Method for preparing battery-grade manganese sulfate from manganese oxide ore

A manganese oxide ore, battery-level technology, applied in the field of hydrometallurgy, can solve the problems affecting the recovery efficiency of manganese sulfate, complex process, high difficulty, etc., and achieve the effects of improving impurity removal effect, improving recovery rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0141] Example 1, Preparation of Battery Grade Manganese Sulfate Using Corn Cob as Biomass Reductant Pyrolulurite Leaching Solution

[0142] The pyrolusite treated in this embodiment has the characteristics of high Ca and Mg contents, the Ca content is 8.51%, and the Mg content is 6.77%.

[0143] Step 1: Reductive acid leaching in a sulfuric acid solution with corncobs as a reducing agent, and obtaining the reduced leaching residue and acid leaching solution after filtration.

[0144] ① Add 400 mesh (about 38um) corncobs and pyrolusite with a particle size of less than 150um and 22% Mn grade into a 3mol / L sulfuric acid solution. The mass ratio of pyrolusite to corncobs is 1:1, and the liquid-solid ratio of the solution is Immediately, the solution was heated to 90°C and reacted for 4 hours. In order to maintain the volume of the solution, water was replenished once after 1 hour of reaction;

[0145] ②Place the heat treatment of the leaching slag in a high-temperature furnace ...

Embodiment 2

[0159] Compared with embodiment 1, the processing technology of step one is adjusted, and the step one of difference is:

[0160] Reductive acid leaching in sulfuric acid solution with rice straw as a reducing agent, and after filtration, the reduction leaching residue and acid leaching solution are obtained.

[0161] ① Add 400 mesh (about 38um) straw and pyrolusite with a particle size of less than 150um and a Mn grade of 22% into a 3mol / L sulfuric acid solution. The mass ratio of pyrolusite to corn cob is 1:1, and the liquid-solid ratio of the solution is 5:1; Immediately, heat the solution to 90°C and react for 4 hours. In order to maintain the volume of the solution, add water once after 1 hour of reaction; after the reaction, filter to obtain the acid leaching solution and leaching residue;

[0162]② Place the heat treatment of the leaching slag in a high-temperature furnace isolated from air, raise the temperature to 1000°C at a heating rate of 15°C / min, and then keep it...

Embodiment 3

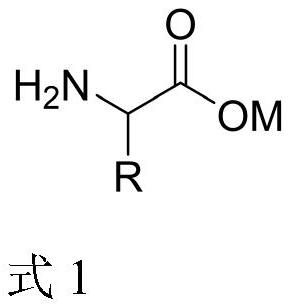

[0168] Compared with Example 1, the only difference is that the compound of formula 1 in the second step of step three is regulated, and the second step of step three is:

[0169] Step 2, according to the liquid-solid ratio of 3:1, deionized water and the above-mentioned manganese hydroxide precipitation beating, add formula 1-B (15 times the total amount of calcium and magnesium) to the slurry, and then add to the slurry Feed carbon dioxide until the pH value of the slurry reaches 7, then stop the carbon dioxide feed, and filter immediately, thereby realizing the removal of calcium and magnesium in manganese hydroxide.

[0170] Other operations and parameters are the same as in Example 1.

[0171] The composition of the prepared battery-grade manganese sulfate solution is shown in Table 3.

[0172] Impurity requirements and the impurity content (ppm) of the present embodiment product in table 3 battery grade manganese sulfate

[0173] element ΣFe K Na Ca ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com