Dynamic monitoring system and method for material levels of stock bins on top of submerged arc furnace

A dynamic monitoring, submerged arc furnace technology, applied in furnace monitoring devices, furnaces, furnace components, etc., can solve the problems of material level monitoring that cannot be automated, high cost, etc., and achieves high reliability and optimized design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

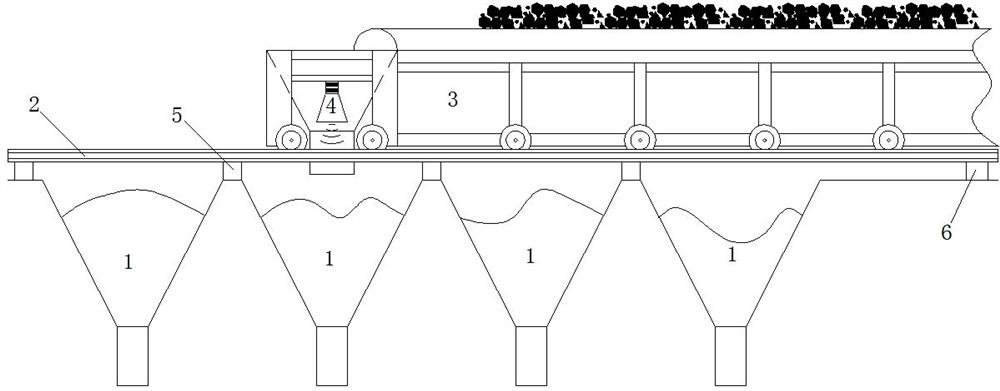

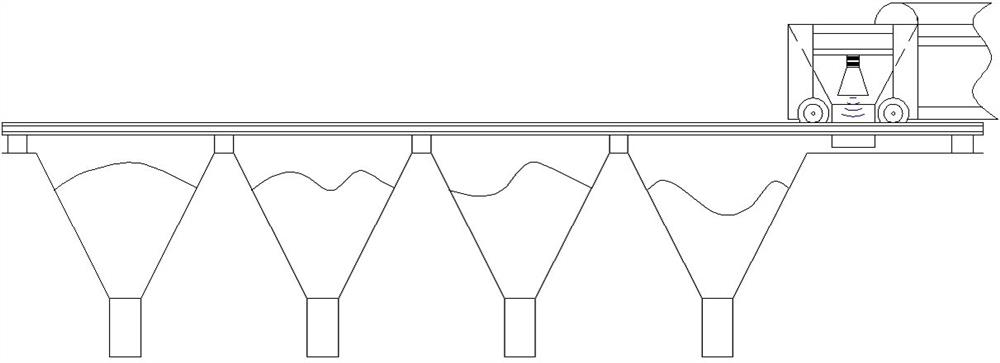

[0032] Such as figure 1 Shown, a kind of dynamic monitoring system of the material level of the furnace top silo of submerged arc furnace comprises several hoppers 1, is provided with guide rail 2 above described silo 1, is provided with feeding equipment 3 slidingly on described guide rail 2, It is used to feed each silo 1, and the feeding device 3 is equipped with a level meter 4, which is used to inspect the material level of each silo 1 along with the feeding device 3 and generate a material level signal to realize the material level of the silo 1. dynamic monitoring.

[0033] The guide rail 2 is provided with a plurality of alignment switches 5 corresponding to each bin 1 for detecting the position information of each bin 1 so that the generated material level signal includes the position information of each bin 1 .

[0034] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com