Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

523results about "Fuel cell manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

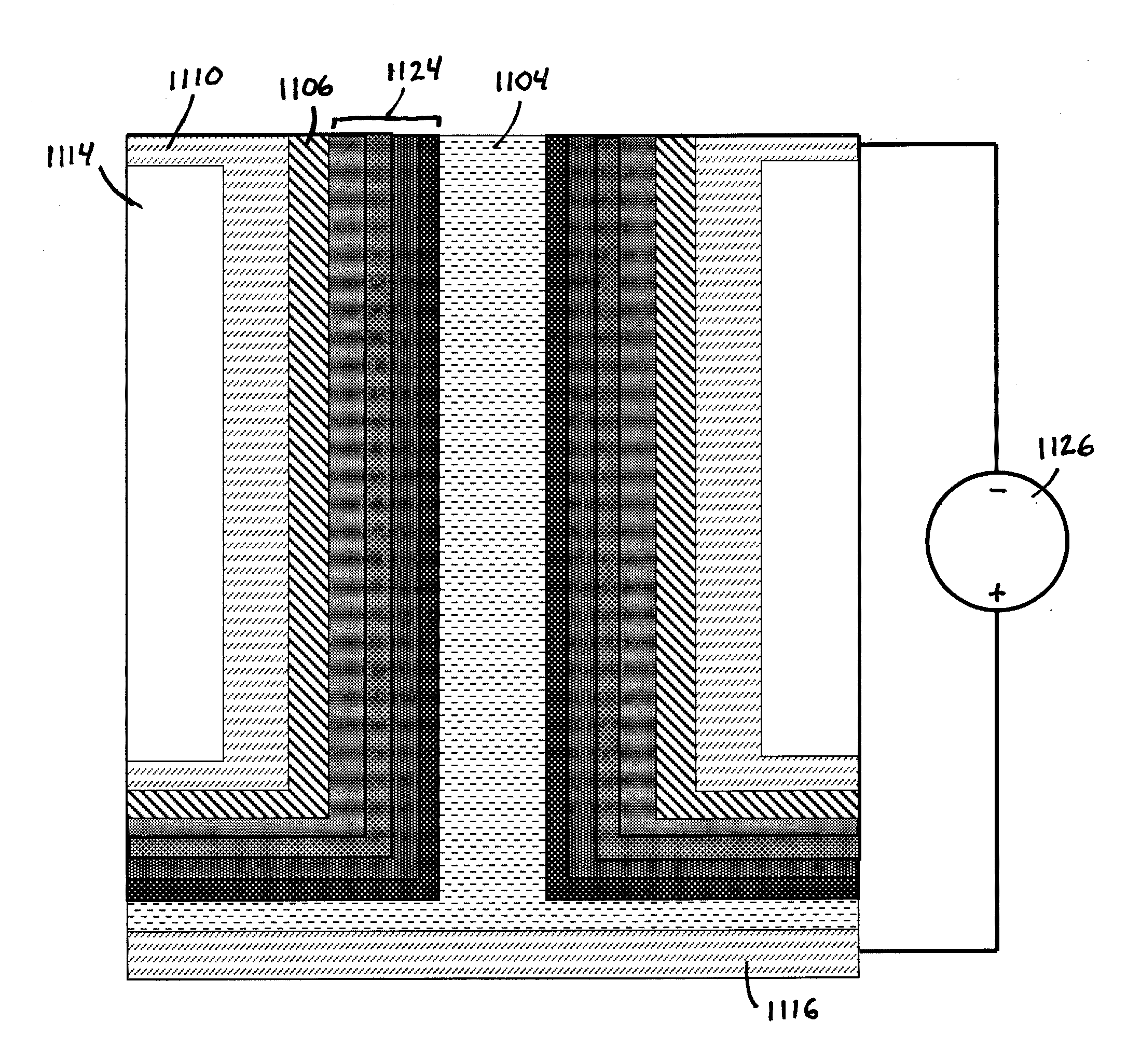

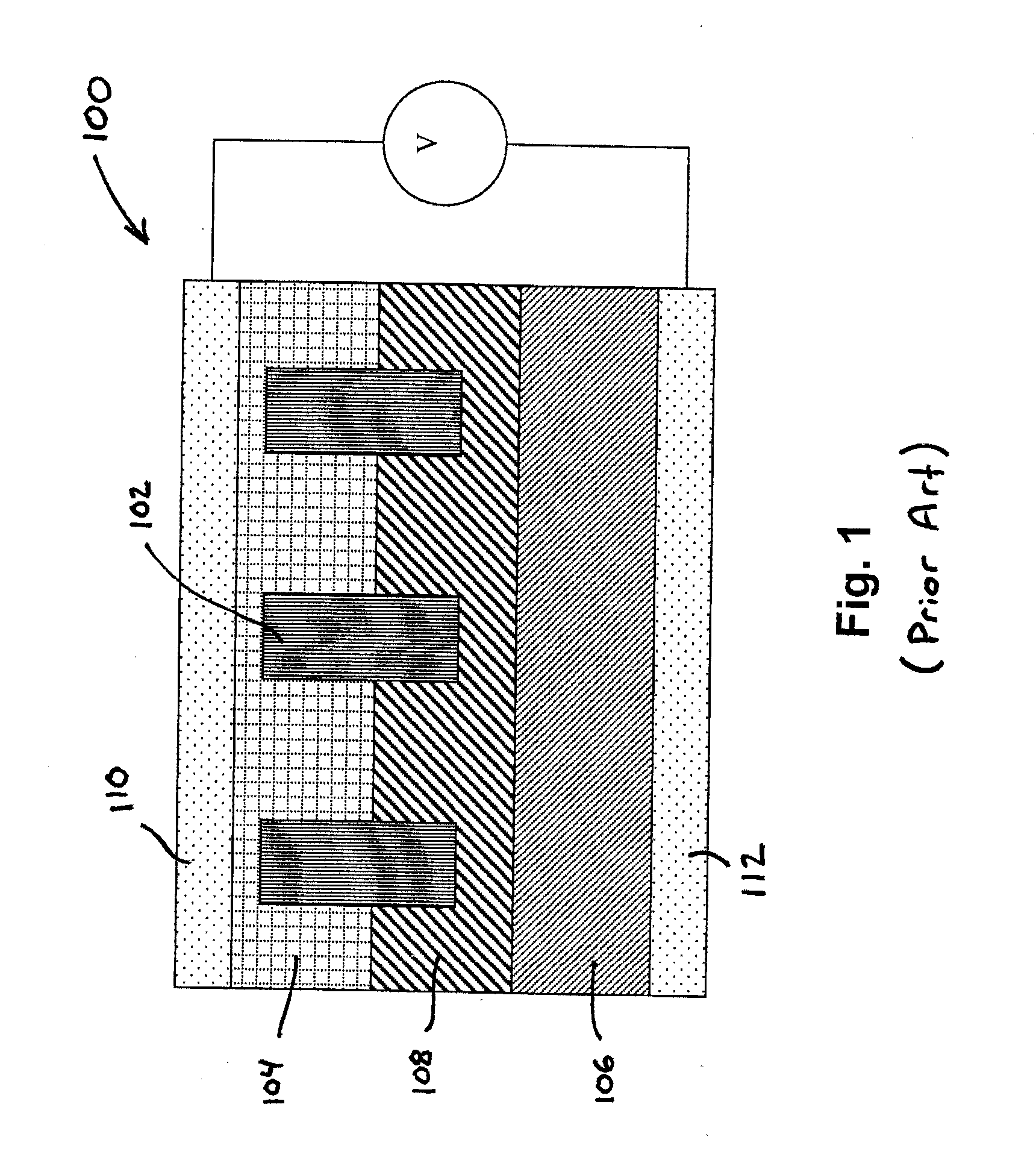

Energy conversion and energy storage devices and methods for making same

ActiveUS20100304204A1Improve efficiencyReduce lossesSolid-state devicesPrinted batteriesEngineeringConductive materials

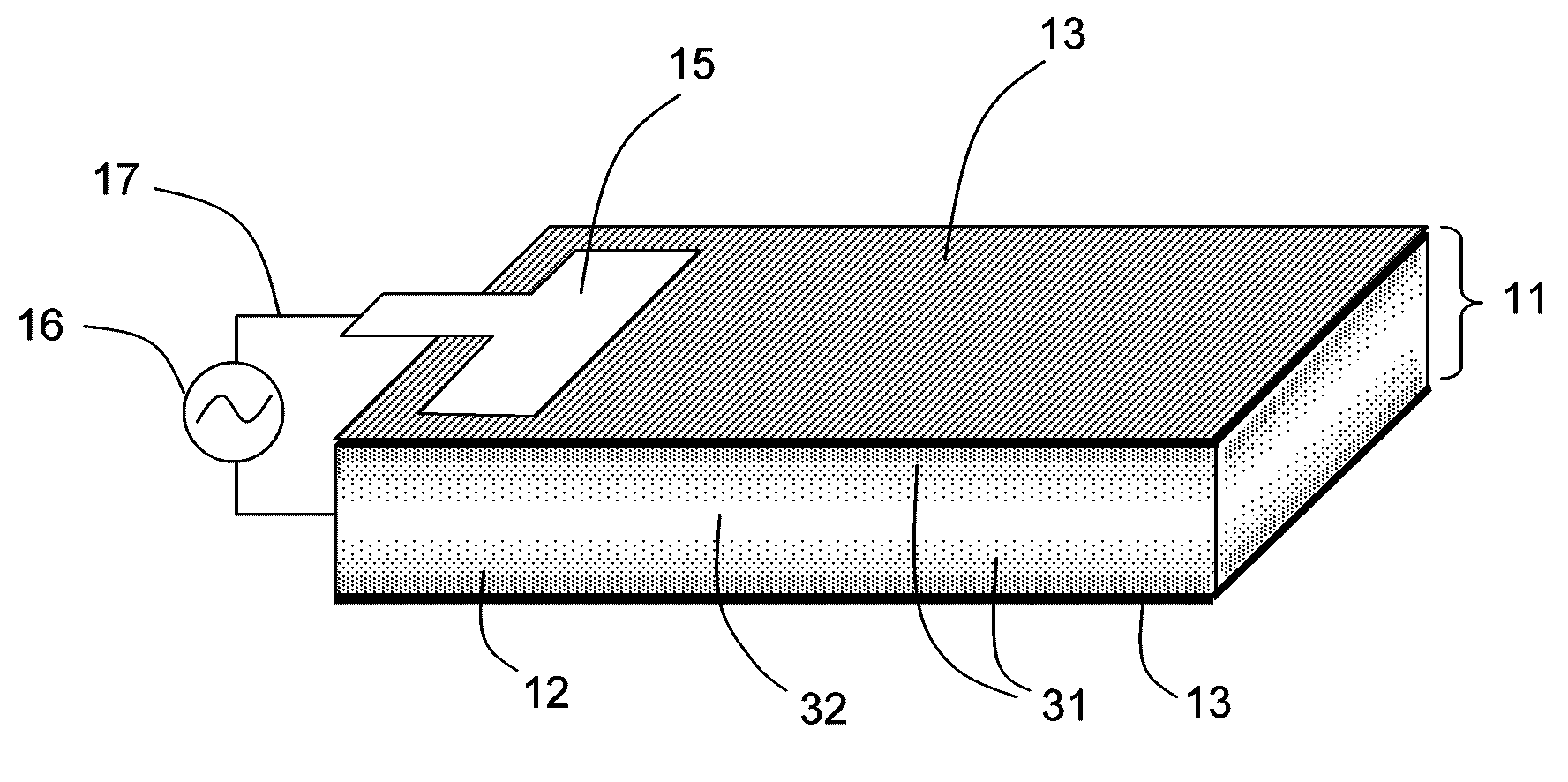

Energy devices such as energy conversion devices and energy storage devices and methods for the manufacture of such devices. The devices include a support member having an array of pore channels having a small average pore channel diameter and having a pore channel length. Material layers that may include energy conversion materials and conductive materials are coaxially disposed within the pore channels to form material rods having a relatively small cross-section and a relatively long length. By varying the structure of the materials in the pore channels, various energy devices can be fabricated, such as photovoltaic (PV) devices, radiation detectors, capacitors, batteries and the like.

Owner:INTEGRATED DEVICE TECH INC

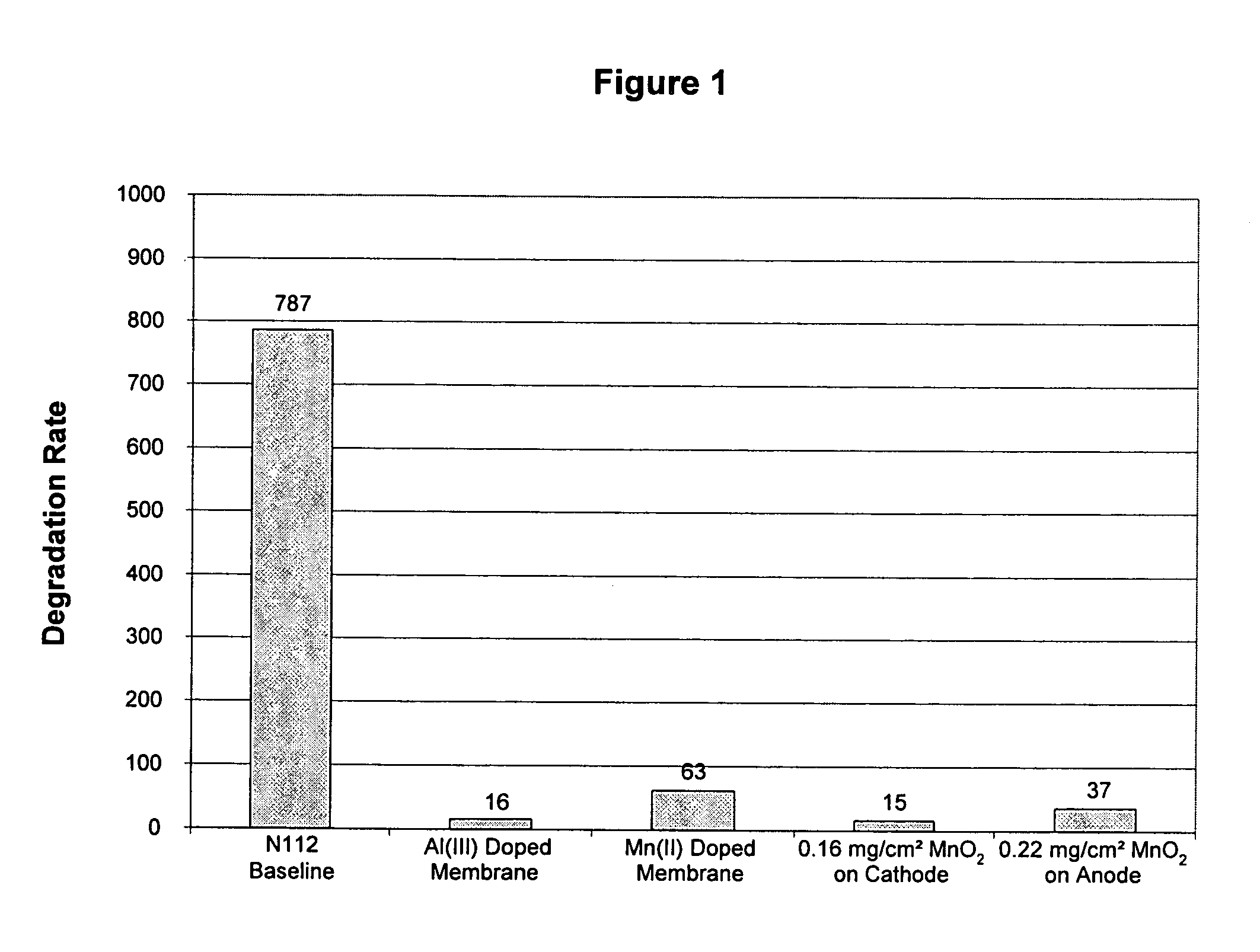

Reduced degradation of ion-exchange membranes in electrochemical fuel cells

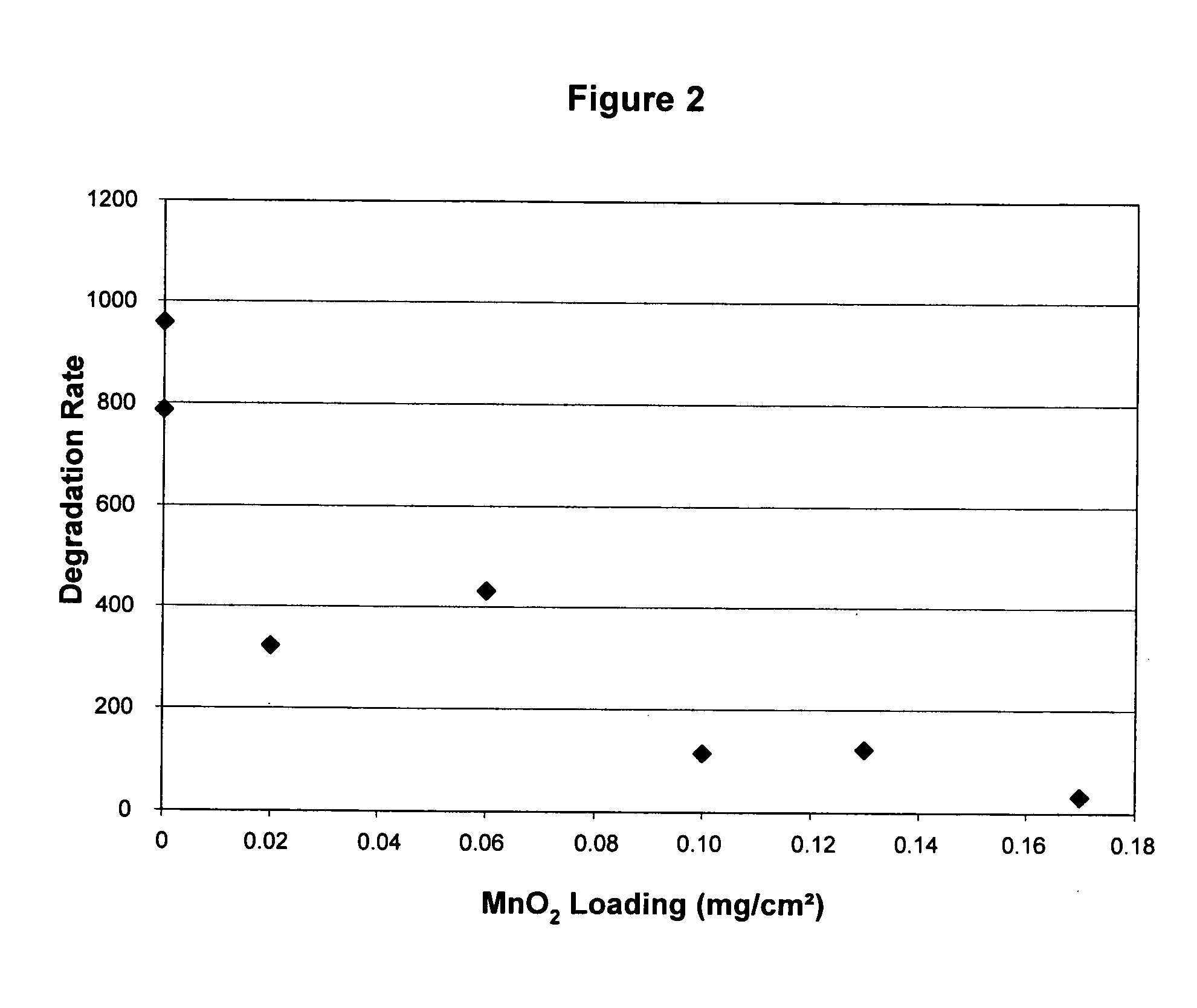

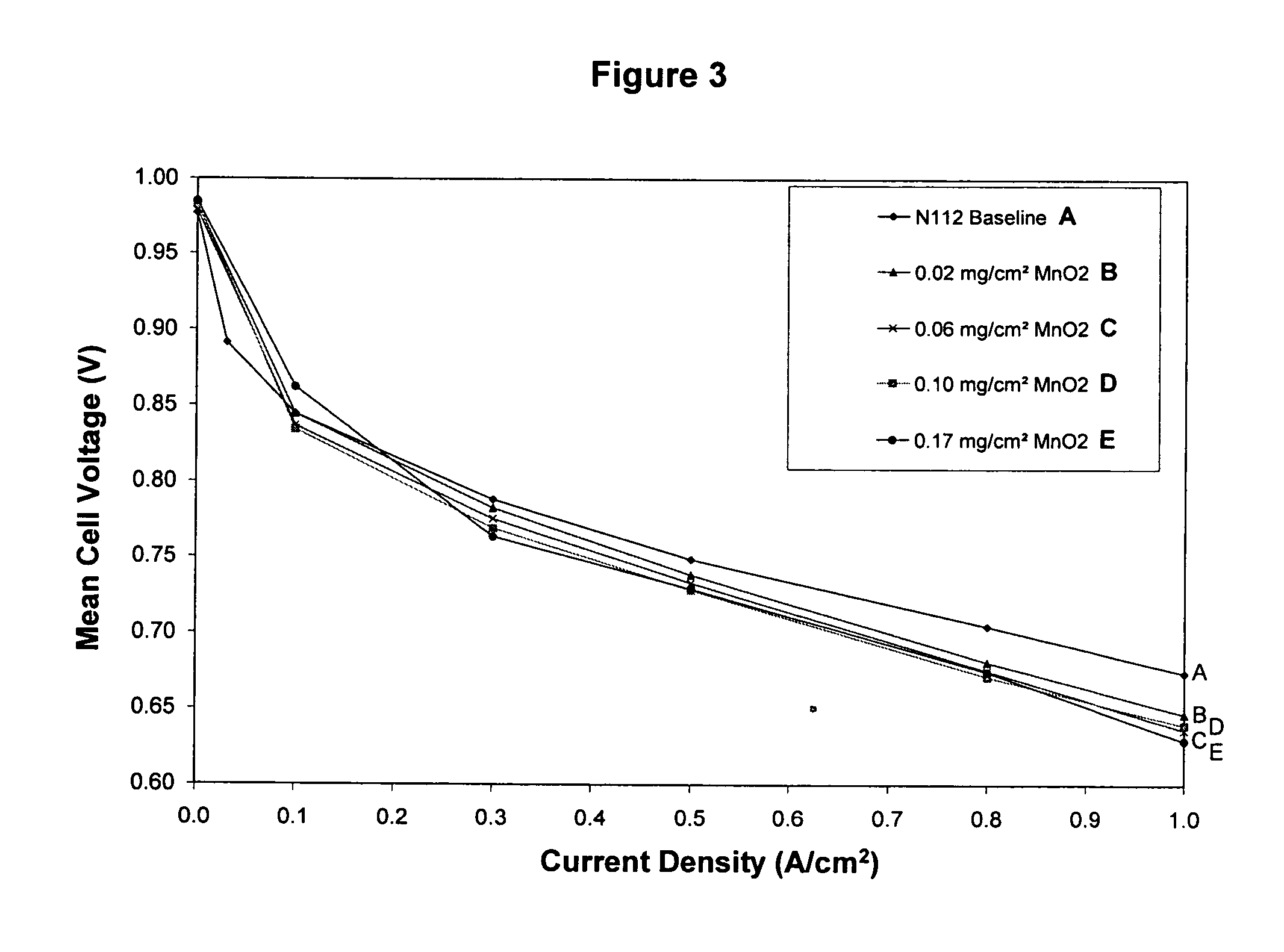

ActiveUS20050136308A1Easy loadingIncreased susceptibilityFuel cells groupingIon-exchanger regenerationHydrogen peroxide breakdownScavenger

A significant problem in PEM fuel cell durability is in premature failure of the ion-exchange membrane and in particular by the degradation of the ion-exchange membrane by reactive hydrogen peroxide species. Such degradation can be reduced or eliminated by the presence of an additive in the anode, cathode or ion-exchange membrane. The additive may be a radical scavenger, a membrane cross-linker, a hydrogen peroxide decomposition catalyst and / or a hydrogen peroxide stabilizer. The presence of the additive in the membrane electrode assembly (MEA) may however result in reduced performance of the PEM fuel cell. Accordingly, it may be desirable to restrict the location of the additive to locations of increased susceptibility to membrane degradation such as the inlet and / or outlet regions of the MEA.

Owner:BDF IP HLDG

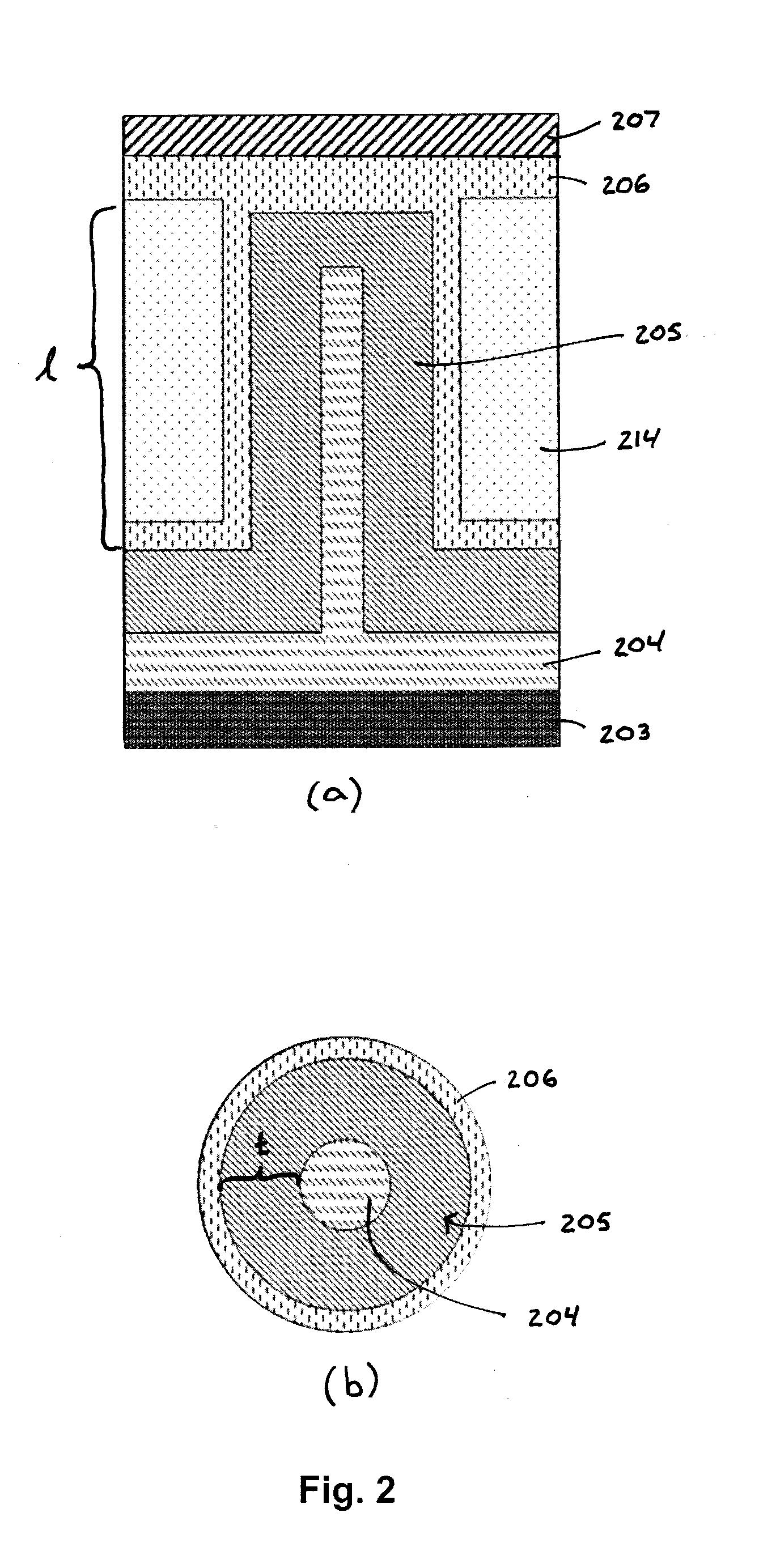

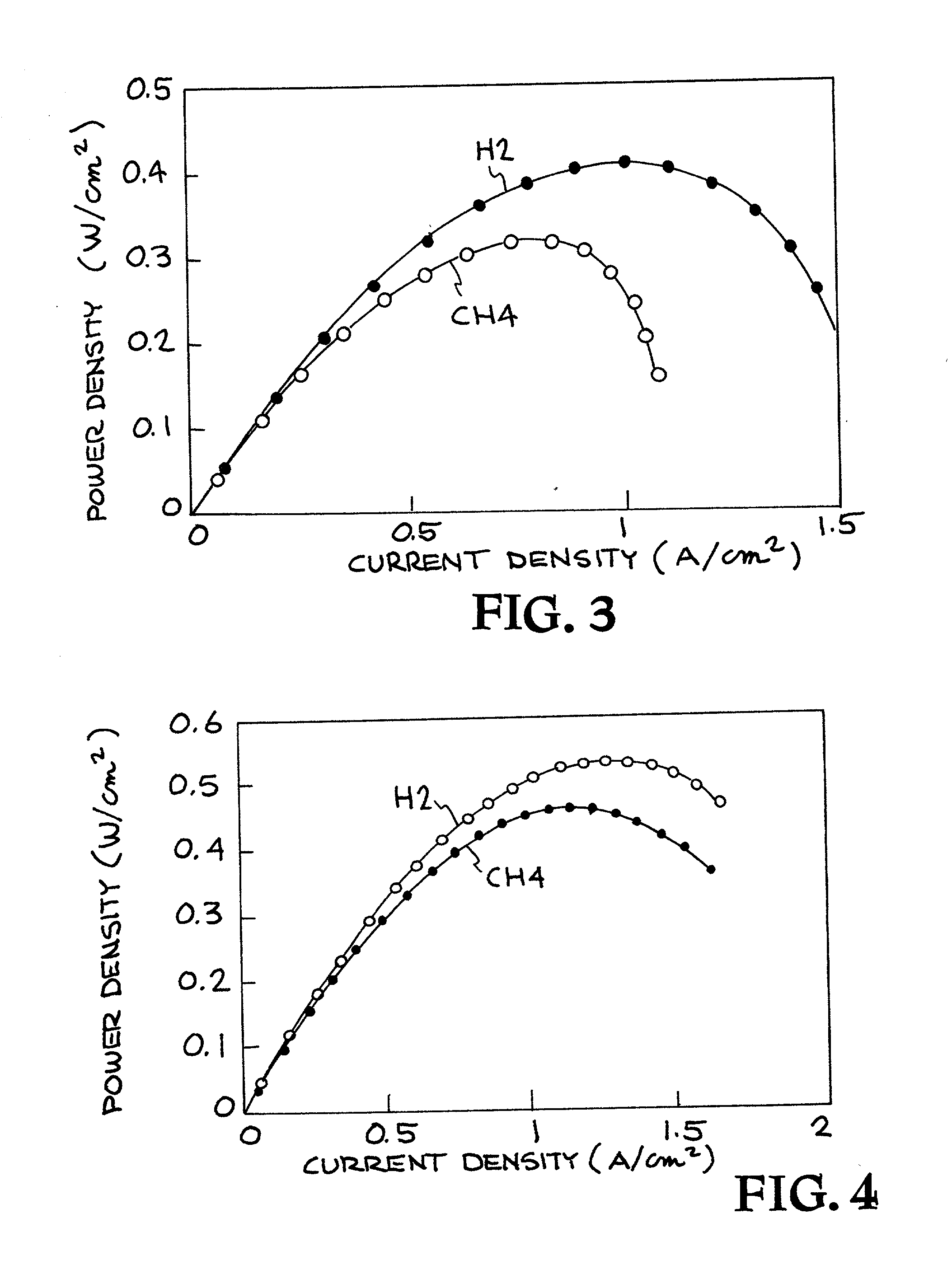

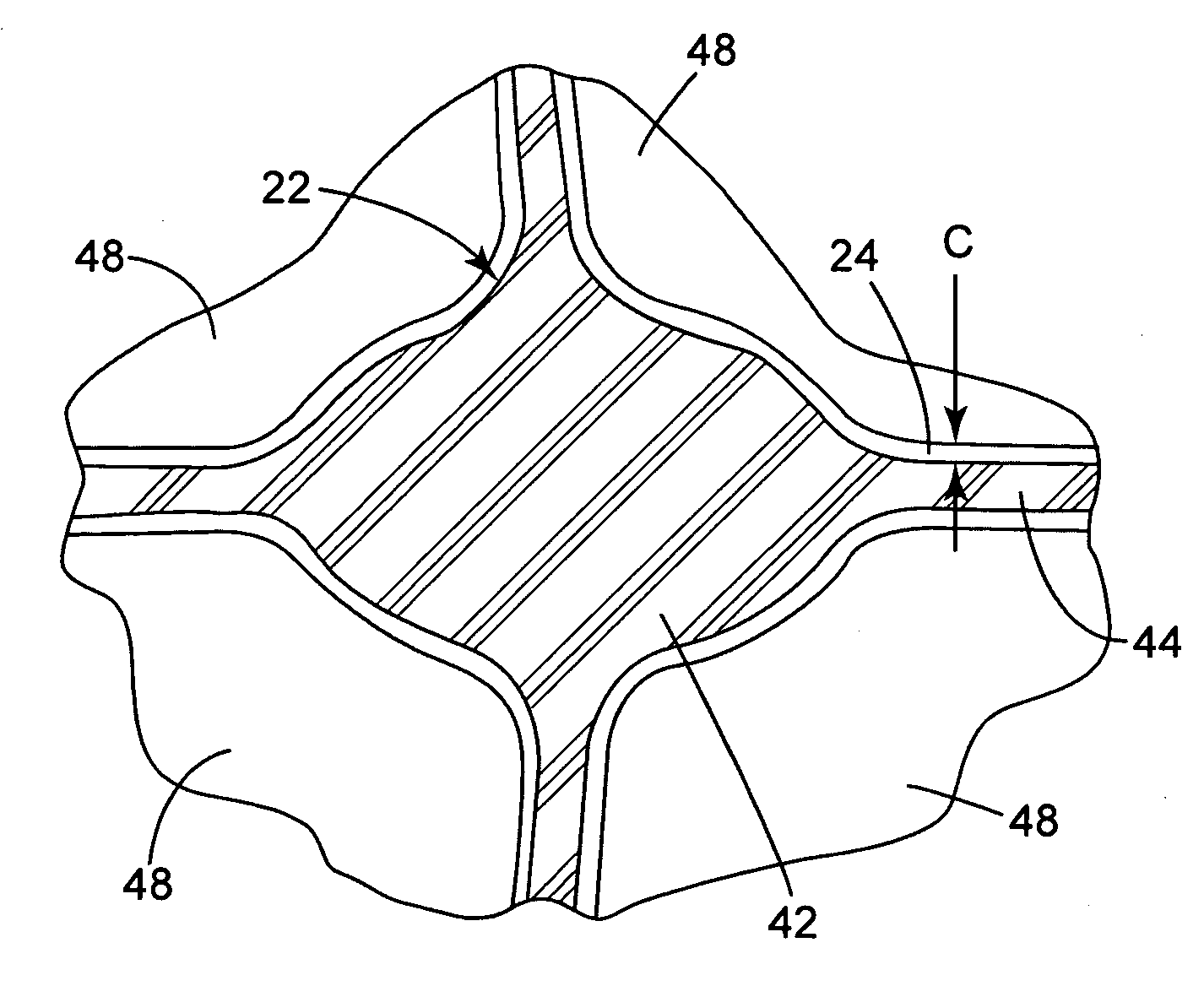

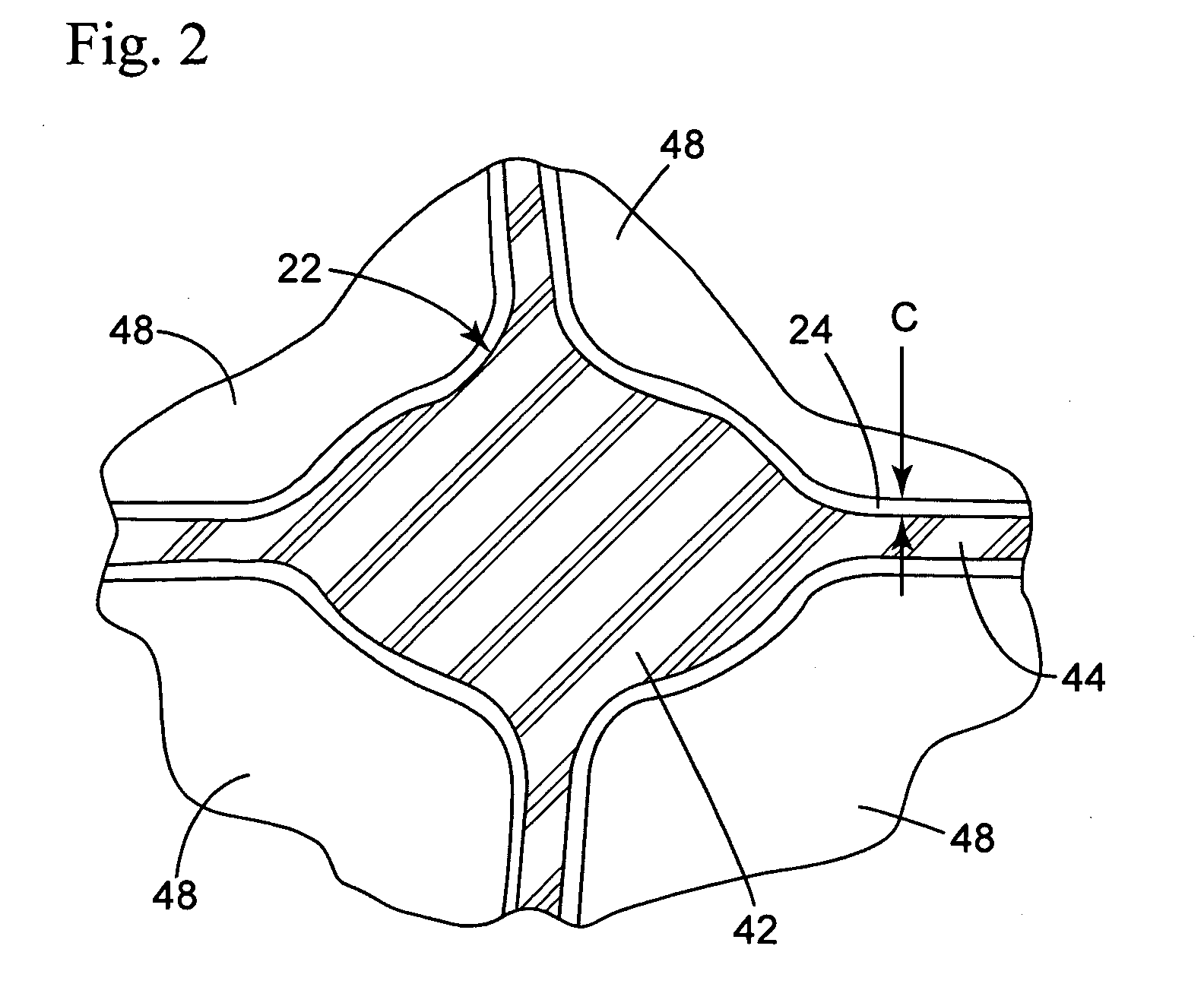

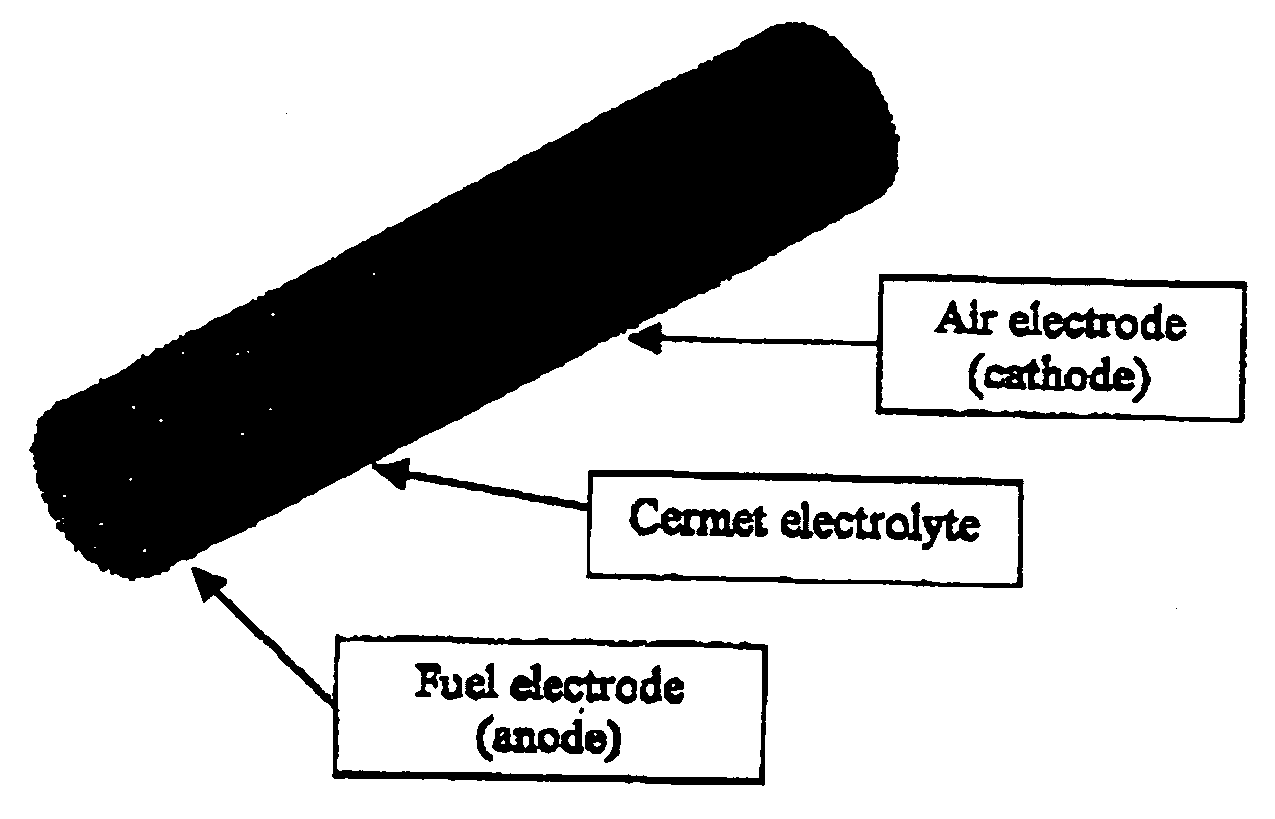

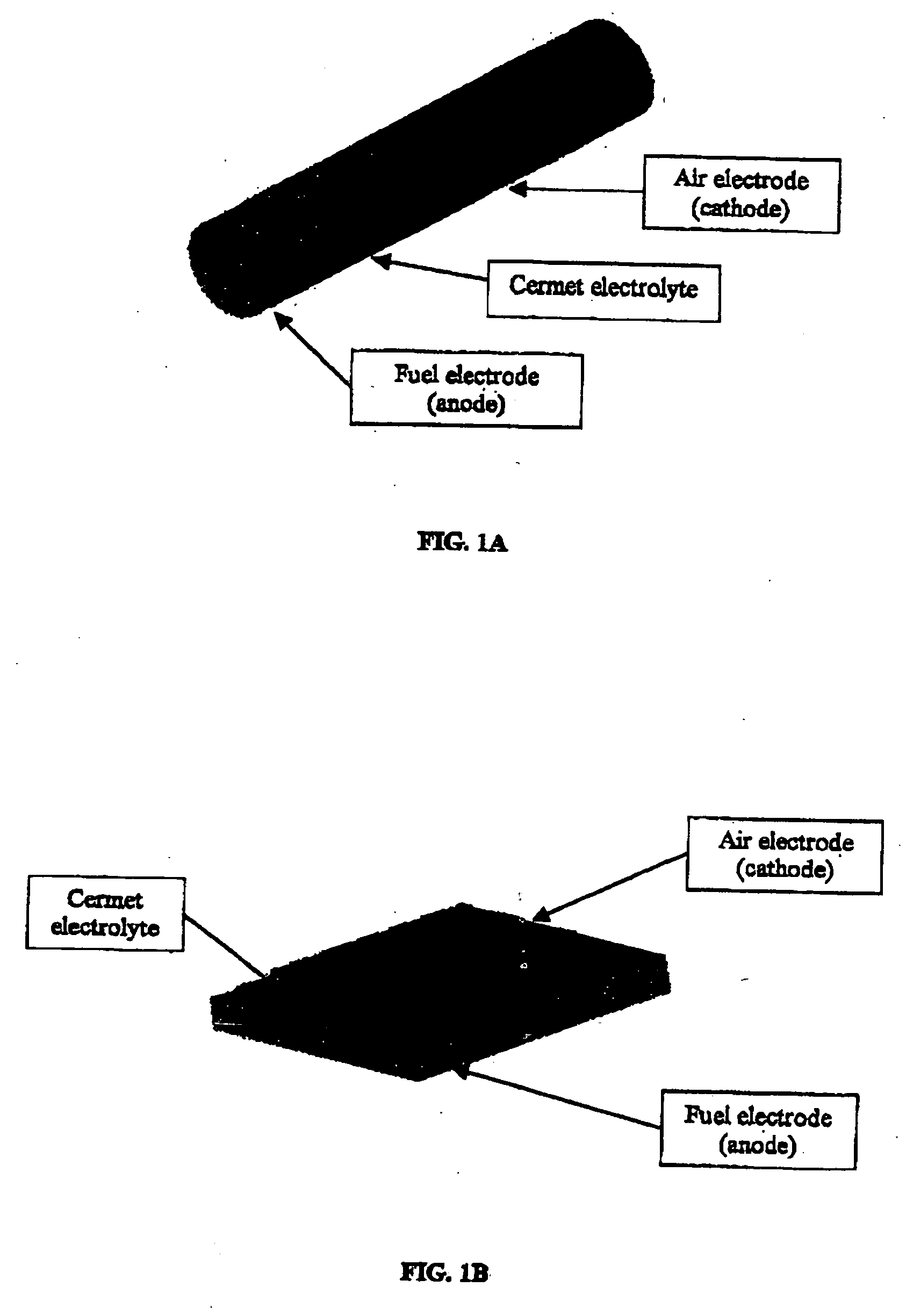

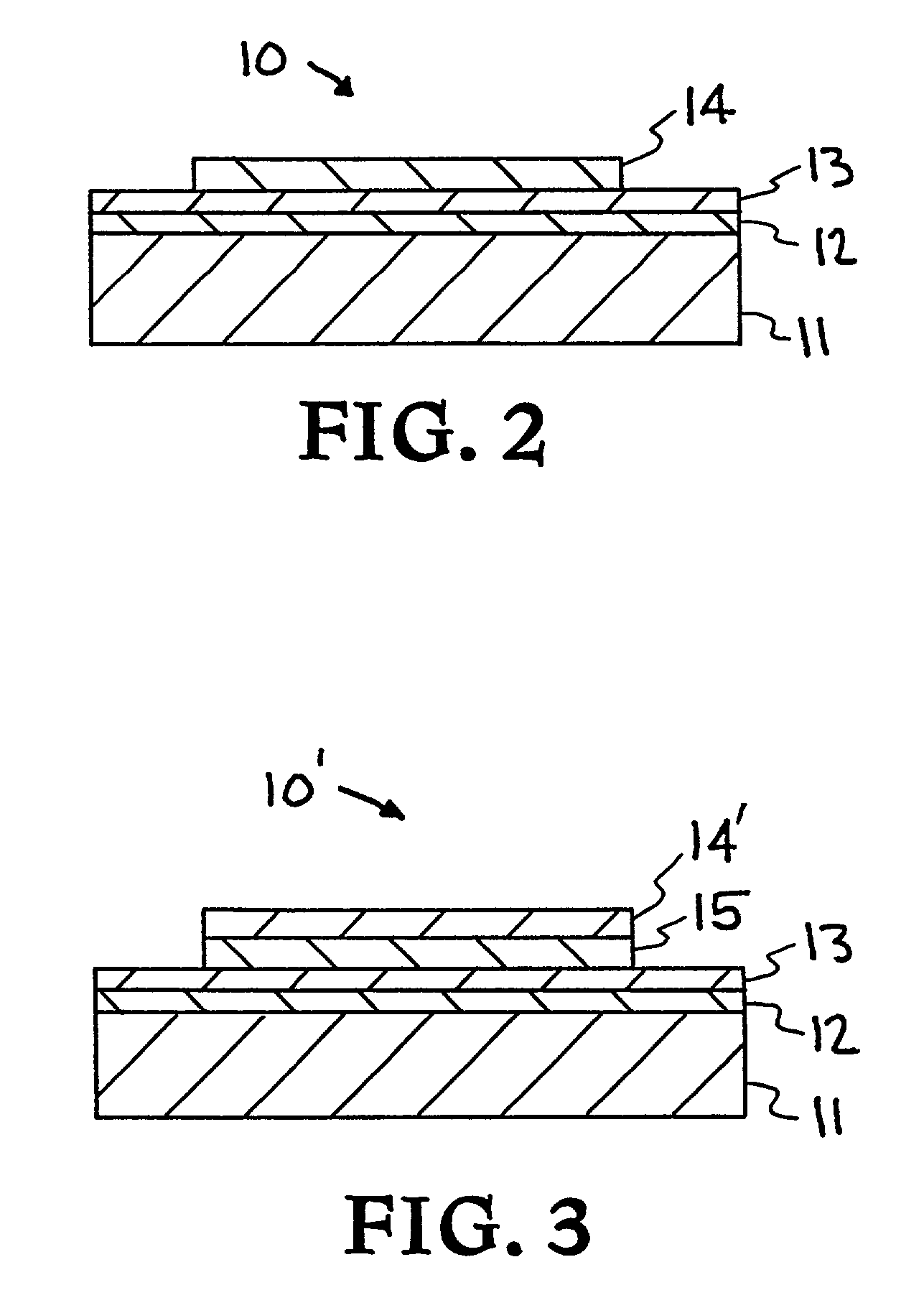

Ceria-based solid oxide fuel cells

InactiveUS20020127455A1Improve power densityMore option for sealingCell electrodesFuel cell auxillariesCerium(IV) oxideCobalt

High-performance intermediate temperature solid oxide fuel cells (SOFCs). The SOFCs are ceria-based structures that can achieve a power output of 300 mW / cm.sup.2 at an operating temperature below 600.degree. C. By way of example, the fuel cell as an anode made of NiO / doped-ceria, a thin film of doped-ceria and / or doped zirconia electrolyte is deposited on the anode, and a cathode of cobalt iron based material, such as (La, Sr)(Co, Fe)O.sub.3 or cobalt, ion, magnesium based material, is deposited on top of the electrolyte, and can operate at a temperature of 550.degree. C. The various layers may be deposited by colloidal spray deposition or aerosol spray casting.

Owner:RGT UNIV OF CALIFORNIA

Composite membrane and method for making

InactiveUS20100167100A1Improve performanceImprove conductivitySemi-permeable membranesMembranesFuel cellsIon exchange

A composite membrane includes a compatibilized porous base membrane and an ion exchange material, which is impregnated into the compatibilized porous base membrane. The base membrane is compatibilized by coating a primer to external and internal surfaces of the porous base membrane and crosslinking the primer. A method for making the membrane, a proton exchange membrane for a fuel cell and a method form making the proton exchange membrane are also provided. The composite membrane is durable, compatible, highly conductive and mechanically stable.

Owner:GENERAL ELECTRIC CO

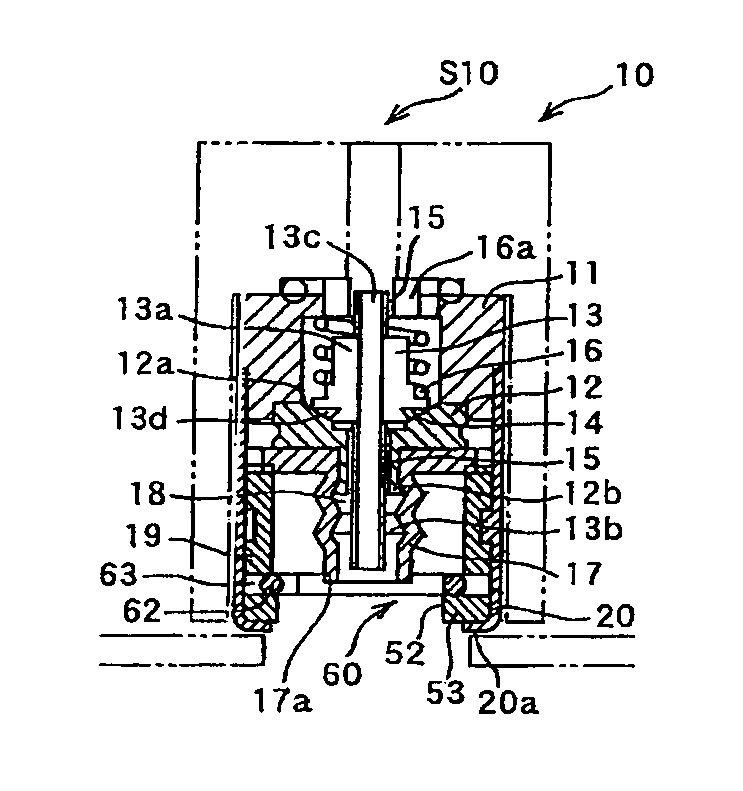

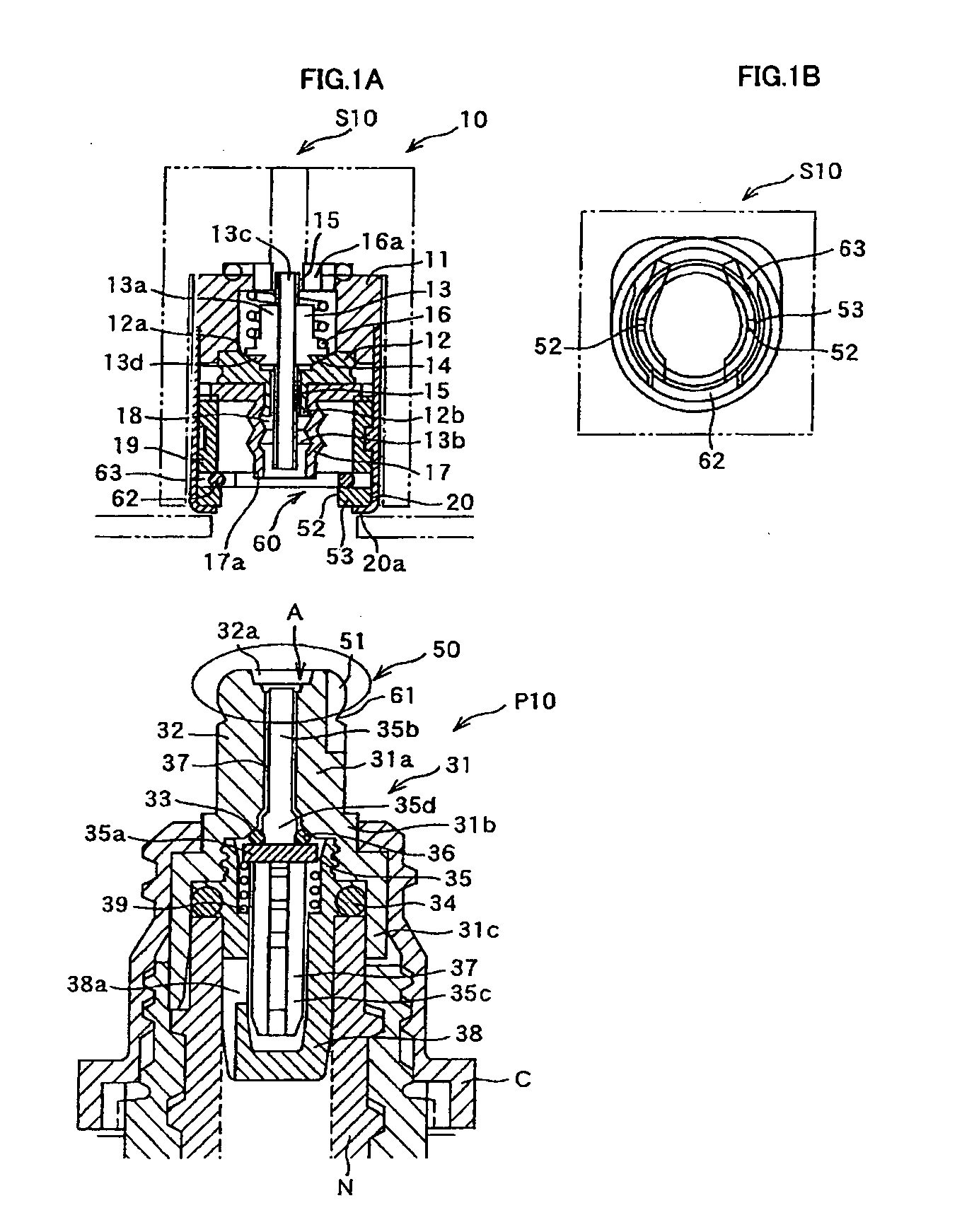

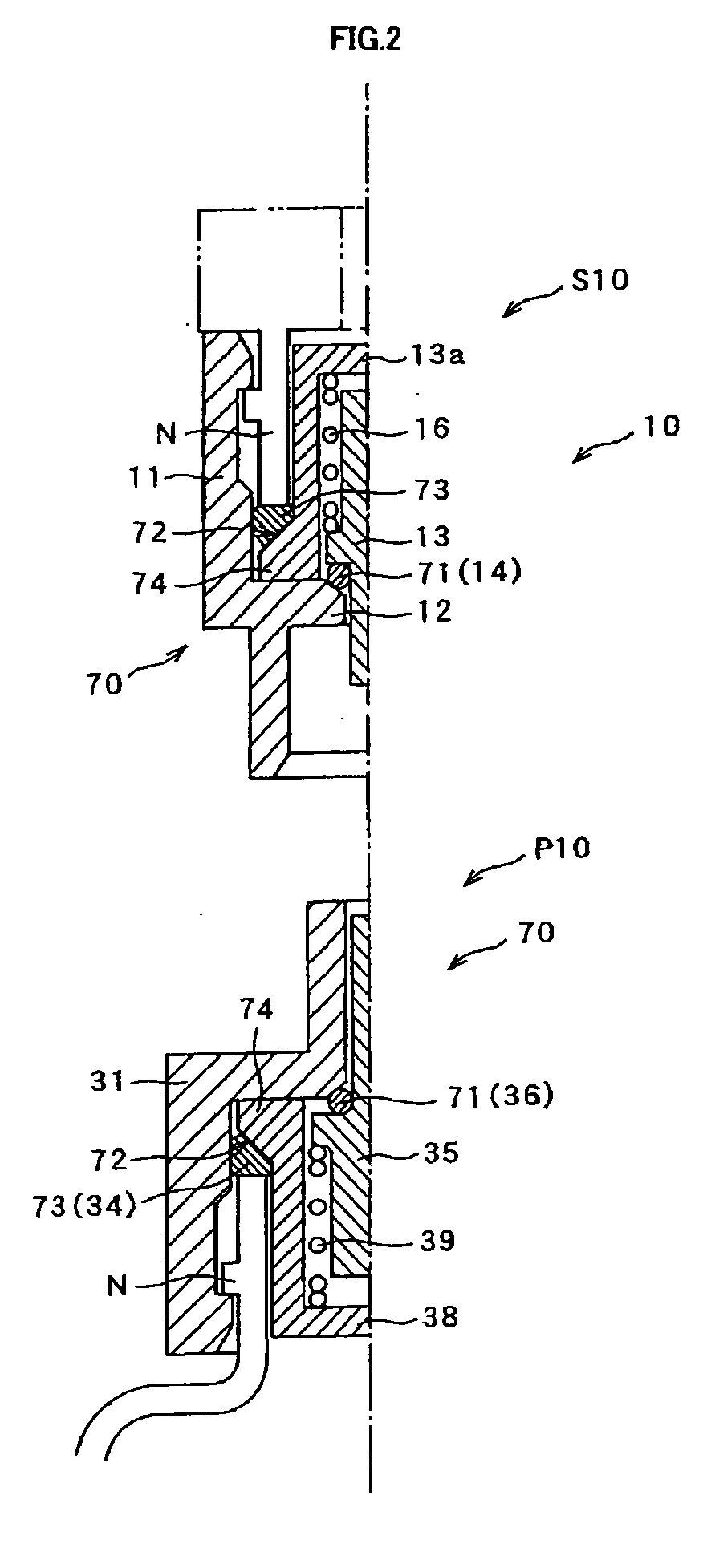

Coupler

InactiveUS20100186836A1Reduce in quantityConstant forceReactant parameters controlCouplingsEngineeringPosition control

A couple 10 includes a valve seal member 71 (36) provided in a flow path between a valve 35 and a coupler main body 31 which can be opened and closed, and a container-inside-outside seal member (73) which is used as both a container seal member (73) for forming a seal between the container main body 31 and a valve holder 38 and a holder seal member (73) for forming a seal between the coupler main body 31 and the valve holder 38. By this arrangement, the number of the seal members can be reduced, processes for assembling can be simplified and the manufacturing cost can be saved. Mounting position of the holder 38 can be controlled by a mounting position control section 74 to enable sealing for maintaining energizing force by energizing means 39 constant and ensuring opening of the coupler as well as for securing the sealed state accurately.

Owner:TOYO SEIKAN KAISHA LTD +1

Polymer composition

InactiveUS20020127454A1Facilitates conversion of fuelPromote lowerElectrolyte holding meansIon-exchanger regenerationElastomerPolymer chemistry

The invention includes compositions comprising at least first and second polymers and optionally a third polymer wherein acid subunits, basic subunits and elastomeric subunits are contained in the polymers. In one aspect, the composition comprises a ternary polymer blend comprising an acidic polymer comprising acidic subunits, a basic polymer comprising basic subunits and an elastomeric polymer comprising elastomeric subunits. In an alternate aspect, the composition comprises a binary polymer blend which comprises acidic or basic subunits in one polymer and a copolymer comprising the other of the acidic or basic subunit and an elastomeric subunit. Such polymer compositions may be formed into a membrane having electrochemical properties which permit the use of such a membrane in an electrochemical device.

Owner:POLYFUEL INC +1

Modified carbon products, their use in bipolar plates and similar devices and methods relating to same

InactiveUS20050221139A1Improve hydrophobicityReduce hydrophobicityElectrolyte holding meansFuel cells groupingFuel cellsModified carbon

Bipolar plates incorporating modified carbon products. The modified carbon products advantageously enhance the properties of the bipolar plates, leading to more efficiency within a fuel cell or a similar device.

Owner:CABOT CORP

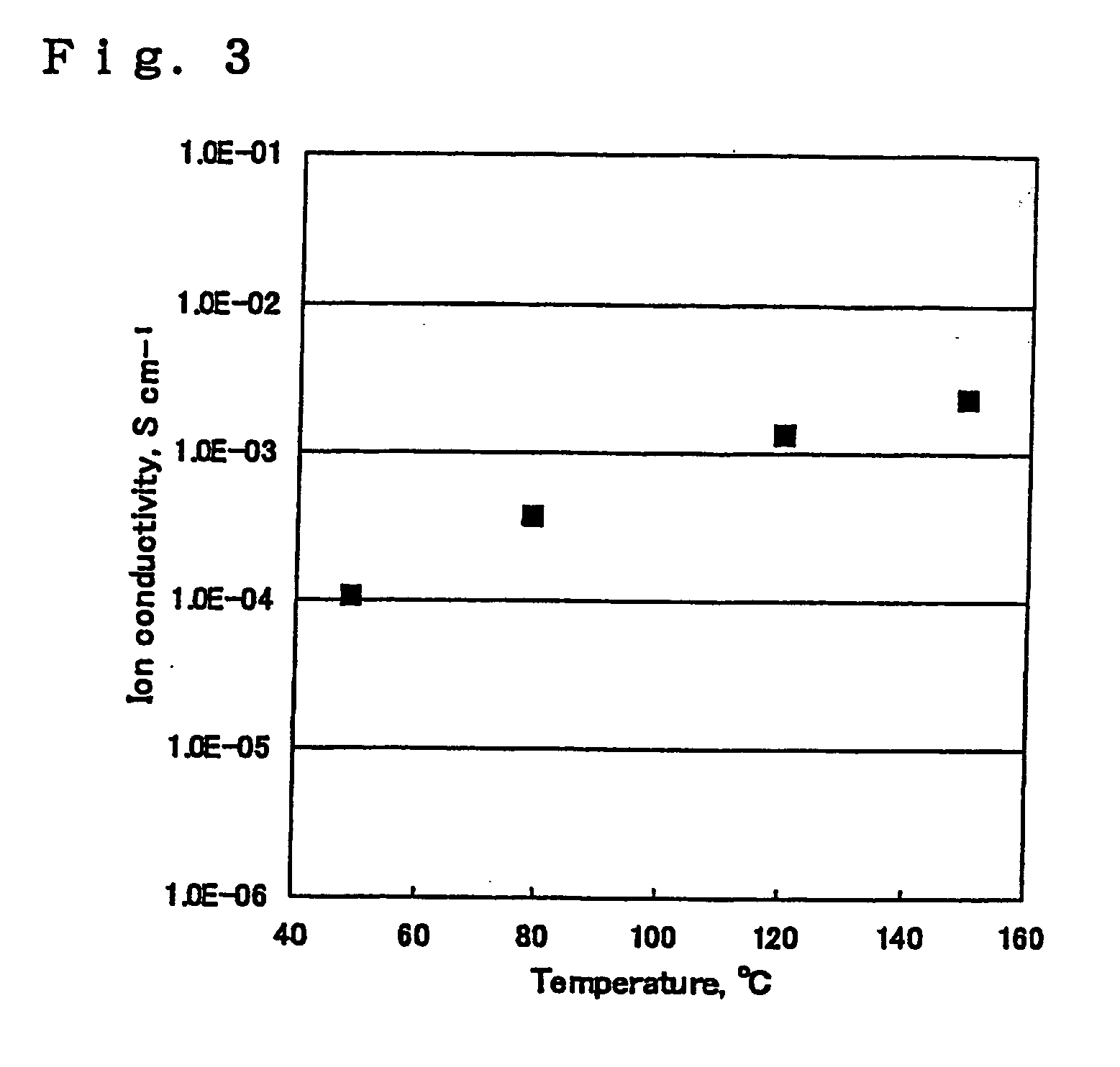

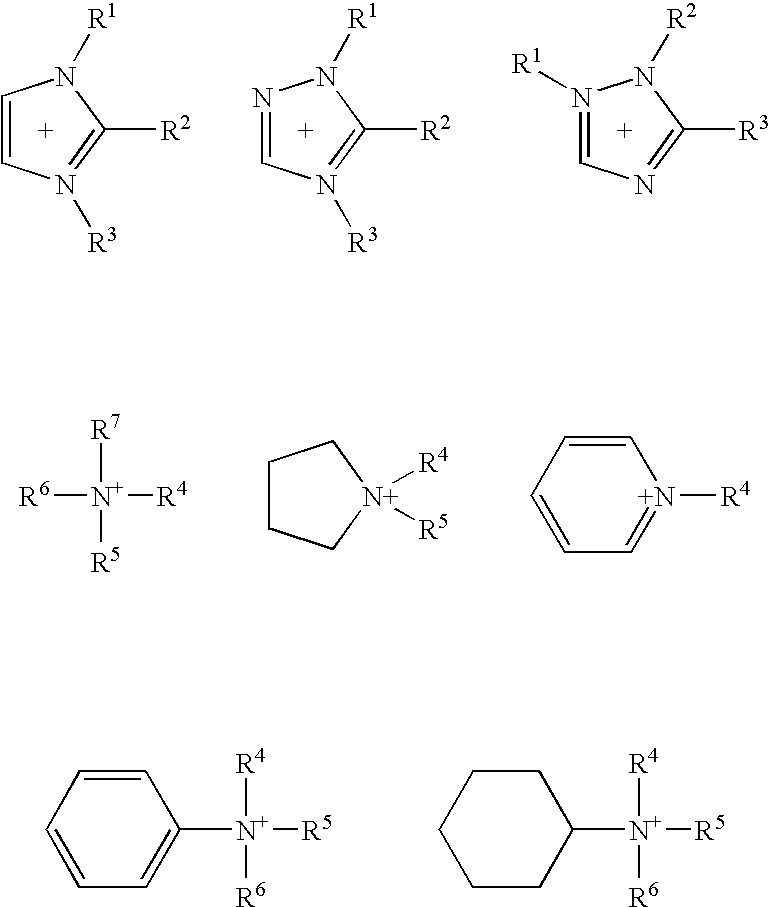

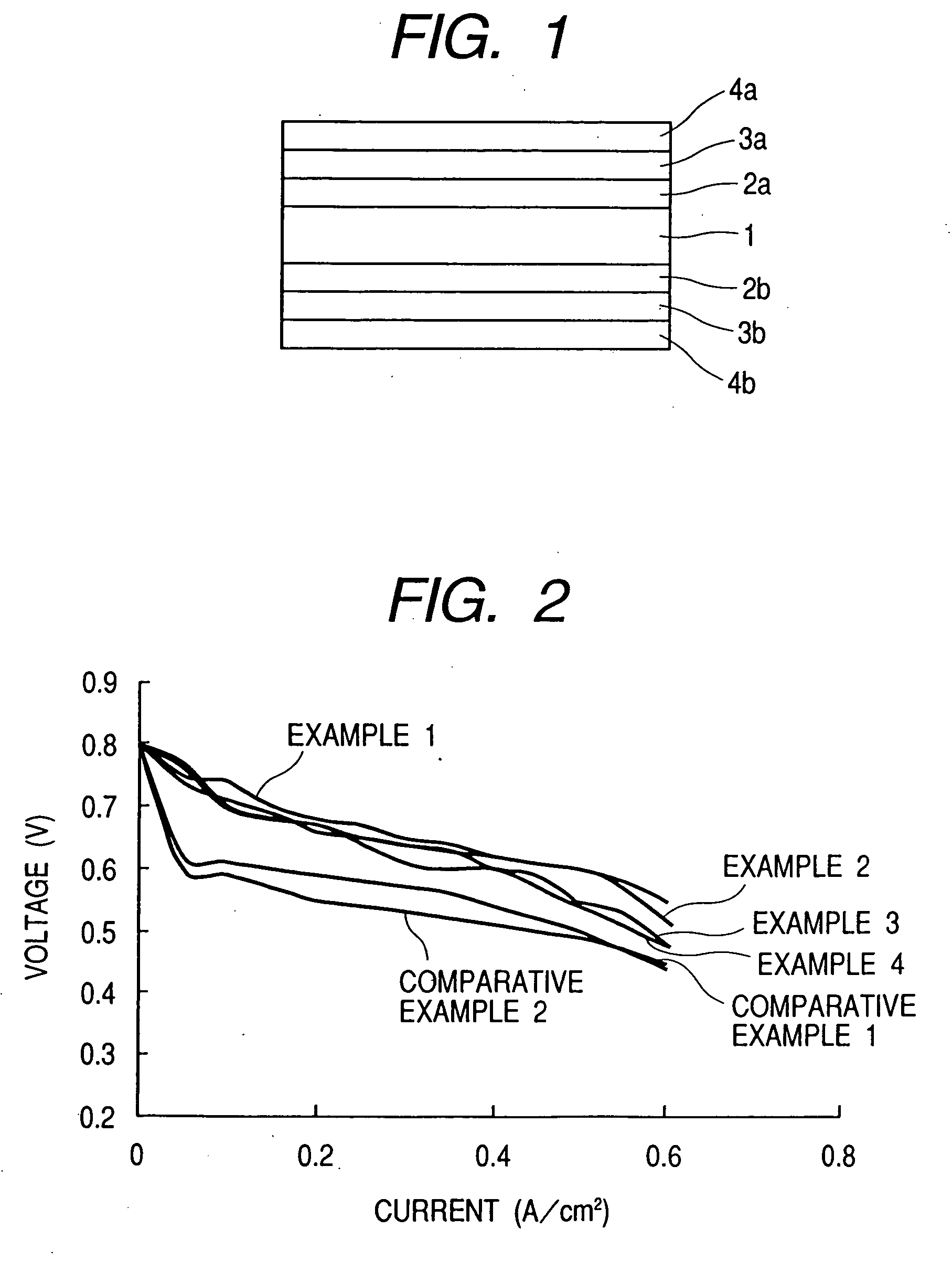

Polyelectrolyte membrane and production method therefor

InactiveUS20050221193A1High mechanical strengthSecures high ion conductivityCell electrodesFuel cell auxillariesPolymer scienceElectrolysis

A polymer electrolyte membrane comprising a microporous polymer membrane having pores penetrating through the opposite sides thereof. The microporous polymer membrane holds a mixture of a polymer and a molten salt at a weight ratio of 1 / 99 to 99 / 1 and / or a molten salt. The polymer electrolyte membrane is inexpensive, durable, excellent in mechanical strength, excellent in structural retention in high temperatures, and capable of stably holding a molten salt in its porous polymer membrane structure, shows high heat resistance, and secures high ionic conductivity in the absence of water or a solvent and is therefore useful in fuel cells, secondary batteries, electric double layer capacitors, electrolytic capacitors, and the like.

Owner:UBE IND LTD

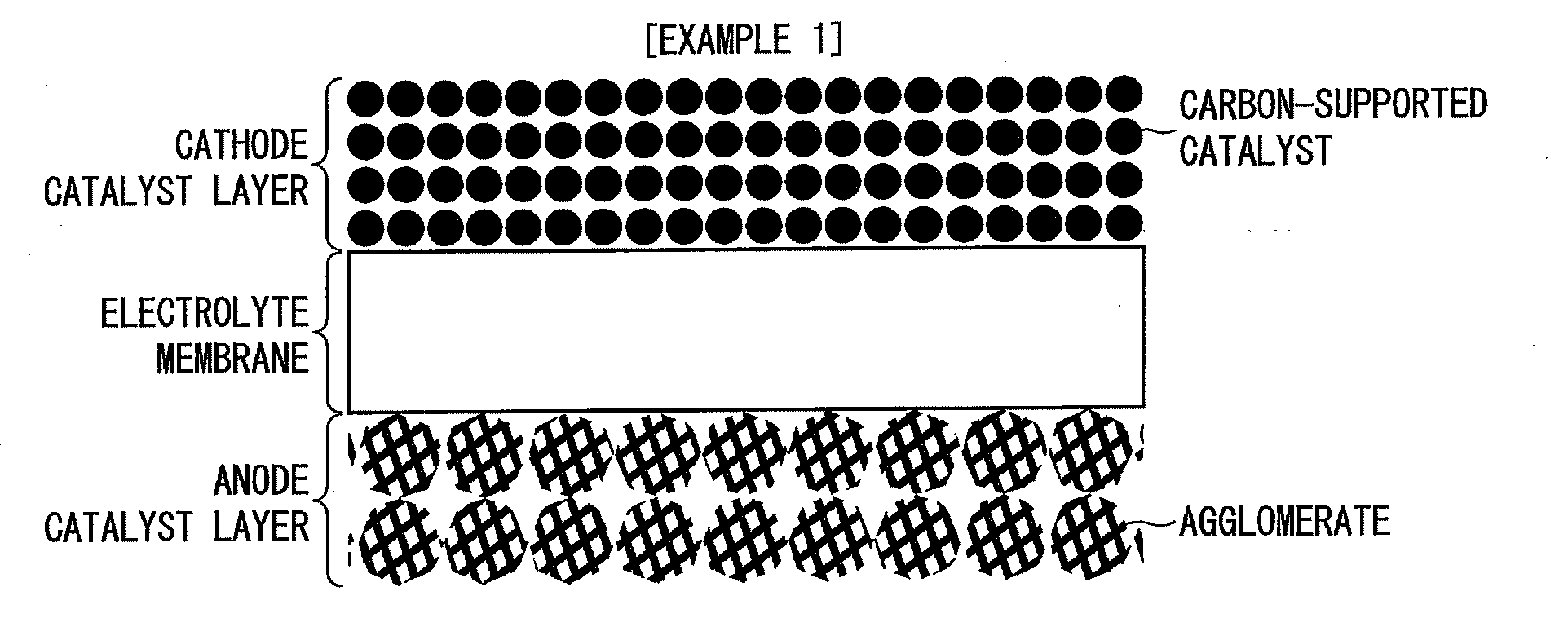

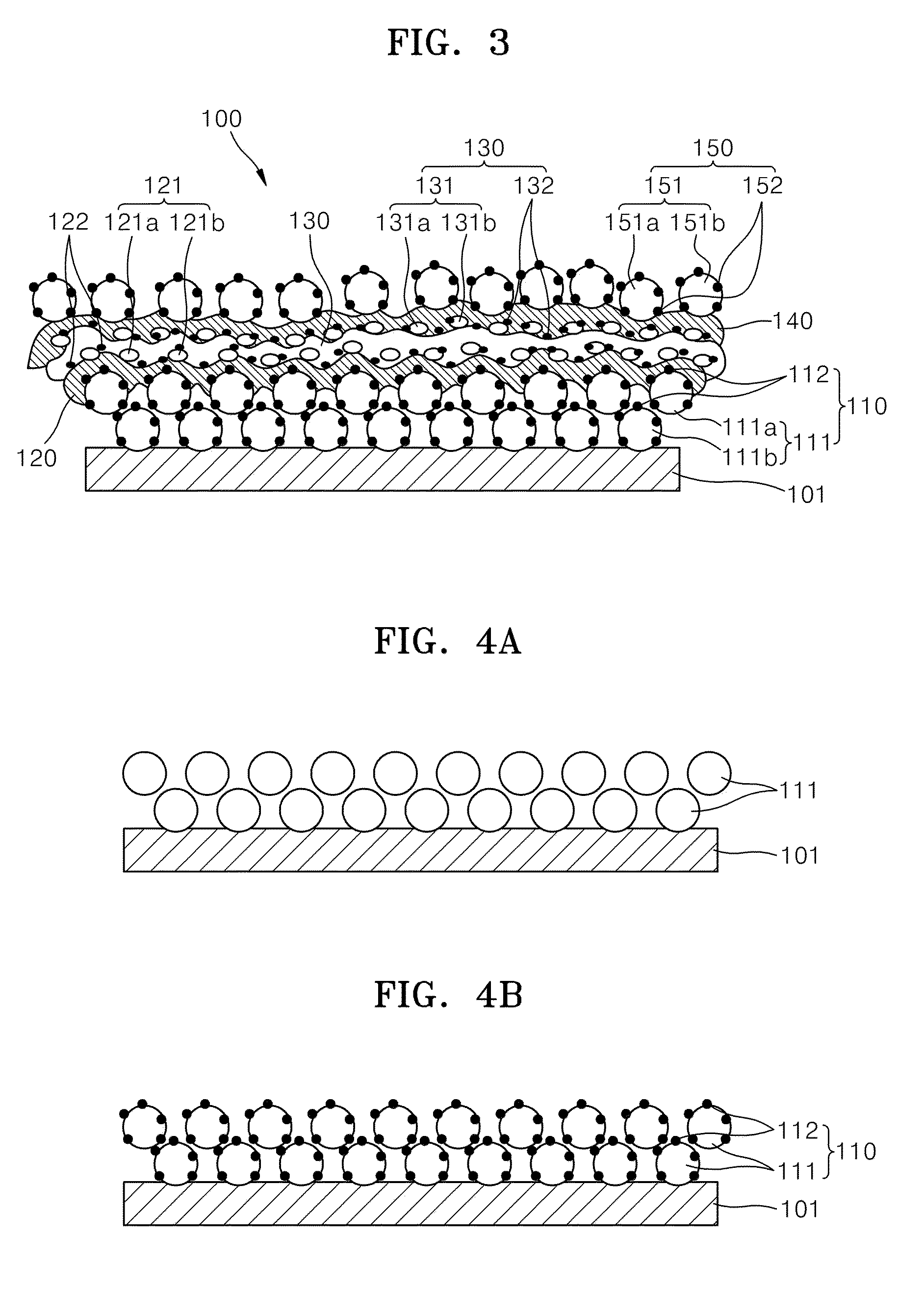

Catalyst Layer for Fuel Cell Membrane Electrode Assembly, Fuel Cell Membrane Electrode Assembly Using the Catalyst Layer, Fuel Cell, and Method for Producing the Catalyst Layer

ActiveUS20110008707A1Material diffusibilityAvoid power failureCell electrodesSolid electrolyte fuel cellsFuel cellsEngineering

A catalyst layer for a fuel cell membrane electrode assembly includes a plurality of agglomerates, adjacent ones of the plurality of agglomerates contacting with each other with pores provided between said adjacent ones of the plurality of agglomerates, each of the plurality of agglomerates being formed by packing a plurality of catalysts each consisting of noble metal fine particles supported on a fiber-like support material, adjacent ones of the plurality of catalysts contacting with each other with pores provided between said adjacent ones of the plurality of catalysts, and each of the plurality of catalysts contacting with a plurality of catalysts other than said each catalyst at a plurality of contact points. This allows providing a catalyst layer, a fuel cell membrane electrode assembly, and a fuel cell, each of which has compact size and excellent power generation performance, and a method for producing the same.

Owner:ONED MATERIAL INC

Ordered mesoporous carbon composite catalyst, method of manufacturing the same, and fuel cell using the same

An ordered mesoporous carbon (OMC) composite catalyst includes an OMC; and metal particles and at least one component selected from a group consisting of nitrogen and sulfur included in the OMC. The ordered mesoporous carbon composite catalyst may be formed by impregnating an ordered mesoporous silica with a mixture of at least one selected from the group consisting of a nitrogen-containing carbon precursor, and a sulfur-containing carbon precursor, a metal precursor, and a solvent; drying and heat-treating the impregnated OMS; carbonizing the dried and heat-treated OMS to obtain a carbon-OMS composite; and removing the OMS from the carbon-OMS composite. A fuel cell may contain the OMC composite catalyst.

Owner:SAMSUNG ELECTRONICS CO LTD

Electolyte sheets for solid oxide fuel cell and method for manufacturing same

InactiveUS20050271919A1Reduce warpingImprove productivitySolid electrolytesCell electrodesFuel cellsSurface roughness

The present invention provides electrolyte sheets for solid oxide fuel cells, the electrolyte sheets being able to improve their adhesion to electrode films formed on both surfaces thereof and being also able to improve electric power generation characteristics of fuel cells by an increase in their electrode reaction areas. There is disclosed an electrolyte sheet for solid oxide fuel cells including a sintered sheet, wherein surface roughness of the sheet as measured by an optical and laser-based non-contact three-dimensional profile measuring system is 2.0 to 20 μm in Rz and 0.20 to 3.0 μm in Ra, and wherein a ratio of Rz of one surface (having a greater Rz and a greater Ra) to Rz of the other surface having a smaller Rz and a smaller Ra is in a range of 1.0 to 3.0, and a ratio of Ra of one surface (having a greater Rz and a greater Ra) to Ra of the other surface having a smaller Rz and a smaller Ra is in a range of 1.0 to 3.0, and a ratio of Rmax to Rz (Rmax / Rz ratio) of at least one surface is in a range of 1.0 to 2.0.

Owner:NIPPON SHOKUBAI CO LTD

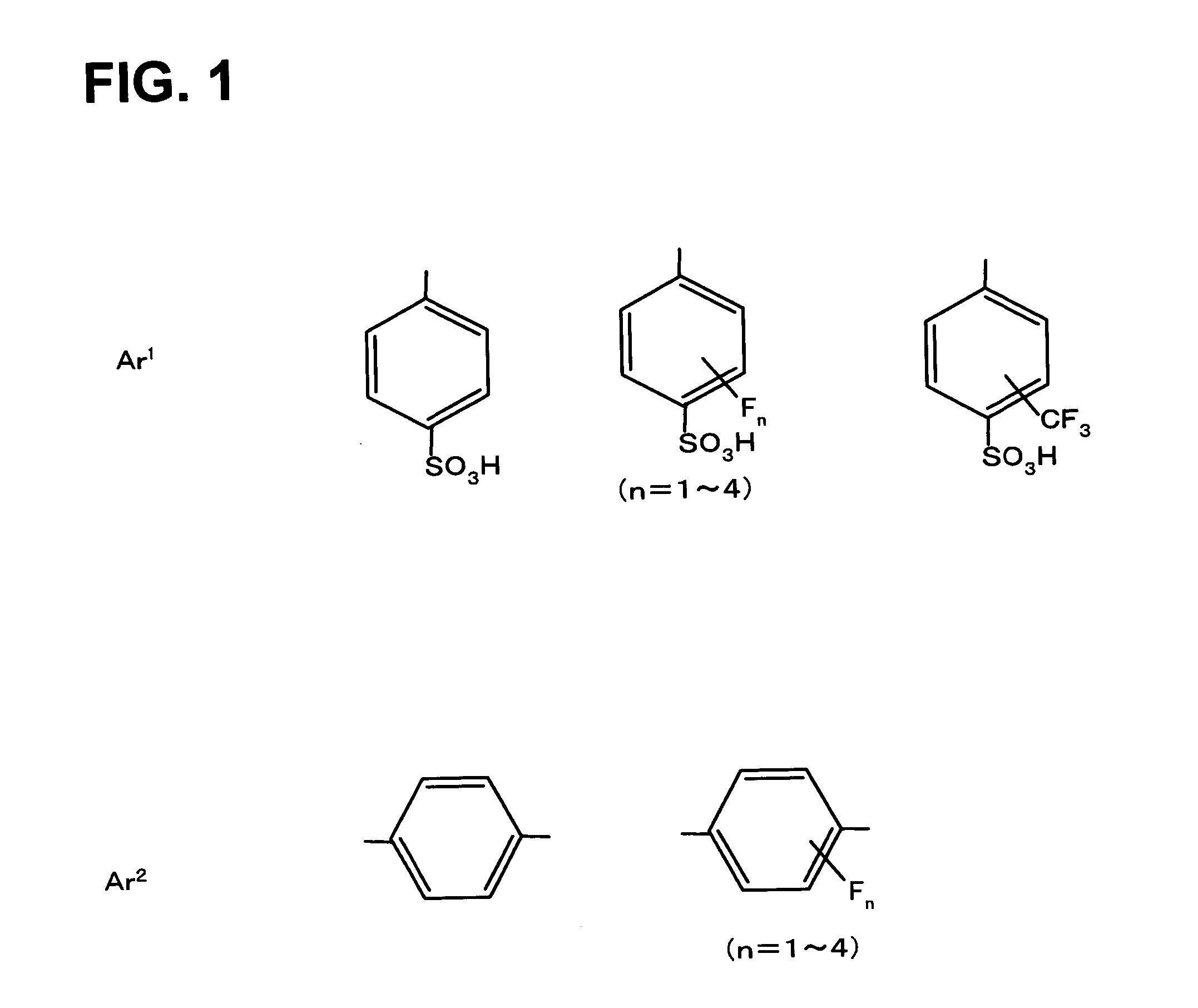

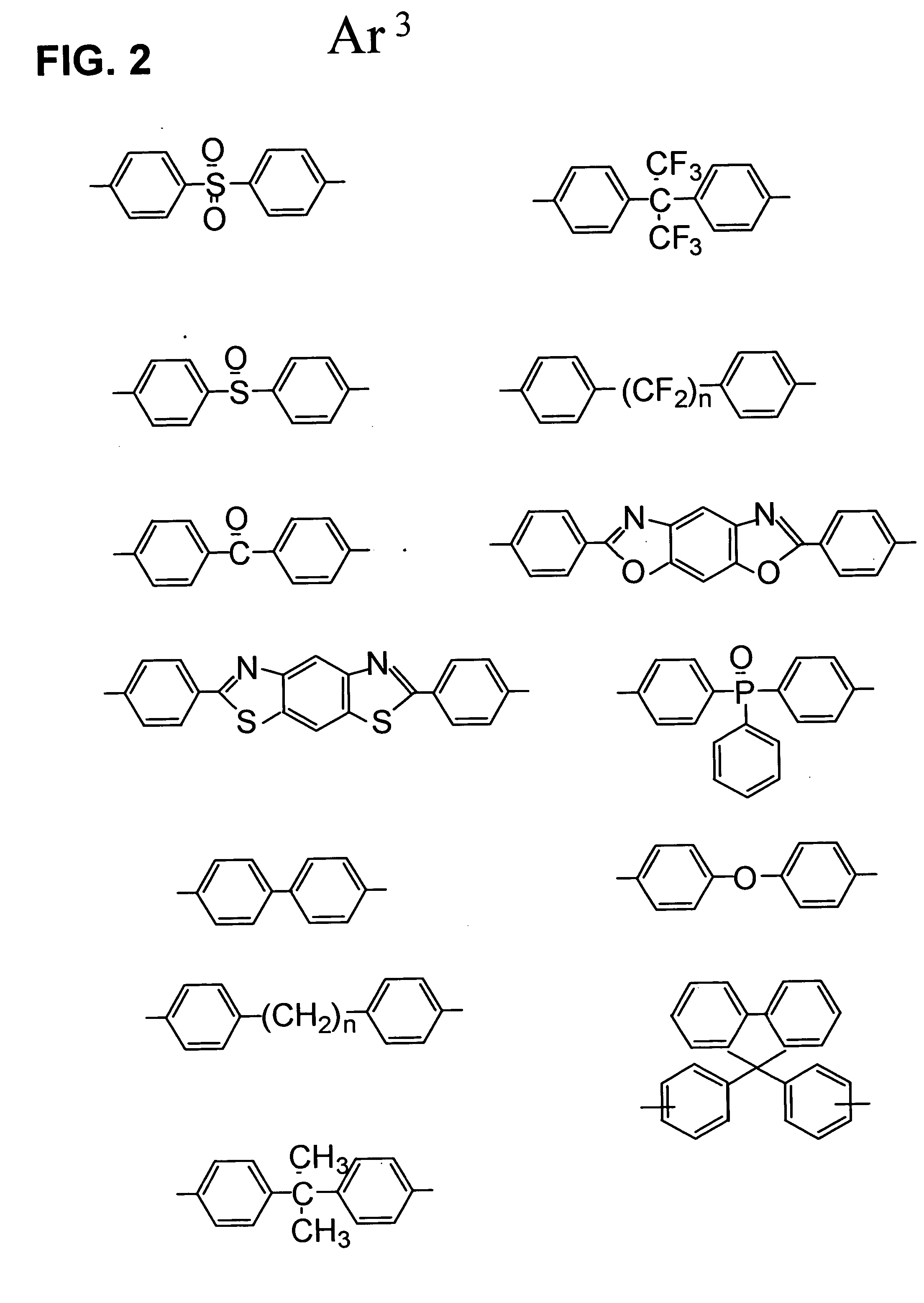

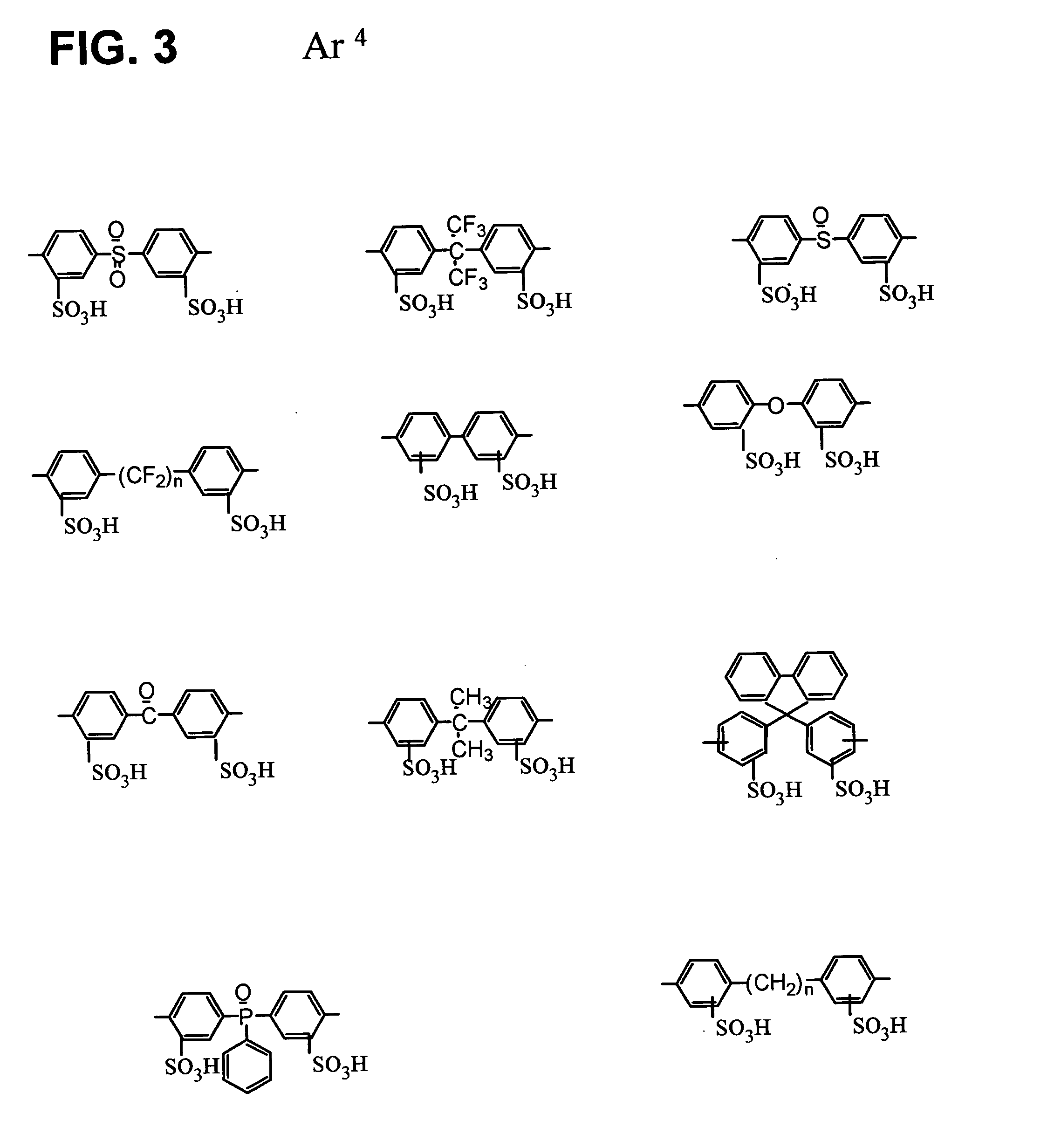

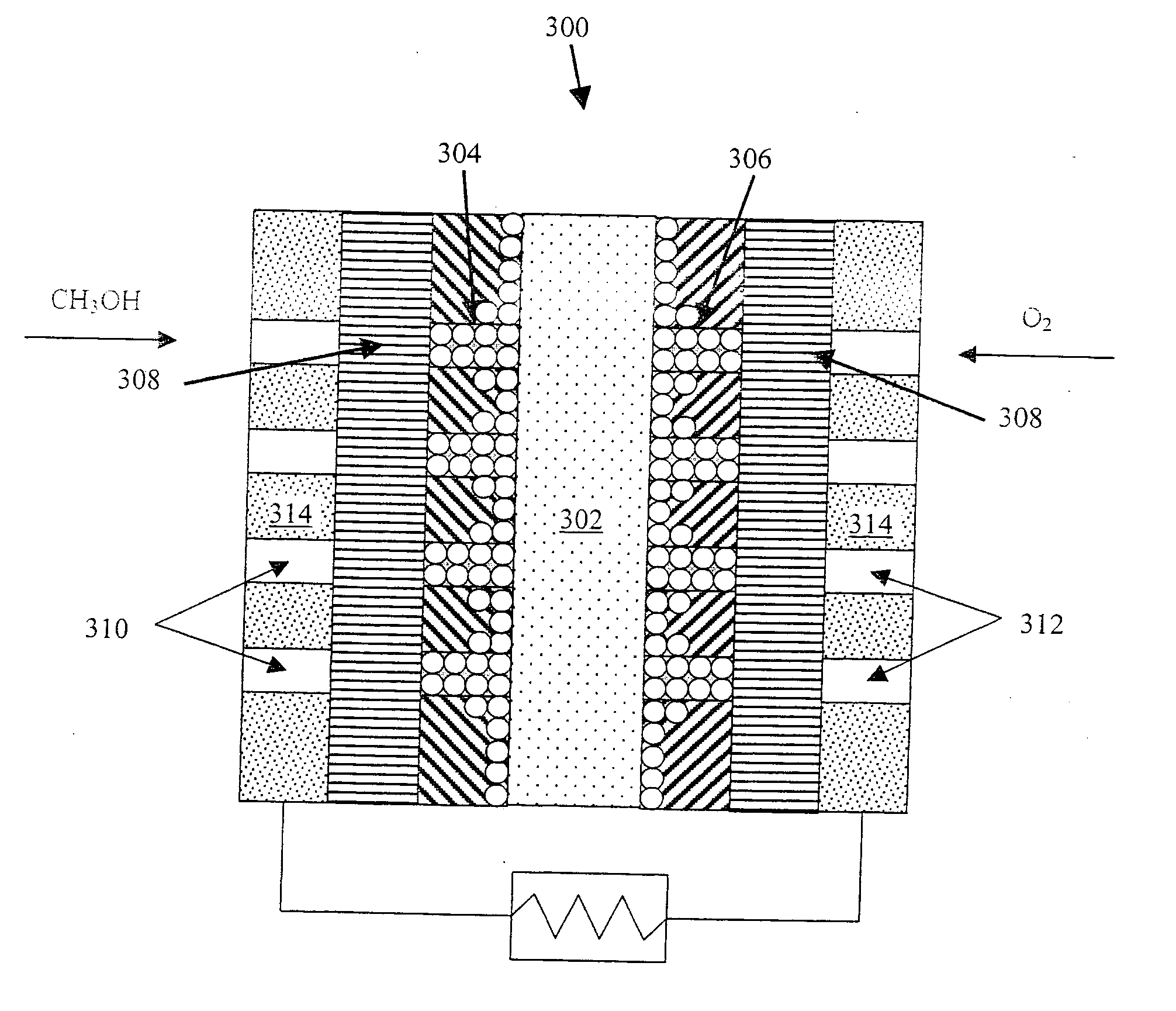

Sulfonic acid group-containing, proton-conducting polymer composition, a solid electrolyte membrane and a solid polymer fuel cell

InactiveUS20050221135A1Low methanol cross-overImprove proton conductivityOrganic chemistryIon-exchanger regenerationFuel cellsTriazine

A solid electrolyte membrane for solid polymer fuel cells, or the like is provided that is chemically stable in a strong acid atmosphere, and has low methanol cross-over as well as high proton conductivity. The solid electrolyte membrane is manufactured, using an electrolyte composition comprising a sulfonic acid group-containing polymer having a specific triazine structure. This polymer can be synthesized, for example, from a sulfonic acid group-containing dihydroxy compound having a triazine structure, and a difluoride.

Owner:FUJITSU LTD

Modified carbon products, their use in proton exchange membranes and similar devices and methods relating to the same

InactiveUS20050221141A1High mechanical strengthDecrease in proton conductivityElectrolyte holding meansIon-exchanger regenerationFuel cellsModified carbon

Proton exchange membranes incorporating modified carbon products. The modified carbon products advantageously enhance the properties of proton exchange membranes, leading to more efficiency within a fuel cell or similar device.

Owner:CABOT CORP

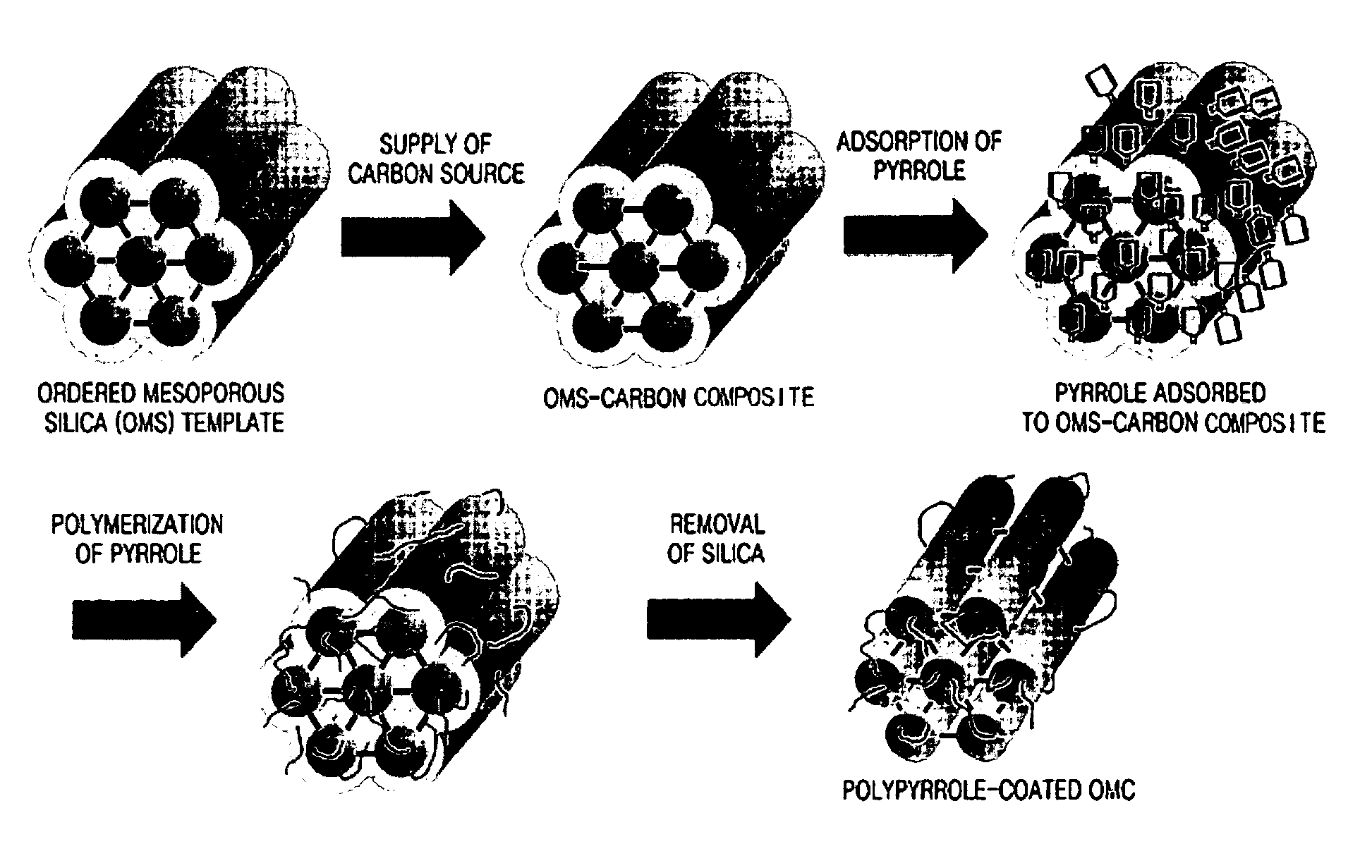

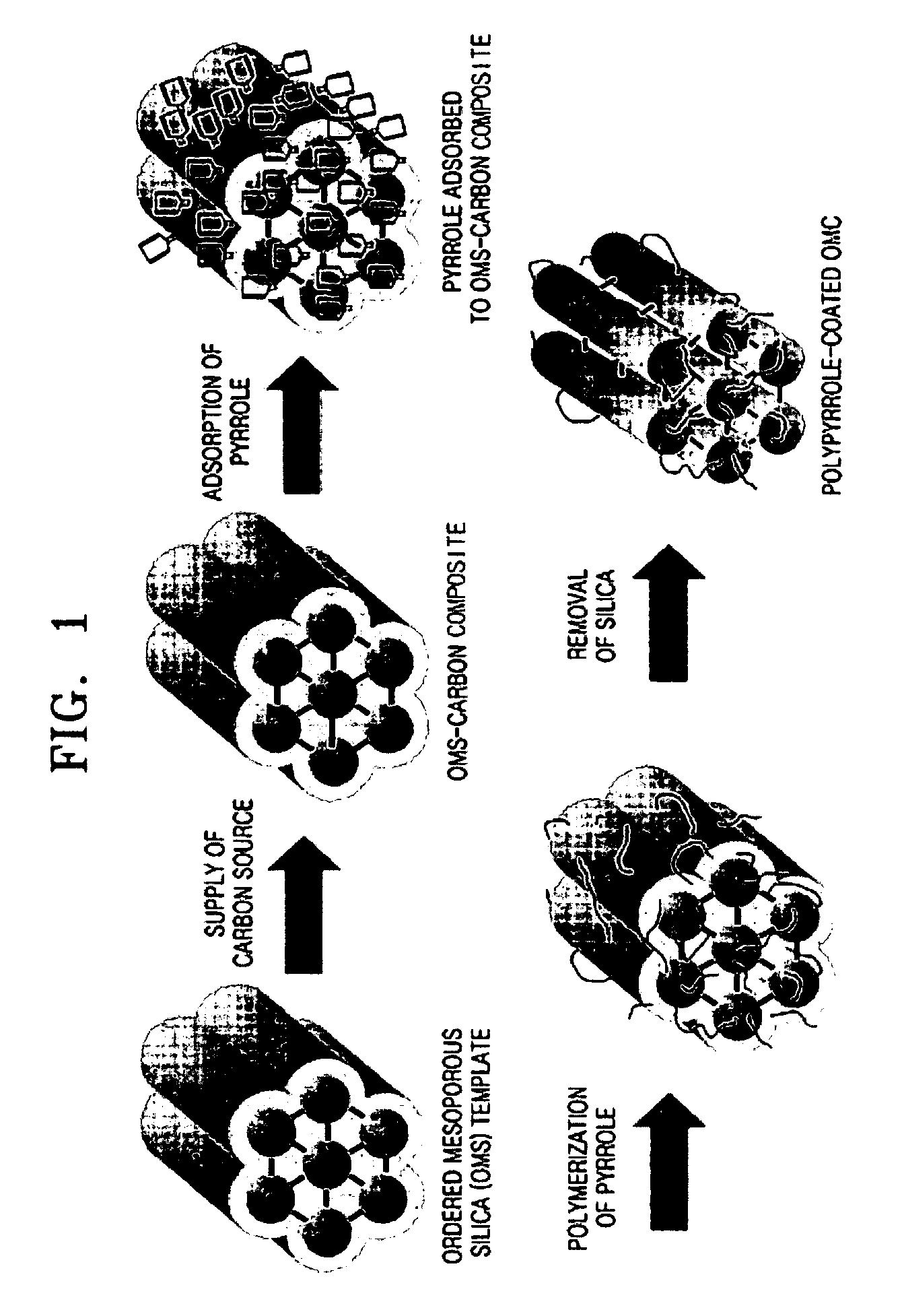

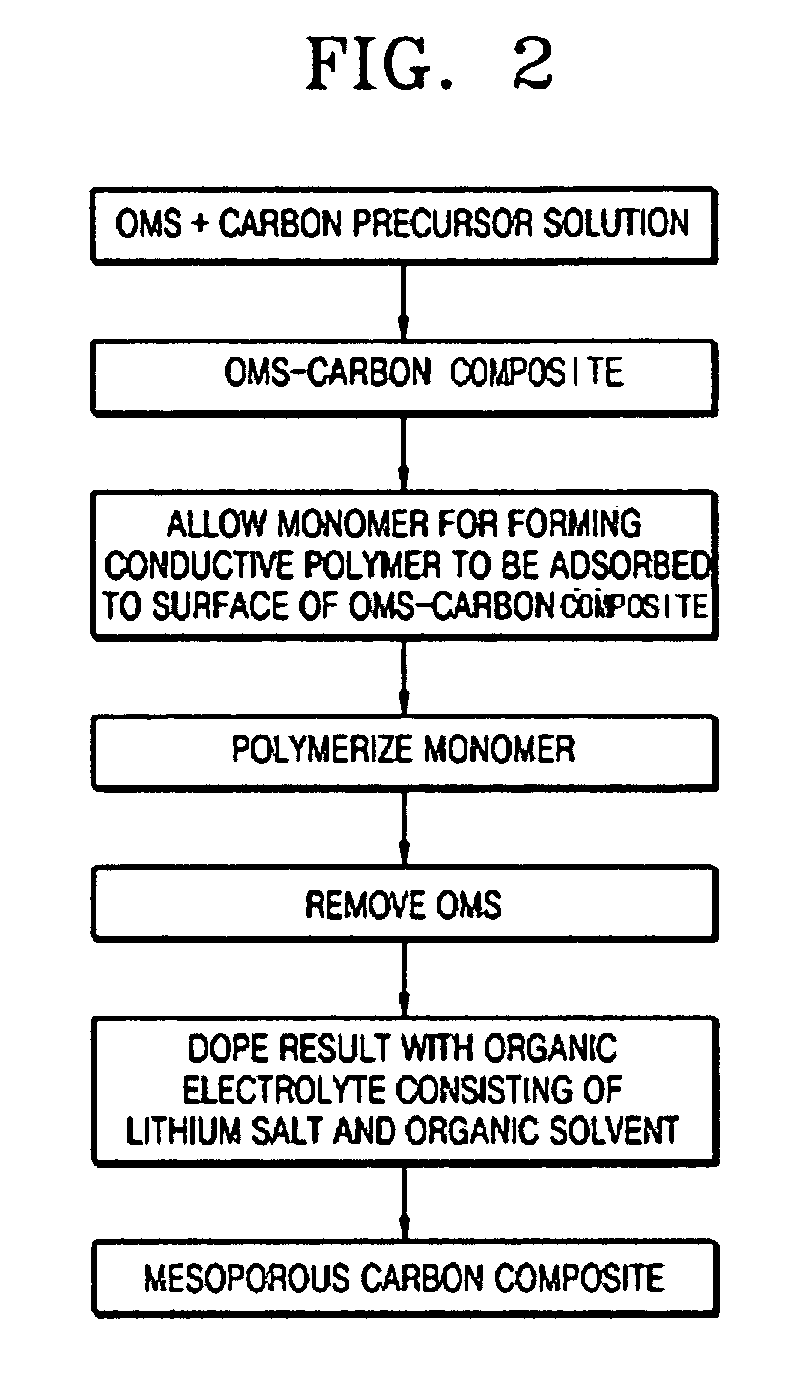

Mesoporous carbon composite, method of preparing the same, and fuel cell using the mesoporous carbon composite

InactiveUS20070042268A1Reduce sheet resistanceImprove efficiencyMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsCarbon compositesConductive polymer

A mesoporous carbon composite includes mesoporous carbon having mesopores; a conductive polymer coated on only an outer surface of the mesoporous carbon; and an organic electrolyte comprising a lithium salt and an organic solvent. The mesoporous carbon composite may be prepared by impregnating an ordered mesoporous silica (OMS) with a carbon precursor mixture comprising a carbon precursor, an acid, and a solvent; heat-treating and carbonizing the impregnated OMS to form an OMS-carbon composite; mixing the OMS-carbon composite with a monomer that forms a conductive polymer and a solvent to provide a surface of the OMS-carbon composite with the monomer that forms a conductive polymer; polymerizing the monomer to obtain a conductive polymer-coated OMS-carbon composite; removing the OMS from the conductive polymer-coated OMS-carbon composite to obtain a conductive polymer-coated mesoporous carbon; and doping the conductive polymer-coated mesoporous carbon with an organic electrolyte comprising a lithium salt and an organic solvent to form the mesoporous carbon composite. A supported catalyst contains the mesoporous carbon composite, and a fuel cell uses an electrode containing the mesoporous carbon composite.

Owner:SAMSUNG SDI CO LTD

Methods for the electrochemical optimization of solid oxide fuel cell electrodes

ActiveUS20050271931A1Easy to operatePower generationActive material electrodesSolid electrolyte fuel cellsFuel cellsEngineering

The present invention provides a solid oxide fuel cell which contains an anode, a cathode, and an electrolyte, where at least one of the electrode contains a wash-coat composition that improves the performance of the solid oxide fuel cell. Also provided is a method for making the solid oxide fuel cell.

Owner:CP SOFC IP

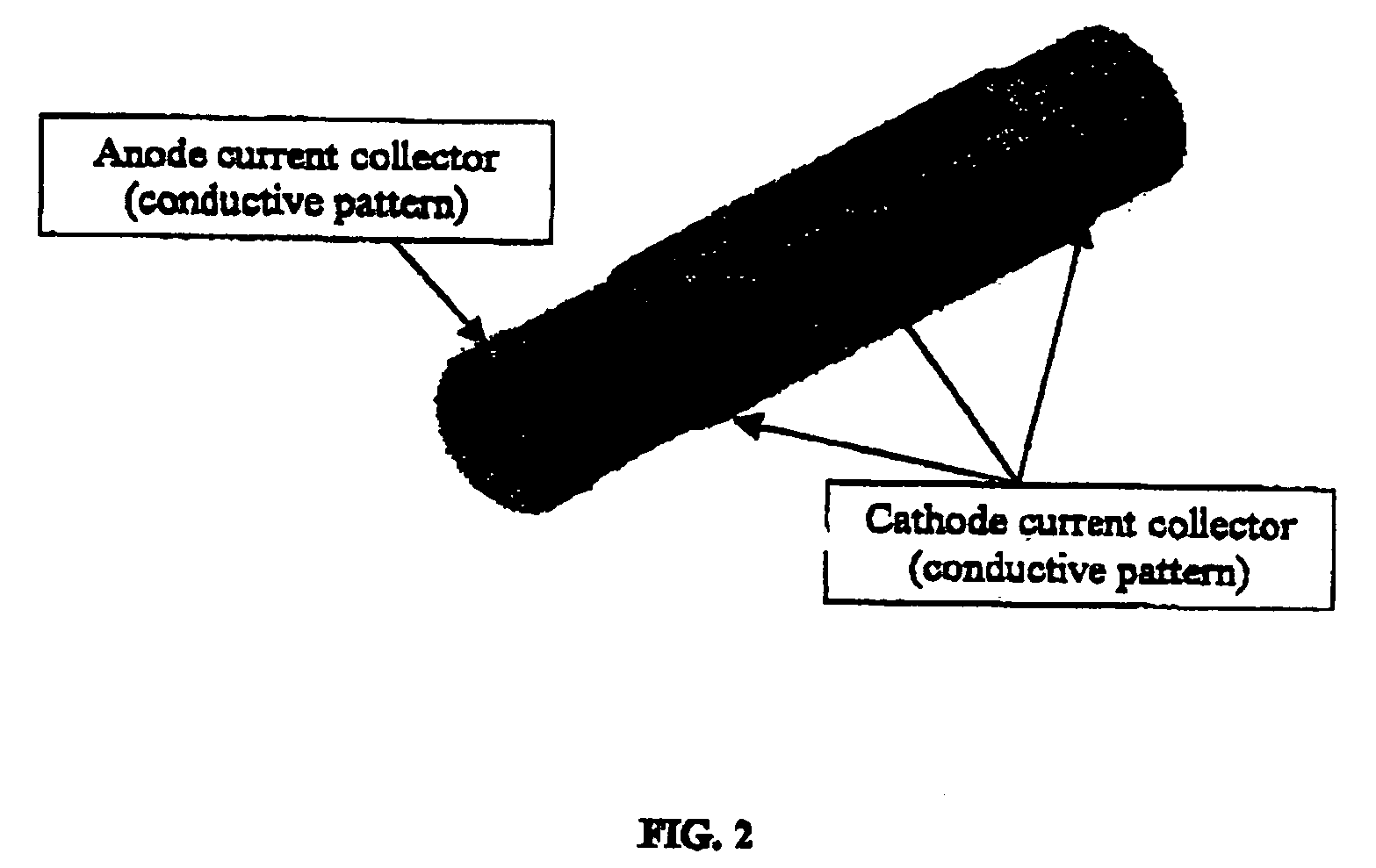

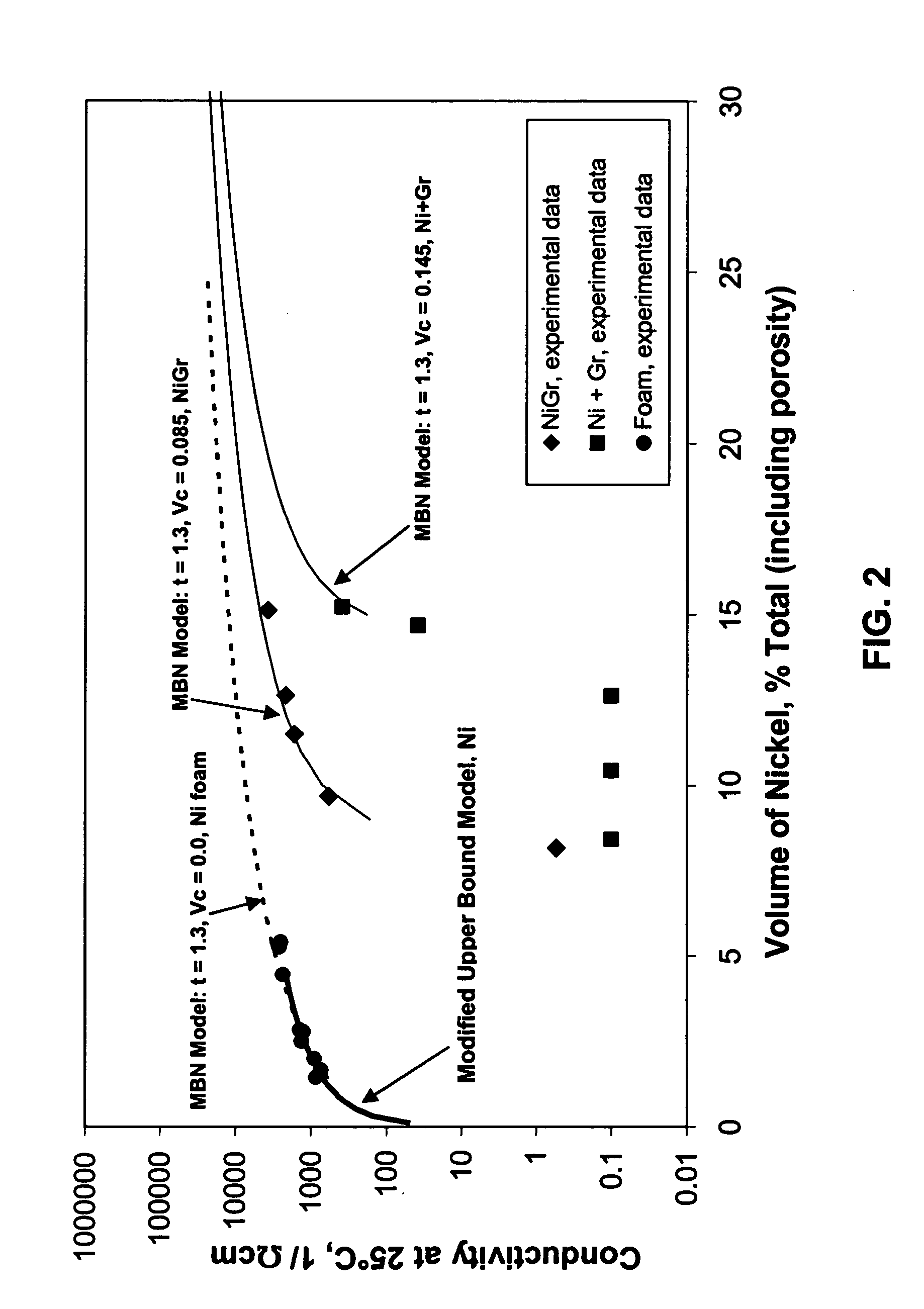

Nickel foam and felt-based anode for solid oxide fuel cells

InactiveUS20050221163A1Improve conductivityReduce in quantityPhotography auxillary processesVacuum evaporation coatingFuel cellsThermal expansion

A solid oxide fuel cell anode is comprised of a nickel foam or nickel felt substrate. Ceramic material such as yttria stabilized zirconia or the like is entrained within the pores of the substrate. The resulting anode achieves excellent conductivity, strength and low coefficient of thermal expansion characteristics while effectively reducing the overall quantity of nickel contained in the fuel cell. Equivalent or better fuel cell anode characteristics result in the present invention as compared to conventional anode designs while simultaneously employing significantly less nickel.

Owner:INCO

Proton conducting electrolyte membranes having nano-grain YSZ as protective layers, and membrane electrode assemblies and ceramic fuel cells comprising same

InactiveUS20110262839A1Prevent penetrationMaterial nanotechnologyCell electrodesElectrical conductorFuel cells

A proton conducting electrolyte membrane comprising a ceramic electrolyte layer including an inorganic proton conductor and a ceramic protective layer formed on at least one surface of the ceramic electrolyte layer and having proton conductivity; a membrane electrode assembly including the proton conducting electrolyte membrane; and a proton conducting ceramic fuel cell including the membrane electrode assembly. In the proton conducting electrolyte membrane, the ceramic protective layer may have an improved chemical bond with the ceramic electrolyte layer compared with a Pd metal protective layer, such that interlayer delamination may be lessened. Also, compared with a Pd metal protective layer, the ceramic protective layer is more appropriate for ceramic electrolytes such as BYZ and BYC that transmit protons or simultaneously transmit protons and oxygen ions used in a fuel cell operating at a temperature range of about 200 to about 500° C., for example, about 250 to about 500° C.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Ionic polymer devices and methods of fabricating the same

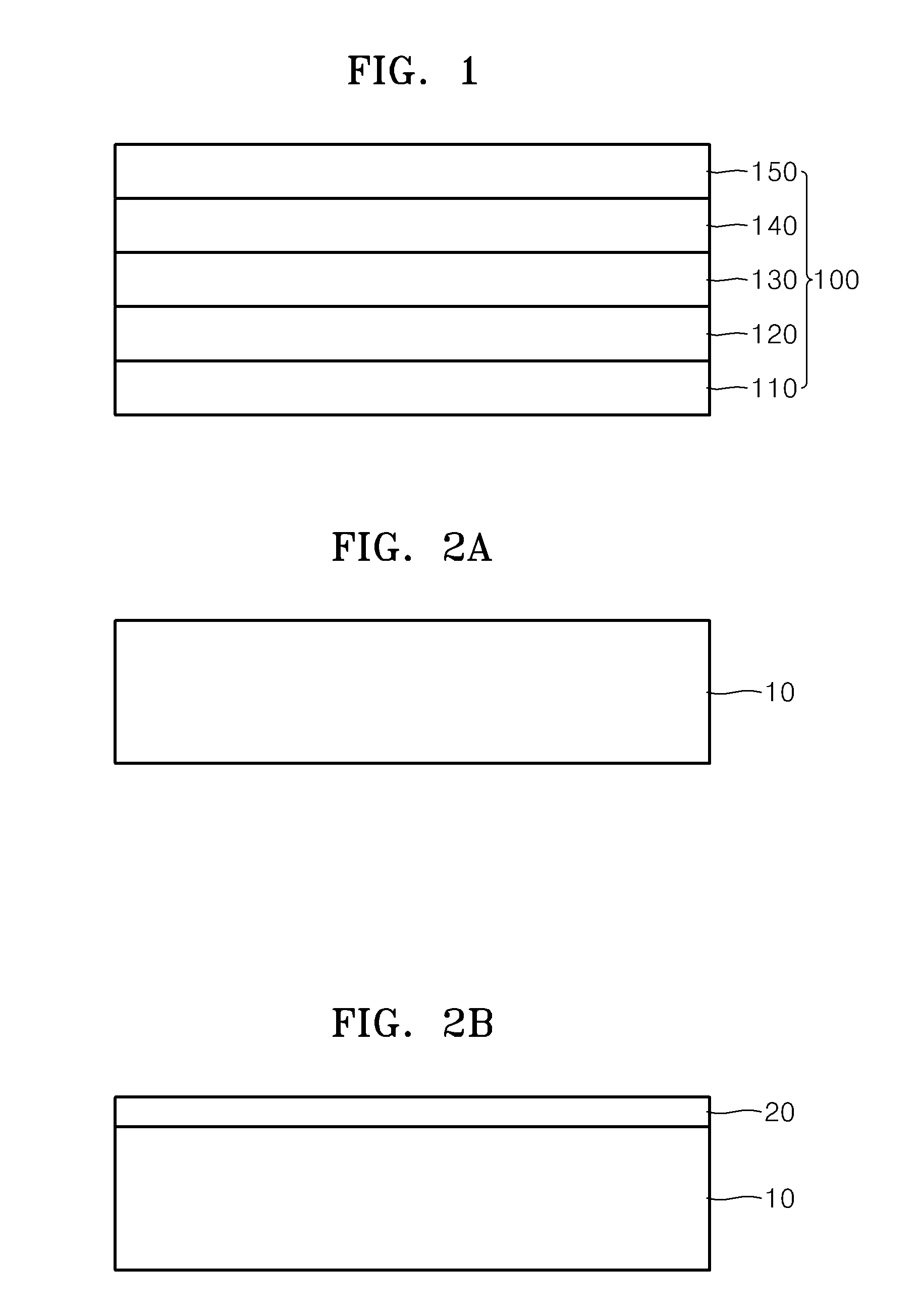

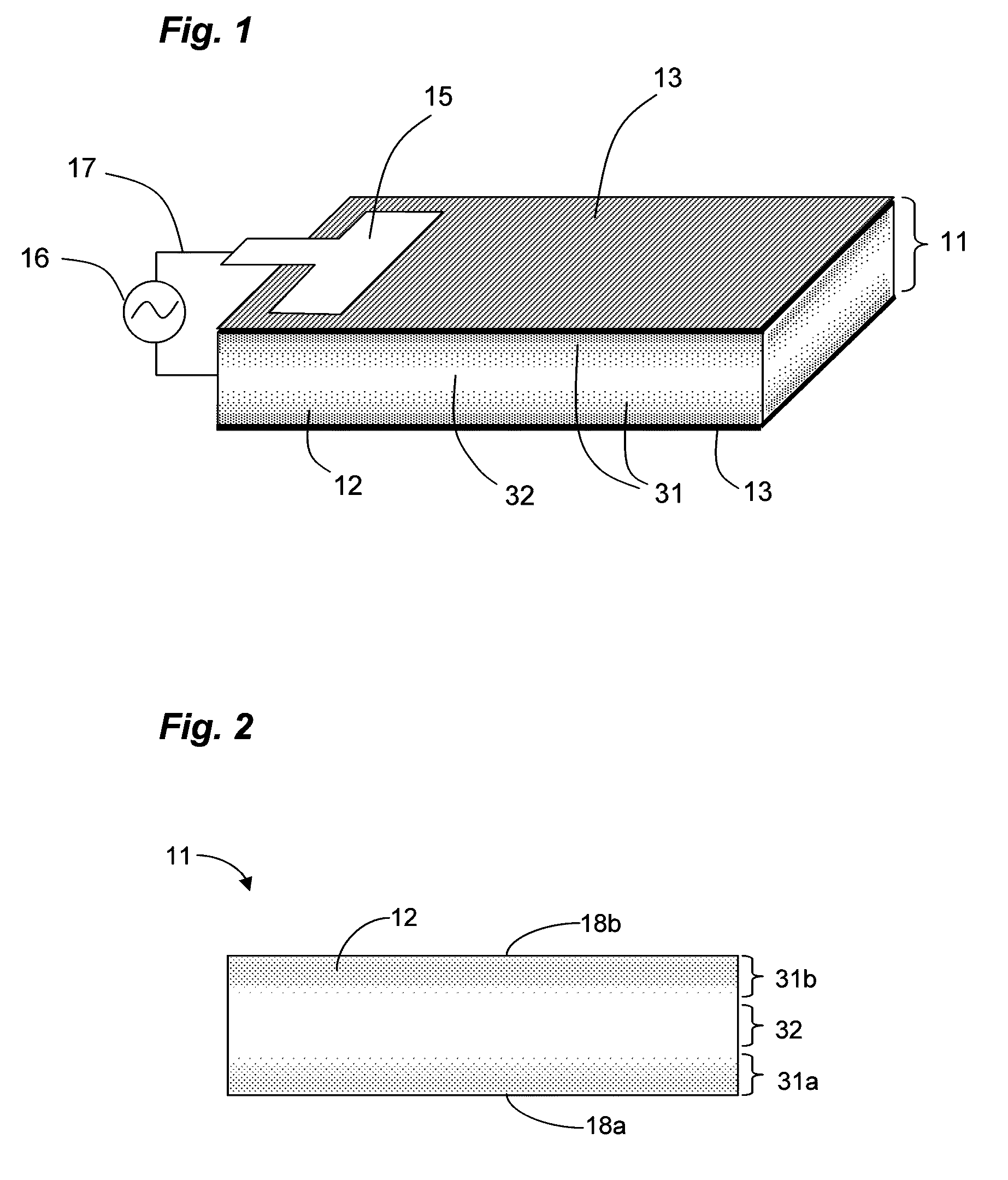

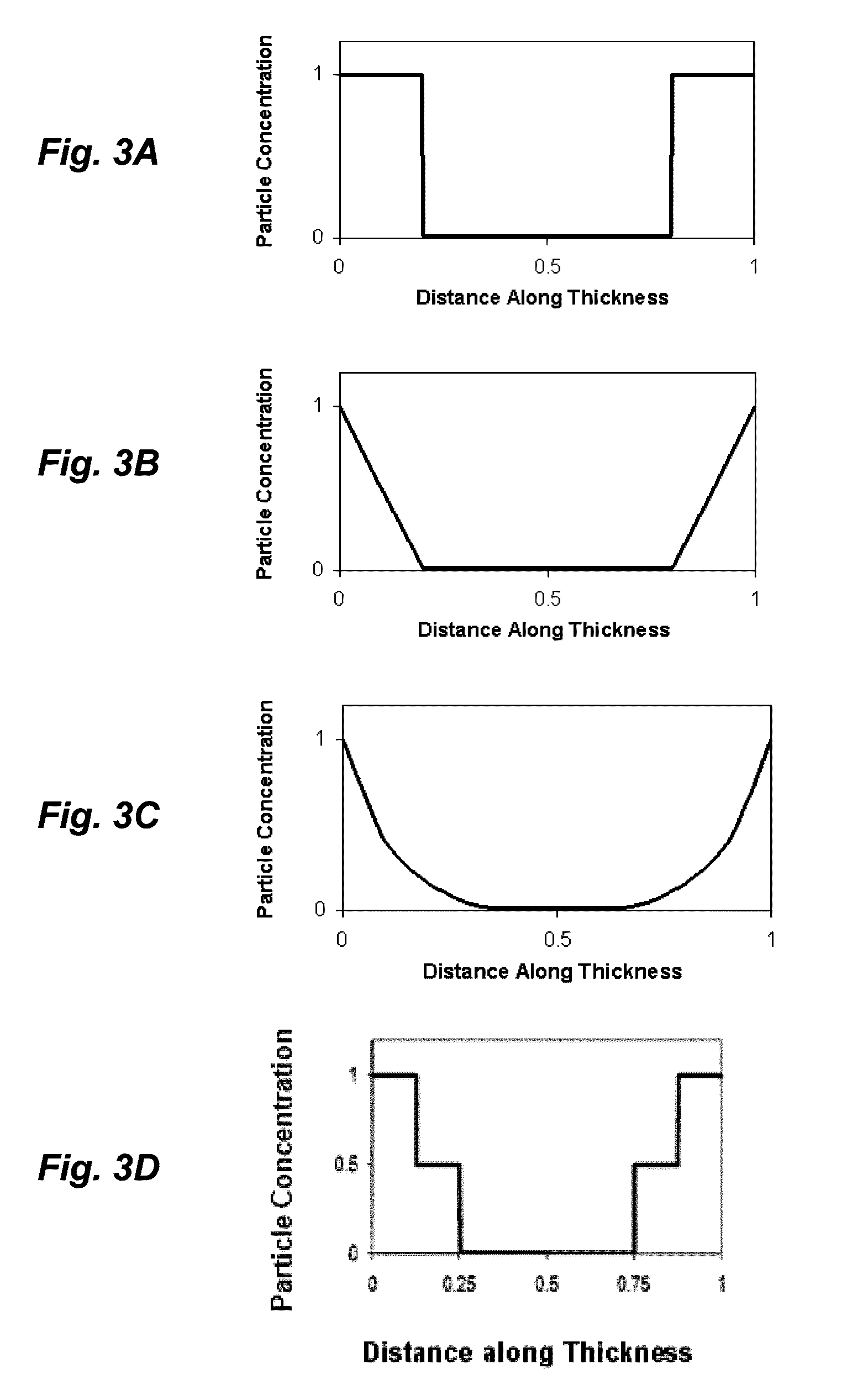

InactiveUS20100141085A1Simpler and cheap and faster processIncrease capacitancePiezoelectric/electrostriction/magnetostriction machinesVacuum evaporation coatingEtherPolymer composites

An ionic polymer composite device and methods for fabricating the ionic polymer composite device are provided. The ionic polymer composite device includes two extended electrode layers, each extended electrode layer including at least one ionic polymer with a plurality of electrically conductive particles, and a dielectric layer including at least one sulfonated poly ether sulfone polymer or a derivative between the two extended electrode layers.

Owner:HITACHI CHEM CO LTD +1

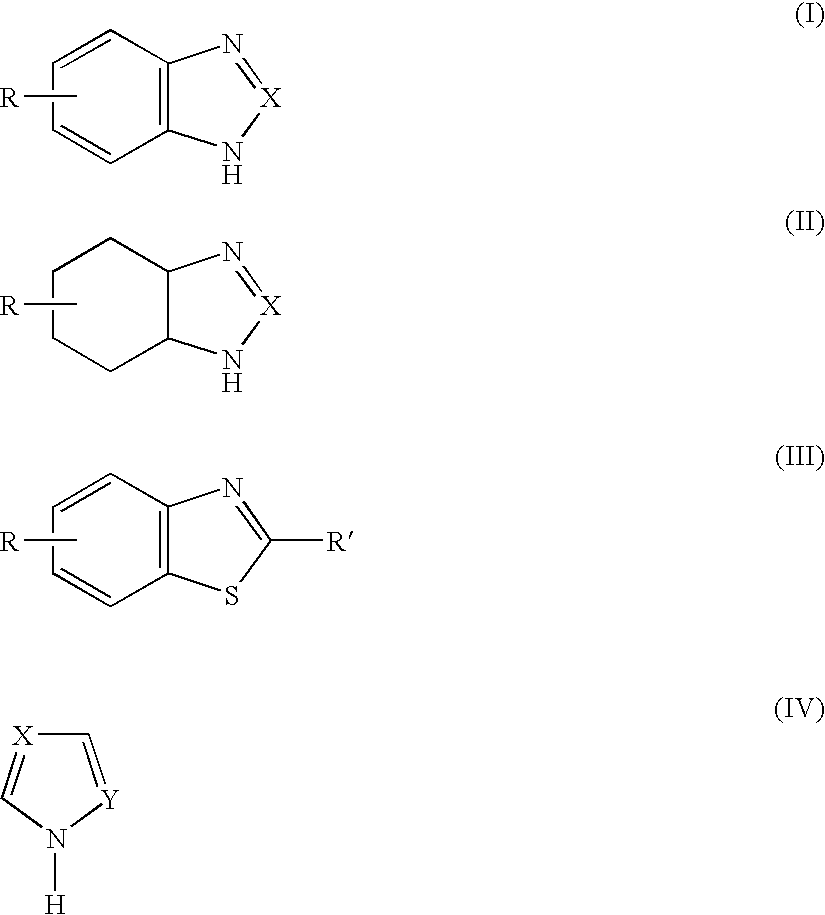

Corrosion inhibitors, corrosion inhibiting heat transfer fluids, and the use thereof

Disclosed is a corrosion inhibitor for use in heat transfer fluids having a conductivity of less than 200 μS / cm, the corrosion inhibitor having an azole compound, and at least one of a siloxane based surfactant, colloidal silica, or a mixture thereof. Also disclosed is a corrosion inhibiting heat transfer fluid, the heat transfer fluid having a conductivity of no more than or equal to 200 μS / cm and comprising the disclosed corrosion inhibitor. Also provided is an assembly comprising an alternative power source and a heat transfer system in thermal communication with the alternative power source, the heat transfer system comprising the disclosed corrosion inhibiting heat transfer fluid. In addition, a method of making a corrosion inhibiting heat transfer fluid is disclosed wherein the disclosed corrosion inhibitor is added to heat transfer fluid having a conductivity of less than 200 μS / cm.

Owner:PRESTONE PROD CORP

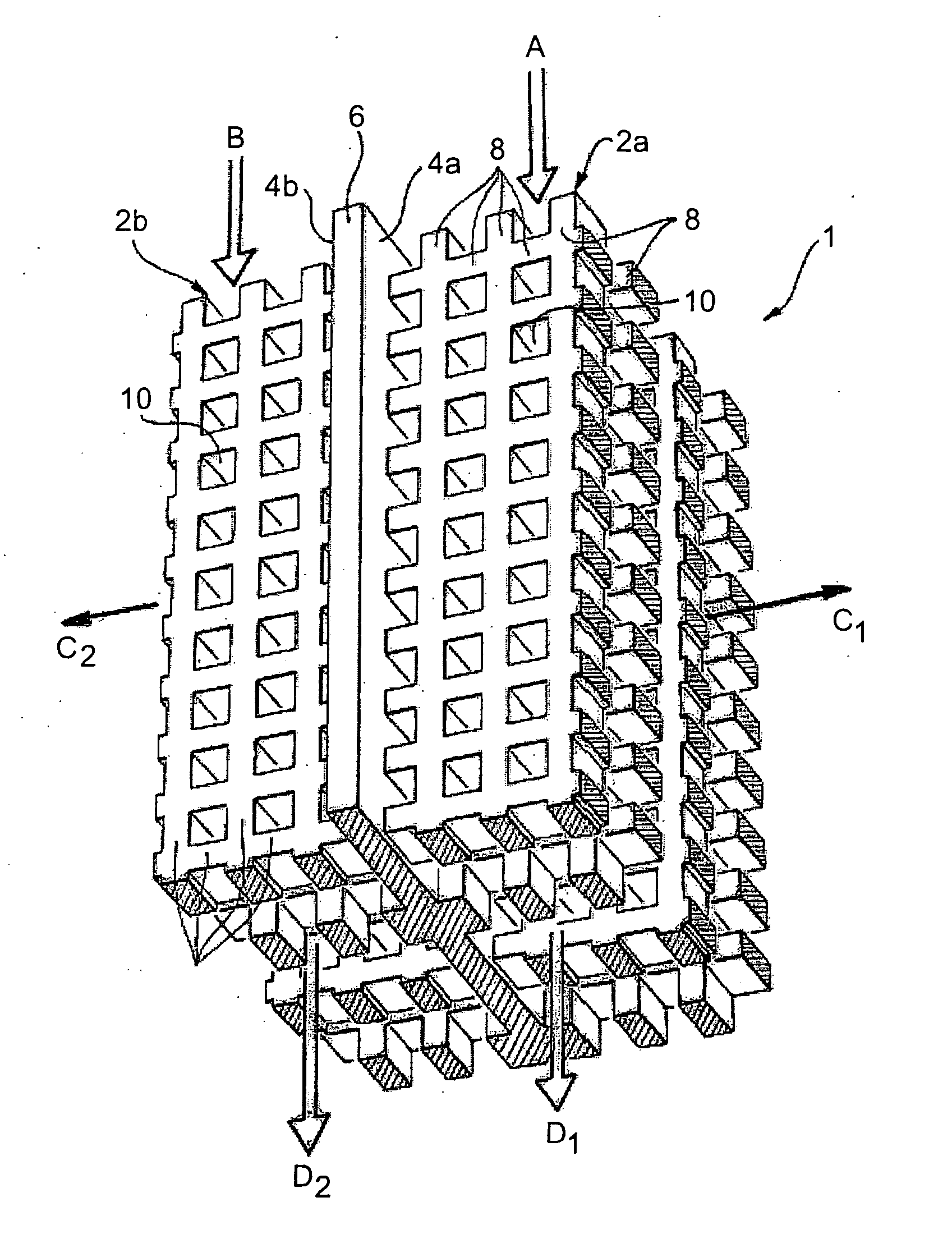

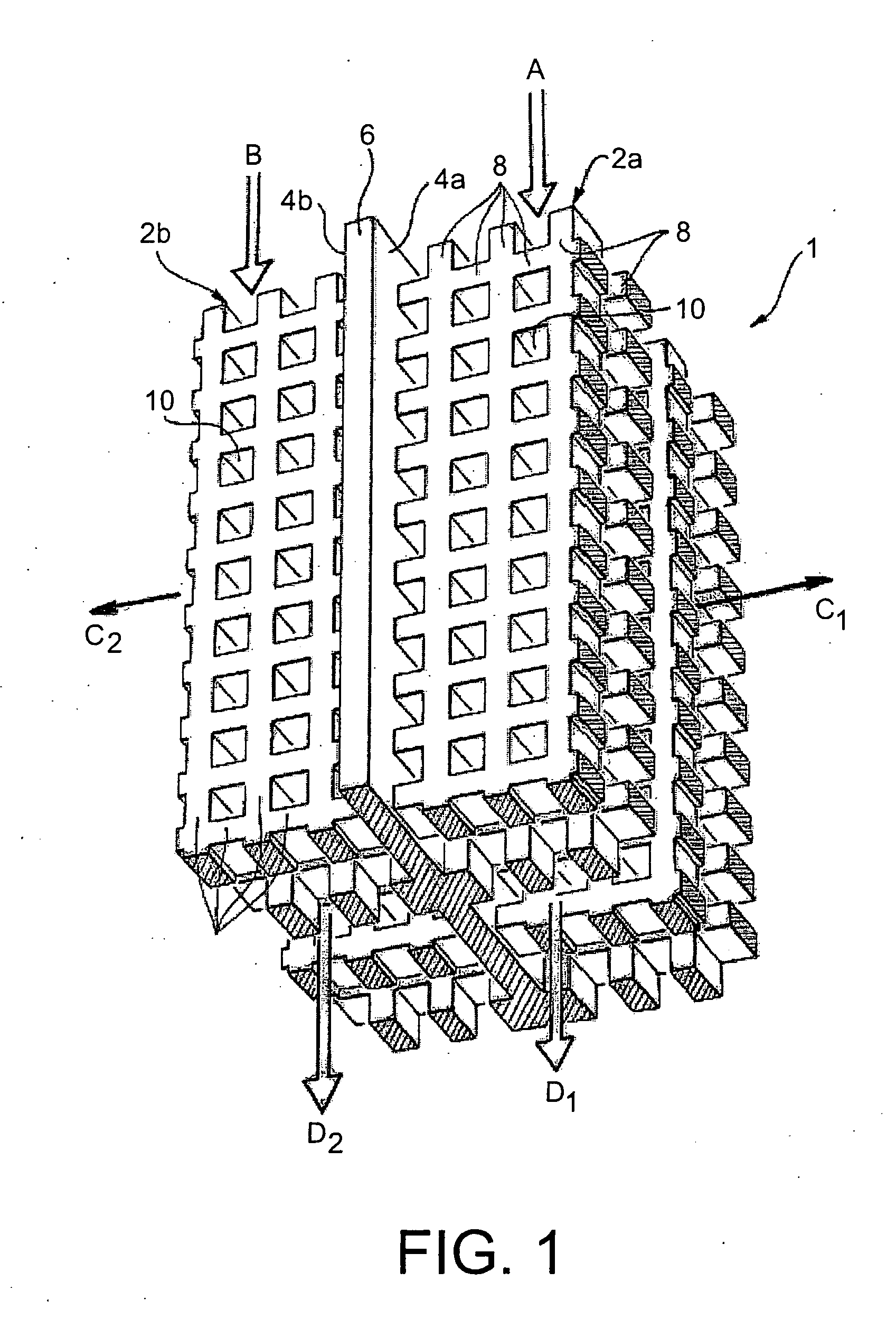

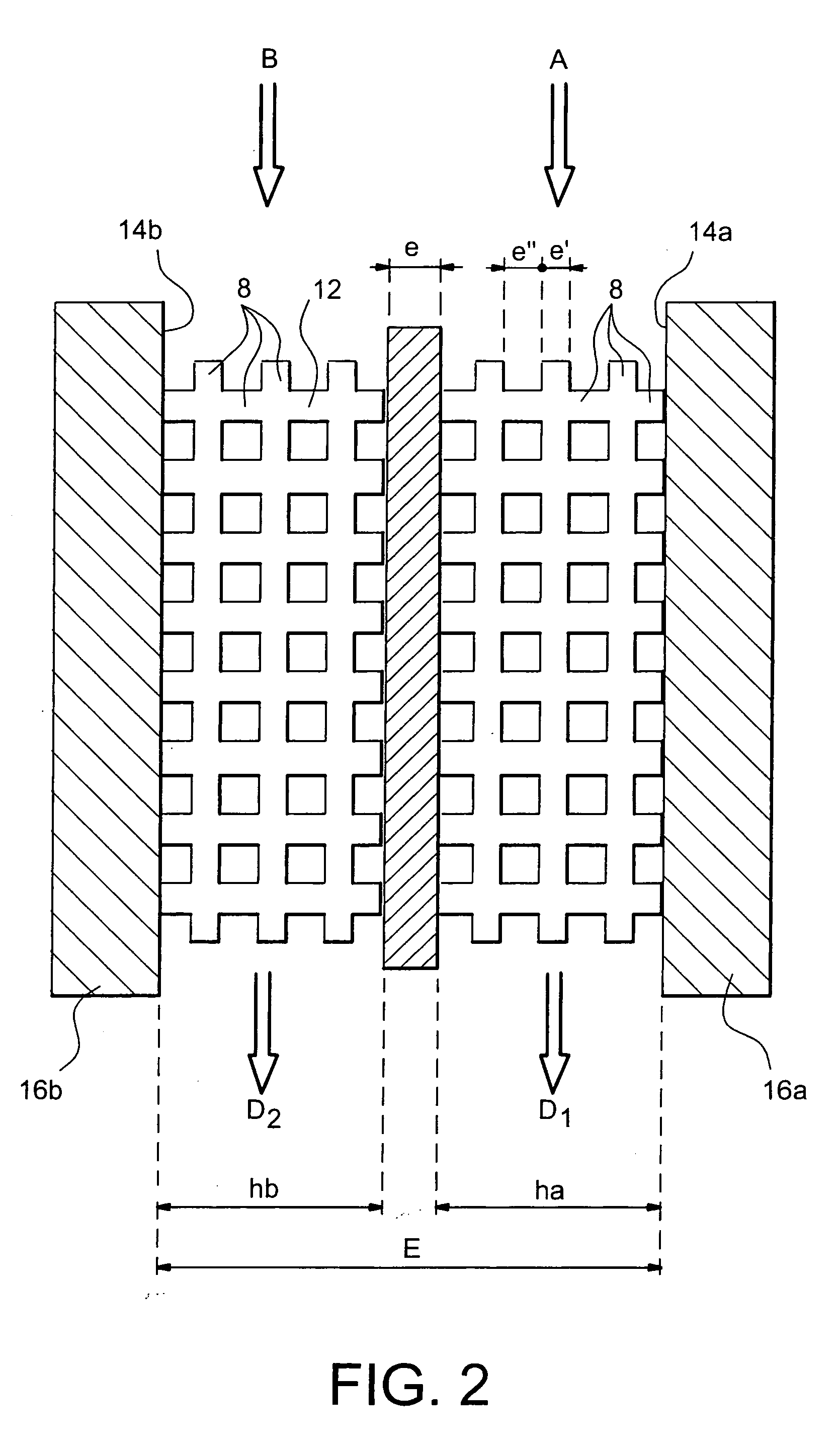

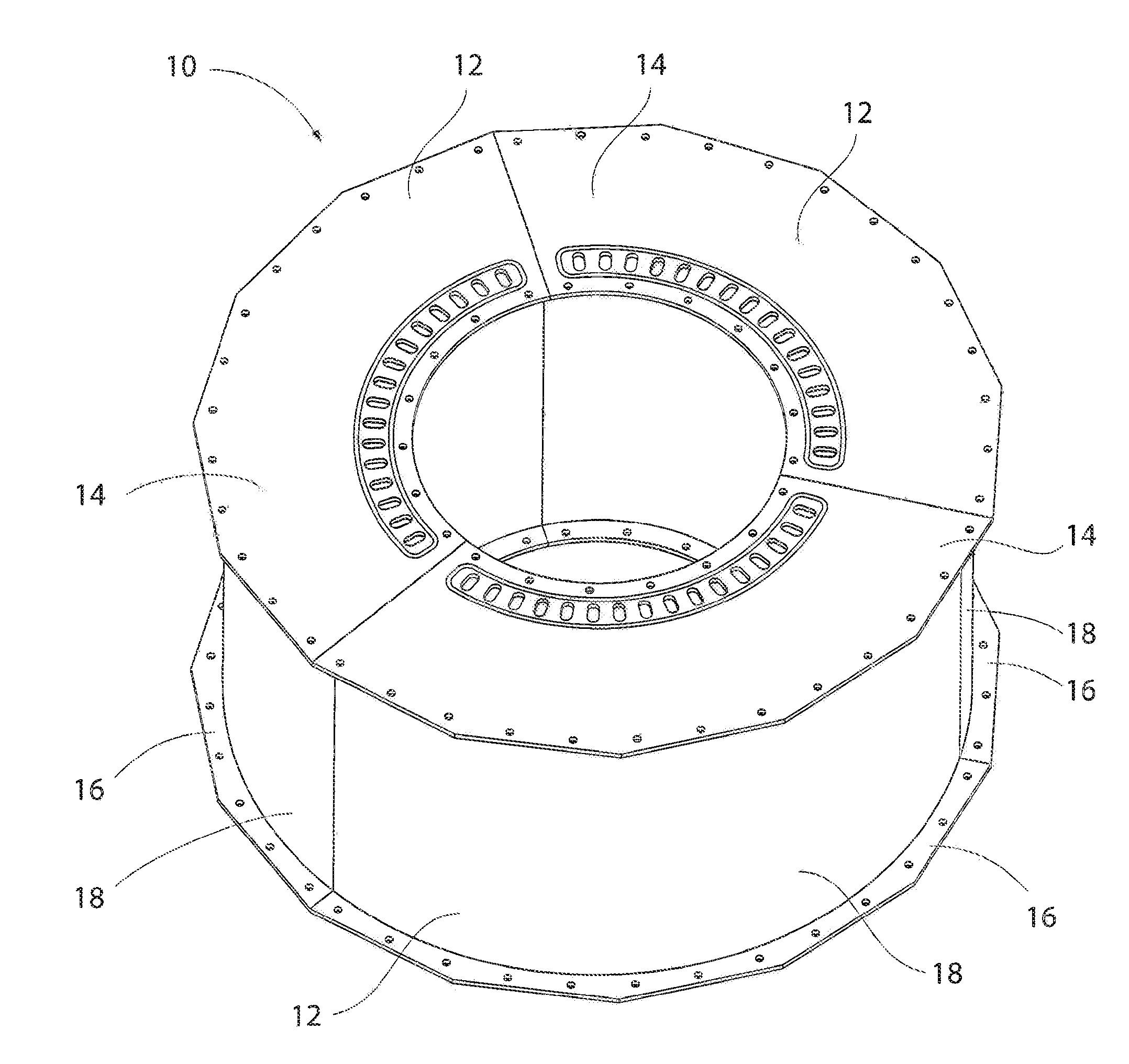

Honeycomb structure and method for production of said structure

InactiveUS20050221150A1Simple designEasy to controlAdditive manufacturing apparatusLayered productsFuel cellsEngineering

An alveolar structure and a method of manufacturing an alveolar structure. The alveolar structure includes at least one alveolar zone partially delimited by an associated leak tight surface. Each alveolar zone is formed of a plurality of metallic layers superimposed parallel to the associated leak tight surface, each metallic layer including a network of passages opening out on either side of the each metallic layer. The alveolar structure may find particular application to fuel cells and heat exchangers.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

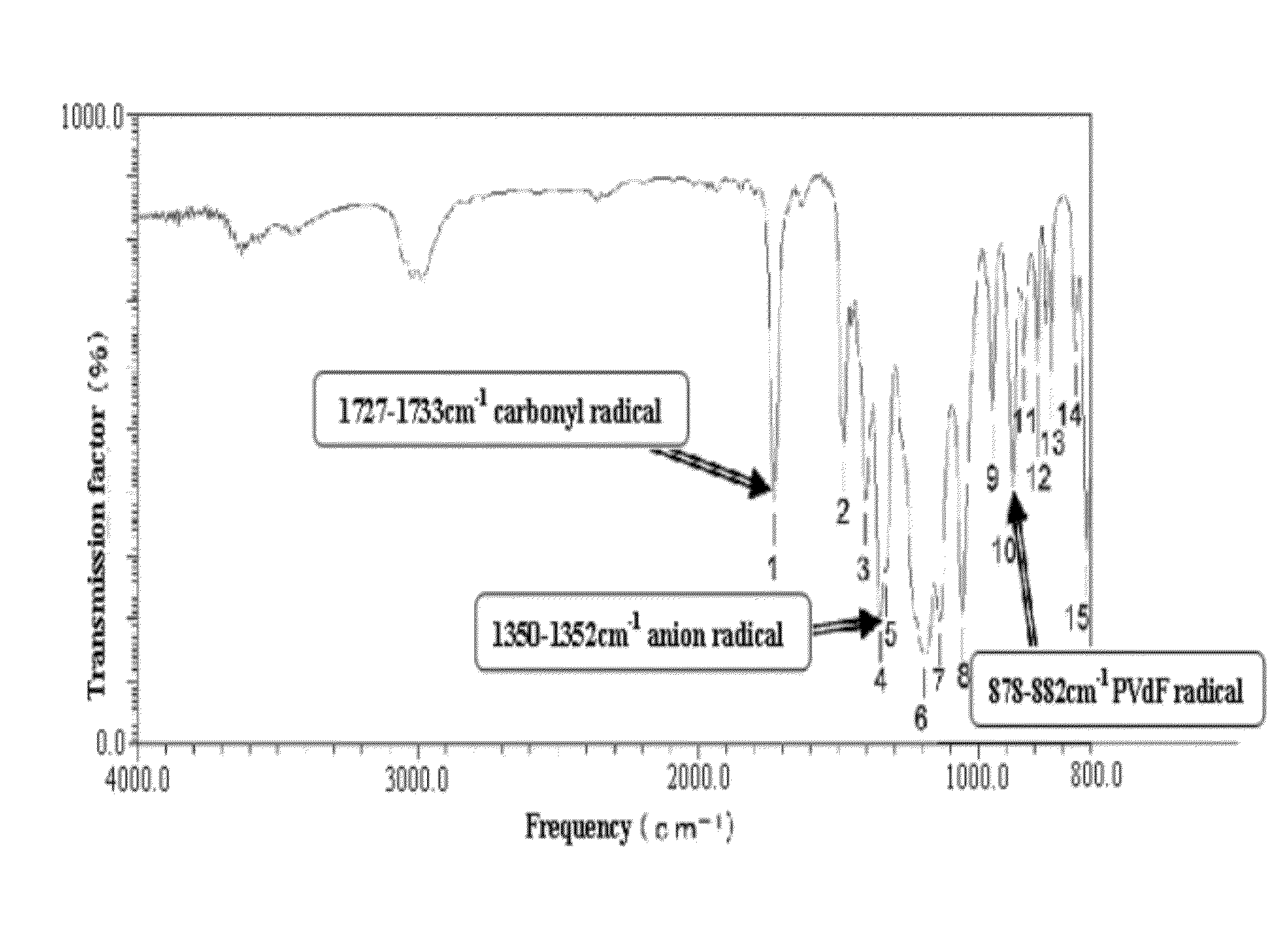

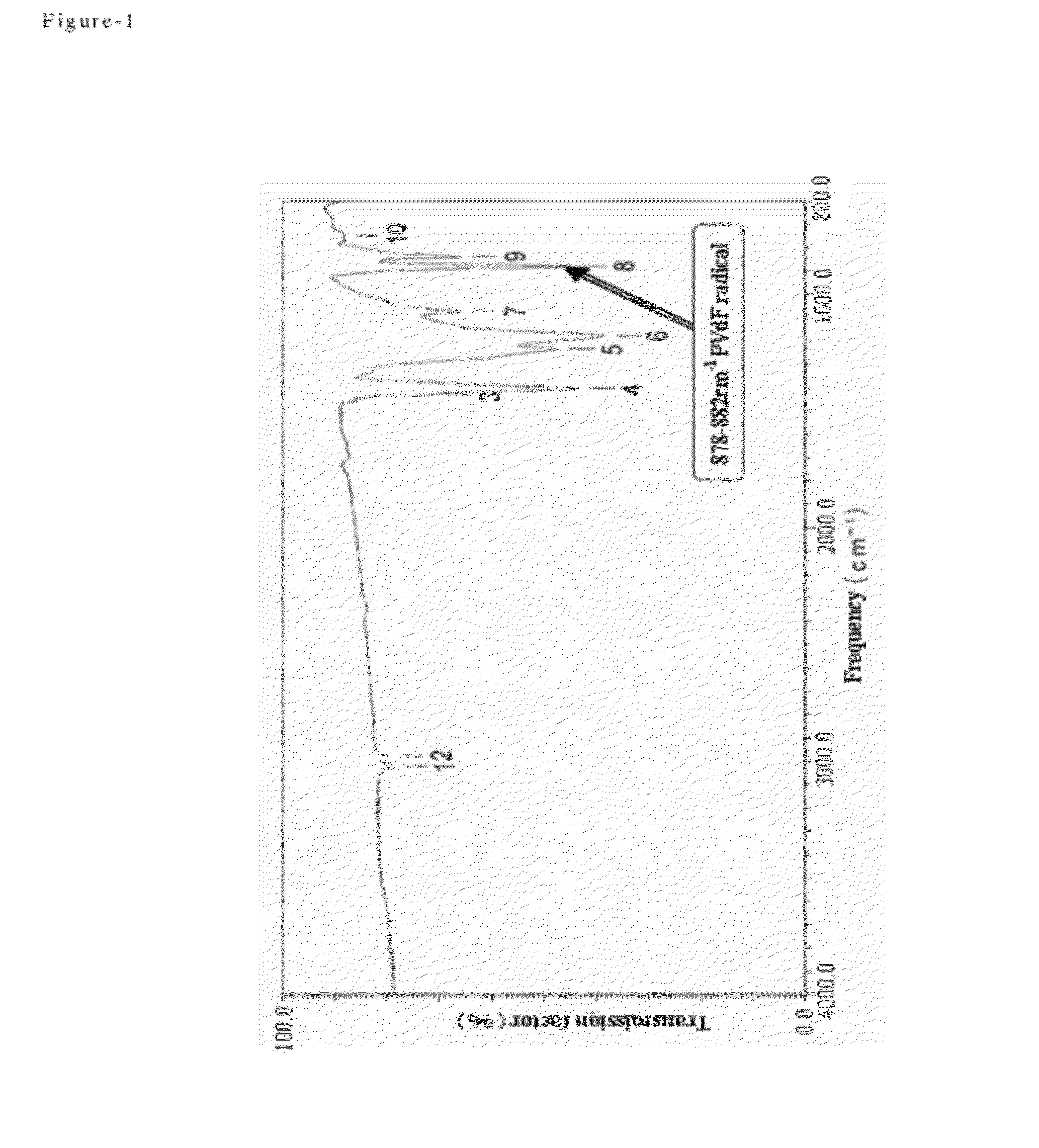

Process for producing fluorine containing polymer

According to this invention, a process for producing fluorine containing polymer to obtain composite polymer electrolyte composition having excellent ion transport number, that is, ion transfer coefficient, for example, excellent transport number of lithium ion, is provided.A process for producing fluorine containing polymer comprising graft-polymerizing a molten salt monomer having a polymerizable functional group and a quaternary ammonium salt structure having a quaternary ammonium cation and anion, with a polymer having the following unit;—(CR1R2—CFX)—X means halogen atom except fluorine atom,R1 and R2 mean hydrogen or fluorine atom, each is same or different atom.

Owner:PIOTREK

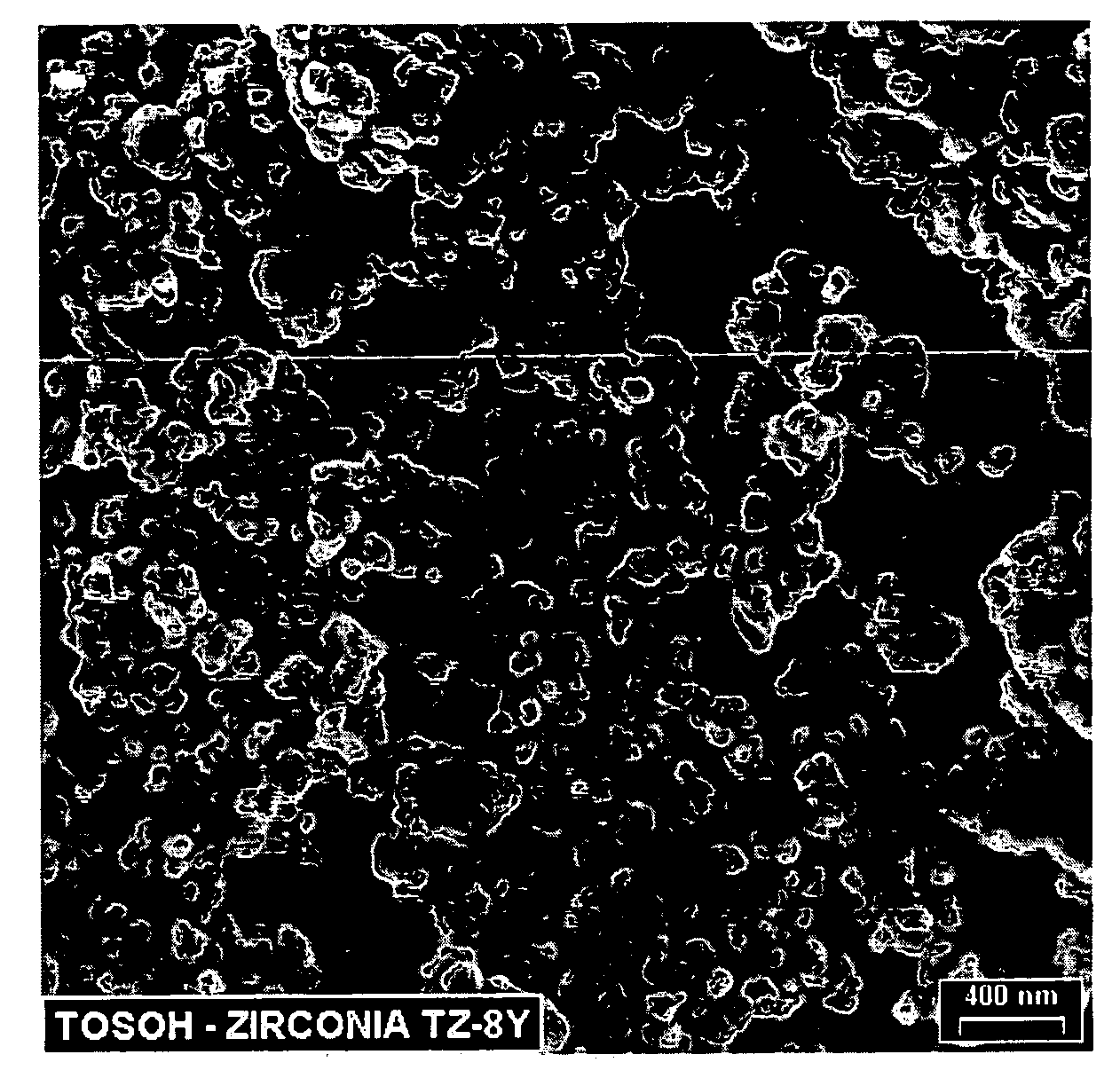

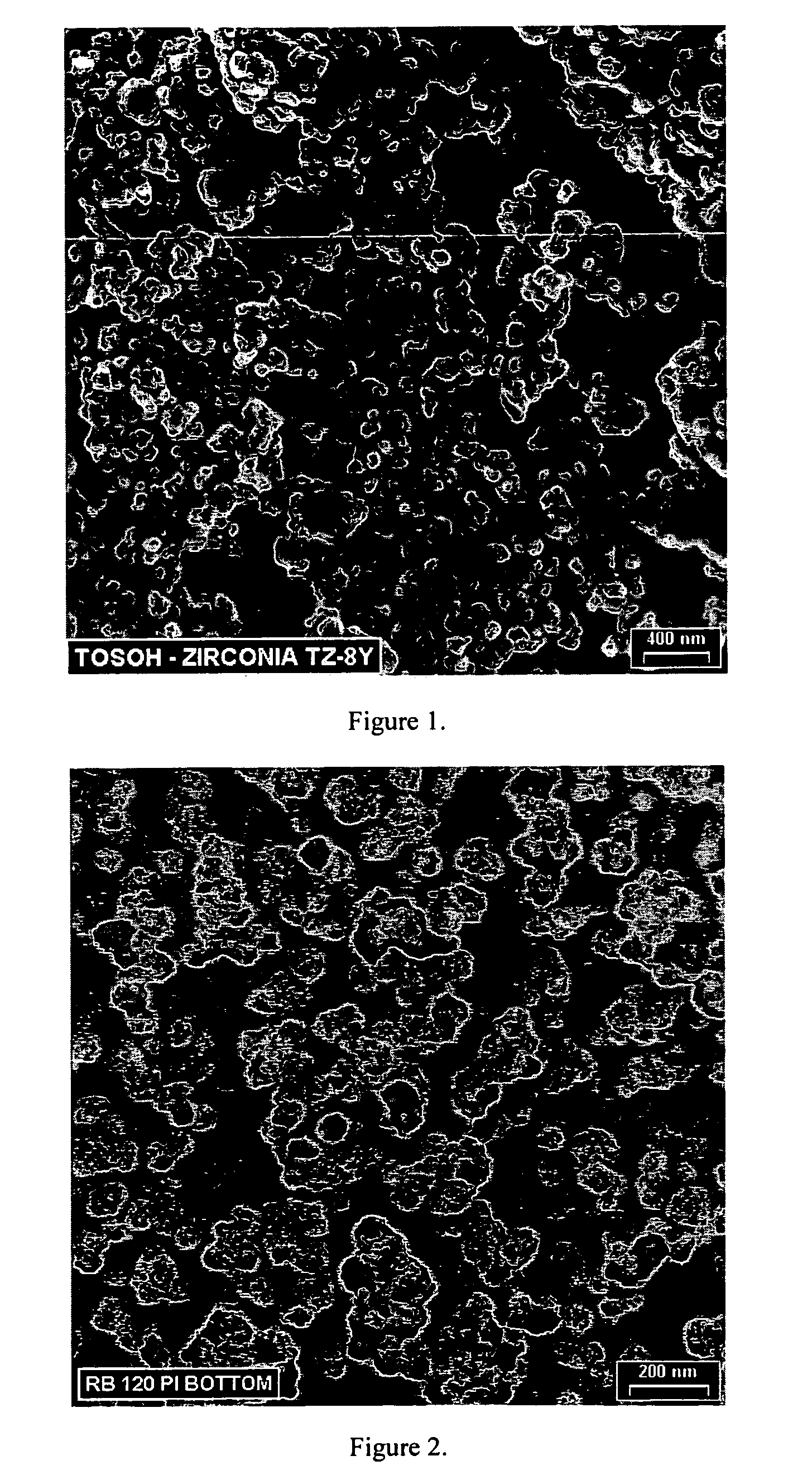

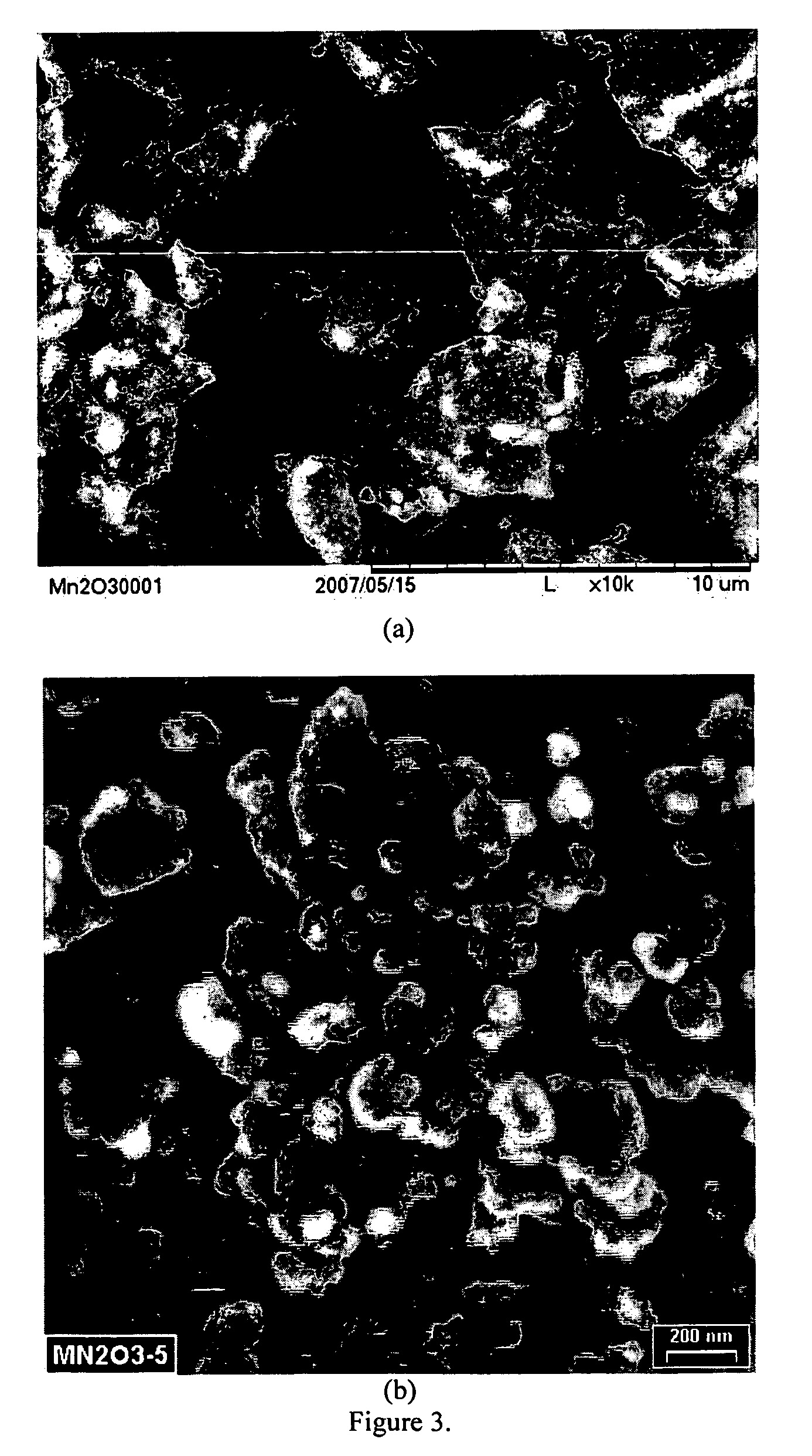

Co-doped YSZ electrolytes for solid oxide fuel cell stacks

ActiveUS20100167170A1Improve performanceLow costMaterial nanotechnologyFuel cells groupingElectrolysisFuel cells

A solid oxide fuel cell electrolyte is fabricated by combining an yttria-stabilized zirconia powder with α-Al2O3 having a d50 particle size in a range of between about 10 nm and about 200 nm and Mn2O3 to form an electrolyte precursor composition, and then sintering the electrolyte precursor composition to thereby form the electrolyte. The α-Al2O3 and Mn2O3 can be present in the electrolyte precursor composition in an amount in a range of between about 0.25 mol % and about 5 mol %. The electrolyte can be a component of a solid oxide fuel cell of the invention.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

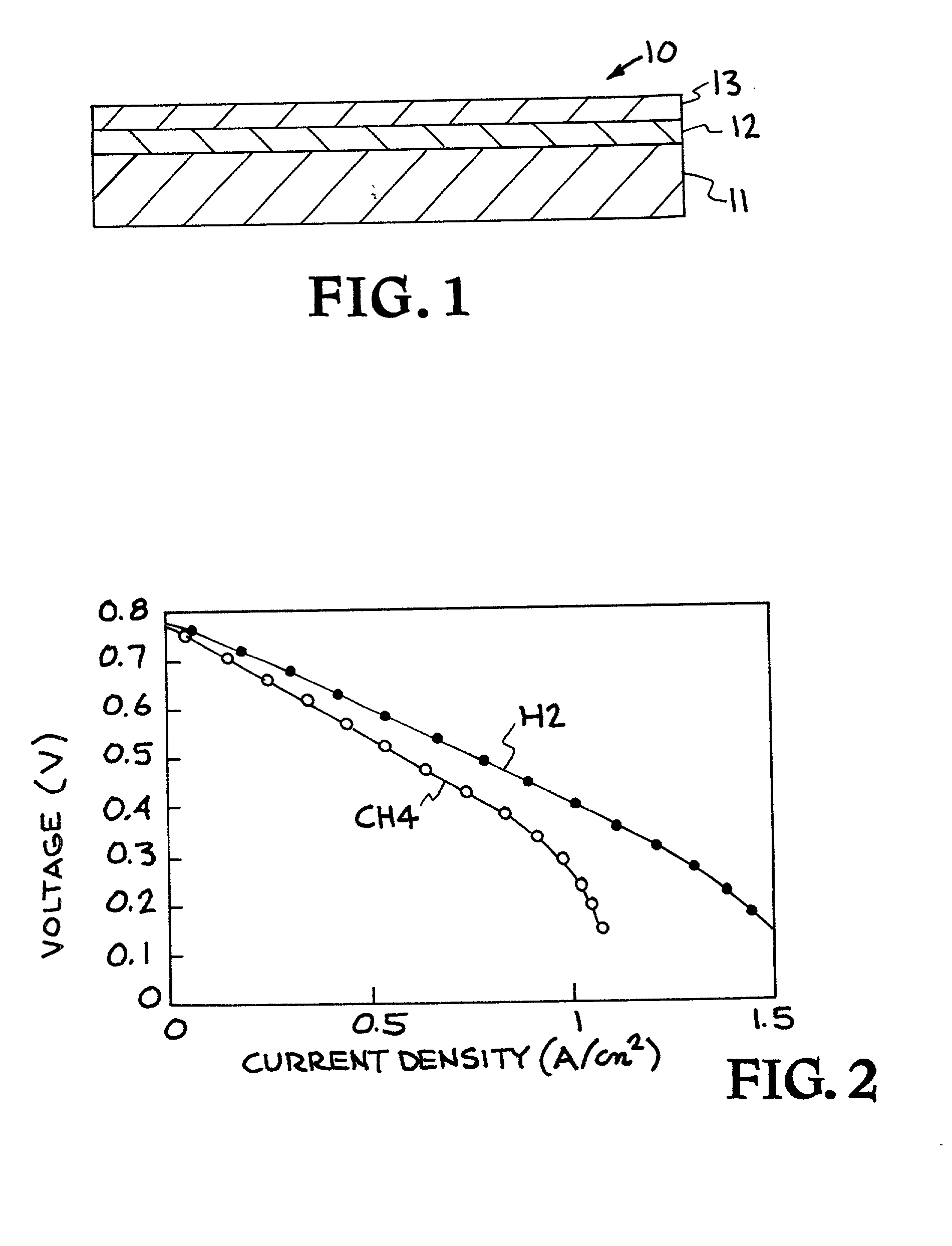

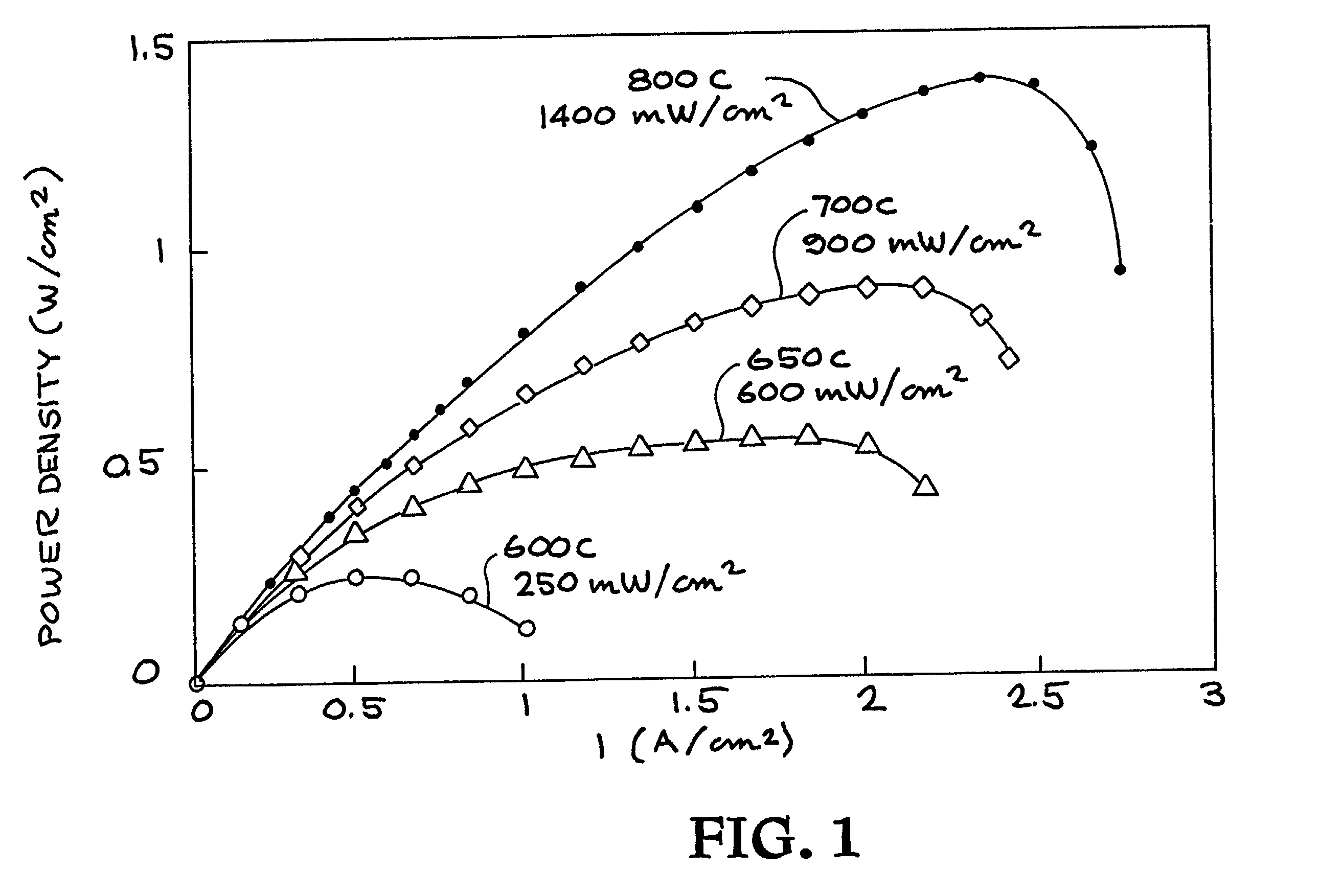

High power density solid oxide fuel cells and method of fabrication

A method for producing ultra-high power density solid oxide fuel cells (SOFCs). The method involves the formation of a multilayer structure cells wherein a buffer layer of doped-ceria is deposited intermediate a zirconia electrolyte and a cobalt iron based electrode using a colloidal spray deposition (CSD) technique. For example, a cobalt iron based cathode composed of (La,Sr)(Co,Fe)O (LSCF) may be deposited on a zirconia electrolyte via a buffer layer of doped-ceria deposited by the CSD technique. The thus formed SOFC have a power density of 1400 mW / cm.sup.2 at 600.degree. C. and 900 mW / cm.sup.2 at 700.degree. C. which constitutes a 2-3 times increased in power density over conventionally produced SOFCs.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

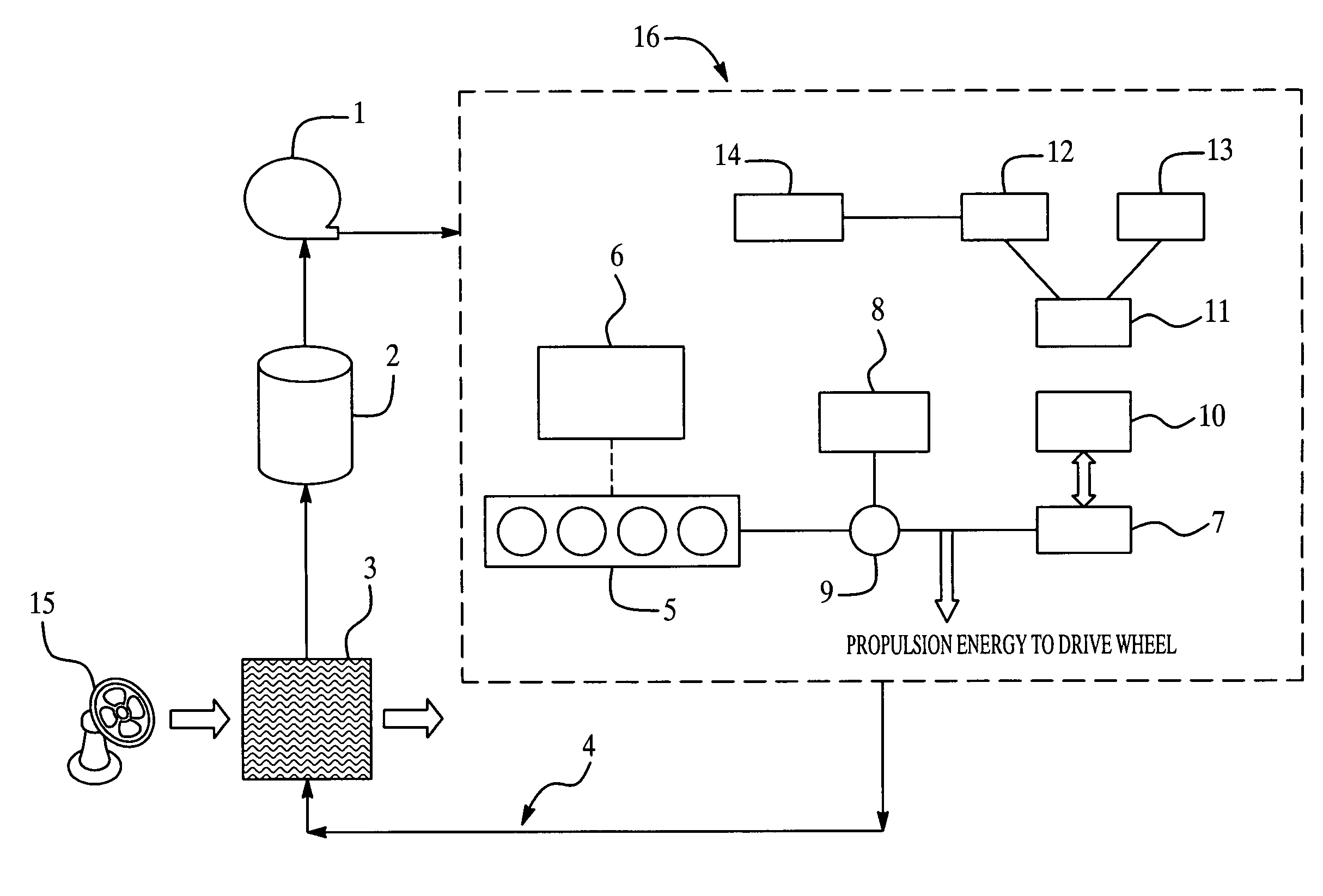

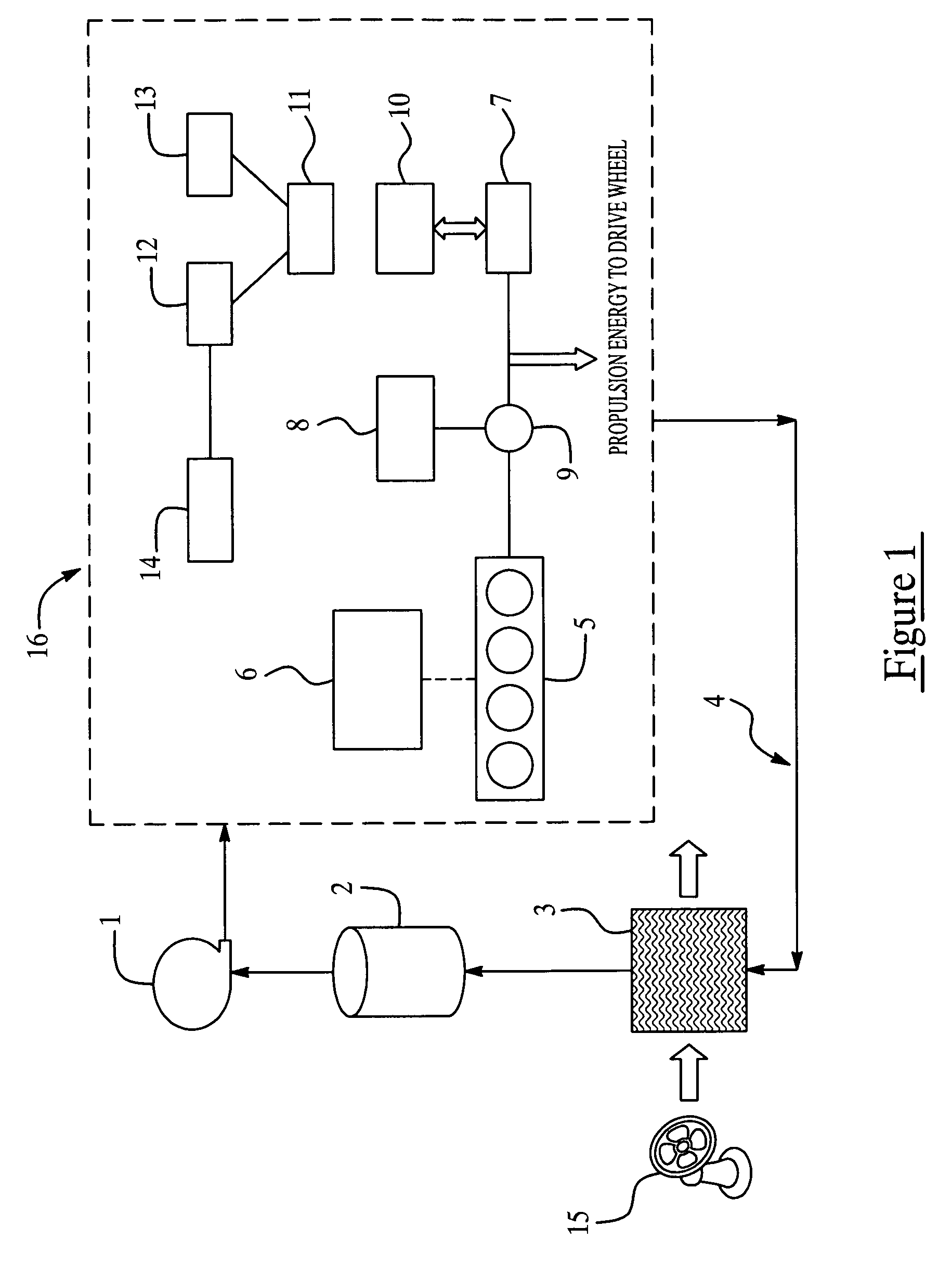

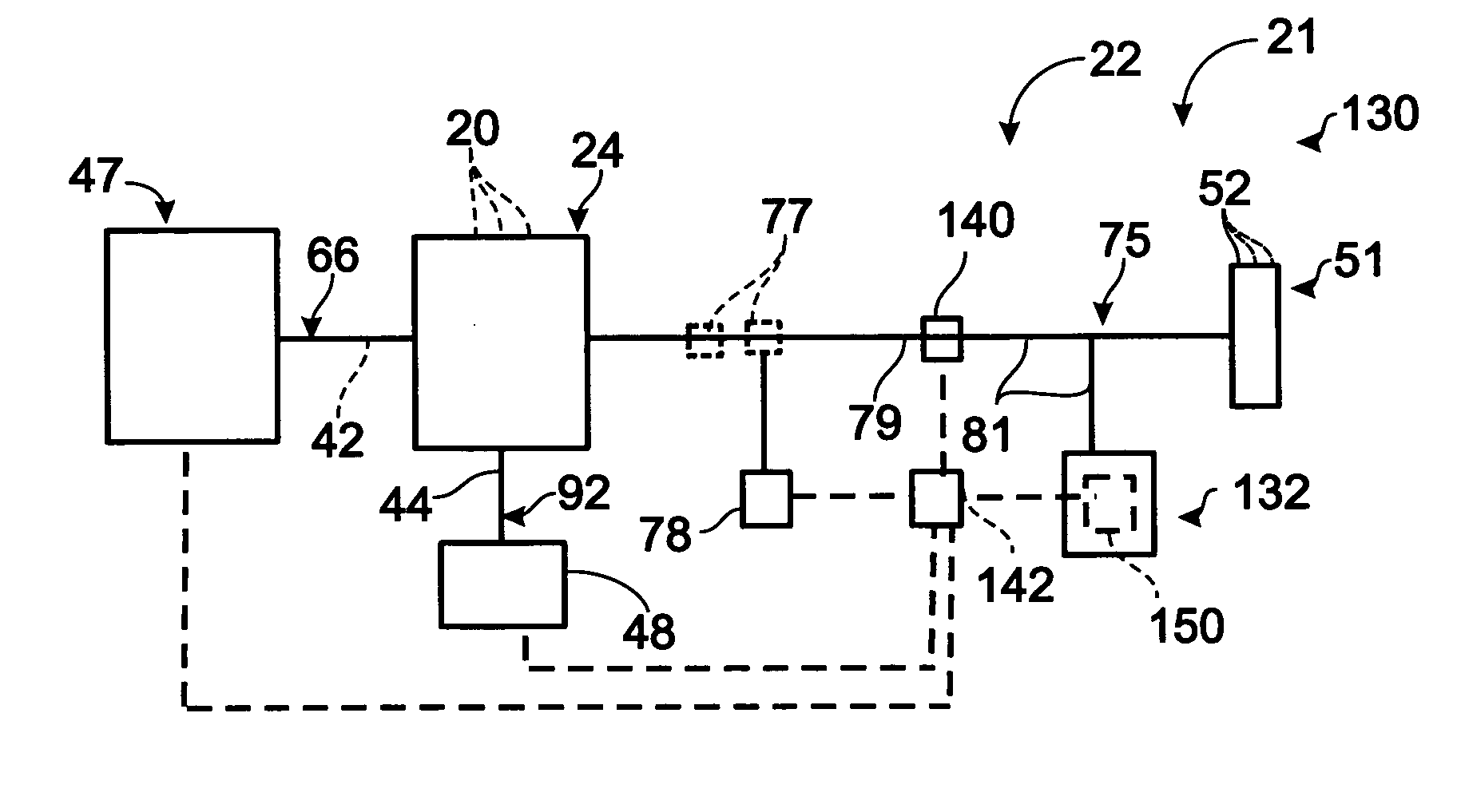

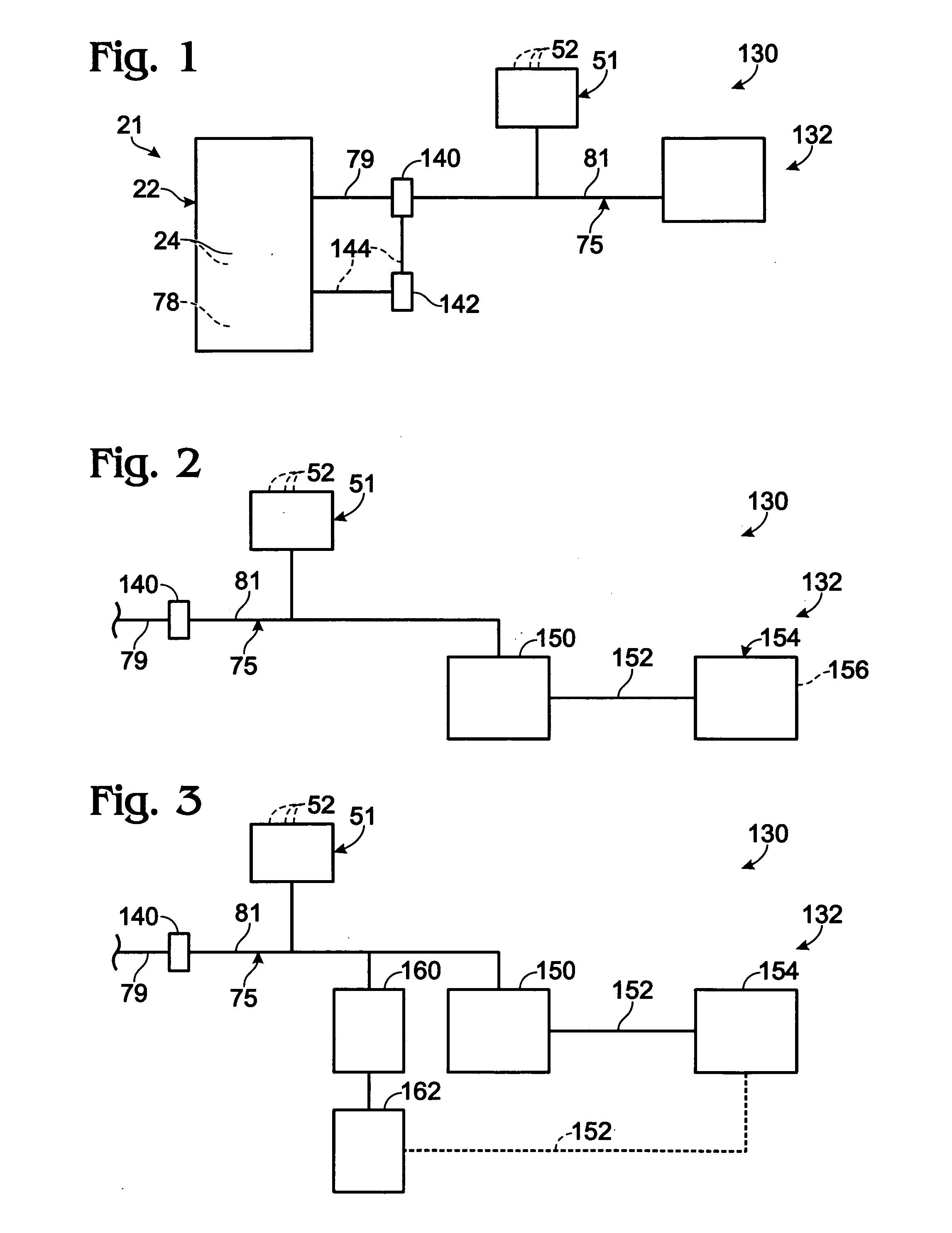

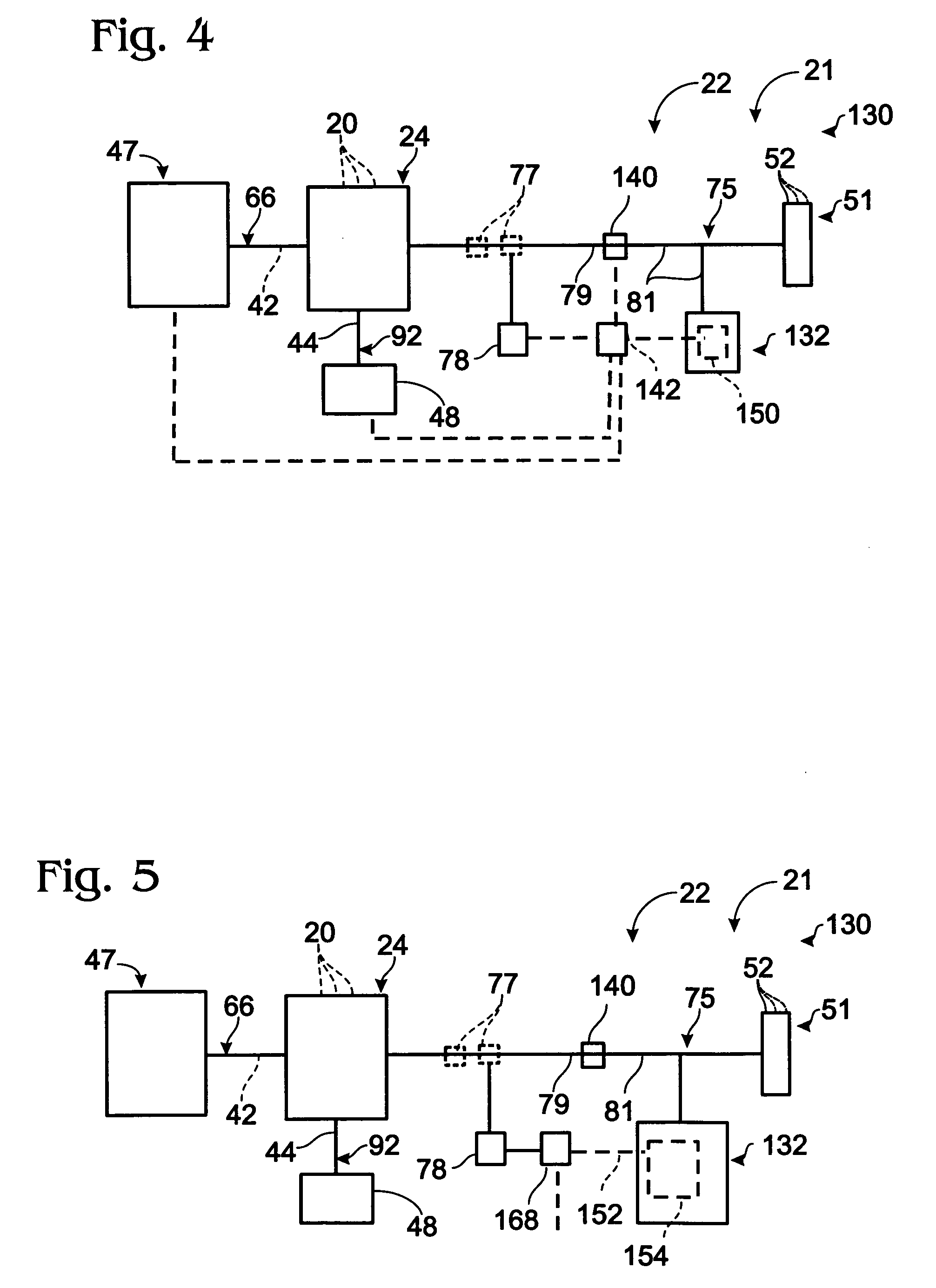

Systems and methods for initiating auxiliary fuel cell system operation

InactiveUS20070042233A1Dc network circuit arrangementsBatteries circuit arrangementsFuel cellsElectric power system

Fuel cell systems that provide backup, or auxiliary, power to one or more energy-consuming devices normally powered by a primary power source (PPS). Operating methods and controllers for auxiliary fuel cell systems and / or for power systems that include a PPS and an auxiliary power source in the form of an auxiliary fuel cell system (AFCS) are also disclosed. In some embodiments, the fuel cell system includes, or is in communication with, a controller that selectively initiates the production of an electric current by the AFCS responsive to a triggering event. An illustrative triggering event includes a predetermined voltage drop across a diode or similar current-regulating, or flow-regulating, device that is electrically between the AFCS and the energy-consuming device(s) and / or the PPS. Another illustrative triggering event includes the voltage (or state of charge or readiness to satisfy an applied load) of a battery or other energy-storage device associated with the AFCS.

Owner:IDATECH LLC

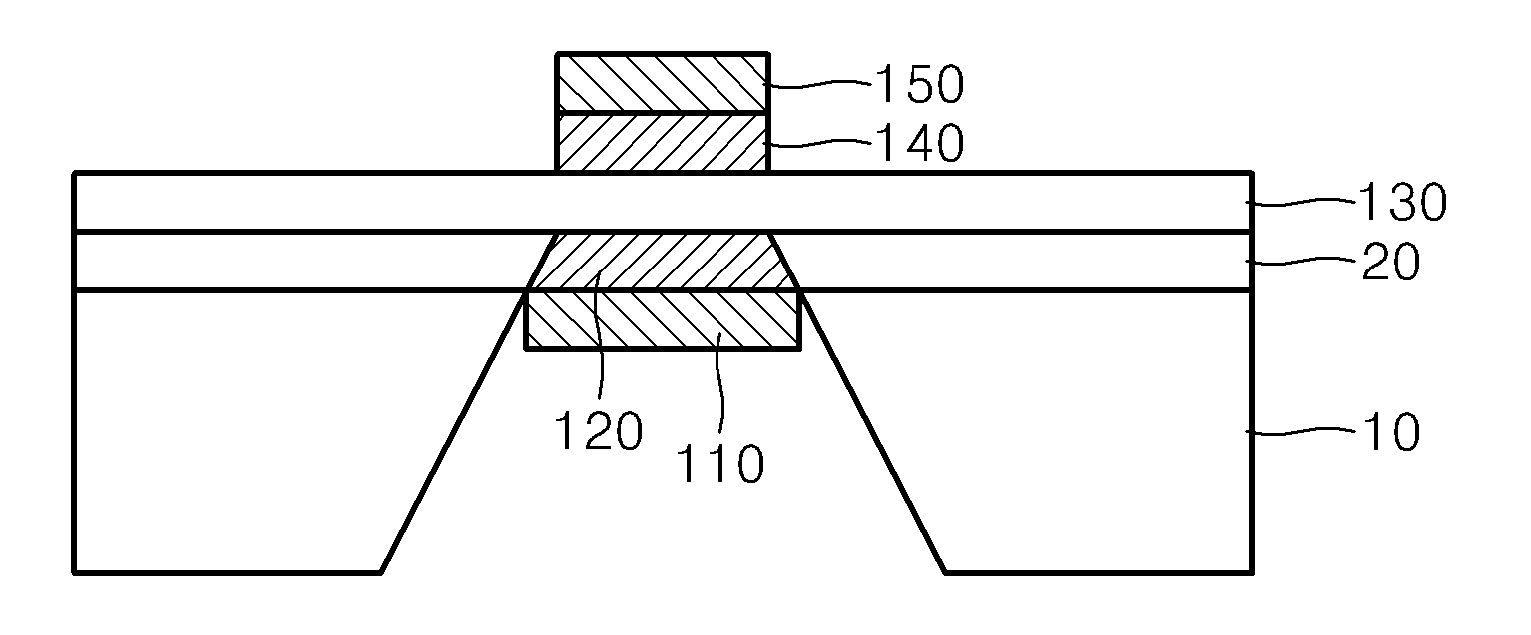

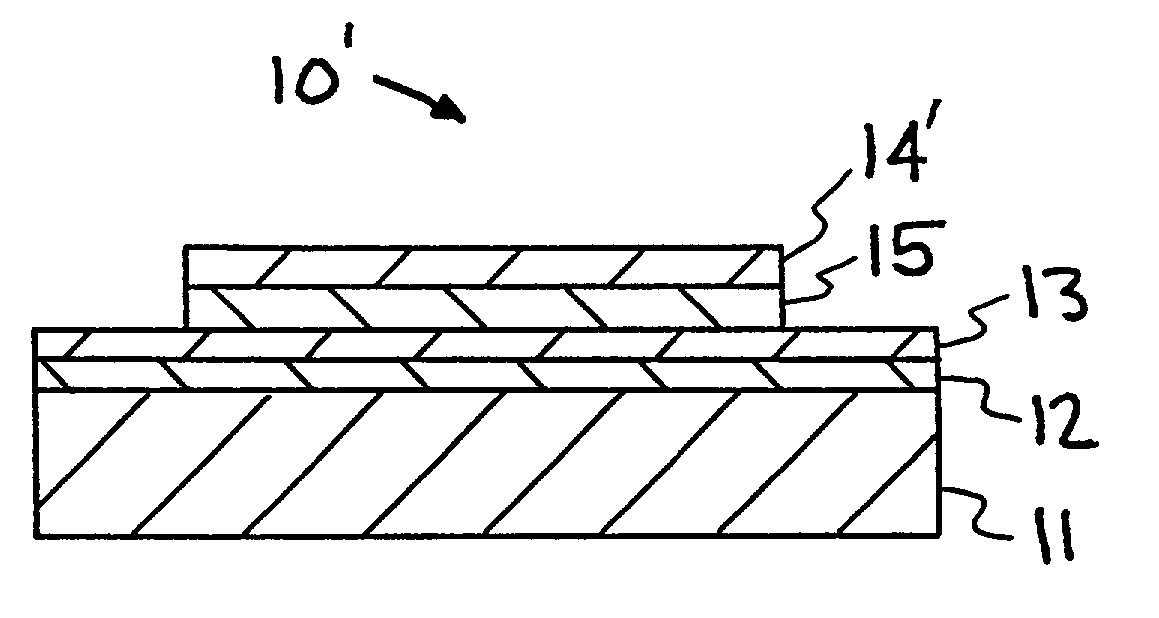

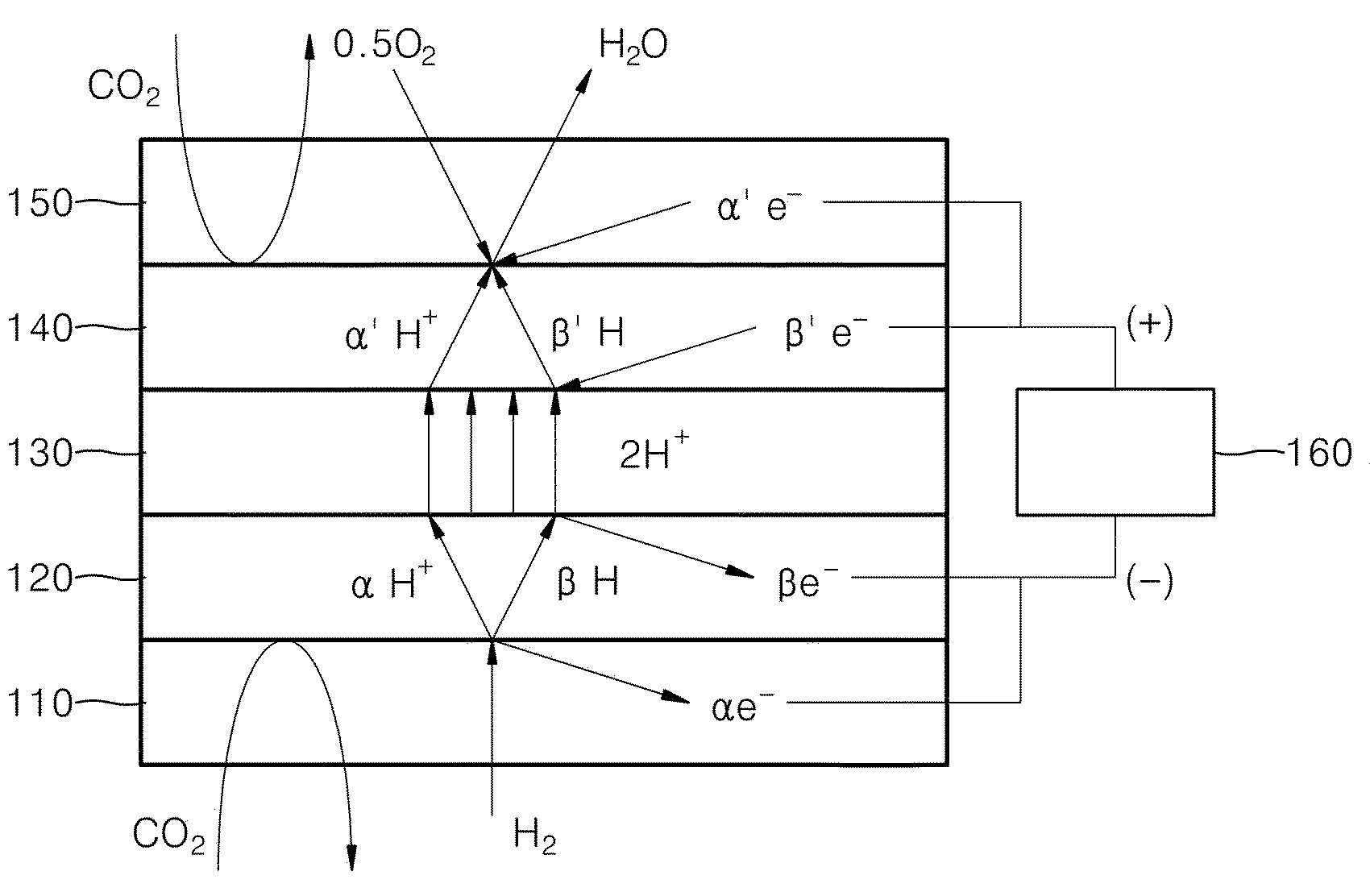

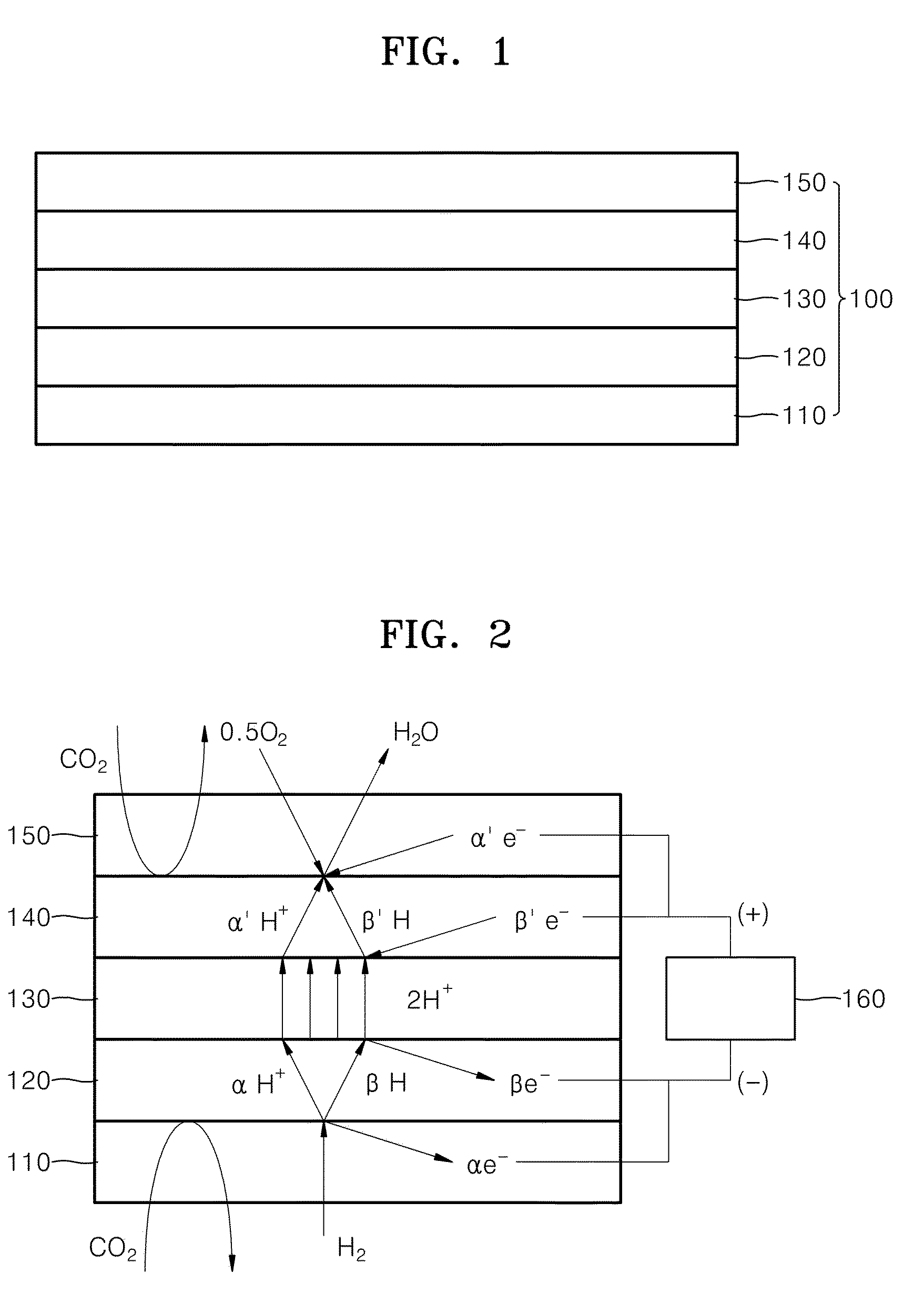

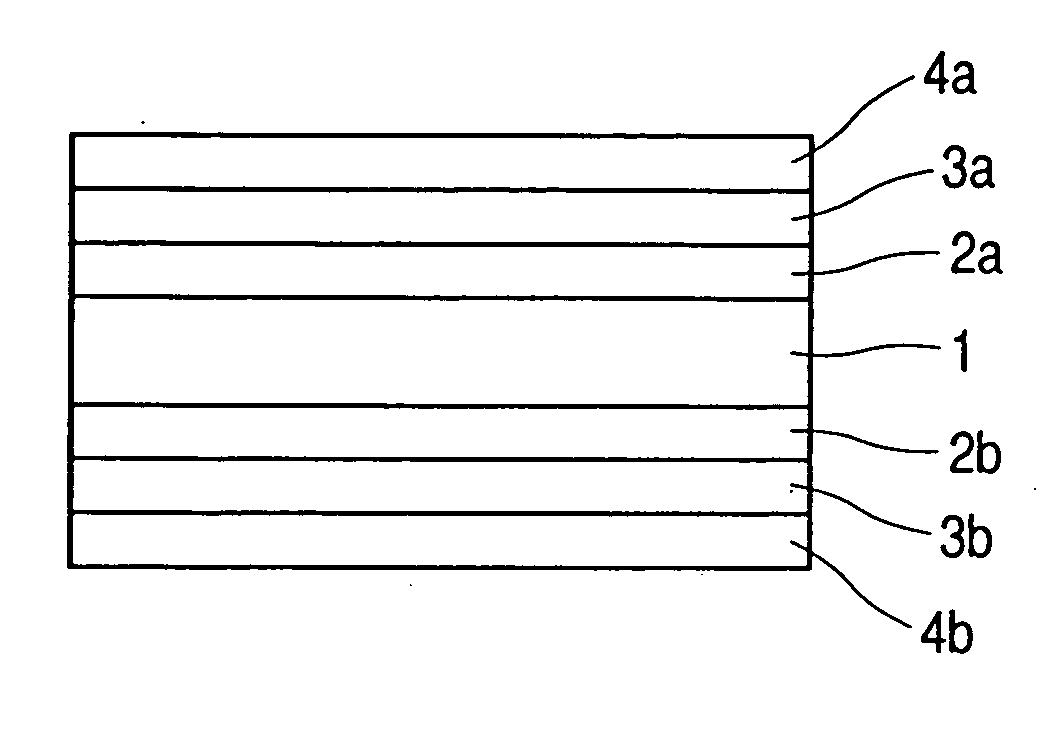

Solid-state fuel cell including chemical electrolyte protection layer and method of manufacturing same

A solid-state fuel cell includes: an anode; an anode side chemical electrolyte protection layer disposed on the anode; a hydrogen ion conductive solid oxide film disposed on the anode side chemical electrolyte protection layer; a cathode side chemical electrolyte protection layer disposed on the hydrogen ion conductive solid oxide film; and a cathode disposed on the cathode side chemical electrolyte protection layer.

Owner:SAMSUNG ELECTRONICS CO LTD +1

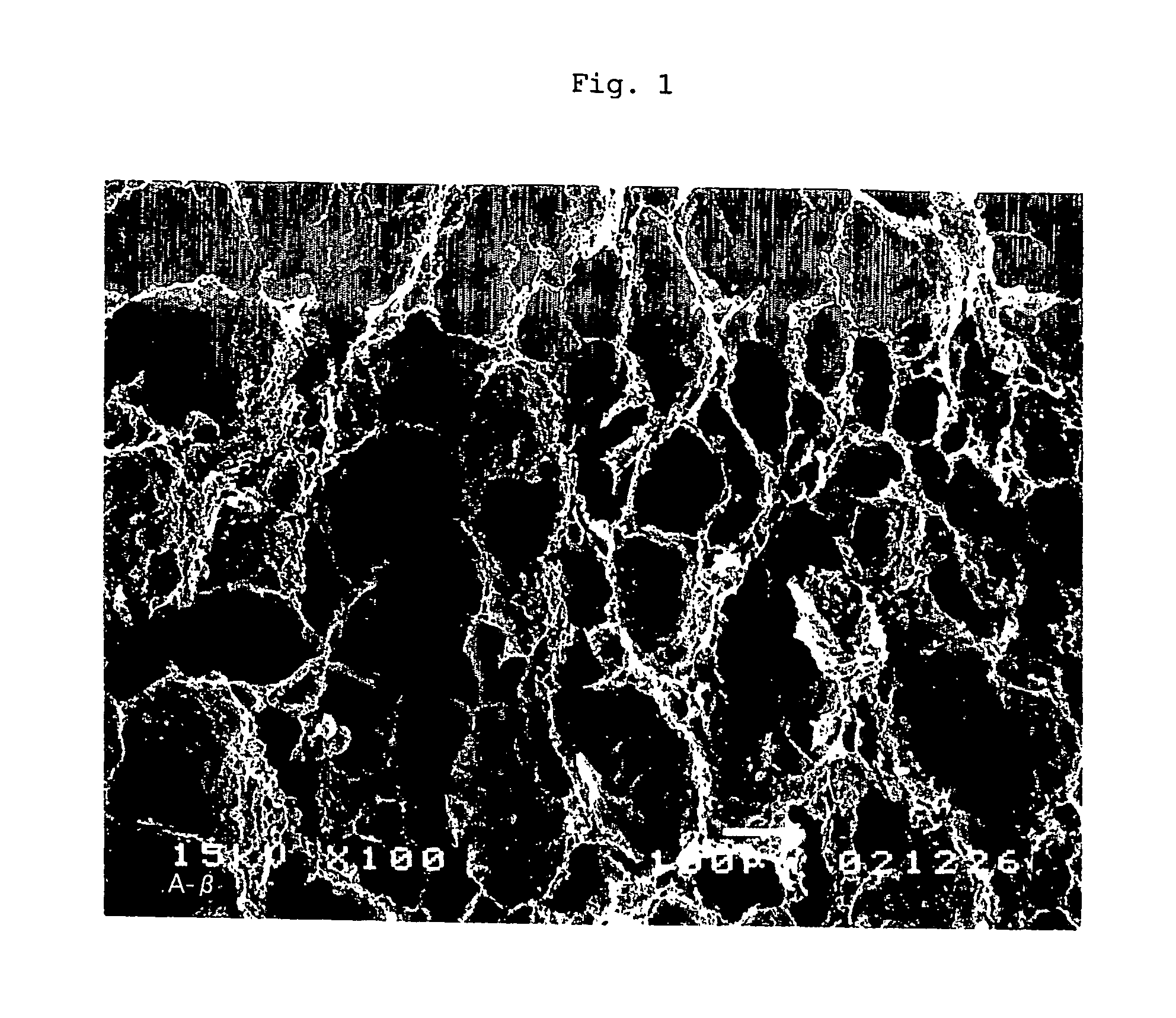

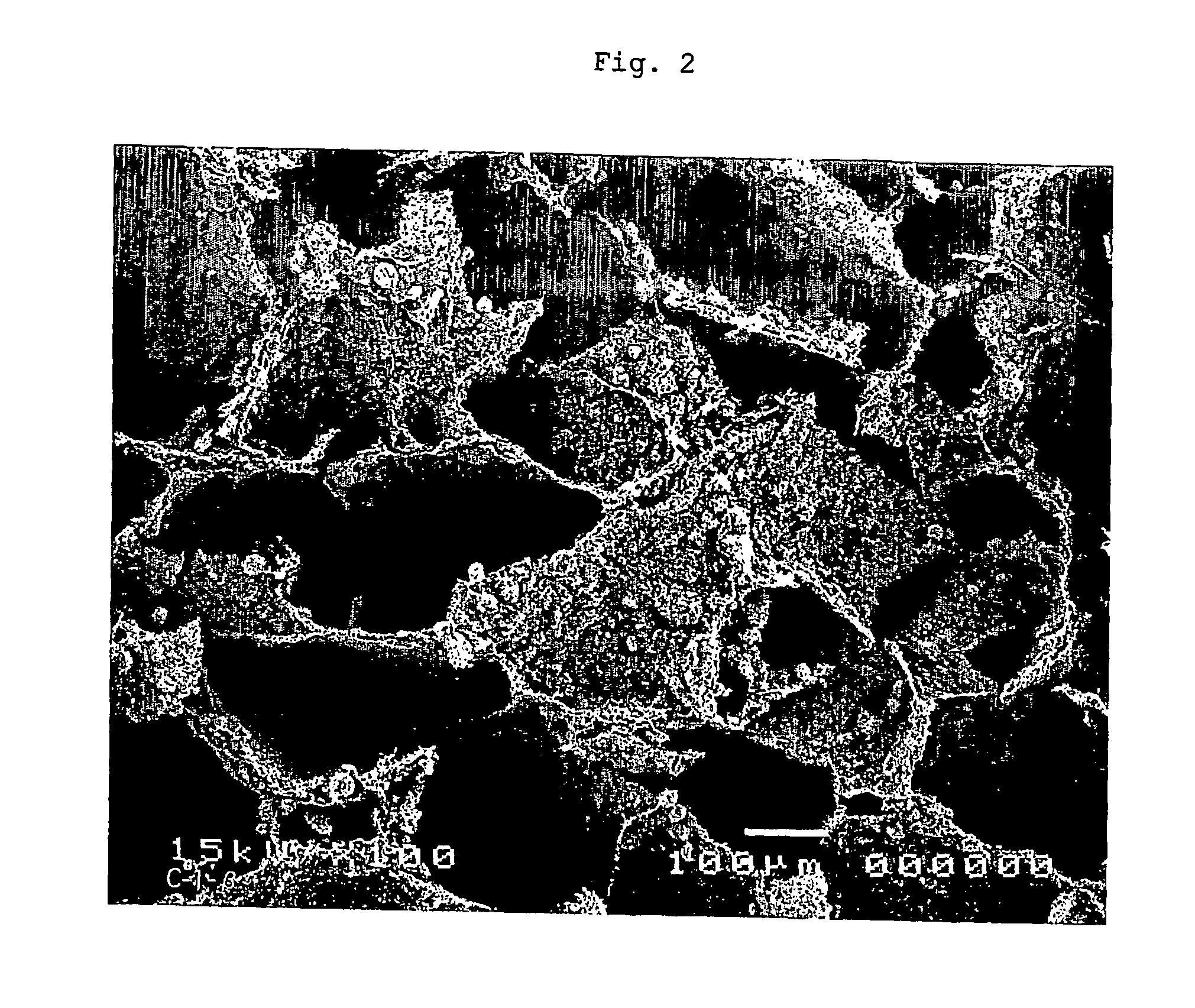

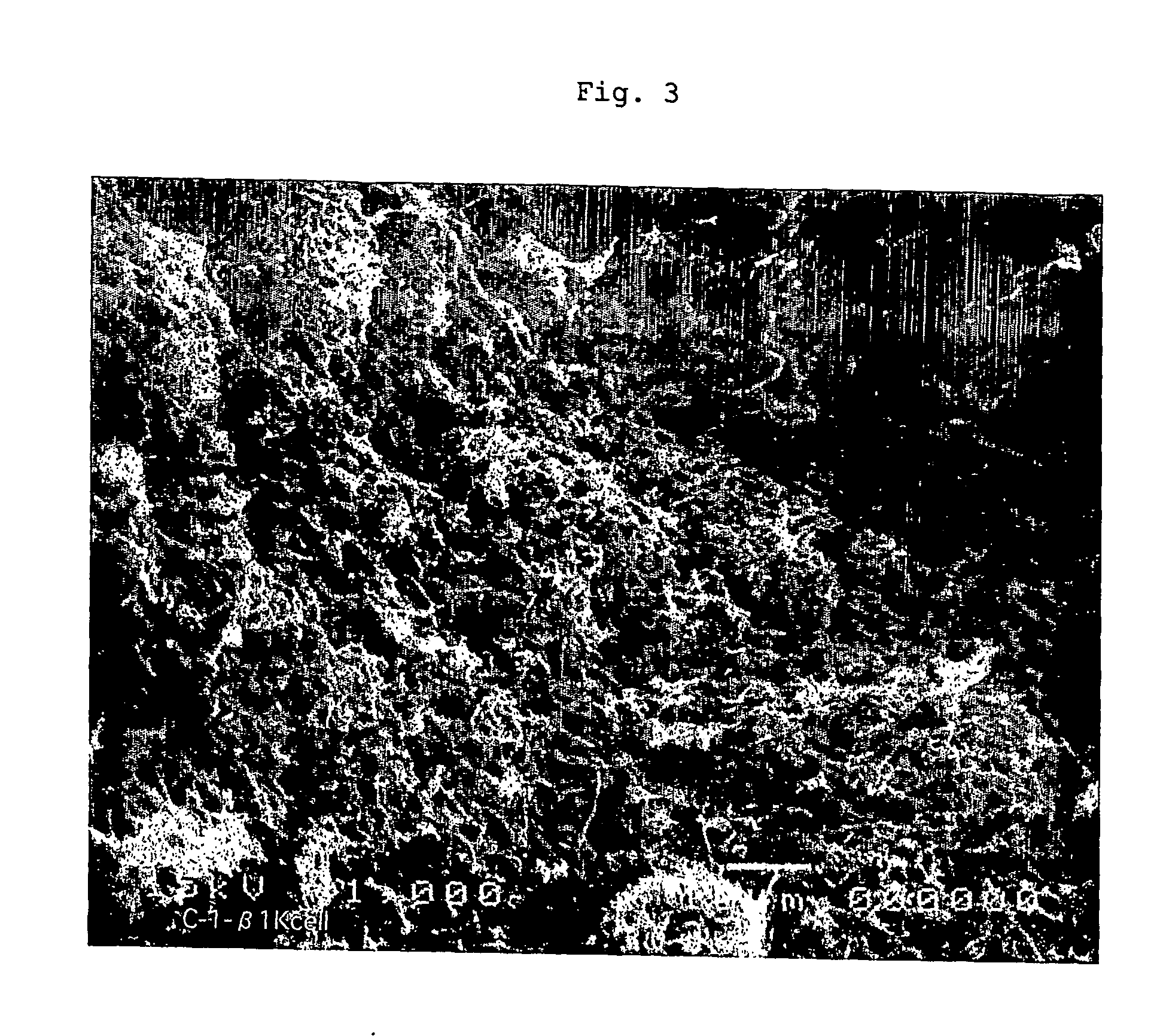

Porous body, production method thereof and composite material using the porous body

InactiveUS20070042901A1Low volumetric shrinkageDifficult to designNanotechCell electrodesFiberPorosity

A porous material comprising vapor grown carbon fiber in an amount of 10 to 90 mass %, fiber filaments of the carbon fiber forming a three-dimensional network and having a diameter of 1 to 1,000 nm, an aspect ratio of 5 to 15,000, a specific surface area (by BET method) of 2 to 2,000 m2 / g, and the ratio of the intensity of the peak at 1,360 cm−1 in a Raman scattering spectrum of the carbon fiber to that of the peak at 1,580 cm−1 in the spectrum(I1360 / I1580) is 0.1 to 2.0, wherein the porosity of the porous material (V / V0) is 0.50 to 0.99 and a specific surface area is 5 to 1,000 m2 / g; and a production method and use thereof. The vapor grow carbon fiber impregnated in the porous material of the present invention does not contain aggregates and a three-dimensional network is formed between the fiber filaments, wherein length of each of the fiber filaments is maintained. Therefore, the vapor grown carbon fiber enables to readily produce a composite material (porous material), in which even a small amount of addition of vapor grown carbon fiber can exhibit sufficient effect.

Owner:SHOWA DENKO KK

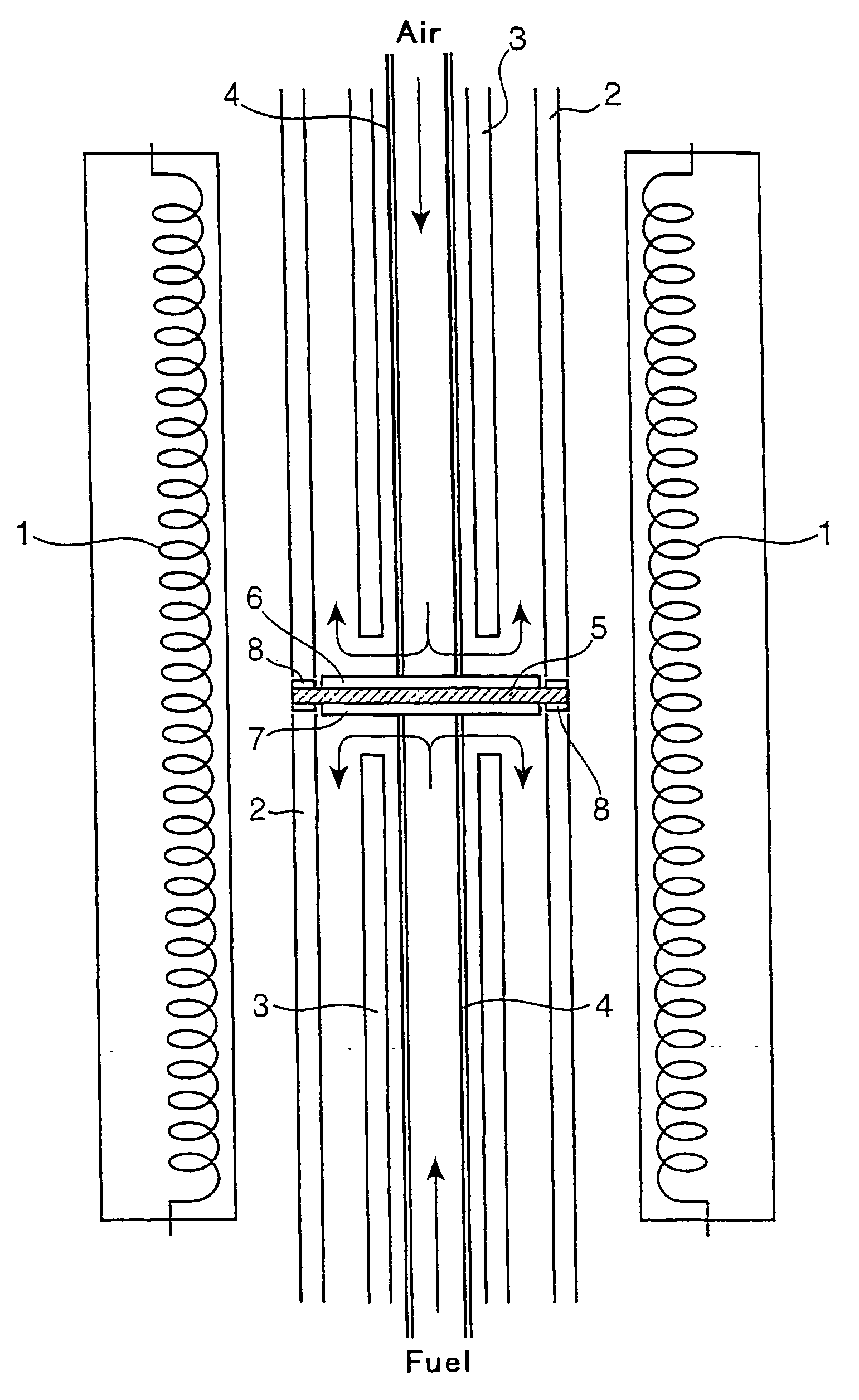

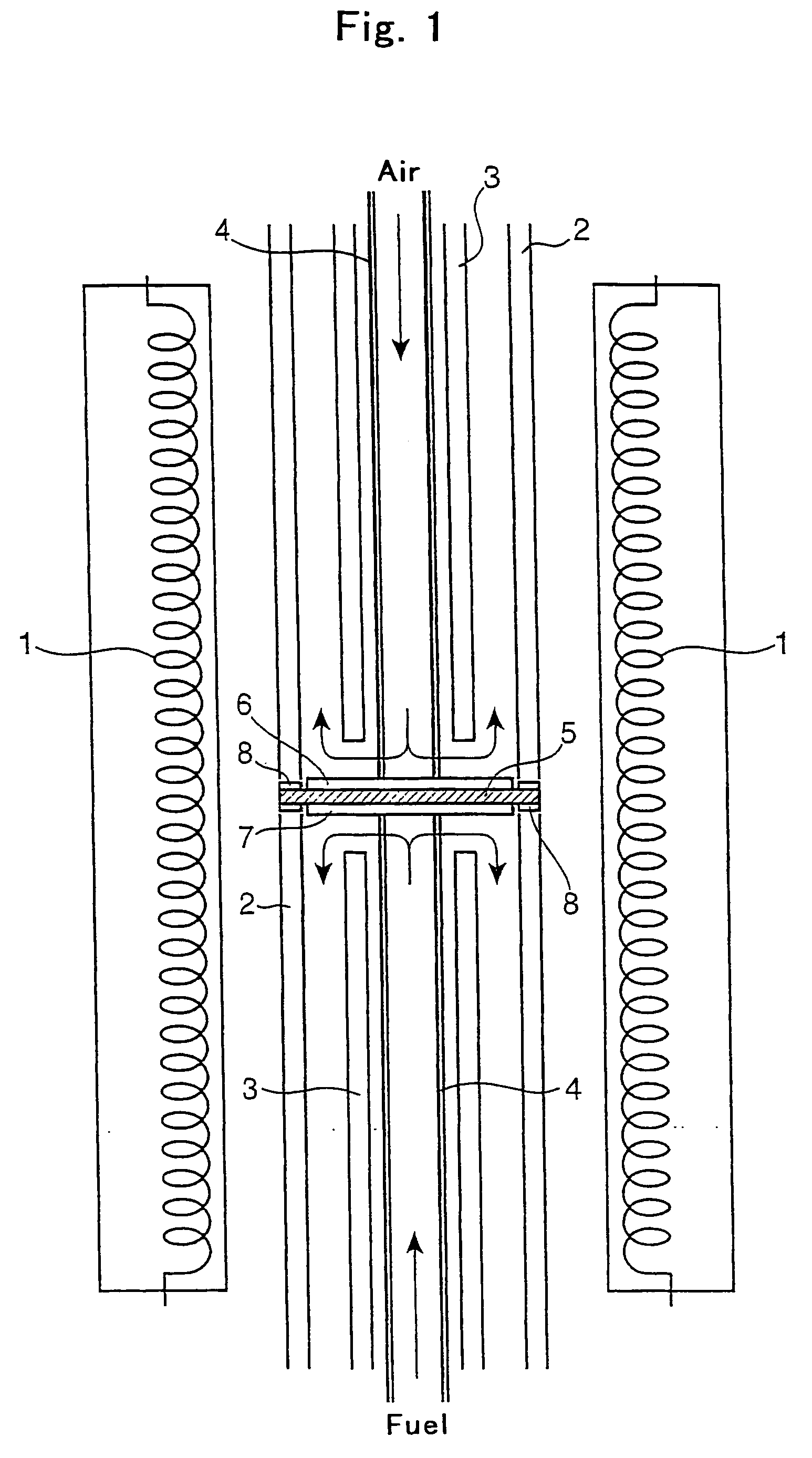

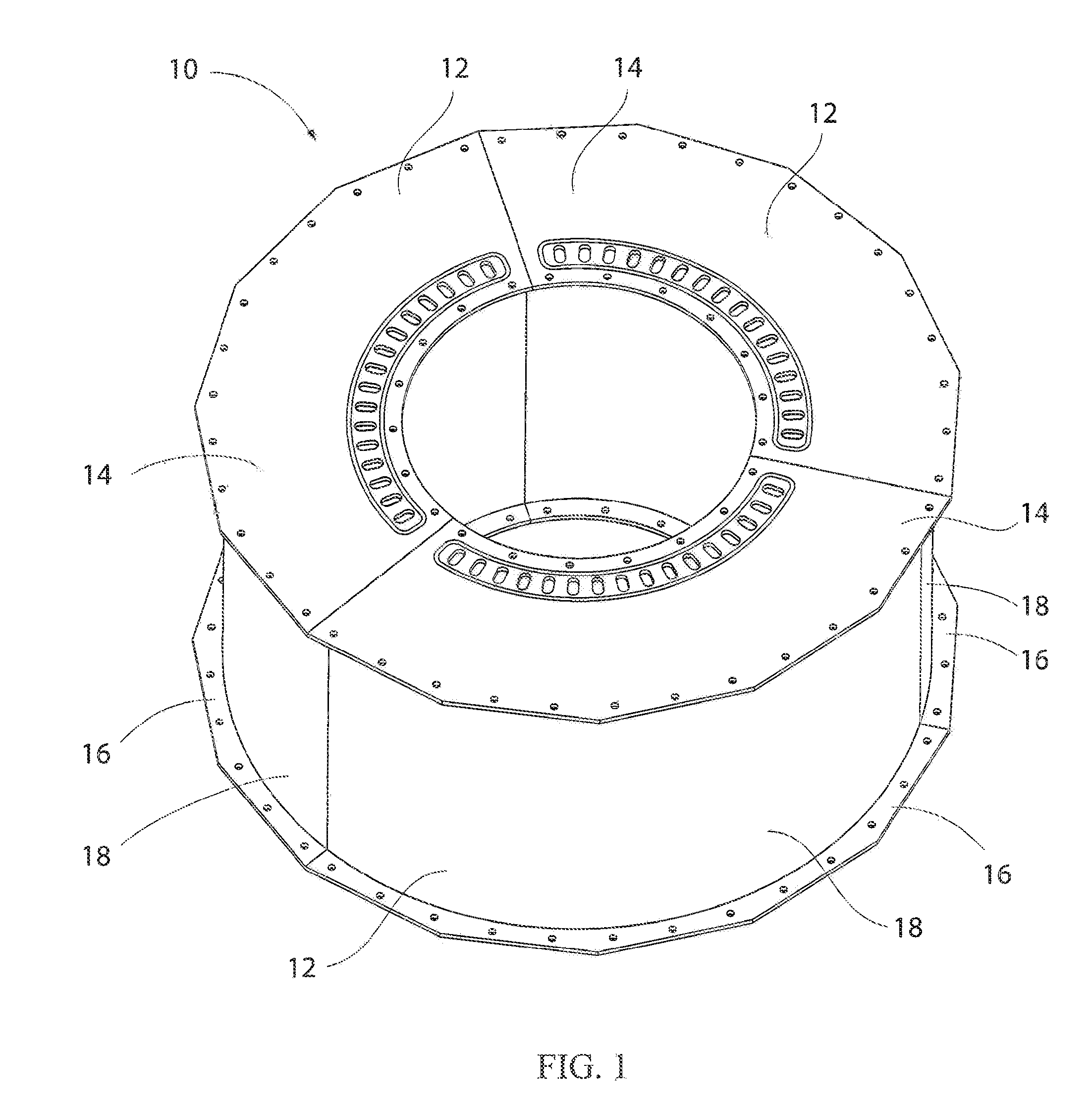

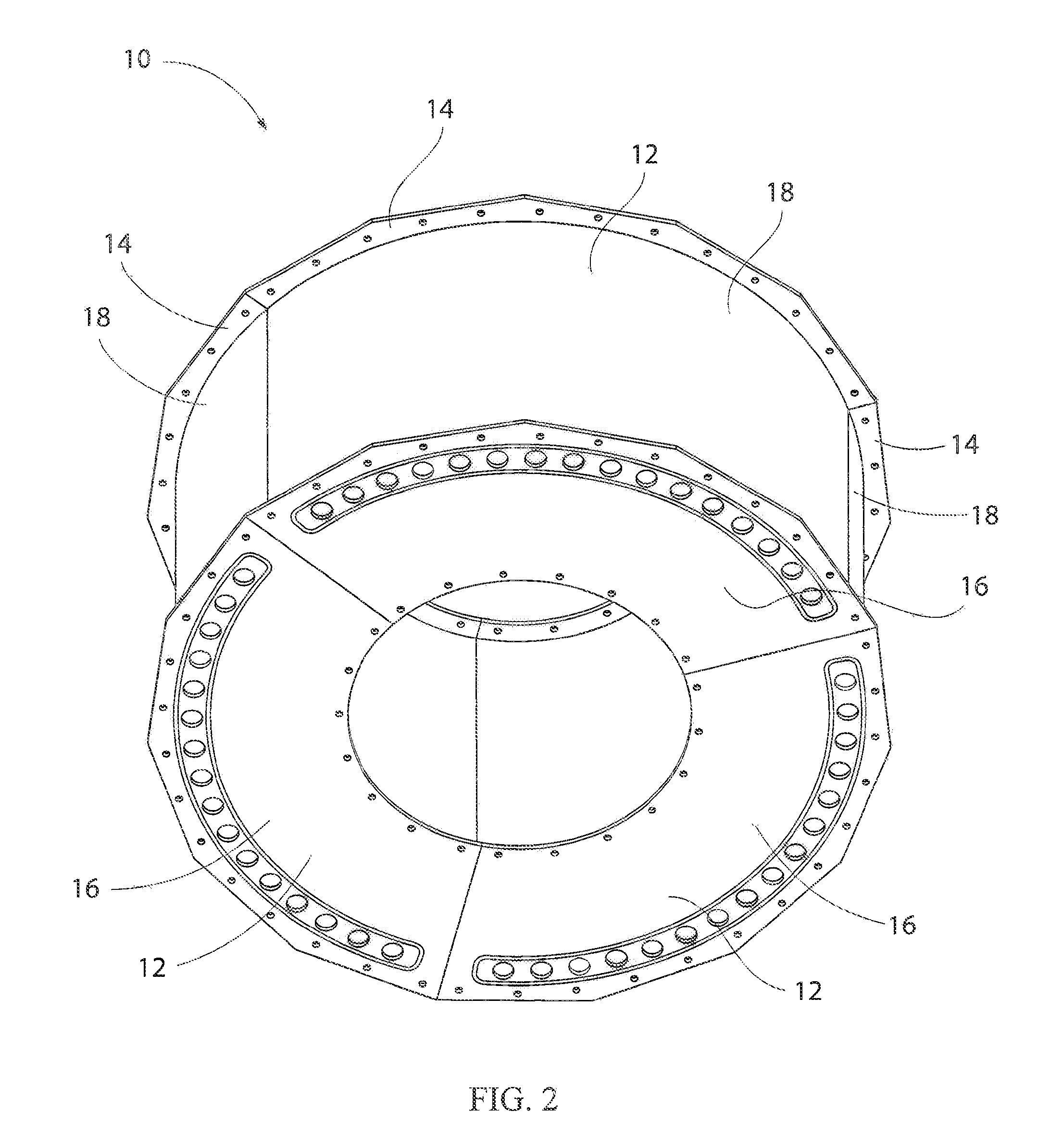

Heat Exchanger and Method of Making and Using the Same

InactiveUS20100170666A1Increase volumeReduce the temperatureFuel cell heat exchangeSemiconductor/solid-state device detailsProcess engineeringChiller

A method of transferring heat from a warmer stream of gas to a cooler stream of gas comprises flowing the warmer stream of gas through a heat exchanger in a manner such that the warmer stream of gas converges as the warmer stream of gas flows through the heat exchanger. The method further comprises flowing the cooler stream of gas through the heat exchanger in a manner such that the cooler stream of gas diverges as the cooler stream of gas flows through the heat exchanger. Another method comprises forming a heat exchanger by solid state welding a plurality of laminate members to each other. The heat exchanger may be a heatsink. The heat exchanger may also condense gas into a liquid.

Owner:ZESS

Manufacturing process for fuel cell, and fuel cell apparatus

InactiveUS20050272595A1Accurate coverageSimply provideActive material electrodesSolid electrolyte fuel cellsFuel cellsEngineering

In a manufacturing process for a fuel cell having a fuel electrode, an oxidizer electrode, and a polymer electrolyte membrane held between both the electrodes, and having electrode catalyst layers which are individually provided between both the electrodes and the polymer electrolyte membrane, the process has the step of ejecting an electrode catalyst composition containing conductive particles carrying thereon at least a catalyst, by an ink-jet process to form the electrode catalyst layers. This provides a fuel cell manufacturing process which can accurately control the coverage of catalyst layers and also can simply provide pores while controlling the same.

Owner:CANON KK

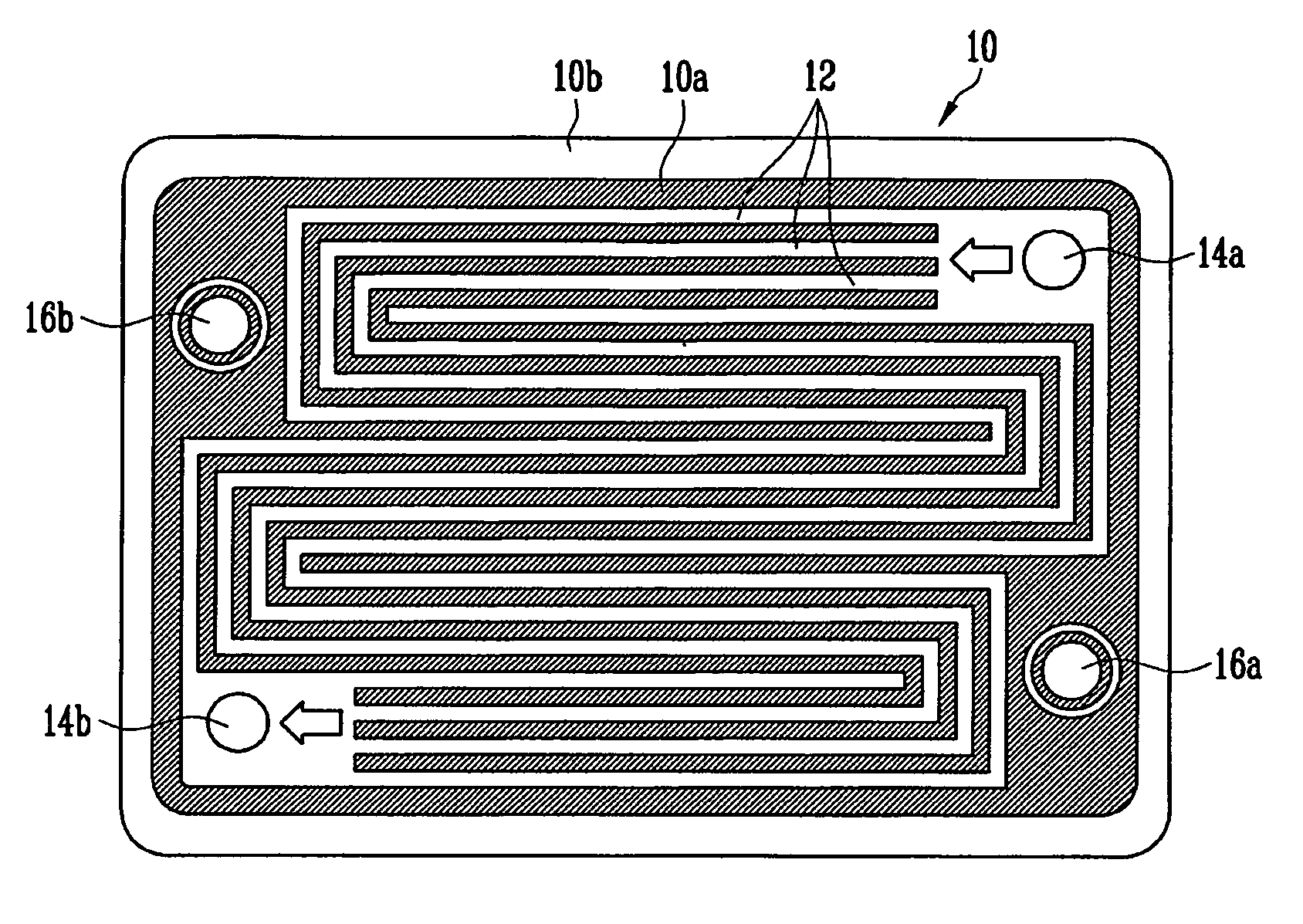

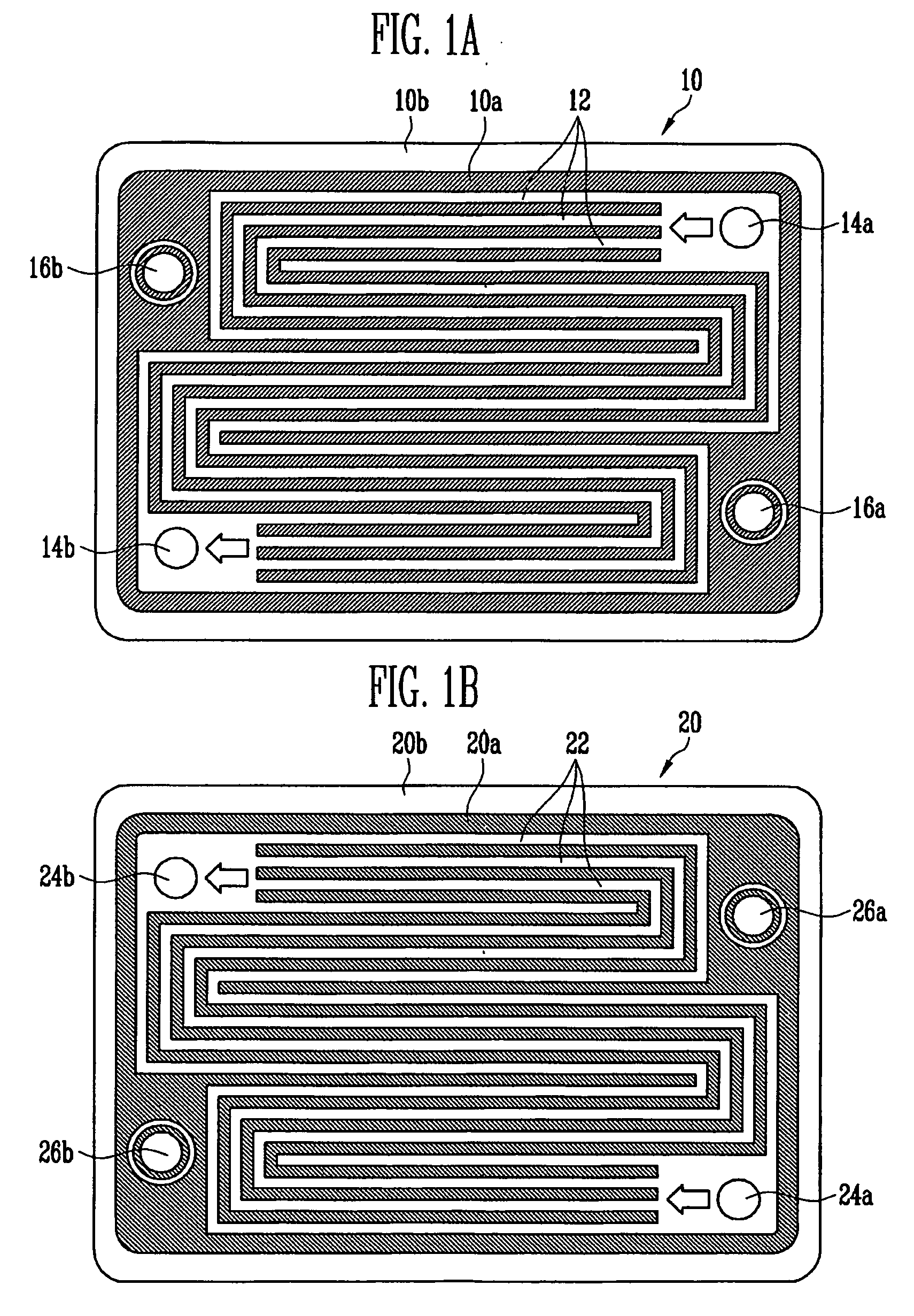

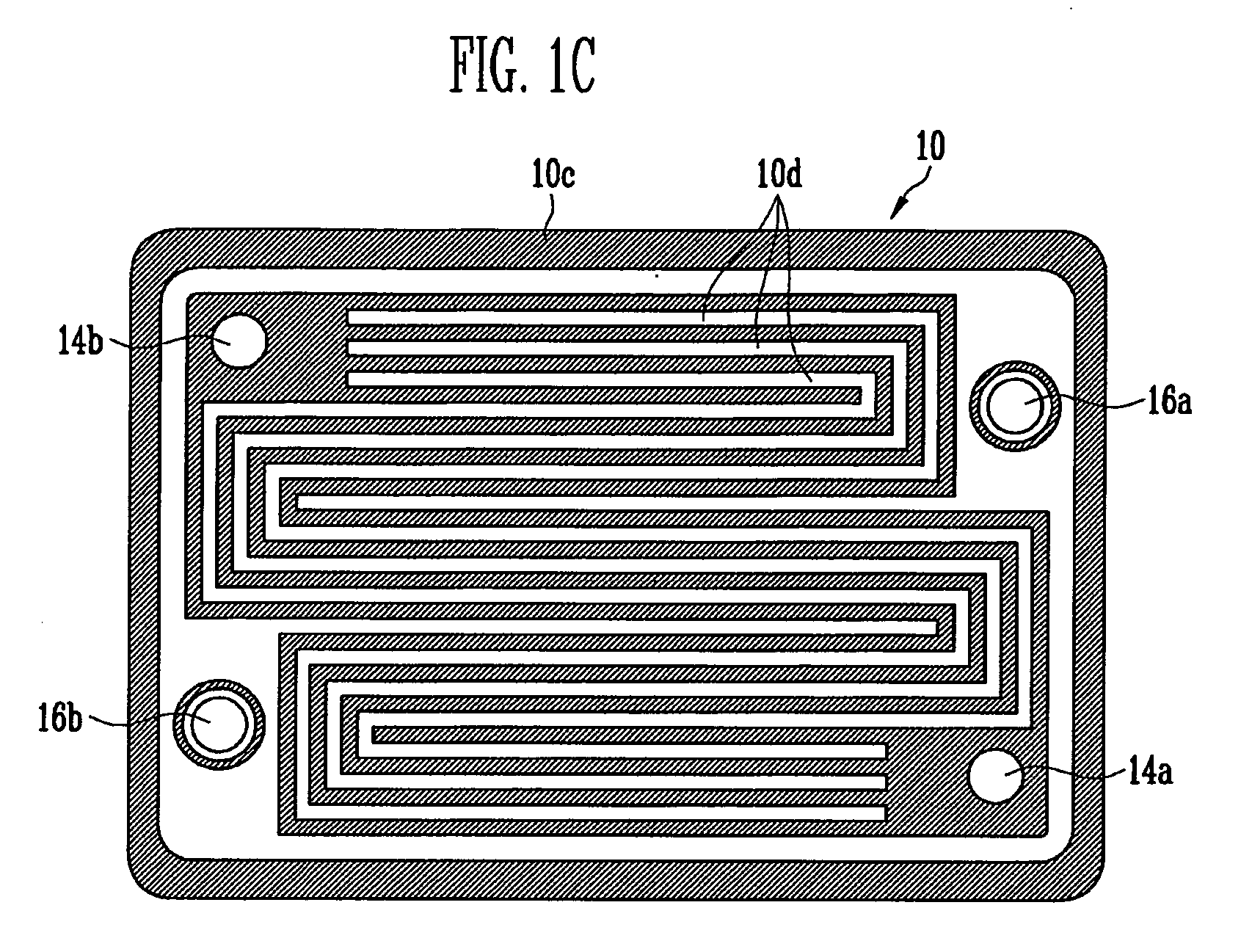

Separator for fuel cell and its manufacturing method and fuel cell stack using the separator

InactiveUS20080318114A1Small sizeEasy to manufacturePrimary cellsFuel cell auxillariesFuel cellsEngineering

A separator for a fuel cell, including: a plate; a first flow channel having a first depth on a first side of the plate; a first inlet hole coupled to the first flow channel; a first outlet hole coupled to the first flow channel; a second flow channel on a second side of the plate; a second inlet hole coupled to the second flow channel; a second outlet hole coupled to the second flow channel; and a bridge unit having a second depth less than the first depth at a region where a direction of flow of at least one of the first inlet hole or the first outlet hole and a direction of flow of the second flow channel cross.

Owner:SAMSUNG SDI CO LTD

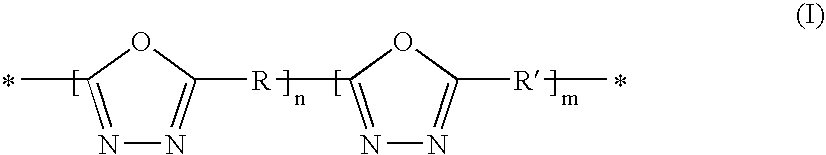

Method for the production of a sulfonated poly (1, 3, 4-oxadiazole) polymer

A sulfonated poly(1,3,4-oxadiazole) polymer is produced by producing of a solution of hydrazine sulfate salt and a non-sulfonated dicarboxylic acid or derivative thereof in polyphosphoric acid; heating the solution under an inert gas atmosphere; and precipitating sulfonated poly(1,3,4-oxadiazole) polymer in a basic solution.

Owner:GKSS FORSCHUNGSZENTRUM GEESTHACHT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com