Method for recovering soluble manganese and ammonium from electrolytic manganese slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

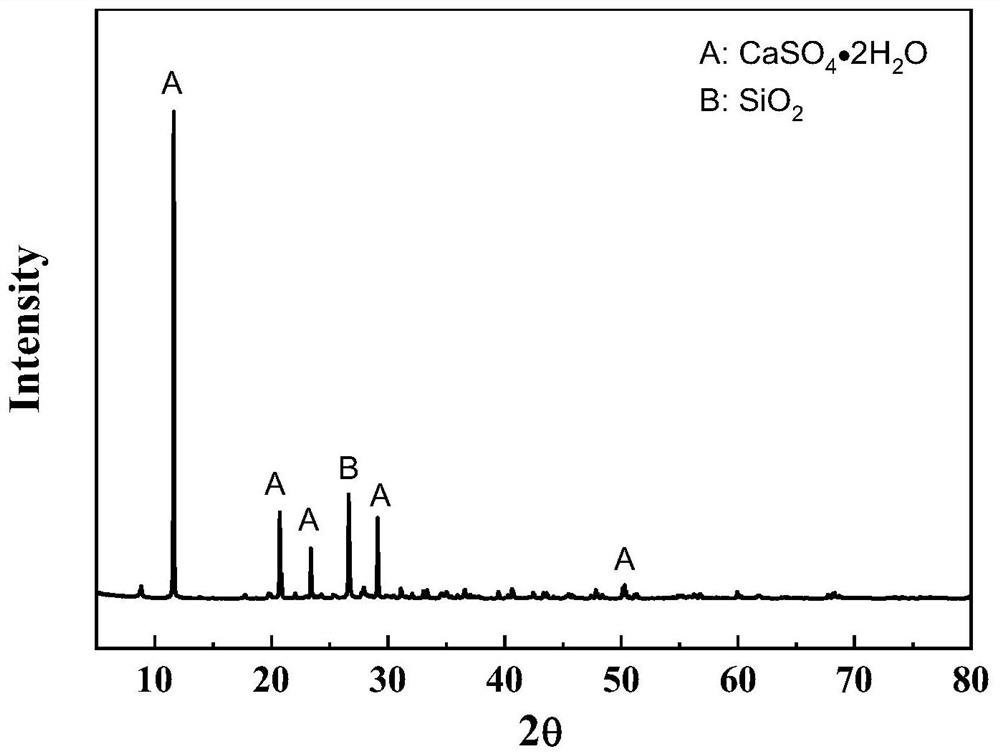

Image

Examples

Embodiment 1

[0030] The method for economically and efficiently recovering soluble ammonium manganese in electrolytic manganese slag of the present invention is applied to the manganese smelting slag of Zhenxing Chemical Plant in Huayuan County, Hunan Province. The composition analysis of the manganese smelting slag is shown in Table 1. Manganese smelting slag was treated with a three-stage countercurrent washing process with a solid-to-liquid mass ratio of 1:1.5 and a single-tank washing time of 30 minutes. The results of manganese and ammonium / nitrogen contents in washing water and slag are listed in Table 2. Washing slag is used as a common inorganic material for building materials. The washing water is firstly extracted and concentrated with manganese ions, and then the raffinate is purified with alkalization stripping method to recover ammonia resources. Among them, three-stage normal extraction and two-stage back-extraction processes are used in the extraction process. The oil-water r...

Embodiment 2

[0032] The method for economically and efficiently recovering soluble ammonium manganese in electrolytic manganese slag of the present invention is applied to the manganese smelting slag of Zhongfa Manganese Industry in Huayuan County, Hunan Province. The composition analysis of the manganese smelting slag is shown in Table 1. Manganese smelting slag was treated with a three-stage countercurrent washing process with a solid-to-liquid mass ratio of 1:1.5 and a single-tank washing time of 30 minutes. The results of manganese and ammonium / nitrogen contents in washing water and slag are listed in Table 2. Washing slag is used as a common inorganic material for building materials. The washing water is firstly extracted and concentrated with manganese ions, and then the raffinate is purified with alkalization stripping method to recover ammonia resources. Among them, three-stage normal extraction and two-stage back-extraction processes are used in the extraction process. The oil-wate...

Embodiment 3

[0034] The method for economically and efficiently recovering soluble manganese ammonium in electrolytic manganese slag of the present invention is applied to the manganese smelting slag of Jili Baikuang Manganese Industry in Jingxi County, Guangxi Province. The composition analysis of the manganese smelting slag is shown in Table 1. Manganese smelting slag was treated with a three-stage countercurrent washing process with a solid-to-liquid mass ratio of 1:1.5 and a single-tank washing time of 50 minutes. Washing slag is used as a common inorganic material for building materials. The washing water is firstly extracted and concentrated with manganese ions, and then the raffinate is purified with alkalization stripping method to recover ammonia resources. In the middle extraction process, three-stage normal extraction and two-stage back-extraction processes are adopted. The oil-water ratio of normal extraction is 1:3, and the oil-water ratio of back extraction is 5:1. The extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com