Method for recycling purified terephthalic acid wastewater

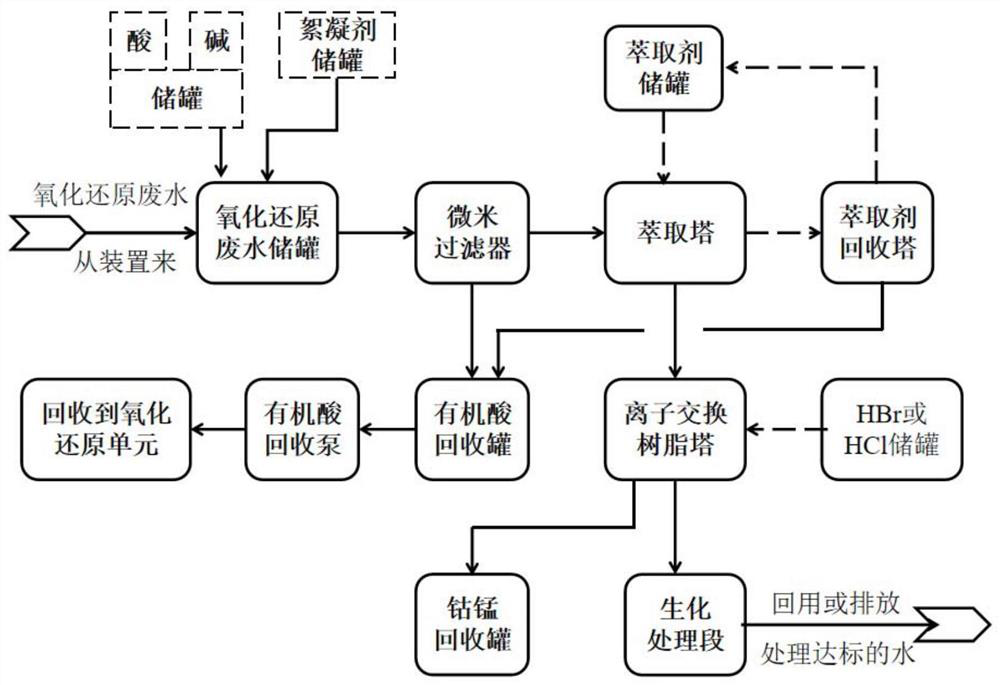

A technology for purifying terephthalic acid and terephthalic acid, which is applied in the field of wastewater treatment and reuse, can solve the problems of not considering precious metal catalyst ions, not considering the reuse of metal ions, and the process is difficult to operate stably, so as to reduce the load and extractant dosage, convenient operation and management, and large operation flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The production capacity of a PTA plant is 120wt / a, and the oxidation residue wastewater comes from the redox section of the PTA production process; the reaction conditions are: 1.15MPaG; 189°C. Wastewater volume: 10m 3 / h; the method for resource utilization of the oxidation residue wastewater comprises the following steps:

[0055] 1) First, send the oxidation residue wastewater from the PTA unit to the wastewater storage tank, and lower the temperature of the wastewater to 30-45°C, and use dilute sulfuric acid to adjust the pH value of the wastewater to 2.5-4.5. Under this condition, the waste water Aromatic carboxylic acids such as terephthalic acid will be precipitated;

[0056] 2) Add polyacrylamide to the waste water, mix it uniformly and let it stand for 1.0 h to gather the precipitated aromatic carboxylic acid, wherein the amount of polyacrylamide added is 0..05wt% of the waste water mass;

[0057] 3) Pump the settled waste water into the micron filter (the mi...

Embodiment 2

[0067] The production capacity of a PTA plant is 120wt / a, and the oxidation residue wastewater comes from: the redox section of the PTA production process; the reaction conditions are: 1.15MPaG, 187°C, and the wastewater volume is: 9.5m 3 / h; the method for resource utilization of the oxidation residue wastewater comprises the following steps:

[0068] 1) First, the oxidation residue wastewater from the PTA unit is sent to the wastewater storage tank, and the temperature of the wastewater is lowered to 35°C, and the pH value of the wastewater is adjusted to 3.0 with dilute sulfuric acid. Under this condition, the p-benzene in the wastewater Precipitation of aromatic carboxylic acids such as dicarboxylic acid;

[0069] 2) Add polyacrylamide to the waste water, mix it uniformly and let stand for 1.5h to flocculate the precipitated aromatic carboxylic acid, wherein the amount of polyacrylamide added is 0.1wt% of the waste water mass;

[0070] 3) Pump the settled waste water into...

Embodiment 3

[0080] The production capacity of a PTA plant is 120wt / a, and the oxidation residue wastewater comes from: the redox section of the PTA production process; the reaction conditions are: 1.15MPaG, 187°C, and the wastewater volume is: 11m 3 / h, the method for resource utilization of the oxidation residue wastewater comprises the following steps:

[0081] 1) Firstly, the oxidation residue wastewater from the PTA unit is sent to the wastewater storage tank, and the temperature of the wastewater is lowered to 30°C, and the pH value of the wastewater is adjusted to 2.5 with dilute sulfuric acid. Under this condition, the terephthalate in the wastewater Precipitation of aromatic carboxylic acids such as formic acid;

[0082] 2) Add a polyacrylamide flocculant to the wastewater, mix it uniformly and let it stand for 2.0 hours to flocculate the precipitated aromatic carboxylic acid, wherein the amount of the polyacrylamide added is 0.2wt% of the wastewater mass

[0083] 3) Pump the set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com