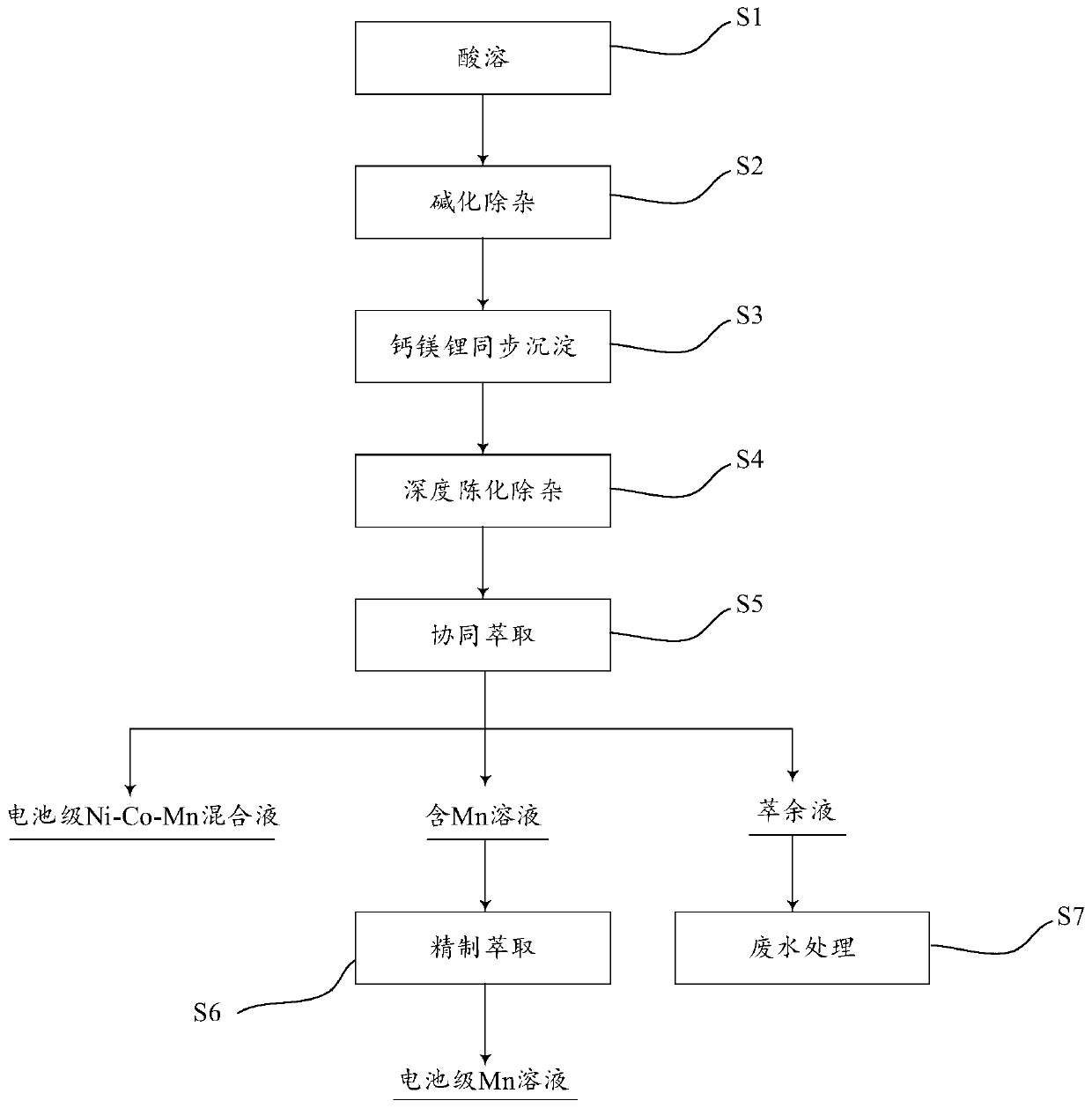

Preparation method of battery-grade Ni-Co-Mn mixed solution and battery-grade Mn solution

A ni-co-mn, battery-level technology, applied in the field of lithium-ion batteries, can solve the problems of low recovery rate and unsatisfactory impurity removal effect, and achieve the effect of improving recovery rate, reducing impurity content, and improving large-scale application of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 100g of mixed positive and negative electrode powder of lithium ion battery, add 100ml of sulfuric acid, 60g of 30% hydrogen peroxide for acid leaching, filter to remove insoluble residue to obtain leaching solution, and the leaching rates of cobalt, nickel and manganese are: 91.64%, 91.65%, and 90.67%, respectively. The leaching solution was adjusted to pH 5.0 with 10% liquid caustic soda while being fed with air, and filtered to remove iron and aluminum after reacting for 2 hours to obtain an alkalized mixed solution. Add 1.5 times the theoretical amount of sodium fluoride to the alkalized mixed solution, stir and react at 60°C for 2 hours, then filter to remove lithium, calcium and magnesium, and obtain a synchronous precipitation filtrate; age the obtained synchronous precipitation filtrate at room temperature for 4 hours to remove calcium, magnesium, lithium, Filter to obtain the aged filtrate containing 55g / L of cobalt, nickel and manganese, wherein Fe: 0.000...

Embodiment 2

[0030] Weigh 100g of the positive and negative electrode mixed powder of the lithium-ion battery, add 123ml of sulfuric acid, 135g of 30% hydrogen peroxide for acid leaching, and filter to remove the insoluble residue to obtain the leaching solution. The leaching rates of cobalt, nickel and manganese are: 99.64%, 99.65%, and 98.67%, respectively. Filter to remove insoluble residue, add 1.05 times the theoretical molar amount of hydrogen peroxide to the leaching solution, and add 10% liquid caustic soda to adjust the pH to 4.5, react for 2 hours and filter to remove iron and aluminum to obtain an alkalized mixed solution. Add 1.2 times the theoretical amount of sodium fluoride to the alkalized mixture, stir and react at 60°C for 2 hours, then filter to remove lithium, calcium and magnesium to obtain a synchronous precipitation filtrate; age the obtained synchronous precipitation filtrate at room temperature for 4 hours to remove calcium and magnesium Lithium, filtered to obtain ...

Embodiment 3

[0032] Using the aging filtrate prepared in Example 1, the aging filtrate and the P204 organic solvent with a saponification rate of 45% were subjected to 7-stage countercurrent extraction at a ratio of 1:3, and all the nickel, cobalt, and manganese in the solution were extracted, and the obtained The organic phase loaded with nickel, cobalt and manganese was washed with 0.8mol / L dilute acid at a ratio of 3:1 for 8 stages of countercurrent washing. After washing, the organic phase and 4mol / L sulfuric acid are subjected to 8-stage countercurrent back-extraction at a ratio of 8:1, and the back-extraction solution can obtain a battery-grade nickel-cobalt-manganese solution, wherein the total content of nickel-cobalt-manganese is >100g / L. A manganese-containing solution outlet is set up in the middle of the stripping section, and the manganese-containing solution is refined and removed with P204 extractant to obtain a battery-grade manganese sulfate solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com