Resourceful treatment method of phosphating waste liquid

A processing method and resource-recycling technology, applied in chemical instruments and methods, preparation of phosphorus compounds and zinc compounds, etc., can solve the problems of not realizing phosphorus and iron resource processing, high cost, and not considering resource utilization, etc. The effect of high product added value, high added value and less waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

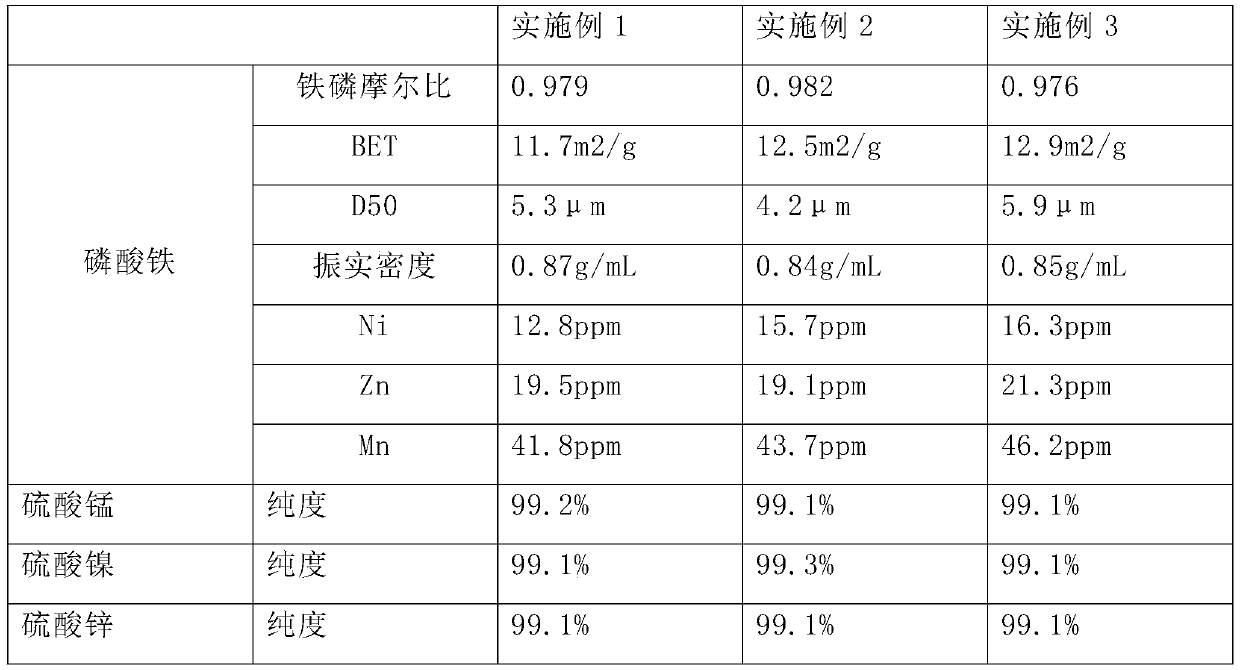

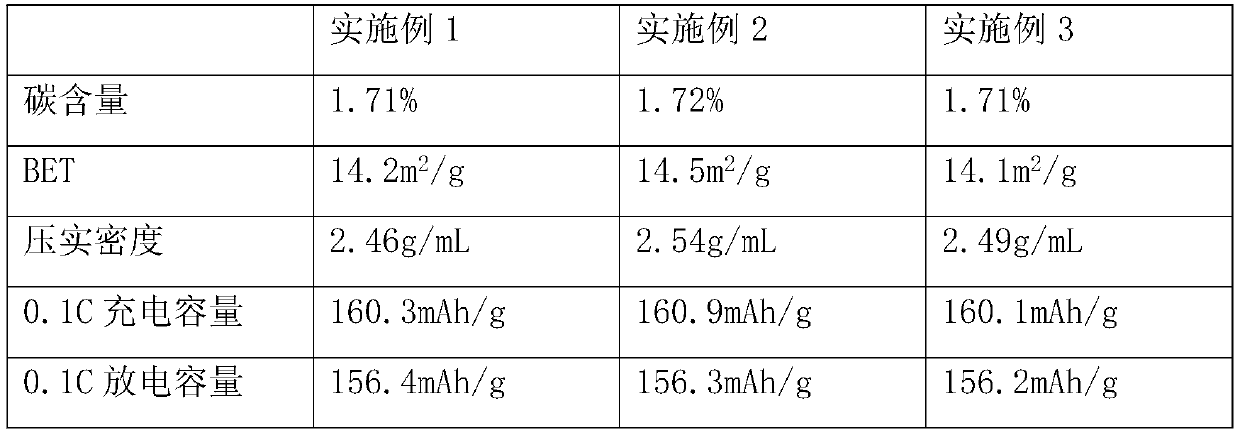

Embodiment 1

[0038] A kind of resource processing method of phosphating waste liquid, it is the following steps:

[0039] 1) Add phosphoric acid to the phosphating waste liquid, adjust the pH of the solution to 0.8, heat up to 70°C, stir and react for 20 minutes, then add ferric nitrate to maintain the molar ratio of iron and phosphorus in the solution at 1.18, and then filter to obtain Add hydrogen peroxide to the filtrate, oxidize to stop reaction after the nitrite content in the solution is lower than 20ppm;

[0040] 2) put the solution after the reaction of step (1) into the reactor and carry out vacuum distillation. During the vacuum distillation, the temperature is 65° C. and the pressure is 10KPa. Stop the distillation after the pH of the solution is 2.1, then stir and react at a temperature of 60° C. for 50 minutes to obtain a slurry;

[0041] 3) Filter the slurry to obtain the first filtrate and the first filter residue, add sodium hydroxide to the first filtrate, adjust the pH o...

Embodiment 2

[0052] A kind of resource processing method of phosphating waste liquid, it is the following steps:

[0053] 1) Add phosphoric acid to the phosphating waste liquid, adjust the pH of the solution to 0.6, heat up to 80°C, stir and react for 25 minutes, then add ferric nitrate to maintain the molar ratio of iron and phosphorus in the solution to 1.18, and then filter to obtain Add hydrogen peroxide to the filtrate, oxidize to stop reaction after the nitrite content in the solution is lower than 20ppm;

[0054] 2) put the solution after the step (1) reaction into the reaction kettle and carry out vacuum distillation. During the vacuum distillation, the temperature is 60° C., and the pressure is 12KPa. The gas distilled out is absorbed by water spraying to obtain nitric acid solution, which is distilled to Stop the distillation after the pH of the solution is 2.1, then stir and react at a temperature of 60° C. for 50 minutes to obtain a slurry;

[0055] 3) Filter the slurry to obt...

Embodiment 3

[0066] A kind of resource processing method of phosphating waste liquid, it is the following steps:

[0067] 1) Add phosphoric acid to the phosphating waste liquid, adjust the pH of the solution to 0.95, heat up to 75°C, stir and react for 20 minutes, then add ferric nitrate to maintain the molar ratio of iron and phosphorus in the solution at 1.2, and then filter to obtain Add hydrogen peroxide to the filtrate, oxidize to stop reaction after the nitrite content in the solution is lower than 20ppm;

[0068] 2) put the solution after the reaction of step (1) into the reactor and carry out vacuum distillation. During the vacuum distillation, the temperature is 65° C. and the pressure is 10KPa. Stop the distillation after the pH of the solution is 2.1, then stir and react at a temperature of 60° C. for 50 minutes to obtain a slurry;

[0069] 3) Filter the slurry to obtain the first filtrate and the first filter residue, add sodium hydroxide to the first filtrate, adjust the pH o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com