Method for preparing electrode material by electrochemical ion exchange method and electrode material

An ion exchange method and a technology for preparing electrodes, which are applied in the field of methods and electrode materials, electrode materials prepared by electrochemical ion exchange method, can solve complex synthesis and other problems, and achieve the effects of simple operation, low temperature and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In order to solve the problems of the technologies described above, the present invention is realized as follows: prepare NiMn by electrochemical ion exchange method 2 o 4 Material. Prepare a square nickel foam (1×1cm) and ultrasonically clean it with absolute ethanol for 15 minutes, dry it at a constant temperature at 60°C for 15 minutes, weigh and record its mass, the mass of square nickel foam is 30mg, and weigh 0.02mol MnCl 2 4H 2 O is dissolved in 20ml deionized water and puts into 3 dry nickel foams, wherein the quality of foam nickel is the same as that of MnCl 2 The volume of the solution has no specific ratio, as long as there are enough reactants to grow on the nickel foam, the nickel foam is only a growth medium and does not affect the reaction, stir for 30 minutes, take another beaker and weigh 0.02mol NaOH, dissolve it in 20ml of deionized water, and stir for 15 minutes , slowly drop the stirred NaOH solution into the stirred MnCl with a dropper 2 solut...

Embodiment 2

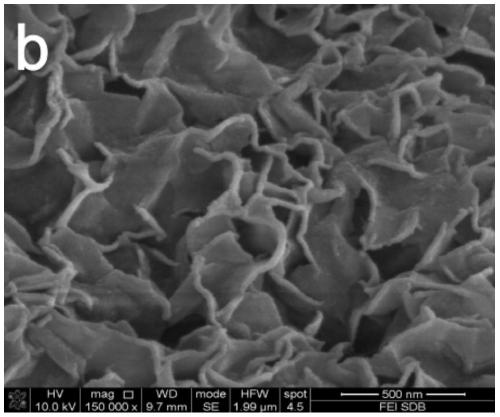

[0038] In order to solve the problems of the technologies described above, the present invention is realized in the following manner, as shown in the figure: NiMn is prepared by electrochemical ion exchange 2 o 4 / Mn 3 o 4 Multi-component composite metal oxide. Prepare a square nickel foam (1×1cm) and ultrasonically clean it with absolute ethanol for 15 minutes, dry it at a constant temperature of 60°C for 15 minutes, weigh and record its mass, and weigh 0.02mol MnCl 2 4H 2 O was dissolved in 20ml of deionized water and put into 3 pieces of dry nickel foam, stirred for 30min, and another beaker was taken to weigh 0.02mol NaOH, dissolved in 20ml of deionized water, stirred for 15min, and the stirred NaOH solution was slowly dripped with a dropper MnCl added to stirring 2 solution, continue to stir for 10 minutes, transfer the obtained suspension to a 50ml polytetrafluoroethylene-lined reaction kettle, put it in an electric heating constant temperature drying oven at 150 ° ...

Embodiment 3

[0040] In order to solve the problems of the technologies described above, the present invention is realized in the following manner,

[0041] Preparation of NiMn by Electrochemical Ion Exchange Method 2 o 4 / Mn 3 o 4 Multi-component composite metal oxide. Prepare a square nickel foam (1×1cm) and ultrasonically clean it with absolute ethanol for 15 minutes, dry it at a constant temperature of 60°C for 15 minutes, weigh and record its mass, and weigh 0.02mol MnCl 2 4H 2 O was dissolved in 20ml of deionized water and put into 3 pieces of dry nickel foam, stirred for 30min, and another beaker was taken to weigh 0.02mol NaOH, dissolved in 20ml of deionized water, stirred for 15min, and the stirred NaOH solution was slowly dripped with a dropper MnCl added to stirring 2 solution, continue to stir for 10 minutes, transfer the obtained suspension to a 50ml polytetrafluoroethylene-lined reaction kettle, put it in an electric heating constant temperature drying oven at 150 ° C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com