Method for recovering electrolyte by pyrogenic process roasting of electrolytic aluminum carbon slag

An electrolyte and electrolytic aluminum technology, which is applied in the maintenance of heating chamber, improvement of process efficiency, furnace monitoring device and other directions, can solve the problem of smoke and fire in furnace door, rapid loss of lining of carbon slag smelting furnace, and low thermal efficiency of carbon slag smelting furnace and other problems to achieve the effect of improving memory life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

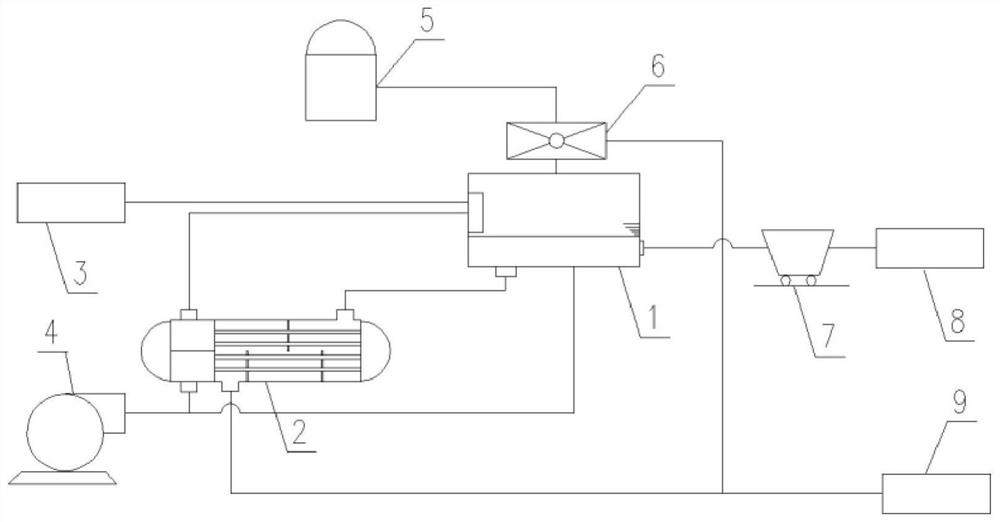

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the schematic diagrams.

[0027] Such as figure 1 As shown, the carbon slag heap removed from the electrolytic cell is stored in the carbon slag temporary storage area 5, and the carbon slag is fed from the furnace door of the smelting furnace 1 by manual or mechanical forklifts. The discharge port flows into the mold trolley 7, and after being cooled and solidified, it is manually crushed. After crushing, the crushed product is added to the jaw crusher by a manual or mechanical forklift for further crushing. The product is bagged and returned to the electrolytic cell for production after passing through the belt. The smelting furnace uses natural gas as fuel, and the combustion-supporting air is blown in from the blower 4, and part of the combustion-supporting air is sprayed into the furnace through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com