Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

153results about "Furnace monitoring devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

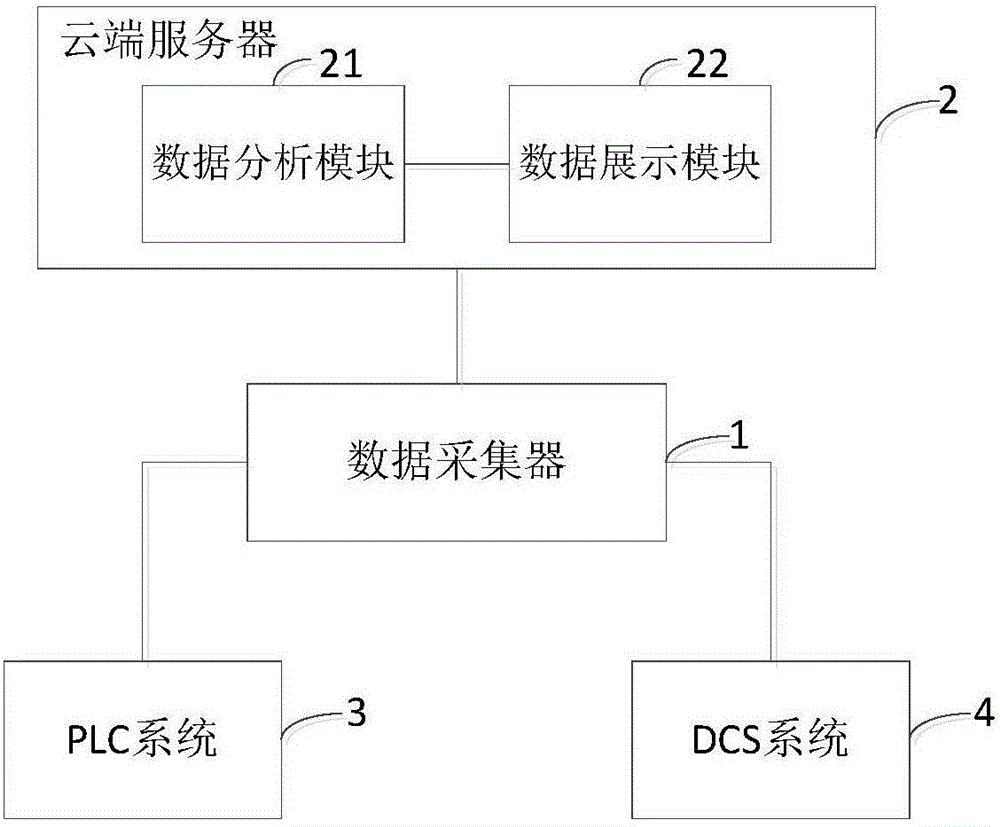

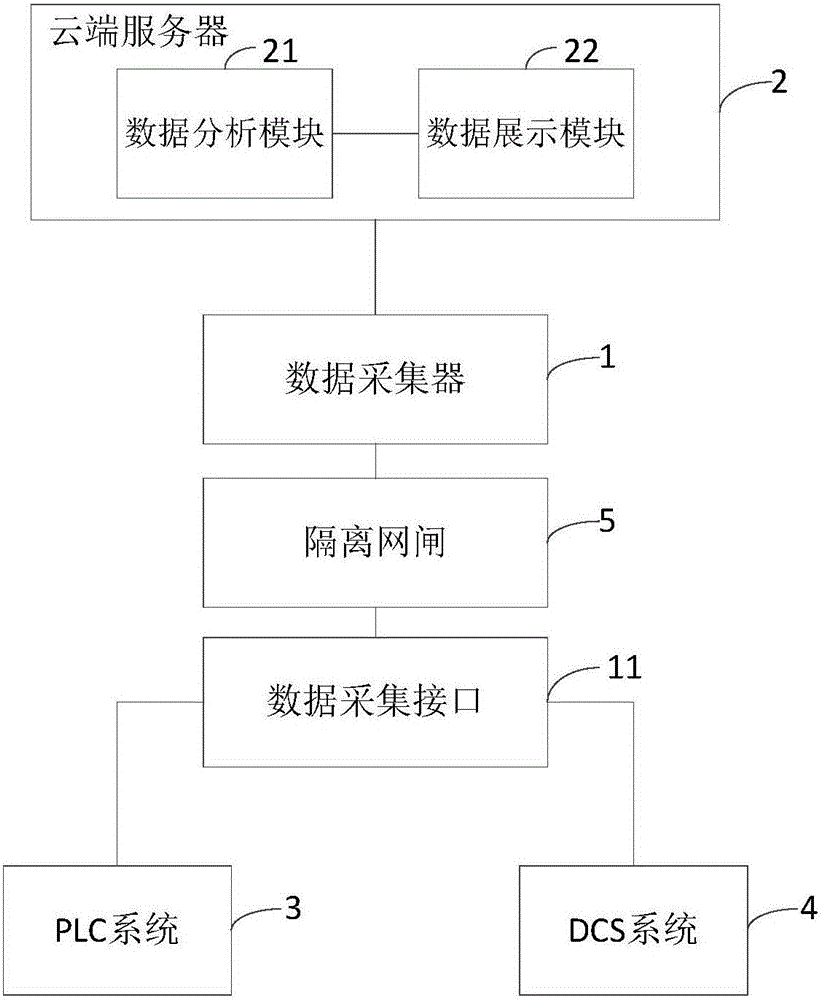

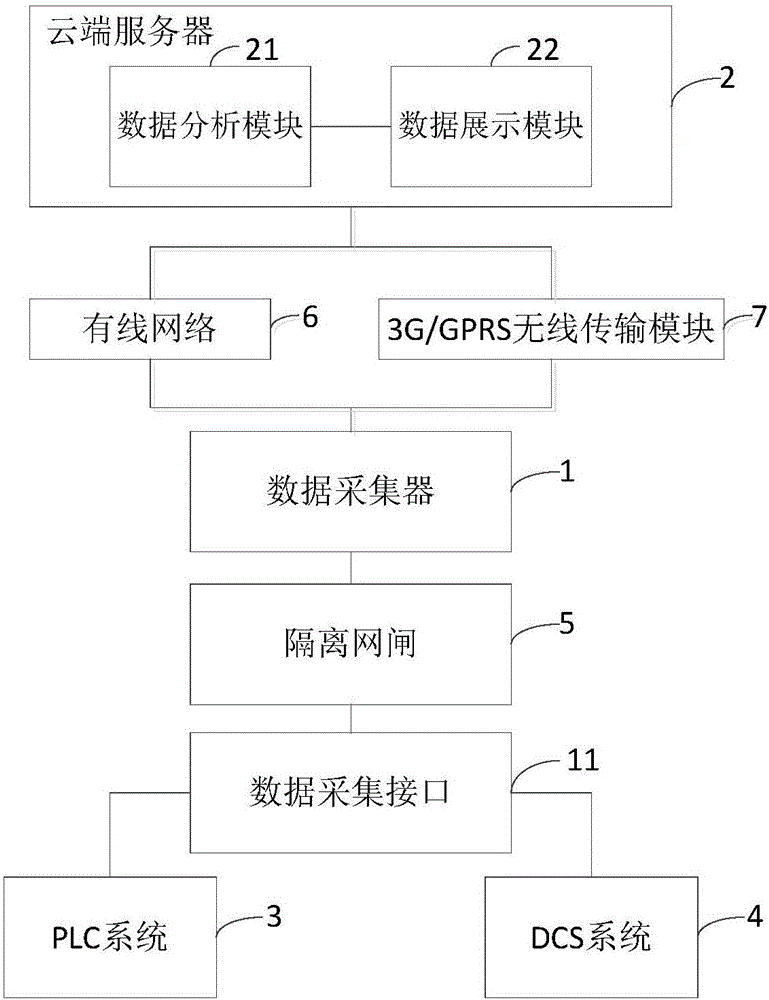

Industrial boiler monitoring and analysis assistant decision-making cloud platform system

PendingCN106302739AEasy to masterMaster quicklyTransmissionTotal factory controlData displayData acquisition

The invention provides an industrial boiler monitoring and analysis assistant decision-making cloud platform system, which comprises a data collector and a cloud-end server, wherein the data collector is used for collecting industrial boiler real-time monitoring data such as boiler operation parameters and environmental protection monitoring data in real time; the cloud-end server comprises a data analysis module and a data displaying module; the data analysis module is used for analyzing the real-time monitoring data to acquire analysis statistics data such as the operation data and the economic data of the industrial boiler, detecting an alarming event to acquire alarming information, detecting the operation condition of instrument equipment of the industrial boiler, providing maintenance information, judging a field fault reason and providing optimization recommendation; and the data displaying module is used for displaying the real-time monitoring data, the analysis statistics data, the alarming information, the maintenance information and the optimization recommendation. The invention can provide a regional industrial boiler remote monitoring and assistant decision-making platform integrating functions of online monitoring, automatic diagnosis, safety early warning, maintenance promoting, optimization recommendation and the like for various parameters for operation of the boiler as a whole.

Owner:BEIJING DABANG SHICHUANG ENERGY SAVING TECHSERVICE

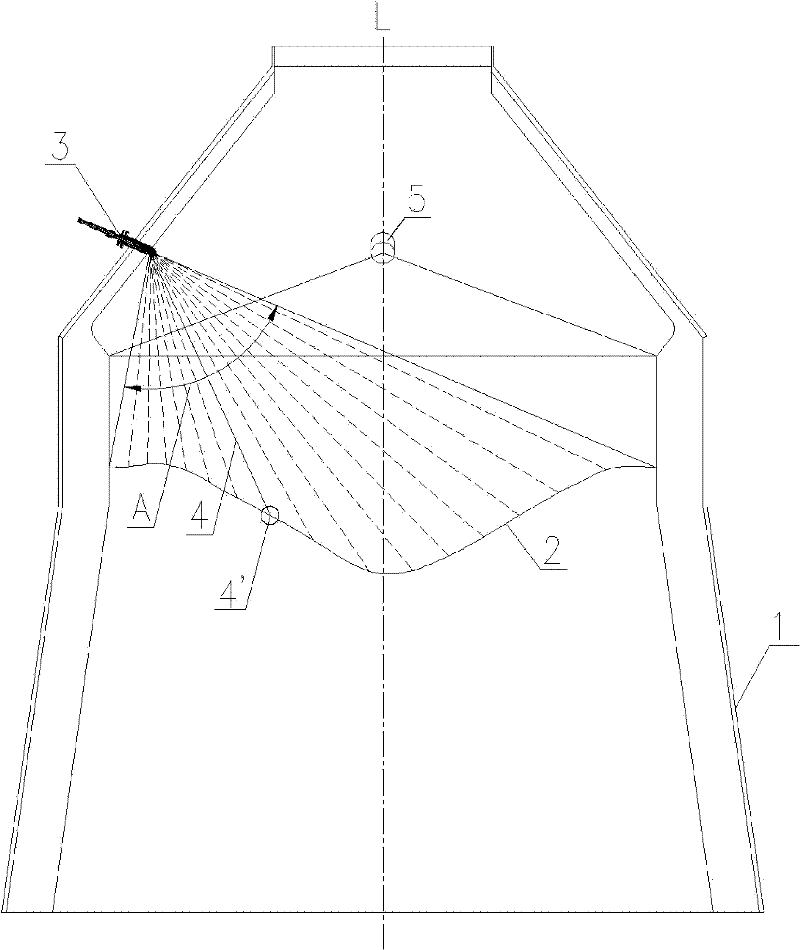

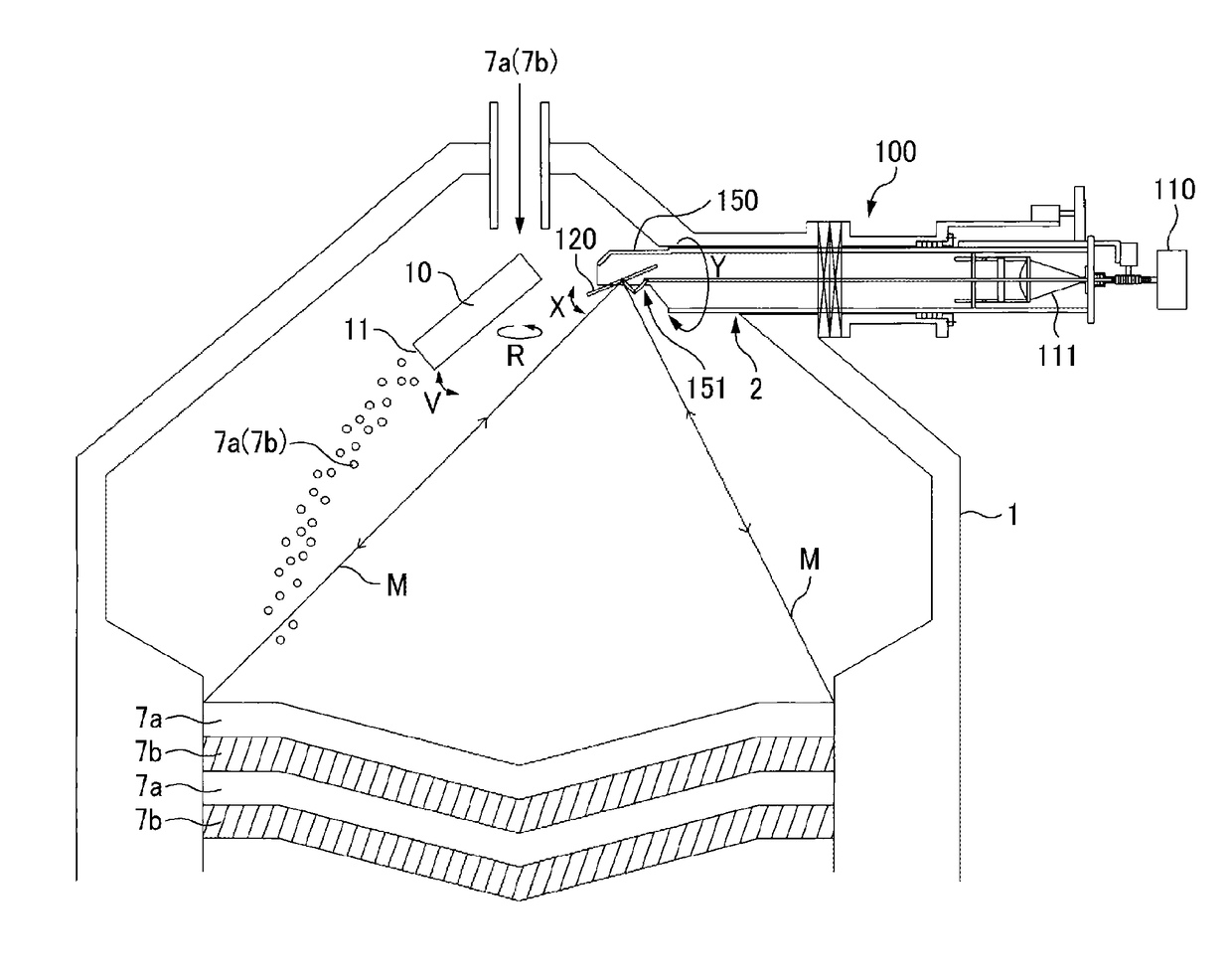

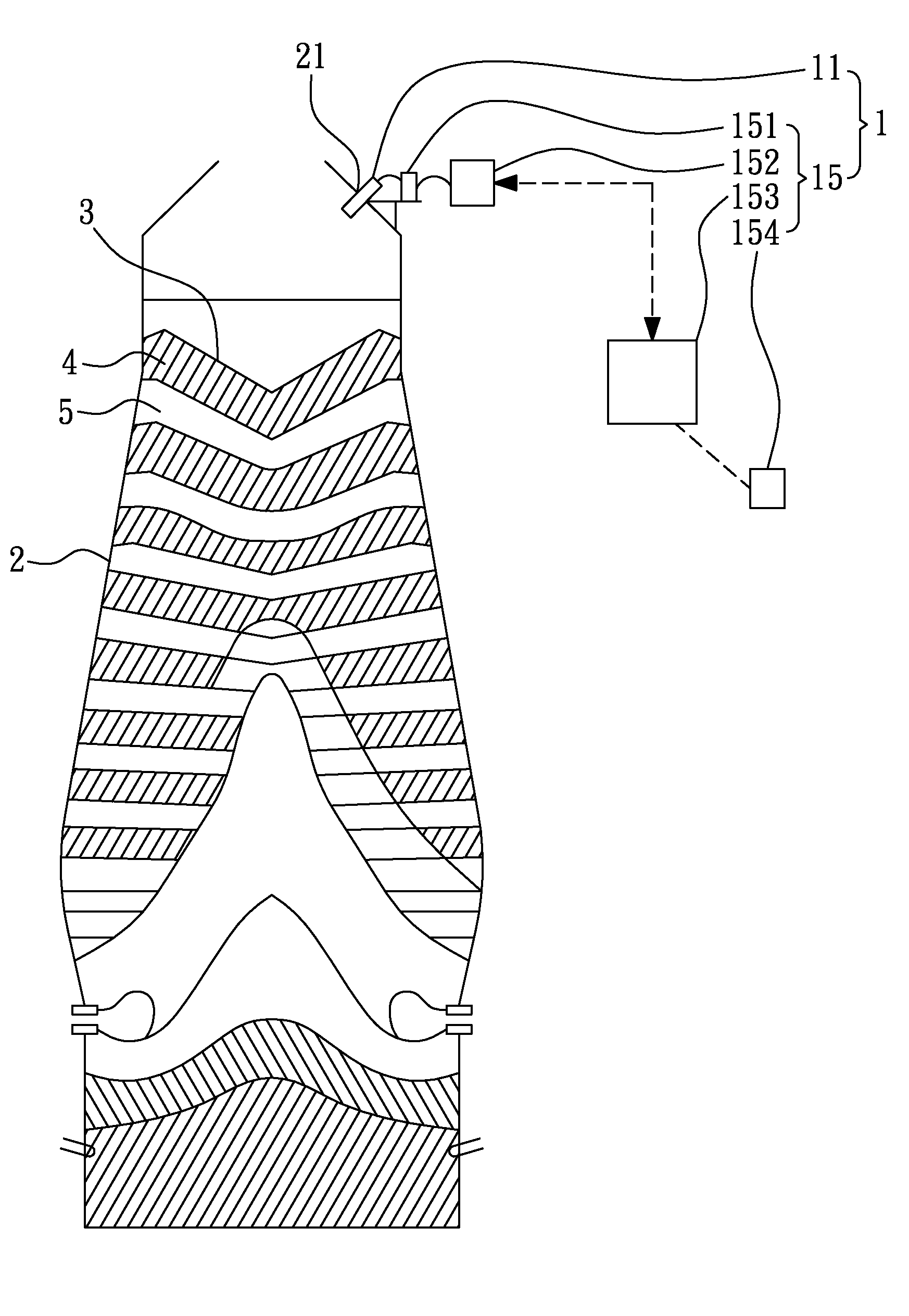

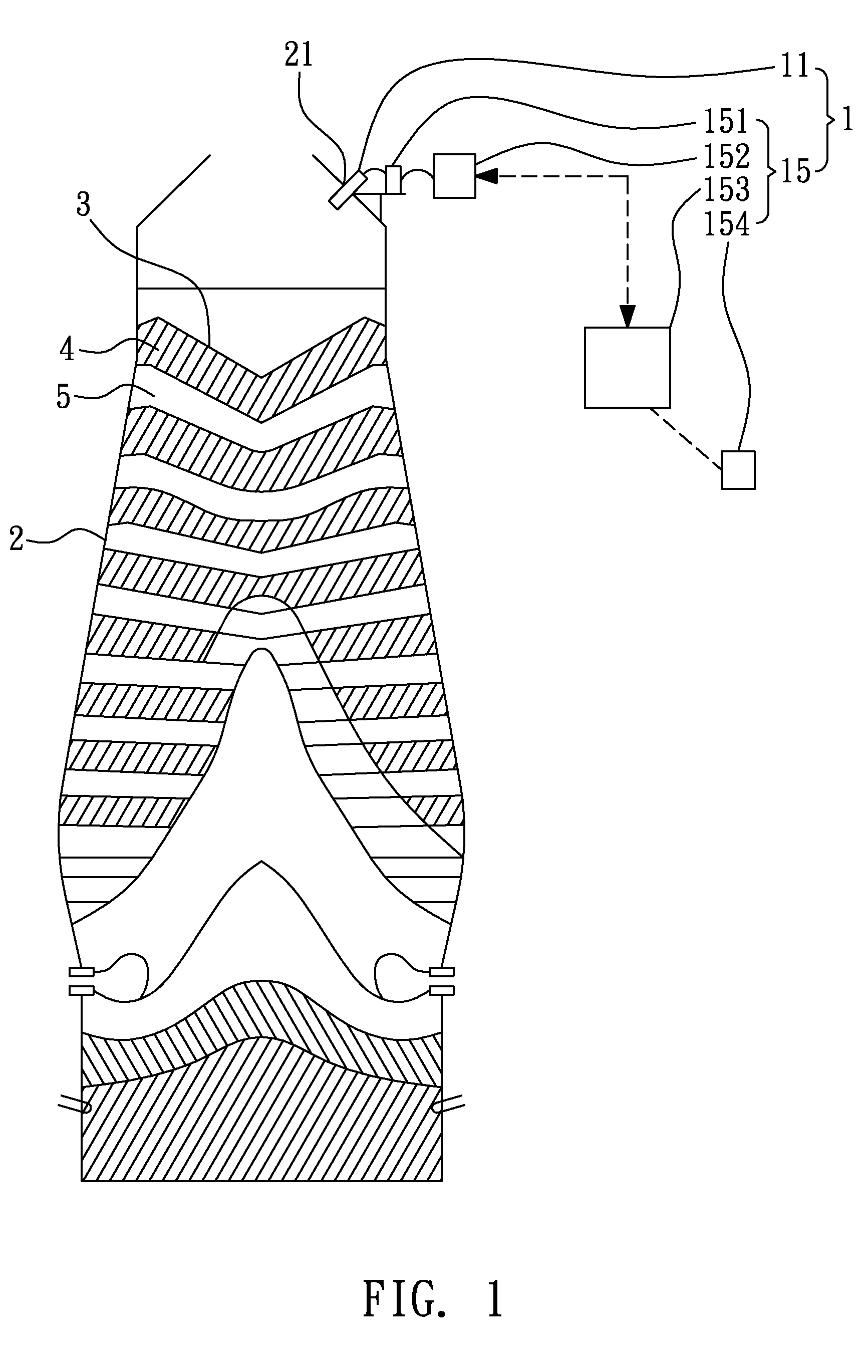

System and method for measuring blast furnace burden surface on line

InactiveCN102382918ALow costComply with material surface informationTelevision systemsVertical furnacesImaging processingMiniaturization

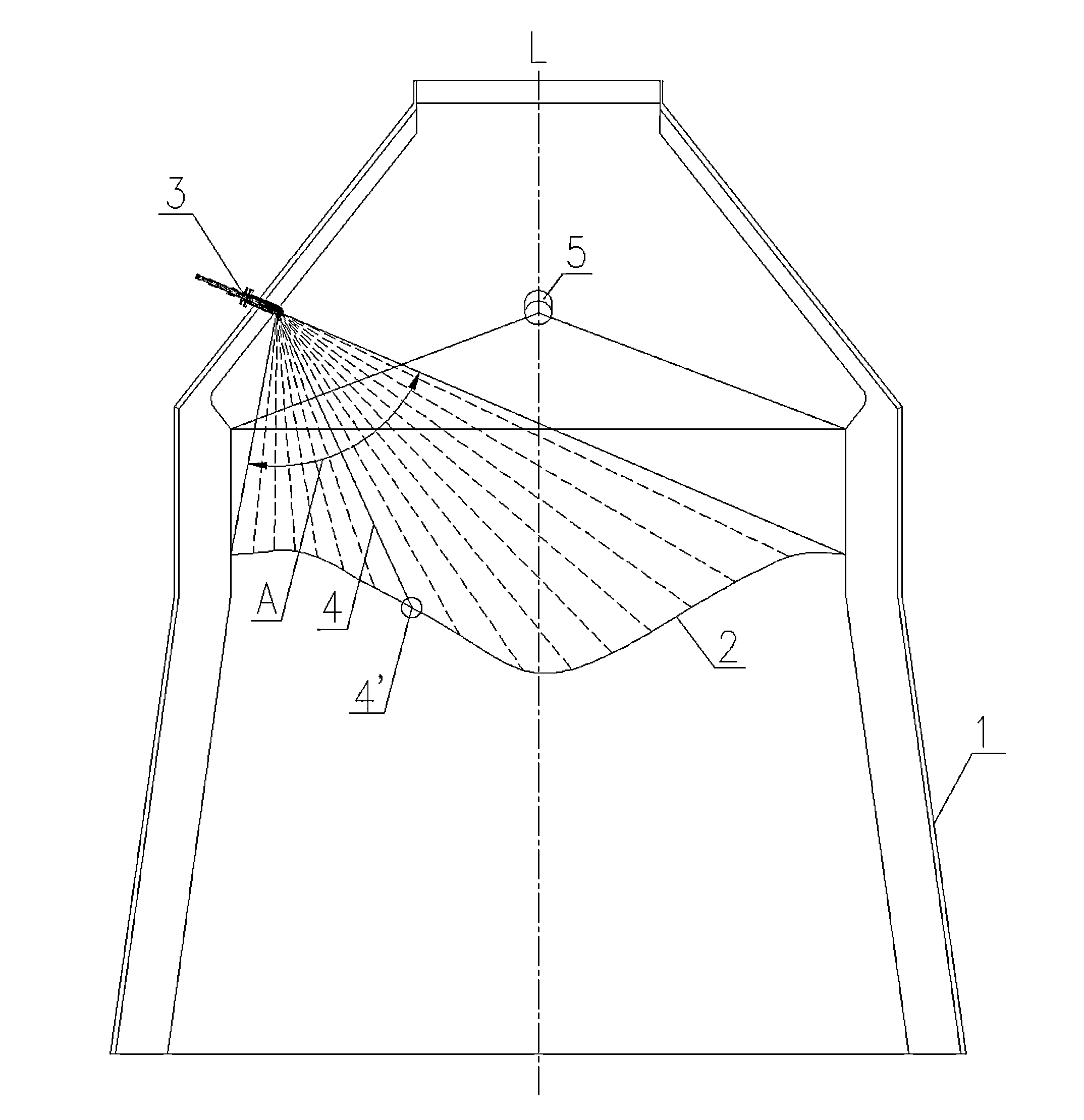

The invention discloses a system and a method for measuring blast furnace burden surface on line so as to detect blast furnace burden surface information. The system provided by the invention comprises a laser disposed over the burden surface. The laser emits laser beams which can continuously scan at least a part of the burden surface. A photography instrument is used for shooting the burden surface image which contains detecting point patterns formed by the emission of the laser beams on the burden surface. An image processing device receives the burden surface image output from the photography instrument and outputs the burden surface information. In comparison with the prior art, the method provided by the invention can be used to greatly reduce the system cost and obtain burden surface information which more conforms to reality by obtaining a lot of actual detecting points. In addition, as the system for measuring blast furnace burden surface on line can require fewer lasers (even one laser), the method has more advantages in the aspect of system miniaturization and can simplify protection measures of the laser.

Owner:SHENVANG PAJONIIR TEK CORP BEJDZHING

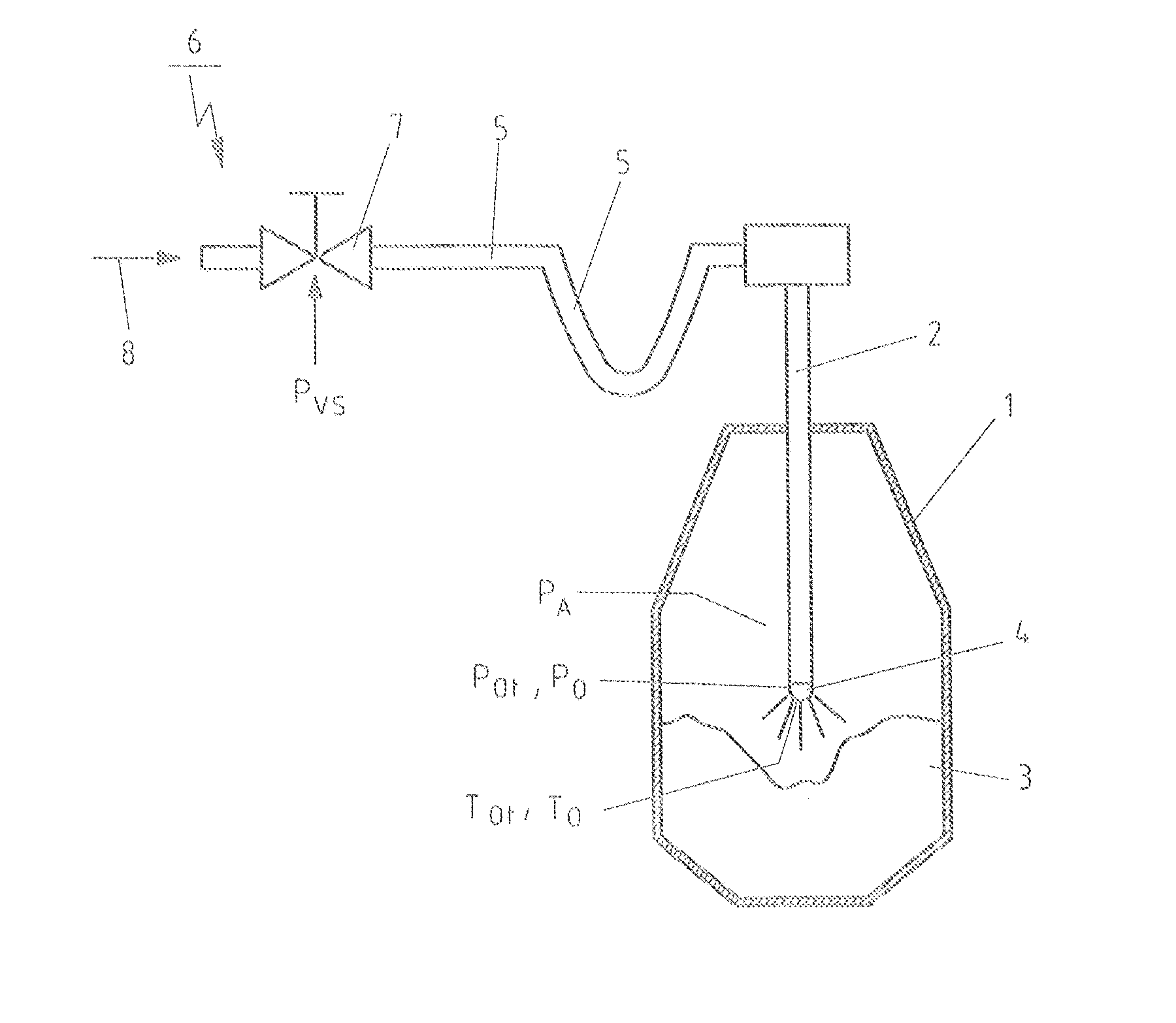

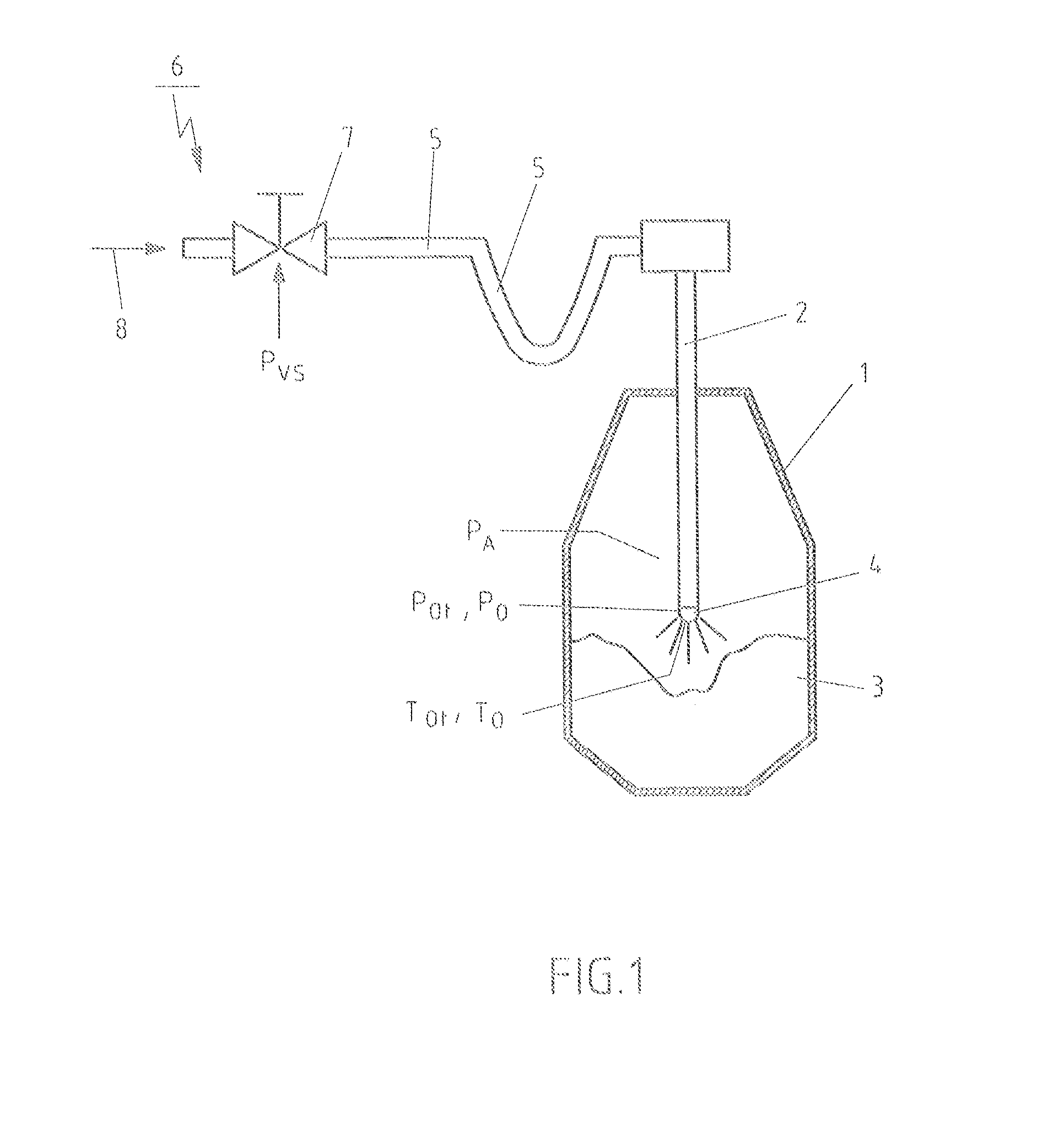

Method for operating an oxygen blowing lance in a metallurgical vessel and a measurement system for determining a measurement signal used in the method

InactiveUS20140327192A1Continuous detectionCharge manipulationManufacturing convertersVibration amplitudeEngineering

A method for operating a blowing lance for blowing a gas in a metallurgical vessel, wherein the head of the blowing lance includes at least one supersonic nozzle, operating parameter measurement signals used for the purpose of process control are continuously acquired. The inlet pressure and / or the inlet temperature of the gas at the supersonic nozzle and / or the vibration amplitude and / or the vibration frequency of the blowing lance and / or the time at which ignition occurs during the oxygen blowing process and / or the location at which ignition occurs during the oxygen blowing process is detected and / or measured in the head of the lance by a detector or sensor arranged in the head of the lance near the supersonic nozzle during operation of the blowing lance. The measurement signal(s) are transmitted to a control unit connected to the detector or sensor and made available for controlling the operation of the blowing lance.

Owner:SMS GRP GMBH

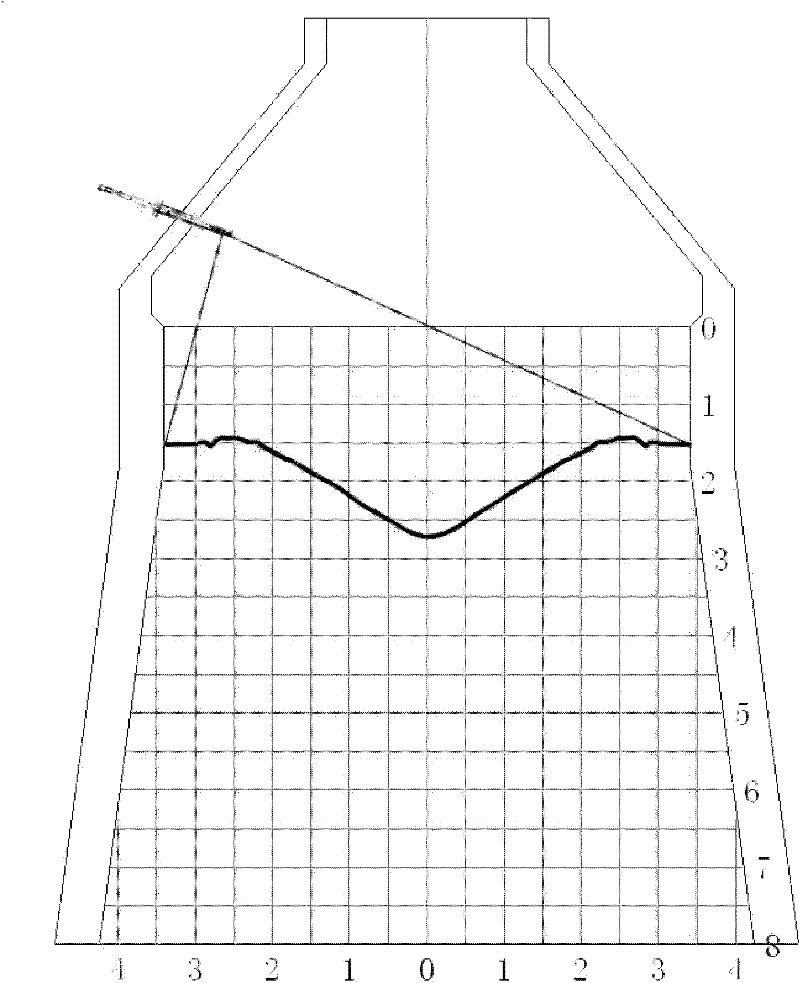

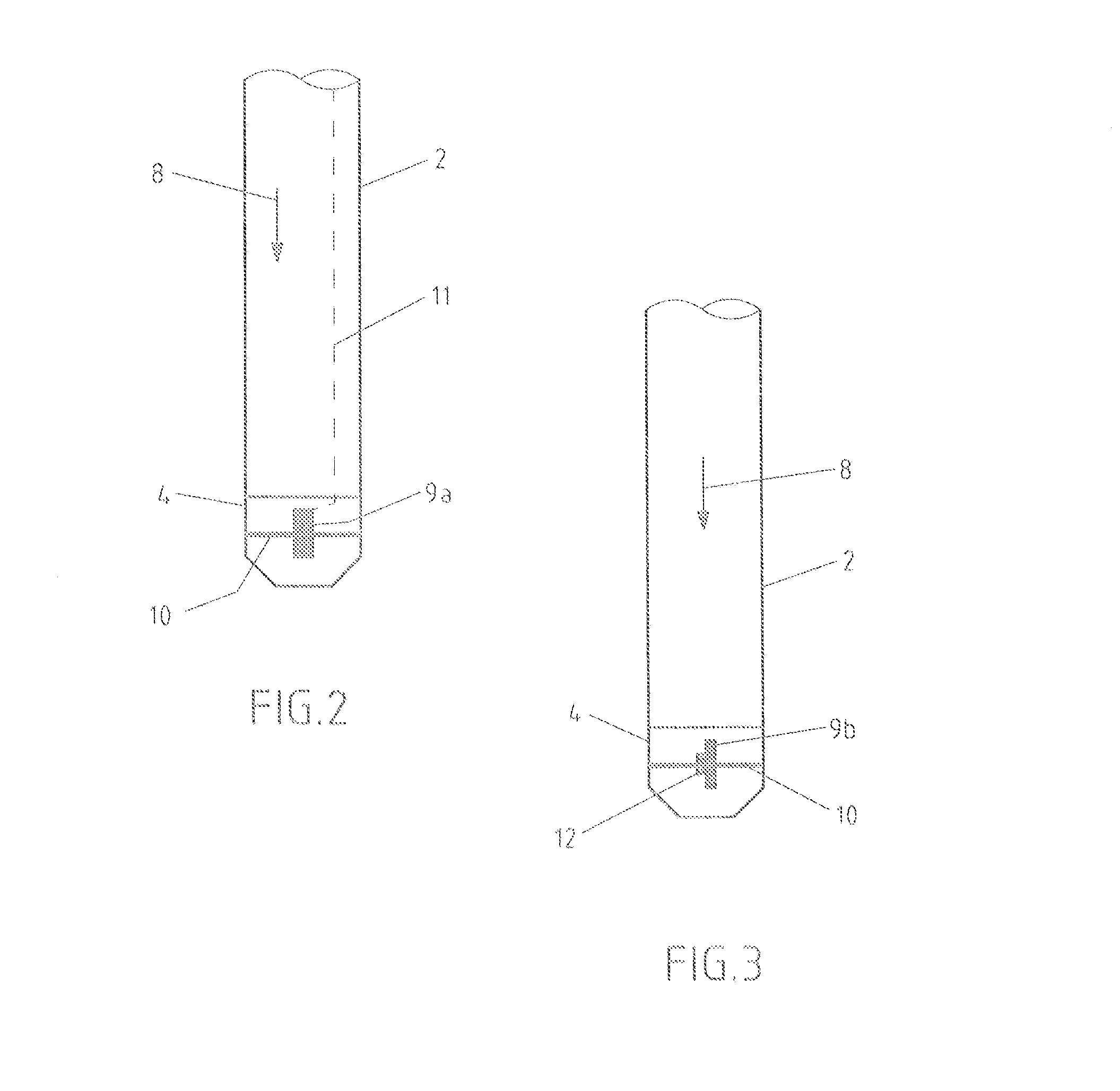

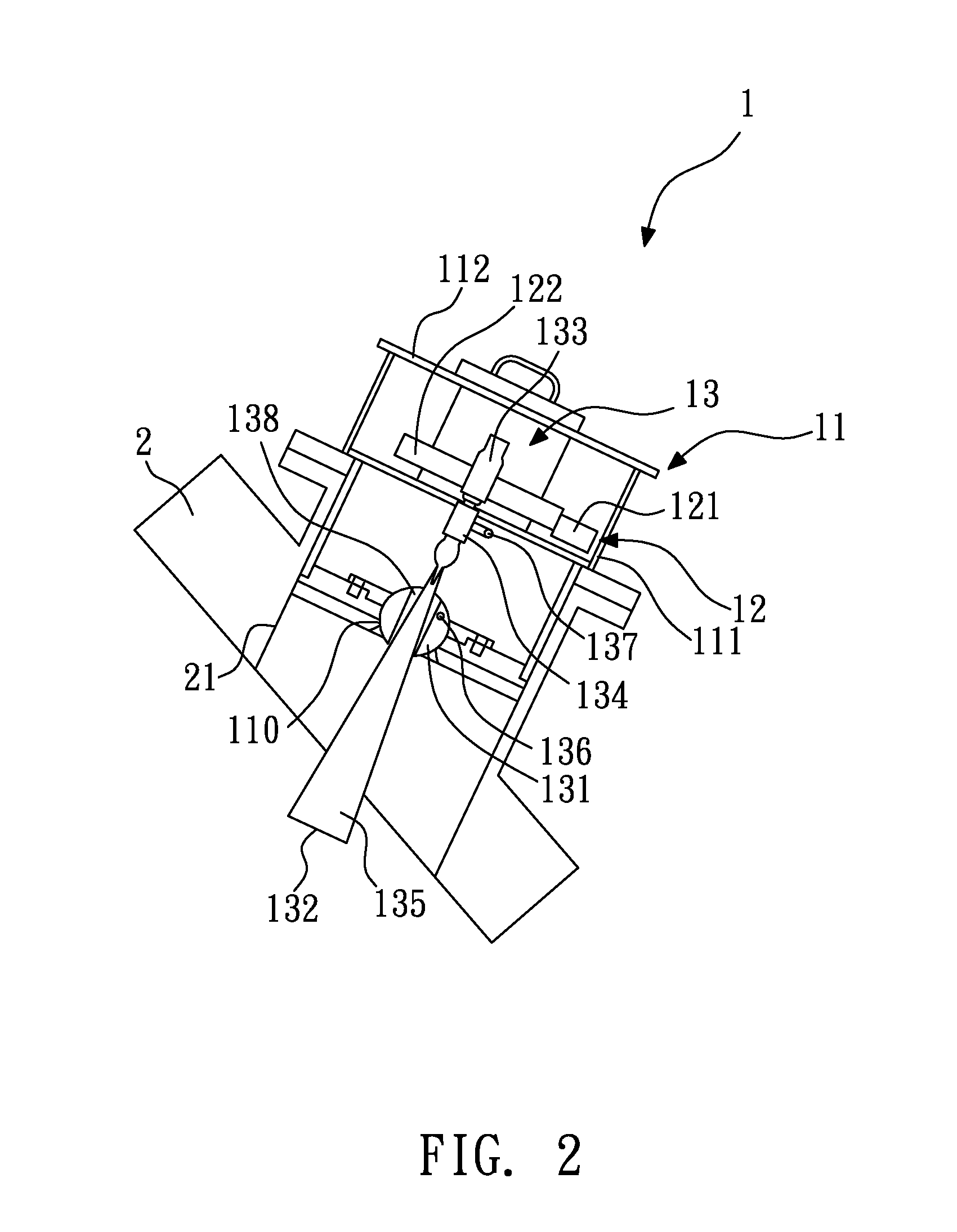

Resident measurement system for charge level of blast furnace

InactiveUS20110193274A1Small dimensionEnsure safetyBlast furnace detailsVertical furnacesHigh concentrationEngineering

A resident measurement system for a charge level of a blast furnace includes a chamber, a servo system, a distance measurement unit, and a cooling-cleaning unit. The chamber is combined with a lateral furnace wall of the blast-furnace, covers an opening of the furnace wall, and has a pivoting hole. A pivot of the distance measurement unit is pivotally disposed at the pivoting hole, and the distance measurement unit is driven by the servo system to perform a motion with the pivot as a movement center, so as to measure the charge level. The cooling-cleaning unit is used to supply a high-pressure gas, which flows through the distance measurement unit to perform cooling and cleansing operations. The measurement system is small in dimension, and capable of scanning the charge level in an environment with high temperature, high concentration of dust, and high corrosion in the blast furnace furnace, establishing charge level information into a two-dimensional charge level mode, and obtaining a charge level profile distribution situation in real time, thereby promptly modifying a burden distribution mode.

Owner:CHINA STEEL

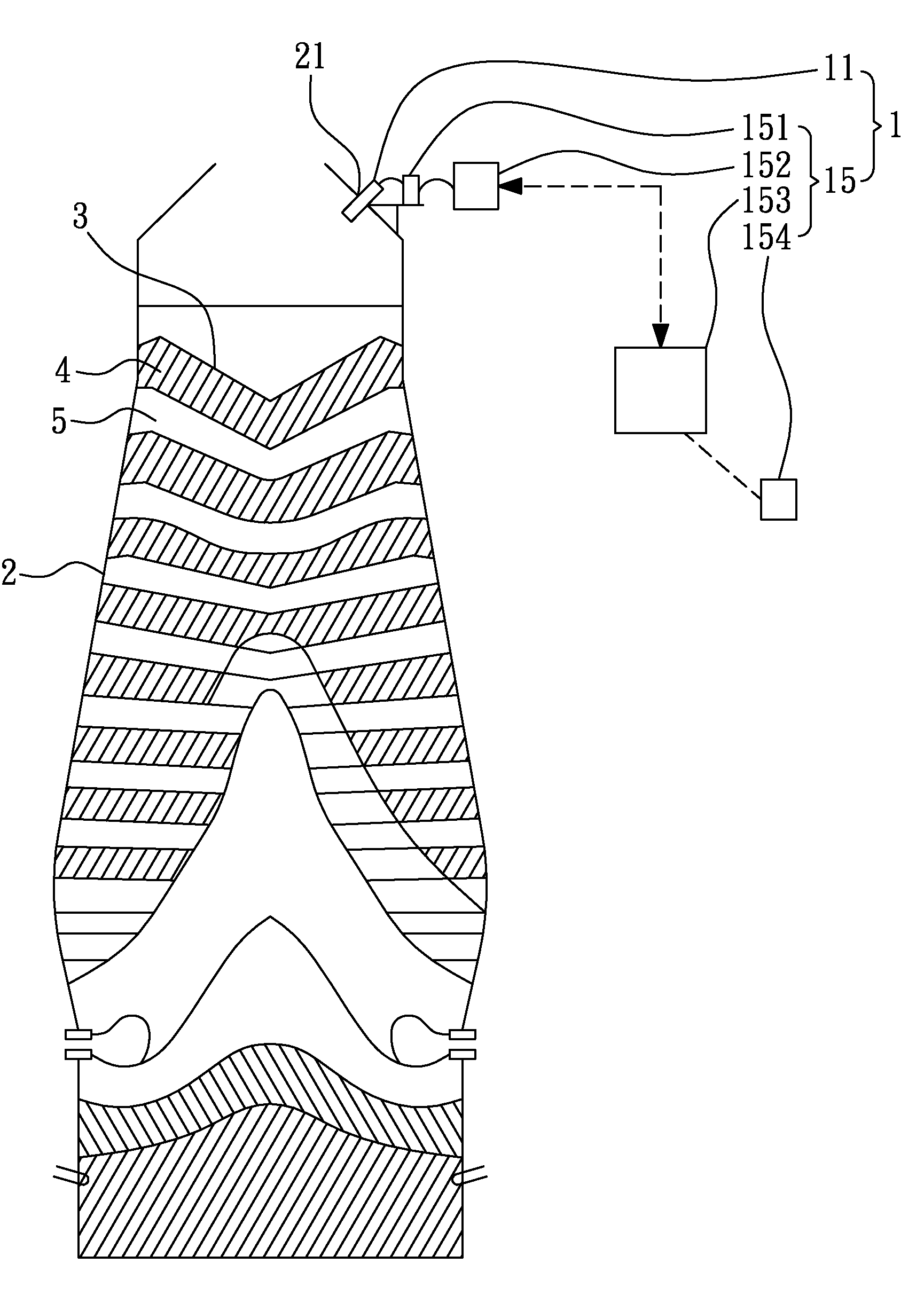

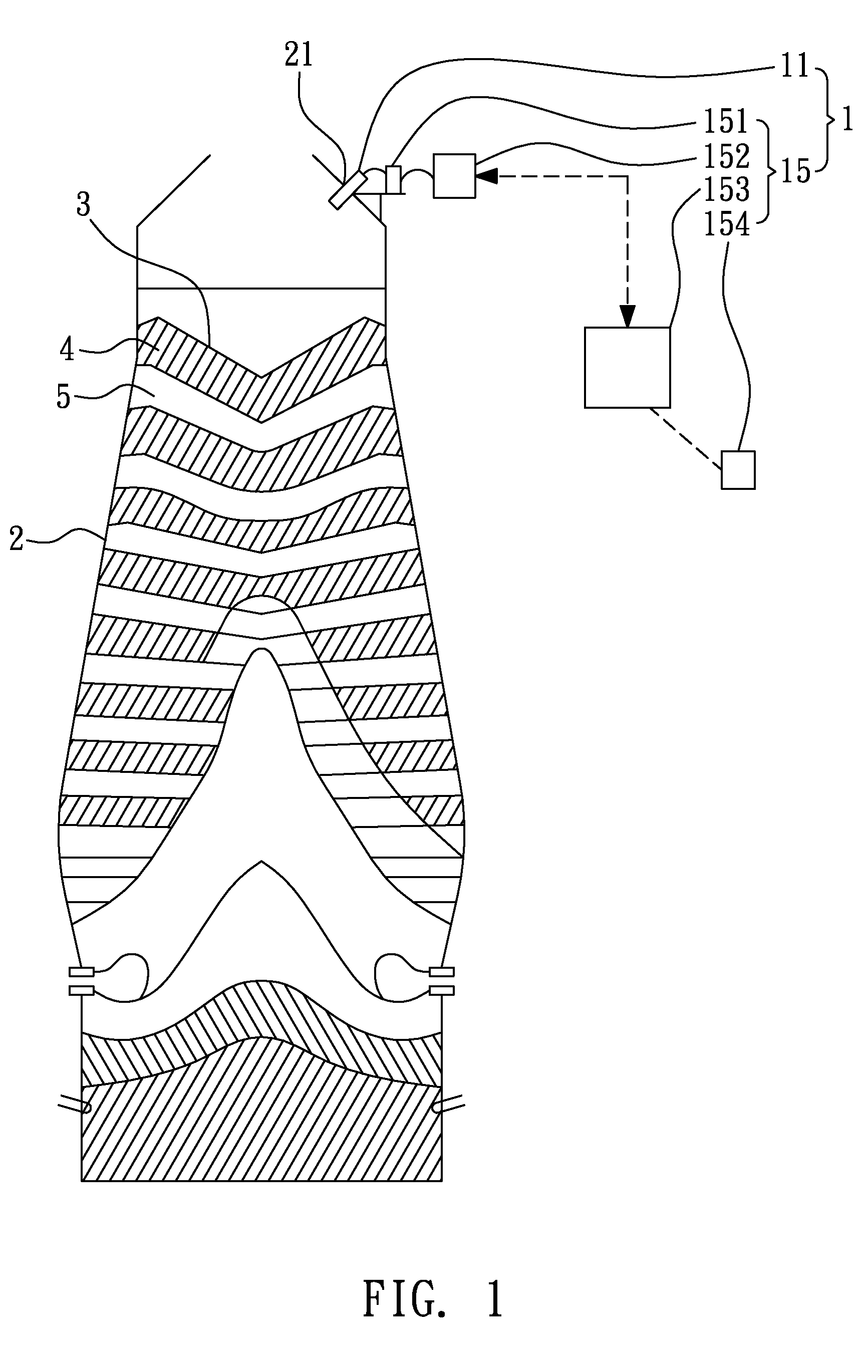

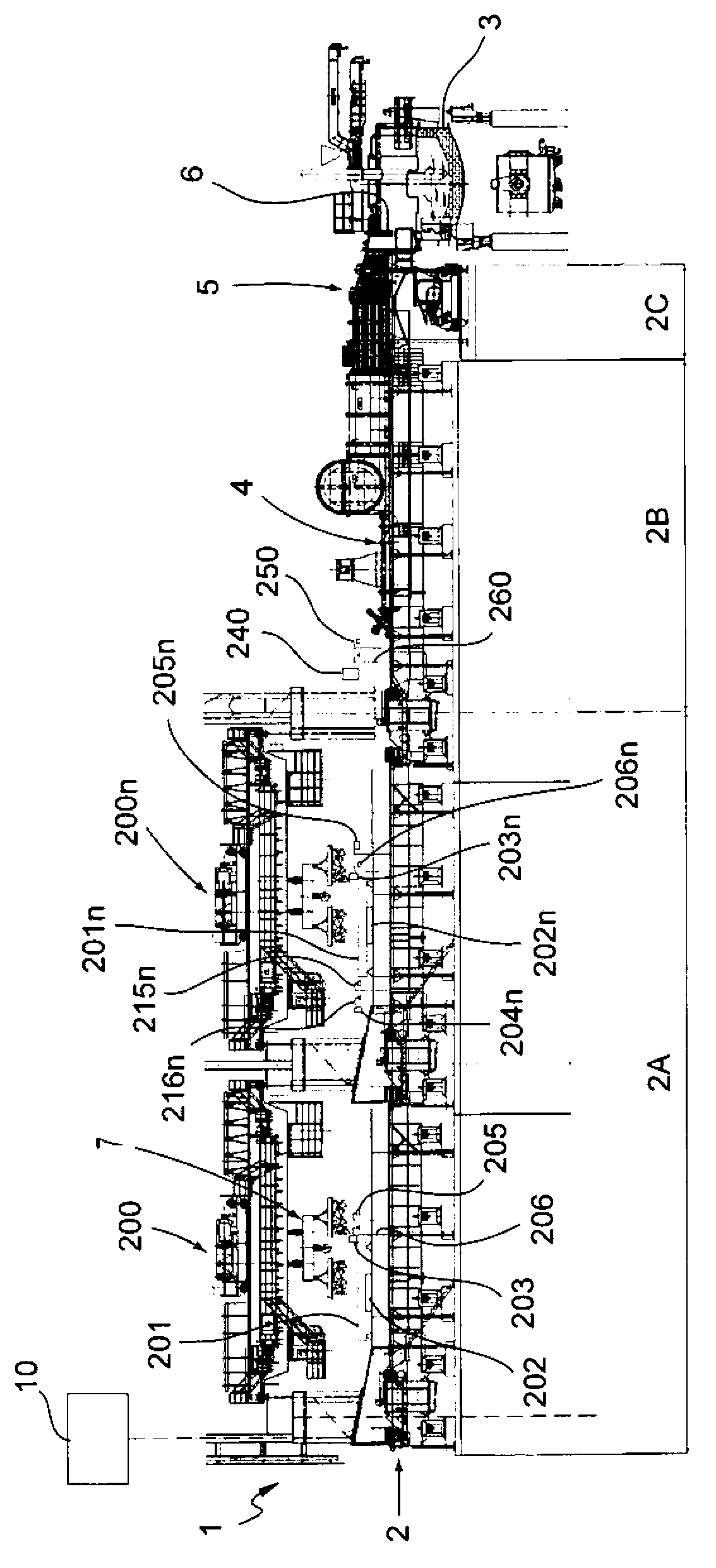

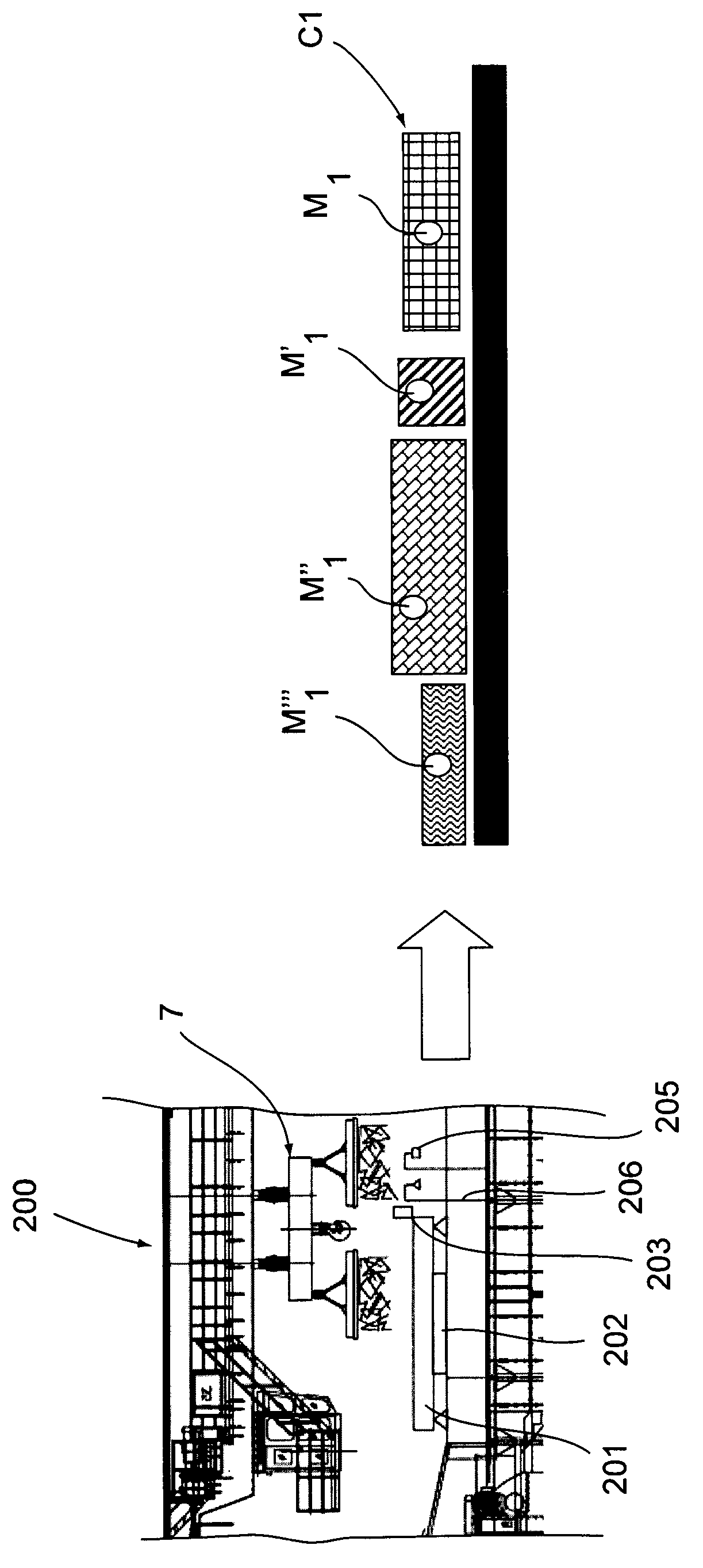

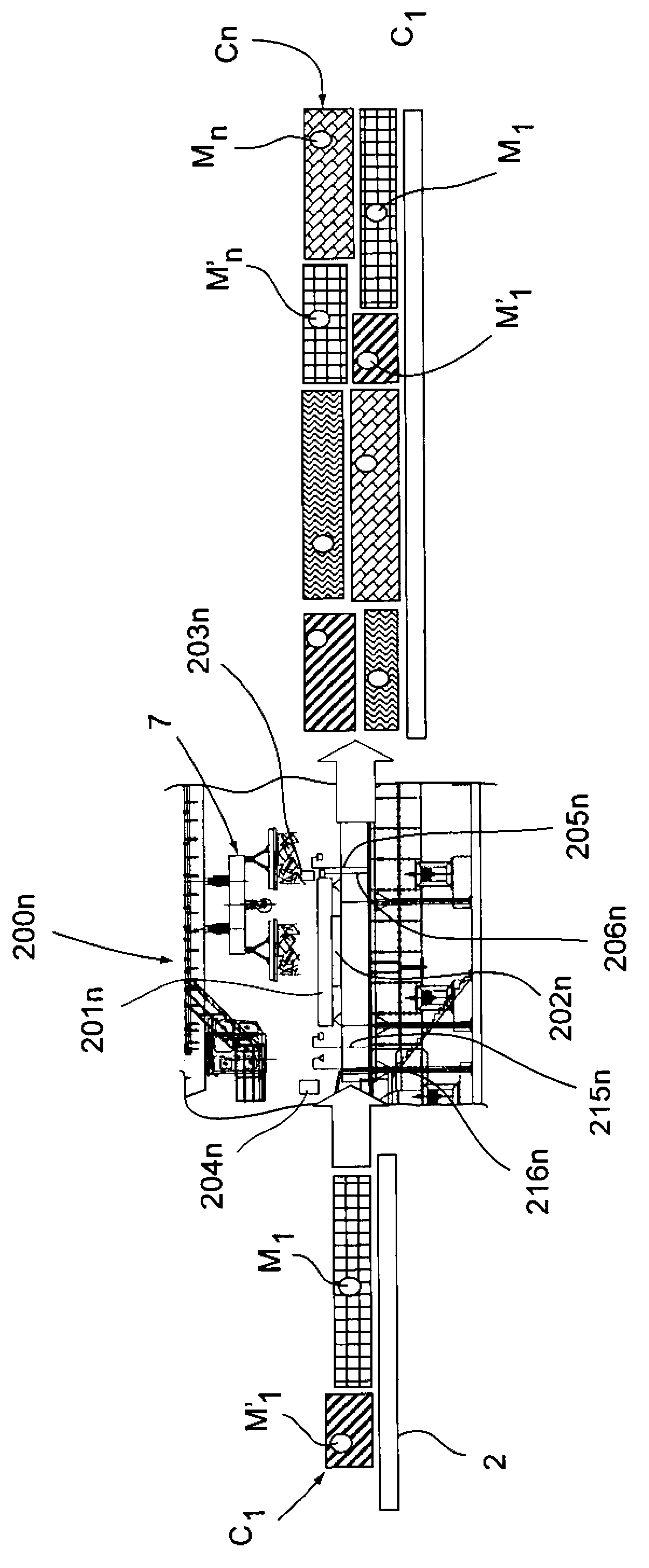

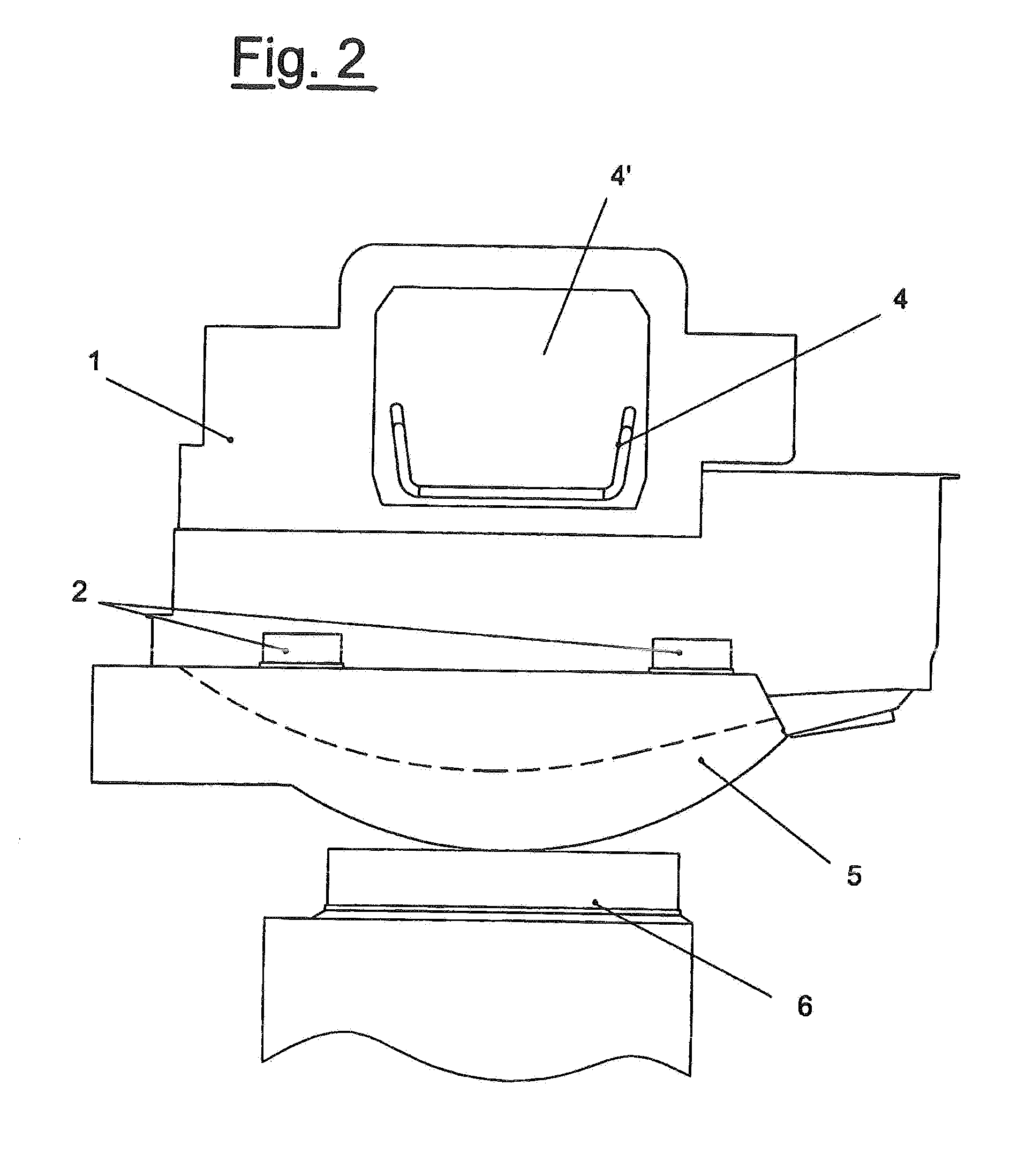

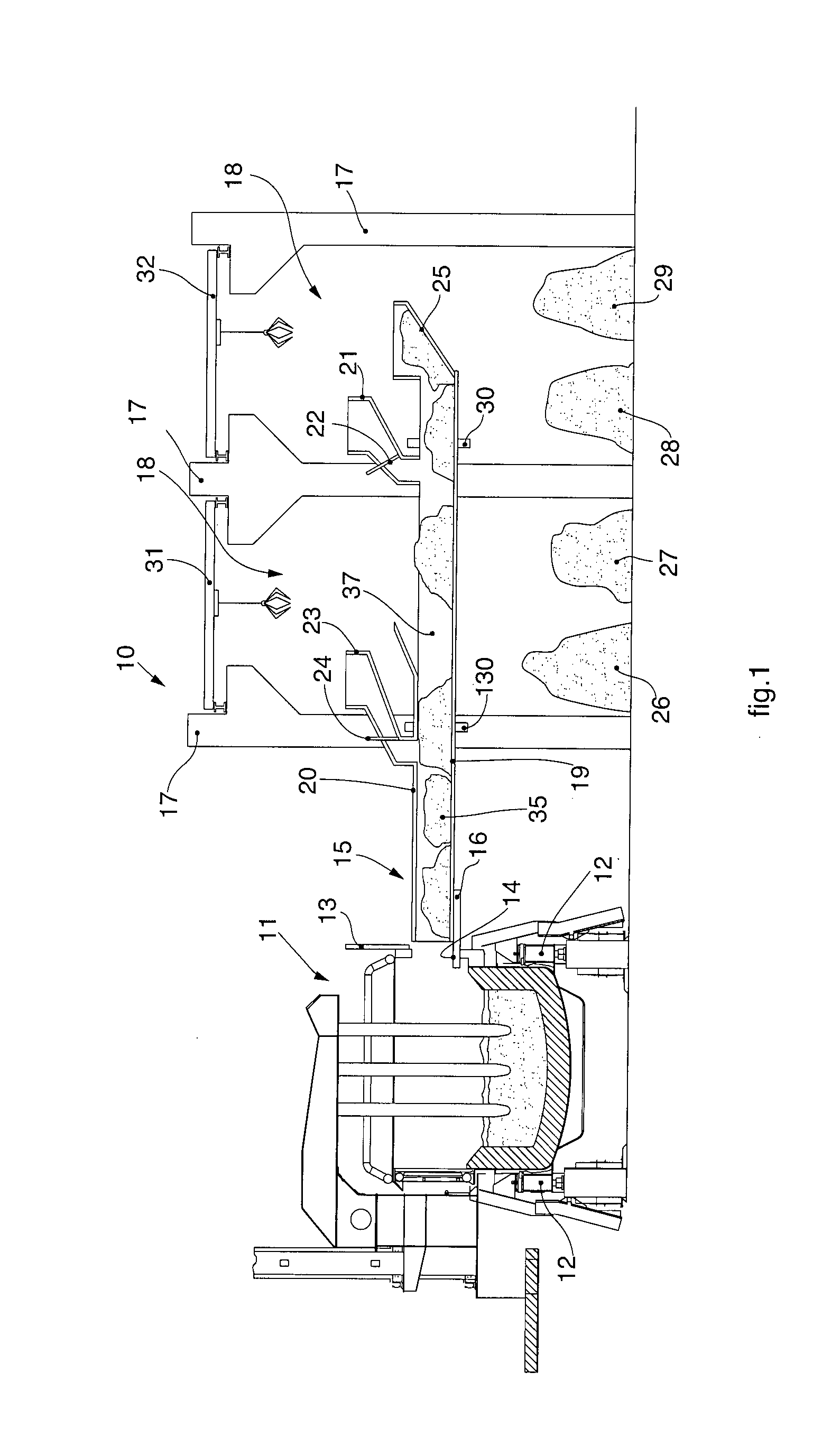

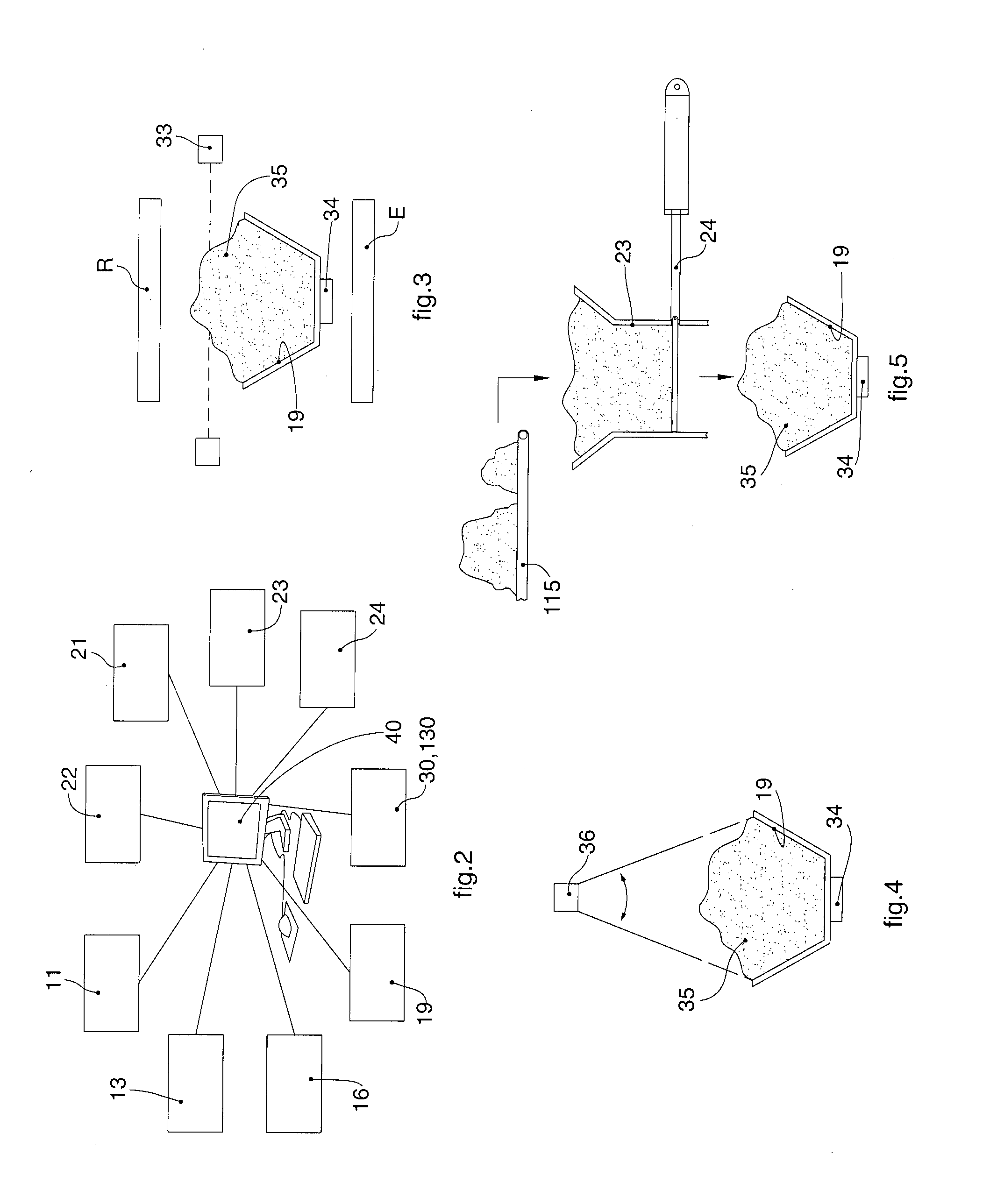

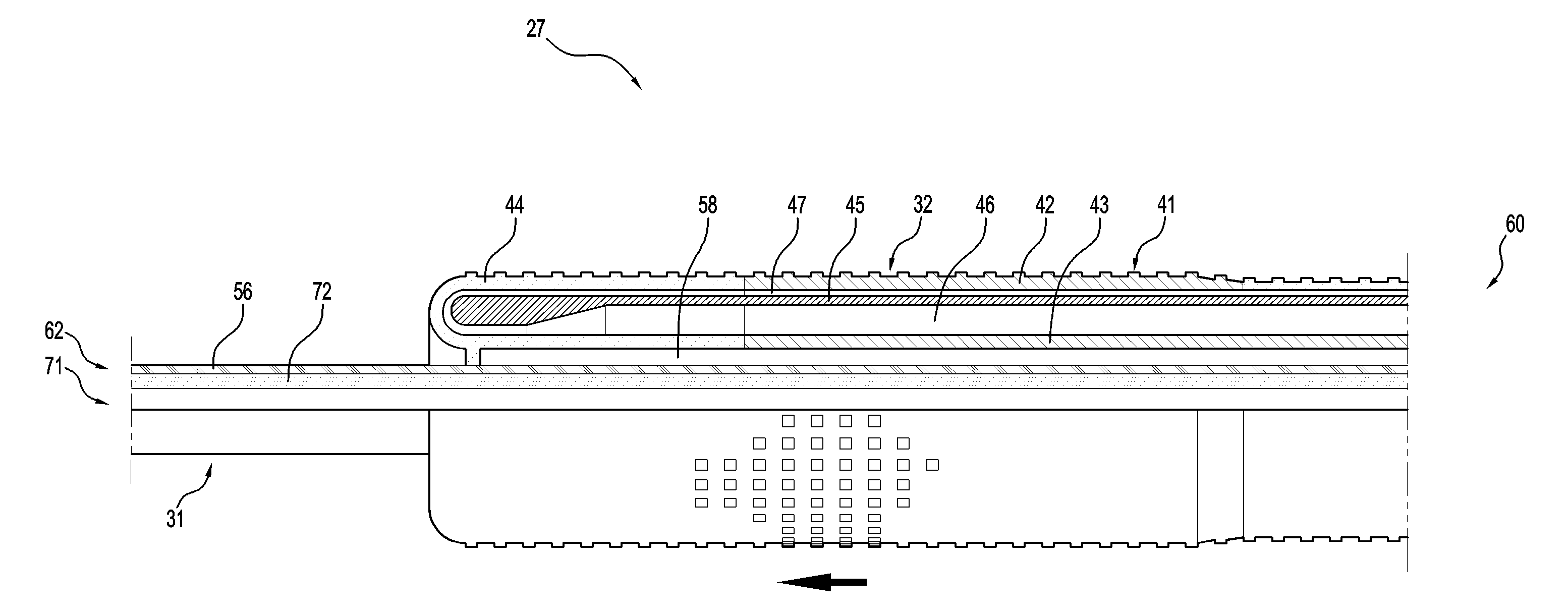

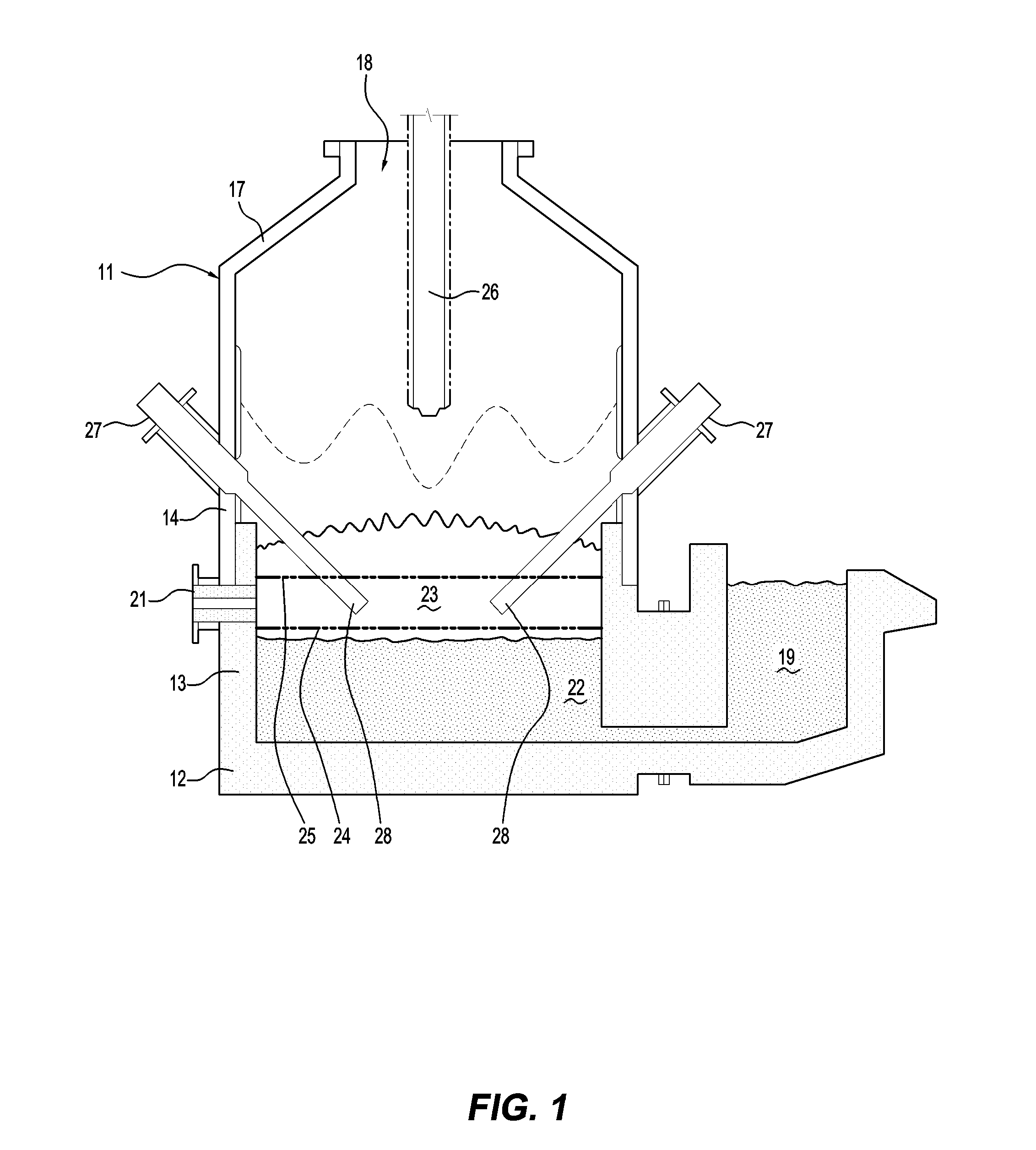

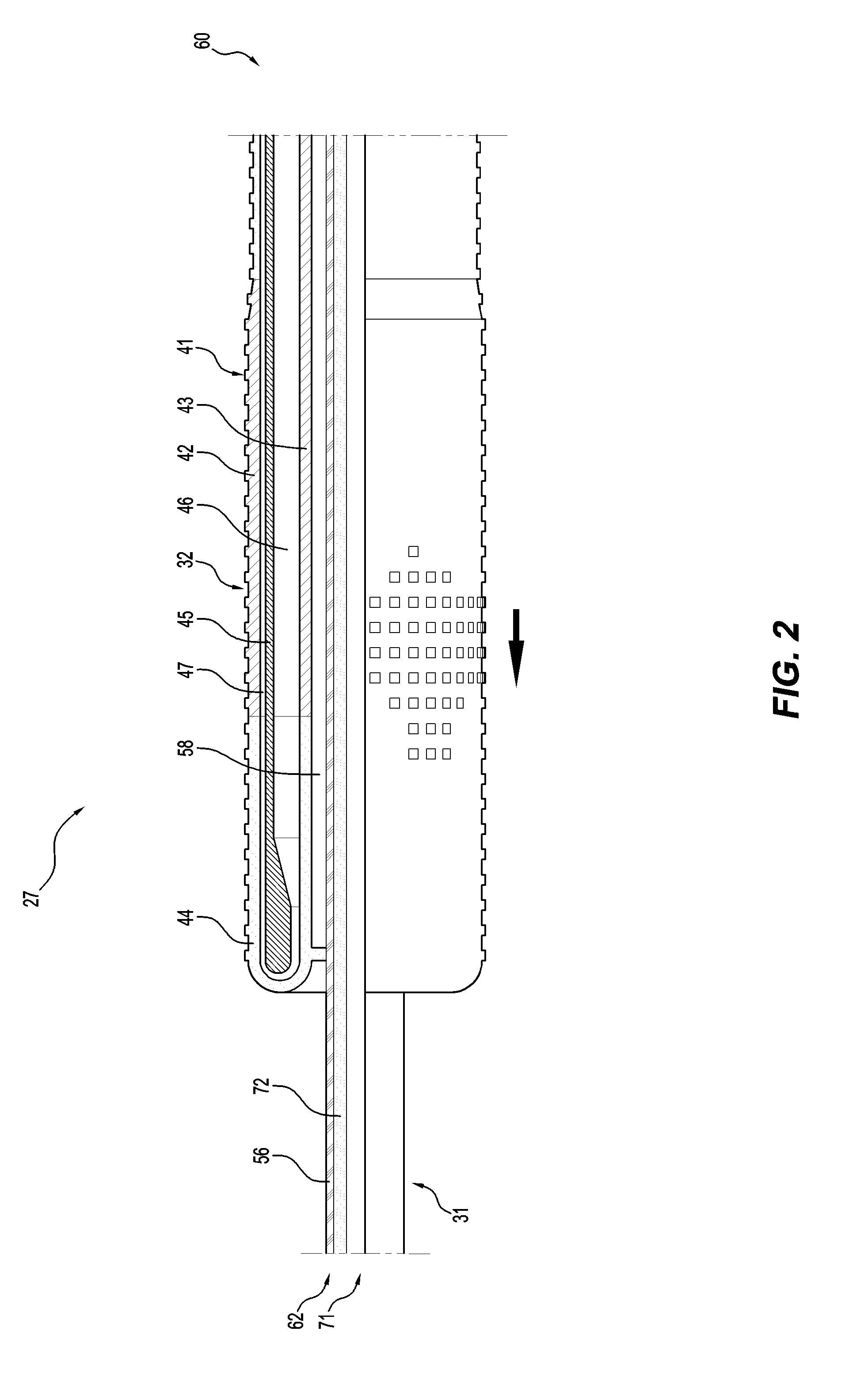

Method and control and tracking system of the charge of material transported by a continuous supply conveyor of a metallurgical furnace, particularly an electric furnace for the production of steel

The present invention refers to a method and to a control and tracking system of the charge of material transported by a continuous supply conveyor (2) of a metallurgical furnace (3), in particular an electric furnace for the production of steel, wherein said continuous conveyor (2) comprises, in sequence starting from its inlet end towards its outlet end, a loading section (2A) of the charge of material to be supplied to said furnace (3), a preheating section (2B) of the charge of material loaded and an introduction section (2C) into said furnace (3) of the preheated charge of material, and wherein along said loading section (2A) at least a first loading station (200) of material is present, wherein the method comprises the steps consisting in determining (101) the type and the weight of the material of a first charge fraction to be loaded into the first loading station (200); in function of a predetermined charge recipe (100), supplying (102) the first loading station (200) with the first charge fraction, detecting (103) the weight of the first charge fraction, discharging (104) the first charge fraction (C1) onto the continuous conveyor (2), marking (105) the first charge fraction (C1) through identification means (M1, M1', M1''), detecting (106) the overall dimensions of the first charge fraction (C1) discharged onto the continuous conveyor (2), estimating (107, 108) the advancing speed of the first charge fraction (C1) along the loading section (2A) of the continuous conveyor (2) and the arrival time of the first charge fraction (C1) entering a possibly subsequent loading station (200n) of a further charge fraction or the preheating section (2B), and, in proximity to the inlet of the preheating section (2B), recognising (115).

Owner:ТЕНОВА ТЕКНОЛОДЖИЗ (ТЯНЬЦЗИНЬ) КО., ЛТД.

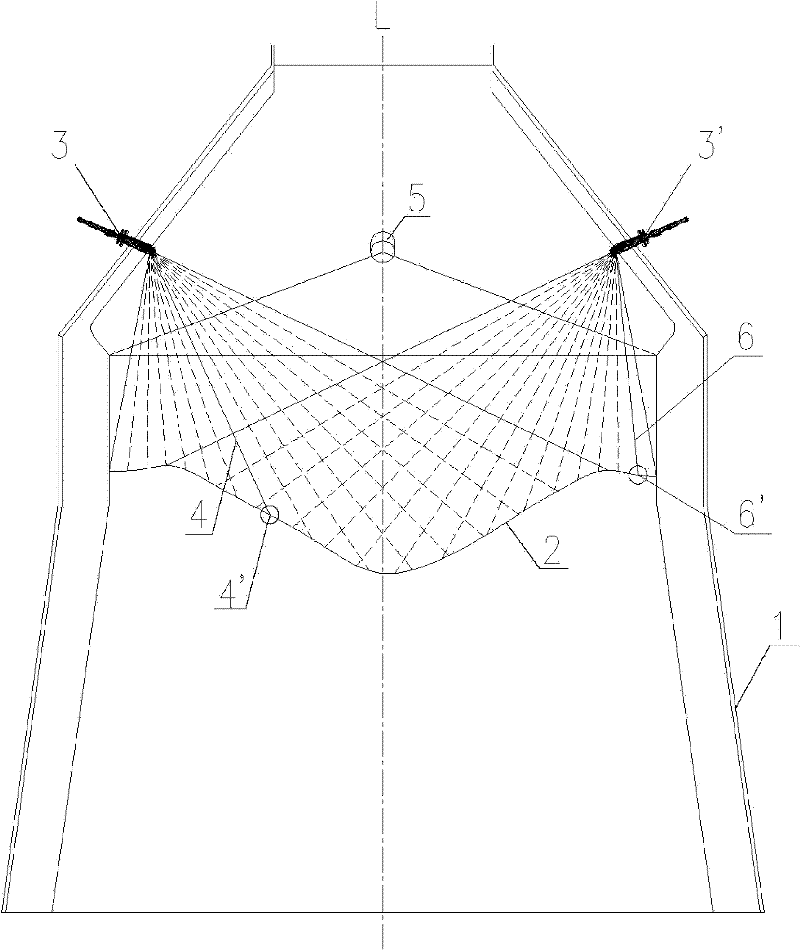

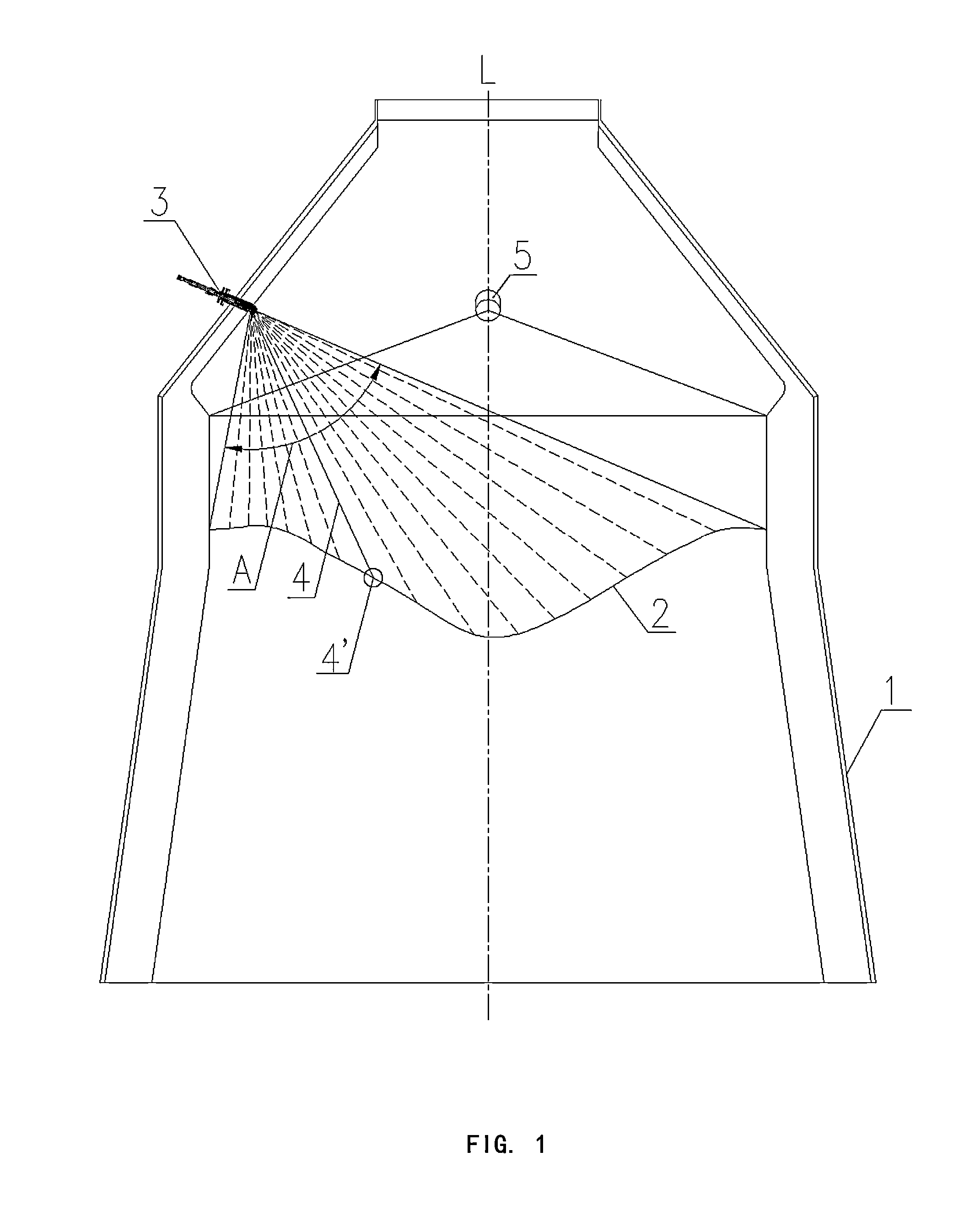

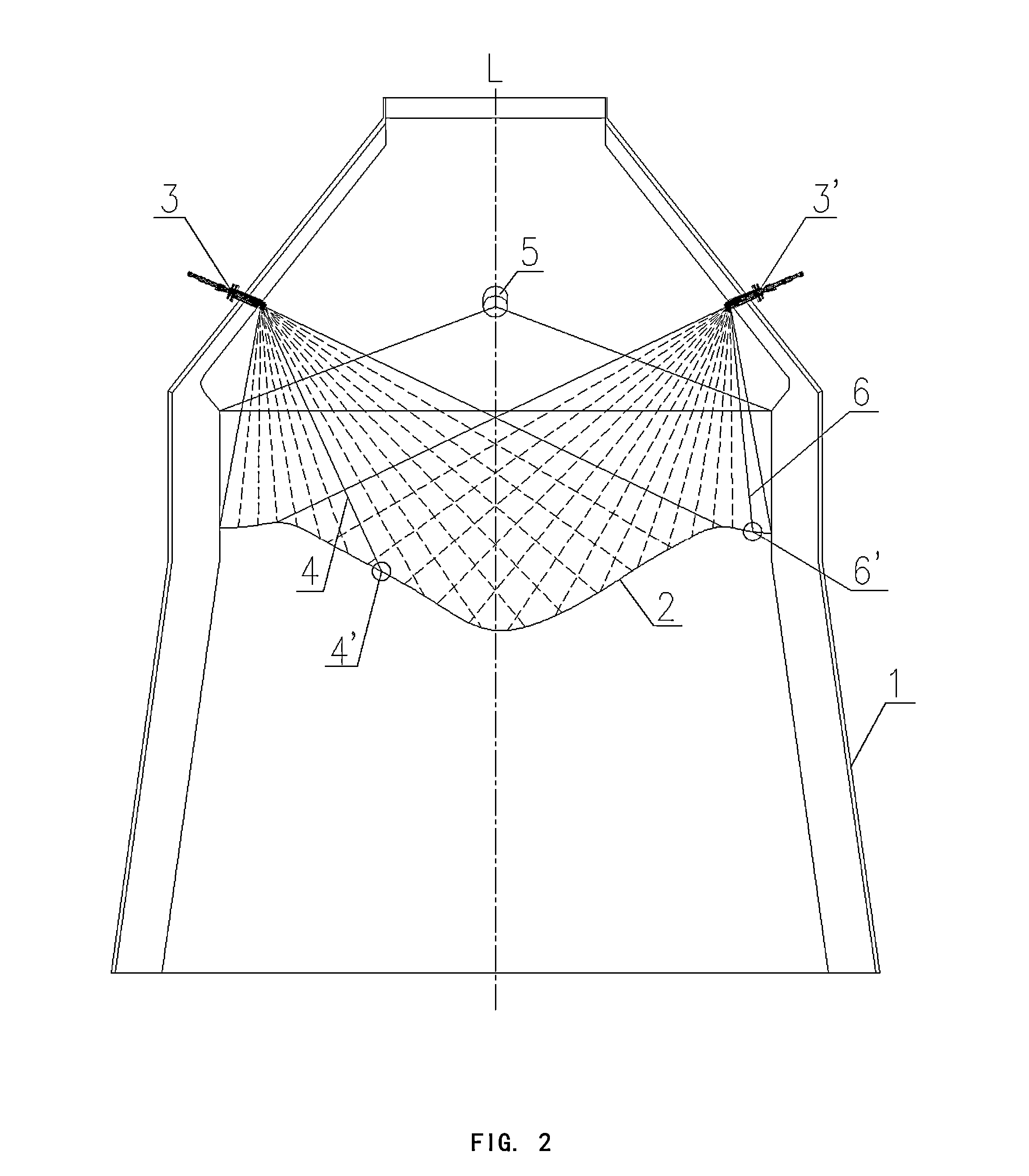

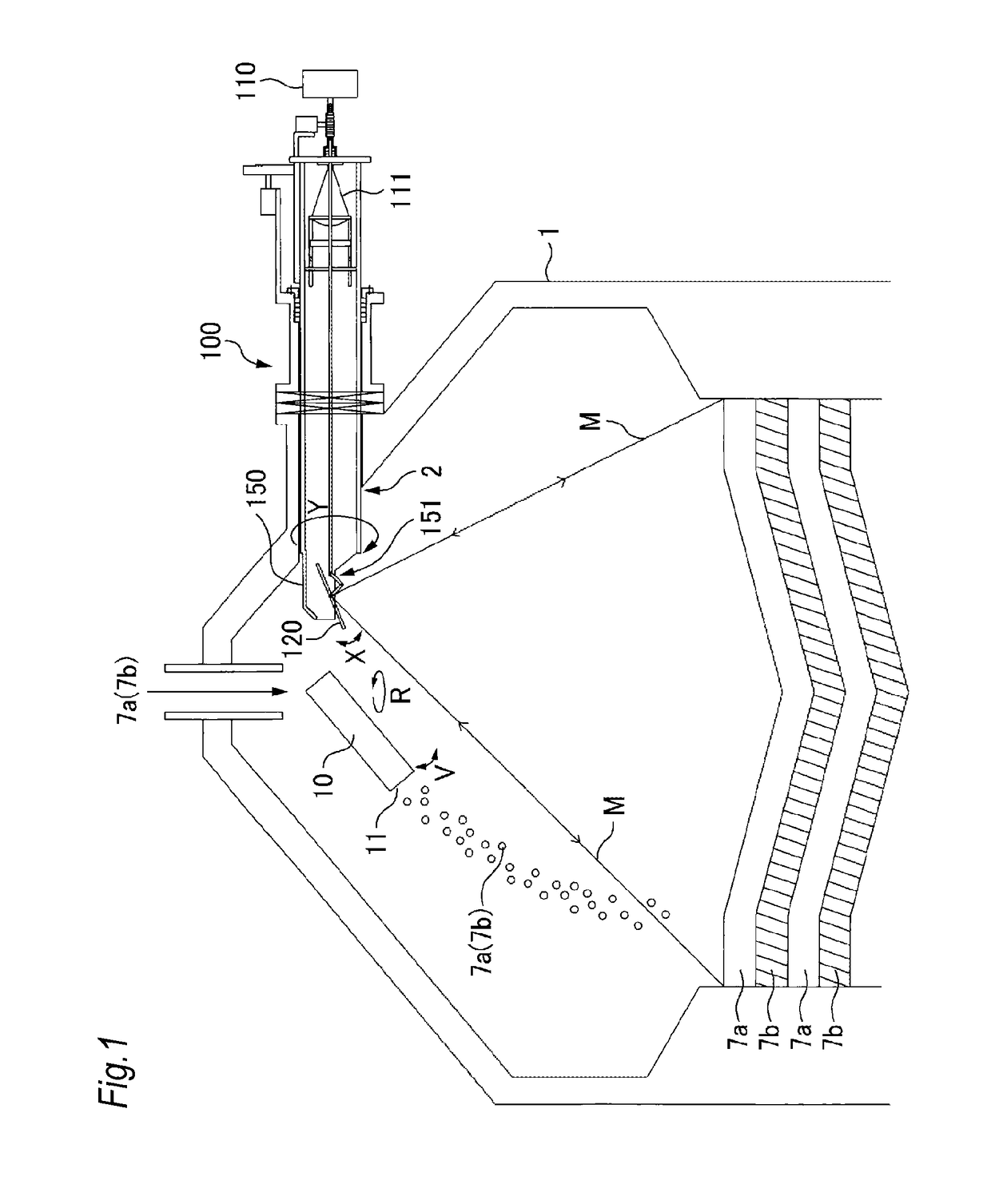

System and method for on-line measuring a burden surface in a blast furnace

InactiveUS20140333752A1Low costMinimizing volume of systemColor television detailsClosed circuit television systemsLaser transmitterImaging processing

The present invention discloses a system and method for on-line measuring a burden surface in blast furnace to get burden surface information. The system comprises laser emitter(s) disposed above the burden surface and emitting laser beam(s) to continuously scan at least one portion of the burden surface; a video camera configured to shoot burden surface images, each of which comprises a detection point pattern formed by the laser beam incident on the burden surface; an image processing device configured to receive the burden surface images transferred from the video camera and output the burden surface information. As compared with the prior art, the present invention may substantially reduce the cost of the measuring system and obtain burden surface information sufficiently accurate with a large number of actual detection points. Furthermore, the system for on-line measuring a burden surface in blast furnace according to the present invention may use less number of laser emitter (even one laser emitter), so it is more advantageous to minimize the system and may simplify laser emitter protective measures.

Owner:GAO ZHENGKAI +4

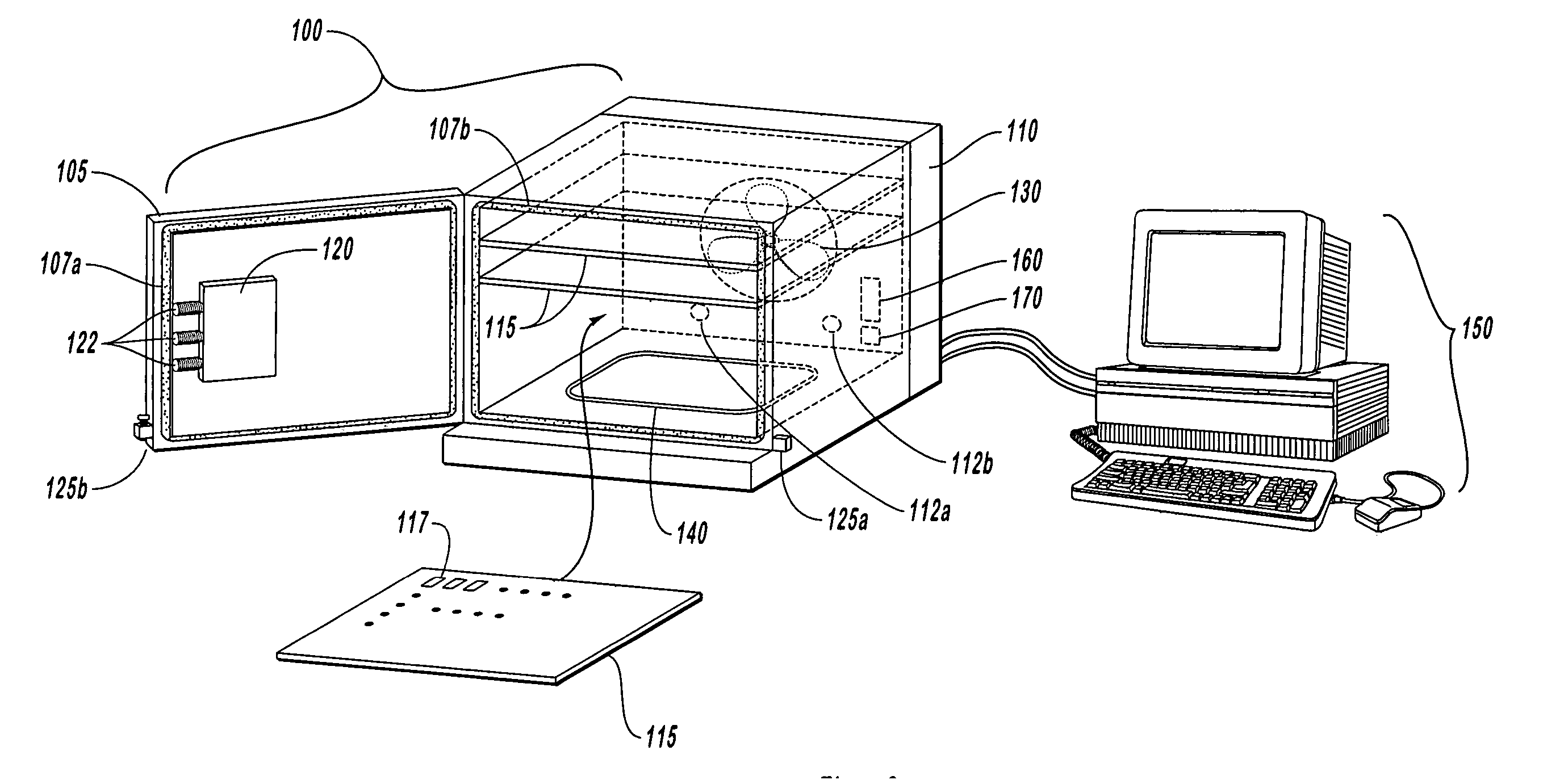

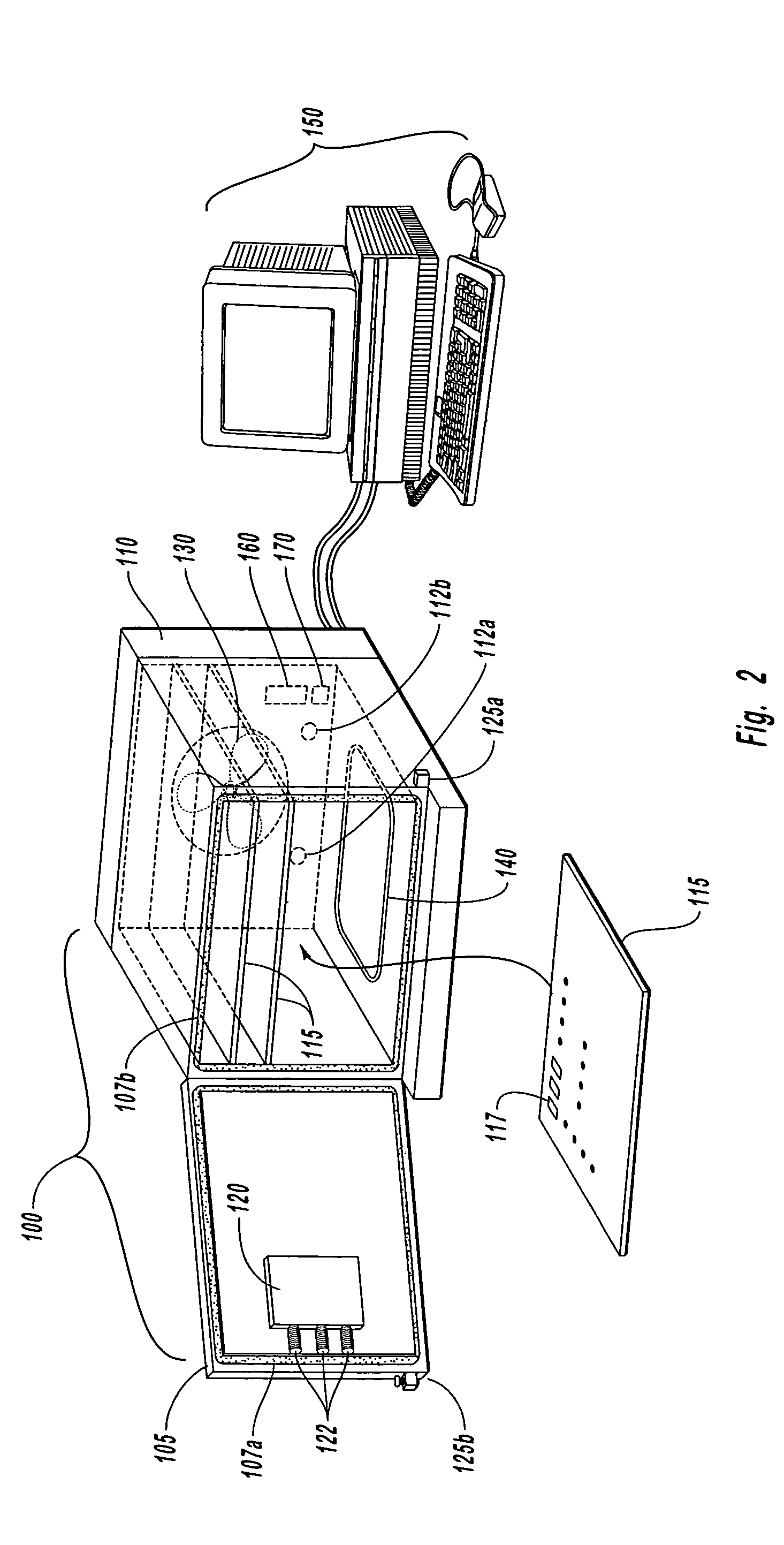

Optical product cure oven

ActiveUS20060032573A1Increase chanceEfficient curingSampled-variable control systemsLamination ancillary operationsHigh rateAdhesive

A cure oven comprises a sealable door and one or more pressure valves mounted inside for curing optical subcomponents that have been assembled using an adhesive. The cure oven comprises a chamber that can be configured to receive several hundreds of assembled optical subcomponents. The cure oven is further coupled to a computerized system via a drive motor. The computerized system initiates the heating and cooling sequences, and indicates whether the door can be opened, or must remain shut. The cure oven maintains a certain pressure inside the oven chamber consistent with a rise in temperature, allowing assembled optical subcomponents to be cured at a much higher rate than possible without disassembling, or being damaged.

Owner:II VI DELAWARE INC

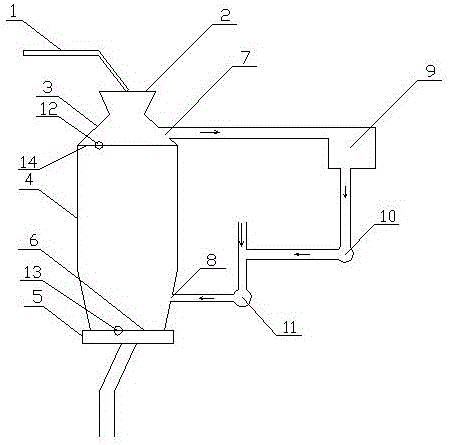

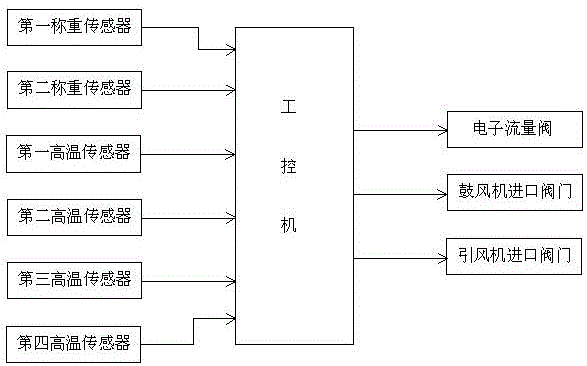

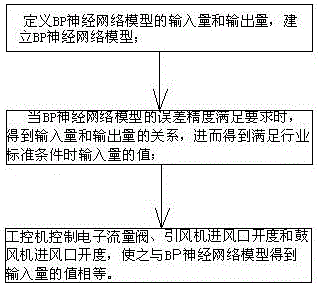

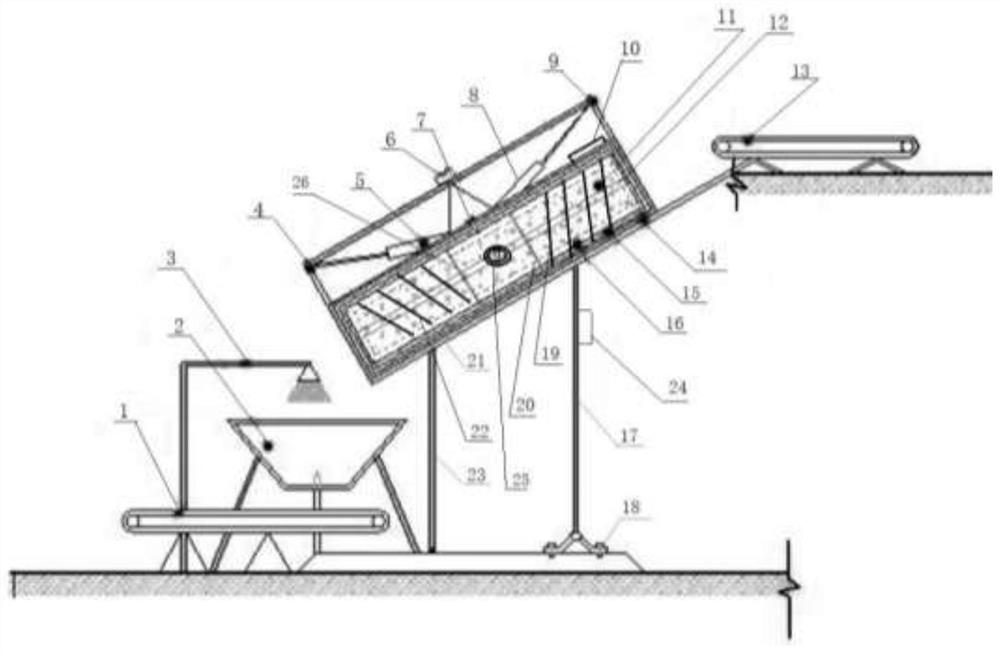

Sinter vertical cooling furnace device and sinter cooling method

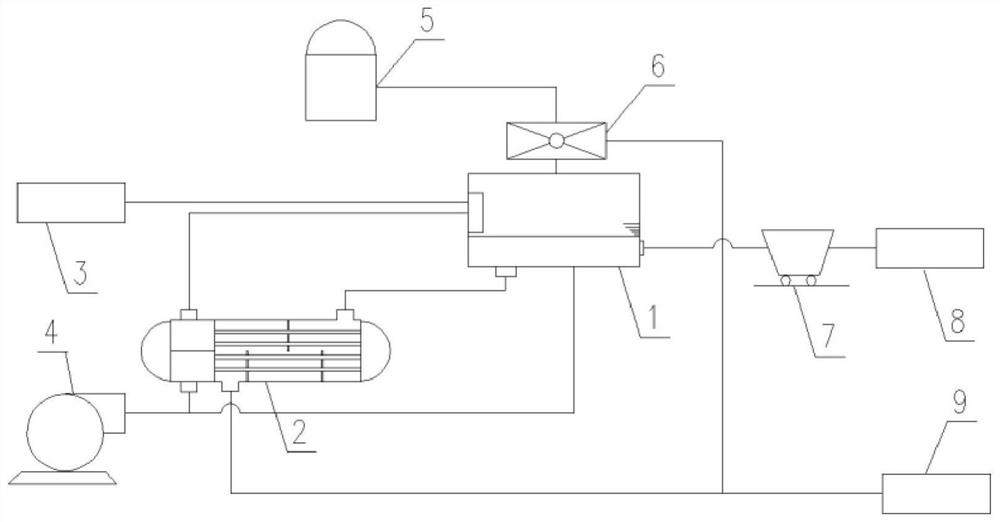

ActiveCN106766943AAdjust air temperatureEfficient use ofFurnace coolingControl devices for furnacesNetwork modelEngineering

The invention provides a sinter vertical cooling furnace device and a sinter cooling method. The sinter vertical cooling furnace device comprises a belt conveying unit, a cooling furnace, a blower, an induced draft fan, a waste heat boiler and a control unit, wherein the belt conveying unit is used for inputting sinter required to be cooled down into the cooling furnace; a vibrating quantitative feeder communicates with the discharge opening of the cooling furnace, and the air outlet of the cooling furnace communicates with the air inlet of the waste heat boiler; the air inlet of the blower communicates with air, and the air outlet of the blower communicates with the air inlet of the cooling furnace; and the air outlet of the induced draft fan communicates with the air inlet of the blower, and the air inlet of the induced draft fan communicates with the air outlet of the waste heat boiler. The modeling method of a BP neural network model is utilized, and the weight value of sinter in a cooling area, the opening degree value of the air inlet of the induced draft fan and the opening degree value of the air inlet of the blower are adjusted according to the relationship between the input quantity and the output quantity, so that the temperature of the cooled sinter meets the industrial standards, the temperature stability of the air outlet of the cooling furnace is improved, and heat in waste gas of a cooler is fully utilized.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER +1

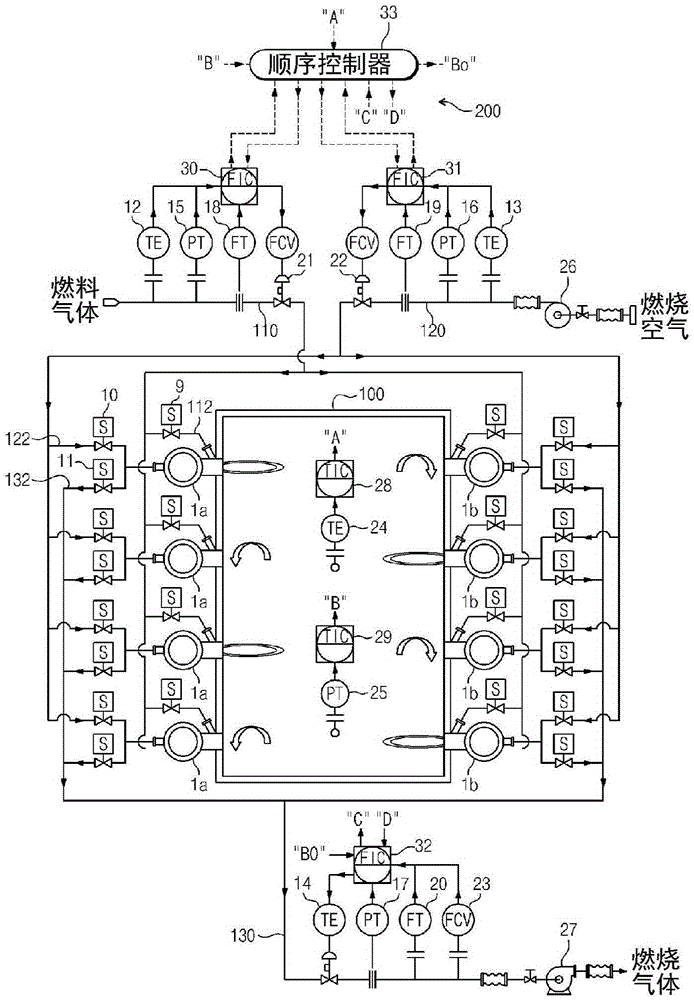

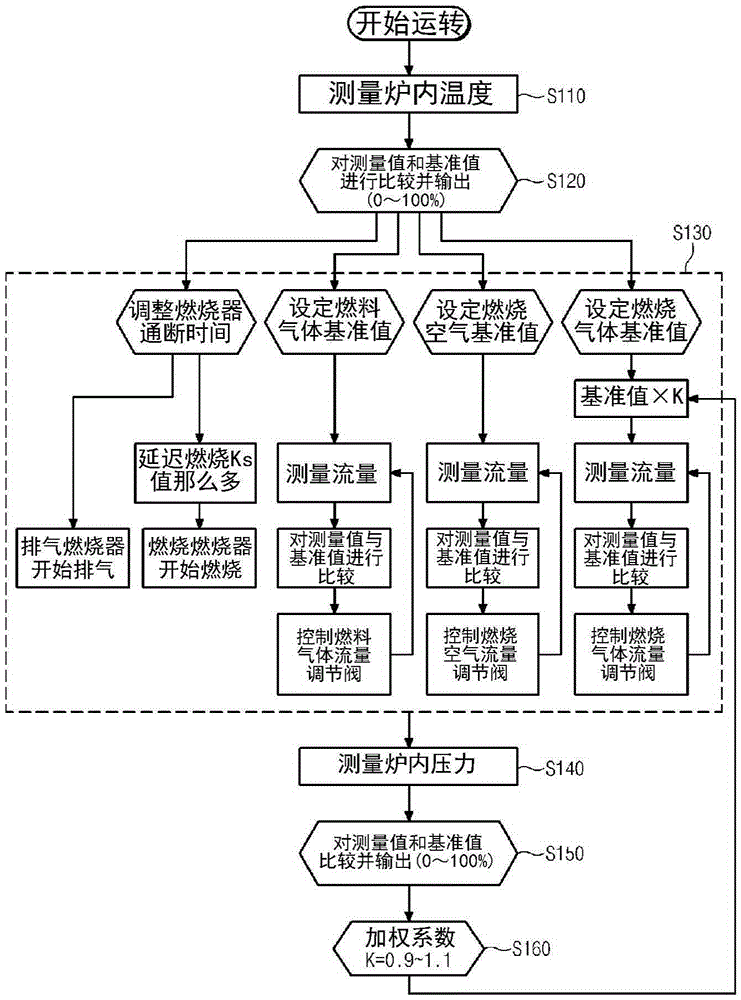

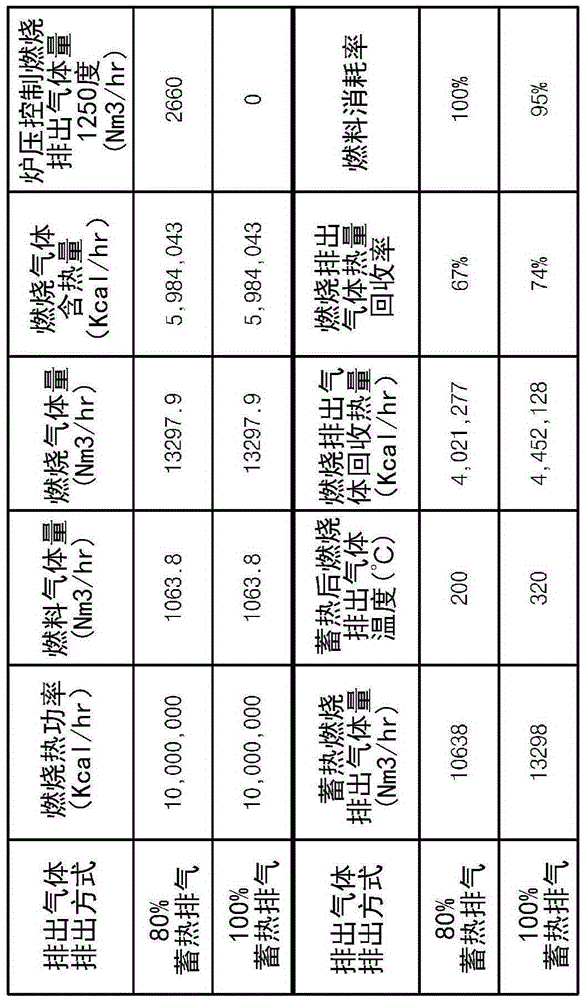

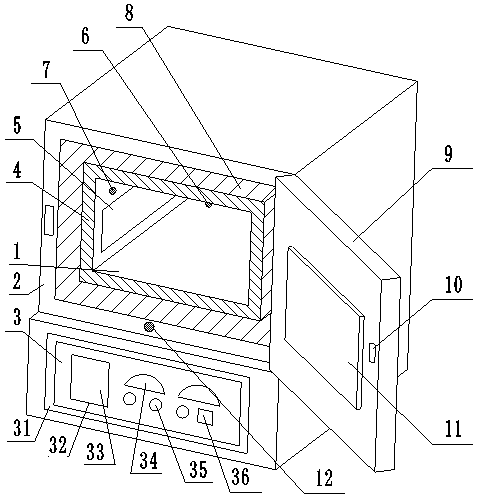

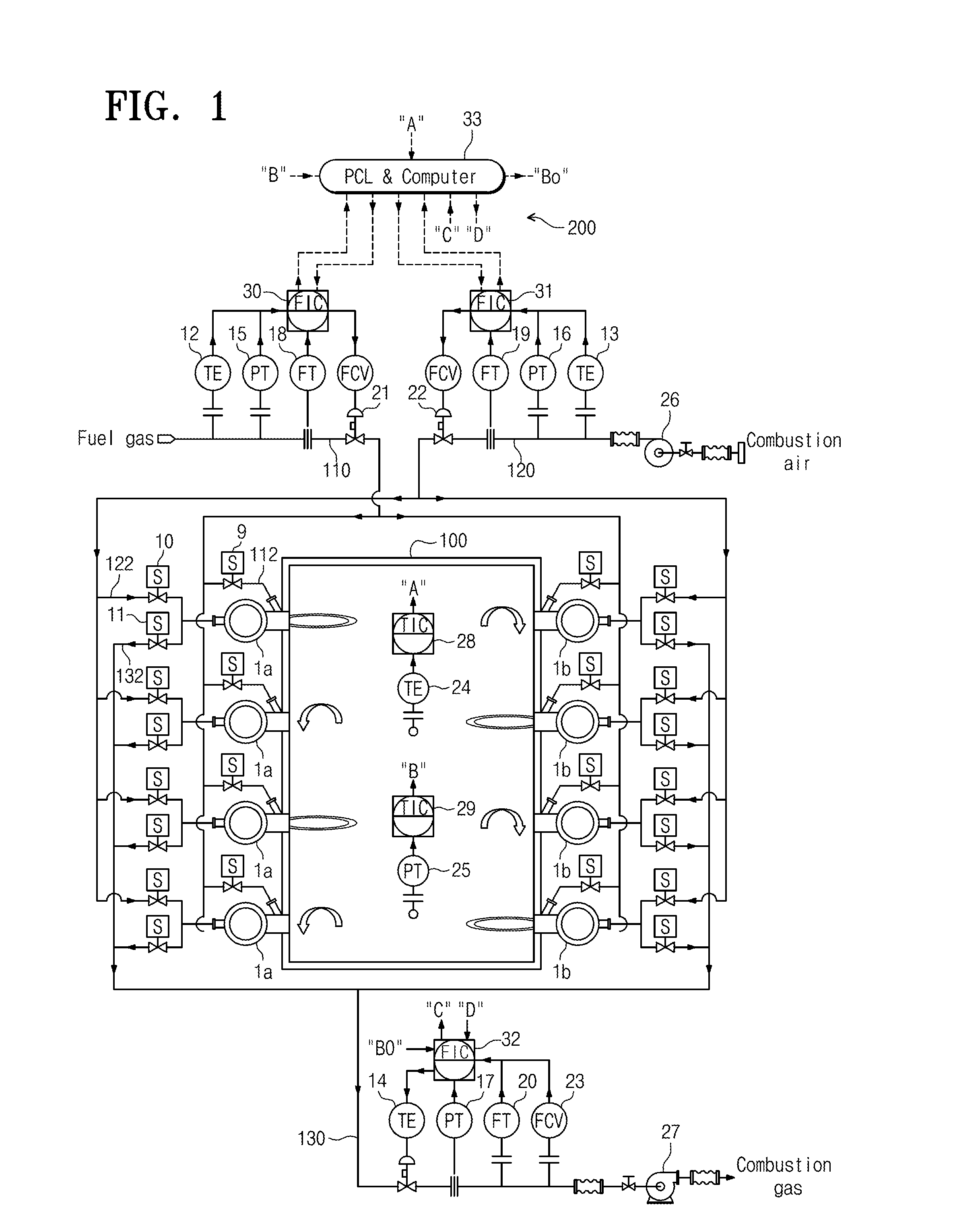

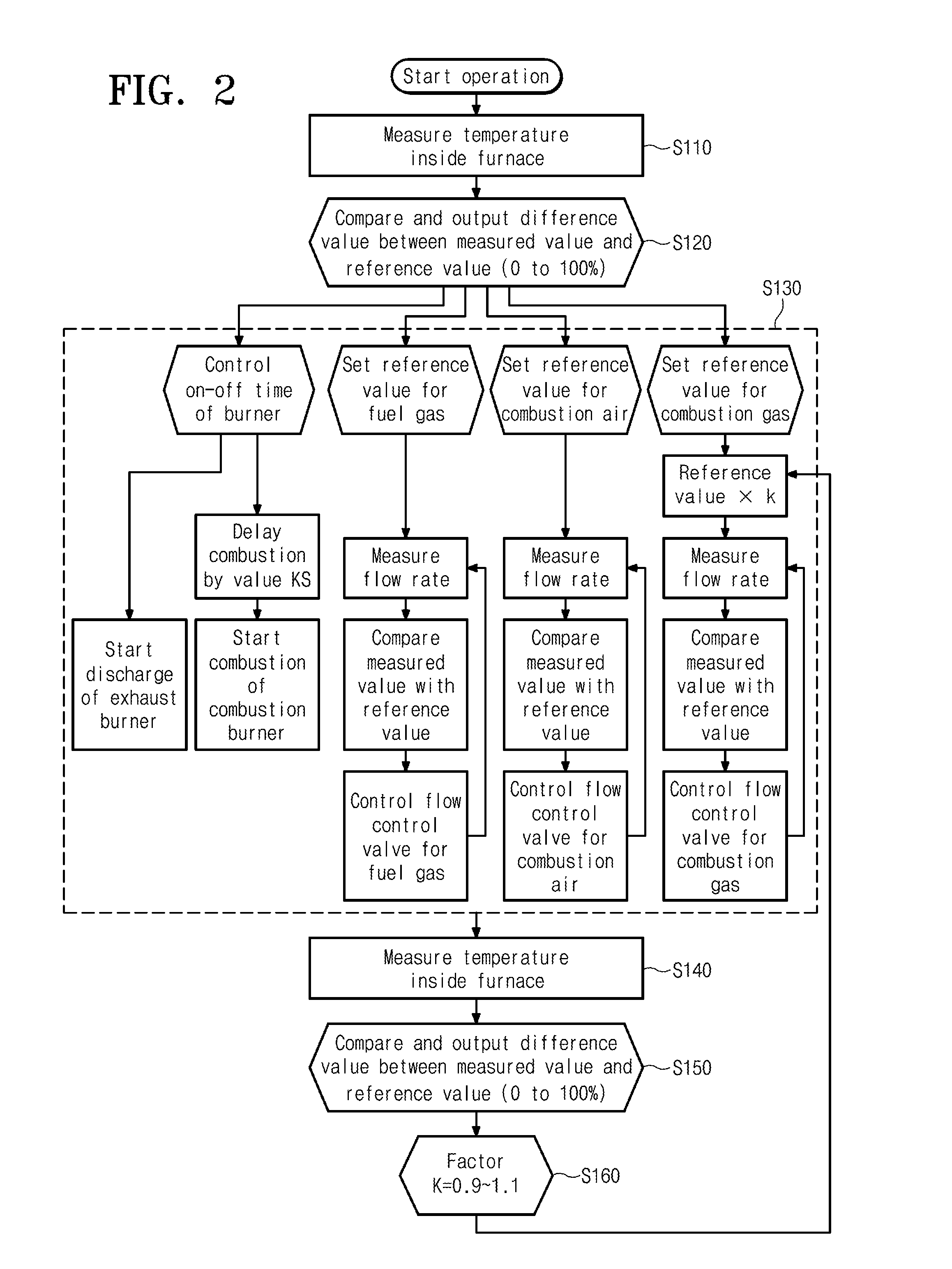

Device and method for controlling combustion exhaust gas of regenerative heating furnace

InactiveCN105408502ARight qualityMaximize savings and efficiencyFurnace typesHeat treatment process controlFurnace temperatureCombustor

The present invention provides a method for controlling the combustion of a regenerative heating furnace. The method for controlling the combustion of a regenerative heating furnace, according to the present invention, comprises: a first step of detecting an in-furnace temperature by using a temperature detection sensor in the heating furnace; a second step of receiving a measured value of the in-furnace temperature, comparing the measured value with a set reference temperature value and outputting an analog signal to a sequence controller according to a value of the comparison; a third step of adjusting combustion, an amount of fuel, an amount of air and a discharge amount of combustion gas of each burner by the sequence controller by means of a program set according to the value outputted in the second step; a fourth step of measuring a pressure in the heating furnace due to the combustion gas according to a combustion load; a fifth step of comparing the measured pressure value with a reference pressure and outputting an analog signal to the sequence controller according to a value of the comparison; and a sixth step of controlling the discharge amount of combustion gas set in the third step by the sequence controller according to the value outputted in the fifth step.

Owner:SAC

Surface detection apparatus of blast furnace burden and detection method

InactiveUS20180209004A1Suppress collisionSurface profile can be correctly and rapidlyWave based measurement systemsBlast furnace detailsEngineeringMechanical engineering

An apparatus includes: a guide portion in which a reflection plate is disposed in an opening portion at one end, and an antenna is disposed at the other end, and which is to be inserted into a blast furnace through an opening of the furnace; a guide portion moving unit which moves the guide portion to the inside or outside of the furnace; a guide portion rotating unit which rotates the guide portion; and a reflection plate tilting unit which changes a tilt angle of the reflection plate with respect to the antenna. During measurement, the opening portion of the guide portion is protruded into the furnace, and the guide portion rotating unit and the reflection plate tilting unit are driven to scan planarly or linearly the surface of a burden in the furnace.

Owner:WADECO

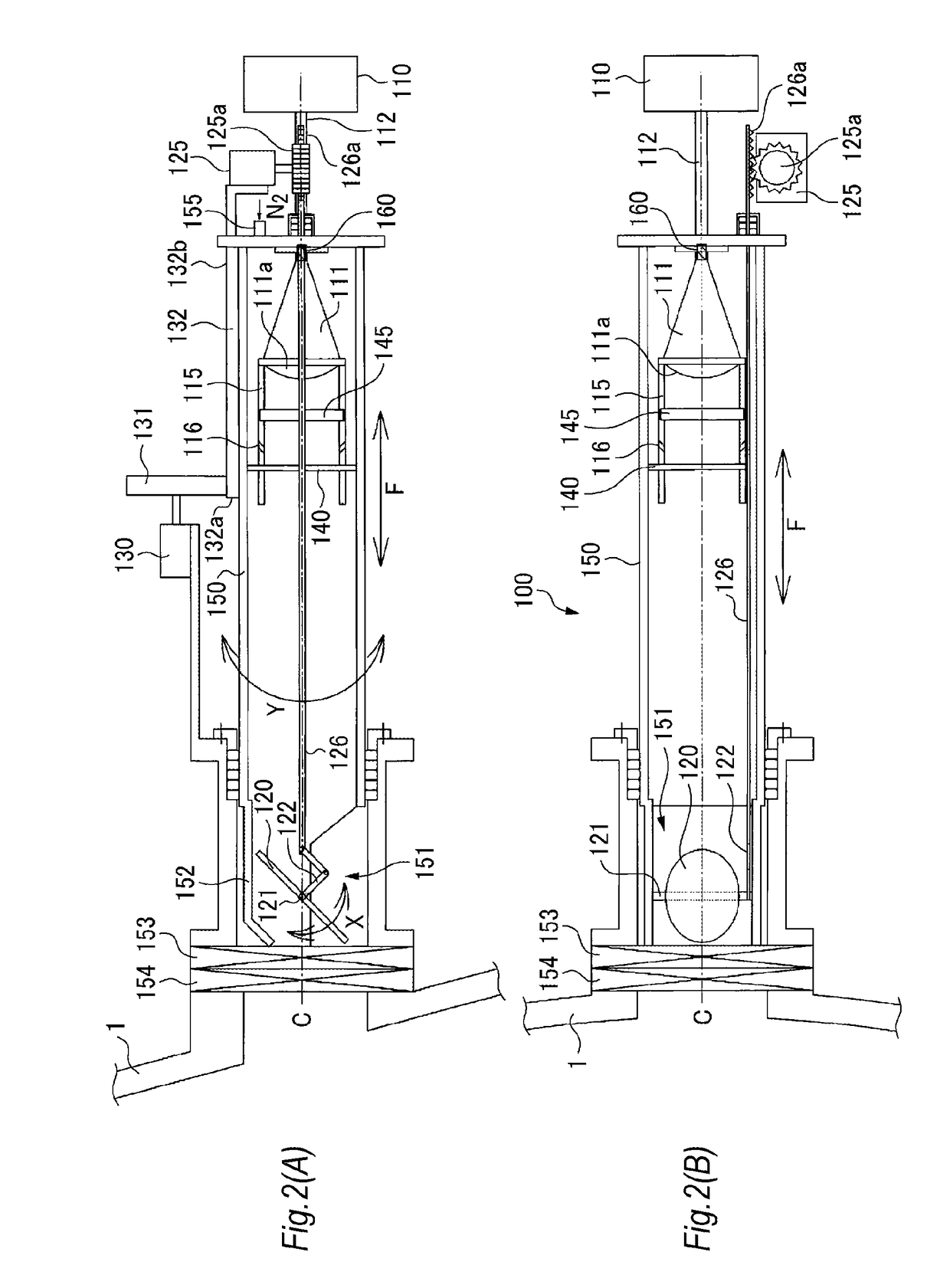

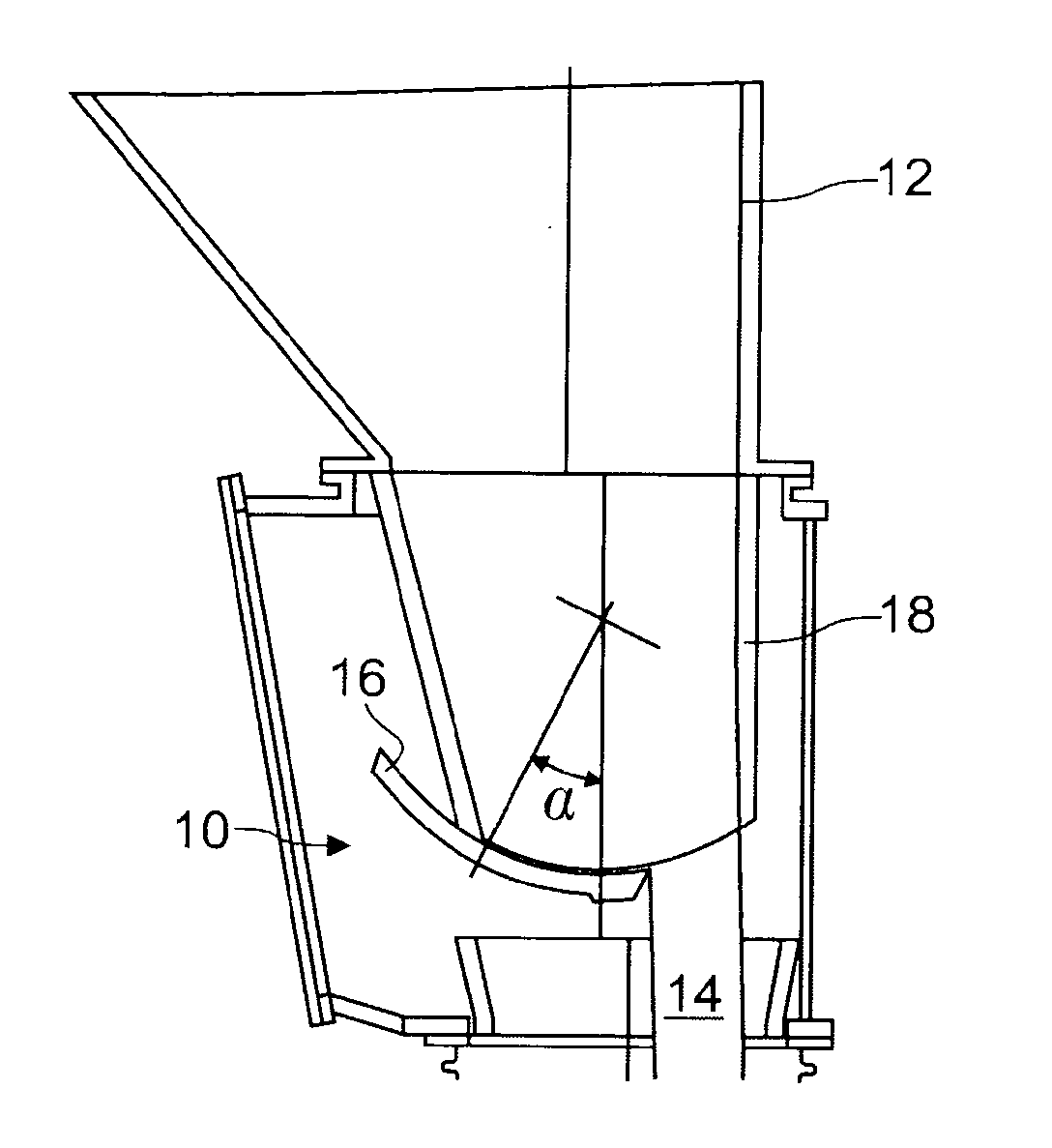

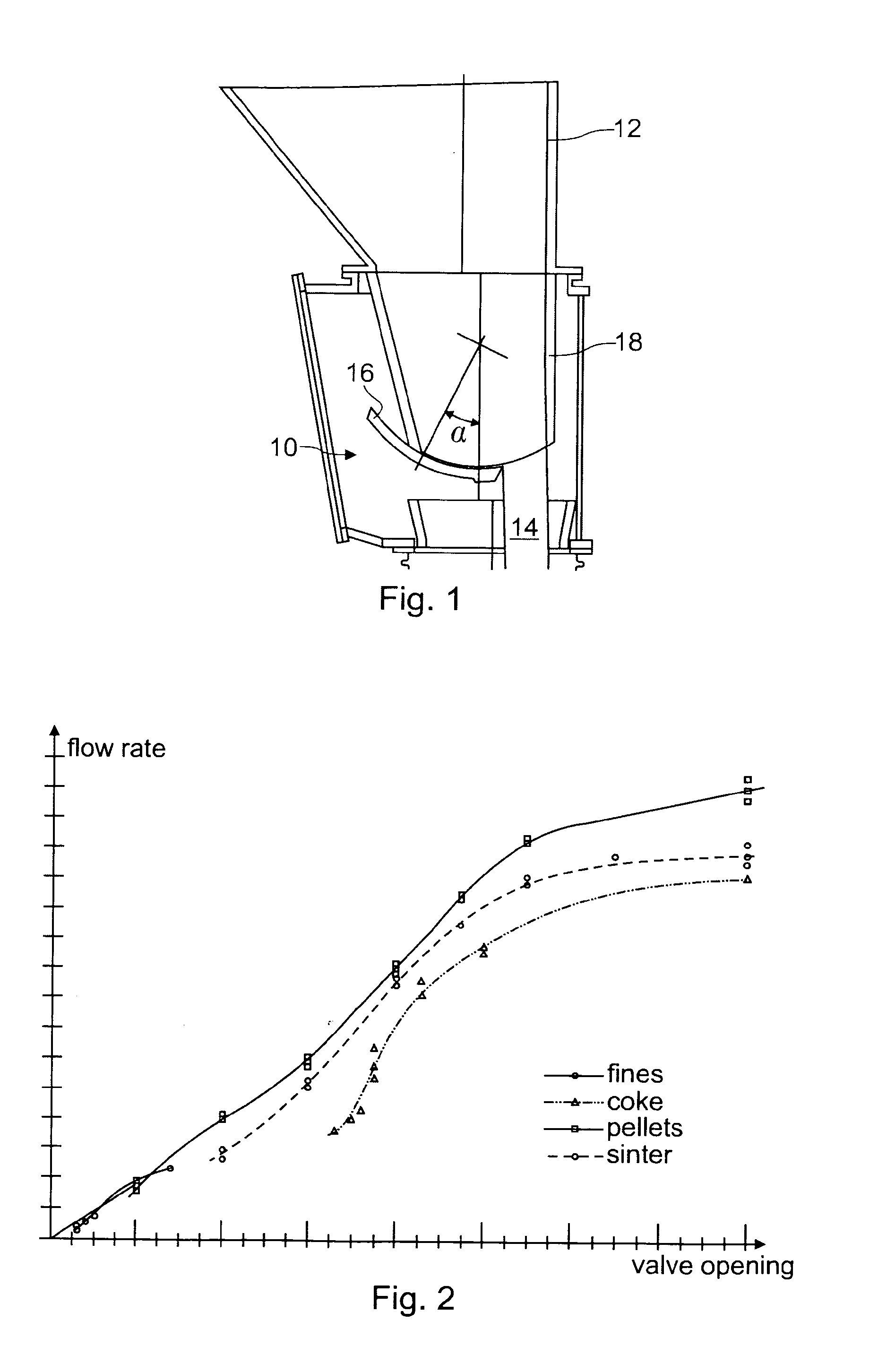

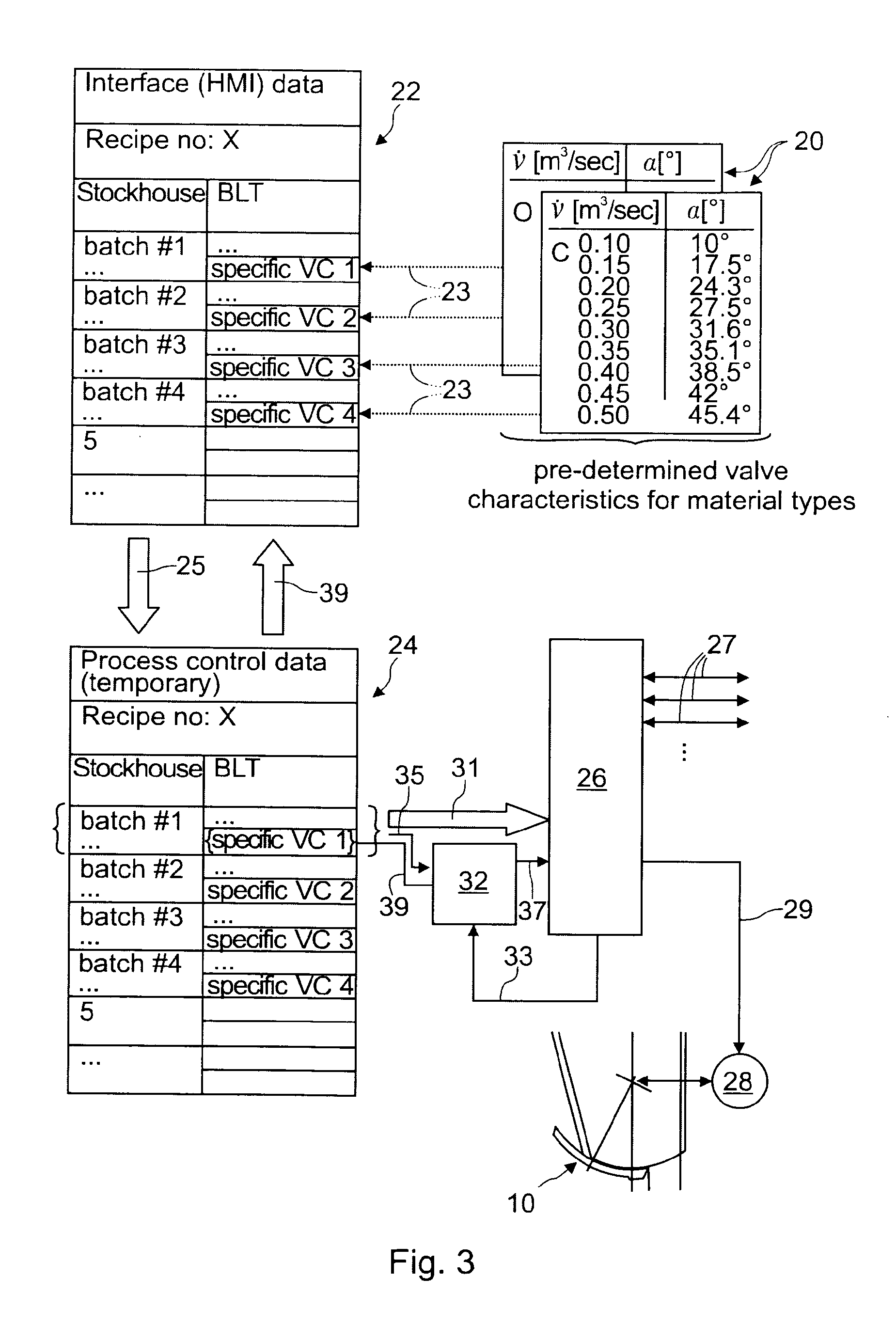

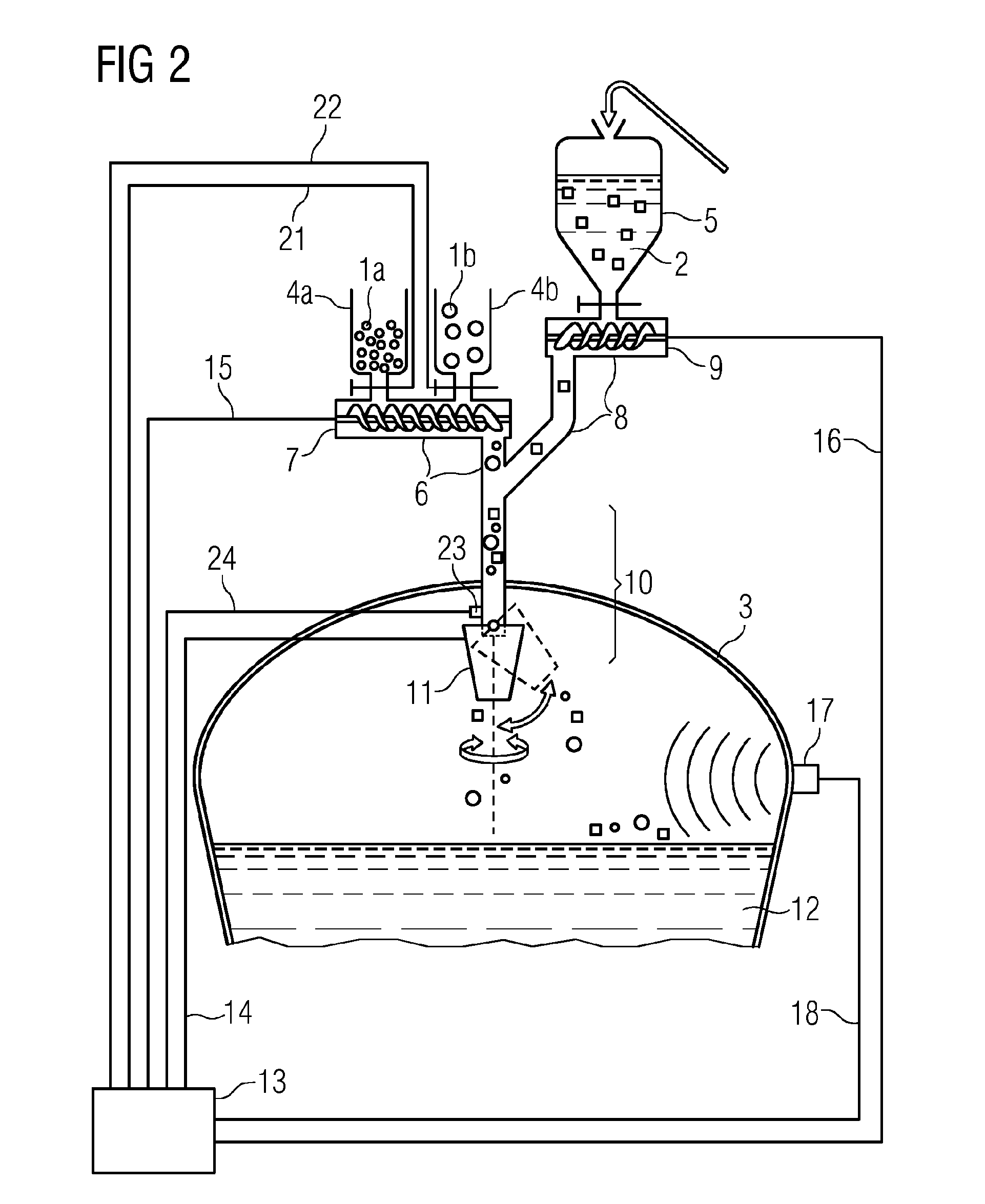

Method and system for adjusting the flow rate of charge material in a charging process of a shaft furnace

ActiveUS20110311926A1Reduce in quantitySteel manufacturing process aspectsBell-and-hopper arrangementEngineeringShaft furnace

In a charging process of a shaft furnace, in particular of a blast furnace, batches of charge material are typically discharged in cyclical sequence into the furnace from a top hopper using a flow control valve. A method and system is proposed for adjusting the flow rate of charge material in such a process. Pre-determined valve characteristics for certain types of material are provided, each indicating the relation between flow rate and valve setting for one type of material. According to the invention, a specific valve characteristic is stored for each batch of charge material, each specific valve characteristic being bijectively associated to one batch and indicating the relation between flow rate and valve setting of the flow control valve specifically for the associated batch. In relation to discharging a given batch of the sequence the invention proposes: using the stored specific valve characteristic associated to the given batch for determining a requested valve setting corresponding to a flow rate setpoint and using the requested valve setting to operate the flow control valve; determining an actual average flow rate for the discharge of the given batch; correcting the stored specific valve characteristic associated to the given batch in case of a stipulated deviation between the flow rate setpoint and the actual average flow rate.

Owner:PAUL WURTH SA

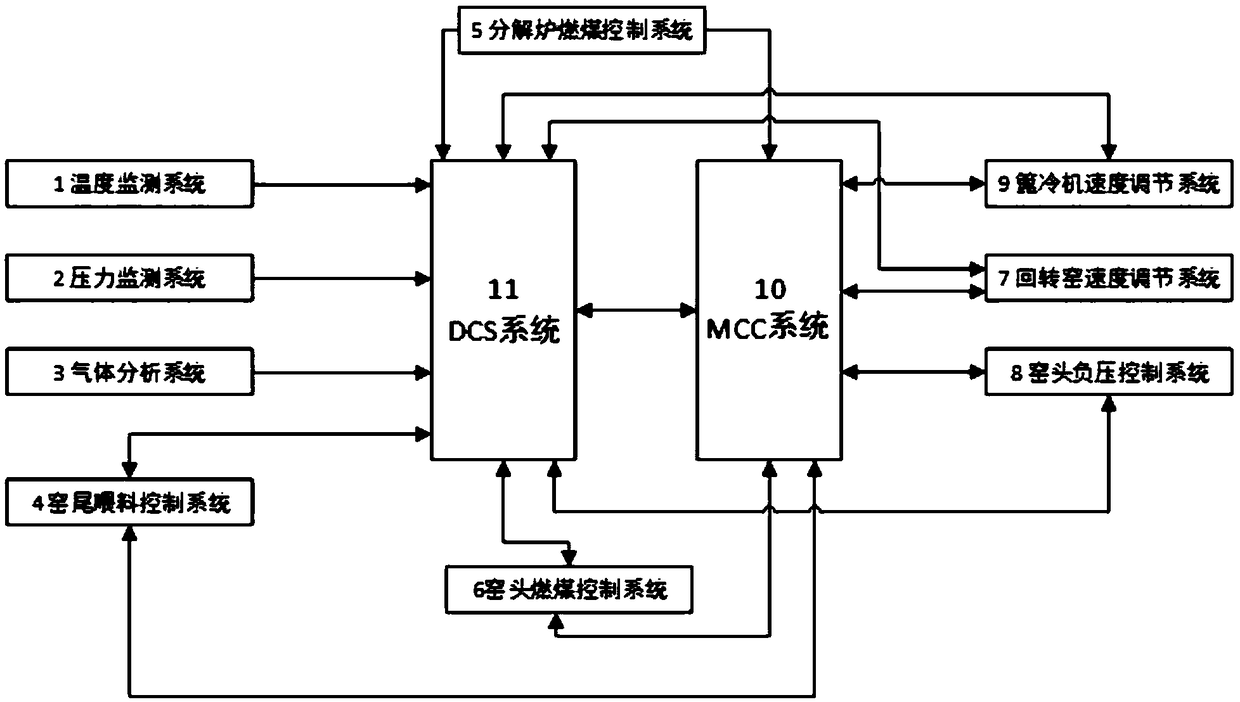

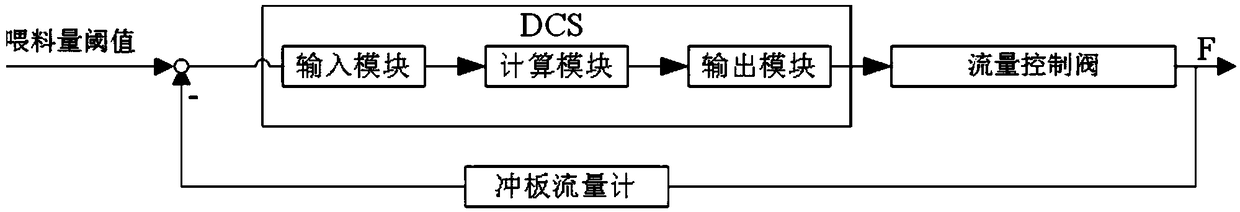

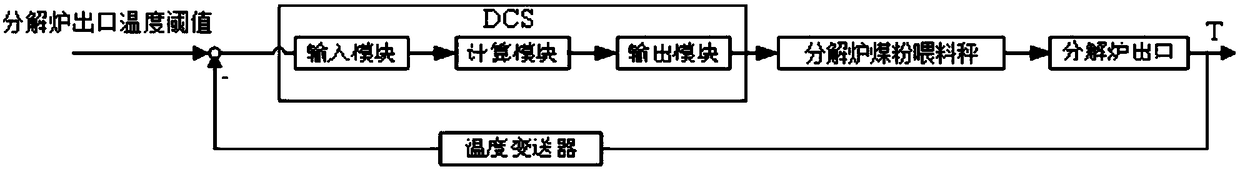

Novel intelligent cement clinker sintering control system

InactiveCN109357539AReduce in quantityReduce points of failureRotary drum furnacesControl devices for furnacesGas analysisControl system

The invention discloses a novel intelligent cement clinker sintering control system. The novel intelligent cement clinker sintering control system comprises a temperature monitoring system, a pressuremonitoring system, a gas analysis system, a kiln tail feeding control system, a decomposing furnace coal-fired control system, a kiln head coal-fired control system, a rotary kiln speed adjusting system, a kiln head negative pressure control system, a grate cooler speed adjusting system, an MCC system and a DCS system; the MCC system is connected with the DCS system; the temperature monitoring system, the pressure monitoring system and the gas analysis system are connected to the DCS system; the kiln tail feeding control system, the decomposing furnace coal-fired control system and the kiln head coal-fired control system, the rotary kiln speed adjusting system, the kiln head negative pressure control system and the grate cooler speed adjusting system are correspondingly connected with theMCC system and the DCS system. The novel intelligent cement clinker sintering control system is high in intelligent degree, labor is greatly saved, full-automatic stable operation can be achieved, and has perfect fault alarming and protecting functions.

Owner:中材海外工程有限公司

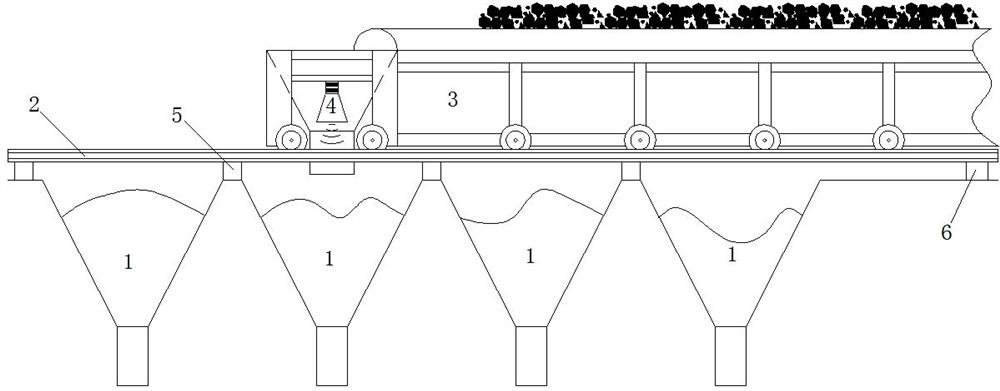

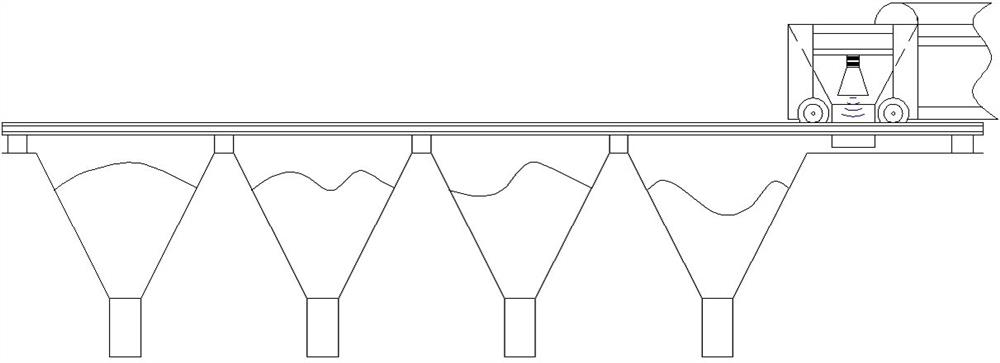

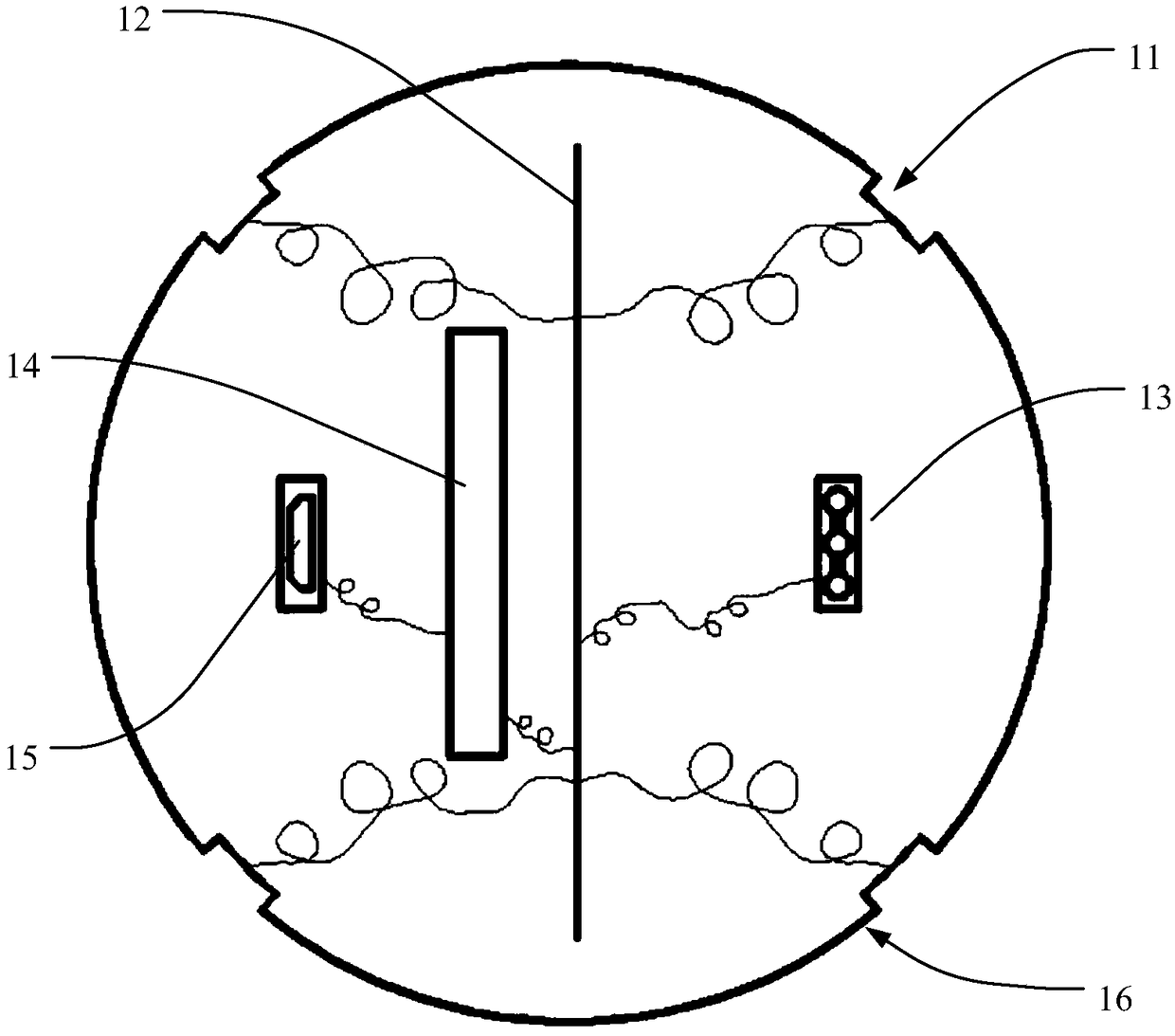

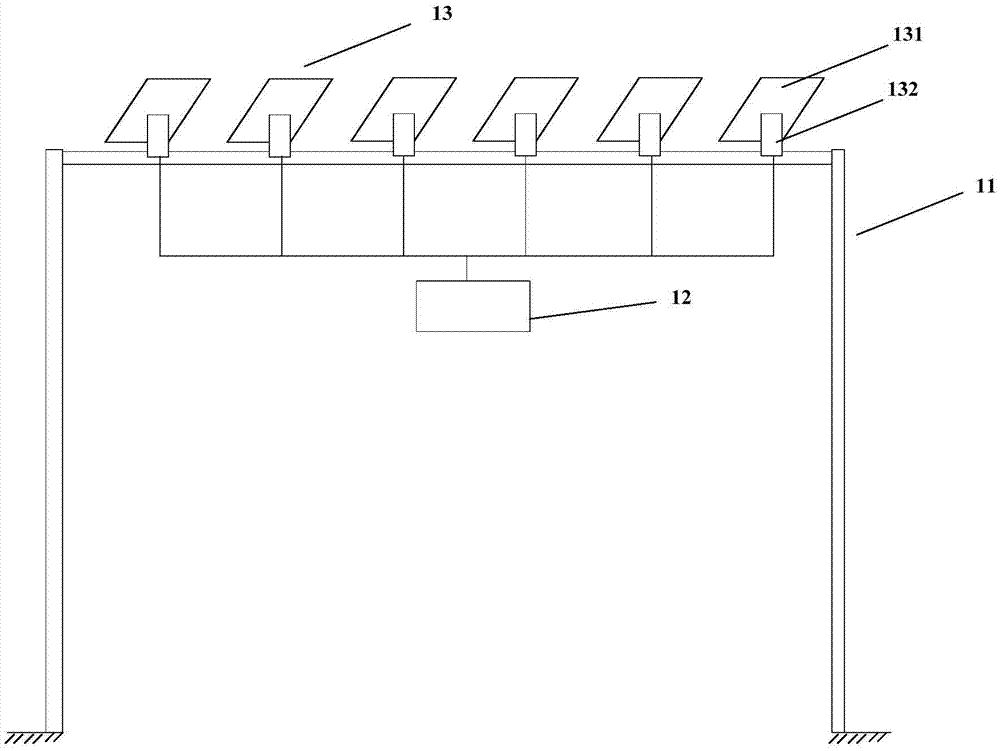

Dynamic monitoring system and method for material levels of stock bins on top of submerged arc furnace

PendingCN113218198ASimple designImprove reliabilityMachines/enginesLevel indicatorsTime informationAutomatic control

The invention relates to a dynamic monitoring system and method for material levels of stock bins on the top of a submerged arc furnace. The system comprises a plurality of stock bins, wherein a guide rail is arranged above the stock bins, a feeding device is slidably arranged on the guide rail and used for feeding all the stock bins, material level instruments are arranged on the feeding device and used for inspecting the material levels of all the stock bins along with the feeding device and generating material level signals, and dynamic monitoring of the material levels of the stock bins is achieved. According to the dynamic monitoring system and method, the material levels of the stock bins are inspected through the at least two material level instruments mounted on the feeding device, the material level signals are output as two sets of continuous curve data containing time information, position information, the material levels of all the stock bins and the material levels between the stock bins, the at least two sets of signals are mutually redundant and mutually overlapped for verification, the reliability is quite high, and a reliable basis is provided for full-automatic control of submerged arc furnace production and optimization of distribution system design.

Owner:SUZHOU SURONG ELECTRIC

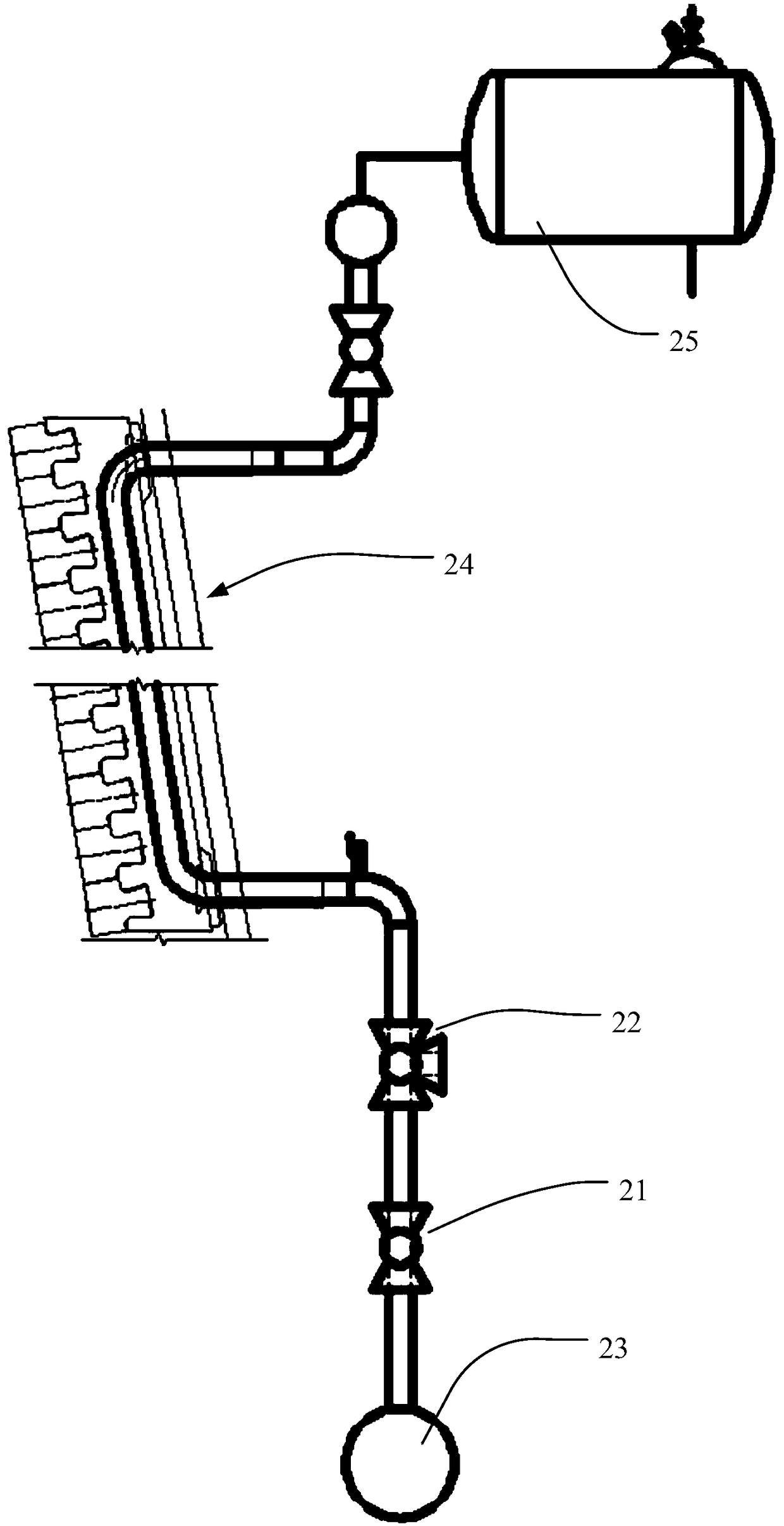

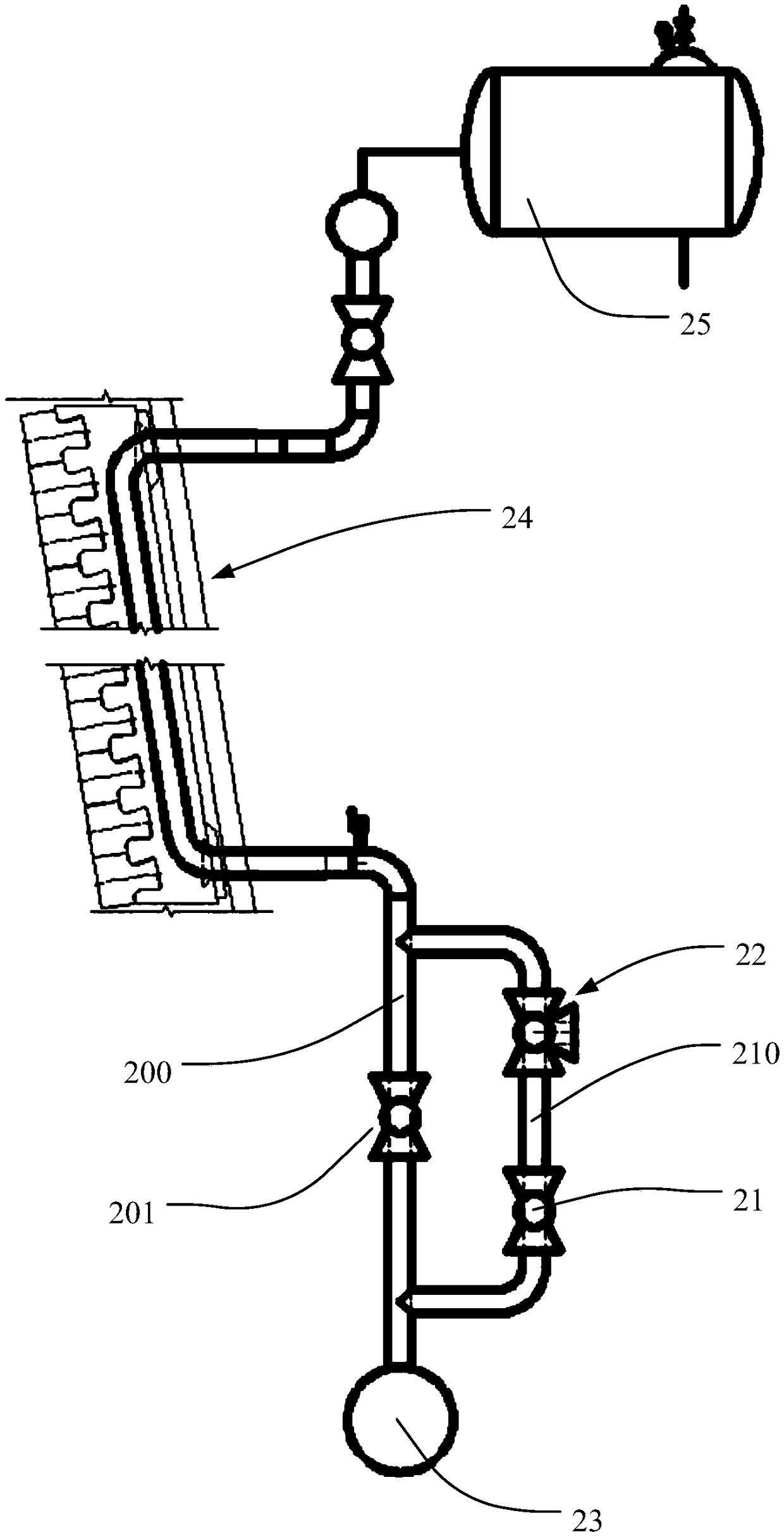

Kiln cooling wall leakage acquisition unit and device and cooling wall detecting method

PendingCN109028992ASolve the problem of inconvenient leak detectionFurnace safety devicesFurnace coolingEngineeringCooling fluid

The invention provides a kiln cooling wall leakage acquisition unit and device and a cooling wall detecting method. The acquisition unit used for acquiring environment information of a cooling wall isprovided, sudden changes of the environment information are read by acquiring the environment information of the cooling wall, and weather the cooling wall has leakage or not and the leaking positionare further judged. By means of the scheme, influences to supply of cooling liquid are small, the acquisition and detection precision is high, and the cooling wall leakage detection precision and convenience are improved.

Owner:CISDI SHANGHAI ENG CO LTD

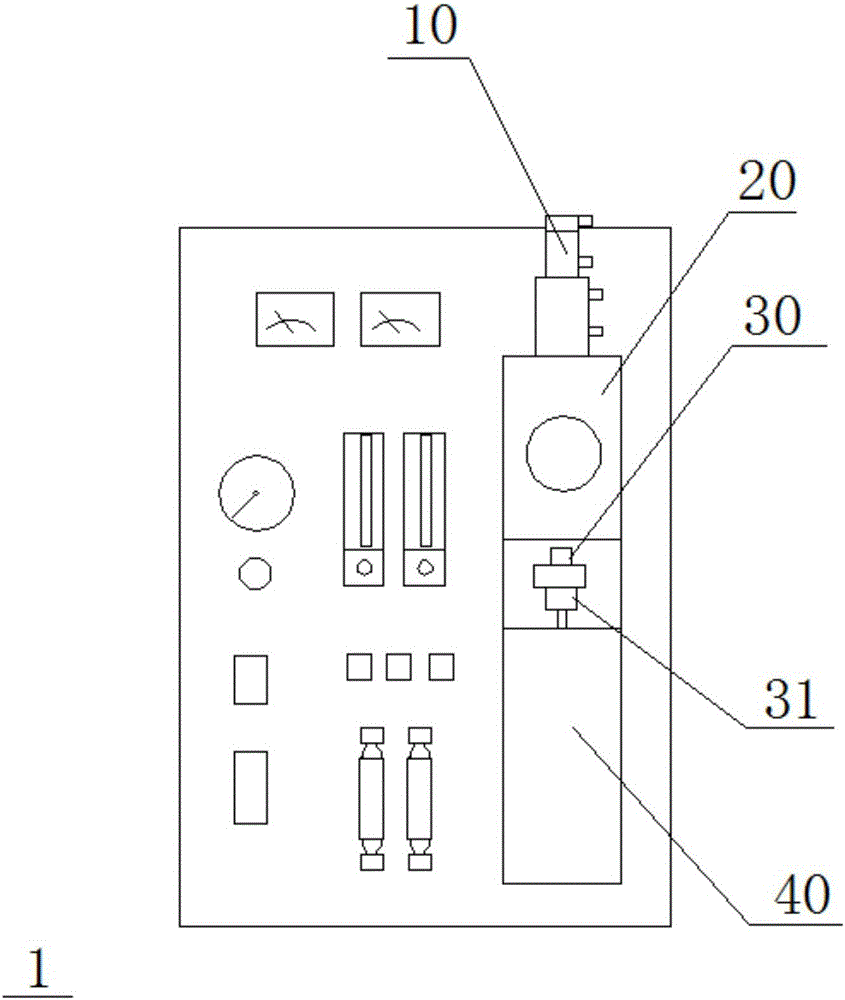

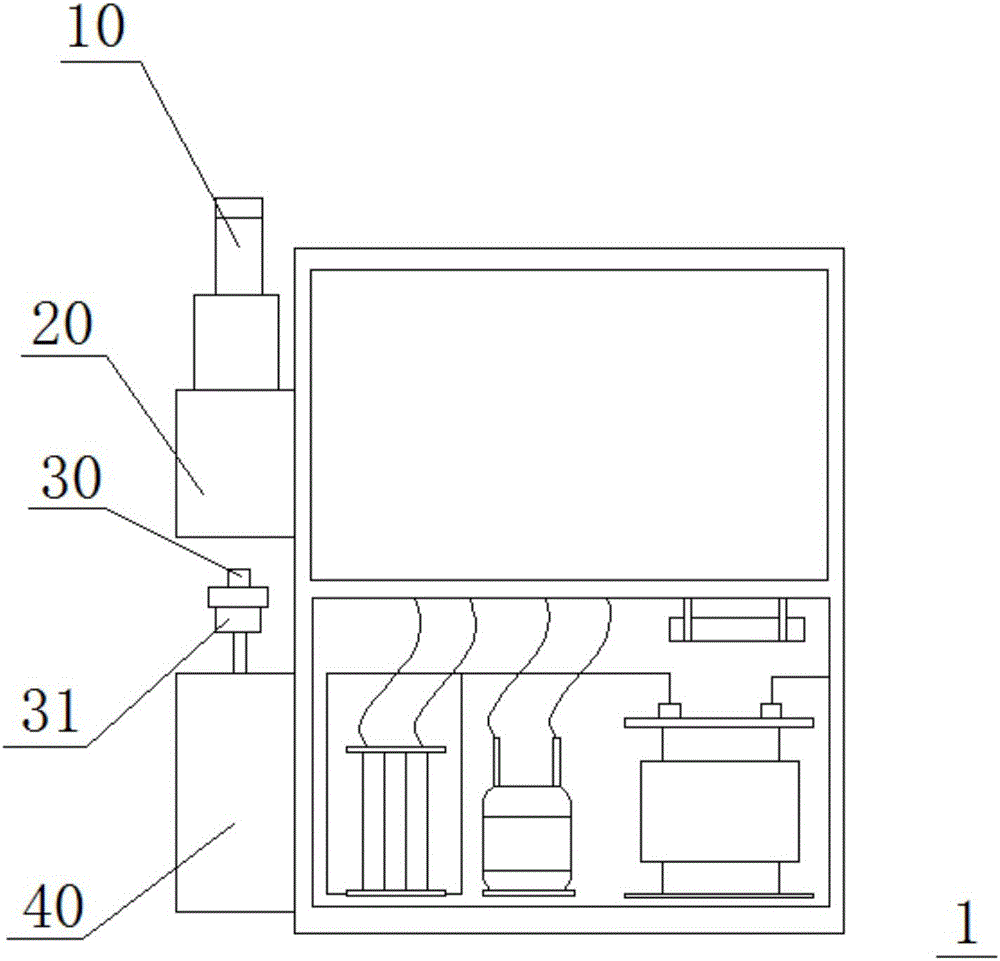

Novel high-frequency furnace and infrared carbon and sulfur analyzer

PendingCN106766913AReduced transfer steps into cruciblesLow costPreparing sample for investigationCharge manipulationCombustion chamberCrucible

The invention relates to a novel high-frequency furnace and an infrared carbon and sulfur analyzer. The novel high-frequency furnace comprises a furnace end and a combustion chamber and is further provided with a crucible and a crucible support. A weight measuring unit is arranged on the crucible support and used for measuring the weight of a sample placed in the crucible. Compared with an existing high-frequency furnace, according to the novel high-frequency furnace provided by the invention, the sample to be detected can be directly weighed through the weight measuring unit arranged on the crucible support, then the crucible is fed into the combustion chamber to be heated, the step that an operator weighs a sample through an electronic scale and then transfers the sample into the crucible is omitted, and the situation that in the sample transferring process, a part of the sample is omitted, the weight of the weighed sample is inconsistent with the weight of the heated sample, and accordingly the final analysis result has a certain error is avoided; and in addition, due to the fact that the sample is transferred manually, the operation steps of the operator are increased to a certain extent, and time is wasted.

Owner:NANJING QILIN SCI INSTR GRP CO LTD

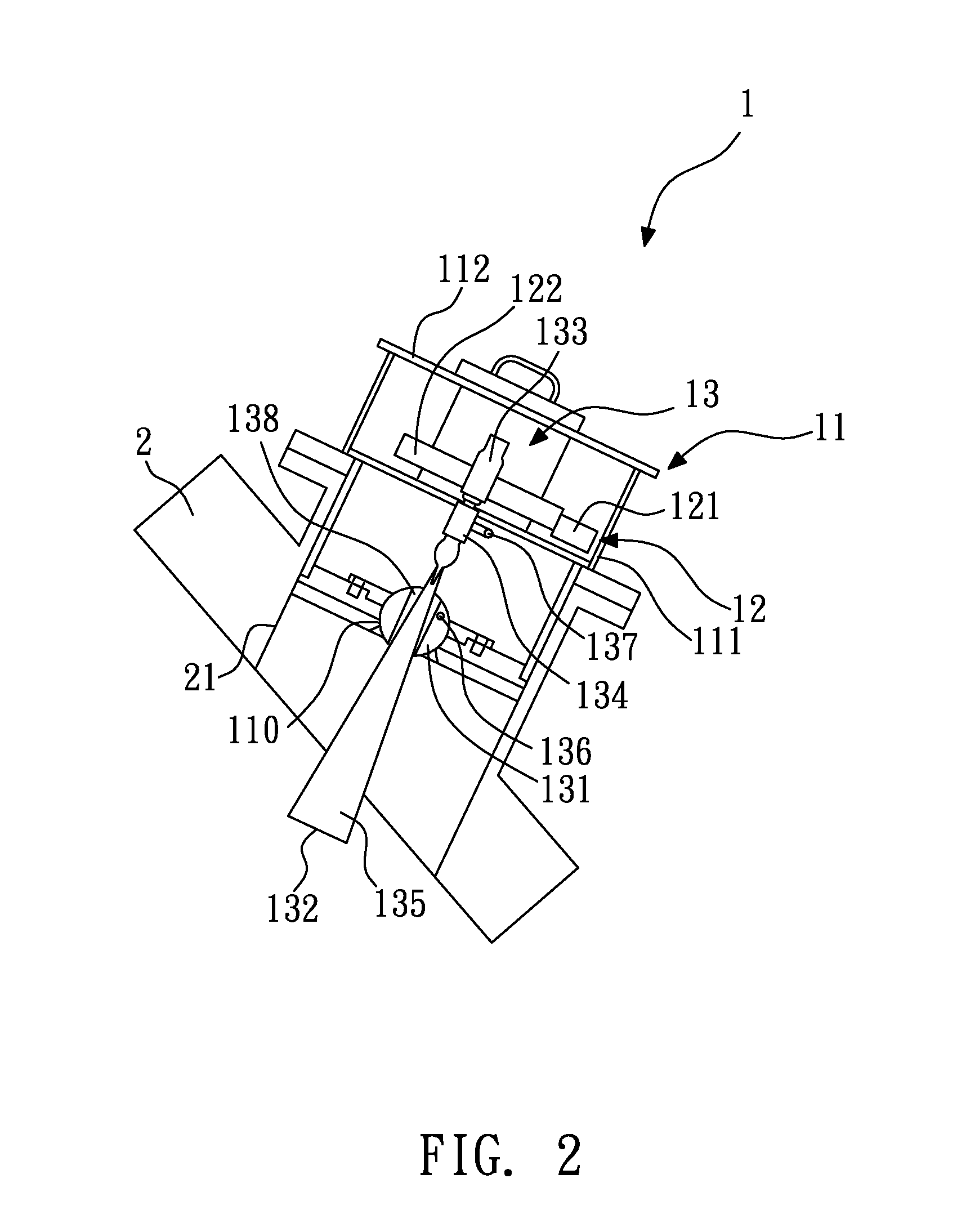

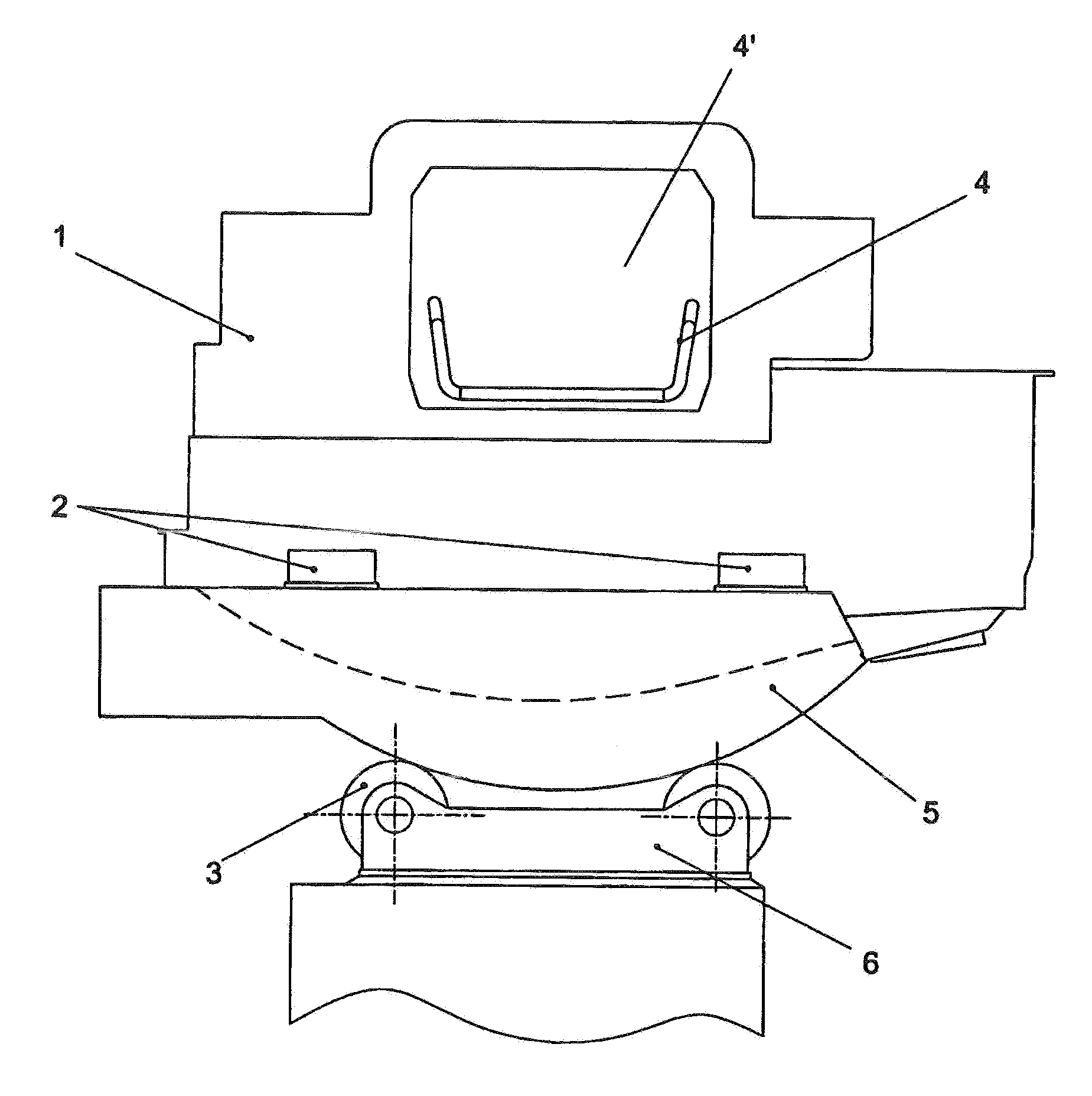

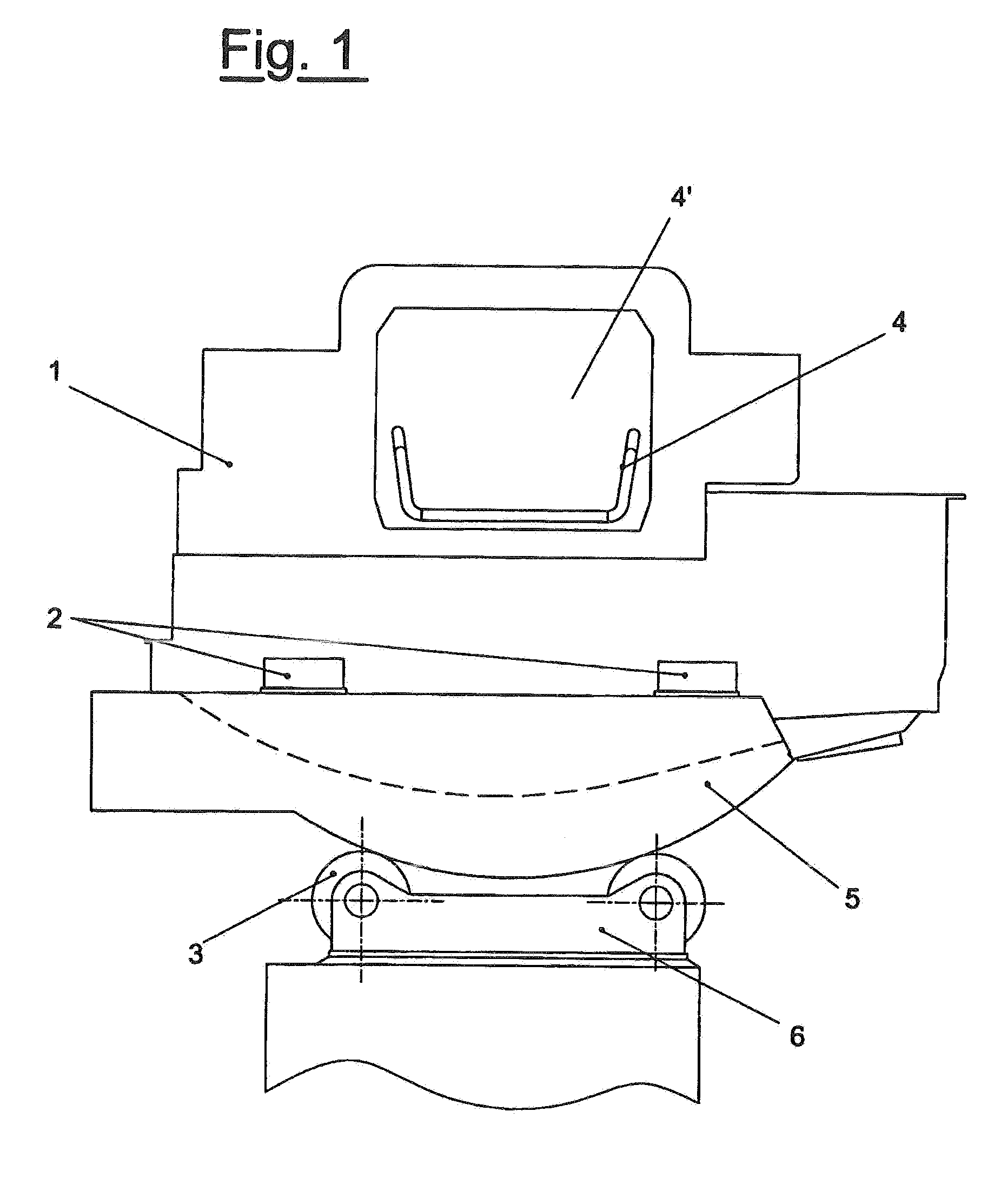

Equipment for measurement and control of load material or scrap feeding into a furnace and relative method

ActiveUS20160061529A1Simple economicalFunction increaseMetal recyclingSteel manufacturing process aspectsMelting tankElectric arc furnace

Equipment for the measurement and control of load material and scrap metal feeding into an electrical arc furnace includes an automatic control device for feeding control of load material or scrap according to the energy supplied to the bath, and a measuring device for the added load material, in correlation with the automatic control device, and a weighing device for the furnace shell, its contents and any other components it may support.

Owner:TENOVA

Device and method to control the charge in electric arc furnaces

Device to control the feed of the metal charge in an electric arc furnace, comprising a conveyor associated at the end to a feed mouth provided in said electric arc furnace and, in cooperation with the conveyor, at least a system to detect the point-by-point profile of the metal charge present on the conveyor.

Owner:DANIELI AUTOMATION SPA

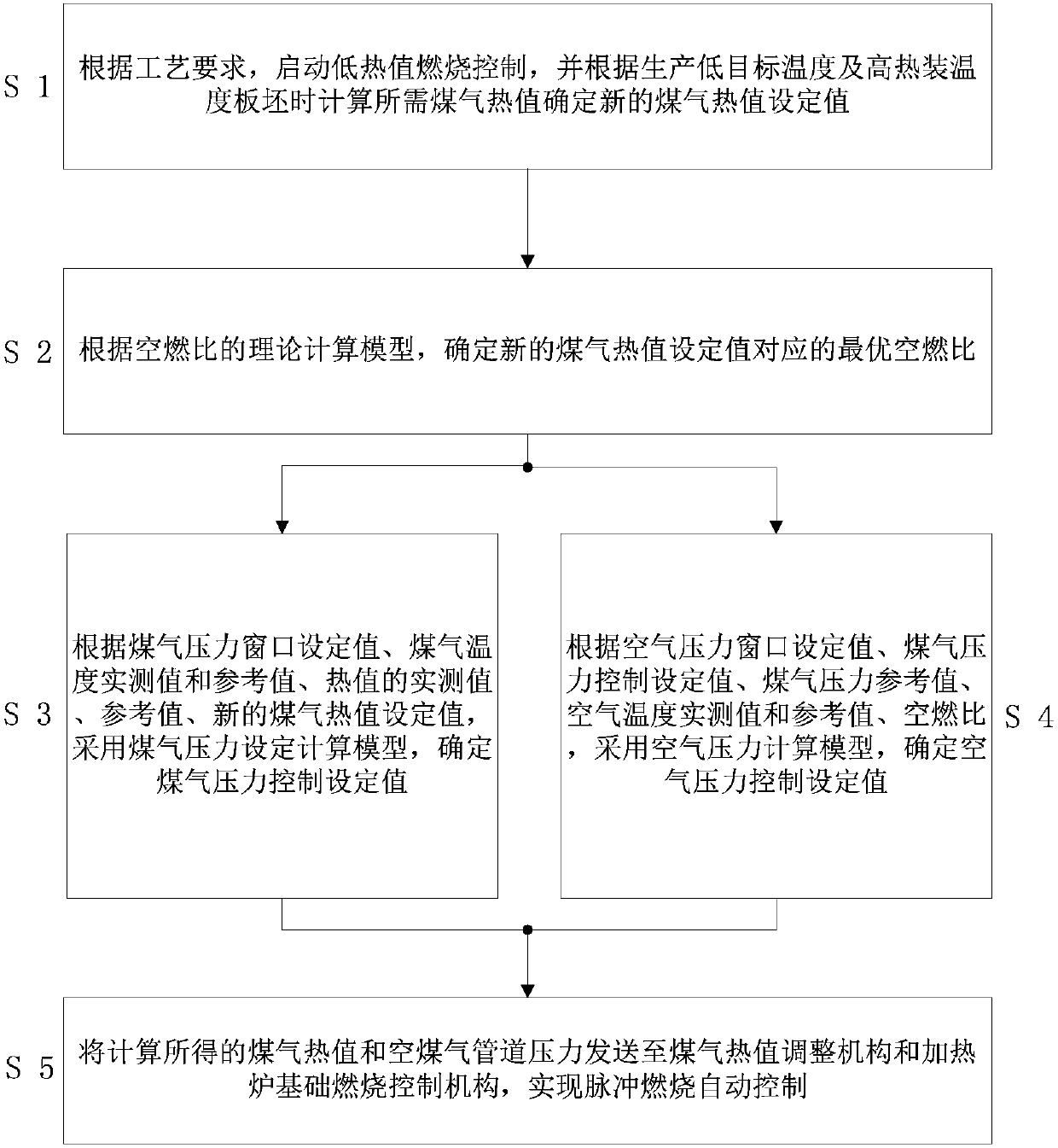

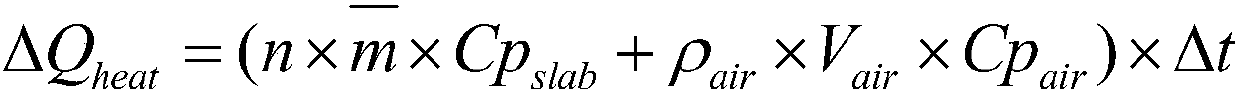

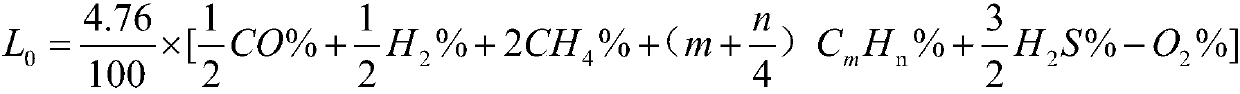

Combustion control method for hot rolling pulse heating furnace

InactiveCN108800968AExtended burn timeReduce switching timesControl devices for furnacesFurnace monitoring devicesProcess engineeringHeating furnace

The invention discloses a combustion control method for a hot rolling pulse heating furnace, and the combustion control method is suitable for low heating loads and particularly suitable for pulse combustion during low-target-temperature and high-hot-charging-temperature slab production. On the basis of pulse combustion, for the low heating loads, low-heating-value combustion control is introduced, the gas heating value corresponding to the low loads is calculated, and the air-fuel ratio and the air-gas pipeline pressure needed for pulse combustion on the basis of gas heating value are established, the gas heating value and the air-gas pipeline pressure obtained through calculation are sent to a gas heating value adjusting mechanism and a heating furnace base combustion control mechanism,automatic pulse combustion control is achieved, and accordingly the purposes that the pulse nozzle combustion time is prolonged, the nozzle valve opening and closing frequency is reduced, and the furnace interior temperature uniformity is improved are achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

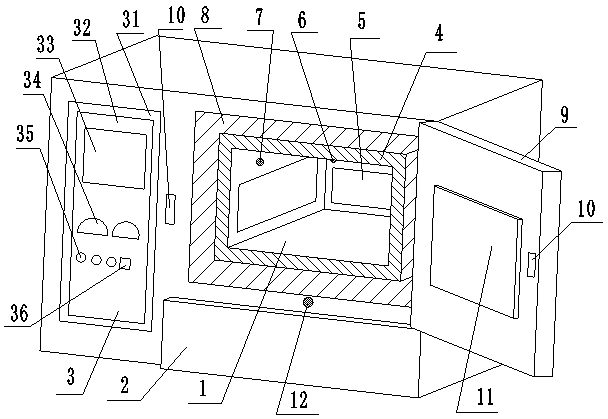

Box type electric furnace with intelligent temperature control function

InactiveCN110763038ASimple structureEasy to operateControl devices for furnacesFurnace monitoring devicesTemperature controlCombustion chamber

The invention discloses a box type electric furnace with an intelligent temperature control function. The box type electric furnace with the intelligent temperature control function comprises a combustion chamber, a furnace body and a control system. A heat-resistant layer and a heating device are arranged in the combustion chamber, a pressure sensor and a temperature sensor are further arranged in the combustion chamber, and a heat preservation layer is arranged between the combustion chamber and the furnace body. A furnace door is arranged on one side of an opening of the combustion chamberand arranged in the furnace body in a hinge joint mode, and locking mechanisms which cooperate with each other are arranged on the furnace door and the furnace body. A heat insulation layer is furtherarranged on the inner side face of the furnace door, and an inductive switch which cooperates with the furnace door is arranged in the furnace body. The heating device, the pressure sensor, the temperature sensor, the locking mechanisms and the inductive switch are electrically connected with the control system. By the adoption of the box type electric furnace, the box type electric furnace withthe intelligent temperature control function has the advantages of being simple in structure, convenient to operate and use, flexible and adjustable in heating range, high in heat efficiency and goodin heat stability, having the function that a power source can be disconnected when the door is opened, being high in safety and high in practicability and being particularly suitable for popularization and application.

Owner:贵州云弗电炉制造有限公司

Apparatus and method of controlling combustion exhaust for regenerative heating furnace

InactiveUS20160161119A1Consumption energy can be savedMaximize efficiencyFurnace typesHeat treatment process controlCombustorProcess engineering

Provided is a method of controlling combustion of a regenerative heating furnace. The method controlled includes: a first step of sensing the temperature inside the furnace by a temperature sensor inside the heating furnace; a second step of receiving the measured temperature value inside the furnace, comparing the measured temperature value with a set reference temperature value, and outputting, to a sequence controller, an analog signal corresponding to a difference between the measured temperature value inside the furnace and the set reference temperature value; a third step of controlling combustion, and amounts of fuel, air, and discharged combustion gas of each of the burners by the sequence controller by a program set according to the outputted value in the second step; a fourth step of measuring the pressure inside the heating furnace due to combustion gas according to a combustion load; a fifth step of comparing the measured pressure value with the reference pressure, and outputting, the sequence controller, an analog signal corresponding to a difference between the measured pressure value and the reference pressure; and a sixth step of controlling, according to the outputted value of the fifth step, the discharge amount of combustion gas set in the third step by the sequence controller.

Owner:SAC

Resident measurement system for charge level of blast furnace

InactiveUS8568652B2Small dimensionEnsure safetyBlast furnace detailsChecking devicesHigh concentrationEngineering

Owner:CHINA STEEL

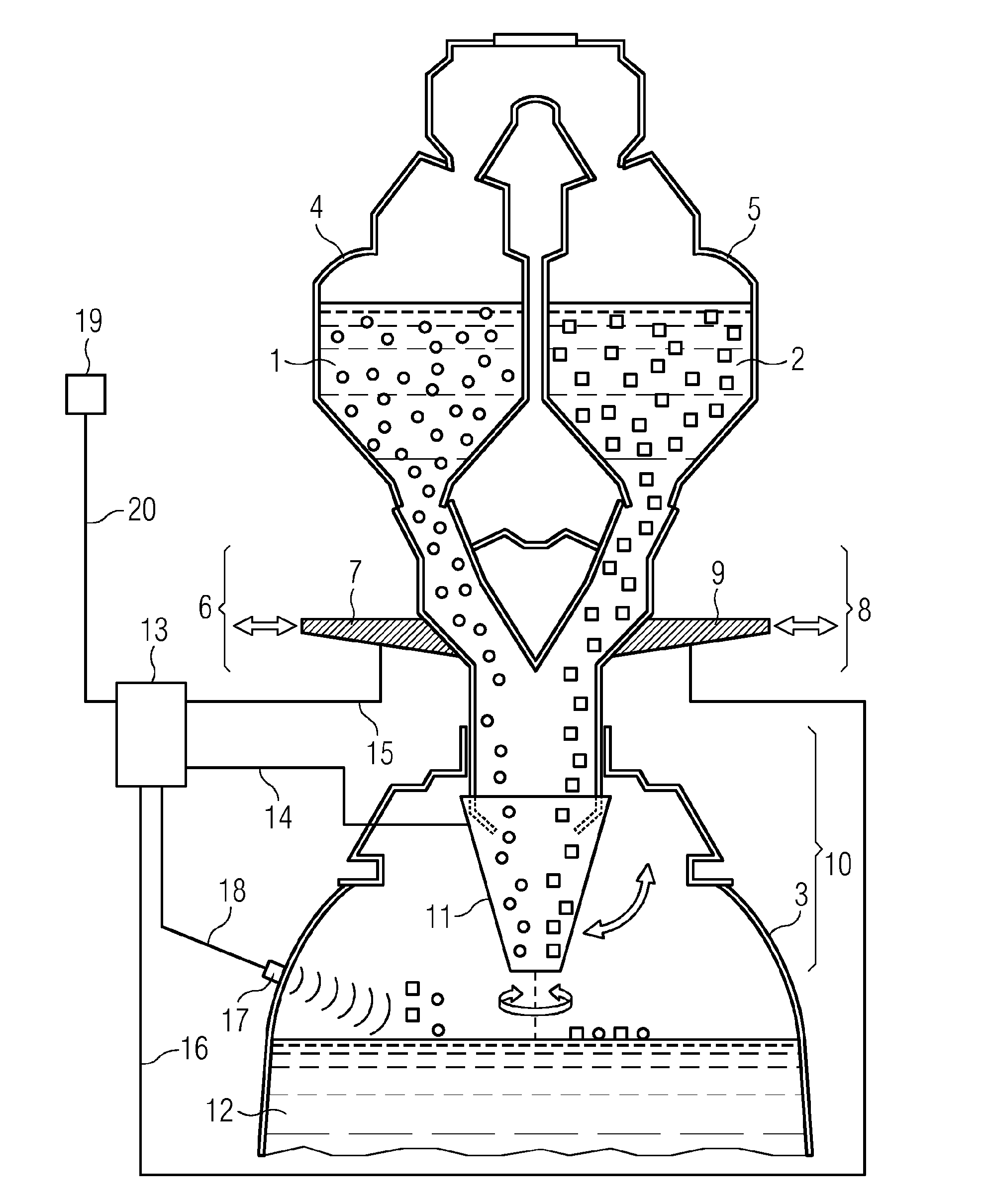

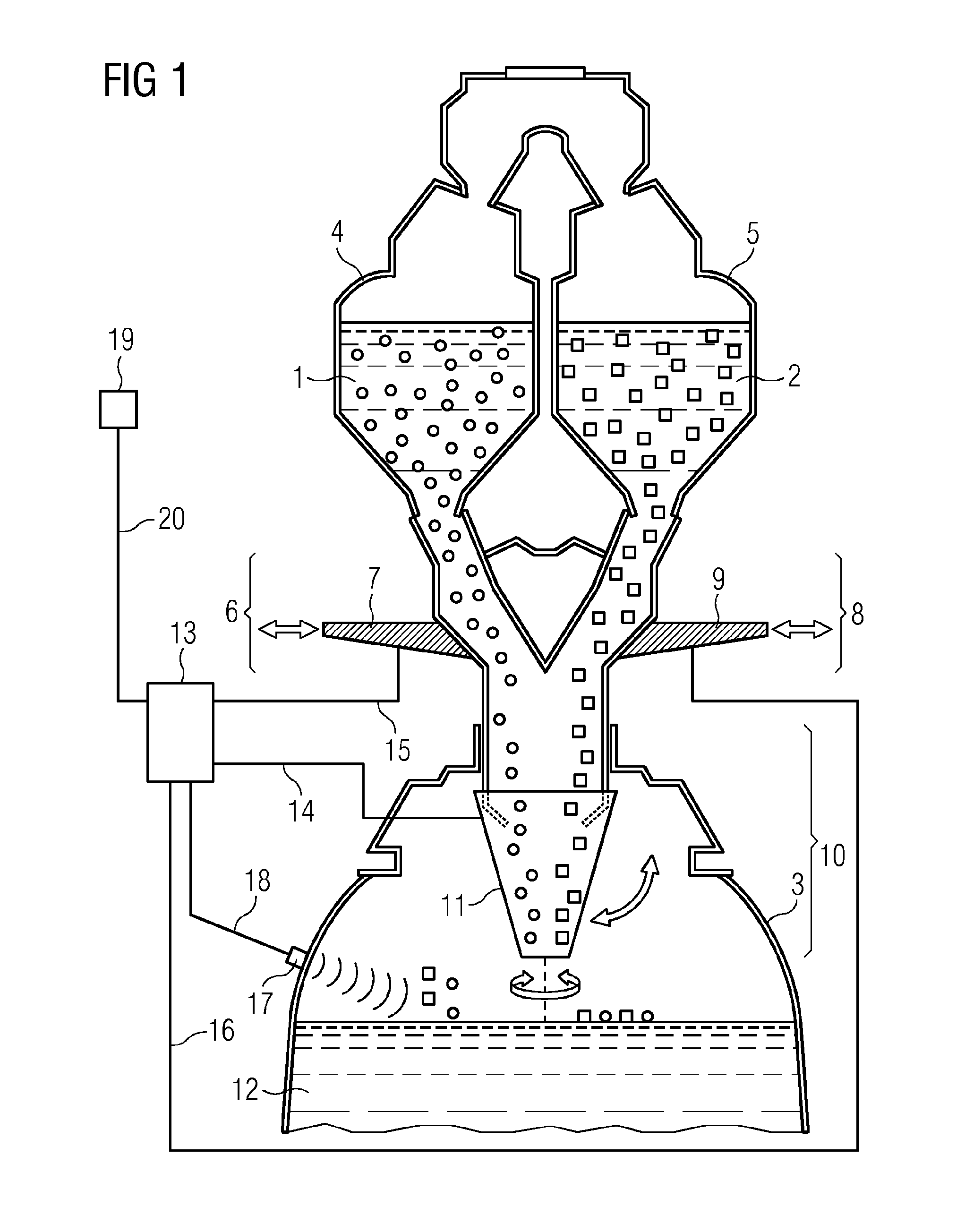

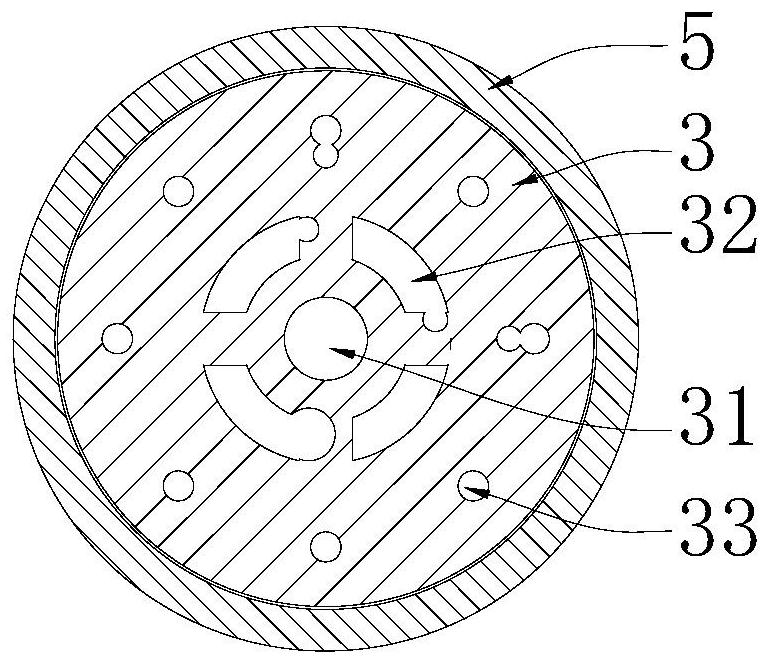

Method and device for charging coal-containing material and iron carrier material

ActiveUS20140110891A1Few partsReduce riskCharge manipulationControl devices for furnacesCoalMaterials science

A melter gasifier of a smelting reduction installation is charged by bringing together coal-containing material in lump form and iron carrier material (which may be hot) before and / or while they enter the melter gasifier. The ratio of the combined amounts of iron carrier material and coal-containing material in lump form is variable. The combined amounts of iron carrier material and coal-containing material in lump form are distributed over the cross section of the melter gasifier by a dynamic distributing device, and the ratio of the combined amounts of the iron carrier material and coal-containing material in lump form is set depending on the position of the dynamic distributing device.

Owner:POHANG IRON & STEEL CO LTD +1

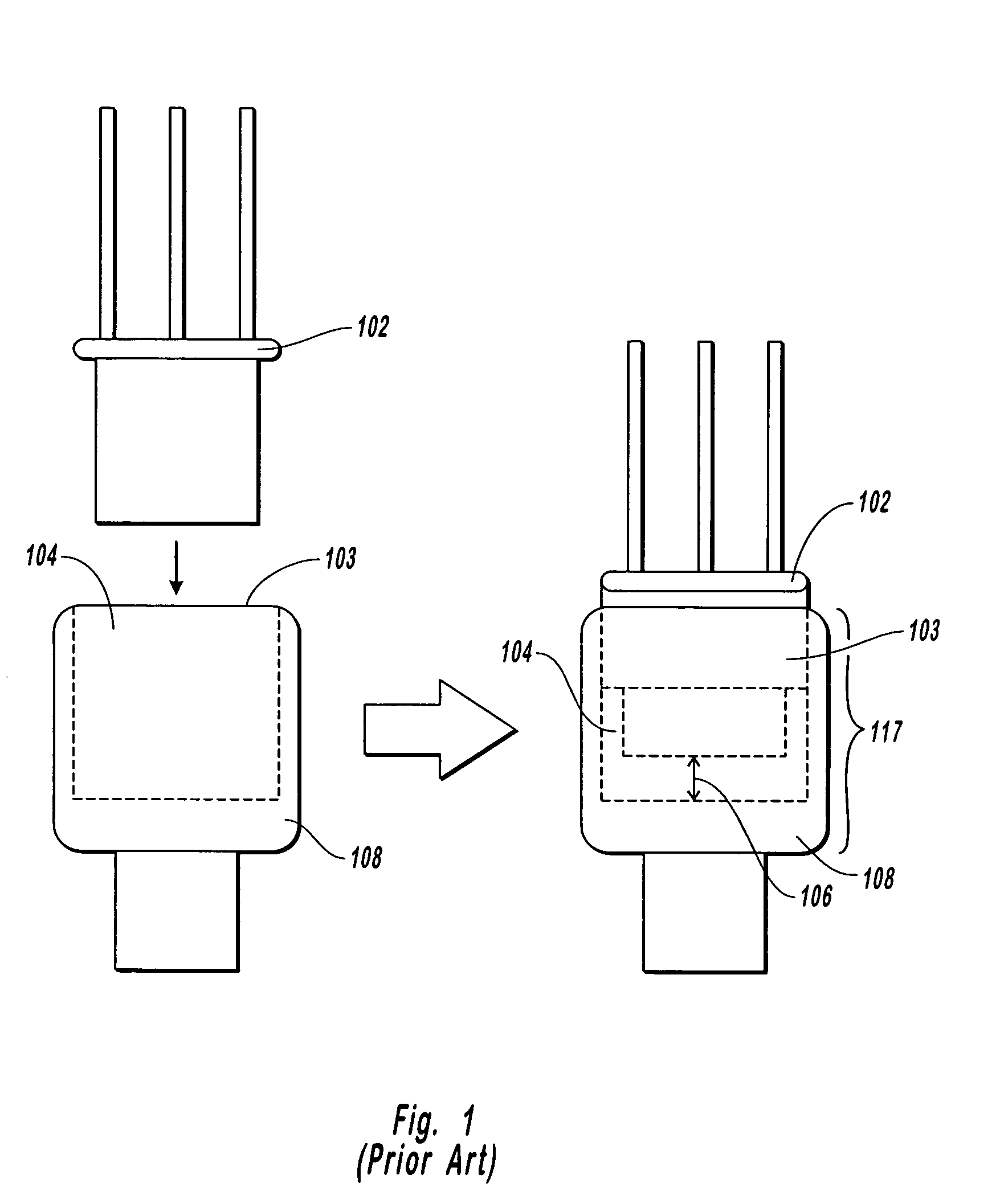

A solids injection lance

ActiveUS20160153715A1Minimises riskMinimises safety concernTuyeresCharge manipulationEngineeringSolid material

A solids injection lance includes (a) a tube that defines a passageway for solid feed material to be injected through the tube and has an inlet for solid material at a rear end and an outlet for discharging solid material at a forward end of the tube and (b) a puncture detection system for detecting a puncture in the solids injection tube.

Owner:TATA STEEL

Method for recovering electrolyte by pyrogenic process roasting of electrolytic aluminum carbon slag

PendingCN111850608AAvoid corrosionImprove memory lifeMaintainance of heating chambersIncreasing energy efficiencySlagFlue gas

The invention discloses a method for recovering electrolyte by pyrogenic process roasting of electrolytic aluminum carbon slag. The method is characterized in that the carbon slag is roasted in a smelting furnace to extract the electrolyte, the generated liquid electrolyte is solidified and conveyed through a mold vehicle, and a product is crushed through a crusher, conveyed through a belt, bagged, and returned to an electrolytic cell for production. The method can achieve the following goals that 1), the electrolyte is extracted from the carbon slag, a carbon impurity component is lower than0.5%, and the electrolyte can be directly returned to the electrolytic cell for use; 2), waste heat of smelting furnace flue gas is recovered, the thermal efficiency of the smelting furnace is improved, and a flue gas cooling treatment process is simplified; 3), the problem of blockage of a conventional heat accumulating type furnace heat accumulator is avoided; 4), the problem that a conventionalfurnace lining is prone to corrosion is avoided, and the service life of the lining is greatly prolonged; 5), slagging-off operation is reduced or even avoided; and 6), a workshop working environmentis purified.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Intelligent coal gangue activation device

PendingCN113790601APrecise temperature controlGuarantee activation qualityFurnace typesHandling discharged materialHydraulic ramEngineering

The invention discloses an intelligent coal gangue activation device which comprises a box body, an automatic locking device and a controller. A pressure safety valve, a micro air compressor and a microwave generator are arranged on the box body, a microwave uniform distribution and diffusion pipe is arranged in the box body, and the micro air compressor is connected with the microwave uniform distribution and diffusion pipe. The upper side and the lower side of the microwave uniform distribution and diffusion pipe are provided with interval hollowed-out protection plates correspondingly, and the microwave uniform distribution and diffusion pipe and the interval hollowed-out protection plates are parallel to the bottom face of the box body. The microwave generator is connected with spiral wave guide tubes oppositely arranged on two sides in the box body, and is used for forming a rotary microwave field. The automatic locking device comprises an upper gangue gate, a lower gangue gate and a hydraulic oil cylinder, and the upper gangue gate and the lower gangue gate form a hinge connection mechanism with the box body through the hydraulic oil cylinder. The micro air compressor, the microwave generator and the automatic locking device are all connected with the controller. The device can achieve clean, safe and large-scale industrial application.

Owner:中科鼎干北京环保发展有限公司

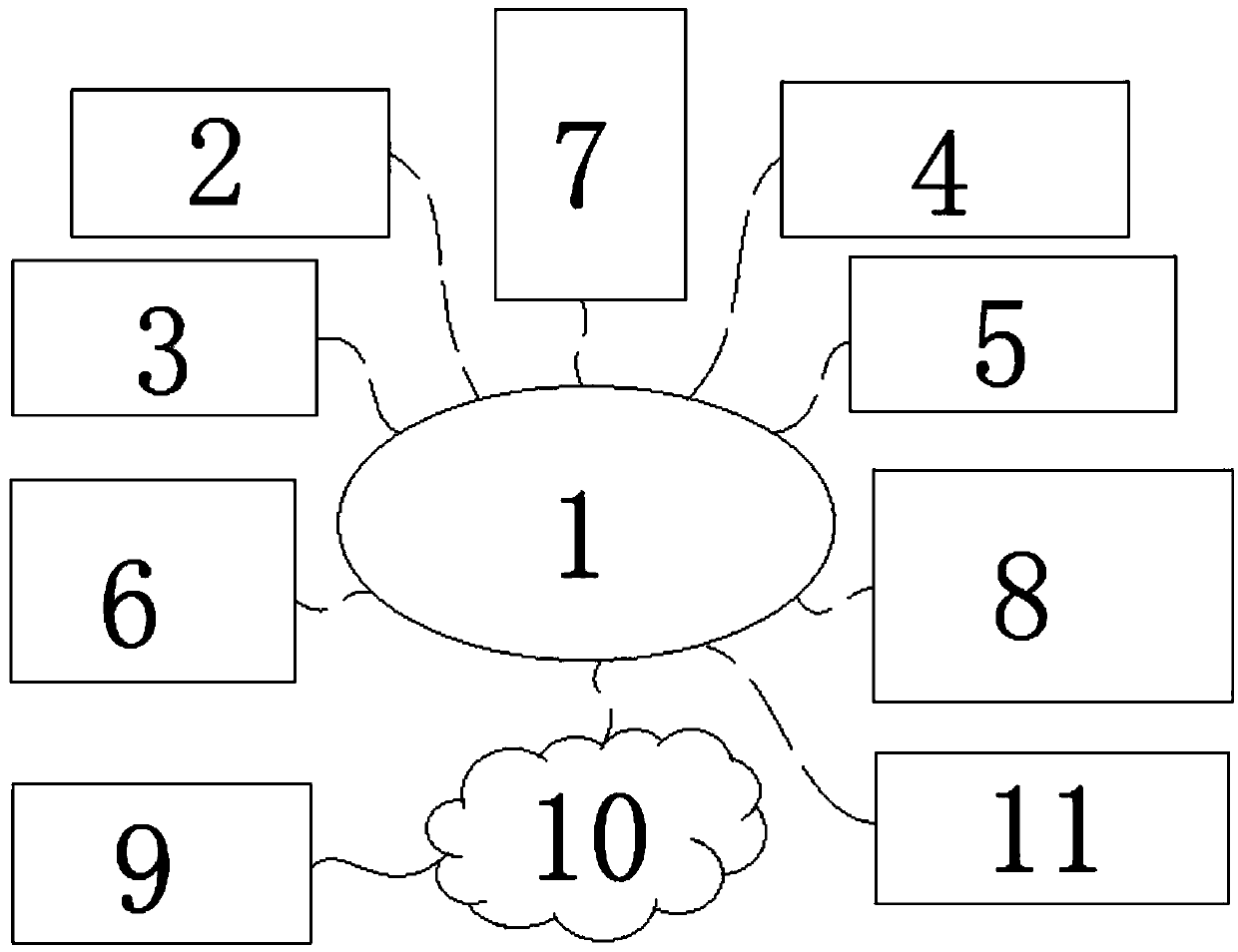

Safety warning control system for material regeneration vacuum smelting furnace

InactiveCN107677143AImprove the safety factor of the working environmentReduce safety incidentsCharge treatment typeControl devices for furnacesDisplay deviceCommunication device

The invention discloses a safety warning control system for a material regeneration vacuum smelting furnace and relates to the technical field of production safety warning. The safety warning controlsystem comprises a control device, a temperature sensor, a humidification sensor, an oxygen sensor, an air pressure sensor, an input module, a power supplying system, a display device, a remote controller, a wireless communication device and a warning device. The temperature sensor, the humidification sensor, the oxygen sensor and the air pressure sensor are connected with the control device in acommunication mode, and the control device is connected with the remote controller through the wireless communication device. According to the safety warning control system for the material regeneration vacuum smelting furnace, the working state of the vacuum furnace is controlled through the control device, the working environment safety coefficients of an existing vacuum smelting furnace duringproduction are increased, and the probability of safety accident occurrence is decreased; data in the whole production process are all real-time data, and production process analysis is facilitated; and the working state of the vacuum smelting furnace in the whole production process is monitored on site, and the on-site production situation and parameters are transmitted to the remote controller immediately to achieve remote control.

Owner:安徽省金鸿再生资源科技有限公司

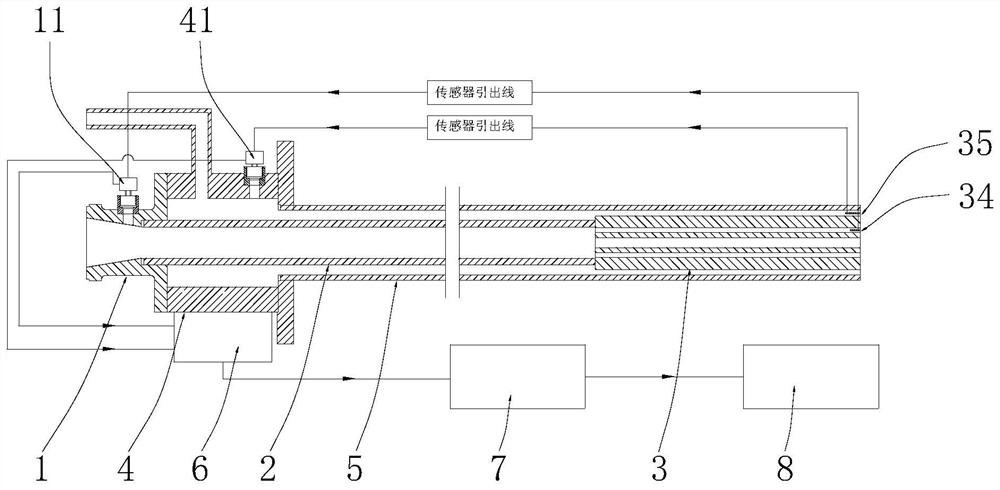

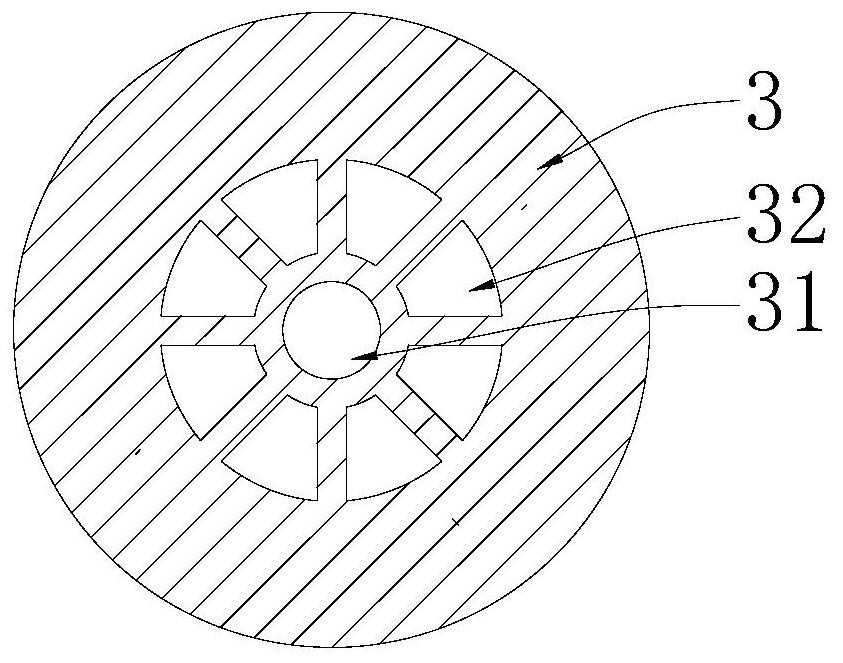

Intelligent diagnosis spray gun

PendingCN113048794ACharge manipulationFurnace monitoring devicesControl engineeringProcess engineering

The invention provides an intelligent diagnosis spray gun. The intelligent diagnosis spray gun comprises a central pipe, a gun head and a data processing unit, a central channel is formed in the central pipe, a first channel is formed in the gun head along the axis of the gun head, the central channel and the first channel communicate with each other and form an inner layer channel, an inner channel microsensor is arranged in the inner layer channel, and the data processing unit is used for receiving a detection result of the inner channel microsensor and detecting and pre-judging the working state of the intelligent diagnosis spray gun according to the detection result. According to the intelligent diagnosis spray gun, the sensor is implanted in the spray gun, so that the working state and the burning loss condition of the spray gun are monitored in real time, in addition, a flow and heat transfer model is established based on the parameters acquired by the sensor, so that the working state of a spray gun body and the working state of a kiln device are intelligently diagnosed and accurately pre-judged, the planned replacement of the spray gun and the planned maintenance of the kiln device can be facilitated, the operation rate is increased, and the safety risk of equipment and operators is reduced.

Owner:CHINA ENFI ENGINEERING CORPORATION

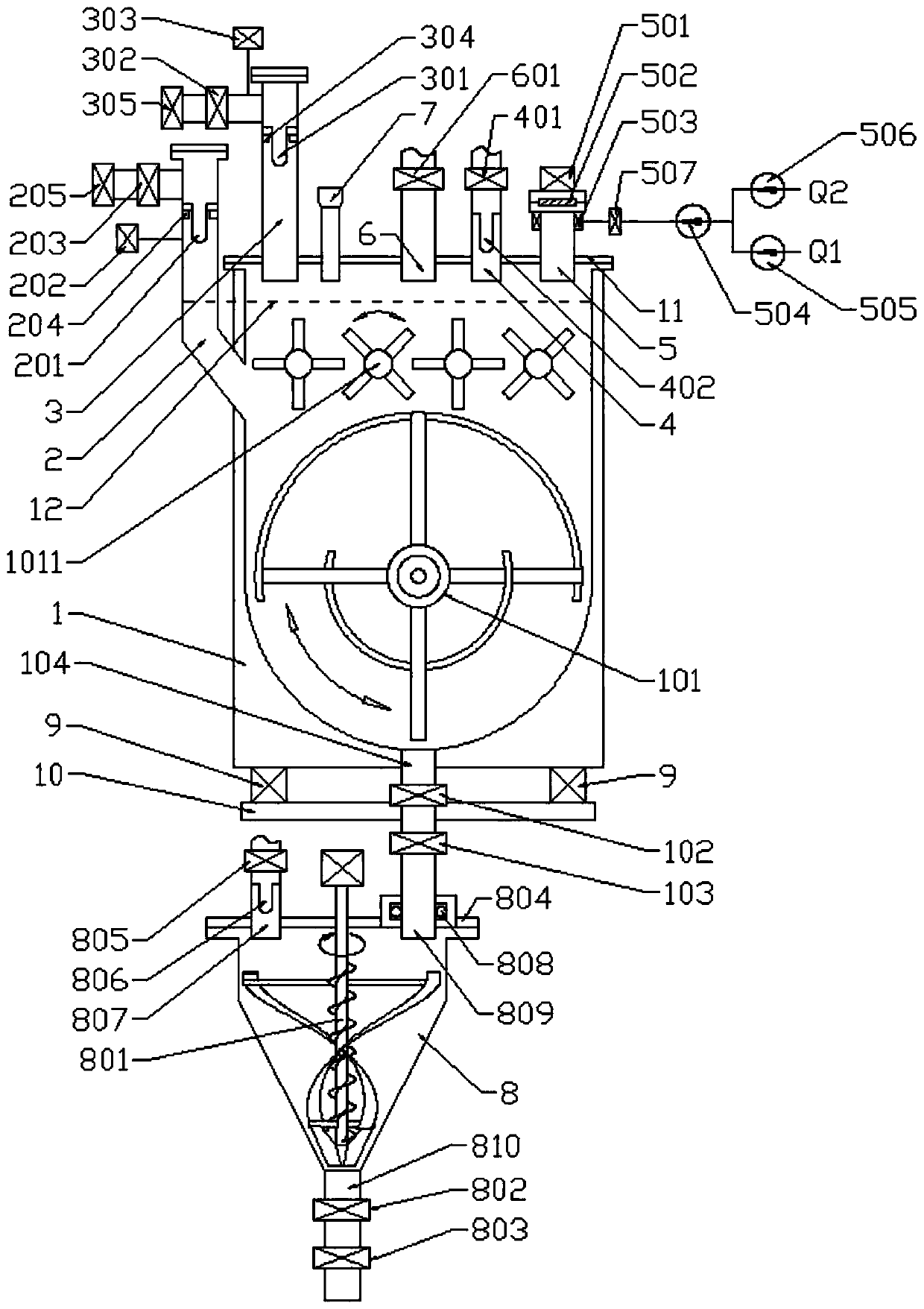

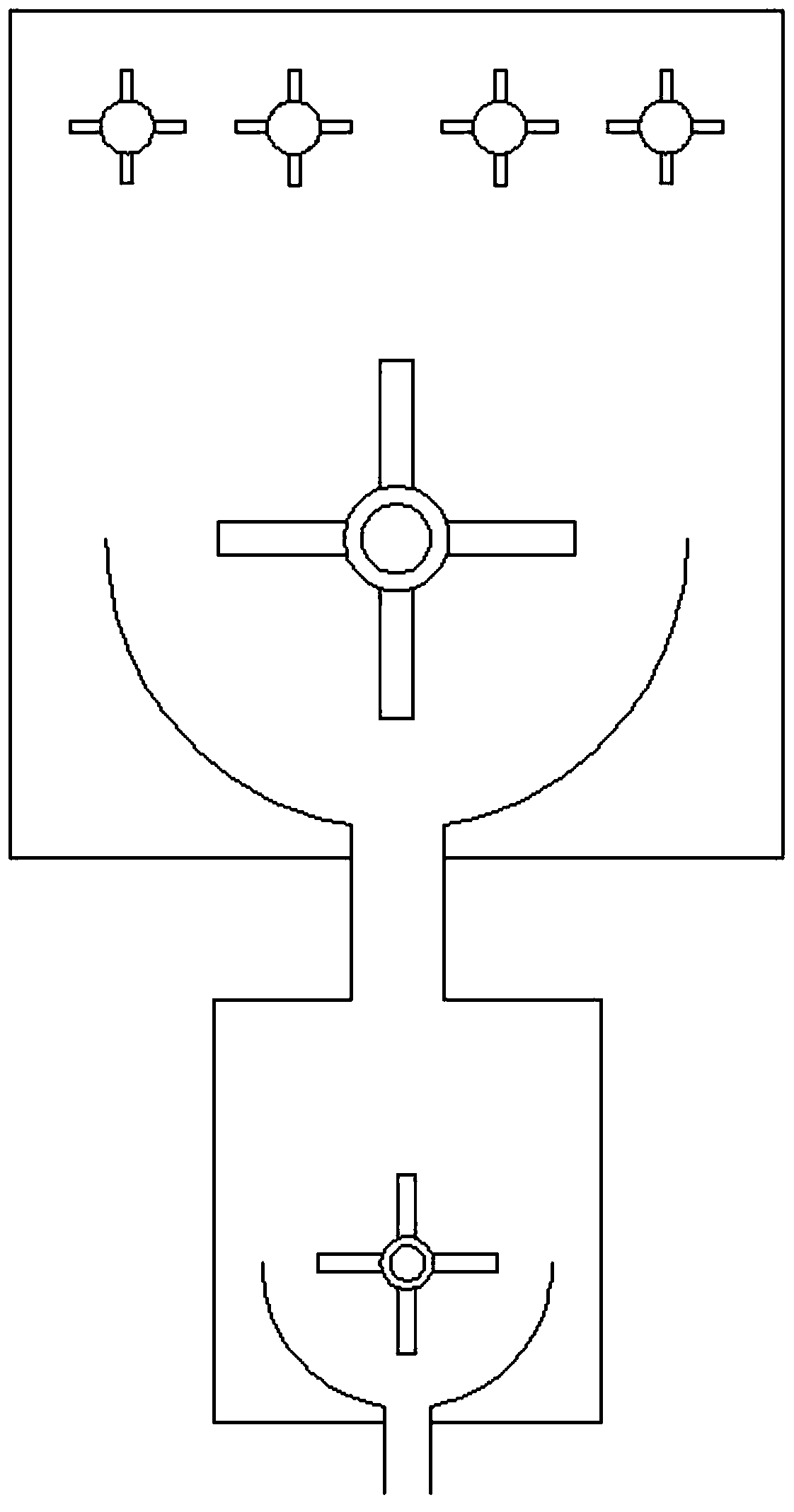

Multi-stirring-shaft vacuum microwave oven special for powder and heating method

InactiveCN111521025AQuick switchFully contactedMaintainance of heating chambersFurnace coolingMicrowave ovenEngineering

The invention provides a multi-stirring-shaft vacuum microwave oven special for powder. The vacuum microwave oven comprises a heating oven body, a cooling oven body, a weighing sensor, lower vacuum channels, an upper vacuum channel, an exhaust channel, a microwave input pipe, a feeding pipe and a temperature measuring component; and high-speed stirring shafts and a low-speed stirring shaft are arranged in the heating oven body. According to the multi-stirring-shaft vacuum microwave oven special for the powder, the oven can work in a vacuum state and can also work in an atmospheric pressure state; the oven can work in a plasma environment microwave heating state and can also work in a non-plasma environment microwave heating state; the oven can work in a microwave heating state, can work ina resistance heating state and can also work in a microwave heating and resistance heating dual-heating state; the oven can work in an oxidizing atmosphere state, can work in a reducing atmosphere state and can also work in other atmosphere states; and based on the action of the multiple stirring shafts, the heat treatment on materials can be sufficiently performed.

Owner:株洲弗拉德科技有限公司

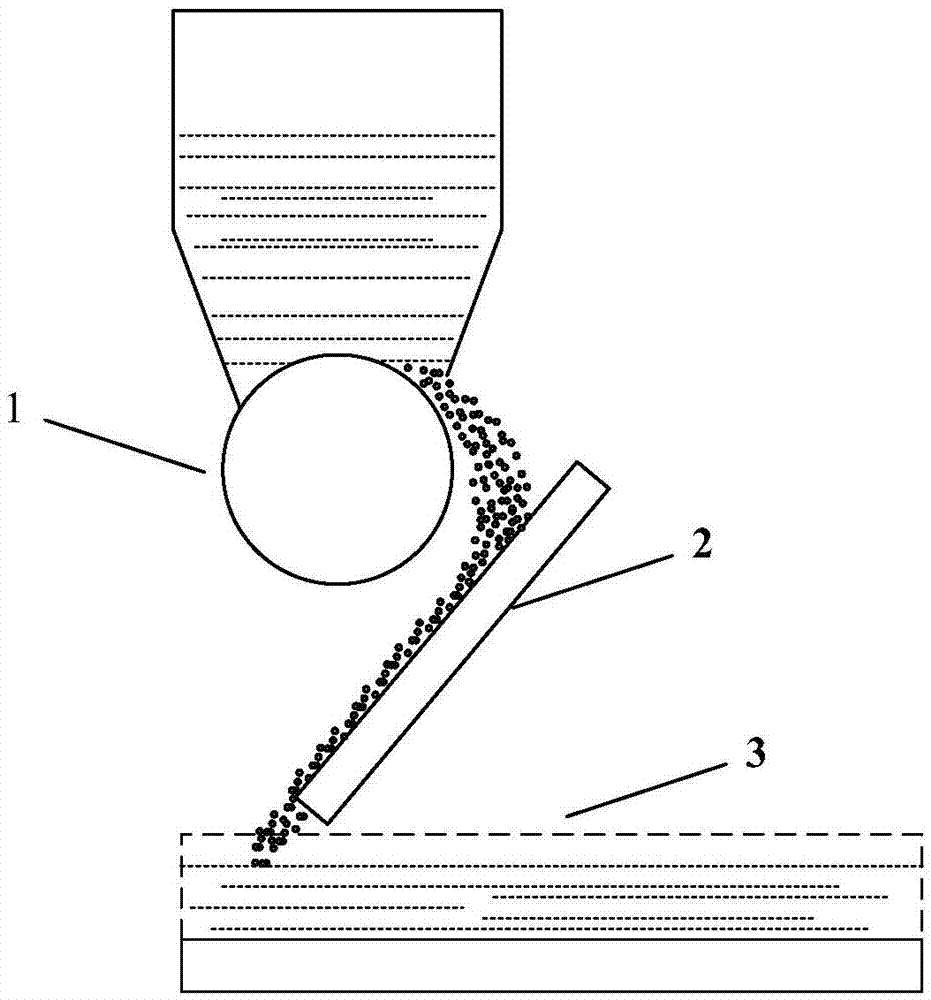

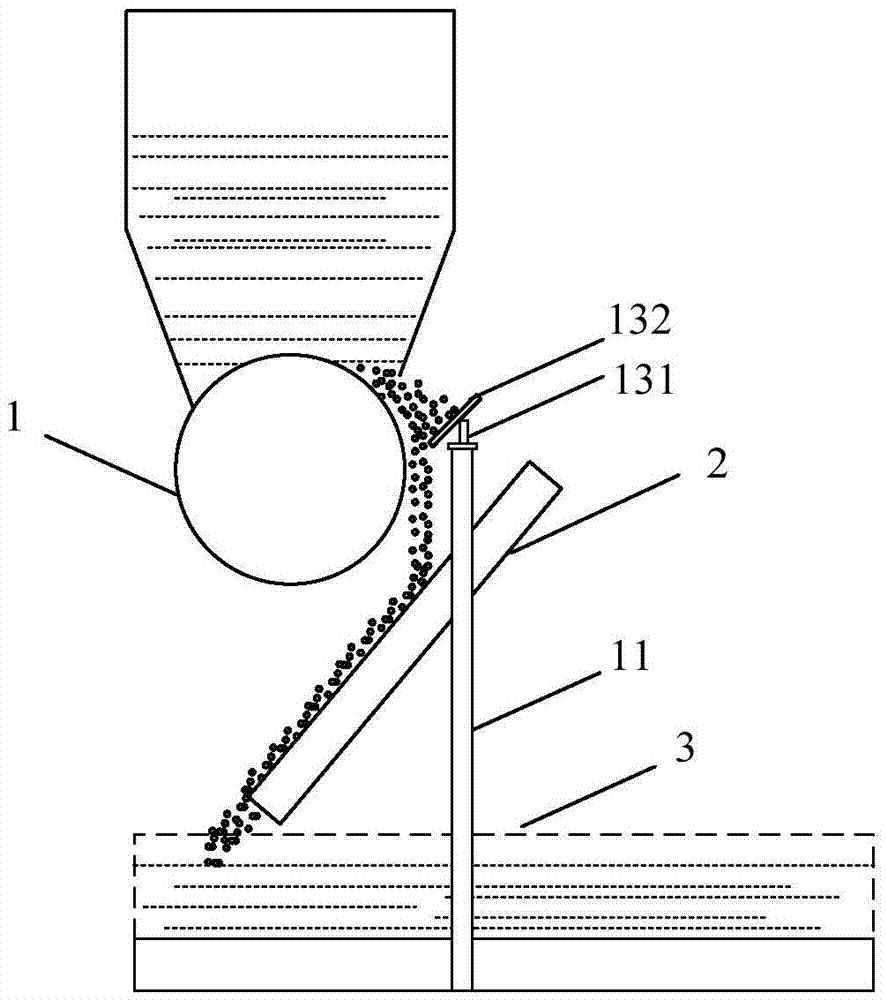

Material layer thickness detection apparatus and method

ActiveCN106940176ASimple structureReduce maintenance workloadMeasurement devicesFurnace monitoring devicesEnvironment effectEngineering

The embodiment of the invention discloses a material layer thickness detection apparatus and method capable of detecting the material layer thickness of a material transmitted on a sintering machine trolley. Firstly, the detection apparatus is installed beside a discharge position of a feeding machine instead of being installed above the sintering machine trolley as the conventional material layer thickness detection apparatus, the detection time point for detecting the material layer thickness is arranged ahead of schedule, and before the material is transmitted to the sintering machine trolley, the material layer thickness of the material on the sintering machine trolley can be obtained in advance. Then, the material layer thickness detection apparatus is advantaged by simple structure and small maintenance workload, the severe on-site environment can be well adapted, and the probability of damage to the detection apparatus due to the influence of the external environment is effectively reduced. Besides, according to the detection apparatus, the composition parts are simple, the cost is low, the material layer thicknesses in a plurality of detection areas on the sintering machine trolley can be simultaneously detected by employing multiple groups of weight detection apparatuses, and the detection cost is greatly reduced.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

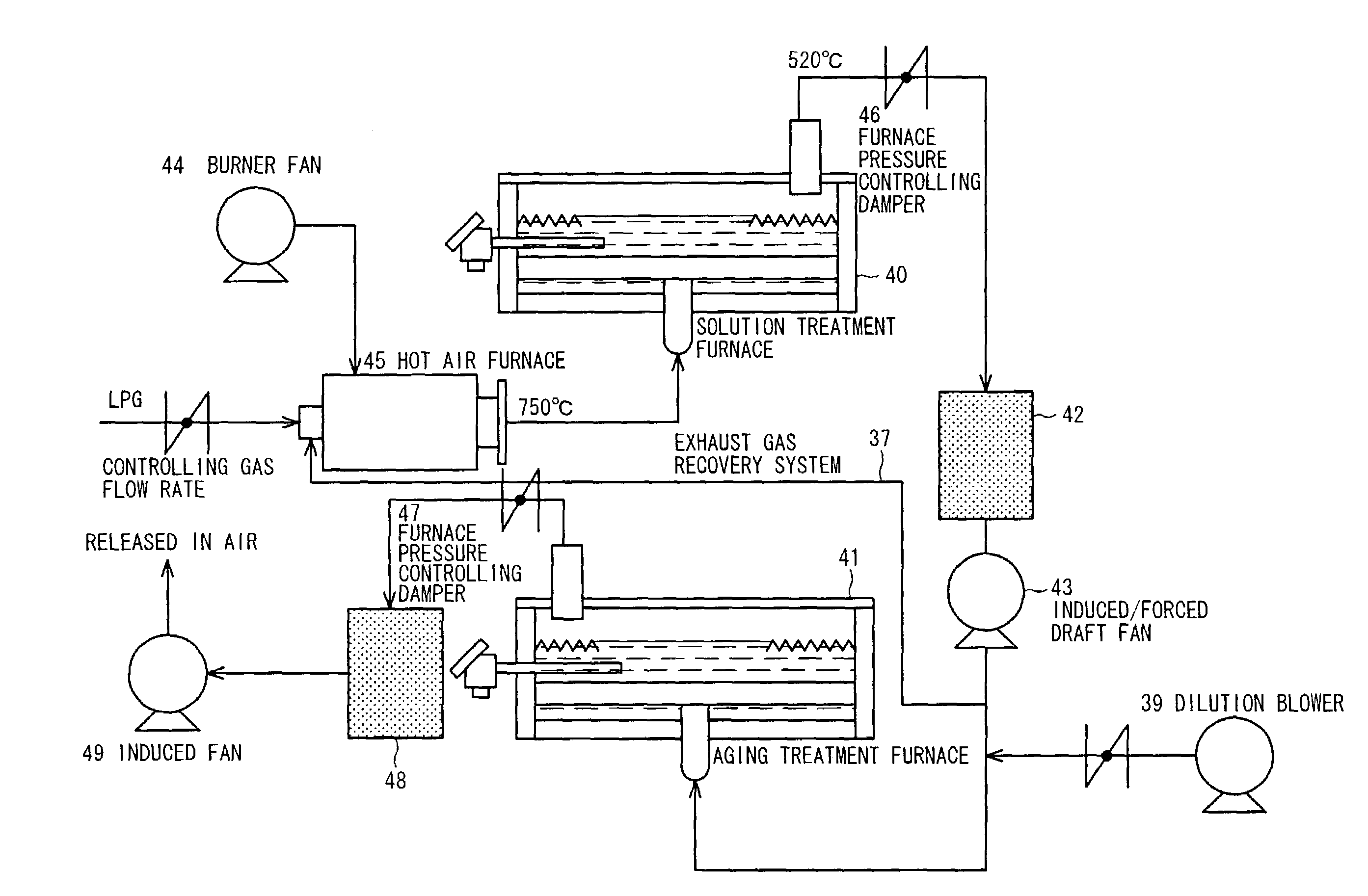

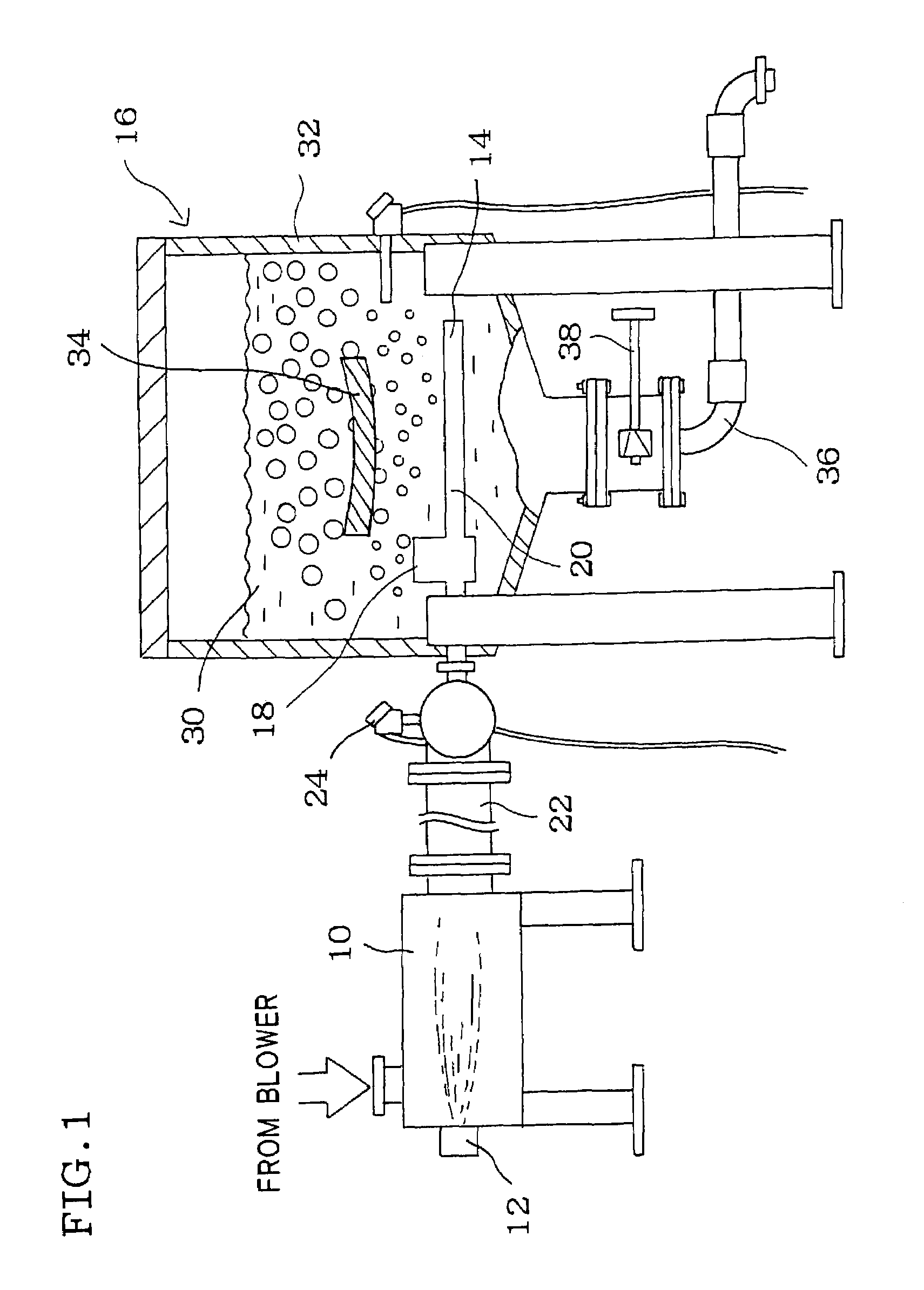

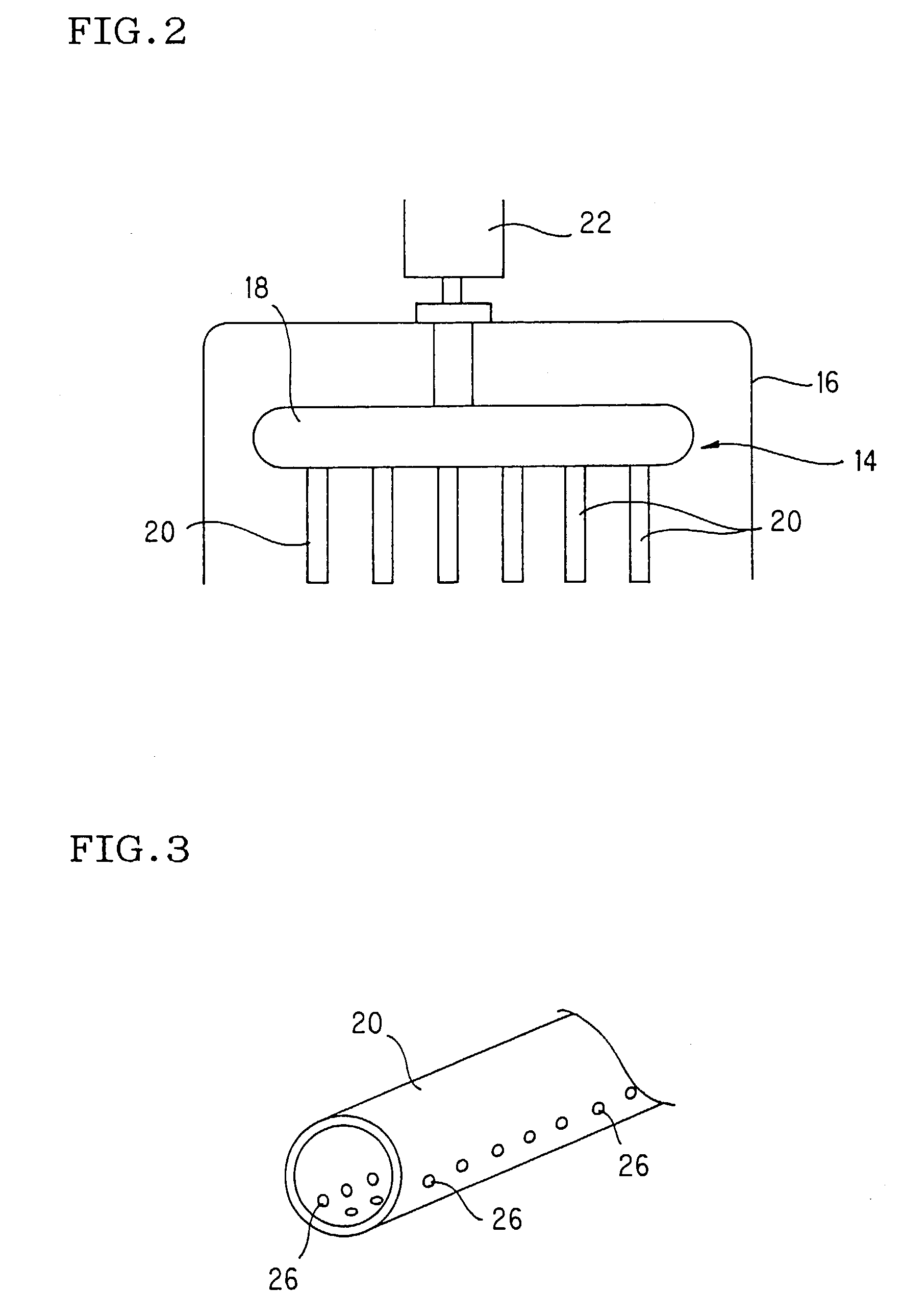

Hot air blowing type fluidized-bed furnace, rotary heat-treatment furnace, heat-treatment apparatus, and method of heat treatment

InactiveUS7025927B2Avoid volatilityRotary drum furnacesCharge manipulationSolution treatmentFluidized bed

A heat-treatment apparatus including a first furnace for heat treatment and solution treatment of a work piece, and a second furnace for heat treatment and aging treatment of a work piece, wherein each furnace includes a dispersion tube cantilevered and immersed within a fluidized bed, the tube for blowing hot air into the fluidized bed. The first furnace includes a heat exchanger for recovering waste heat from gases discharged the first furnace for use as a heat source for the second furnace.

Owner:ASAHI TEC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com