Method for preparing industrial-grade manganese carbonate by utilizing copper chloride manganese liquid

A technology of manganese carbonate and copper chloride, which is applied in the preparation of manganese compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as waste of resources, and achieve the effects of reducing processing costs, low production costs, and short processing procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

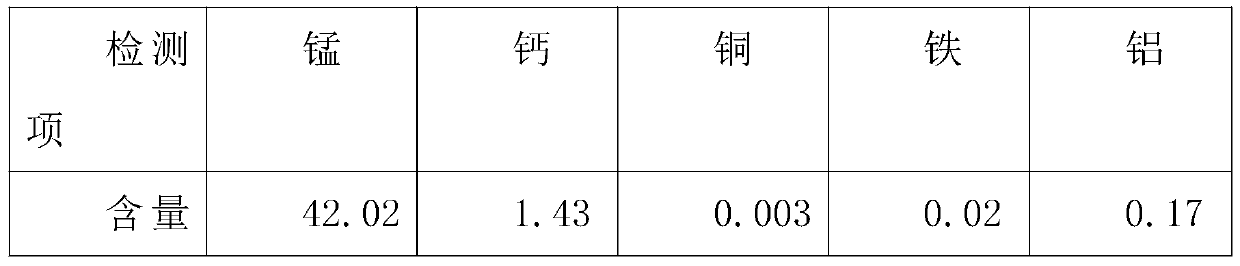

Examples

Embodiment 1

[0029] A kind of method utilizing copper manganese chloride liquid to prepare technical grade manganese carbonate, is characterized in that: comprise the steps:

[0030] S1 copper replacement: add iron powder to the copper-manganese solution, after the reaction is complete, filter out the copper slag to obtain a copper-removed solution. After copper removal, the solution only contains 0.04g / L of copper, and the copper recovery rate reaches 99.2%.

[0031] S11: get 500ml copper manganese liquid in 2L beaker, its composition is to contain copper 4.8g / L, manganese 82.3g / L, calcium 19.6g / L, aluminum 7.1g / L for subsequent use;

[0032] S12: Heating the reserved copper-manganese liquid in a water bath at 60°C, adding 3.0 g of iron powder, stirring and reacting for 1 hour, filtering to remove copper slag, and obtaining a copper-removed liquid;

[0033] S2 calcium iron and aluminum removal: add P507 raffinate to the liquid after copper removal. After the reaction is complete, add hyd...

Embodiment 2

[0042] A kind of method utilizing copper manganese chloride liquid to prepare technical grade manganese carbonate, is characterized in that: comprise the steps:

[0043] S1 copper replacement: add iron powder to the copper-manganese solution, after the reaction is complete, filter out the copper slag to obtain a copper-removed solution. After copper removal, the solution only contains 0.04g / L of copper, and the copper recovery rate reaches 99.2%.

[0044] S11: get 1L copper manganese liquid in 4L beaker, its composition is to contain copper 4.8g / L, manganese 82.3g / L, calcium 19.6g / L, aluminum 7.1g / L for subsequent use;

[0045] S12: Heating the spare copper-manganese solution in a water bath at 60°C, adding 6.0g of iron powder, stirring and reacting for 1 hour, filtering to remove copper slag, and obtaining a copper-removed solution;

[0046] S2 calcium iron and aluminum removal: add P507 raffinate to the liquid after copper removal. After the reaction is complete, add hydrog...

Embodiment 3

[0055] A kind of method utilizing copper manganese chloride liquid to prepare technical grade manganese carbonate, is characterized in that: comprise the steps:

[0056] S1 copper replacement: add iron powder to the copper-manganese solution, after the reaction is complete, filter out the copper slag to obtain a copper-removed solution. After copper removal, the solution only contains 0.04g / L of copper, and the copper recovery rate reaches 99.2%.

[0057] S11: get 2L copper manganese liquid in 8L beaker, its composition is to contain copper 4.8g / L, manganese 82.3g / L, calcium 19.6g / L, aluminum 7.1g / L for subsequent use;

[0058] S12: Heat the spare copper-manganese solution in a water bath at 60°C, add 12.0g of iron powder, stir and react for 1 hour, filter to remove copper slag, and obtain a copper-removed solution;

[0059] S2 calcium iron and aluminum removal: add P507 raffinate to the liquid after copper removal. After the reaction is complete, add hydrogen peroxide. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com