Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about "Manganese compounds preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

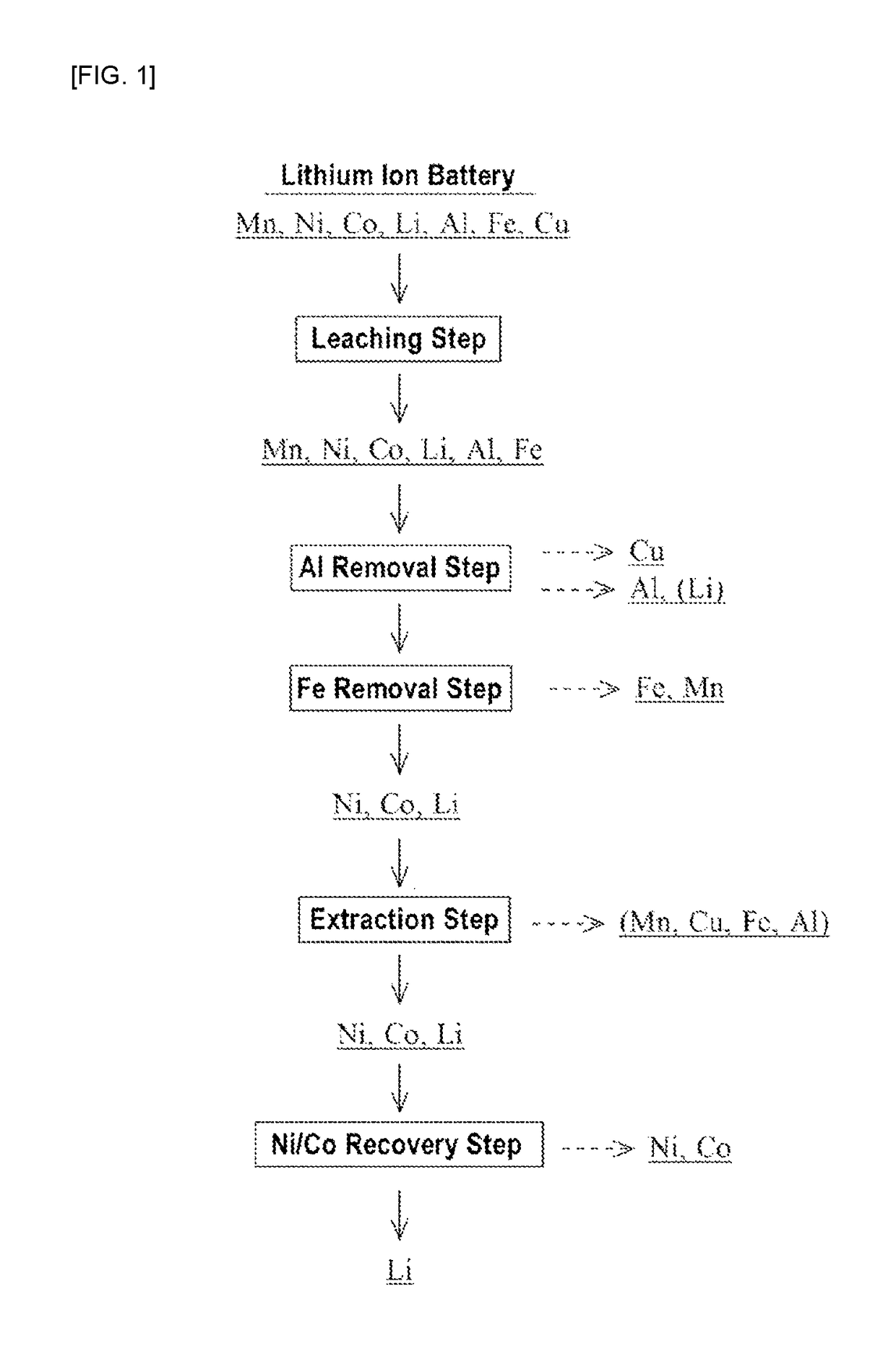

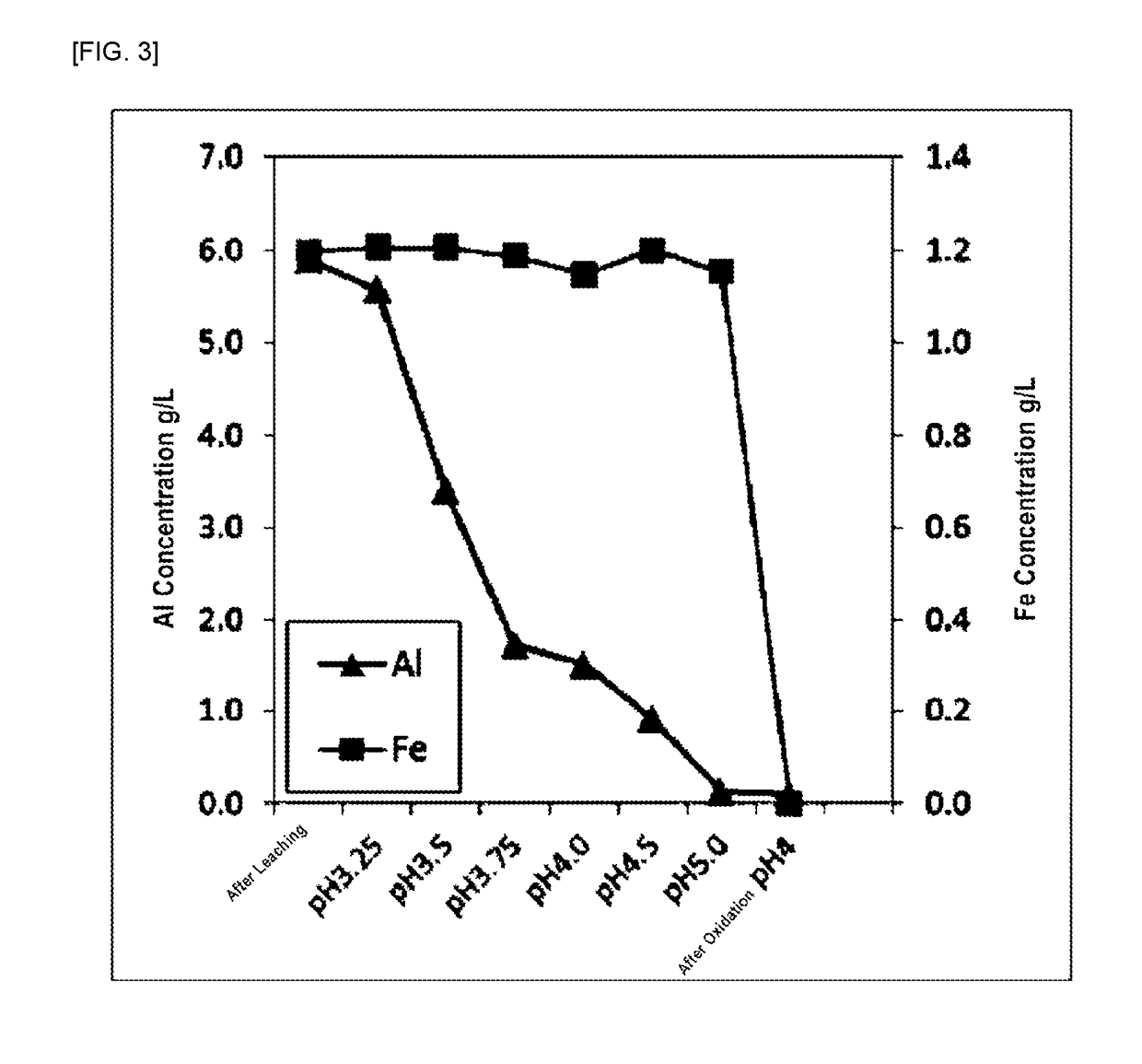

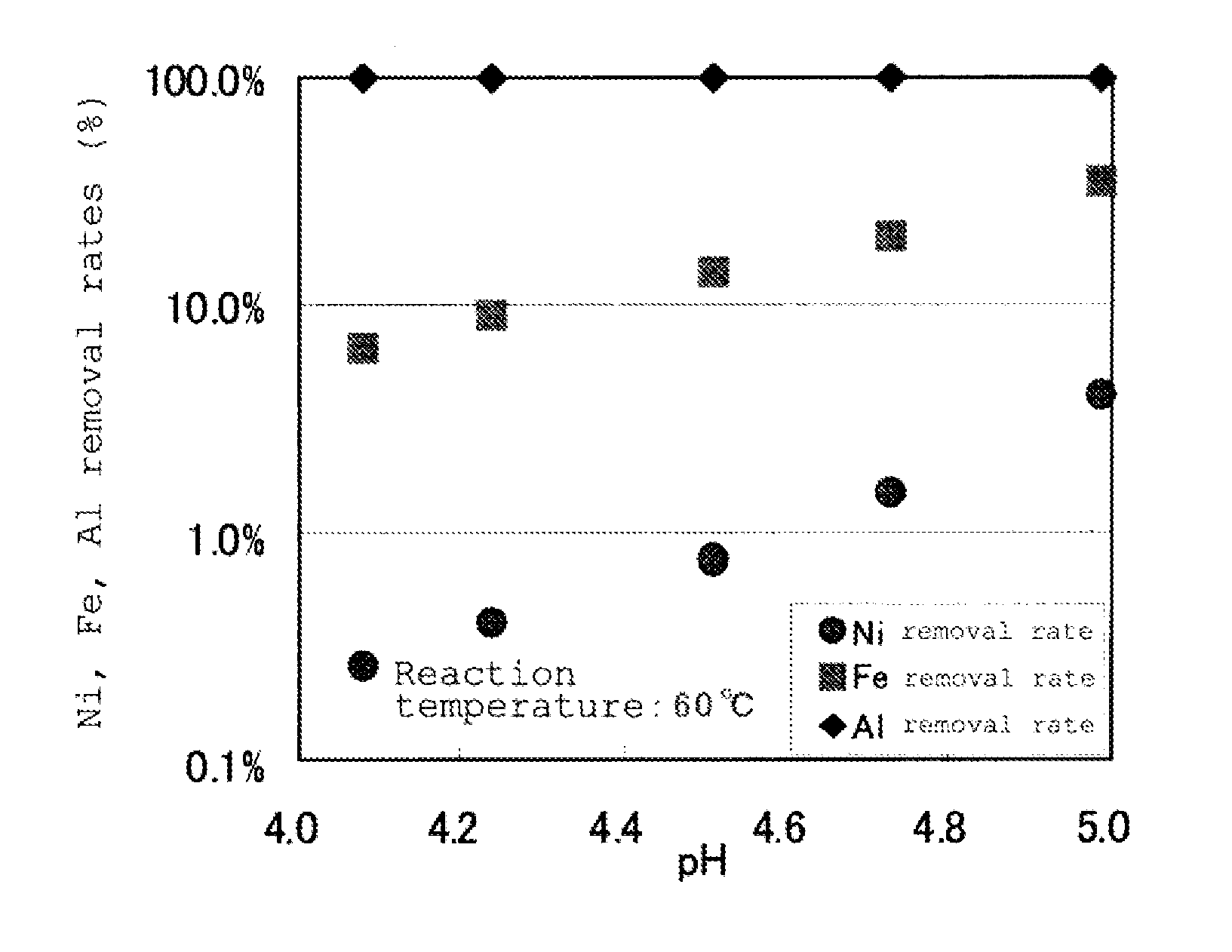

Processing method for lithium ion battery scrap

ActiveUS20190084839A1Transportation and packagingNickel compounds preparationElectrical batteryIron removal

A method for processing lithium ion battery scrap according to this invention includes a leaching step of leaching lithium ion battery scrap to obtain a leached solution; an aluminum removal step of neutralizing the leached solution to a pH range of from 4.0 to 6.0, then performing solid-liquid separation and removing aluminum in the leached solution to obtain a first separated solution; and an iron removal step of adding an oxidizing agent to the first separated solution and adjusting the pH in a range of from 3.0 to 5.0, then performing solid-liquid separation and removing iron in the first separated solution to obtain a second separated solution.

Owner:JX NIPPON MINING& METALS CORP

Method for preparing high-purity manganese sulfate solution with low cost

ActiveCN107416908AAchieve removalSimple preparation processManganese compounds preparationManganese sulfatesSulfateManganese

The invention discloses a method for preparing a high-purity manganese sulfate solution with low cost. The method comprises the following steps: (1) copper removal: obtaining copper-removed raw liquid manganese of which Cu is less than or equal to 0.2g / L; (2) pH value adjustment: adjusting the pH value of the copper-removed raw liquid manganese to be 1.5 to 5.0; (3) saponification: saponifying an extraction agent by using NaOH, Na2CO3, KOH, K2CO3 or ammonium hydroxide, so as to obtain sodium salt, potassium salt or ammonium salt containing the extraction agent; (4) manganese transforming saponification; (5) Mn and Ca extraction separation: making Ca in the raw liquid manganese enter an organic phase to be separated from Mn, and making all or most of Cu, Al, Zn and Cd enter the organic phase, so as to obtain extraction raffinate namely decalcified liquid manganese of which Ca is less than or equal to 5ppm; (6) deep purification: adding Na2S, NaHS, K2S, KHS or (NH4)2S into the decalcified liquid manganese, adjusting the pH value to be 4.0 to 6.0, and performing solid-liquid separation, so as to obtain a high-purity MnSO4 solution satisfying production of a positive precursor of a lithium ion battery.

Owner:广东芳源新材料集团股份有限公司 +1

Calcium removal method for manganese sulfate solution

InactiveCN111392777AHigh purityNo lossManganese compounds preparationManganese sulfatesManganese sulphatePhysical chemistry

The invention provides a calcium removal method for a manganese sulfate solution. The manganese sulfate solution contains impurity calcium ions. The method comprises the following steps: adjusting thepH value of the manganese sulfate solution to 0.5-3; mixing an extraction agent P204 with sulfonated kerosene to obtain an extraction organic phase, the volume concentration of the extraction agent P204 being 5-30%; extracting the manganese sulfate solution by adopting the extraction organic phase to obtain a manganese sulfate calcium-removed raffinate and a calcium-manganese-rich organic phase;carrying out multistage reverse extraction on the calcium-manganese-rich organic phase to obtain a reverse extraction water phase and a reverse extraction organic phase; and carrying out evaporative crystallization on the reverse extraction water phase to obtain a manganese sulfate solid. The process provided by the invention is used for removing calcium from the manganese sulfate solution, givesconsideration to environmental friendliness, low cost and calcium ion removal rate, and has a wide application prospect.

Owner:CHINA ENFI ENGINEERING CORPORATION

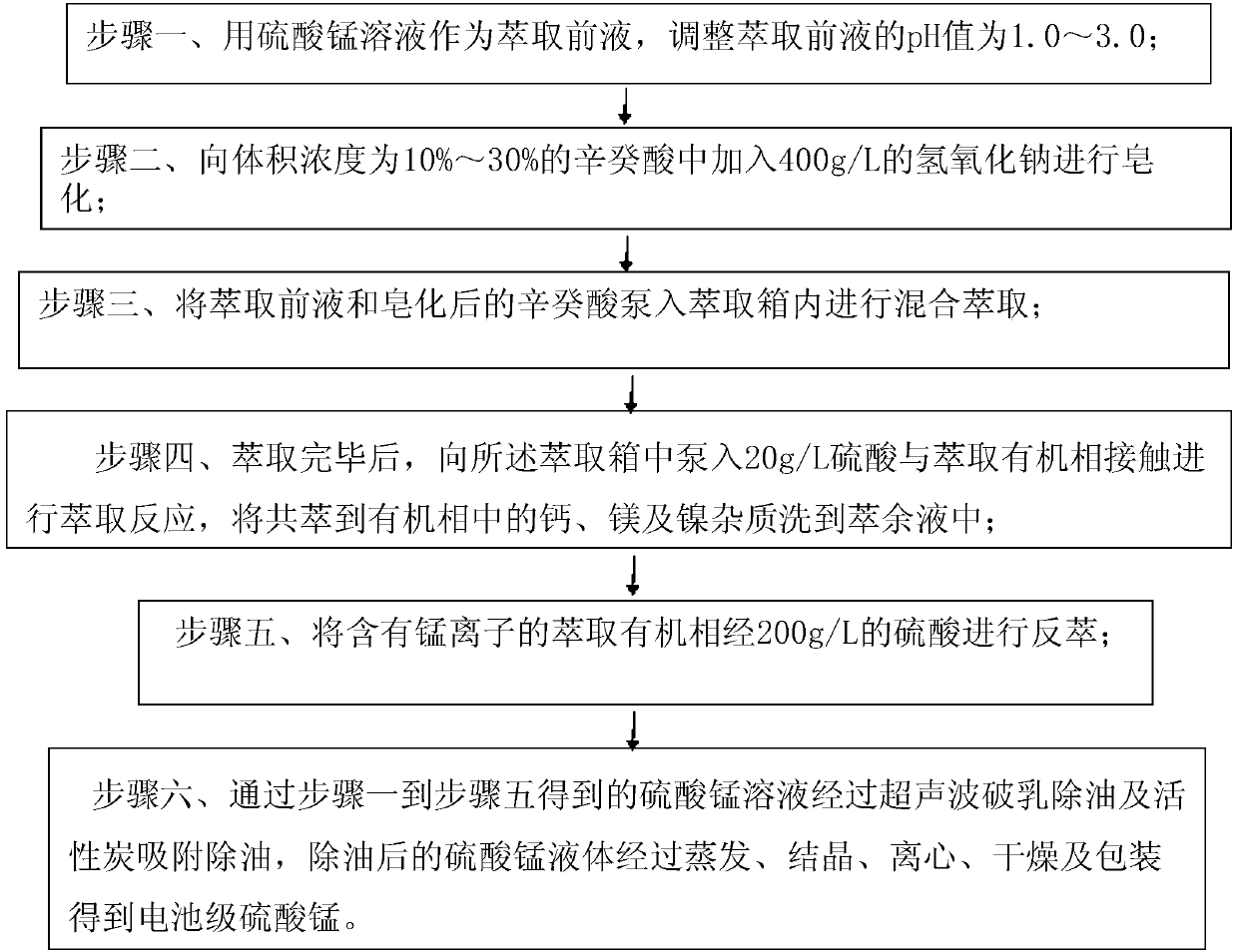

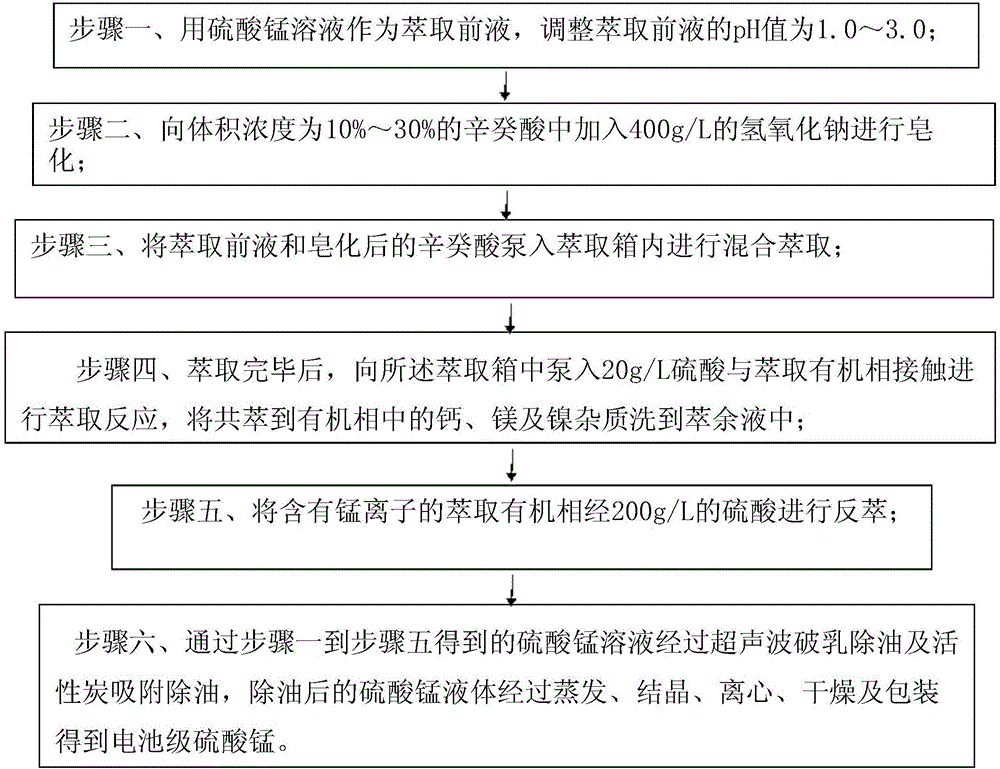

A kind of preparation method of battery grade manganese sulfate

ActiveCN106517347BSave energySave auxiliary materialsManganese compounds preparationManganese sulfatesManganeseHydrometallurgy

The invention provides a preparation method of battery-grade manganese sulfate and belongs to the technical field of hydrometallurgy. The method comprises steps as follows: step one, a manganese sulfate solution is taken as a pre-extraction solution; step two, 400 g / L of sodium hydroxide is added to octocapric acid for saponification; step three, the pre-extraction solution and octocapric acid after saponification are subjected to mixed extraction; step four, 20 g / L of sulfuric acid is pumped into an extraction box to be contacted with an extracted organic phase for the extraction reaction; step five, the extracted organic phase containing manganese ions is subjected to reverse extraction with 20 g / L of sulfuric acid; step six, battery-grade manganese sulfate is obtained. According to the method, the manganese sulfate solution with higher impurity content is enabled to enter an extraction system and the purpose of removing impurities is achieved by extraction, washing and reverse extraction of the solution; the overall technological process avoids chemical purification, chemical calcium removal and chemical magnesium removal processes, so that energy and auxiliary materials are saved, besides, no negative ions such as fluoride ions are introduced, and the requirement for equipment is reduced.

Owner:JILIN JIEN NICKEL IND

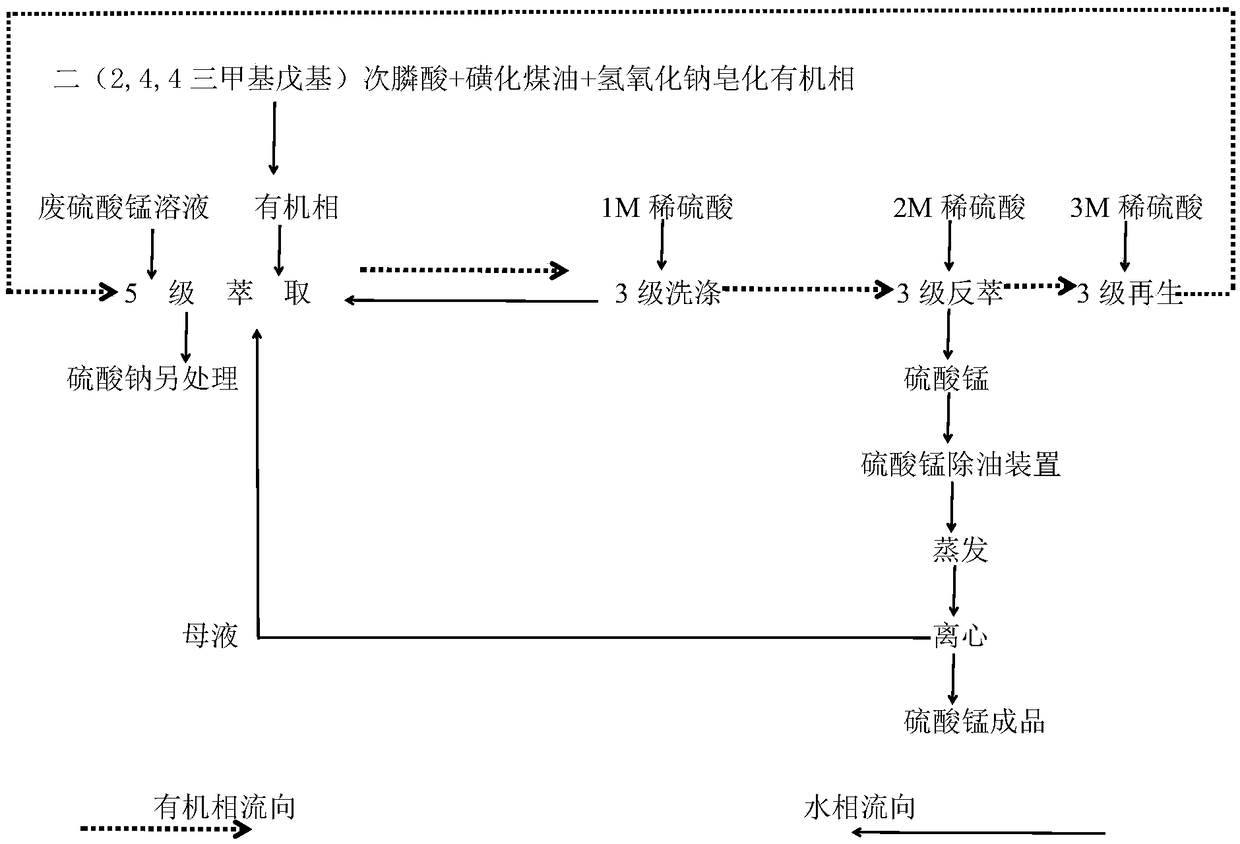

Method for removing calcium ions from manganese sulfate solution

InactiveCN109384261AHigh yieldNothing producedManganese compounds preparationManganese sulfatesPhosphinic AcidsIon

The invention discloses a method for removing calcium ions from a manganese sulfate solution, and belongs to the technical field of hydrometallurgy. According to the method, a calcium-containing manganese sulfate solution is taken as a raw material, an extraction agent, namely bi(2,4,4trimethylamyl) phosphinic acid, with a certain concentration is taken as an organic phase, a manganese sulfate solution is taken as an aqueous phase and multistage countercurrent extraction is carried out, wherein strip liquor is a relatively-pure manganese sulfate solution with extremely-low impurity content andcan be used for directly preparing a battery grade manganese sulfate product. The organic phase is recycled after being washed and regenerated. The method has the advantages of short process flow, fast onset, low cost, low consumption of auxiliary materials and power, high labor production efficiency, clean production process, no pollution and the like.

Owner:JILIN JIEN NICKEL IND

Preparation method of battery-grade manganese sulfate

ActiveCN106517347ASave energySave auxiliary materialsManganese compounds preparationManganese sulfatesManganeseHydrometallurgy

The invention provides a preparation method of battery-grade manganese sulfate and belongs to the technical field of hydrometallurgy. The method comprises steps as follows: step one, a manganese sulfate solution is taken as a pre-extraction solution; step two, 400 g / L of sodium hydroxide is added to octocapric acid for saponification; step three, the pre-extraction solution and octocapric acid after saponification are subjected to mixed extraction; step four, 20 g / L of sulfuric acid is pumped into an extraction box to be contacted with an extracted organic phase for the extraction reaction; step five, the extracted organic phase containing manganese ions is subjected to reverse extraction with 20 g / L of sulfuric acid; step six, battery-grade manganese sulfate is obtained. According to the method, the manganese sulfate solution with higher impurity content is enabled to enter an extraction system and the purpose of removing impurities is achieved by extraction, washing and reverse extraction of the solution; the overall technological process avoids chemical purification, chemical calcium removal and chemical magnesium removal processes, so that energy and auxiliary materials are saved, besides, no negative ions such as fluoride ions are introduced, and the requirement for equipment is reduced.

Owner:JILIN JIEN NICKEL IND

Purification treatment method of manganese sulfate solution

ActiveCN111285403AAchieve high purificationAchieve primary separationManganese compounds preparationManganese sulfatesManganese sulphateSulfate

The invention provides a purification treatment method of a manganese sulfate solution. The purification treatment method comprises the following steps: S1, preparing an extraction organic phase, andsaponifying the extraction organic phase to obtain a saponified organic phase; S2, extracting the manganese sulfate solution by using the saponified organic phase to obtain a manganese-rich organic phase; S3, washing the manganese-rich organic phase for the first time by adopting water to obtain a primary purified manganese-rich organic phase; S4, washing the primary purified manganese-rich organic phase for the second time by adopting a manganese-containing strong acid solution to obtain a secondary purified manganese-rich organic phase; and S5, carrying out reverse extraction on the secondary purified manganese-rich organic phase by using sulfuric acid to obtain a high-purity manganese sulfate solution and a regenerated organic phase. According to the method, pure manganese sulfate doesnot need to be adopted for carrying out manganese conversion saponification on the saponification organic phase, and the used washing liquid is cheap water and a manganese-containing strong acid solution, so that the purification treatment cost is relatively low.

Owner:CHINA ENFI ENGINEERING CORPORATION

Method of recovering metal compounds from solid oxide fuel cell scrap

A method of recovering metal compounds from solid oxide fuel cell scrap includes processing the solid oxide fuel cell scrap to form a powder, digesting the processed scrap, extracting lanthanum oxide and cerium oxide from a solution containing the digested processed scrap, extracting a zirconium compound from the solution after extracting the lanthanum oxide and cerium oxide, and extracting scandium compound from the solution extracting the zirconium compound from the solution.

Owner:BLOOM ENERGY CORP

Method for recycling waste lithium battery and preparing ternary precursor

PendingCN113802003AHigh recovery rateAvoid the effects of extractionCobalt sulfatesNickel compounds preparationManganese sulphateMetal chloride

The invention discloses a method for recycling a waste lithium battery and preparing a ternary precursor. The method comprises the following steps of pretreating the waste lithium battery to obtain battery powder and aluminum slag, roasting the battery powder, adding water into the roasted battery powder to prepare slurry, adding metal chloride to carry out leaching reaction, and carrying out solid-liquid separation to obtain nickel-cobalt-manganese slag and a lithium chloride solution; adding sulfuric acid into nickel-cobalt-manganese slag for acid leaching, adding aluminum slag into an acid leaching solution to remove copper, adjusting the pH value of the acid leaching solution to remove aluminum, mixing the aluminum-removed solution with a compound extraction agent, extracting to obtain a manganese-containing organic phase and a nickel-cobalt-containing raffinate, wherein the organic phase can be used for preparing manganese sulfate, and the raffinate can be used for preparing a high-purity nickel-cobalt sulfate mixed crystal through crystallization; and after the obtained battery-grade manganese sulfate and nickel-cobalt sulfate mixed crystal is dissolved in water, a certain amount of nickel-cobalt-manganese sulfate is supplemented to prepare a ternary precursor. The recovery process route provided by the invention has the advantages of simplicity in operation, low production cost, stability and reliability.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

Method for recovering soluble manganese and ammonium from electrolytic manganese slag

ActiveCN112408488AReduce dosageLow running costCement productionAmmonium sulfatesElectrolytic agentManganese

The invention discloses a method for recovering soluble manganese and ammonium from electrolytic manganese slag. The method comprises the following steps: washing the electrolytic manganese slag withwater to obtain water washing liquid and water washing slag; extracting manganese ions from the water washing liquid by adopting an organic phase containing an extracting agent to obtain raffinate anda loaded organic phase, and performing reverse extraction on the loaded organic phase by adopting an acidic solution to obtain an organic phase containing the extracting agent and reverse extractionliquid; stripping ammonia gas from the raffinate through alkalinity, absorbing part of the ammonia gas by adopting an organic phase containing an extracting agent for saponification of the extractingagent, and absorbing a part of the ammonia gas by adopting strip liquor to obtain a solution containing ammonium ions and manganese ions for electrolyzing manganese, wherein the water washing residueis used as a cement retarder or roadbed backfill. According to the method, extraction and enrichment of soluble manganese and ammonium in the electrolytic manganese residues can be achieved to obtainthe manganese electrolyte, and the washed residues can be used for building materials or road pavement to be digested, so that a present problem that the electrolytic manganese residues are piled up for a long time is thoroughly avoided.

Owner:CENT SOUTH UNIV

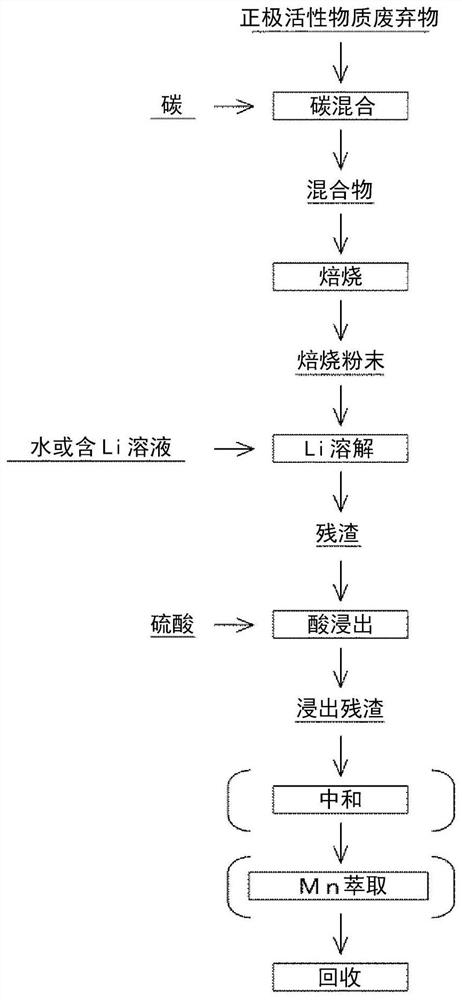

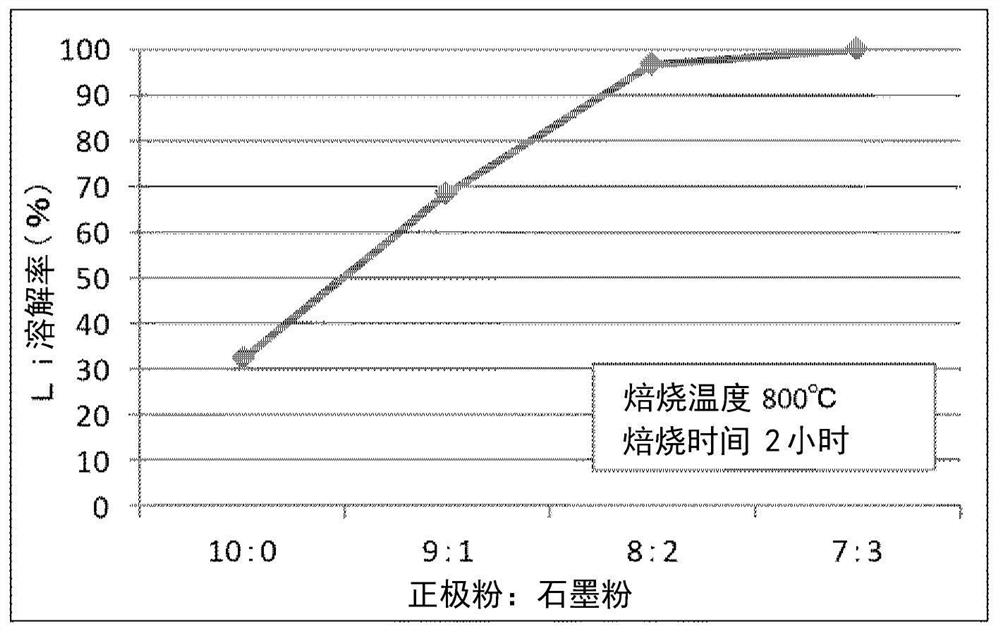

Treatment method of positive electrode active substance waste product of lithium ion secondary battery

PendingCN112930618AEfficient recyclingElectrode manufacturing processesTransportation and packagingManganeseBattery cell

A method is for treating a lithium ion secondary battery positive electrode active substance waste product that contains cobalt, nickel, manganese and lithium, and involves: a carbon mixing step in which a powder-form positive electrode active substance waste product is mixed with carbon to obtain a mixture in which the ratio of the mass of the carbon is 10-30% of the total mass of the positive electrode active substance waste product and the carbon; a roasting step for roasting the mixture at a temperature of 600-800 DEG C to obtain a roasted powder; a lithium dissolving step which involves a first dissolving process for dissolving the lithium in the roasted powder in water or a lithium-containing solution and a second dissolving process for dissolving the lithium in the residue obtained in the first dissolving process in water; and an acid leaching step in which the residue obtained in the lithium dissolving step is leached with acid.

Owner:JX NIPPON MINING & METALS CO LTD

Method for preparing industrial-grade manganese carbonate by utilizing copper chloride manganese liquid

ActiveCN111573736AShort processSimple processManganese compounds preparationManganese(II) carbonateFiltration

The invention discloses a method for preparing industrial-grade manganese carbonate by utilizing copper chloride manganese liquid. The method is characterized by comprising the following steps: S1, copper replacement: adding iron powder into the copper manganese liquid, filtering out copper slag after complete reaction to obtain copper-removed liquid, and after copper removal, ensuring that the solution only contains 0.04 g / L of copper and the recovery rate of copper reaches 99.2%; S2, removing calcium, iron and aluminum, namely adding P507 raffinate into the copper-removed solution; after thereaction is completed, adding hydrogen peroxide; after complete oxidation, slowly adding an alkaline substance, after further complete reaction, filtering out waste residues, and separating to obtaincalcium, iron and aluminum removed liquid; S3, manganese precipitation: slowly adding soluble carbonate into the calcium, iron and aluminum removed liquid, carrying out carbonation to precipitate manganese, precipitating manganese and a small amount of other metal ions, and filtering to obtain crude manganese carbonate. The method is short in treatment process and simple in process, copper replacement, impurity removal and manganese precipitation are completed in three steps, and only three times of filtration and separation are adopted. Most impurity metal elements except copper and manganese are removed in an impurity removal step in a coprecipitation form.

Owner:浙江格派钴业新材料有限公司

Production process of manganese sulfate

ActiveCN109133178AAchieve recyclingReduce pollutionManganese compounds preparationManganese sulfatesSolubilityManganese

The invention discloses a production process of manganese sulfate. The process comprises the following steps of 1) extracting by-products of cobalt after smelting by using Lix series organic extractant to remove copper, and stripping copper liquid into a copper electrodeposition system, and extracting remaining liquid as a first intermediate mixed solution; 2) adding sodium hypochlorite to the above extracting remaining liquid, stirring for reaction, standing to precipitate, and separating the precipitate to obtain a second intermediate mixture; 3) using a P507 organic extractant to extract the second intermediate mixture to collect an oil phase to obtain a manganese-loaded organic phase; 4) stripping the manganese-loaded organic phase with sulfuric acid, and collecting an aqueous phase toobtain a manganese sulfate solution; 5) making the manganese sulfate solution subjected to evaporative crystallization, centrifugal dehydration and drying to obtain a manganese sulfate product. The process adopts the copper extractant to extract copper in a high chloride ion solution, adopts a sodium hypochlorite calcium removing method, and removes calcium by using the poor solubility of calciumhypochlorite, thereby replacing the method of removing the calcium by using environmentally polluting fluoride in the prior art, and reducing the pollution to the environment.

Owner:GEM JIANGSU COBALT IND CO LTD

Method for removing zinc, calcium and magnesium ions in manganese sulfate solution by synergistic extraction method

ActiveCN111533174AEasy to separateReduce consumptionProcess efficiency improvementManganese compounds preparationPhosphatePhosphoric acid

The invention discloses a method for removing zinc, calcium and magnesium ions in a manganese sulfate solution by a synergistic extraction method and belongs to the technical field of hydrometallurgy.The method comprises the following steps of: mixing di(2-ethylhexyl) phosphate, tributyl phosphate and dinonyl naphthalene sulfonic acid according to a certain ratio to prepare an extraction agent, and adding sulfonated kerosene to prepare an organic phase; saponifying the organic phase, and extracting and purifying zinc, calcium and magnesium ions in the manganese sulfate solution so as to prepare high-purity battery-grade manganese sulfate. According to the method, a byproduct, namely a manganese sulfate solution with relatively high impurity content, produced from production of nickel sulfate and cobalt sulfate is used as a water phase; an extraction agent prepared in proportion is used as an organic phase; after multi-stage counter-current extraction, a liquid from a water-phase outlet is a pure manganese sulfate solution; the organic phase is recycled after being subjected to segmented pickling for regeneration; and a water phase produced from the regenerative section is a zinc sulfate product. The method has the advantages that the raw material cost is low, the alkali consumption is greatly reduced, the process is simple, the flow is short, the production efficiency is high,the production process is clean, no waste water is discharged and the like.

Owner:JILIN JIEN NICKEL IND +1

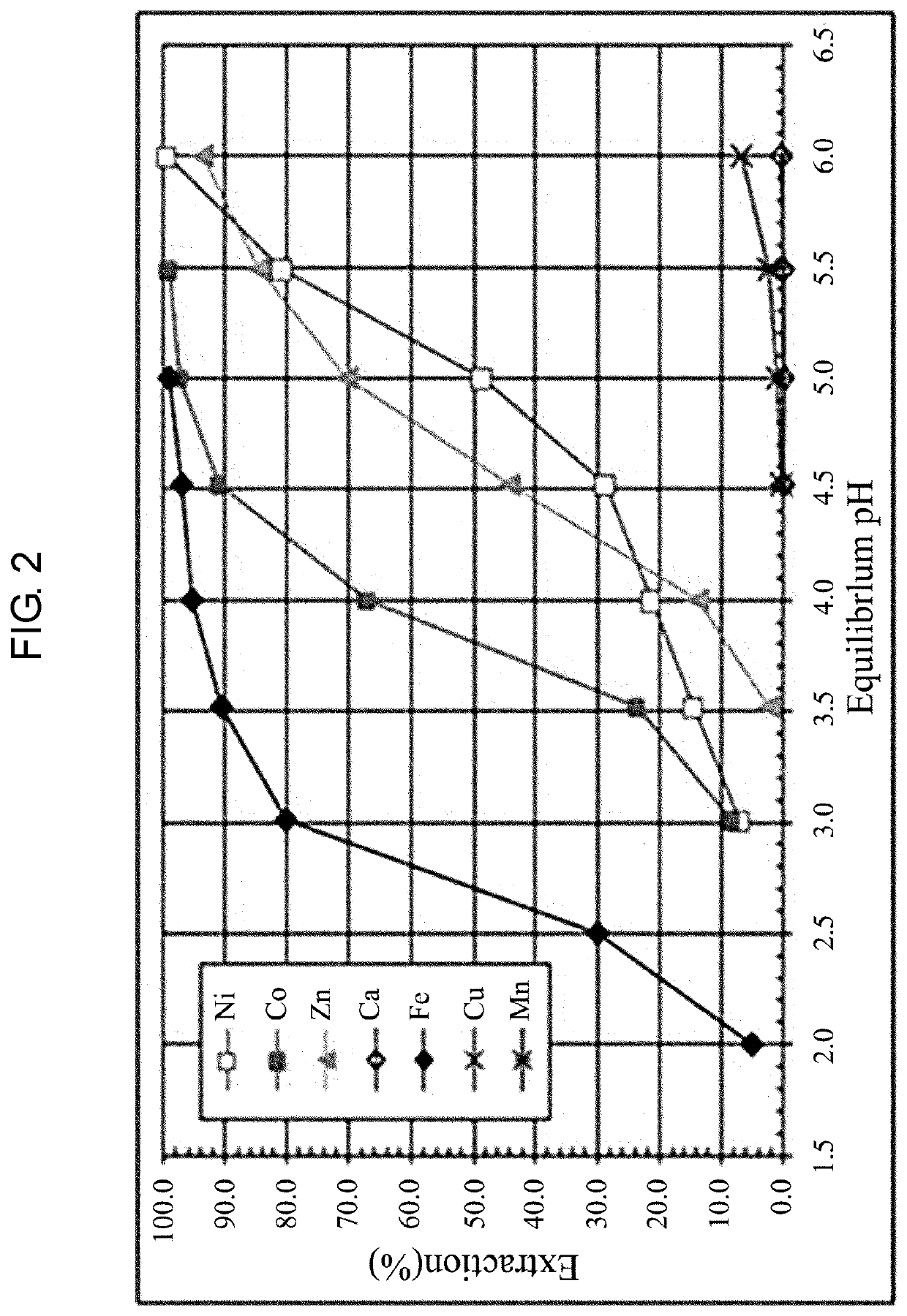

Method for recovering nickel from sulfuric acid aqueous solution

ActiveUS8580213B2Easy to useImprove economySolvent extractionNickel compounds preparationPhosphateManganese

A method for recovering nickel from sulfuric acid aqueous solution, for recovering nickel in an effectively utilizable form as a raw material of nickel industry material, by separating efficiently impurity elements of iron, aluminum, manganese, etc., from the sulfuric acid aqueous solution containing nickel and cobalt, and the impurity elements, iron, aluminum, manganese, etc. The method comprises the following steps: subject the sulfuric acid aqueous solution to oxidation neutralization treatment; then subject the solution to neutralization treatment, and separate and recover mixed hydroxides containing nickel and cobalt; subject the mixed hydroxides to dissolution treatment in a sulfuric acid solution having a concentration of equal to or higher than 50% by mass; subject the concentrated solution to solvent extraction treatment, using a phosphate ester-based acidic extraction agent; add a neutralizing agent to the resultant extraction residual liquid; subject the solution to the neutralization treatment, and separate and recover nickel hydroxide generated.

Owner:SUMITOMO METAL MINING CO LTD

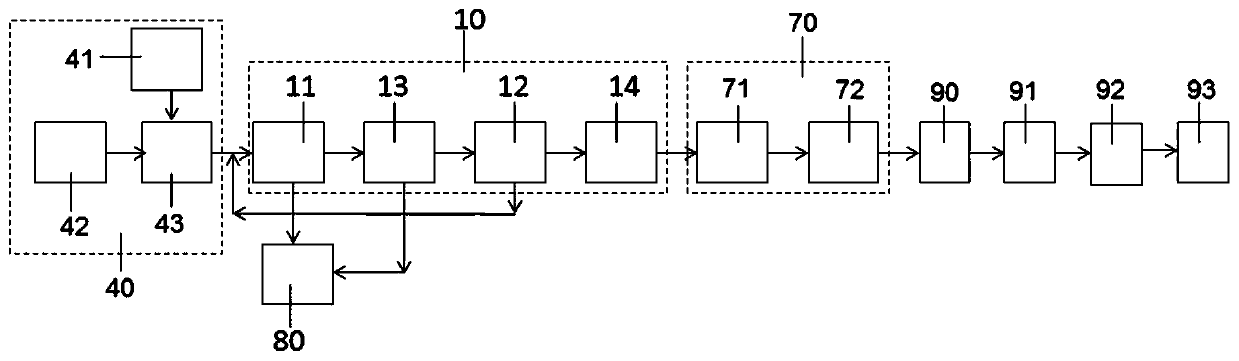

Treatment system and treatment method for reducing content of impurities in soluble manganese sulfate solution

PendingCN111170368AIncrease the content of manganeseSimple structureManganese compounds preparationManganese sulfatesManganese sulphateSulfate

The invention provides a treatment system and a treatment method for reducing the content of impurities in a soluble manganese salt solution. The impurities comprise calcium ions and magnesium ions, the treatment system comprises an extraction unit and an evaporative crystallization device or a precipitation unit, the extraction unit is used for removing the magnesium ions, and the extraction unitis provided with a soluble manganese salt solution inlet, an extraction agent inlet and a primary purified product outlet; the evaporative crystallization device is provided with a primary purified product inlet, and the primary purified product inlet is communicated with the primary purified product outlet through a primary purified product conveying pipeline; the precipitation unit is providedwith a primary purification product inlet and a precipitant inlet, and the primary purification product inlet is communicated with the primary purification product outlet through a primary purification product conveying pipeline. By adopting the treatment system, the impurity content in the soluble manganese salt solution can be greatly reduced. The treatment system and a treatment method for reducing the content of impurities in a soluble manganese salt solution have the advantages of being simple in structure, small in solid slag and hazardous waste discharge amount and the like, and therefore good environmental friendliness is achieved.

Owner:CHINA ENFI ENGINEERING CORPORATION

Method for purifying manganese sulfate solution

The invention provides a method for purifying a manganese sulfate solution. The purification method comprises the steps of S1, removing heavy metals from a manganese sulfate solution to be purified by using a sulfide, and carrying out first solid-liquid separation to obtain a first intermediate liquid; S2, removing calcium from the first intermediate liquid by using fluoride, and carrying out second solid-liquid separation to obtain a second intermediate liquid; S3, removing fluorine from the second intermediate liquid by using magnesium sulfate or magnesium chloride, and performing third solid-liquid separation to obtain a third intermediate liquid; S4, extracting the third intermediate liquid by adopting a saponified organic phase to obtain a manganese-rich organic phase; S5, washing the manganese-rich organic phase with first sulfuric acid to obtain a purified manganese-rich organic phase; and S6, conducting reverse extraction on the purified manganese-rich organic phase through second sulfuric acid, and obtaining a high-purity manganese sulfate solution and a regenerated organic phase. Manganese ions and magnesium ions in the third intermediate liquid arepurified by adopting the extraction-washing-reverse extraction process to obtain the high-purity manganese sulfate solution.

Owner:CHINA ENFI ENGINEERING CORPORATION

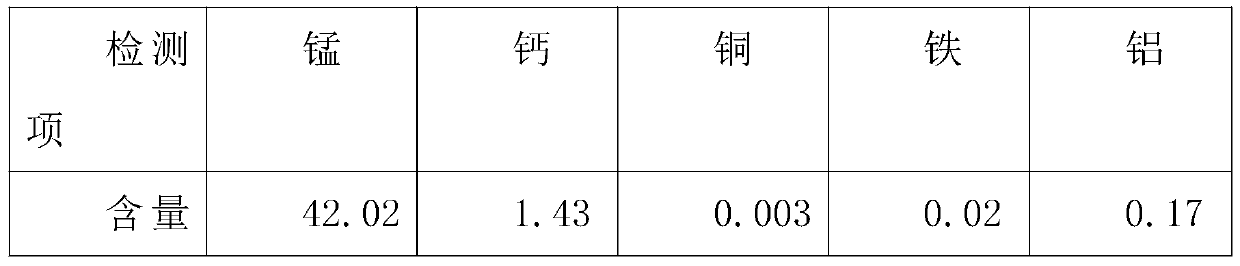

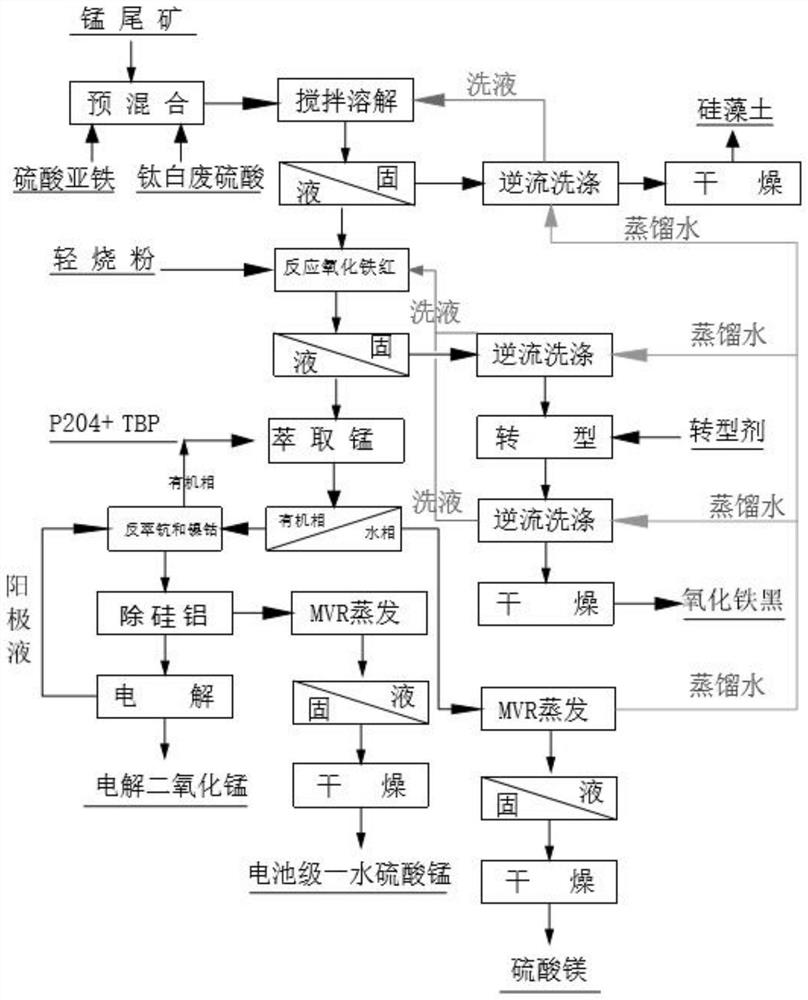

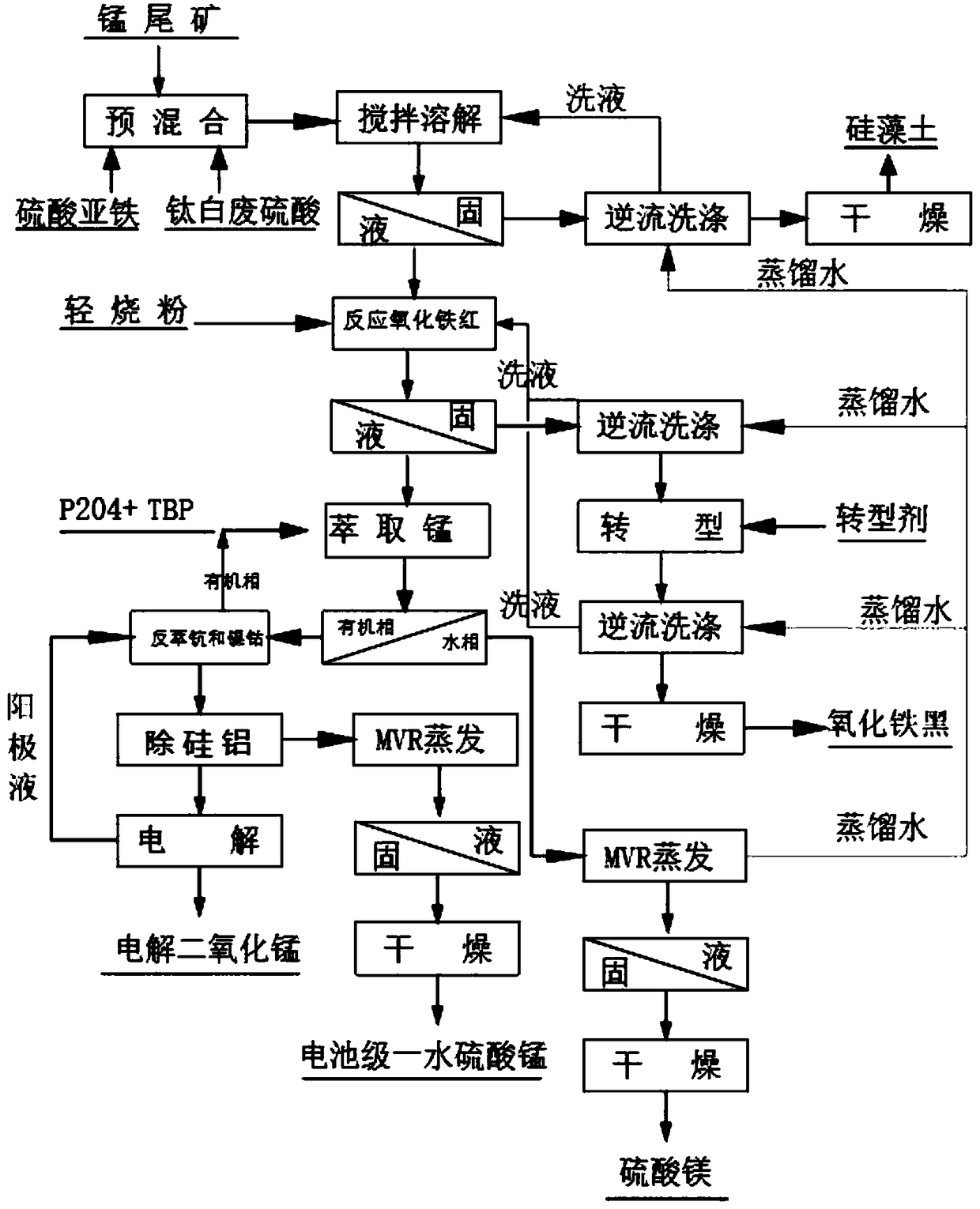

A method for producing electrolytic manganese dioxide by using manganese tailings and titanium white waste sulfuric acid

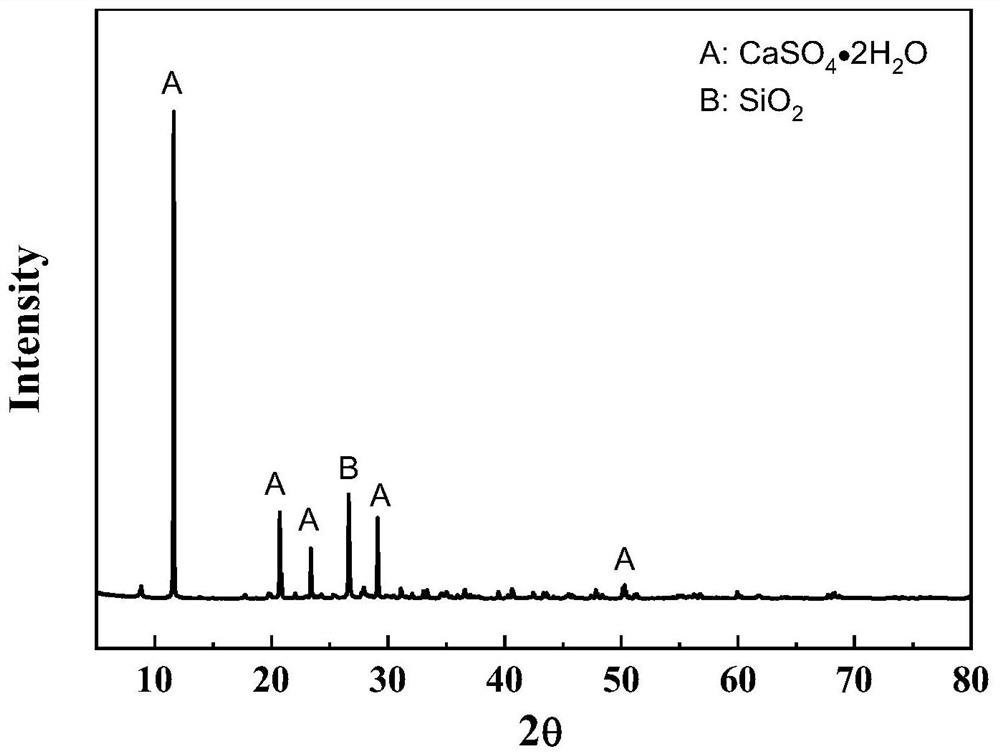

ActiveCN109399723BReduce consumptionReduce manufacturing costIron compounds preparationFerroso-ferric oxidesPhosphateEcological safety

The invention discloses a method for producing electrolytic manganese dioxide from manganese gangue and titanium dioxide waste sulfuric acid. The method particularly includes carrying out reduction leaching and fine grinding on the manganese gangue by the aid of the titanium dioxide waste sulfuric acid; carrying out solid-liquid separation to obtain a white filter residue used as diatomaceous earth; extracting leach liquid by di-(2-ethylhexyl)phosphate extraction agents; carrying out saponification by light burning powder (or magnesium oxide); removing impurities and then carrying out electrolysis to obtain the electrolytic manganese dioxide, iron black and magnesium sulfate. The iron black and the magnesium sulfate are byproducts. The method has the advantages that the manganese gangue and titanium dioxide waste acid can be synergistically disposed by the aid of the method, accordingly, the problems in the aspect of ecological safety due to manganese gangue accumulation can be solvedby the aid of the method, a brand new way can be provided to utilizing the titanium dioxide waste acid, and the comprehensive utilization additional values of the manganese gangue and the titanium dioxide waste acid can be increased; the electrolytic manganese dioxide prepared by the aid of the method is high in quality and low in production cost, processes for the electrolytic manganese dioxide are simple, the manganese gangue and the titanium dioxide waste sulfuric acid can be completely recycled, secondary pollution can be prevented, wastewater is free of discharge, and the method is favorable for protecting environments and comprehensively utilizing resources.

Owner:宣城市安工大工业技术研究院有限公司

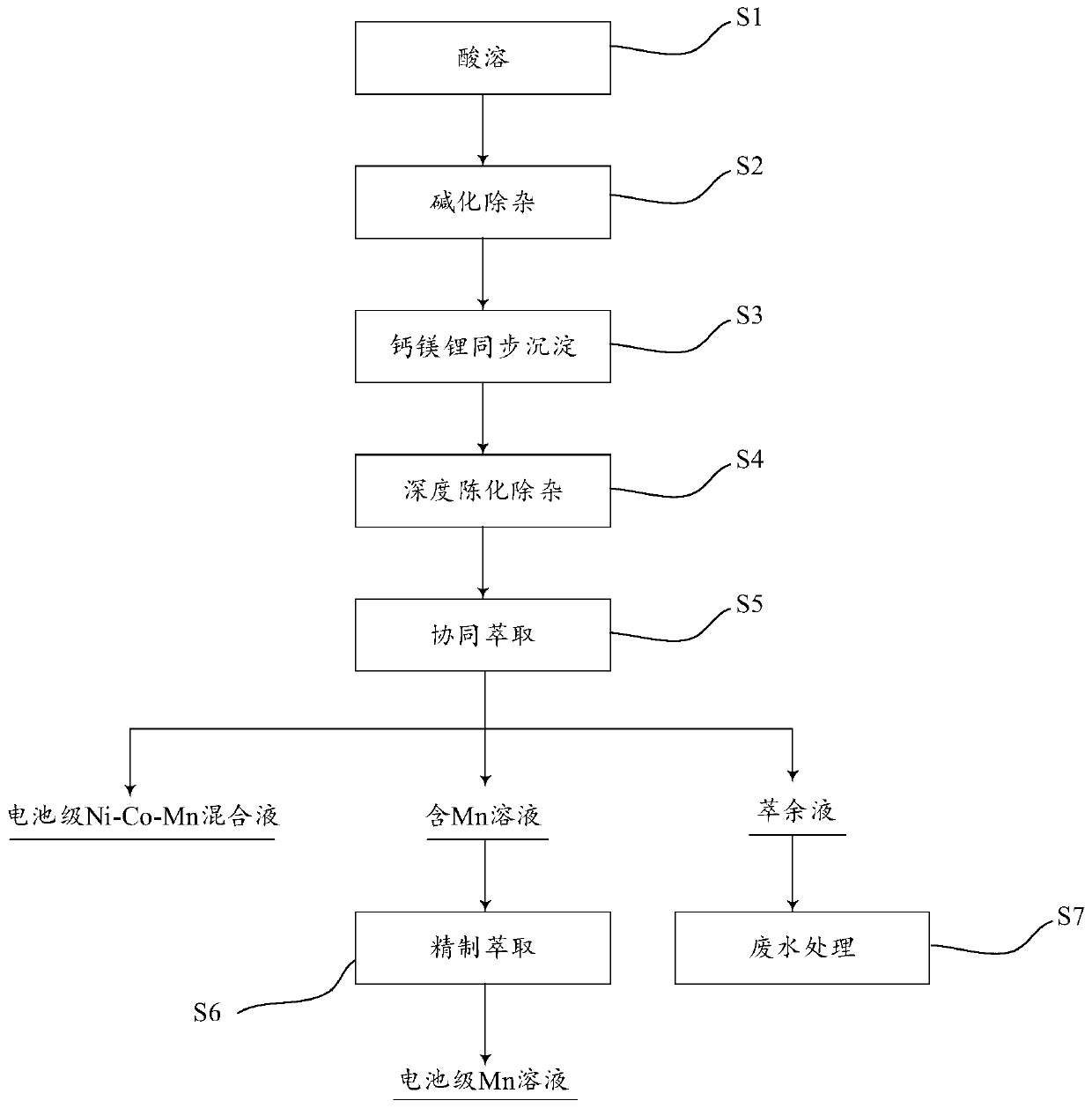

Preparation method of battery-grade Ni-Co-Mn mixed solution and battery-grade Mn solution

ActiveCN111180819ALow impurity contentHigh recovery rateMagnesium fluoridesCell electrodesPhysical chemistryAcid dissolution

The invention discloses a preparation method of a battery-grade Ni-Co-Mn mixed solution and a battery-grade Mn solution. The preparation method comprises the following steps: acid dissolution, alkalization and impurity removal, calcium-magnesium-lithium synchronous precipitation, deep aging and impurity removal, collaborative extraction and refined extraction. The deep aging impurity removal and synergistic extraction step comprises the following steps: carrying out deep aging on filtrate obtained after the calcium-magnesium-lithium synchronous precipitation step, and performing filtering to remove impurities, so as to obtain aged filtrate; and extracting the aged filtrate by using P204 to obtain a loaded organic phase, and carrying out graded reverse extraction on the loaded organic phaseto obtain a battery-grade Ni-Co-Mn mixed solution and a Mn-containing solution. Through cooperation of multiple process steps of calcium-magnesium-lithium synchronous precipitation, deep aging impurity removal and synergistic extraction, the impurity content of the obtained battery-grade Ni-Co-Mn mixed solution is remarkably reduced, and the battery-grade Ni-Co-Mn mixed solution can be directly applied to preparation of a lithium battery ternary precursor material; and meanwhile, a battery-grade Mn solution can be obtained, large-scale application of the process is facilitated, and economic benefits are improved.

Owner:JINGMEN GEM NEW MATERIAL +1

Method for producing electrolytic manganese dioxide from manganese gangue and titanium dioxide waste sulfuric acid

ActiveCN109399723AReduce consumptionReduce manufacturing costIron compounds preparationFerroso-ferric oxidesElectrolysisPhosphate

The invention discloses a method for producing electrolytic manganese dioxide from manganese gangue and titanium dioxide waste sulfuric acid. The method particularly includes carrying out reduction leaching and fine grinding on the manganese gangue by the aid of the titanium dioxide waste sulfuric acid; carrying out solid-liquid separation to obtain a white filter residue used as diatomaceous earth; extracting leach liquid by di-(2-ethylhexyl)phosphate extraction agents; carrying out saponification by light burning powder (or magnesium oxide); removing impurities and then carrying out electrolysis to obtain the electrolytic manganese dioxide, iron black and magnesium sulfate. The iron black and the magnesium sulfate are byproducts. The method has the advantages that the manganese gangue and titanium dioxide waste acid can be synergistically disposed by the aid of the method, accordingly, the problems in the aspect of ecological safety due to manganese gangue accumulation can be solvedby the aid of the method, a brand new way can be provided to utilizing the titanium dioxide waste acid, and the comprehensive utilization additional values of the manganese gangue and the titanium dioxide waste acid can be increased; the electrolytic manganese dioxide prepared by the aid of the method is high in quality and low in production cost, processes for the electrolytic manganese dioxide are simple, the manganese gangue and the titanium dioxide waste sulfuric acid can be completely recycled, secondary pollution can be prevented, wastewater is free of discharge, and the method is favorable for protecting environments and comprehensively utilizing resources.

Owner:宣城市安工大工业技术研究院有限公司

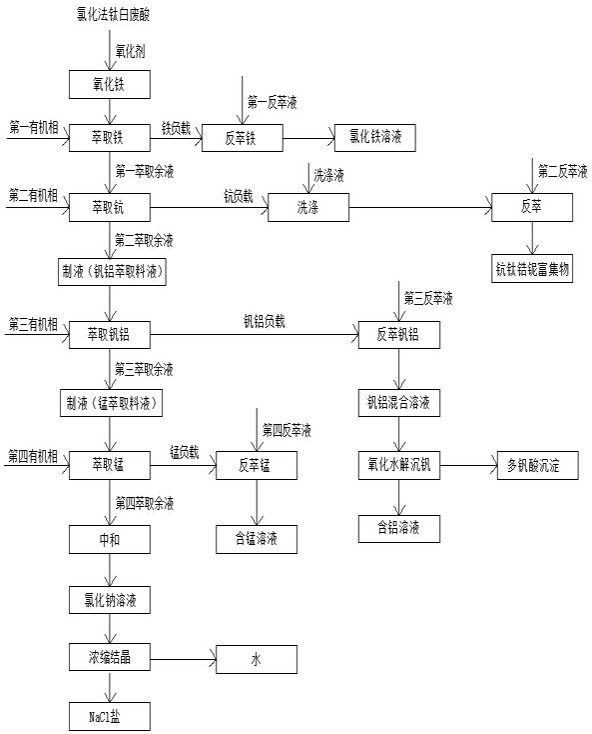

Method for recovering valuable elements from chlorination-process titanium dioxide waste acid through sectional extraction

ActiveCN112429780AAchieve recyclingIncrease valueTreatment involving filtrationWater/sewage treatment by neutralisationTitanium zirconiumNiobium

The invention discloses a method for recovering valuable elements from chlorination-process titanium dioxide waste acid through sectional extraction. The method comprises the following steps: S1, adding a first organic phase into the chlorination-process titanium dioxide waste acid to obtain a first extraction raffinate and an iron load, and carrying out back extraction on the iron load to obtaina ferric chloride solution; S2, adding a second organic phase into the first extraction raffinate to obtain second extraction raffinate and a scandium-titanium-zirconium-niobium load; S3, carrying outback extraction on the scandium load to obtain a scandium-titanium-zirconium-niobium enriched product; S4, adjusting the pH value of the second extraction raffinate to prepare a liquid; S5, adding athird organic phase after liquid preparation to obtain a vanadium-aluminum load and a third extraction raffinate; S6, carrying out back extraction on the vanadium-aluminum load to obtain a vanadium-aluminum mixed solution; S7, adjusting the pH value of the third extraction raffinate to prepare a liquid; S8, after liquid preparation, adding a fourth organic phase into manganese extraction feed liquid to obtain a manganese load and a fourth extraction raffinate, and carrying out back extraction on the manganese load to obtain a manganese-containing solution; and S9, neutralizing the fourth extraction raffinate, carrying out filtering, then performing concentrating and crystallizing to obtain NaCl edible salt and water, and recycling the NaCl edible salt and water.

Owner:河南荣佳钪钒科技有限公司

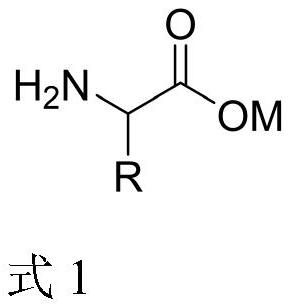

Method for preparing battery-grade manganese sulfate from manganese oxide ore

ActiveCN114162872AHigh recovery rateGood effect of removing impuritiesProcess efficiency improvementManganese compounds preparationIron sulfateManganese sulphate

The invention belongs to the field of smelting, and particularly relates to a method for preparing battery-grade manganese sulfate from manganese oxide ore, which comprises the following steps of: (1) leaching: carrying out first-stage leaching on manganese oxide ore, biomass and sulfuric acid, roasting leaching slag, mixing the roasted material and first-stage leaching liquid, carrying out second-stage leaching, and separating to obtain leaching liquid; (2) first-stage impurity removal: adding ferric sulfate, a manganese oxidizing agent and sulfide into the leachate to obtain first-stage impurity removal liquid; (3) second-stage impurity removal: carrying out manganese precipitation treatment on the first-stage impurity removal liquid to obtain a manganese hydroxide precipitate, dispersing the precipitate and a compound shown in the formula 1 in a solvent to obtain slurry, introducing carbon dioxide into the slurry, and carrying out second-stage impurity removal and solid-liquid separation to obtain impurity-removed manganese hydroxide; and (3) third-stage impurity removal: dissolving the impurity-removed manganese hydroxide with sulfuric acid, and then adding BaS and BaF2 to obtain a battery-grade manganese sulfate solution. The method disclosed by the invention is high in recovery rate and can be used for preparing high-quality battery-grade manganese sulfate.

Owner:湖南烯富环保科技有限公司

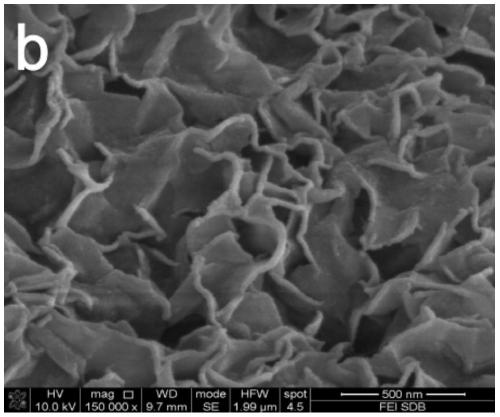

Method for preparing electrode material by electrochemical ion exchange method and electrode material

PendingCN111517376ANo pollution in the processShorten the timeHybrid capacitor electrodesNickel compounds preparationIon exchangeSupercapacitor

The Mn3O4 / NiMn2O4 composite structure and the pure substance NiMn2O4 are prepared to serve as the supercapacitor electrode, the two structures serve as the electrode, the electrochemical performance is greatly improved, and the cost of the electrode material can be greatly reduced; the preparation technology of NiMn2O4 is mainly a high-temperature solid-phase reaction or solvothermal combined subsequent calcination oxidation method. The application of the electrochemical ion exchange technology or the electrochemical ion exchange technology in the aspect is rarely reported, the Mn3O4 / NiMn2O4 composite structure and the pure substance NiMn2O4 are prepared by using electrochemical ion exchange, the time is short, the temperature is low, the operation is simple and pollution is avoided.

Owner:SHANDONG UNIV OF SCI & TECH

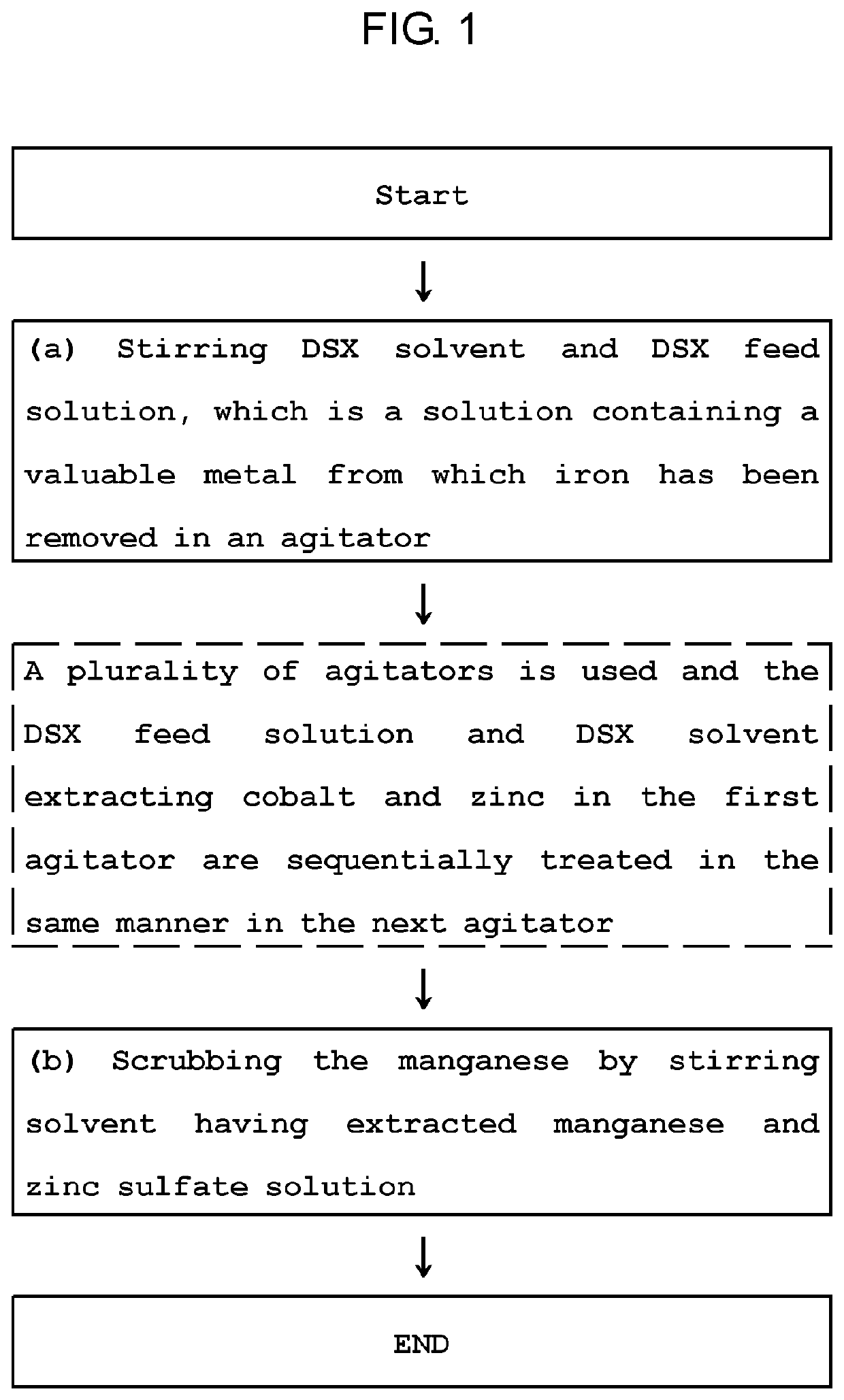

Method for inhibiting extractant degradation of dsx process through manganese extraction control

ActiveUS20210024366A1Minimizing extractionPrevent degradationZinc compounds preparationProcess efficiency improvementManganeseSolvent

Provided is a method for inhibiting extractant degradation in the DSX process through the manganese extraction control, the method comprising: (a) stirring DSX solvent and DSX feed solution, which is a solution containing a valuable metal from which iron has been removed in an agitator, in which soda ash (Na2CO3) is further added to maintain a constant pH; and (b) scrubbing the manganese from the DSX solvent, extracted in step (a).

Owner:KOREA MINE REHABILITATION & MINERAL RESOURCES CORP

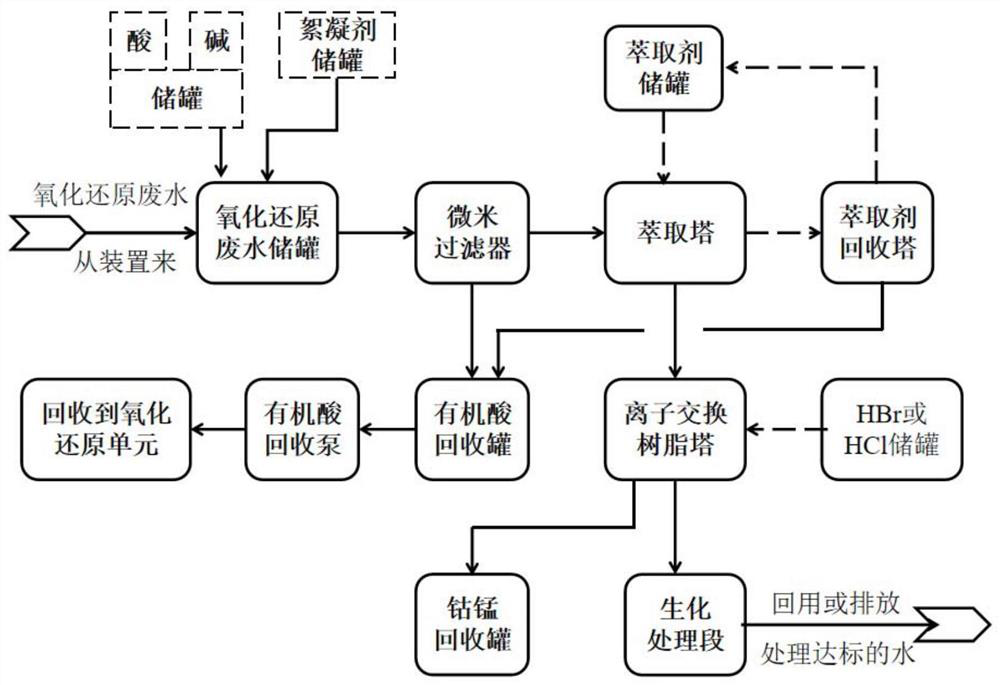

Method for recycling purified terephthalic acid wastewater

PendingCN113105056AReduce processing loadThe logic of the operation process is clearWater treatment parameter controlWater contaminantsIon exchangeCarboxylic acid

The invention discloses a method for recycling purified terephthalic acid wastewater. The method comprises the following steps: providing purified terephthalic acid wastewater, adjusting the temperature of the purified terephthalic acid wastewater to 30-45 DEG C, adjusting the pH value of the purified terephthalic acid wastewater to 2.5-4.5, and filtering the purified terephthalic acid wastewater to obtain a filtrate and a first solid which contains aromatic carboxylic acid; feeding the filtrate into an extraction system for extraction treatment to obtain an extraction phase and a raffinate phase; feeding the extraction phase into a rectifying tower, performing regeneration treatment to obtain a second solid matter containing aromatic carboxylic acid, feeding the raffinate phase into an ion exchange system, and performing ion exchange treatment; and carrying out desorption treatment on ion exchange resin in the ion exchange system to obtain cobalt and manganese ions. According to the method provided by the invention, recovery treatment of organic carboxylic acid and metal ions in the PTA wastewater is comprehensively considered, and the treatment load of a downstream section is remarkably reduced while effective recycling of resources is realized.

Owner:新疆中泰创新技术研究院有限责任公司

Method for inhibiting extractant degradation of DSX process through manganese extraction control

ActiveUS11203531B2Minimizing extractionPrevent degradationZinc compounds preparationProcess efficiency improvementManganeseSolvent

Provided is a method for inhibiting extractant degradation in the DSX process through the manganese extraction control, the method comprising: (a) stirring DSX solvent and DSX feed solution, which is a solution containing a valuable metal from which iron has been removed in an agitator, in which soda ash (Na2CO3) is further added to maintain a constant pH; and (b) scrubbing the manganese from the DSX solvent, extracted in step (a).

Owner:KOREA MINE REHABILITATION & MINERAL RESOURCES CORP

Resourceful treatment method of phosphating waste liquid

InactiveCN111392703AAchieve regenerationRealize resource utilizationZinc sulatesZinc compounds preparationO-Phosphoric AcidDistillation

The invention discloses a resourceful treatment method of phosphating waste liquid. The method is as follows: adding phosphoric acid into the phosphating waste liquid, filtering after reaction, addinghydrogen peroxide into filtrate, and continuously reacting; putting the reacted solution into a reaction kettle for reduced pressure distillation, and stirring for reaction to obtain slurry; filtering the slurry to obtain a first filtrate and a first filter residue, adding sodium hydroxide into the first filtrate, reacting, precipitating and filtering to obtain a second filtrate and a second filter residue, adding sulfuric acid into the second filter residue, dissolving to obtain a dissolved solution, adding ammonia water into the dissolved solution to adjust the pH value of the solution, stirring, reacting, and filtering to obtain a third filtrate and a third filter residue; adding pure water into the first filter residue for slurrying and washing, and drying, sintering, smashing, screening and deironing the washed filter residue to obtain battery-grade iron phosphate; and returning the second filtrate to prepare a phosphating solution. Resource utilization of nitrate radicals, zinc,iron and the like can be achieved, meanwhile, the wastewater can be returned to be used for preparing the phosphating solution, the treatment cost is low, and the environmental protection property isgood.

Owner:蒋央芳

Method of inhibiting extractant degradation by controlling extractive capacity and preventing direct degradation

ActiveUS20210024369A1Inhibits extractant degradationImprove extraction efficiencyZinc compounds preparationProcess efficiency improvementSulfate zincSolvent

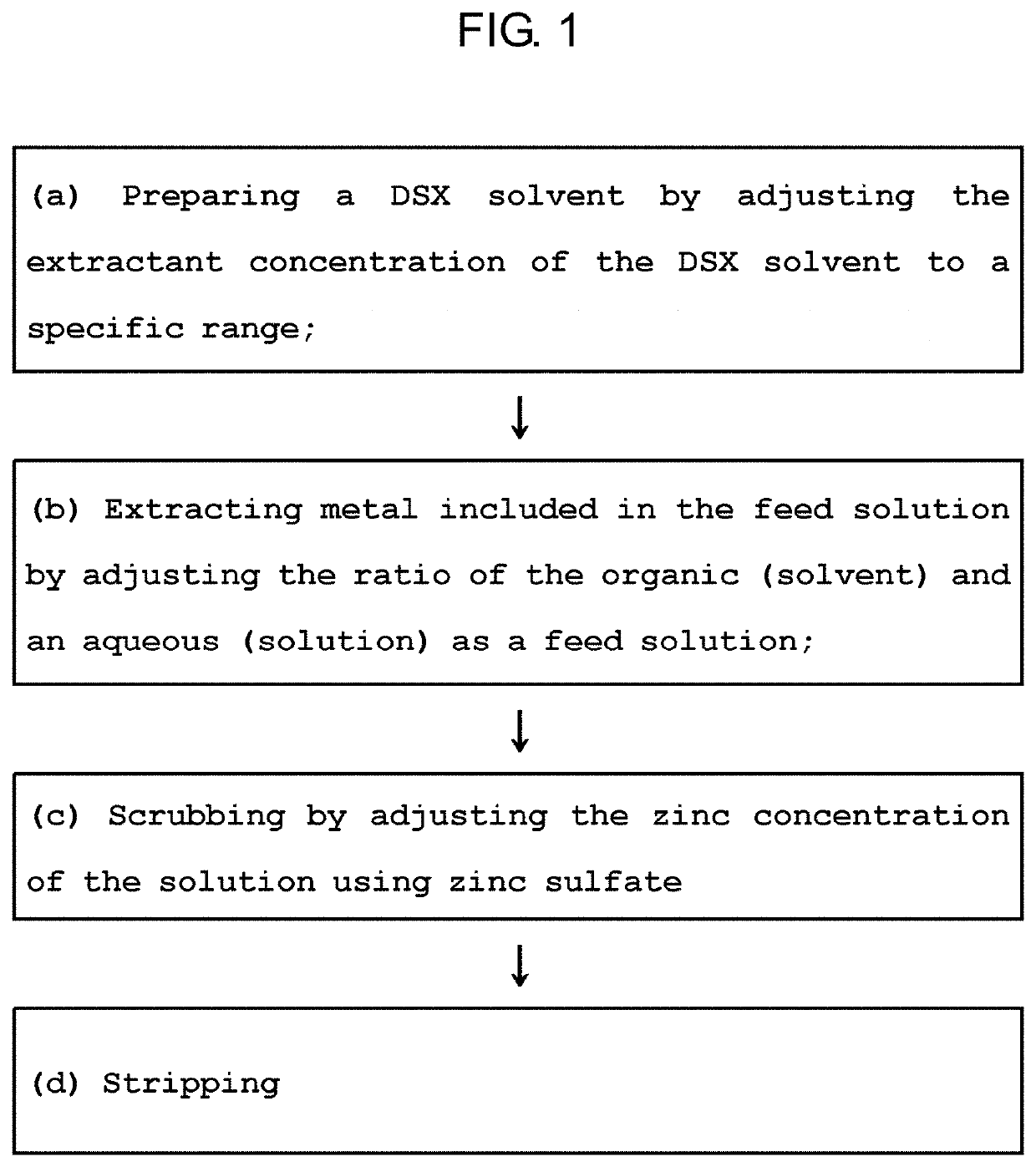

Provided is a method for inhibiting extractant degradation comprising preparing step, extracting step and scrubbing step, the method including: (a) the preparing step of a DSX solvent by adjusting the extractant concentration of the DSX solvent to a specific range; (b) the extracting step of metal included in the feed solution by adjusting the ratio of the organic (solvent) and an aqueous (solution) as a feed solution; (c) the scrubbing step of adjusting the zinc concentration of the solution using zinc sulfate; and (d) stripping step.

Owner:KOREA MINE REHABILITATION & MINERAL RESOURCES CORP

Decontamination of radioactive metals

The present invention relates to a method for the volumetric decontamination of radioactive metals. The method includes the step of precipitating out radioactive gamma and beta emitting nucleotides and then recovering non-radioactive metal compounds.

Owner:RETRIEV TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com