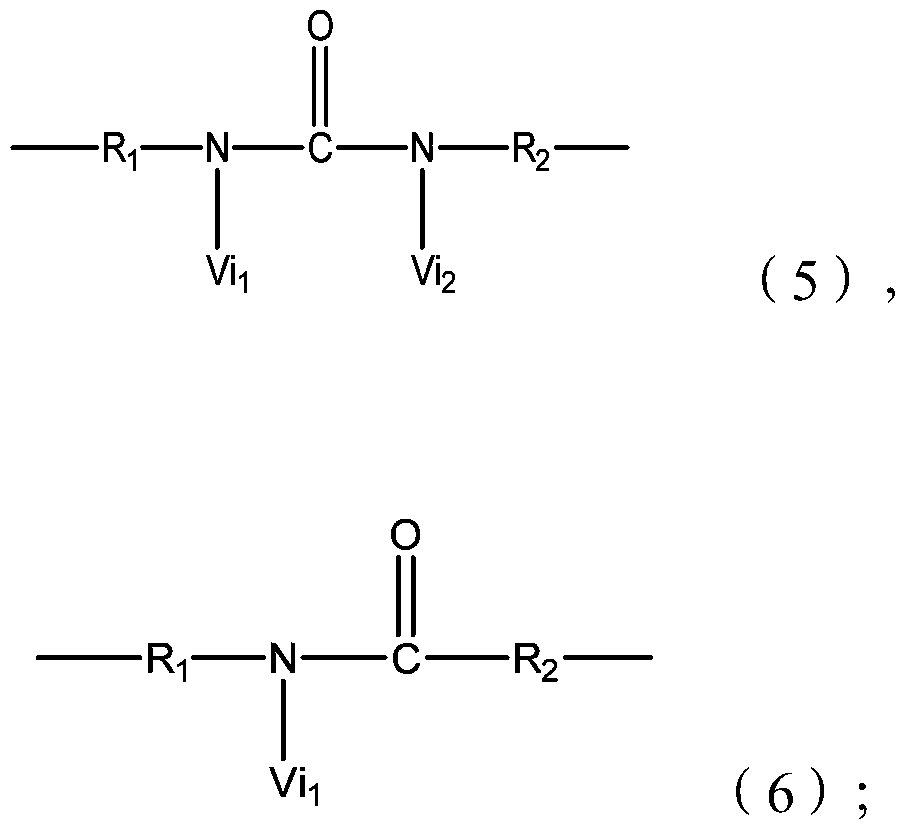

A kind of polyurethane catalyst and its application

ActiveCN104558467BHigh speedGood physical propertiesPolyureas/polyurethane adhesivesFibre treatmentPolyurethane adhesiveSlurry

A polyurethane catalyst comprises a sodium compound which is 1-60 wt% of the polyurethane catalyst, and a tertiary amine and / or pyridine compound. The sodium compound and the tertiary amine and / or pyridine compound achieve the synergistic effect; during the catalysis of the polymerization of isocyanate and polyalcohol, the speed of the polymerization reaction is increased; the prepared polyurethane material has excellent physical properties, does not contain any heavy metal element at all, is an environment-friendly catalyst, solves the technical problem about the guarantee of both the environmental protection safety and the catalytic efficiency of the polyurethane catalyst, and is particularly applicable to the preparation of polyurethane synthetic leather resin slurry, a polyurethane elastomer (prepolymer), a polyurethane coating, a polyurethane adhesive and a polyurethane composite material.

Owner:JIANGSU OSIC PERFORMANCE MATERIALS CO LTD

High-hardness epoxy-modified polyurethane composite material and preparation method thereof

The invention relates to a high-hardness epoxy modified polyurethane composite material, which is prepared by adding a component A and a component B into a vacuumable sealed container and carrying out a mixed reaction by using a prepolymer method, wherein the component A is a mixture of a terminal isocyanate prepolymer and an epoxy resin, and the component B is a mixture of a chain extender and a catalyst. The preparation method comprises: weighing 130-140 parts of the component A and 2.4-15.2 parts of the component B, respectively pre-heating, adding the pre-heated components A and B to a vacuumable sealed container, mixing, carrying out vacuum deaeration while stirring, taking out after the gas bubbles are completely removed, pouring into a corresponding mold, carrying out low temperature curing, demolding, and carrying out heating vulcanization to prepare the high-hardness epoxy modified polyurethane composite material. According to the present invention, the product has advantages of high toughness, prolonged service life in the kettle, controllable reaction speed, low cost, and the like.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

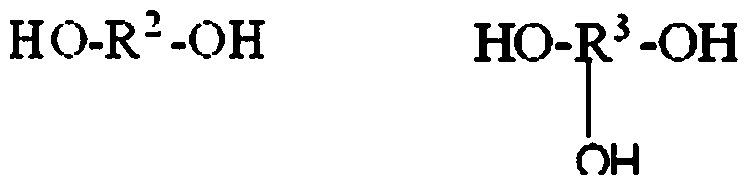

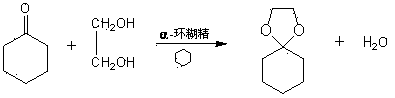

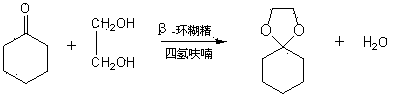

Biomimetic catalyst for preparing acetal or ketal compounds and using method thereof

InactiveCN102172537BGood for offenseIncrease reaction rateOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystAlcohol

The invention discloses a biomimetic catalyst for generating acetal or ketone by catalyzing a condensation reaction between aldehyde or ketone and alcohol. The biomimetic catalyst is cyclodextrin or a derivative of cyclodextrin. The cyclodextrin catalyst has the advantages of no corrosion equipment, no toxic or side effect, and environment friendliness. The invention also discloses a method for preparing acetal or ketal compounds by catalyzing a condensation reaction between aldehyde or ketone and alcohol by cyclodextrin or the cyclodextrin derivative.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

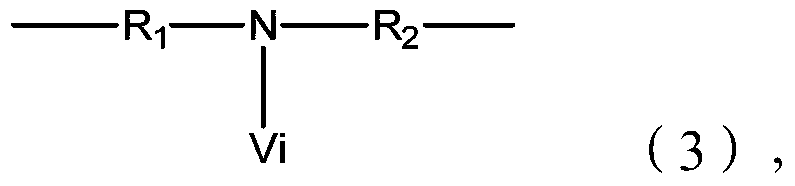

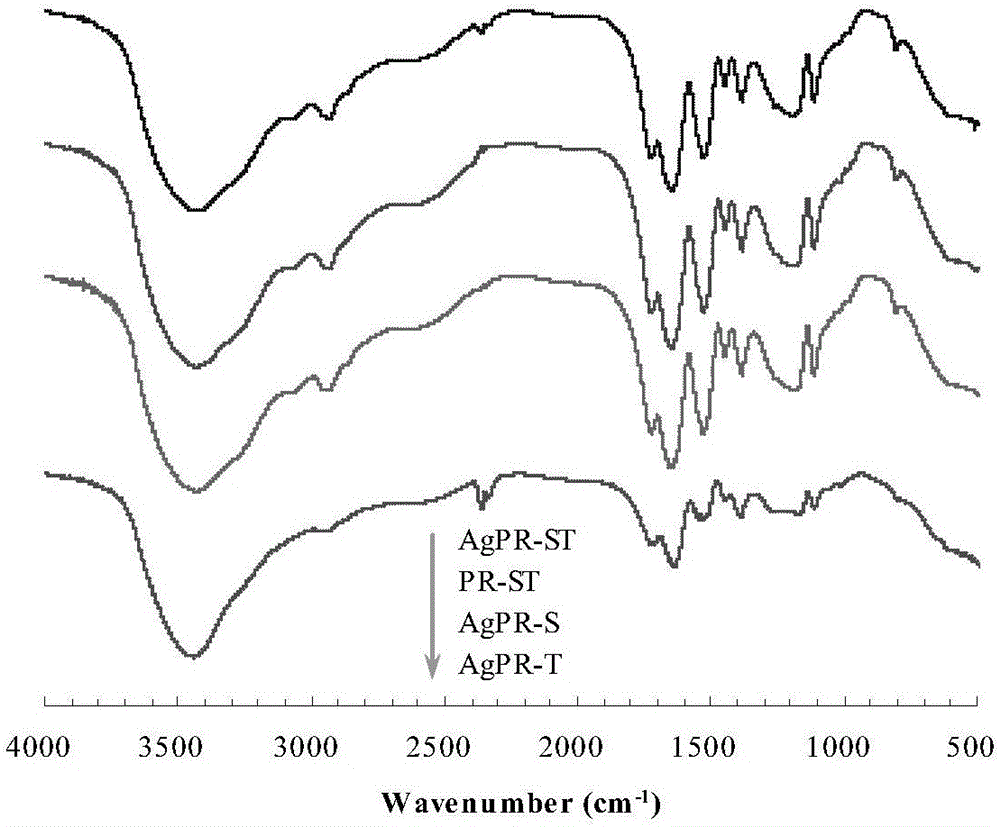

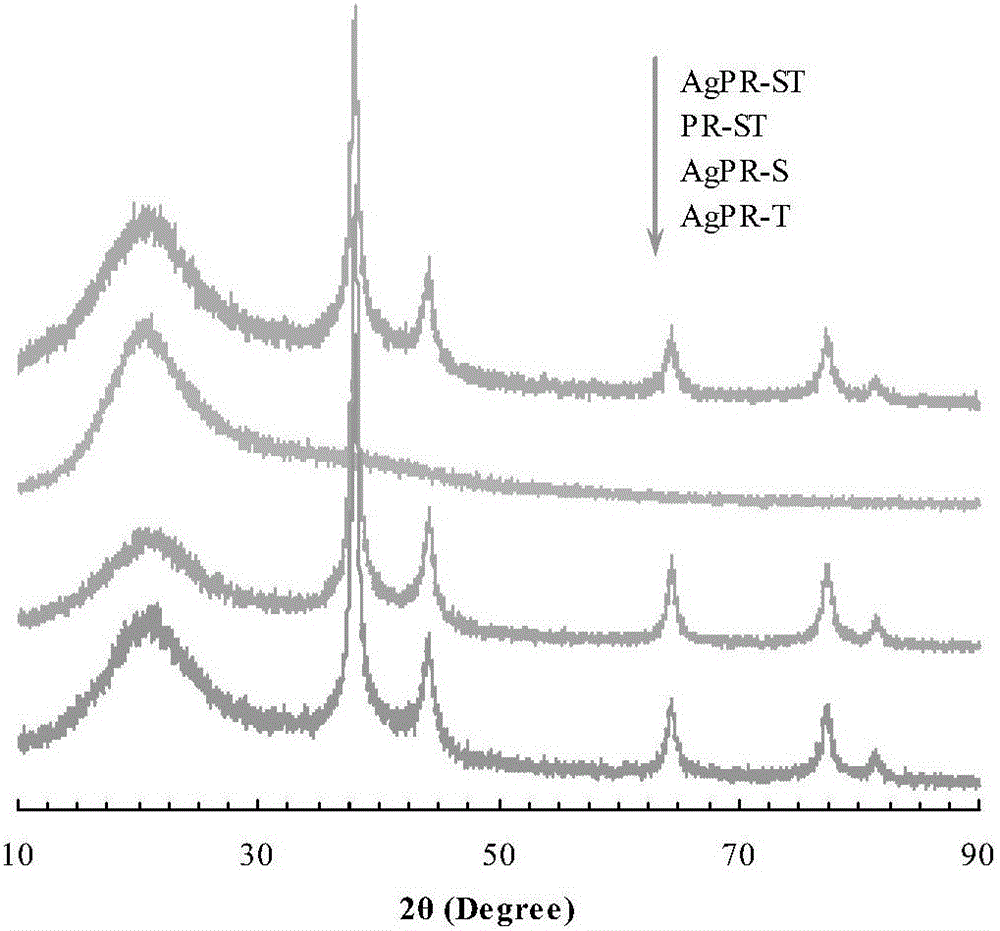

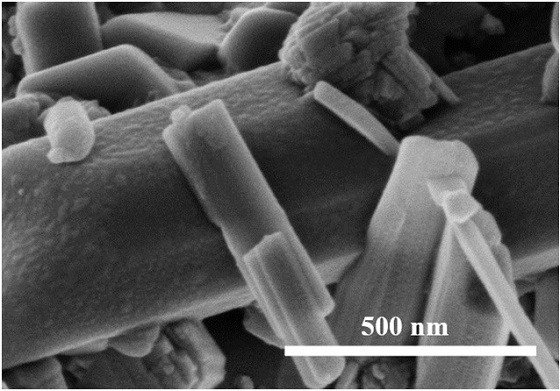

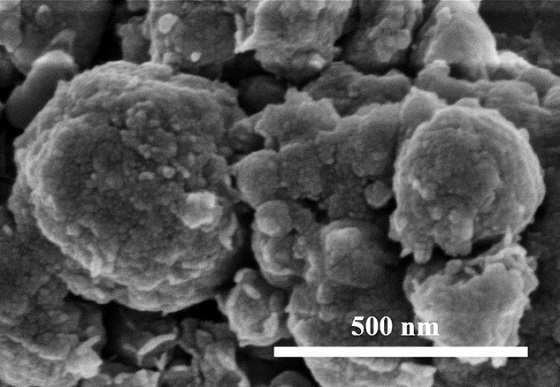

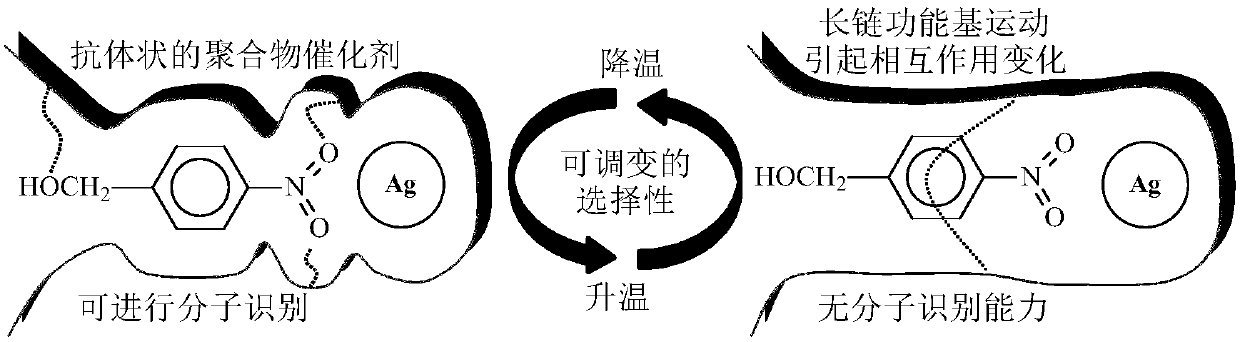

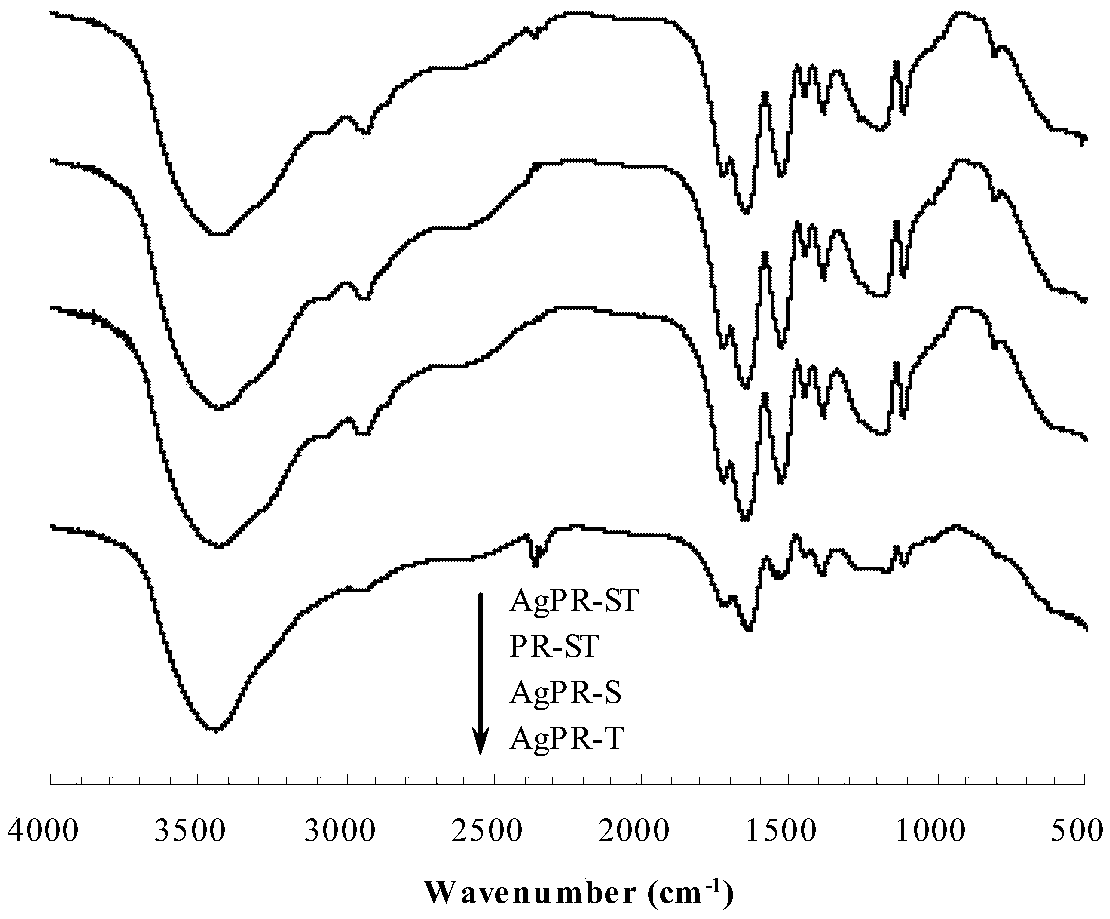

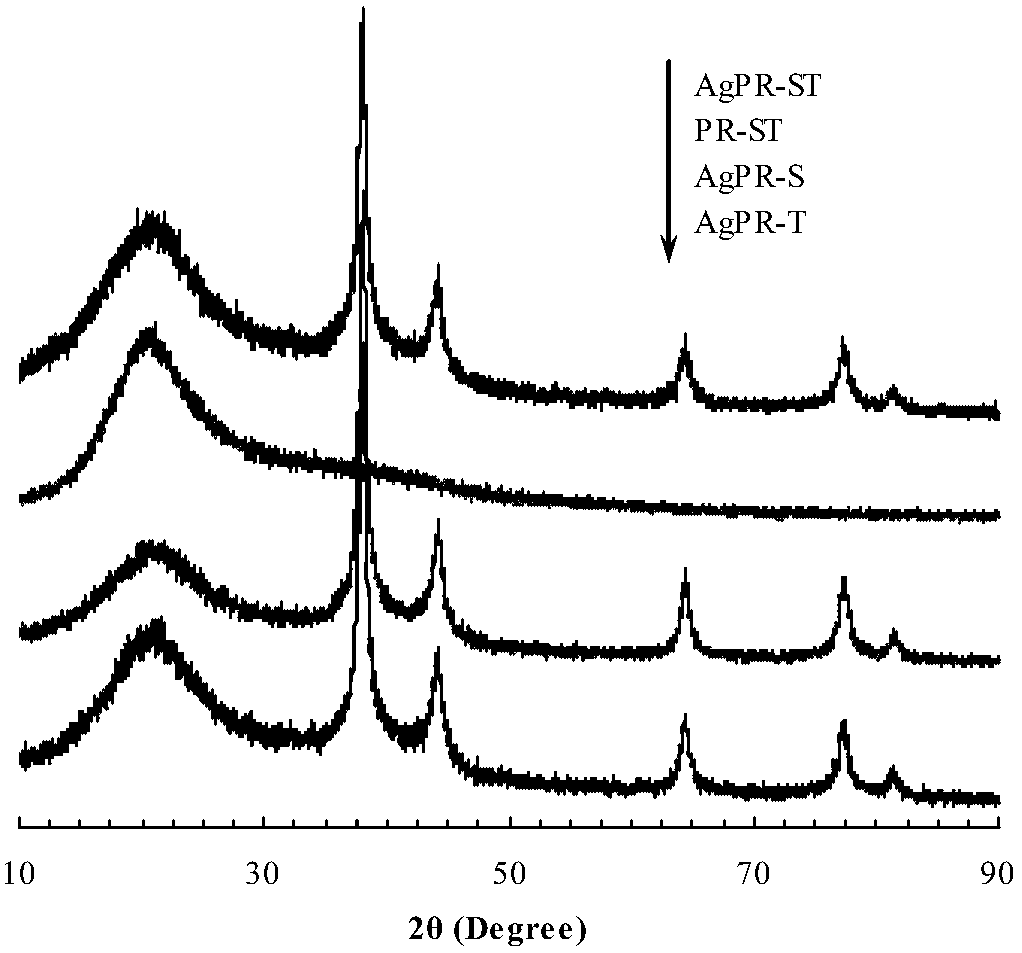

Preparation method of silver-loaded selectivity-changeable polymer catalyst

ActiveCN106311327AAchieve catalytic effectAchieving Catalytic AbilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsFunctional monomerSide chain

The invention provides a preparation method of a silver-loaded selectivity-changeable polymer catalyst. According to the preparation method, functional monomers involved in the method are a binary copolymerization functional monomer system for constructing a polymer molecule recognition framework and a movable functional group side chain structure. A substrate and an active component silver precursor are first dissolved in dimethyl sulfoxide for complexing, then the functional monomers, a crosslinking agent and an initiator are added, nitrogen is injected into the solution for deoxidation, the mixture is sealed and put under an ultraviolet lamp to be irradiated for polymerization initiation, and then a catalyst precursor is formed; Ag ions in the catalyst precursor are subjected to sodium borohydride reaction, an obtained product is washed repeatedly with water and ethylene alcohol to remove blotted substrate molecules, and the silver-loaded selectivity-changeable polymer catalyst is obtained after vacuum drying. The silver-loaded selectivity-changeable polymer catalyst can be used for direct preparation of aminobenzyl alcohol from an isomer mixture of nitrobenzyl alcohol and other industrial raw materials. The preparation method has the advantages of being simple in technical principle, making raw materials obtained easily, convenient to operate and making preparation easy.

Owner:JIANGSU UNIV

A kind of sodium salt-blast furnace dust catalyst and its method for preparing biodiesel

ActiveCN113893861BHigh catalytic activityHigh catalytic efficiencyBiofuelsCatalyst activation/preparationBiodieselPtru catalyst

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

The preparation method of 3,5-dimethylphenol

ActiveCN111253219BReduce moisture contentInhibit side effectsOrganic compound preparationCarbonyl compound separation/purificationIsophoronePtru catalyst

The invention discloses a preparation method of 3,5-dimethylphenol, which uses isophorone as a raw material and carries out a cracking reaction under the action of a catalyst, which specifically includes the following steps: using a water-absorbing agent to remove isophorone Water treatment until the water content of isophorone is ≤0.2%, add catalyst to isophorone after water removal, after uniform mixing, to obtain raw material mixture; under the protection of inert gas, raw material mixture from the top Pumped into the tubular reactor, the residence time of the raw material mixture in the tubular reactor is 40s-48s; the reaction temperature is 480-520°C; the reaction pressure is normal pressure; the product is discharged from the bottom of the tubular reactor. The preparation of 3,5-dimethylphenol by the method has the characteristics of high reaction conversion rate, high selectivity, low catalyst price and the like.

Owner:ZHEJIANG JINKE CHEM

Preparation method of a silver-loaded polymer catalyst with switchable selectivity

ActiveCN106311327BAchieve catalytic effectAchieving Catalytic AbilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsFunctional monomerSide chain

The invention provides a preparation method of a silver-loaded selectivity-changeable polymer catalyst. According to the preparation method, functional monomers involved in the method are a binary copolymerization functional monomer system for constructing a polymer molecule recognition framework and a movable functional group side chain structure. A substrate and an active component silver precursor are first dissolved in dimethyl sulfoxide for complexing, then the functional monomers, a crosslinking agent and an initiator are added, nitrogen is injected into the solution for deoxidation, the mixture is sealed and put under an ultraviolet lamp to be irradiated for polymerization initiation, and then a catalyst precursor is formed; Ag ions in the catalyst precursor are subjected to sodium borohydride reaction, an obtained product is washed repeatedly with water and ethylene alcohol to remove blotted substrate molecules, and the silver-loaded selectivity-changeable polymer catalyst is obtained after vacuum drying. The silver-loaded selectivity-changeable polymer catalyst can be used for direct preparation of aminobenzyl alcohol from an isomer mixture of nitrobenzyl alcohol and other industrial raw materials. The preparation method has the advantages of being simple in technical principle, making raw materials obtained easily, convenient to operate and making preparation easy.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com