Preparation method and application of naphthalene sulfonate-alkyl naphthalene sulfonate-formaldehyde condensate

A technology of alkylnaphthalene sulfonate and formaldehyde condensate is applied in the directions of sulfonate preparation, sulfonic acid preparation, botanical equipment and method, etc. It is difficult to realize industrialization and other problems, and achieve the effect of improving alkylation efficiency, short carbon chain and small steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

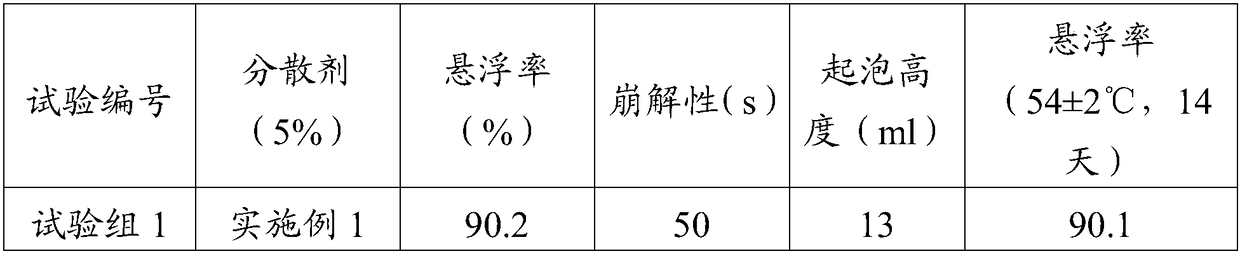

Examples

preparation example Construction

[0031] A kind of preparation method of naphthalenesulfonate-alkylnaphthalenesulfonate-formaldehyde condensate, specifically comprises the steps:

[0032] (1) Alkylation reaction: Mix naphthalene, alkylating agent and sulfuric acid in a molar ratio of 1.0:0.1-2.0:0.05-0.2; then raise the temperature to 80-150°C under stirring conditions, and heat preservation reaction 4- 6h prepares the mixed solution of naphthalene and alkylnaphthalene;

[0033] (2) Sulfonation reaction: According to the molar ratio of naphthalene group and sulfuric acid is 1.0:1.0-1.3, add sulfuric acid to the mixture of above-mentioned naphthalene and alkylnaphthalene, heat up to 150-160°C under stirring condition, heat preservation reaction 3- After 5 hours, add water to adjust the acidity to 24-26%, and prepare the sulfonated liquid;

[0034] (3) Condensation reaction: reduce the temperature of the above-mentioned sulfonated liquid to 80-90°C, then add formaldehyde aqueous solution according to the molar ...

Embodiment 1

[0046] A kind of preparation method of naphthalenesulfonate-alkylnaphthalenesulfonate-formaldehyde condensate, specifically comprises the steps:

[0047] (1) Alkylation reaction: first add 64g of refined naphthalene, 6.5g of isopropanol and 2.5g of concentrated sulfuric acid with a mass concentration of 98%; then the temperature is raised to 90°C under stirring conditions, and the insulation reaction is carried out for 6h to prepare naphthalene and The mixed solution of alkylnaphthalene, the content ratio of naphthalene and isopropylnaphthalene in the mixed solution detected by high performance liquid chromatography is 80:20;

[0048] (2) Sulfonation reaction: Add 50 g of concentrated sulfuric acid with a mass concentration of 98% to the mixed solution of naphthalene and alkylnaphthalene, heat up to 160° C. under stirring conditions, keep the temperature for 5 hours, and then add water to adjust the acidity to 26%. , to prepare sulfonated liquid;

[0049] (3) Condensation rea...

Embodiment 2

[0053] A kind of preparation method of naphthalenesulfonate-alkylnaphthalenesulfonate-formaldehyde condensate, specifically comprises the steps:

[0054] (1) Alkylation reaction: first add 64g of refined naphthalene, 13g of isopropanol and 5.0g of concentrated sulfuric acid with a mass concentration of 98%; then the temperature is raised to 85°C under stirring conditions, and the insulation reaction is carried out for 4h to prepare naphthalene and alkanes The mixed solution of base naphthalene, the content ratio of naphthalene and isopropyl naphthalene in the mixed solution detected by high performance liquid chromatography is 60:40;

[0055] (2) Sulfonation reaction: Add 55 g of concentrated sulfuric acid with a mass concentration of 98% to the mixture of naphthalene and alkylnaphthalene, heat up to 155° C. under stirring, and after 4 hours of heat preservation, add water to adjust the acidity to 25%. , to prepare sulfonated liquid;

[0056] (3) Condensation reaction: reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com