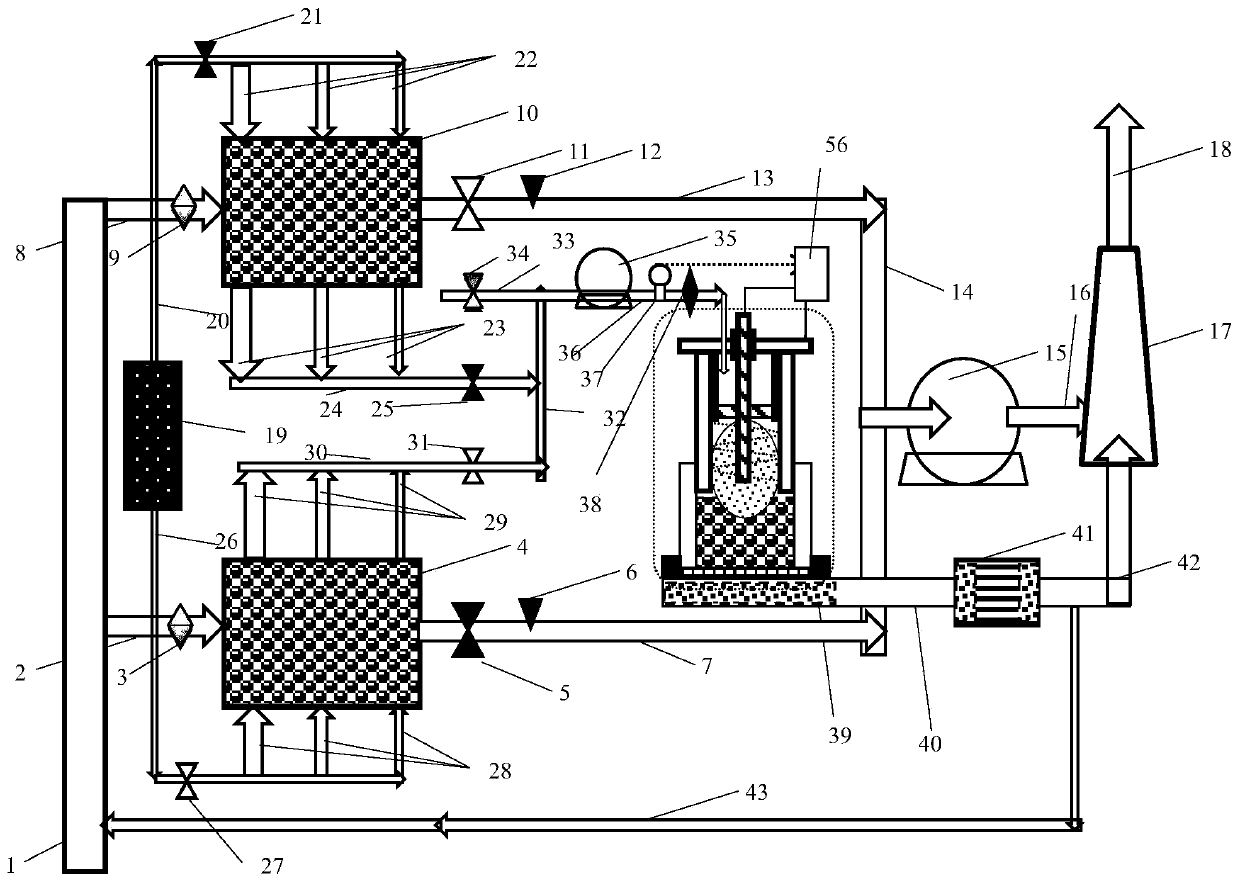

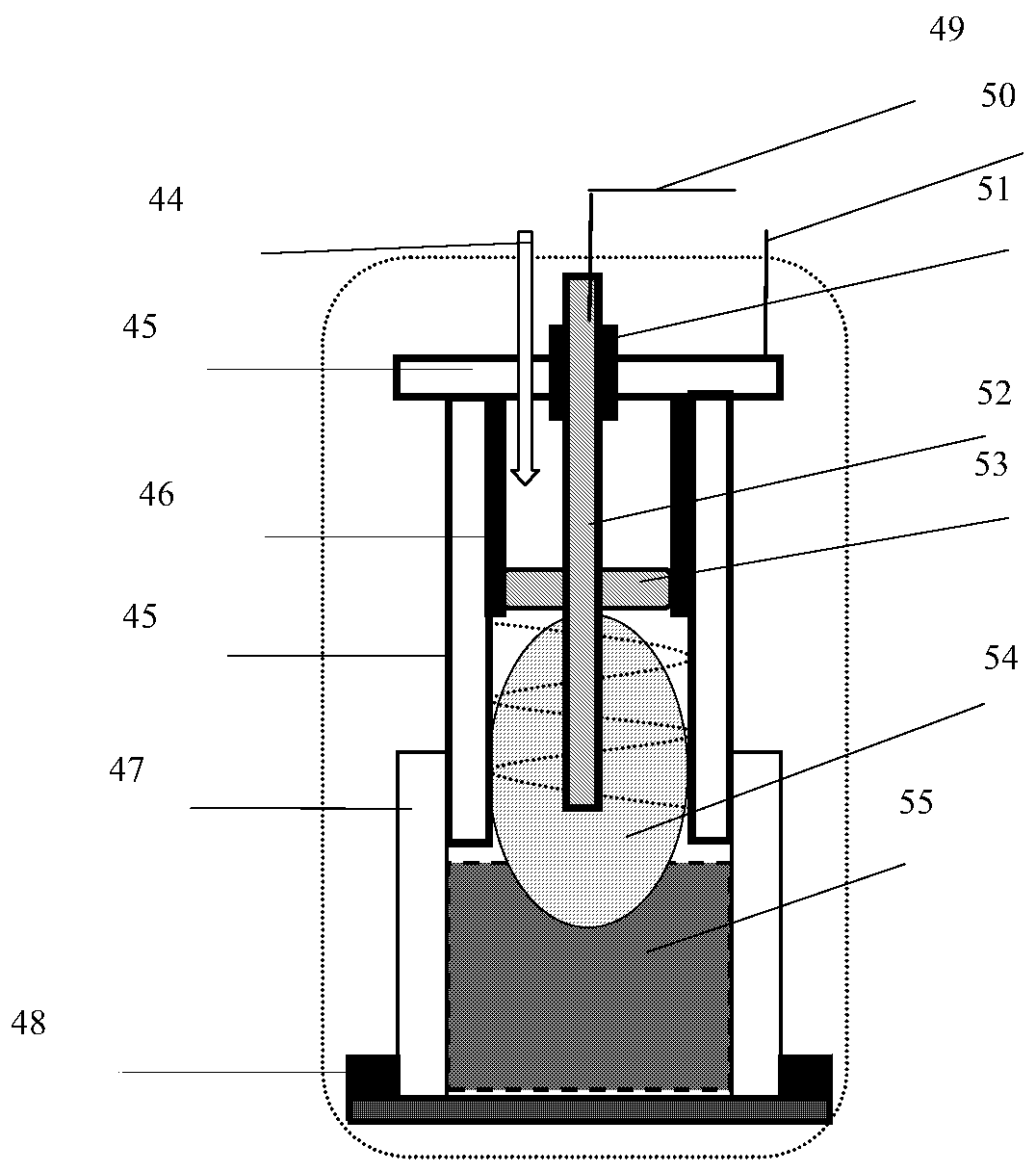

Rotating arc thermal plasma catalytic cracking high-concentration VOC tail gas treatment system and method

A thermal plasma and catalytic cracking technology, applied in the field of ion catalytic cracking high-concentration VOC exhaust gas treatment system, can solve the large-scale technical difficulty of DBD discharge low-temperature plasma device, the application of single-reactor treatment air volume limitation, and the degradation rate of exhaust gas. Insufficient stability, etc., to achieve the effect of flexible switching, less number of reactors, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Only the gas supply valve is opened first, and then all the plasma equipment is turned on to generate a flow of active particles to flow back to the waste gas pipeline for pre-cracking and oxidation, and dissolve into the water to achieve efficient spraying.

[0039] Open one way of adsorption and start to absorb and treat the exhaust gas to be discharged to the spray discharge. When the concentration at the outlet of the first pipeline is about to reach the initial concentration, that is, the adsorption is saturated. Close the valve of the pipeline after the exhaust gas treatment of the first way, turn on the heater, and close the air supply valve. Open the desorption channel valve of the first channel to carry out thermal desorption and plasma catalytic cracking process, and at the same time open the waste gas channel valve of the second channel to continue to adsorb the waste gas to be treated; During the blank time after the initial concentration, adjust the gas supp...

Embodiment 2

[0041] For low-concentration gases that are particularly easy to oxidize and degrade, turn on all plasma equipment to generate active particle flow back to the waste gas pipeline for pre-cracking and oxidation, dissolve it in water to achieve efficient spraying, and open one way to adsorb and start adsorption treatment. Waste gas is discharged to spraying Emission, continuous reaction in adsorption, this process can realize the degradation of exhaust gas without switching.

Embodiment 3

[0043] It can be carried out in the production shutdown stage without waste gas, desorption maintenance, all pipeline valves are closed after adsorption, all desorption pipeline valves are opened, and then all plasma equipment is turned on to treat residual waste gas, generate active particle airflow and dissolve it into water to achieve efficient spraying Deep governance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com