Device and method for controlling combustion exhaust gas of regenerative heating furnace

A technology of control method and control device, which is applied in the direction of furnace control device, combustion method, furnace monitoring device, etc., can solve problems such as energy loss, and achieve the effect of reducing energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, a combustion exhaust gas control device and control method for a regenerative heating furnace according to an embodiment of the present invention will be described in detail with reference to the drawings. When describing the present invention, when it is judged that the detailed description of related known structures or functions will affect the gist of the present invention, the detailed description will be omitted.

[0035] The heating furnace in this embodiment may be a heating furnace for heating materials to a temperature capable of forging in a forged steel production process. But not limited thereto, the heating furnace can be other types of heating furnaces.

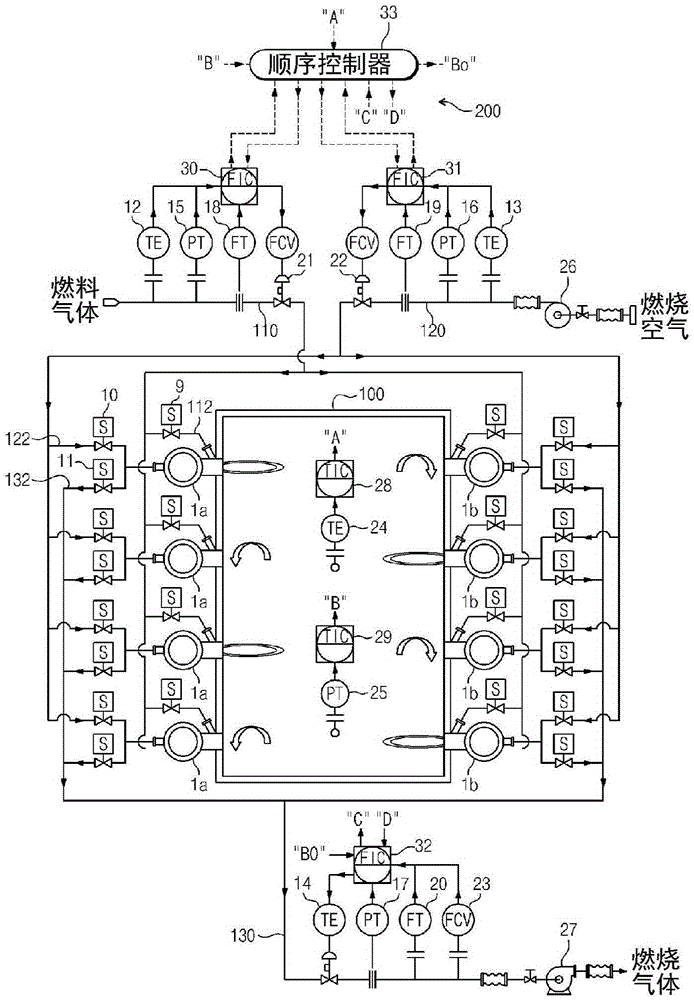

[0036] figure 1 It is a figure which schematically shows the control apparatus of the regenerative heating furnace which concerns on one Example of this invention.

[0037] like figure 1 As shown, on the left and right side surfaces of the regenerative heating furnace 100, the regenerativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com