Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56 results about "Zirconium oxide hydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reproducible phosphorus-uptake ceramsite and preparation method thereof

InactiveCN102515830AStrong phosphorus removal capacityAdaptableOther chemical processesCeramic materials productionHydration reactionWastewater

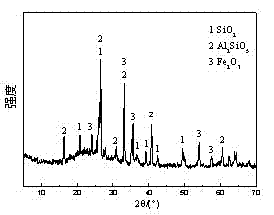

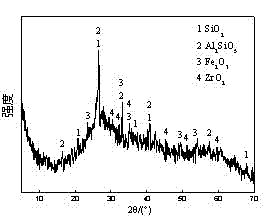

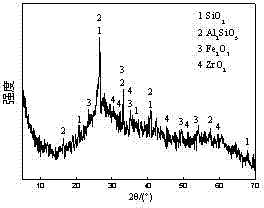

The invention discloses a reproducible phosphorus-uptake ceramsite and a preparation method thereof. The technical scheme provided by the invention comprises the following steps of: respectively drying 70-85 wt% of fly ash, 10-16 wt% of pore-forming agent and 5-14 wt% of clay powder and uniformly mixing the raw materials; after balling the mixture, baking at a temperature in a range of 950-1100 DEG C for 30-50 min to obtain a baked porous ceramsite; sequentially immersing the baked porous ceramsite with HCl, washing with water and drying; and loading zirconium oxide hydrate to obtain the phosphorus-uptake ceramsite. The phosphorus-uptake ceramsite prepared by the invention can be directly added into or filled as a filtering column to remove phosphorus in the water and the adsorbed phosphorus-uptake ceramsite can be desorbed by a NaOH solution to be reproduced; the saturated adsorption capacity to the phosphorus is 10-11 mg / g and the adaptability to the change of the phosphorus concentration in the water is good; after the treatment, the solid-liquid separation is easy to realize and the water quality of the discharged water is better. The reproducible phosphorus-uptake ceramsite provided by the invention has the advantages of strong phosphorus-uptake capability, easiness of realizing the solid-liquid separation, good cyclic usability and higher cost performance, so that the reproducible phosphorus-uptake ceramsite is applicable to phosphorous removal of various types of wastewater and surface water.

Owner:WUHAN UNIV OF SCI & TECH

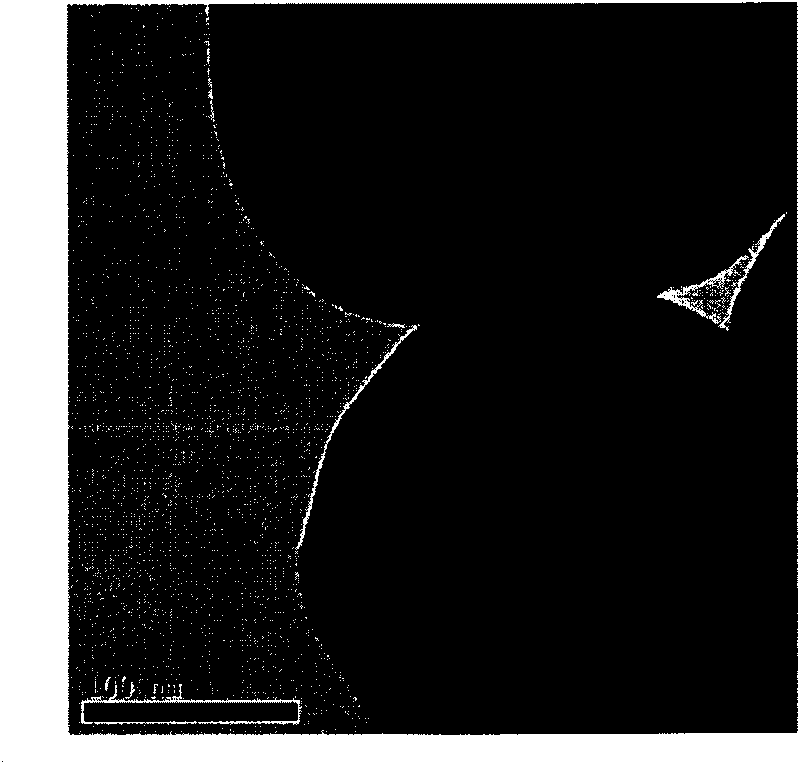

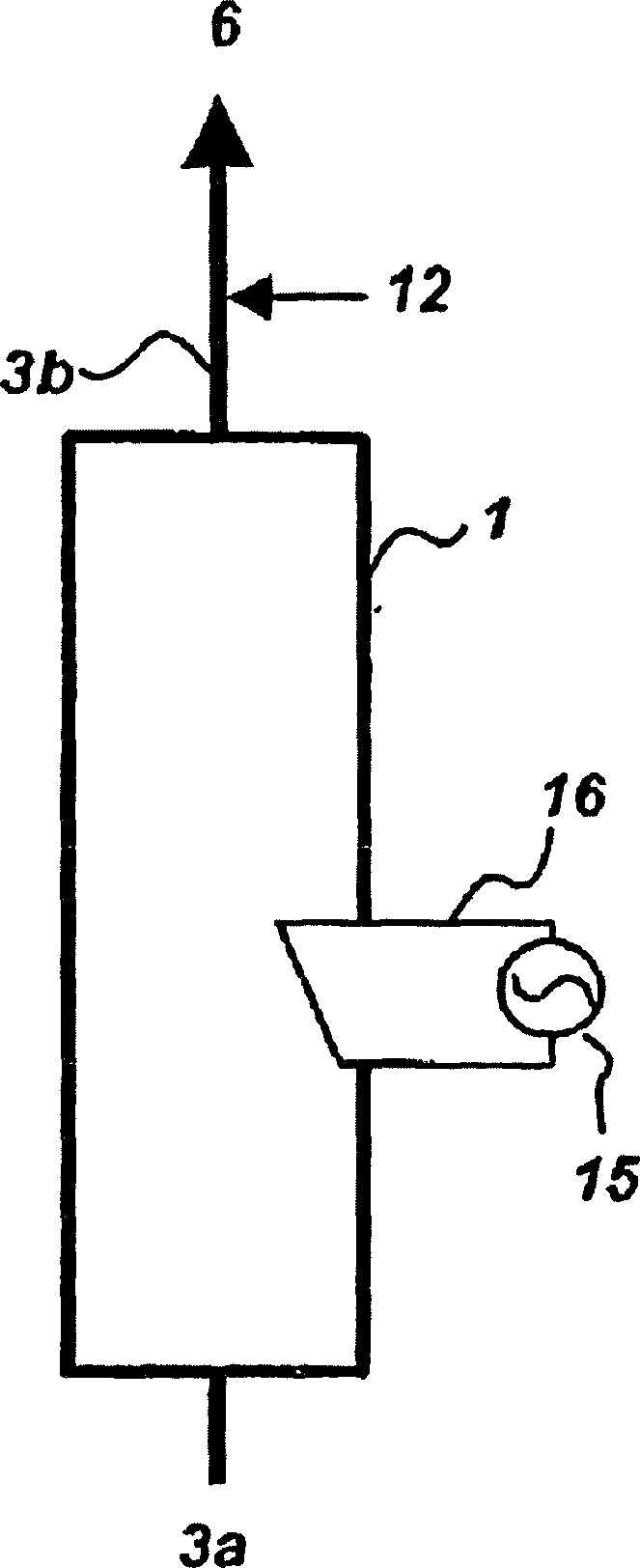

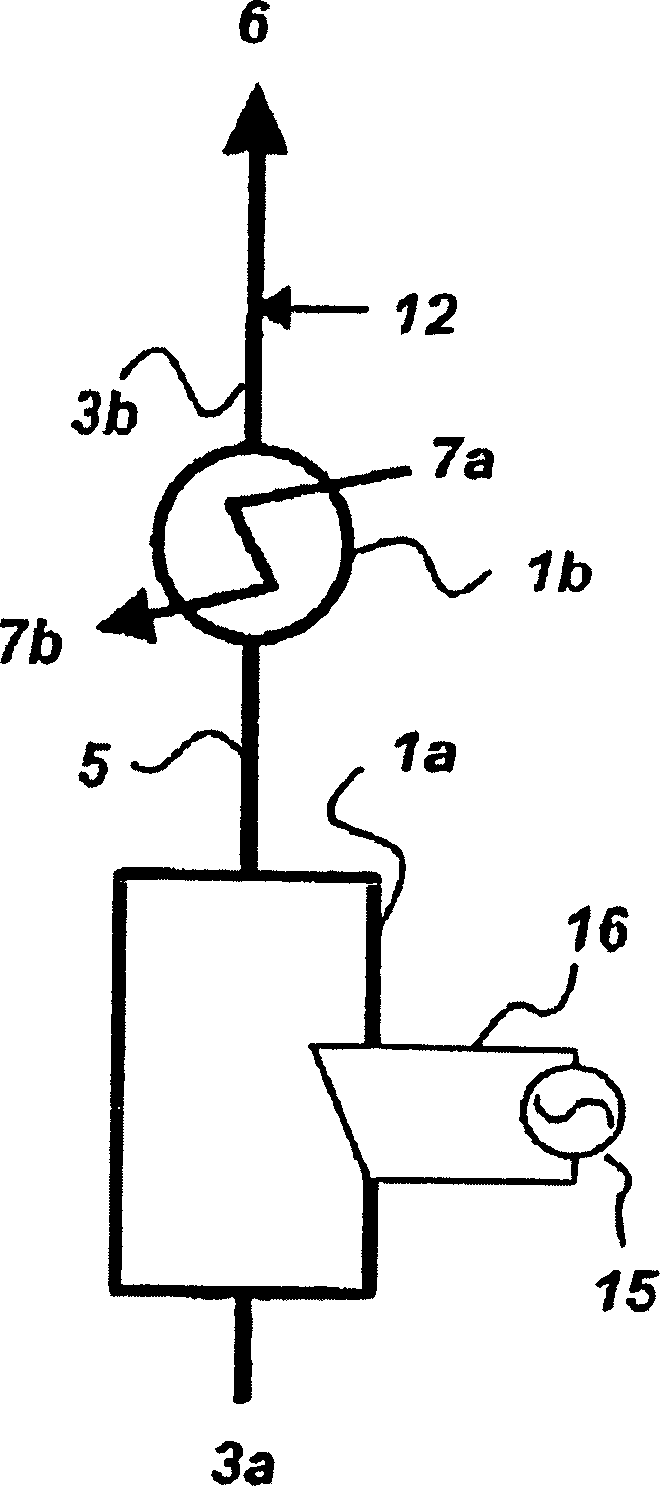

Inorganic fine particles, inorganic raw material powder, and method for production thereof

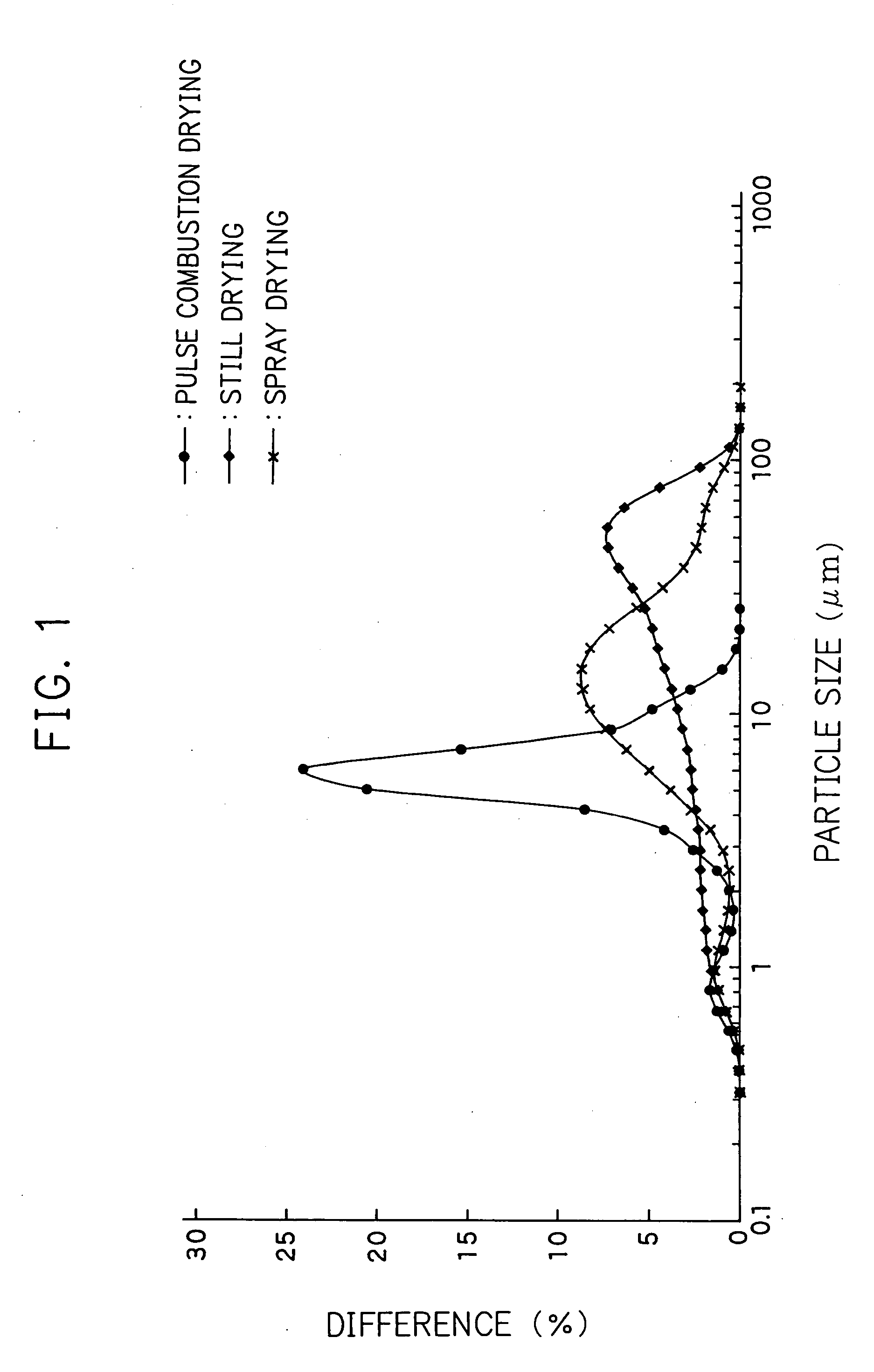

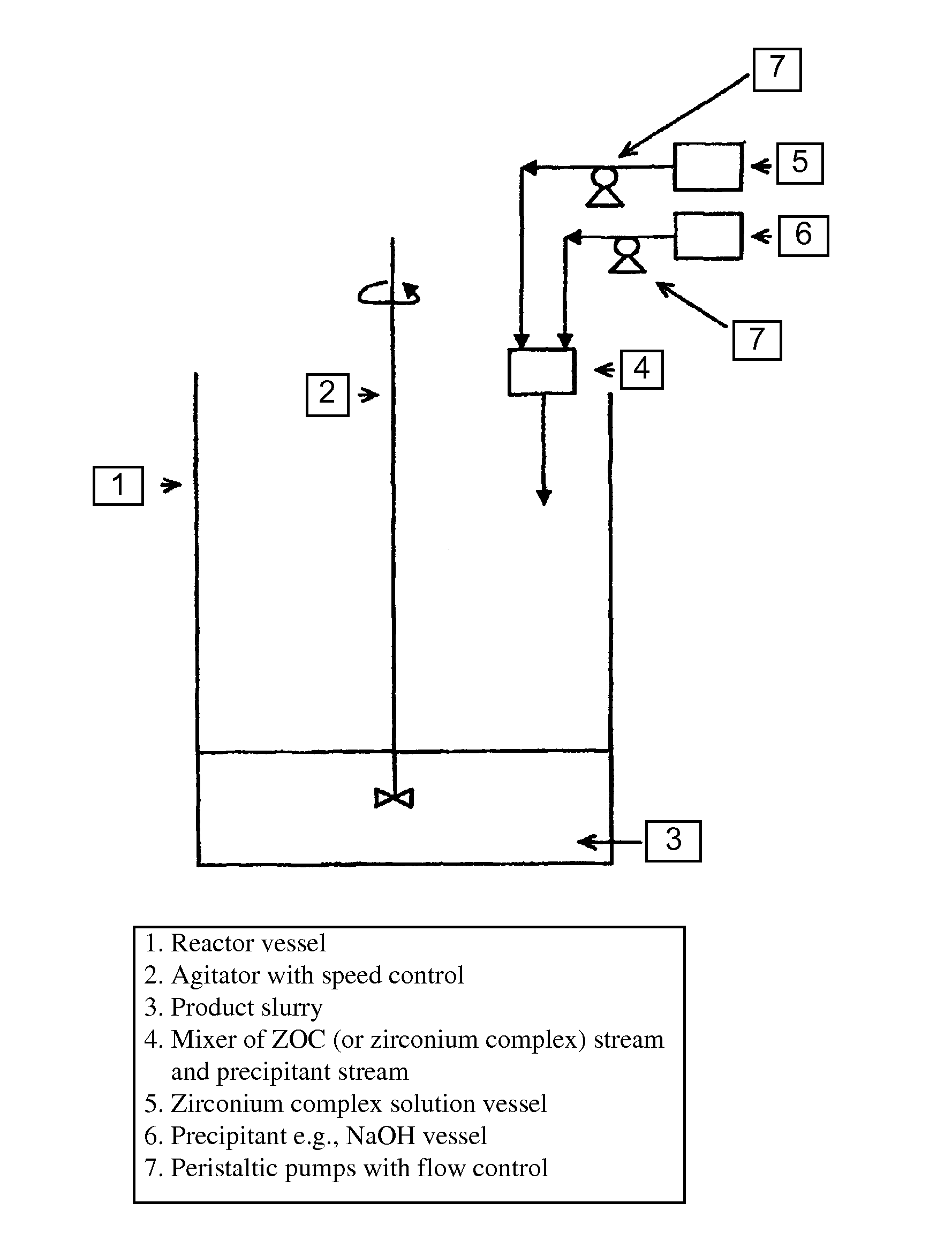

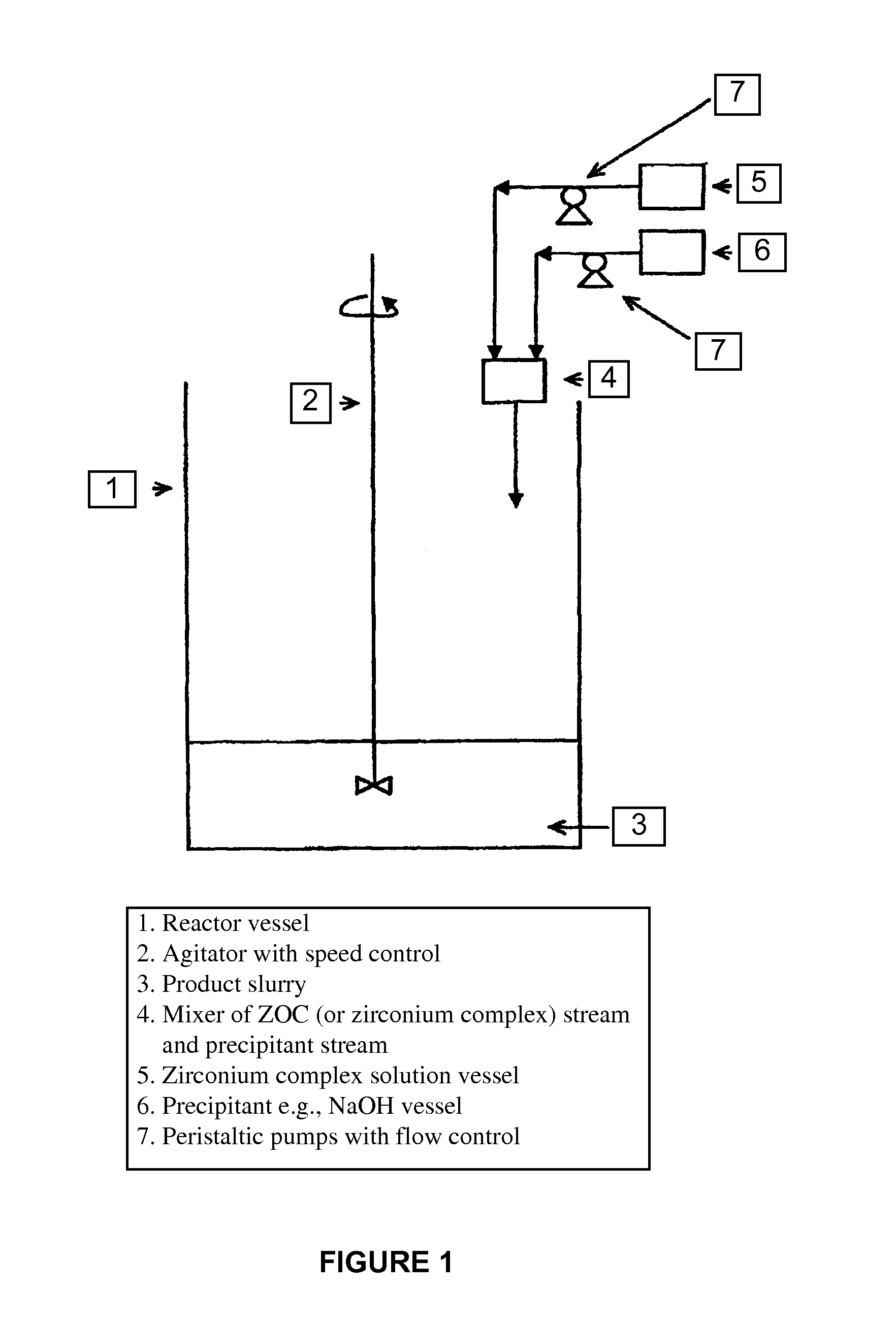

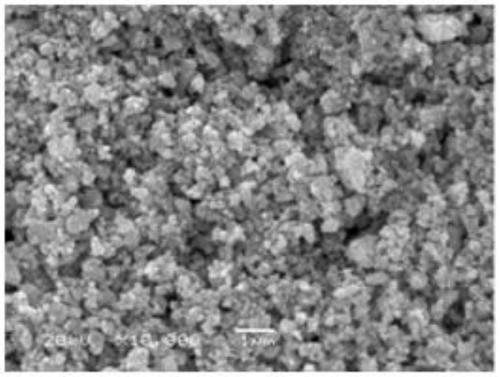

InactiveUS20060051288A1Suppress agglomeration actionShort timeMaterial nanotechnologyDrying solid materials with heatChemical structureSlurry

The present invention provides new process for preparing inorganic fine particles, which suppresses agglomeration and adhesion of particles due to heat when preparing powder from a raw material liquid such as a slurry of zirconia hydrate fine particles in order to obtain inorganic raw material powder having sharp particle size distribution. Furthermore, the present invention provides a new process for preparing inorganic fine particles, which can make the chemical structure homogenous among the produced particles and inside the particles even in a multi-component system. The present invention provides a process for preparing inorganic fine particles, which comprises heating and applying impulse waves to a raw material liquid.

Owner:DAI ICHI KOGYO SEIYAKU CO LTD +2

Methods Of Synthesizing Hydrous Zirconium Oxide And Other Oxides

ActiveUS20130190168A1Avoid particle agglomerationInhibition of agglomerationDialysis systemsComplex ion-exchangersSorbentHYDROSOL

Owner:FRESENIUS MEDICAL CARE HLDG INC

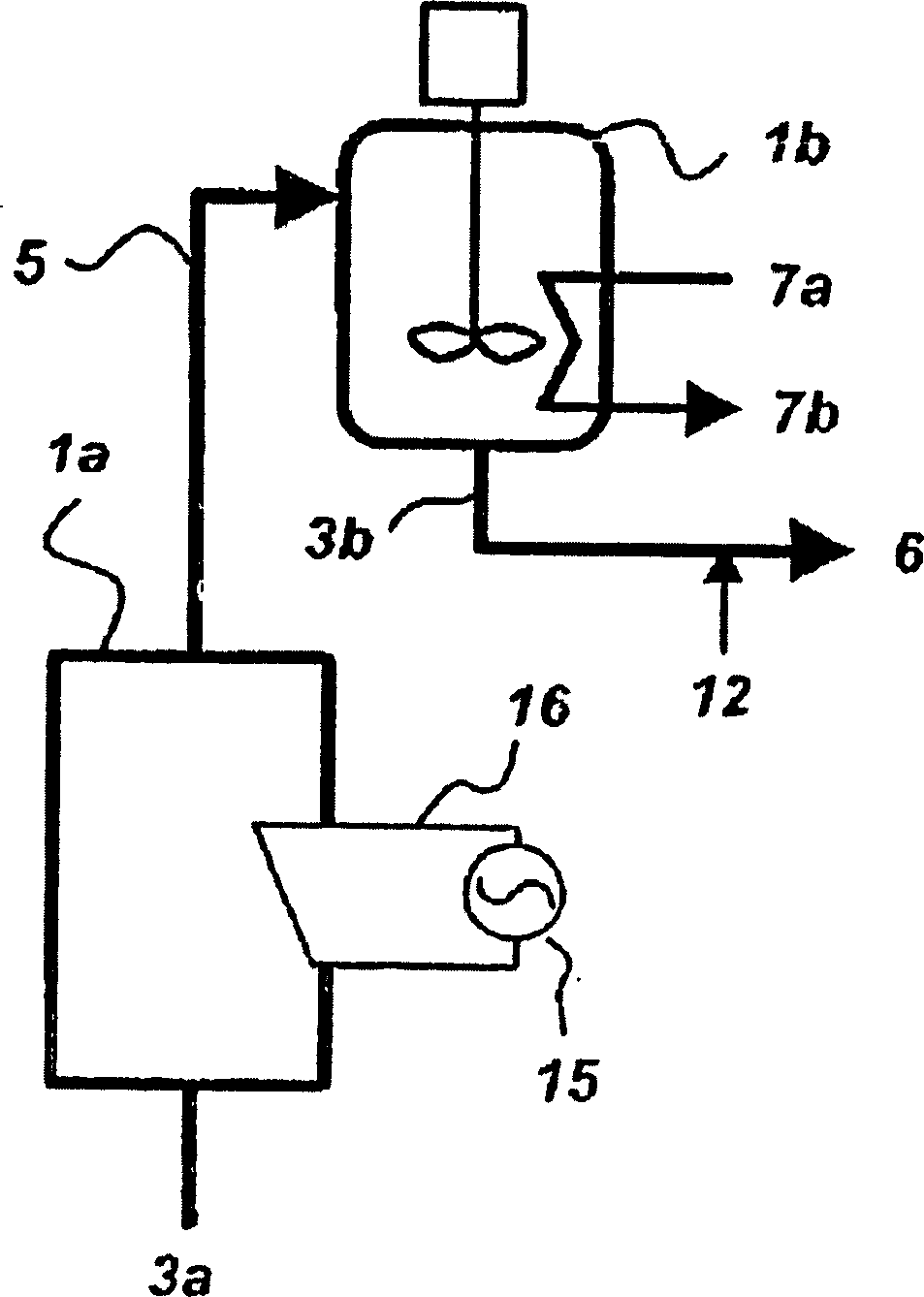

Method for continuous preparation of nanometer-sized hydrous zirconia sol using microwave

The present invention relates to a method for continuous preparation of a hydrous zirconia sol dispersed by nanometer-sized spherical hydrous zirconia particles having an average diameter(dp) of 1˜250 nm, which method comprises supplying the aqueous solution of a zirconium salt at a concentration of 0.001-0.2 mole / l to a reactor consisting of one or more than two reaction tubes, and then irradiating microwave to the stream of the said aqueous solution in the reactor so that the said solution may be heated in a flow state. Contrary to the method employing a conventional batch-type reactor or semi-continuous stirred-type reactor, the method for continuous preparation of a hydrous zirconia sol according to the present invention can allow various operational parameters to be controlled in a certain range and thus contributes to remarkably improve the quality of a hydrous zirconia sol to be prepared or of the zirconia powder obtainable as a final product.

Owner:KOREA RES INST OF CHEM TECH

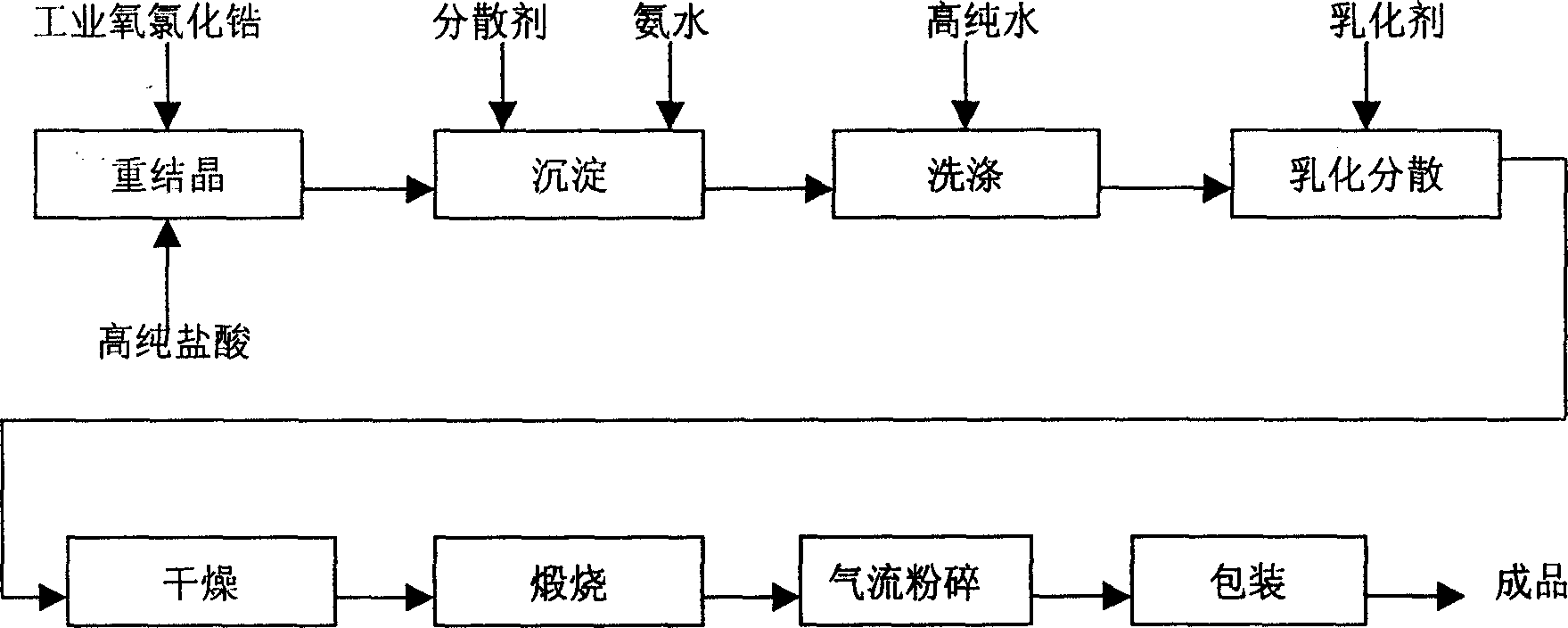

Process for preparing high-purity superfine zirconia by zirconium oxychloride

Disclosed is a process for preparing high-purity superfine zirconia by zirconium oxychloride, which comprises recrystallization purifying, charging ammonia for sedimentation, obtaining zirconium hydroxide colloid that is easy for filtration and washing, after filtering and washing, charging minute quantity of emulsifying agent, carrying out high shearing emulsification and high-energy ball grinding, thus obtaining stable hydrated zirconium dioxide with good dispersity, then drying with spraying drying apparatus, calcining to obtain crude product of high purity ultra-fine zirconium dioxide, finally subjecting the crude product to high pressure disintegration.

Owner:宜兴新兴锆业有限公司

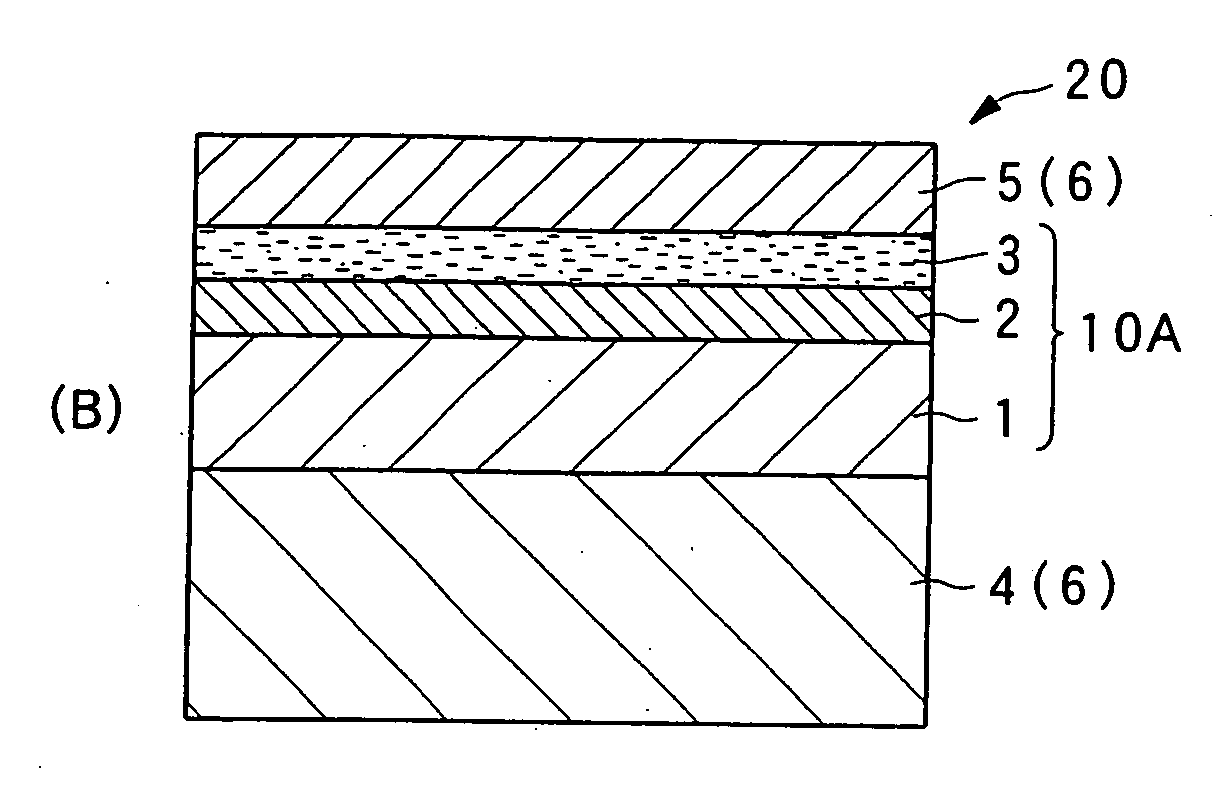

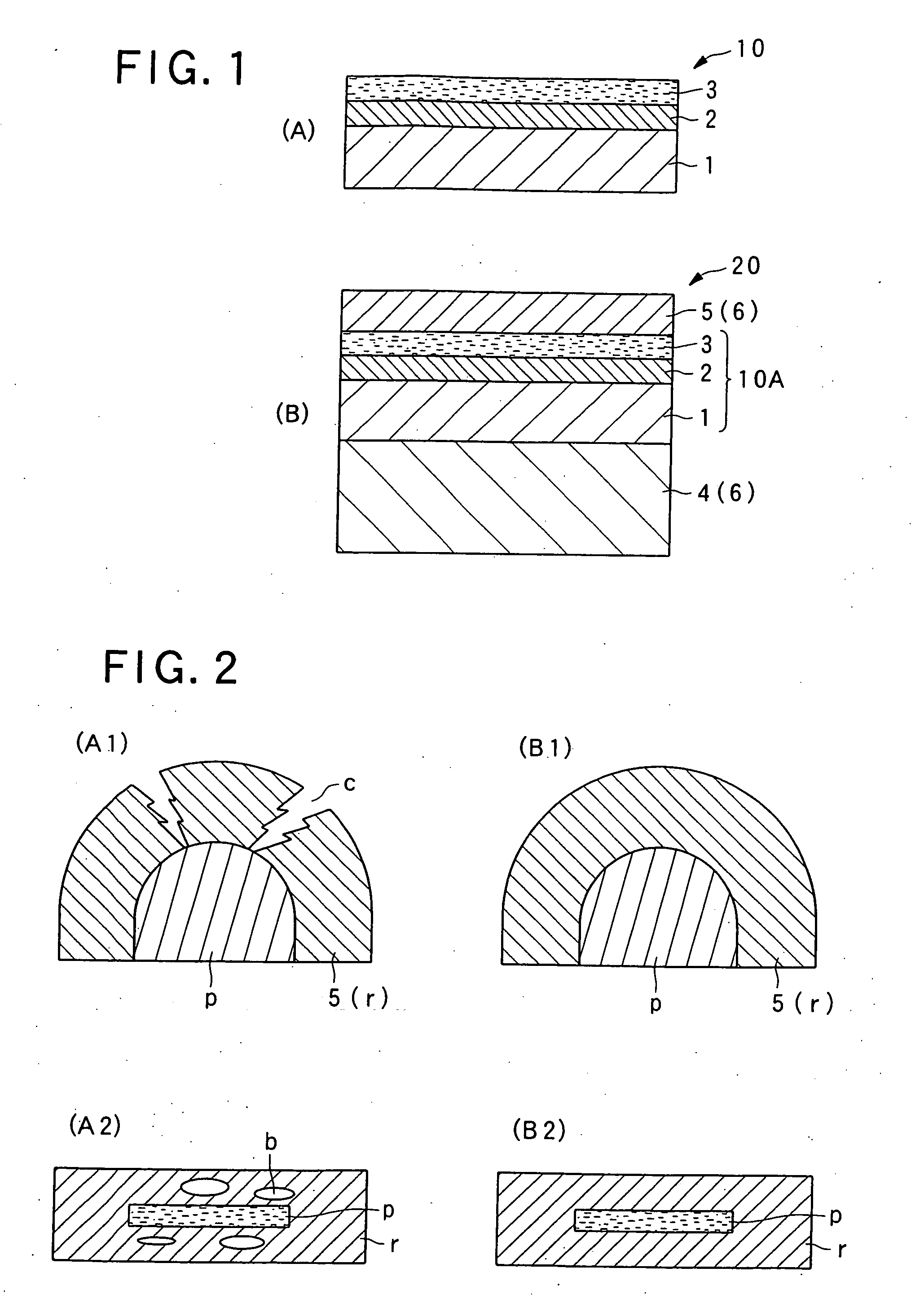

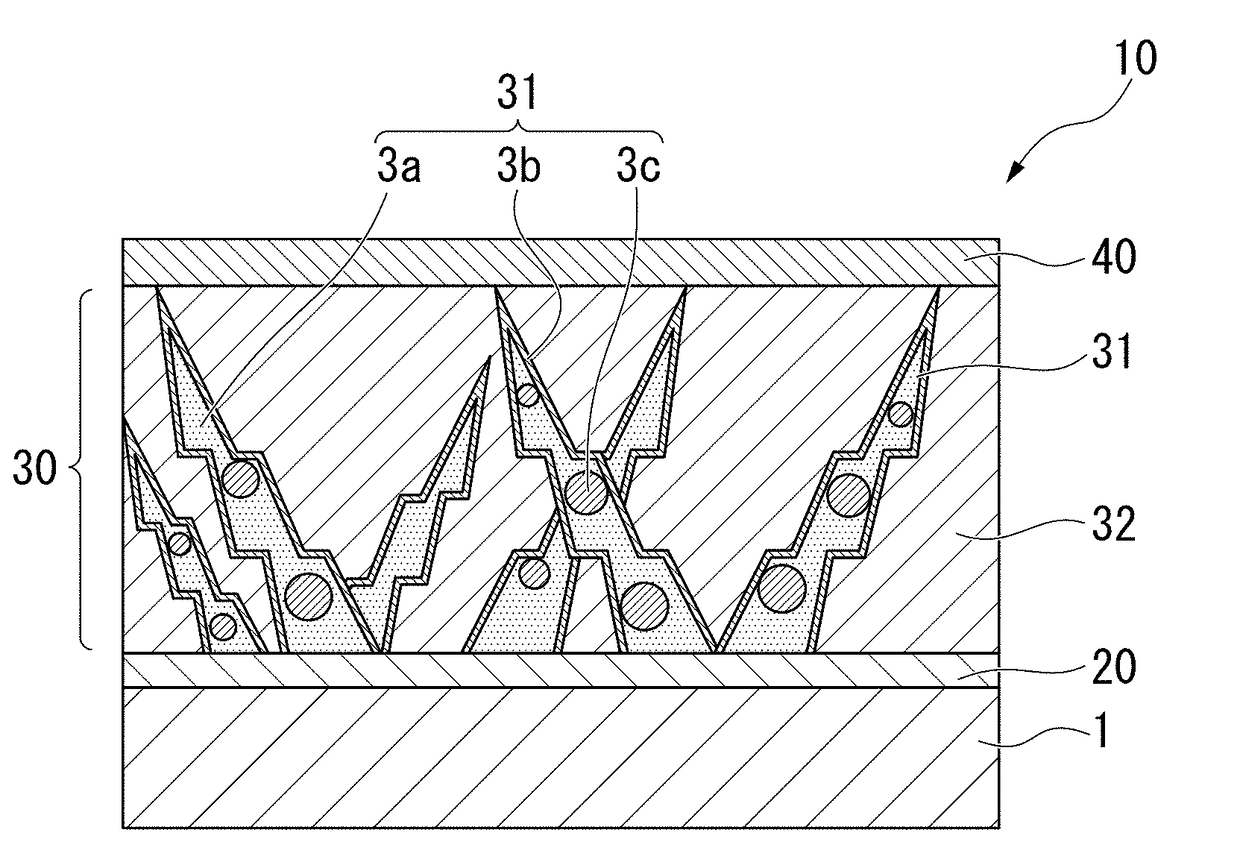

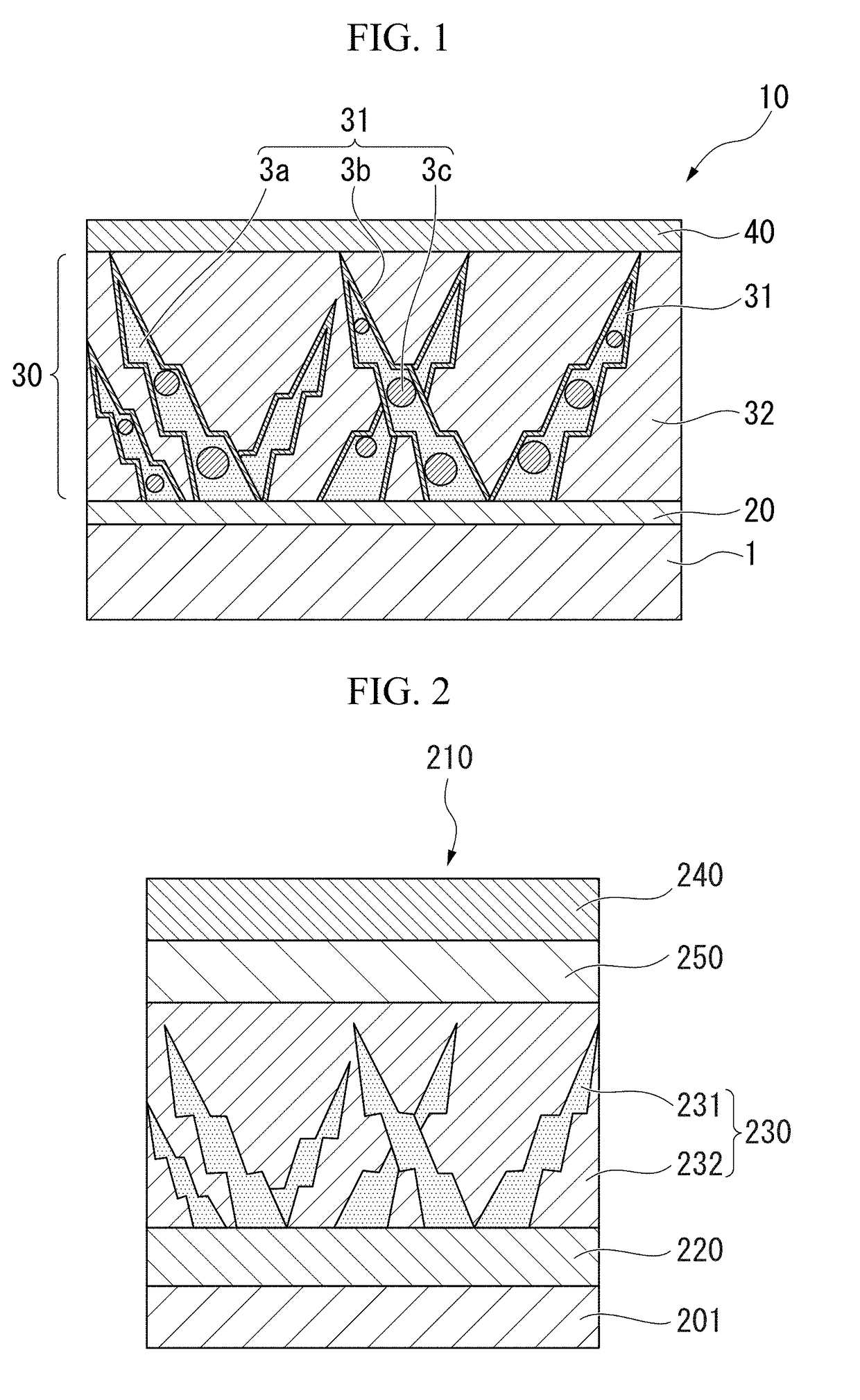

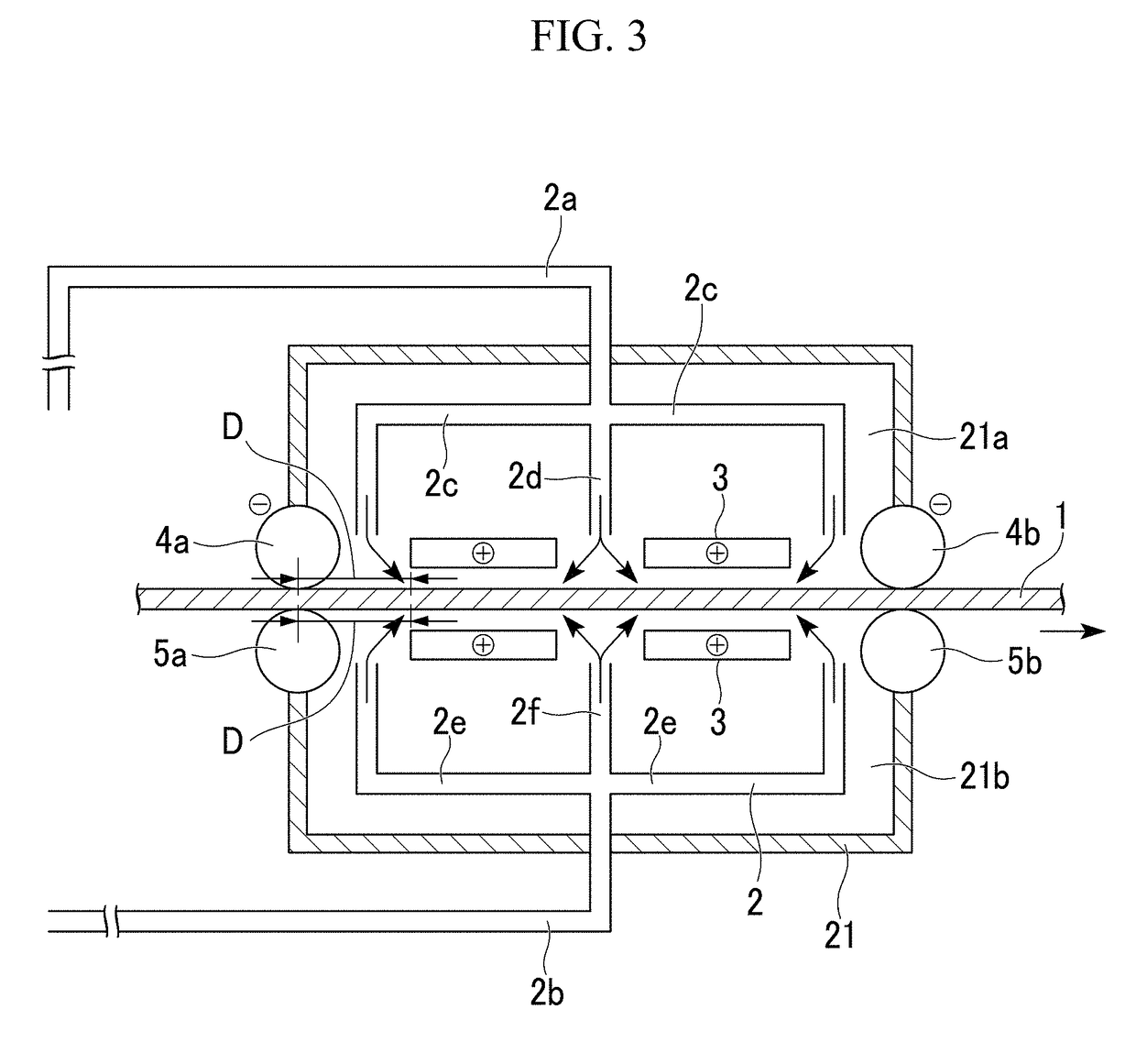

Pearl-like decorative paper having suitability for postforming and thermosetting resin decorative sheet

InactiveUS20070172644A1Avoid it happening againSpecial paperDecorative surface effectsEngineeringMelamine

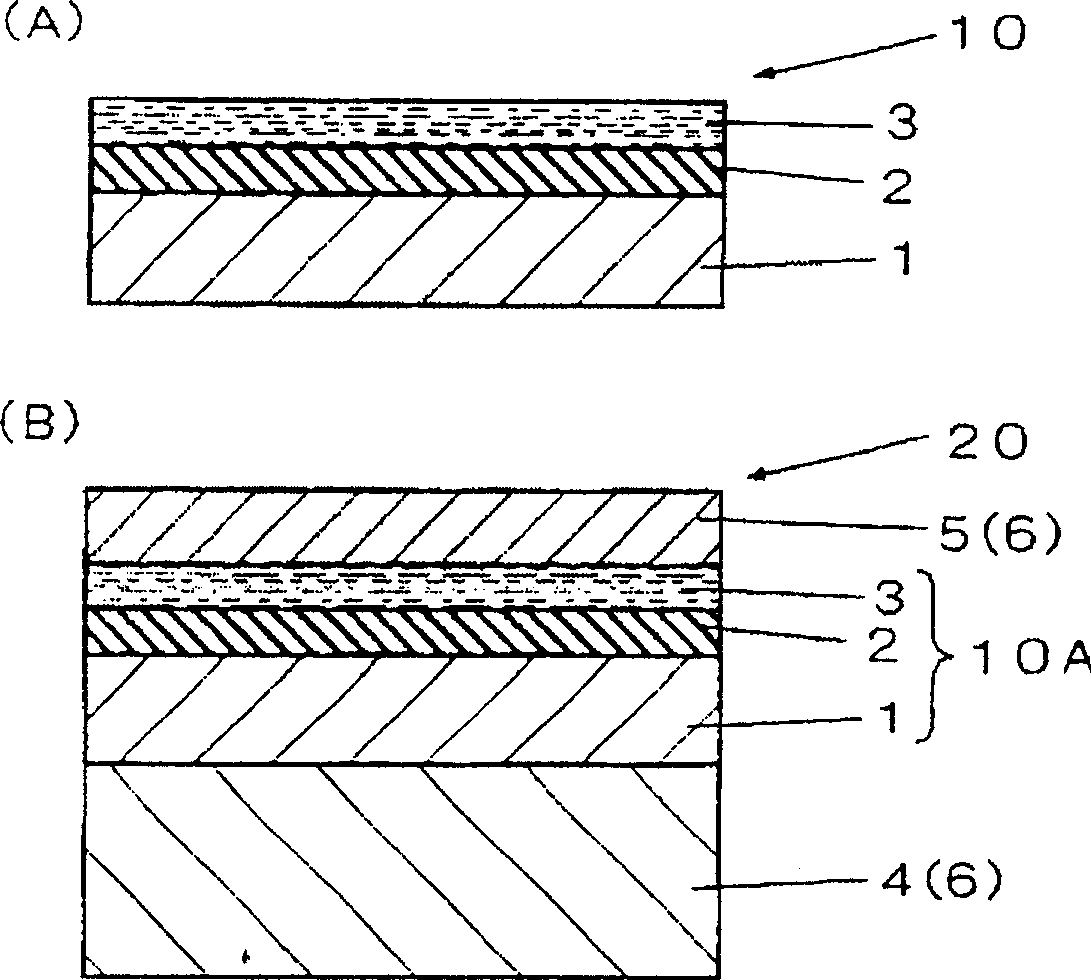

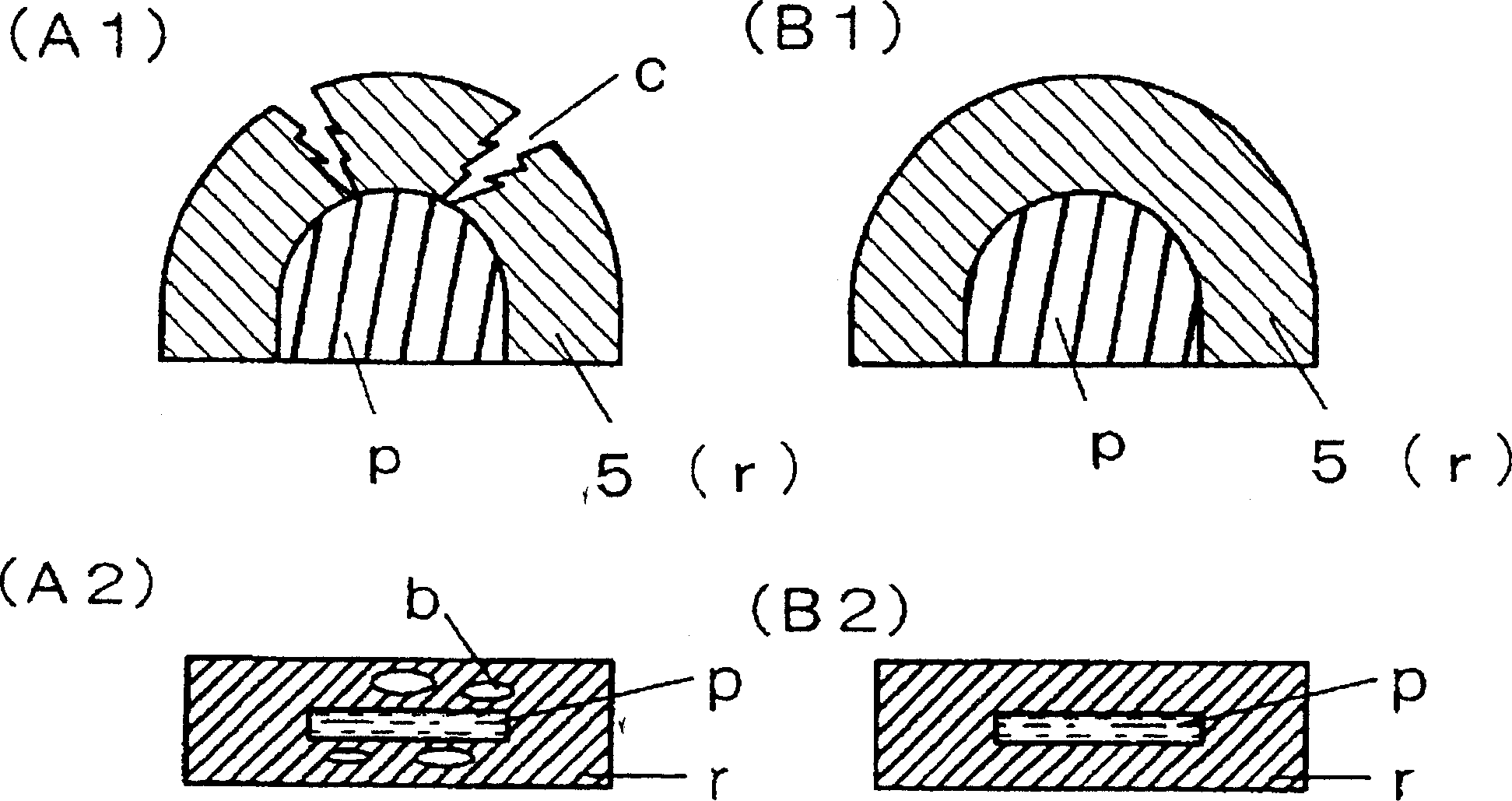

A pearl-like decorative paper and a thermosetting resin decorative sheet having postforming suitability with no blisters or cracking generation by the postforming process even in the case of the pearl-like design are provided. In the pearl-like decorative paper 10 having a pearl ink layer 3 containing a pearl pigment on a paper substrate 1, a pearl pigment of a scaly foil of mica covered with a titanium dioxide and / or an iron oxide, and the surface thereof further treated with a zirconium oxide hydrate is used as the pearl pigment. By providing a pattern ink layer 2 of an ordinary ink therebetween, a further better design can be provided. Then, by impregnating the pearl-like decorative paper with a thermosetting resin such as a melamine resin, laminating the same with an adherend 6 such as a backing substrate 4 and an overlaying paper 5, and applying thermal pressing molding for curing the resin, a pearl-like thermosetting resin decorative sheet 20 including a pearl-like decorative paper 10A with the resin cured can be provided.

Owner:DAI NIPPON PRINTING CO LTD

Method for coating hydrous zirconium oxide on surface of rutile type titanium dioxide

The invention provides a method for coating hydrous zirconium oxide on the surface of rutile type titanium dioxide. The method comprises the following steps of: a, dispersing the rutile type titanium dioxide particles in deionized water and adding 50g / L solution of sodium hexametaphosphate serving as a dispersing agent to prepare a suspension, wherein the concentration of the rutile type titanium dioxide is 0.1g / ml; and the ultrasonical dispersion of the suspension is performed for 30 minutes, wherein the volume ratio of the solution of sodium hexametaphosphate to the suspension of titanium dioxide is 1:130; b, transferring the pulp prepared by the step a to a water bath at a constant temperature of between 50 and 80 DEG C and stirring, adjusting a pH value of the pulp to 7 to 11, adding 1 mass percent solution of zirconium oxychloride and sulfuric acid solution, and ageing the pulp for 2 hours while continuously stirring the pulp, wherein the adding amount of the solution of zirconium oxychloride is 1 to 5 percent of the weight of TiO2 based on ZrO2; and c, pump-filtering the pulp prepared by the step b, washing the pulp by deionized water, pump-filtering the filter cake until the conductivity of the filtrate is less than 20ms / m; and drying the filter cake by blasting at the temperature of 120 DEG C for 24 hours and crushing the filter cake to obtained the finished product.

Owner:JIANGSU UNIV

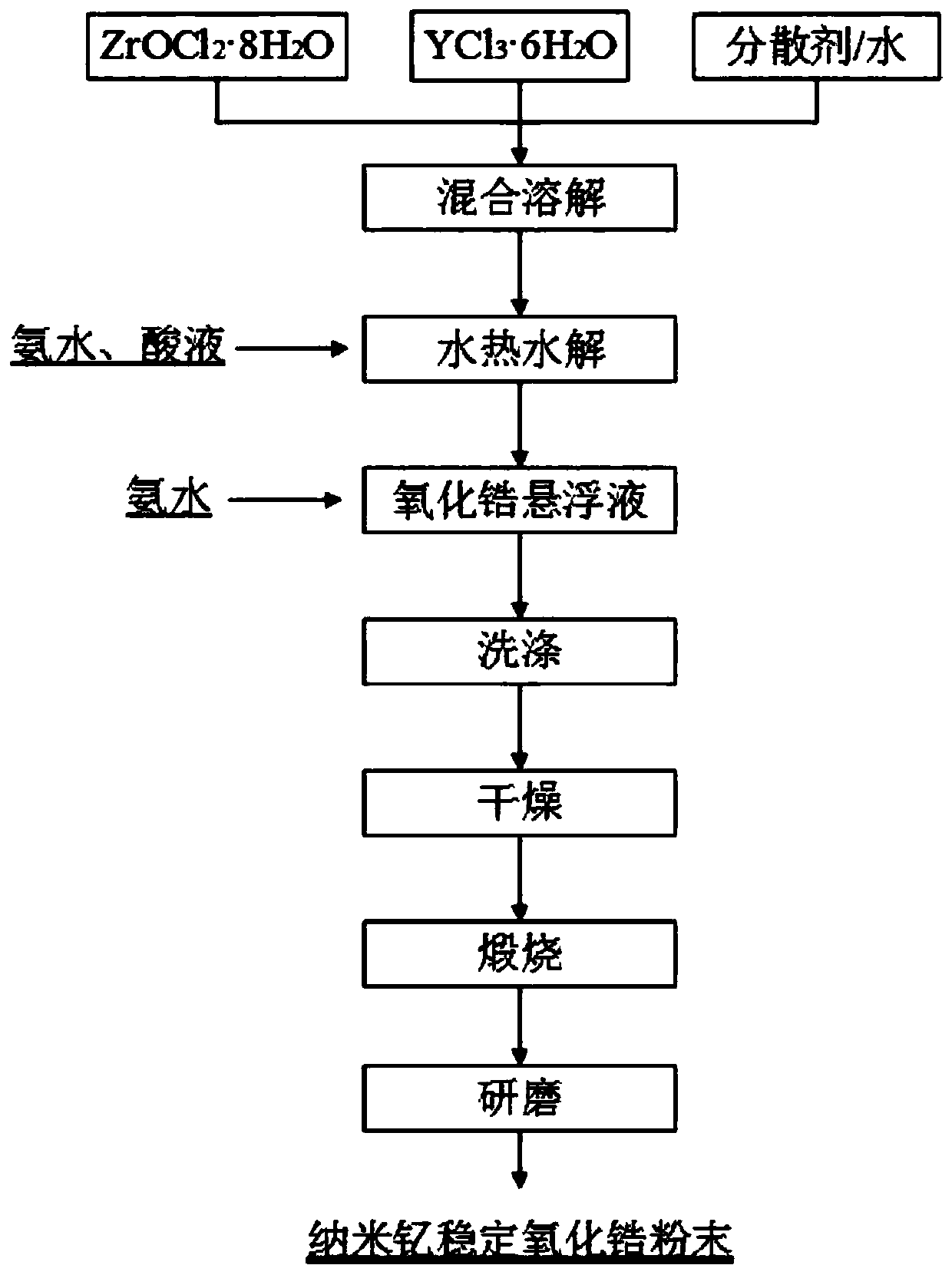

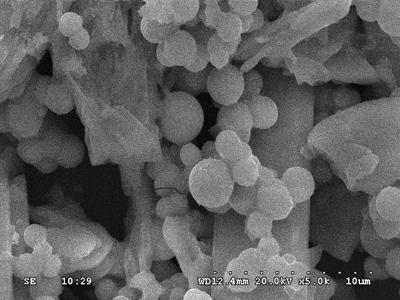

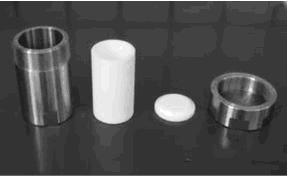

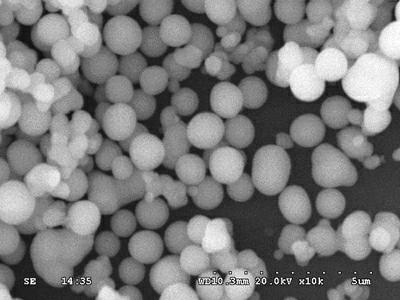

Prepn process of spherical nanometer crystal zirconium dioxide powder for structural ceramic

InactiveCN1673183ALarge specific surface areaUniform particle distributionAdhesiveDeposition process

The present invention is preparation process of spherical nanometer crystal zirconium dioxide powder stabilized with yttrium oxide and belongs to the field of the technology of preparing nanometer zirconium dioxide and specific ceramic, and the zirconium dioxide powder is main material for making structural ceramic. Nanometer crystal zirconium dioxide powder is prepared through hydrothermal decomposition and deposition process and then added with adhesive and dispersant, and the mixture is then spray dried to prepare yttrium doped spherical nanometer crystal zirconium dioxide powder. The present invention features the simple technological process, and the spherical nanometer crystal zirconium dioxide powder has great specific surface area, homogeneously distribution particle size, no coagulation and good dispersivity.

Owner:SHANGHAI UNIV

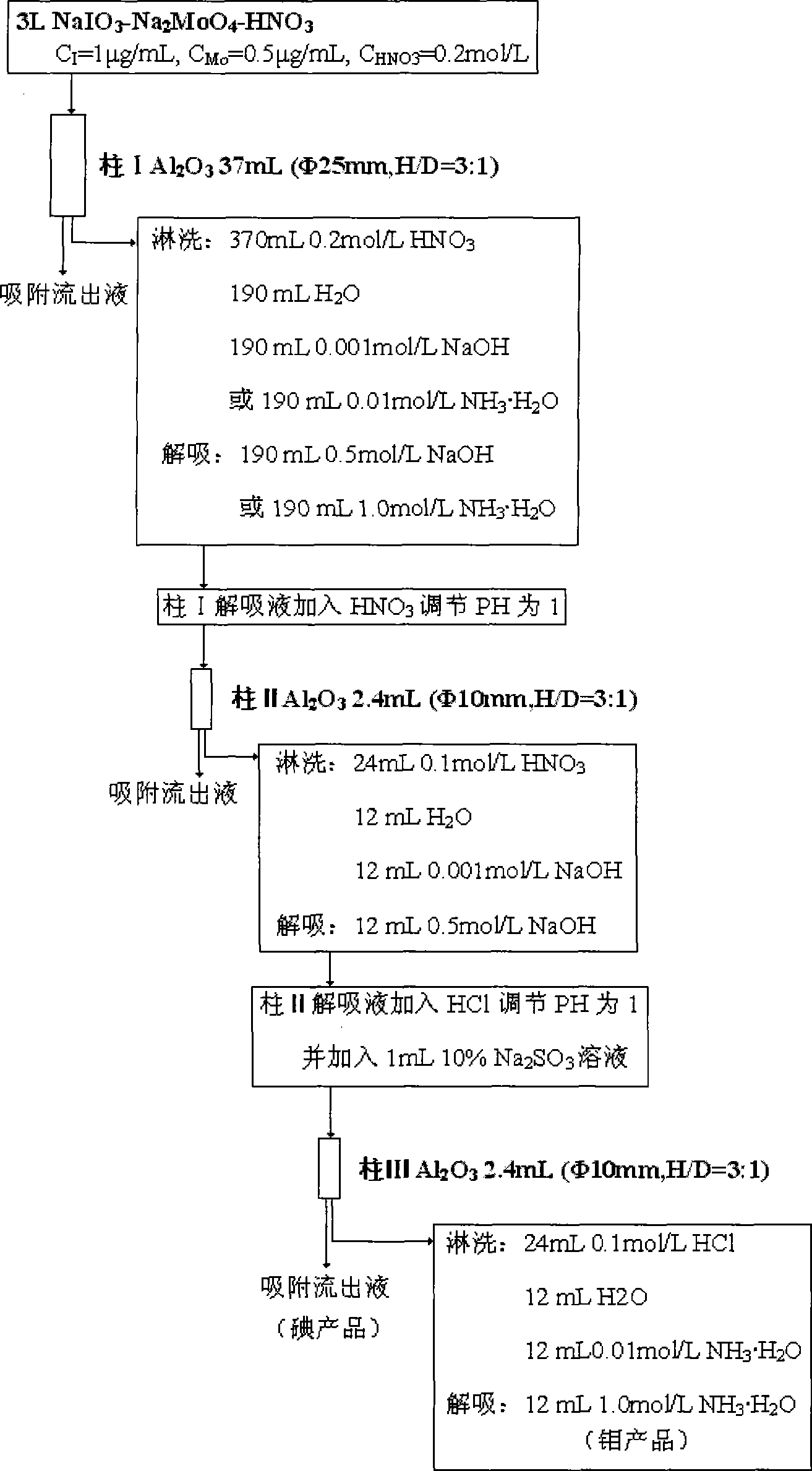

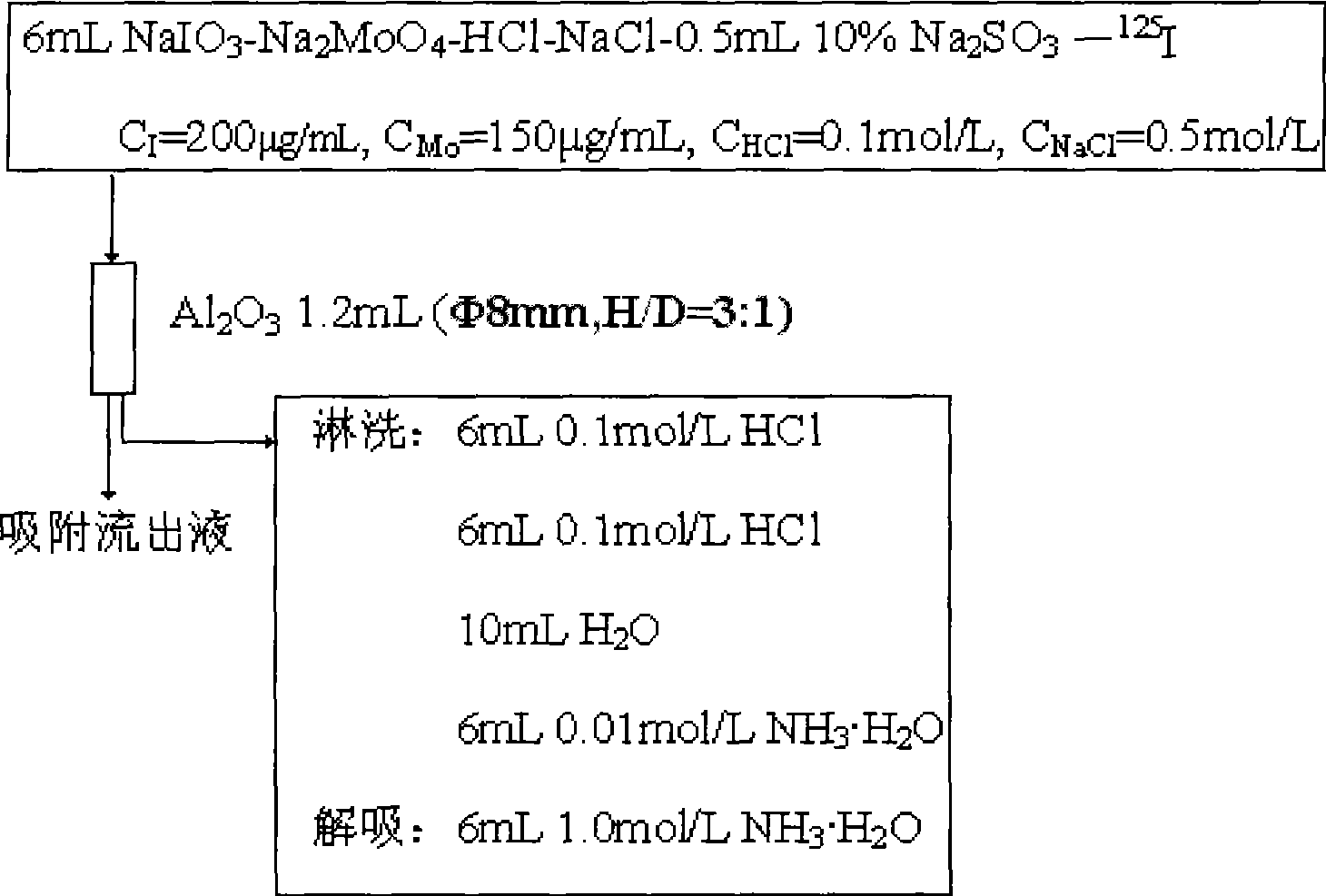

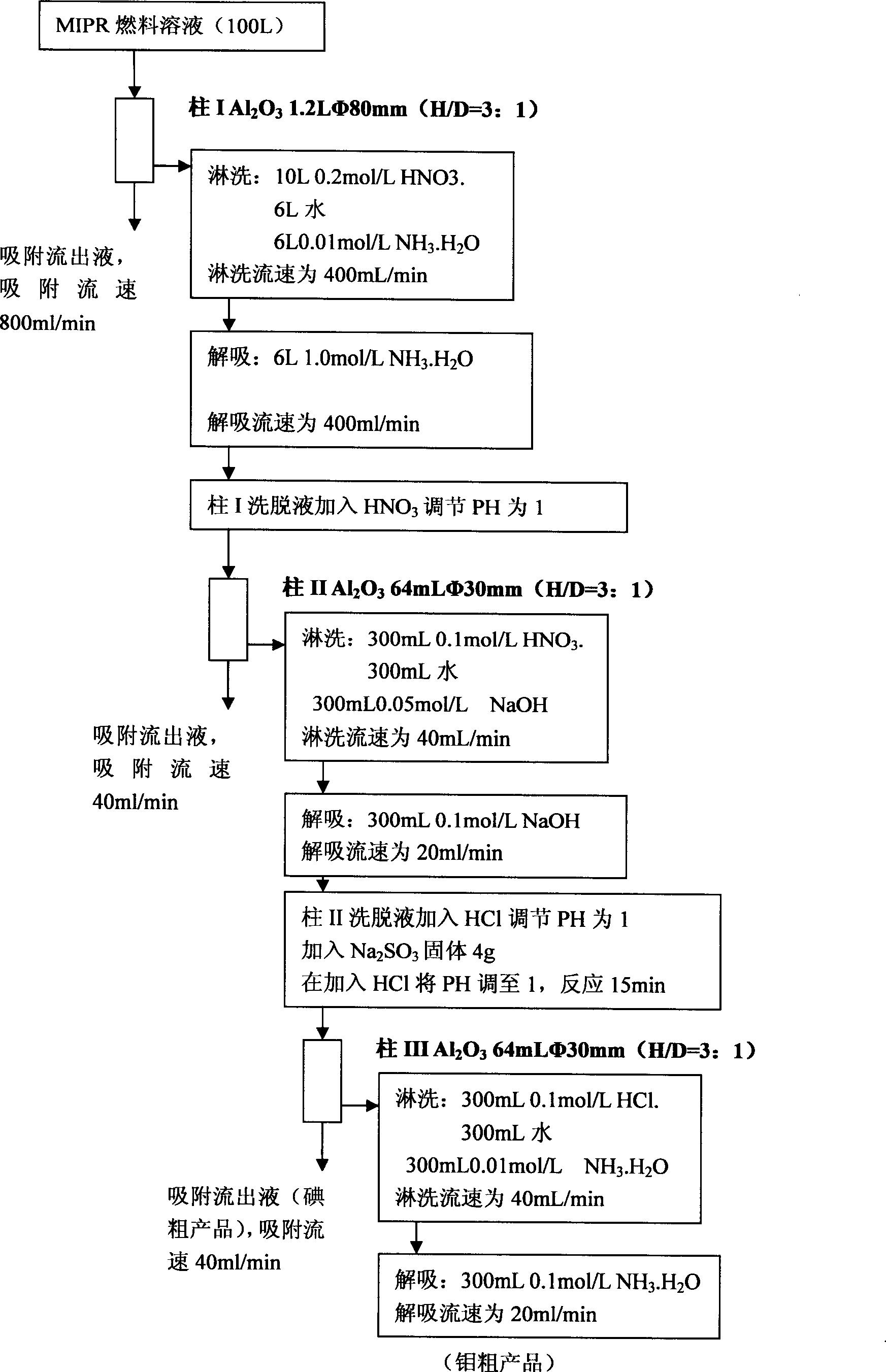

Extraction and purification technique for producing iodine-131 using homogeneous solution-type reactor

ActiveCN101468791AImprove the purification effectHigh recovery rateIodineIsotope separationNuclear reactorIodide-131

The invention belongs to technology of producing medical radioactive nuclide, and in particular relates to a process for extracting and purifying iodine-131 through a homogeneous aqueous solution nuclear reactor. The process comprises the following steps: adsorbing iodine-131 is from a bulk fuel solution after the reactor operates by an aluminum oxide extraction column or a hydrous zirconium oxide extraction column; and then cleaning the extraction column by using diluted HNO3, H20, NH3.H20; desorbing the iodine-131 on the extraction column by an NH3.H20 or NaOH solution; and finally, separating and purifying the desorbed iodine-131. The yield of the I obtained by the process is more than 50 percent, and purity of the I meets the requirement of a medical NaI solution.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Method for preparing fluorinated hydroxyapatite/ zirconium oxide (FHA/ZrO2) composite ceramic powder with good heat stability by hydrothermal synthesis

The invention provides a method for preparing fluorinated hydroxyapatite / zirconium oxide (FHA / ZrO2) composite ceramic powder with good heat stability by hydrothermal synthesis, relates to a preparation method of the composite ceramic powder, and aims at solving the problems that all components in the composite ceramic powder are not evenly dispersed and mixed, and composite ceramic powder is poor in heat stability. The method comprises the steps of: 1, preparing yttrium-stabilized hydrous zirconium oxide powder Y2O3-Zr(OH)4; 2, preparing FHA / ZrO2 composite precursor powder by hydrothermal synthesis; and 3, carrying out heat treatment on the FHA / ZrO2 composite ceramic powder to obtain the FHA / ZrO2 composite ceramic powder with the phase composition including FHA and yttrium-stabilized tetragonal phase ZrO2. The method is applied to the field of preparing the composite ceramic powder by hydrothermal synthesis.

Owner:HARBIN INST OF TECH

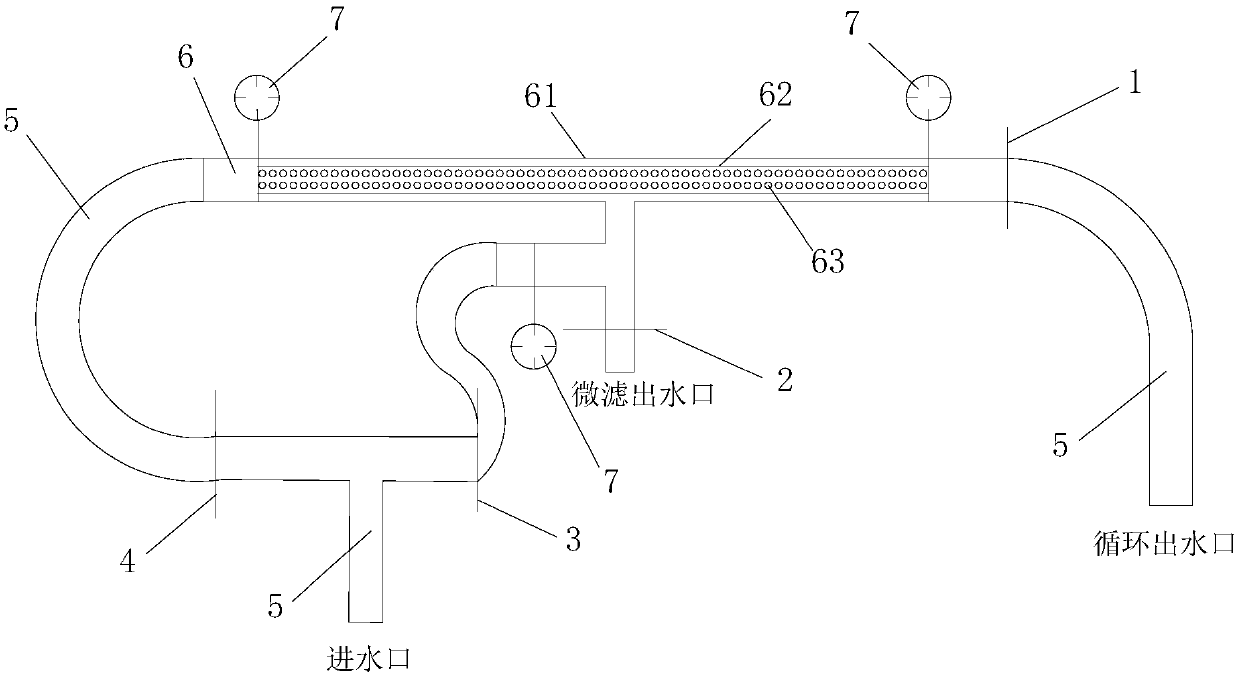

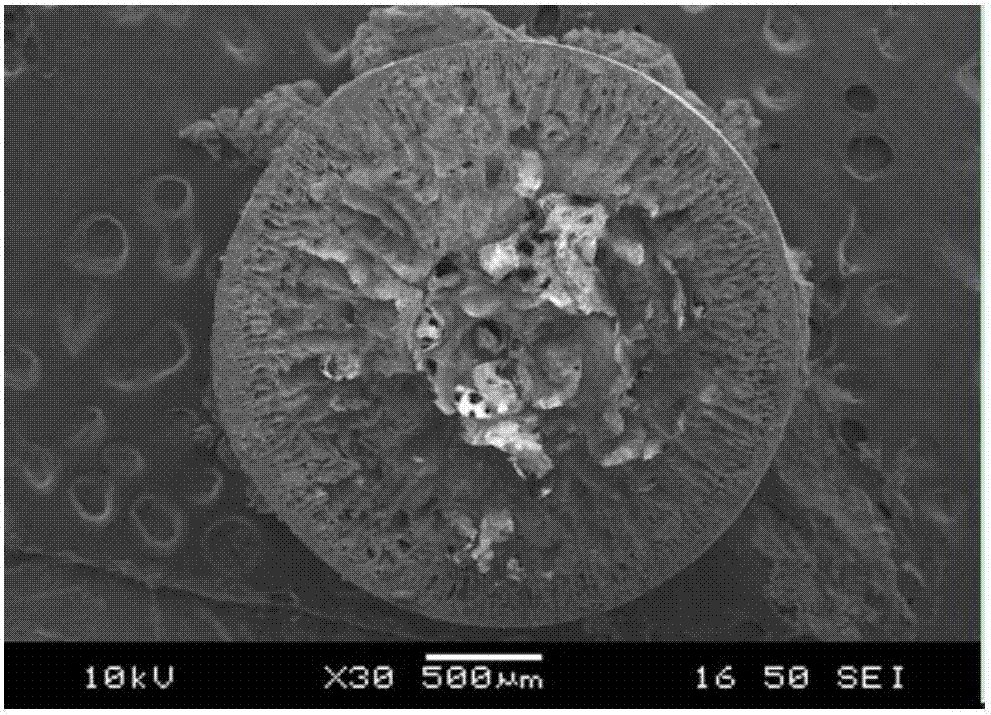

Preparation method of supported zirconia hydrate with high specific surface area through dispersion modification and application thereof

InactiveCN108671900ASolve reunionIncrease surface areaOther chemical processesWater contaminantsIon-exchange resinSurface modification

The invention provides a preparation method of supported zirconia hydrate with a high specific surface area through dispersion modification and an application thereof. The preparation method comprisesfollowing steps: using a surfactant to carry out surface modification on macroporous cation exchange resin with zirconium ions: mixing a surfactant and sodium hydroxide to prepare a mixed solution, adding macroporous cation exchange resin into a zirconium chloride / hydrochloric acid solution to carry out reactions, then adding the macroporous cation exchange resin with zirconium ions into a mixedsolution containing a surfactant to carry out reactions, after reactions, washing the cation exchange resin by distilled water and anhydrous ethanol in sequence, and drying the cation exchange resin to obtain the product. According to the preparation method, a surfactant is used to adjust the dispersion state of zirconia hydrate in the cation exchange resin so that zirconia hydrate is dispersed inthe cation exchange resin in a nanometer level, the specific surface area and heavy metal adsorbing performance of the composite material are both enhanced, the supported zirconia hydrate is used toprocess desulfurization wastewater, zinc ions and organic substances in wastewater can be removed at the same time, the using amount of nano-filter membrane is reduced, and the cost is reduced therefore.

Owner:WUHAN UNIV OF TECH

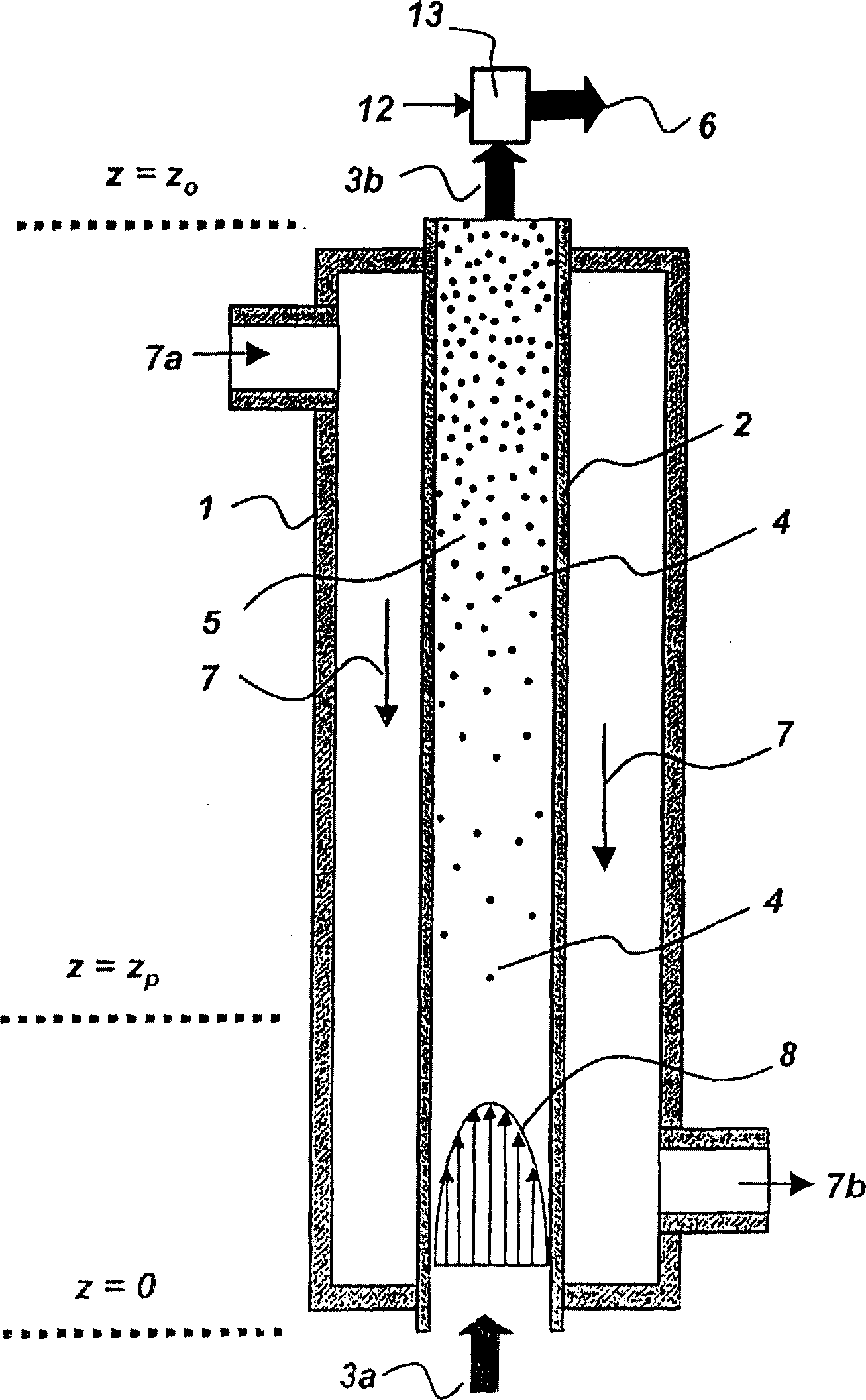

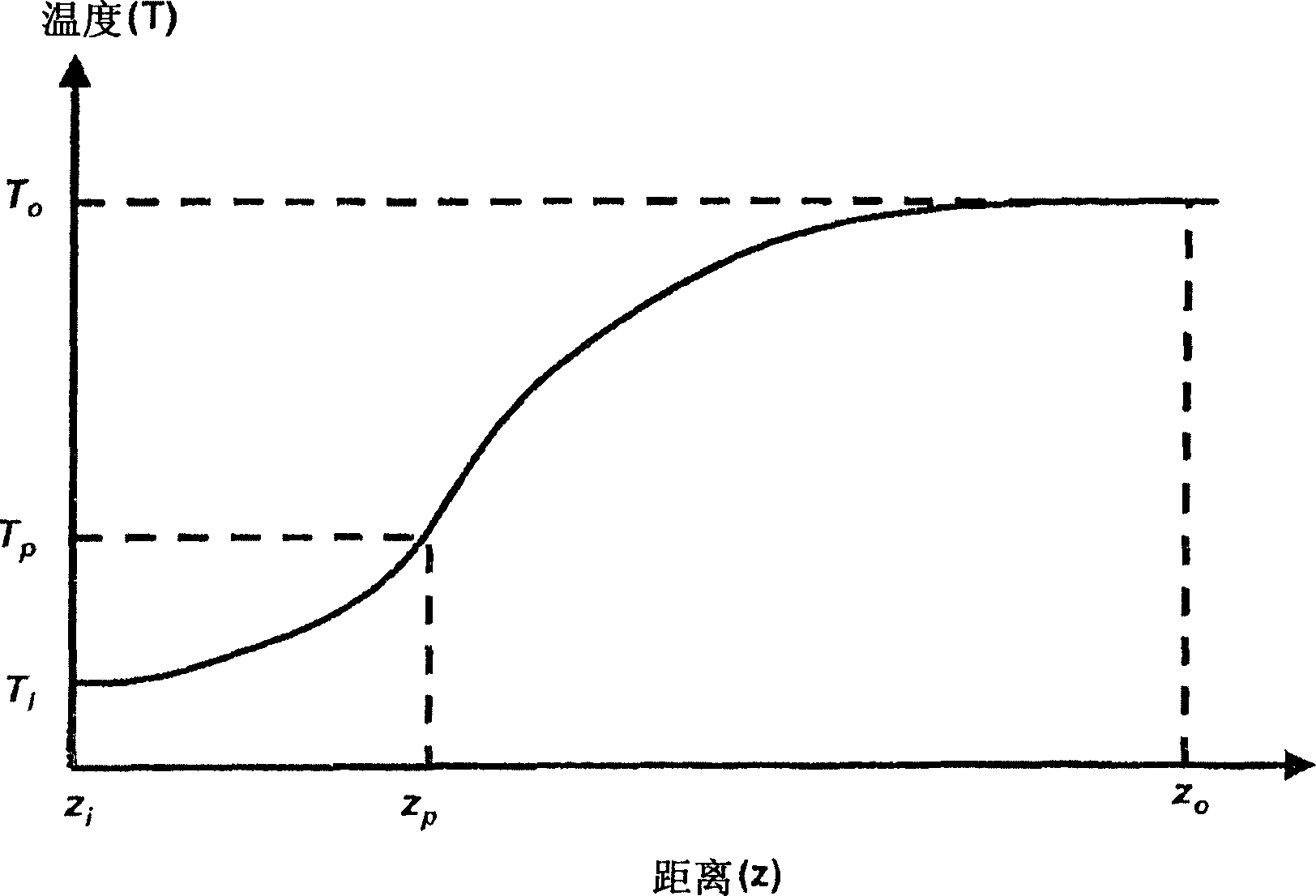

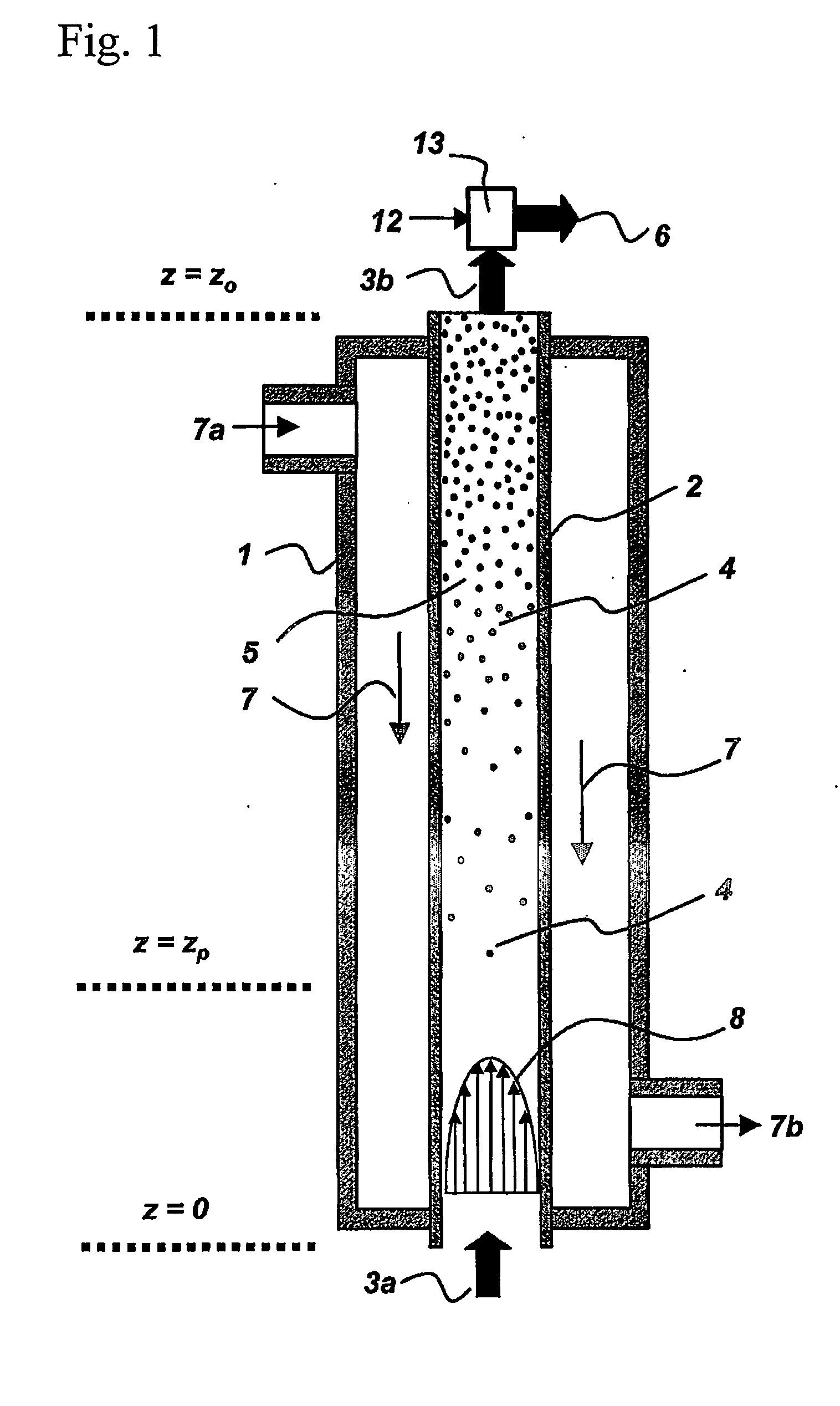

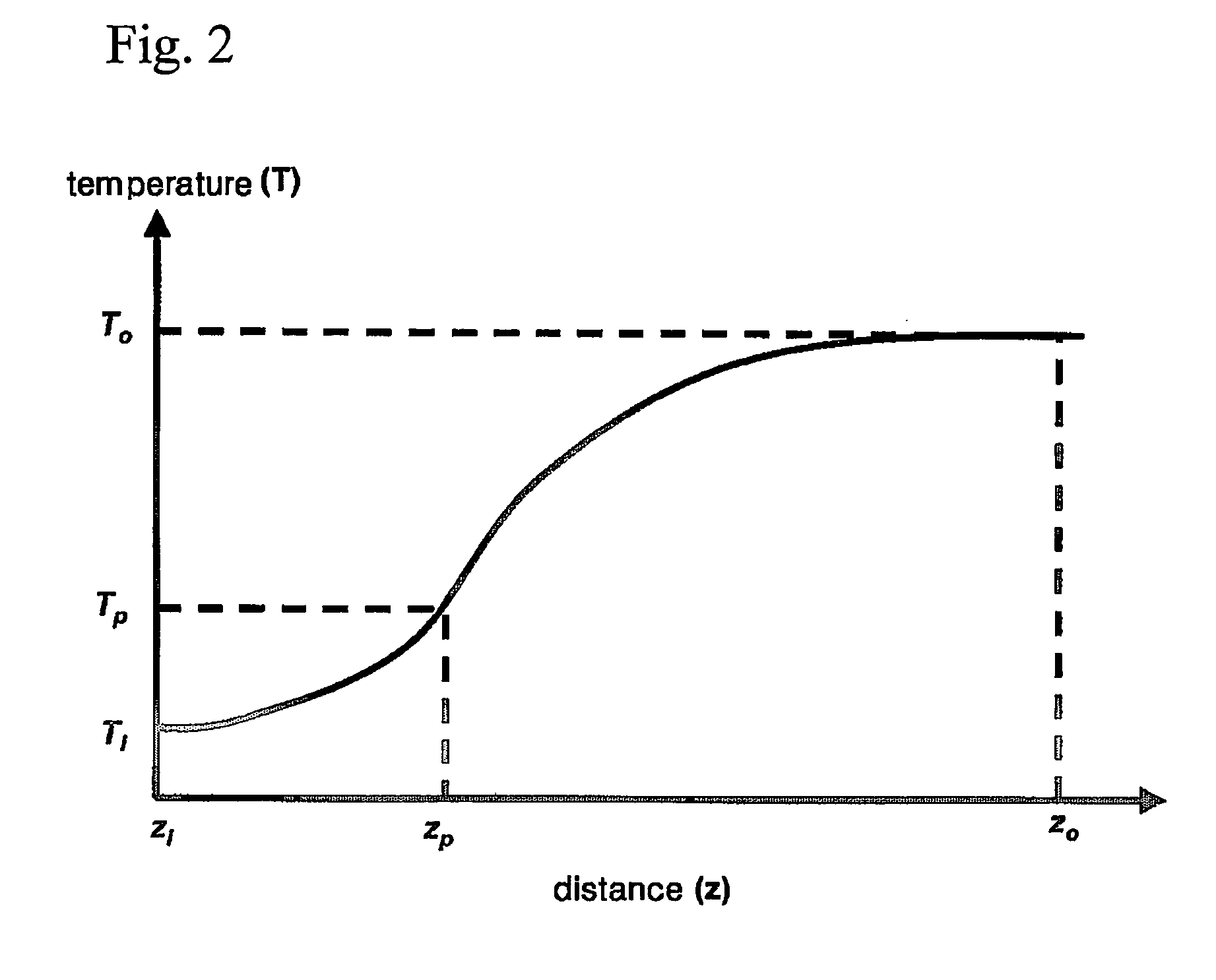

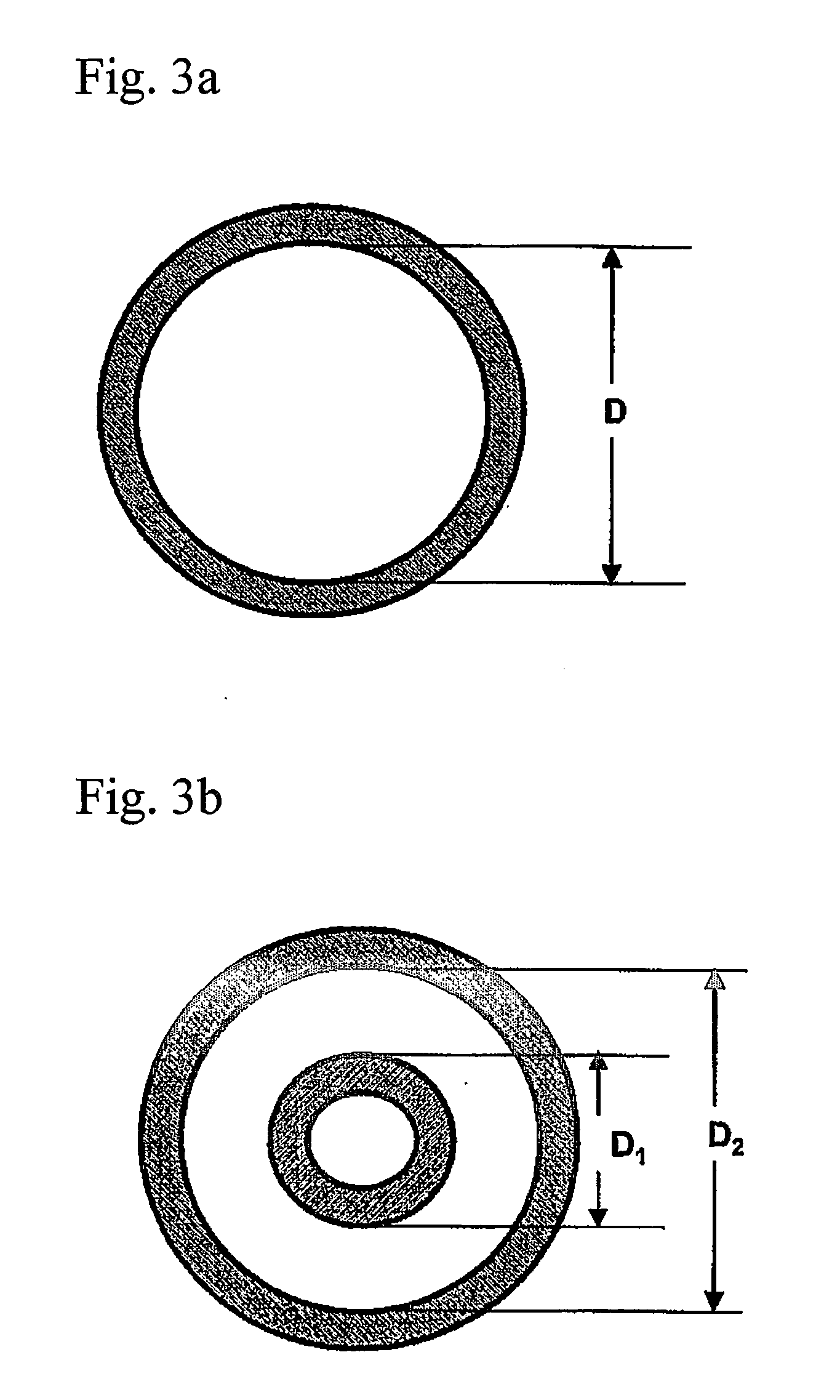

Method for continuous preparation of nanometer-sized hydrous zirconia sol

The present invention relates to a method a method for continuous preparation of a well dispersed spherical hydrous zirconia particles with an average diameter (dp) of 1~1,000 nm in the form of sol solution, which method comprises continuously supplying the aqueous solution of a zirconium salt at a concentration of 0.001~0.5 mole / l to a reactor consisting of one or more than two reaction tubes at a temperature of less than 25 DEG C, heating the said aqueous solution in the reactor(s) in a continuous flow state up to the boiling point, and then discharging the said solution through the outlet of the said reactor(s). Contrary to the method employing a conventional batch-type reactor or semi-continuous stirred-type reactor, the method for continuous preparation of a hydrous zirconia sol according to the present invention can allow various operational parameters to be controlled in a certain range and thus contributes to remarkably improve the quality of a hydrous zirconia sol to be prepared or of the zirconia powder obtainable as a final product.

Owner:KOREA RES INST OF CHEM TECH

Method for continuous preparation of nanometer-sized hydrous zirconia sol

InactiveUS20050118095A1Reduce concentrationMaterial nanotechnologyNanostructure manufactureBoiling pointContinuous flow

The present invention relates to a method a method for continuous preparation of a well dispersed spherical hydrous zirconia particles with an average diameter(dp) of 1˜1,000 nm in the form of sol solution, which method comprises continuously supplying the aqueous solution of a zirconium salt at a concentration of 0.001˜0.5 mole / l to a reactor consisting of one or more than two reaction tubes at a temperature of less than 25° C., heating the said aqueous solution in the reactor(s) in a continuous flow state up to the boiling point, and then discharging the said solution through the outlet of the said reactor(s). Contrary to the method employing a conventional batch-type reactor or semi-continuous stirred-type reactor, the method for continuous preparation of a hydrous zirconia sol according to the present invention can allow various operational parameters to be controlled in a certain range and thus contributes to remarkably improve the quality of a hydrous zirconia sol to be prepared or of the zirconia powder obtainable as a final product.

Owner:KOREA RES INST OF CHEM TECH

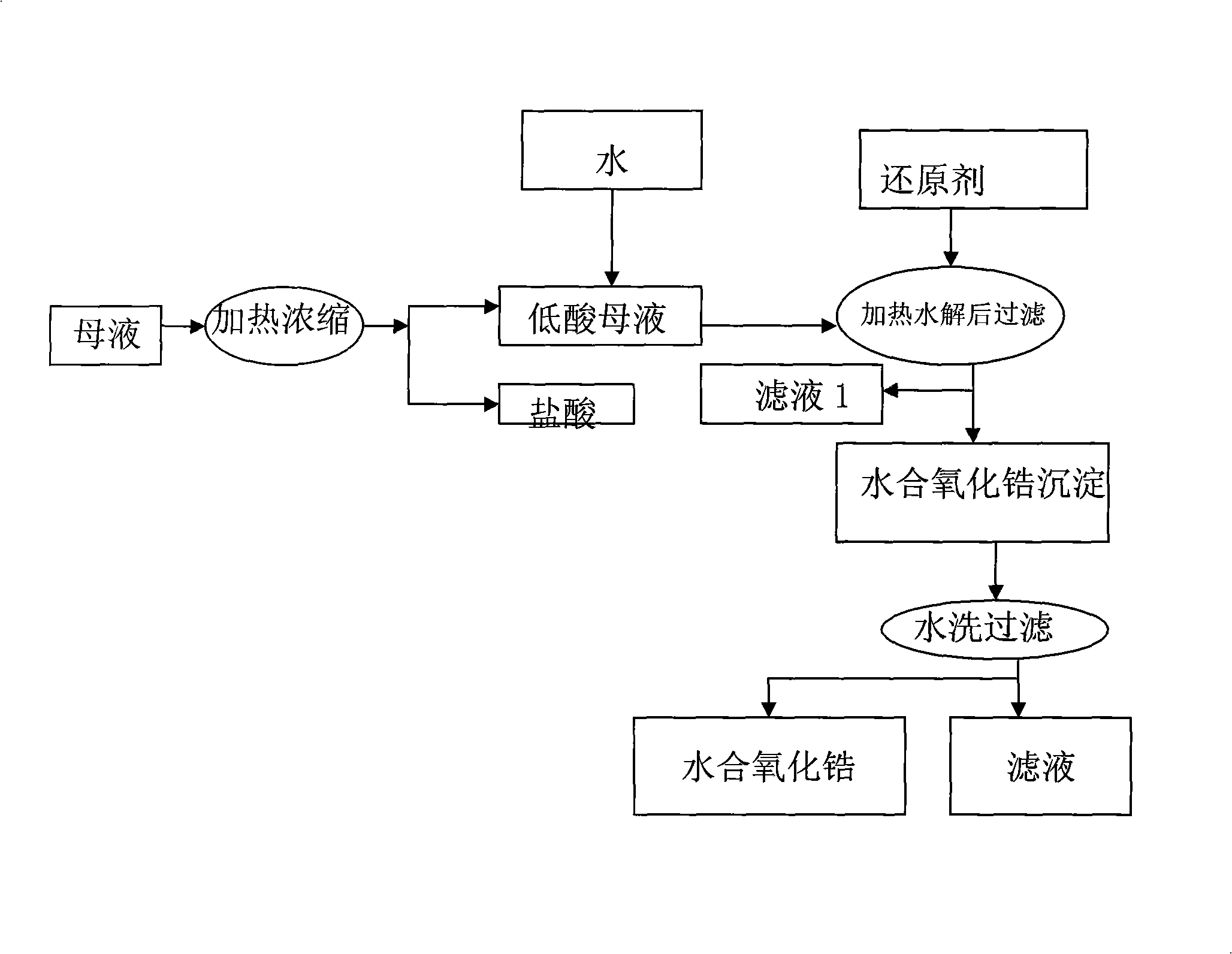

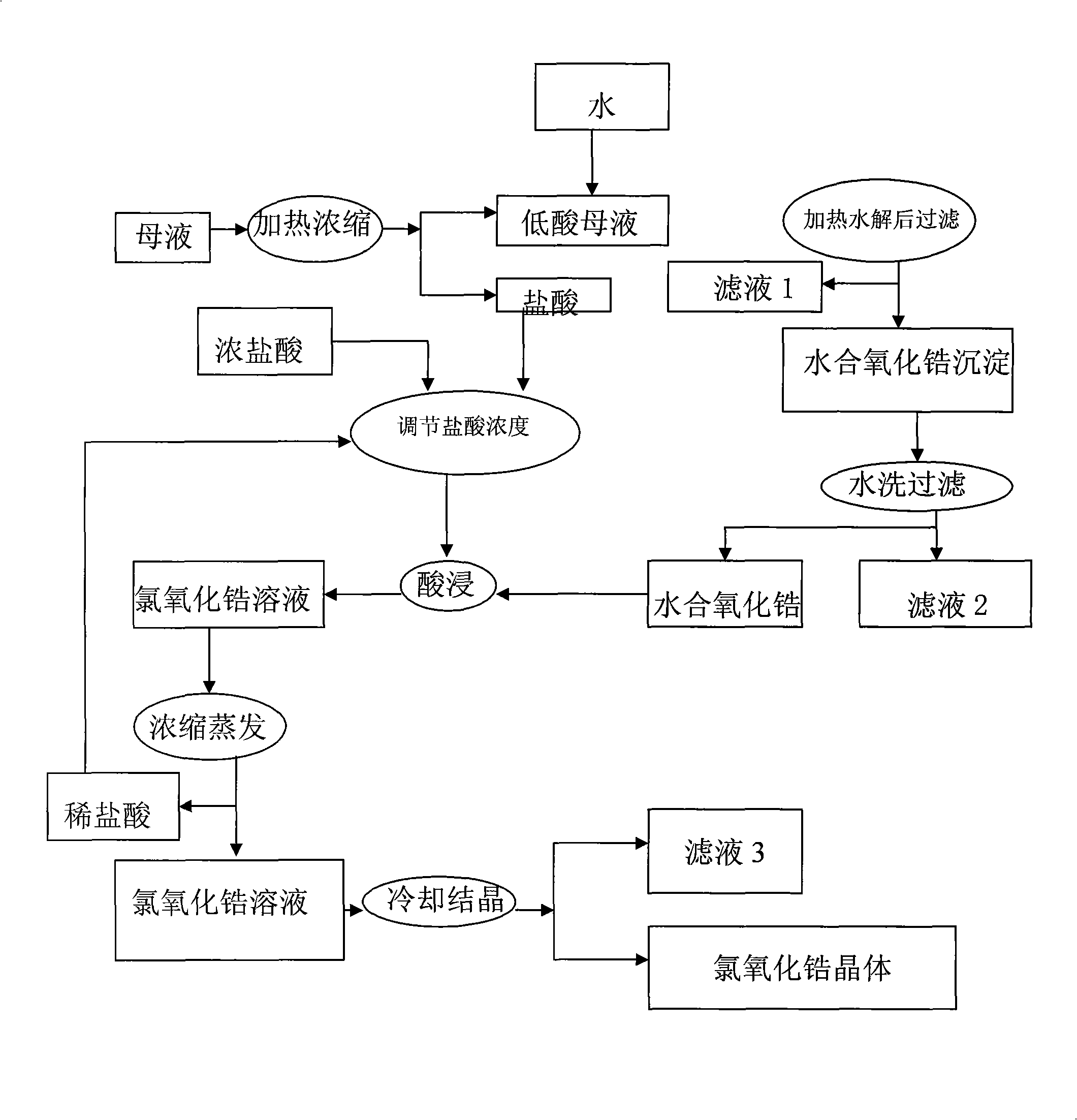

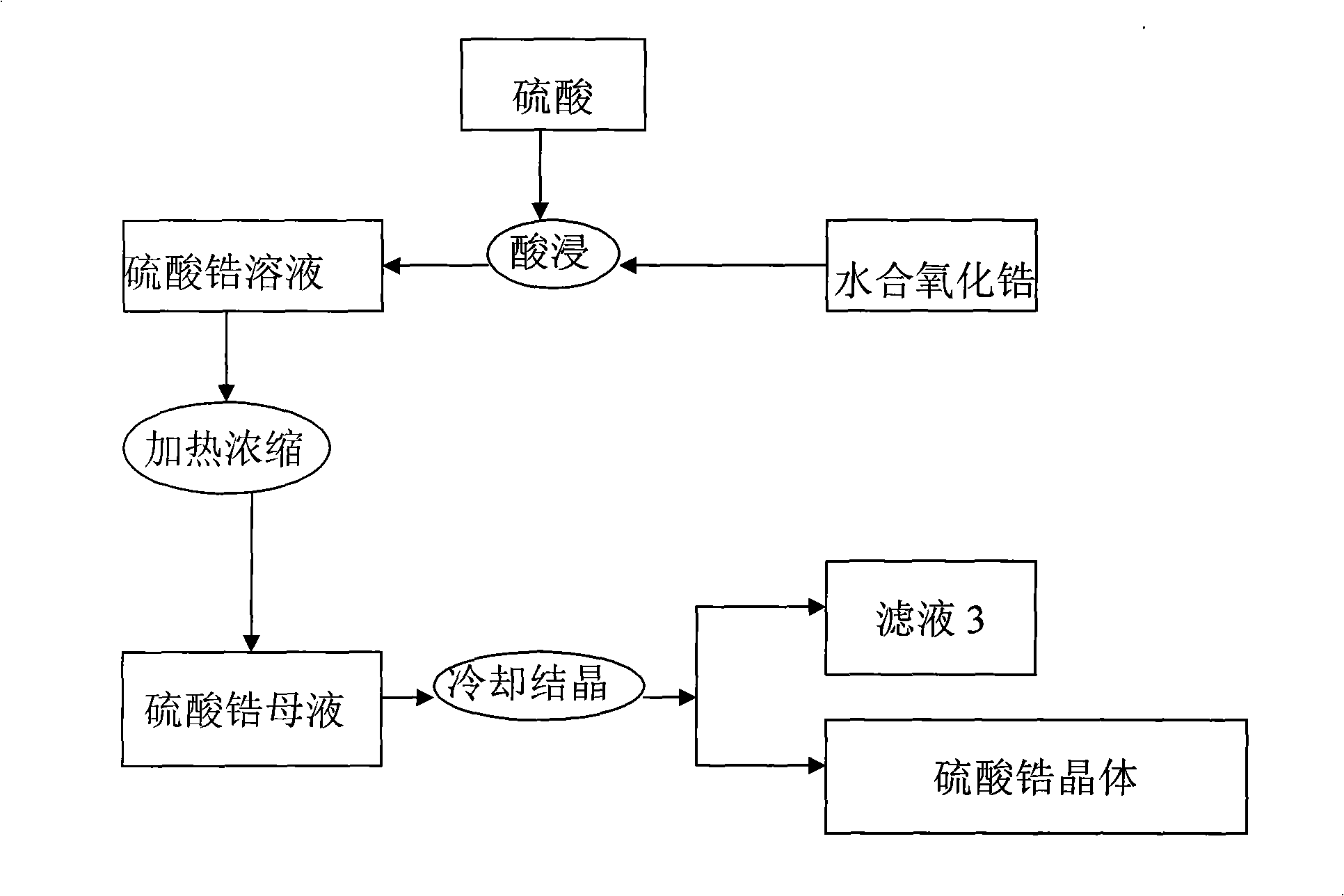

Method for preparing high purity hydrous zirconium oxide and zircon salt with zirconium oxychloride mother solution

The invention discloses a method of a mother liquid for preparing hydrous zirconium oxide with high purity and a zirconium salt in the production process of zirconium oxychloride. The invention comprises the processes of concentration, hydrolysis, acid corrosion, secondary concentration, crystallization and acid pickling. The invention employs the mother liquid that produces the zirconium oxychloride as the raw material to produce the hydrous zirconium oxide with the high purity, prepare the high value zirconium salt and recycle hydrochloride in the solution. In the process of removing impurities from the solution, a lot of impurities are removed, which leads the product to have the high purity, stable performance and good quality; the hydrochloride can be used repeatedly, which reduces the production cost; the production process of the invention is simple and convenient and is suitable for large scale industrial production.

Owner:LOMON BILLIONS GRP CO LTD

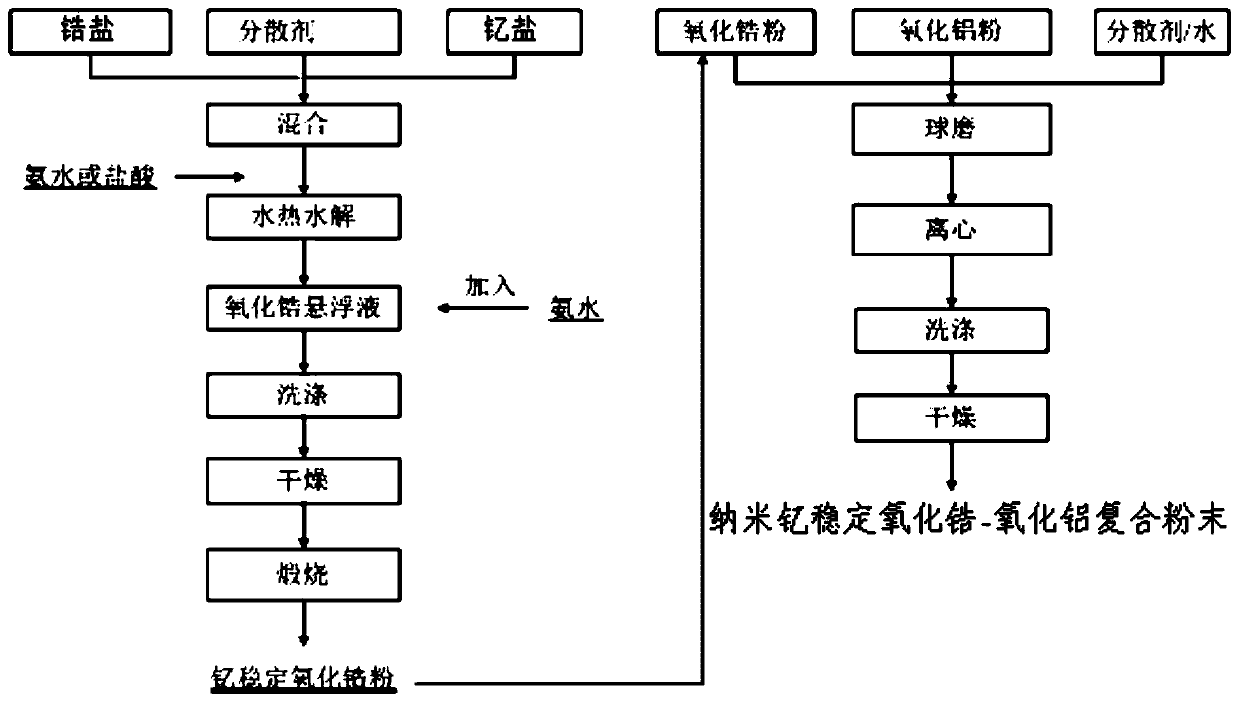

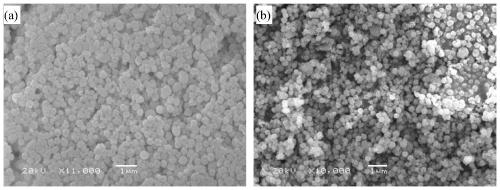

Preparation method of nano-yttrium-stabilized zirconia-alumina composite powder

The invention relates to a preparation method of nano-yttrium-stabilized zirconia-alumina composite powder. The preparation method comprises the following steps: mixing a zirconium salt, a yttrium salt and a dispersing agent, and adding ammonia water or an acid solution into the mixture to adjust the H<+>; heating the solution subjected to adjustment of H<+> concentration to carry out a hydrothermal reaction, and carrying out cooling to 90 DEG C or below after the reaction is completed; adding ammonia water into the obtained hydrated zirconia suspension to adjust the pH to be alkaline, carrying out standing and aging, and carrying out centrifugal separating; washing and drying the hydrated zirconia precipitates and carrying out calcining; and uniformly mixing the obtained nano-yttrium-stabilized zirconia powder with aluminum oxide powder, deionized water and a dispersing agent, then carrying out ball milling, and carrying out grinding, centrifugal separation and drying on the obtainedslurry to obtain the nano-yttrium-stabilized zirconia-alumina composite powder. The high-performance composite powder can be prepared by the method, and the production process is simple to operate andis suitable for large-scale production.

Owner:CENT SOUTH UNIV

Nanometer-hydrous zirconium oxide-loading composite hydrogel having carboxyl and hydroxyl, preparation and applications thereof

ActiveCN105289543AImprove pore structureGood removal effectOther chemical processesAlkali metal oxides/hydroxidesReaction temperatureMonomer

The present invention provides a nanometer-hydrous zirconium oxide-loading composite hydrogel having carboxyl and hydroxyl, preparation and applications thereof. According to the present invention, two monomers such as 2-hydroxyethyl acrylate and trans-aconitic acid are mixed with distilled water, then radiation polymerization is performed to prepare a polymer hydrogel, the polymer hydrogel is adopted as a template to perform in-situ nanometer hydrous zirconium oxide loading, the in-situ nanometer hydrous zirconium oxide loading method is an in-situ chemical precipitation and heat treatment combination method, the concentration of a ZrOCl2 solution for the in-situ chemical precipitation reaction is 0.2-0.6 mol / L, the concentration of a NaOH solution is 0.6-1 mol / L, and the reaction temperature is controlled at 25 DEG C; and the nanometer hydrous zirconium oxide is subjected to in-situ loading, the method is simple, the operation is easy, heavy metals can be effectively removed by using the prepared composite hydrogel in adsorption of heavy metal ions in wastewater, and the service life of the composite hydrogel is long.

Owner:NANJING UNIV

Pearl-like decorative paper having suitability for postforming and thermosetting resin decorative sheet

InactiveCN1849210AAvoid foamingAvoid crackingSpecial visual effect coatingsCoatings with pigmentsEngineeringMelamine

The present invention relates to a pearlescent decorative paper and a thermosetting resin decorative board suitable for post-forming processing. Even if the material has a pearlescent appearance, foaming or cracking will not occur during post-forming processing. In the pearlescent decorative paper (10), there is a pearlescent ink layer (3) containing pearlescent pigments on a paper substrate (1), and as the pearlescent pigments, scale-shaped foils covered with mica with titanium dioxide and / or iron oxide are used A pearlescent pigment whose surface is then treated with zirconia hydrate. If the pattern ink layer (2) made of normal ink is provided therein, the design property will be improved. After the pearlescent decorative paper is impregnated with a thermosetting resin such as melamine resin, it is laminated with an adherend (6) such as a backing substrate (4) or a cover paper (5), and thermocompressed to cure the resin. A pearlescent thermosetting resin decorative plate (20) comprising pearlescent decorative paper (10A) cured with resin can be used.

Owner:DAI NIPPON PRINTING CO LTD

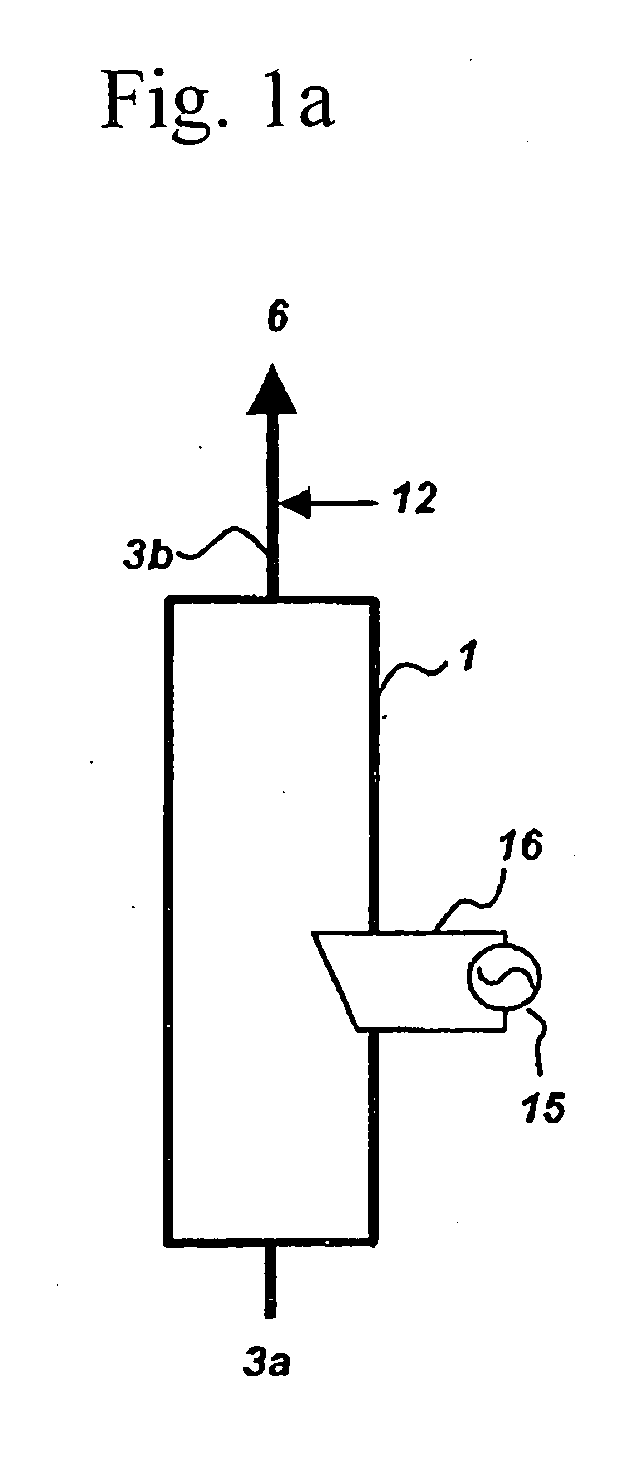

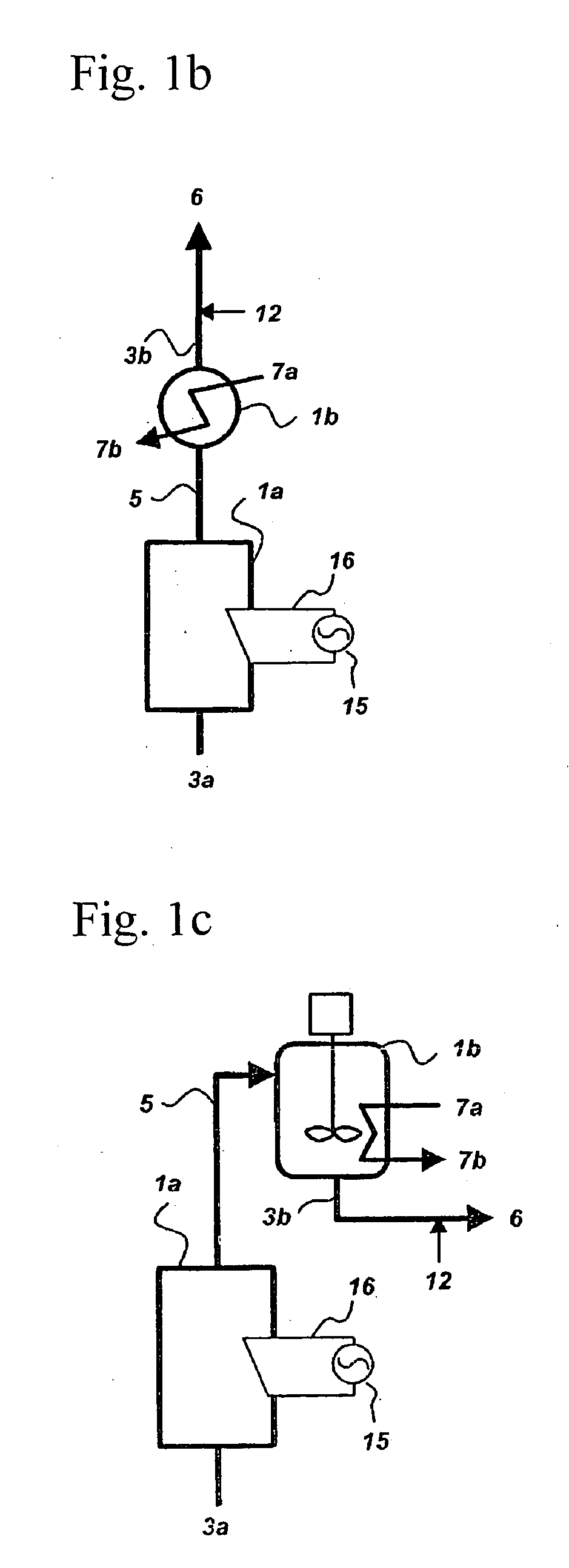

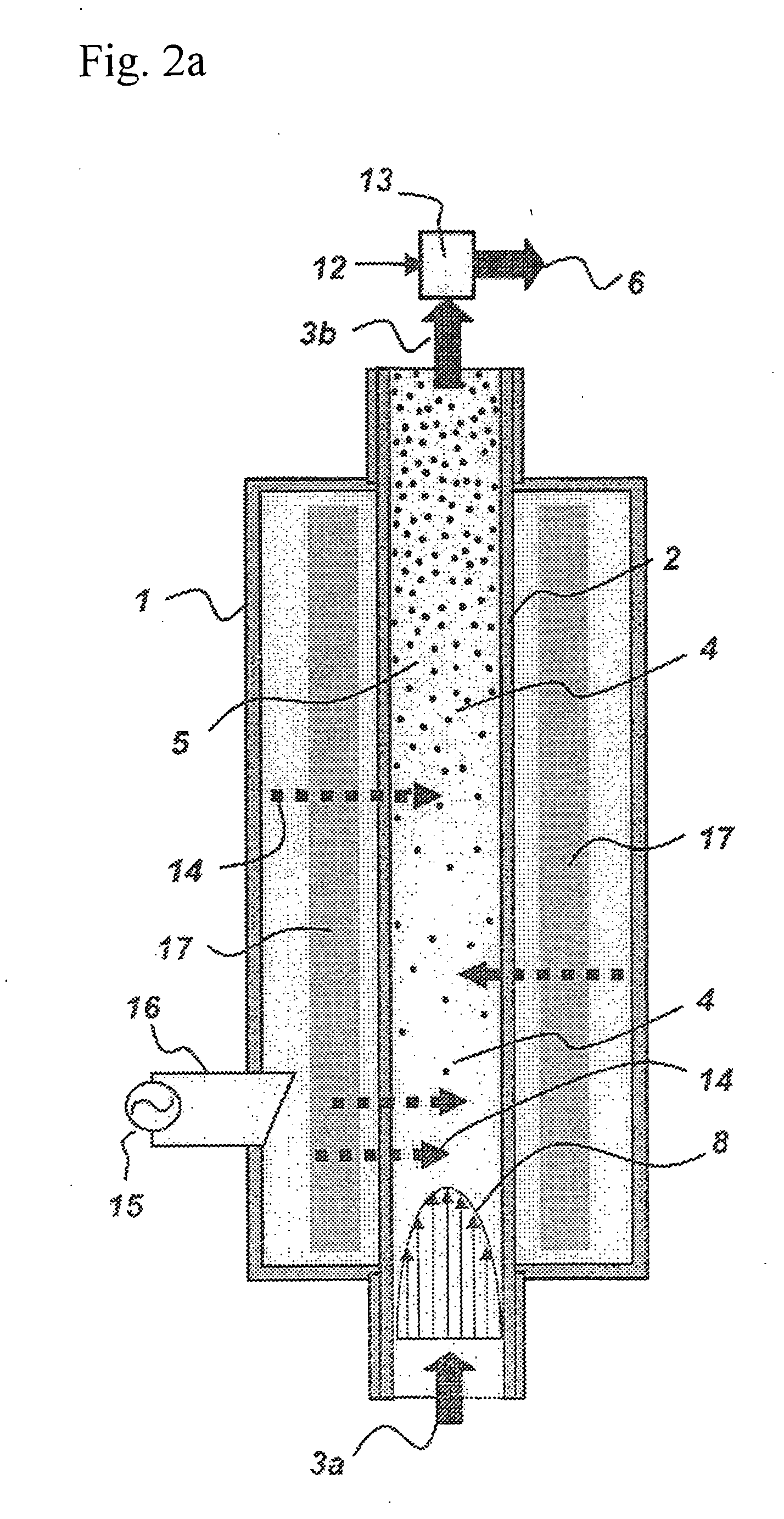

Solid acid catalyst, method for preparing same and reaction using same

InactiveCN1291914AHigh mechanical strengthEasy to recycleHydrocarbon by isomerisationOrganic chemistry methodsHydration reactionHydrated alumina

A method for producting a solid acid catalyst is provided which produces a shaped material of a solid acid catalyst containing a sulfureous component but have a high activity and having a practically sufficient handleability and mechanical strength involves the steps of (a) fabricating a support containing a portion of zirconia and / or hydrated zirconia and a portion of alumina and / or hydrated alumina and having a peak diameter in the range of 0.05 to 1 mum in a pore diameter distribution of 0.05 to 10 mum; and having a sulfuerous component supported on the support or (b) fabricating a support containing a portion of zirconia and / or hydrated zirconia and a portion of alumina and / or hydrated alumina and including pores having a pore diameter of not less than 0.05 mum and not more than 1 mum occupying a pore volume of 0.05 to 0.5 ml / g and pores having a pore diameter of about 1 mum and not more than 10 mum occupying a pore volume of below 0.05 ml / g; and having a sulfuerous component supported on the support.

Owner:JAPAN ENERGY CORP

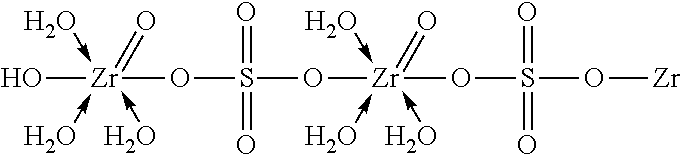

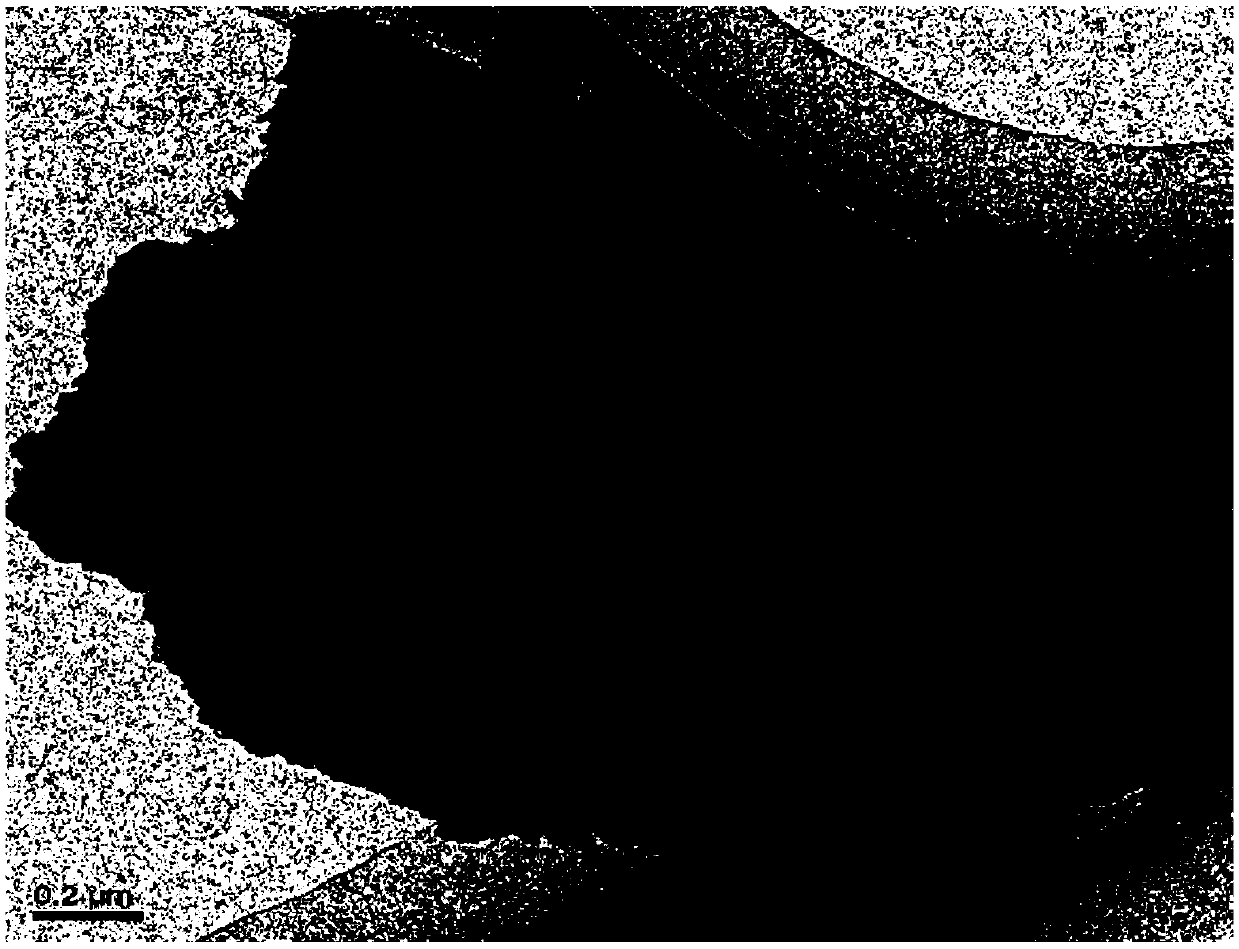

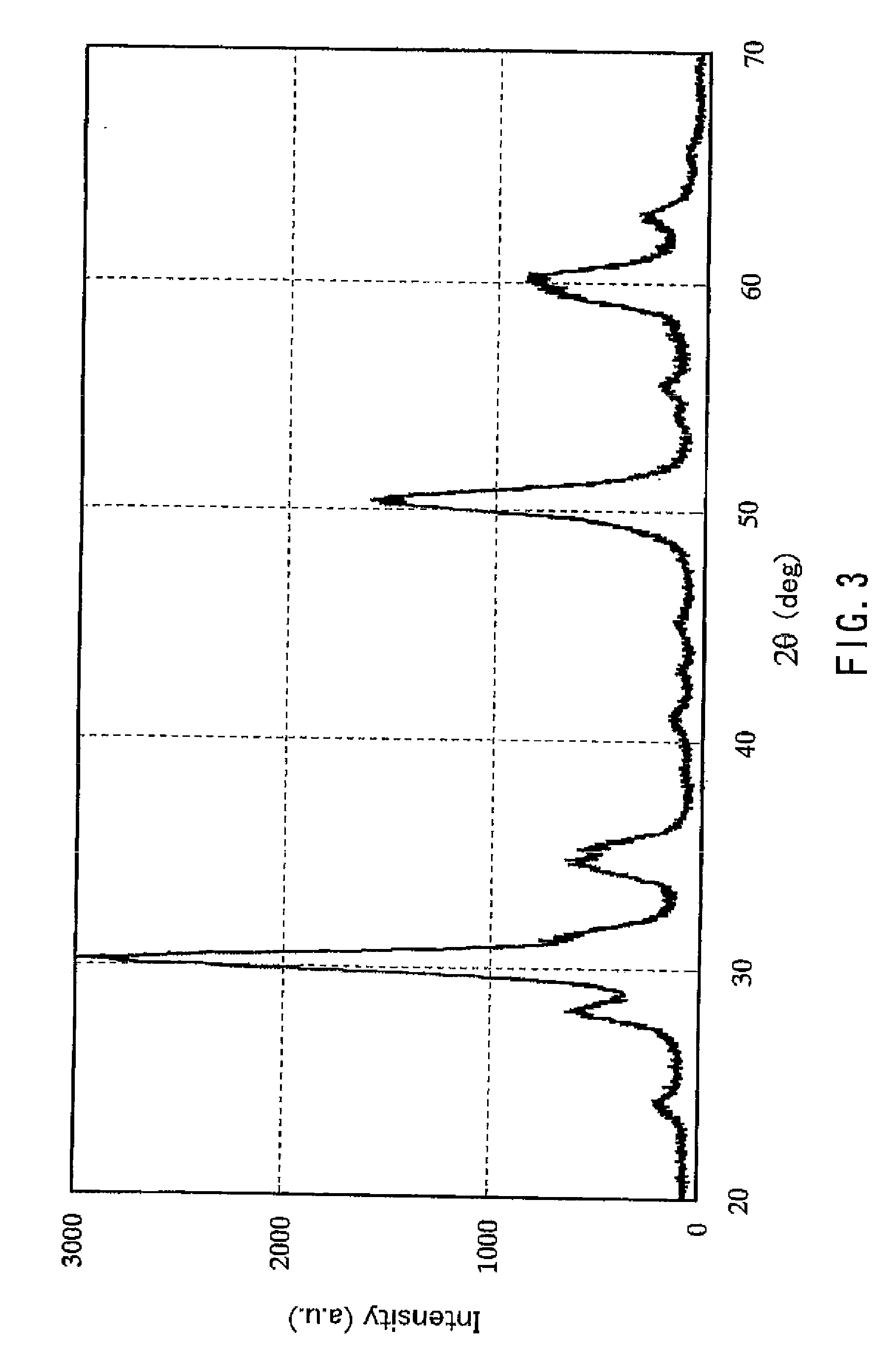

Zirconium oxide hydrate particles and method for producing the same

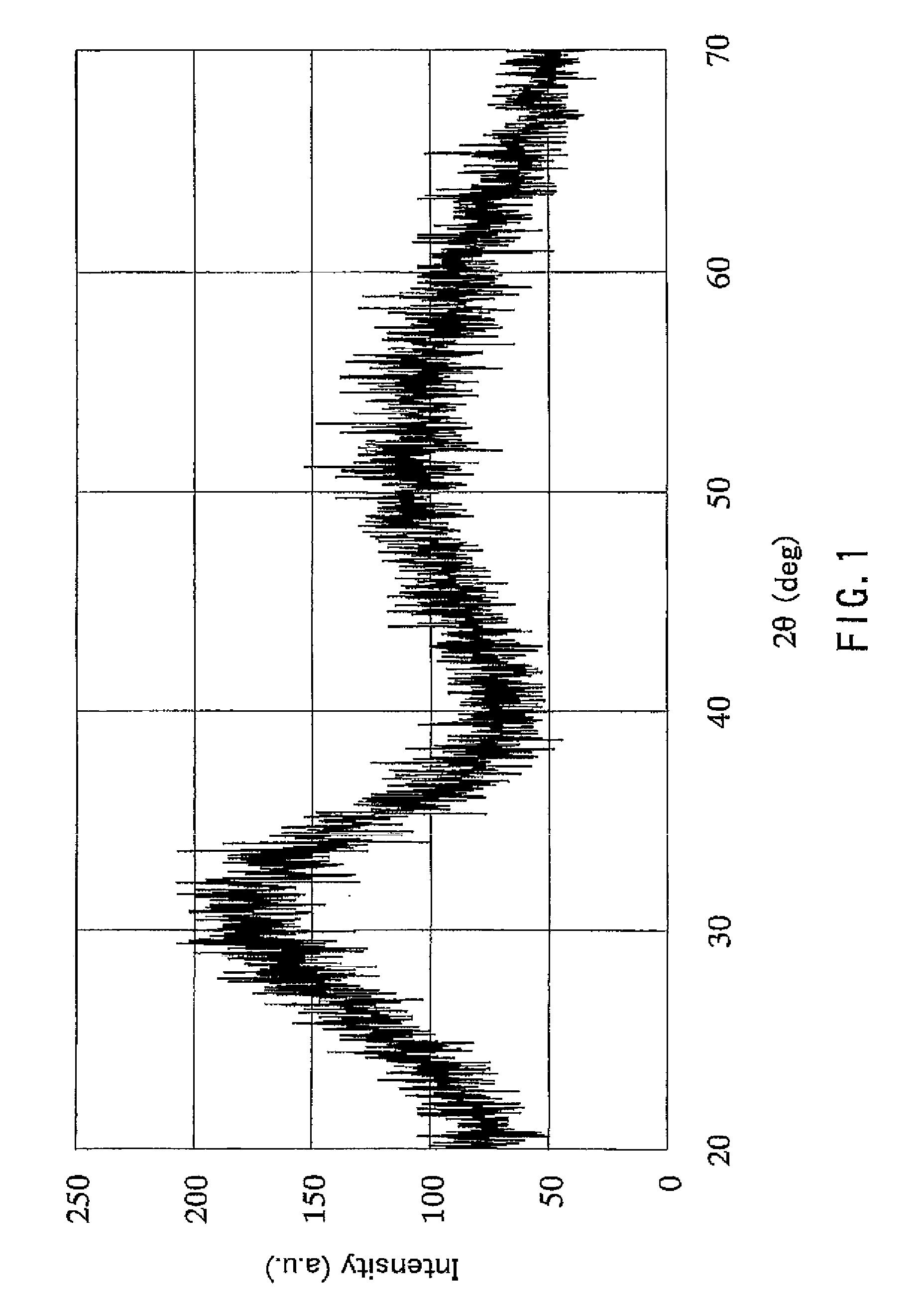

InactiveUS20090011239A1Improve proton conductivityMaterial nanotechnologySynthetic resin layered productsPh controlSalt solution

The zirconium oxide hydrate particles of the present invention are represented by the formula ZrO2.nH2O and have a mean primary particle size of 0.5 nm or more and 5 nm or less, and “n” in the formula represents a number greater than 2.5. Moreover, the method for producing of zirconium oxide hydrate particles of the present invention includes the step of preparing zirconium oxide hydrate particles by adding an aqueous zirconium salt solution to an aqueous alkaline solution while controlling the pH to 7.0 or more and 13.0 or less, and the step of subjecting the zirconium oxide hydrate particles to a hydrothermal treatment in the presence of water at a temperature of 50° C. or more and less than 110° C. for 3 hours or more.

Owner:HITACHT MAXELL LTD +1

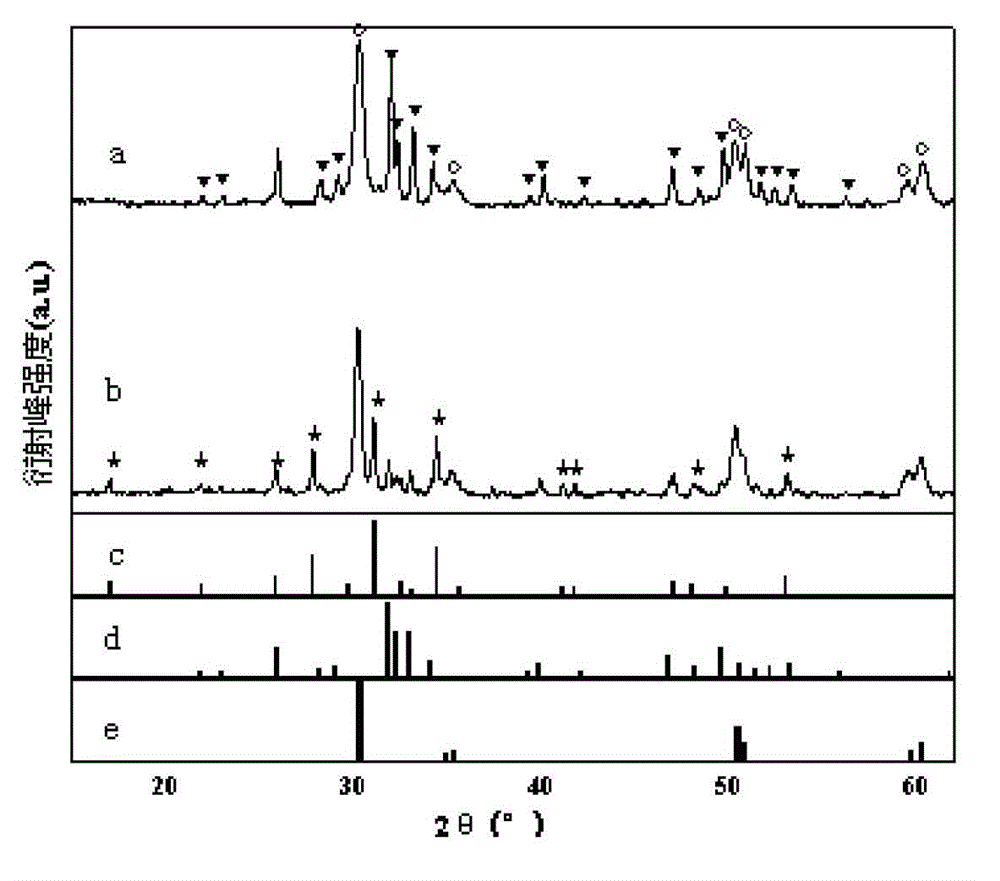

High-toughness zirconia-based composite powder and preparation method thereof

ActiveCN109704403AHigh sphericityImprove mechanical propertiesRare earth metal compoundsMagnesiaHydration reactionHigh fracture

The invention relates to a high-toughness zirconia-based composite powder and a preparation method thereof. The preparation method comprises the following steps: mixing zirconium salt, yttrium salt, third-period metal salt and a dispersant, and adjusting the concentration of H+ in an obtained mixture; carrying out a hydrothermal reaction so as to obtain a hydrated zirconia suspension; adjusting the pH value of the hydrated zirconia suspension to alkaline, and carrying out standing and aging; centrifuging an above-mentioned mixed solution, carrying out washing, drying and calcining, uniformly mixing a calcined powder with deionized water and a dispersant, carrying out ball milling so as to obtain a slurry, and subjecting the slurry to fine grinding, centrifuging, washing and drying so as toobtain the high-toughness zirconia-based composite powder. The ceramic prepared from the above-mentioned nanometer zirconia-based ceramic powder has excellent mechanical properties, especially high fracture toughness, and is specifically applicable to being used as a 5G mobile phone back sheet material.

Owner:CENT SOUTH UNIV

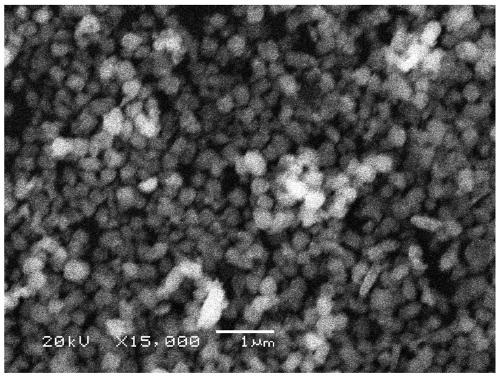

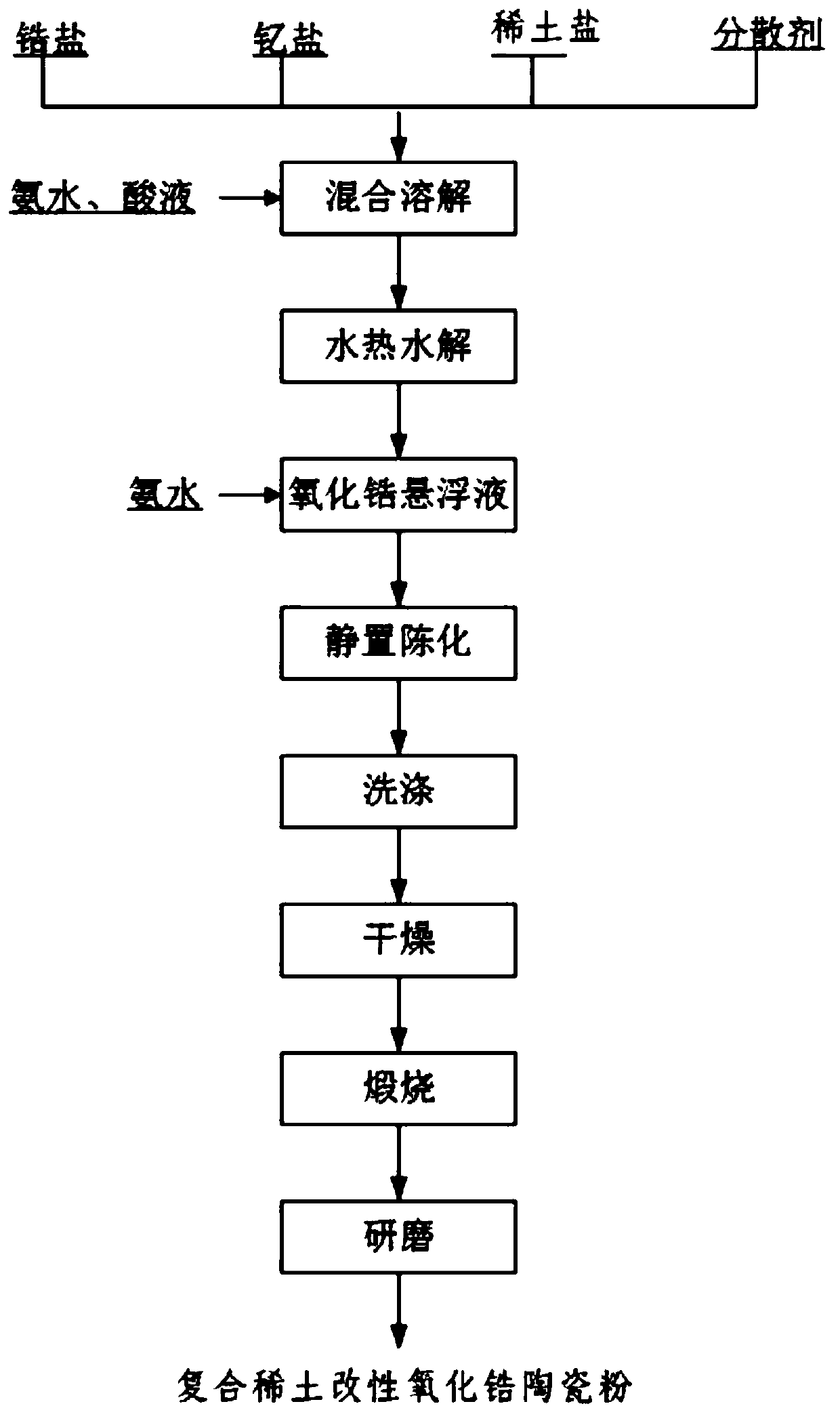

Composite rare earth modified zirconia ceramic powder and preparation method thereof

The invention relates to a composite rare earth modified zirconia ceramic powder and a preparation method thereof. The preparation method comprises the following steps: heating a mixed solution of zirconium salt, rare earth salt and a dispersant to 25 DEG C to 90 DEG C, and adding ammonia water or an acid liquid into the mixed solution so as to adjust the concentration of H+ in the mixed solutionto 0.1 to 5 mol / L; heating the H+ concentration adjusted solution, carrying out a hydrothermal reaction, and after the reaction is completed, carrying out cooling to 90 DEG C or below so as to obtaina hydrated zirconia suspension; adding ammonia water into the hydrated zirconia suspension so as to adjust the pH value of the hydrated zirconia suspension to alkaline, and carrying out standing and aging; and centrifuging the mixed solution, carrying out washing, drying and calcining, uniformly mixing a calcined powder with deionized water and a dispersant, carrying out ball milling so as to obtain a slurry, and subjecting the slurry to fine grinding, centrifuging, washing and drying so as to obtain a nanometer composite rare earth modified zirconia ceramic powder. The method provided by theinvention solves the technical problem of consumption of a large amount of ethylene glycol and polyvinyl alcohol organic matters and difficult treatment of organic-matter wastewater generated in a conventional method.

Owner:CENT SOUTH UNIV

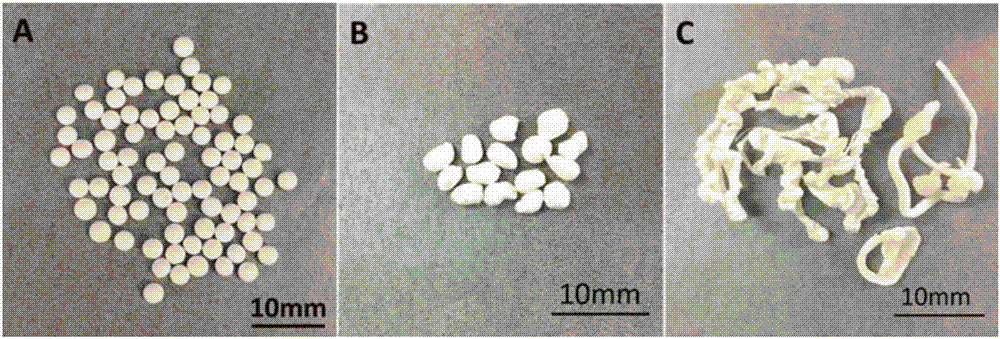

Hydrous zirconium oxide/strontium alginate composite gel bead, and preparation method application thereof

ActiveCN109847718ABig gapWill not cause churnOther chemical processesCombustible gas purificationWater qualityFluoride

The invention relates to a strontium alginate gel bead product coated with hydrous zirconium oxide and an adsorption application of the strontium alginate gel bead product. A hydrous zirconium oxide dispersion liquid is mixed with a sodium alginate water solution according to a certain volume ratio, then the obtained mixture is dropwise added into a strontium salt solution, stirring is carried outto form gel beads, and water washing is carried out to remove excess strontium ions, so that the hydrous zirconium oxide / strontium alginate composite gel beads with a particle size of 0.1-5 mm are obtained. The gel beads can be used for adsorbing and removing anionic pollutants in water. The Langmuir saturated adsorption capacities of the composite gel beads to phosphate micro-polluted water, fluoride micro-polluted water and arsenite micro-polluted water can respectively reach 53 mg / g, 36 mg / g and 61 mg / g. According to the invention, the separation problem of hydrous zirconium oxide can be solved while high adsorption activity of the hydrous zirconium oxide is ensured, and a certain potential application value is achieved in the field of water purification.

Owner:JINAN UNIVERSITY

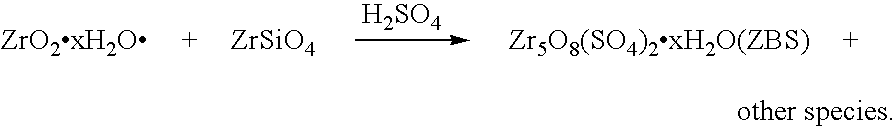

Beneficiation of zircon

InactiveUS7063824B1Improve fusionHigh reactionSulfate preparationTitanium halidesOpacifierAlkali carbonate

This invention relates to a process of treating a zirconium containing product such as zircon. The process comprises providing an alkali fusion decomposed zircon product (AFDZ) formed from reading zircon with a source of alkali metal at elevated temperatures, and treating the AFDZ to form a solid containing hydrated zirconium oxide and / or hydrated zirconium basic carbonate (hereinafter referred to as the hydrated zirconium product). The process further comprises treating the solid hydrated zirconium product to obtain in situ formation of basic zirconium sulphate as a solid thereon. The invention also relates to such a process for producing zircon derived material suitable for pigments and to such a process to produce opacifier material. The invention also relates to products of such processes.

Owner:PRETORIA UNIV OF

Mono-dispersed particle-size-controllable nanometer yttrium stabilized zirconia powder, preparation method and applications thereof

The invention relates to mono-dispersed particle-size-controllable nanometer yttrium stabilized zirconia powder, a preparation method and applications thereof. The preparation method comprises: mixingand dissolving a zirconium salt, an yttrium salt and a dispersing agent according to a certain ratio to obtain a mixed solution; heating the mixed solution, carrying out a hydrothermal reaction, adjusting the H<+> concentration of the solution by adding ammonia water or an acid solution during the hydrothermal process, and cooling to a temperature of less than 90 DEG C after the reaction is completely performed to obtain a hydrated zirconia suspension; adding ammonia water to the zirconia suspension to adjust the pH value to achieve an alkaline state, carrying out standing aging, and carryingout centrifugal separation to obtain zirconia precipitate; and carrying out a series of post-treatment processes on the zirconia precipitate to obtain the nanometer yttrium stabilized zirconia powder. According to the present invention, the method easily controls the shape, the particle size and crystal phase of the product, has simple and convenient operation, and is suitable for factory production.

Owner:CENT SOUTH UNIV

Method for continuous preparation of nanometer-sized hydrous zirconia sol using microwave

The present invention relates to a method for continuously preparing a hydrated zirconia sol dispersed by nanoscale spherical hydrated zirconia particles having an average diameter (dp) of 1 to 250 nm, the method comprising dissolving a zirconium salt solution with a concentration of 0.001 to 0.2 mol / l in aqueous solution The solution is fed into a reactor consisting of one or more reaction tubes, and then microwaves are irradiated onto the flow of the aqueous solution in the reactor so that the aqueous solution can be heated in a flowing state. Compared with conventional batch reactors or semi-continuous stirred reactors, the method for continuously preparing hydrated zirconia sol according to the present invention can allow various operating parameters to be controlled within a certain range, thereby significantly improving The mass of the hydrous zirconia sol prepared or the zirconia powder obtained as the final product.

Owner:KOREA RES INST OF CHEM TECH

Methanol thermosynthesis method for preparing stable spherical tetragonal phase rare-earth yttrium zirconium oxide

InactiveCN102689925AGood dispersionNarrow particle size distributionZirconium oxidesWater methanolPhysical chemistry

The invention discloses a methanol thermosynthesis method for preparing stable spherical tetragonal phase rare-earth yttrium zirconium oxide, comprising the following steps of: accurately weighing ZrOC12.8H2O and YC13.6H2O serving as raw materials according to a molar ratio of 98: (2-87): 13; drying the raw materials under the low temperature of less than 100 DEG C and dissolving the raw materials with absolute methanol; uniformly stirring a mixture and then transferring the mixture to a dry pressure-resistant container; sealing the dry pressure-resistant container and raising the temperature to 160 and 220 DEG C for reacting for 12-48 hours in a heat preservation mode; cooling to room temperature and opening the airtight container; filtering out precipitates; cleaning the mixture for three times with absolute methanol and drying the mixture in a baking oven under the temperature of between 50 and 150 DEG C to prepare zirconium oxide hydrate with stable tetragonal phase rare-earth yttrium having uniform granularity and regular sphere; and forging the zirconium oxide hydrate under high temperature to prepare zirconium oxide powder with stable tetragonal phase rare-earth yttrium. The method has the advantages of being simple in process, easy for operation, low in energy consumption and the like, and can be applied to preparation of high-quality yttrium zirconium ceramic powder in a large scale.

Owner:NANCHANG UNIV

Surface-treated steel sheet

InactiveUS20180100244A1Good film adhesionElectrolytic inorganic material coatingDendriteVanadium oxide

Owner:NIPPON STEEL CORP

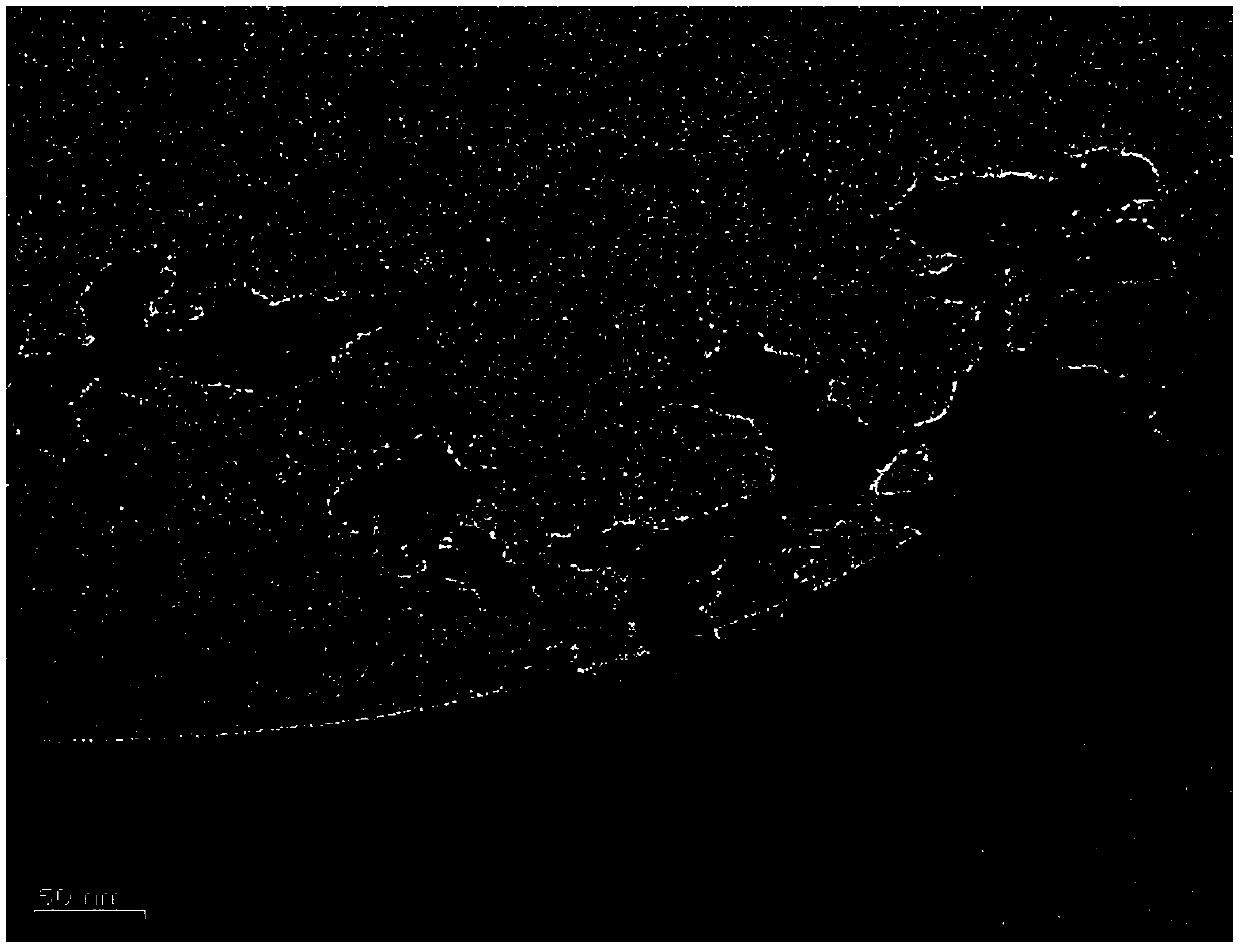

Preparation method of hollow nanometer hydrous zirconium oxide loaded millimeter-level polymer sphere

InactiveCN107511125AGood sphericityHigh strengthOther chemical processesWater contaminantsSorbentSilicon dioxide

The invention discloses a preparation method of a hollow nanometer hydrous zirconium oxide loaded millimeter-level polymer sphere. According to the method, a non-solvent induced phase separation method in the field of membrane separation is used for preparing the hollow nanometer hydrous zirconium oxide loaded millimeter-level polymer sphere; concretely, the hollow nanometer hydrous zirconium oxide sphere is prepared by using a nanometer silicon dioxide sphere as a template; a millimeter-level polymer sphere with the very-narrow particle size distribution is obtained through an injection pump extrusion process; few pore-foaming agents are added, so that the developed pore structure is formed; good sphericity degree and strength are maintained. The loaded hollow nanometer hydrous zirconium oxide prepared by the method has great adsorption capacity and little adsorption capacity loss, can be easily recovered and repeatedly utilized, and is also applicable to relatively harsh application environment; the adsorbent loss is relatively low under the extremely low pH condition; wide application prospects are realized in the field of heavy metal water pollution treatment.

Owner:NANJING UNIV OF SCI & TECH

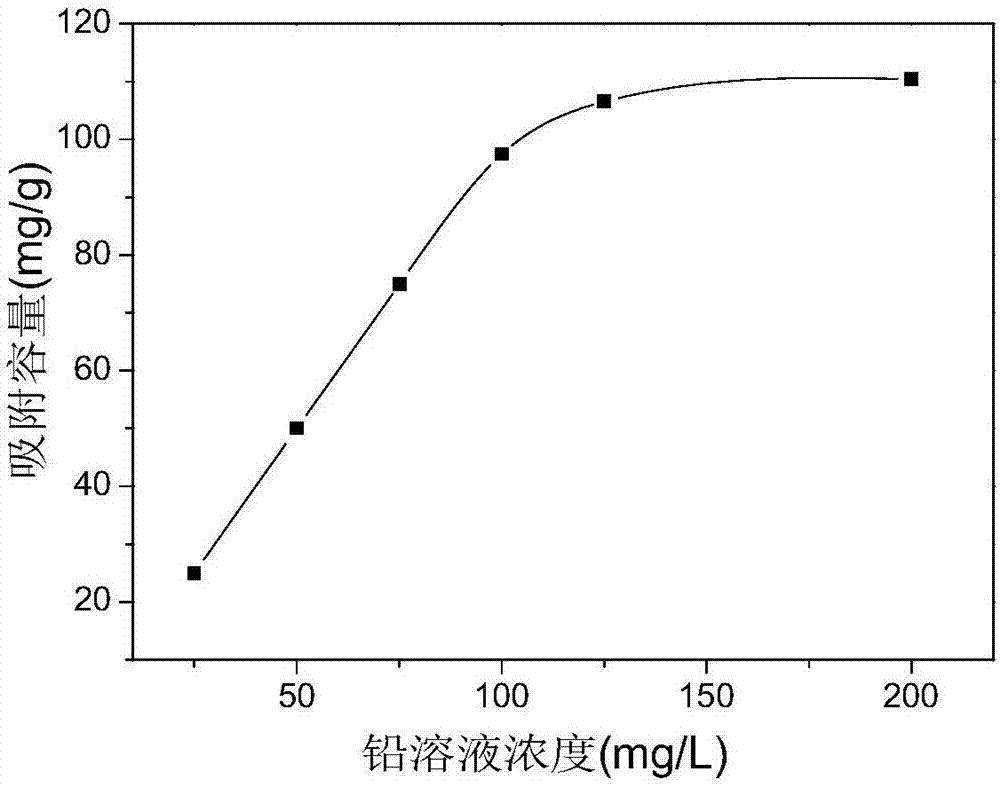

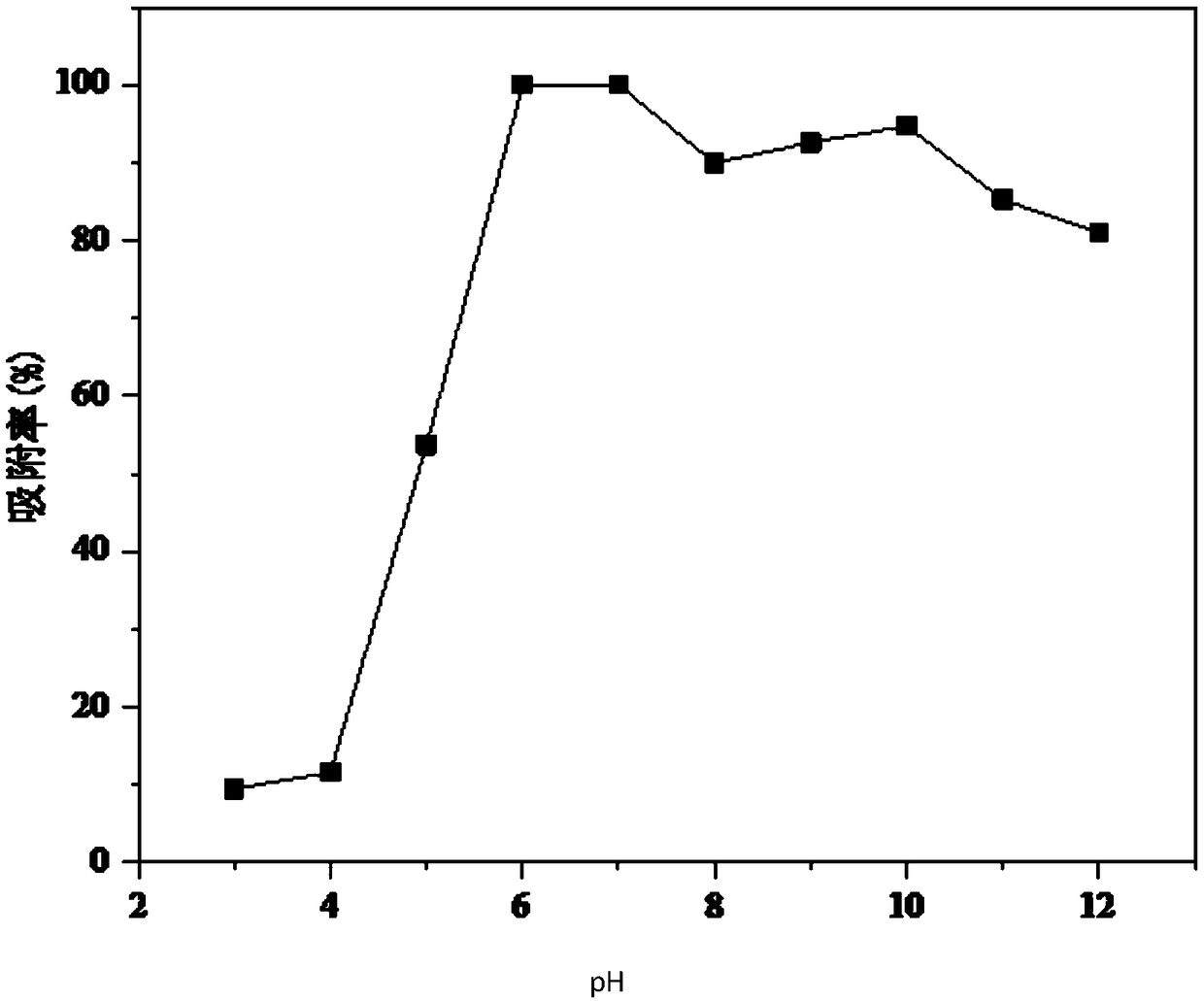

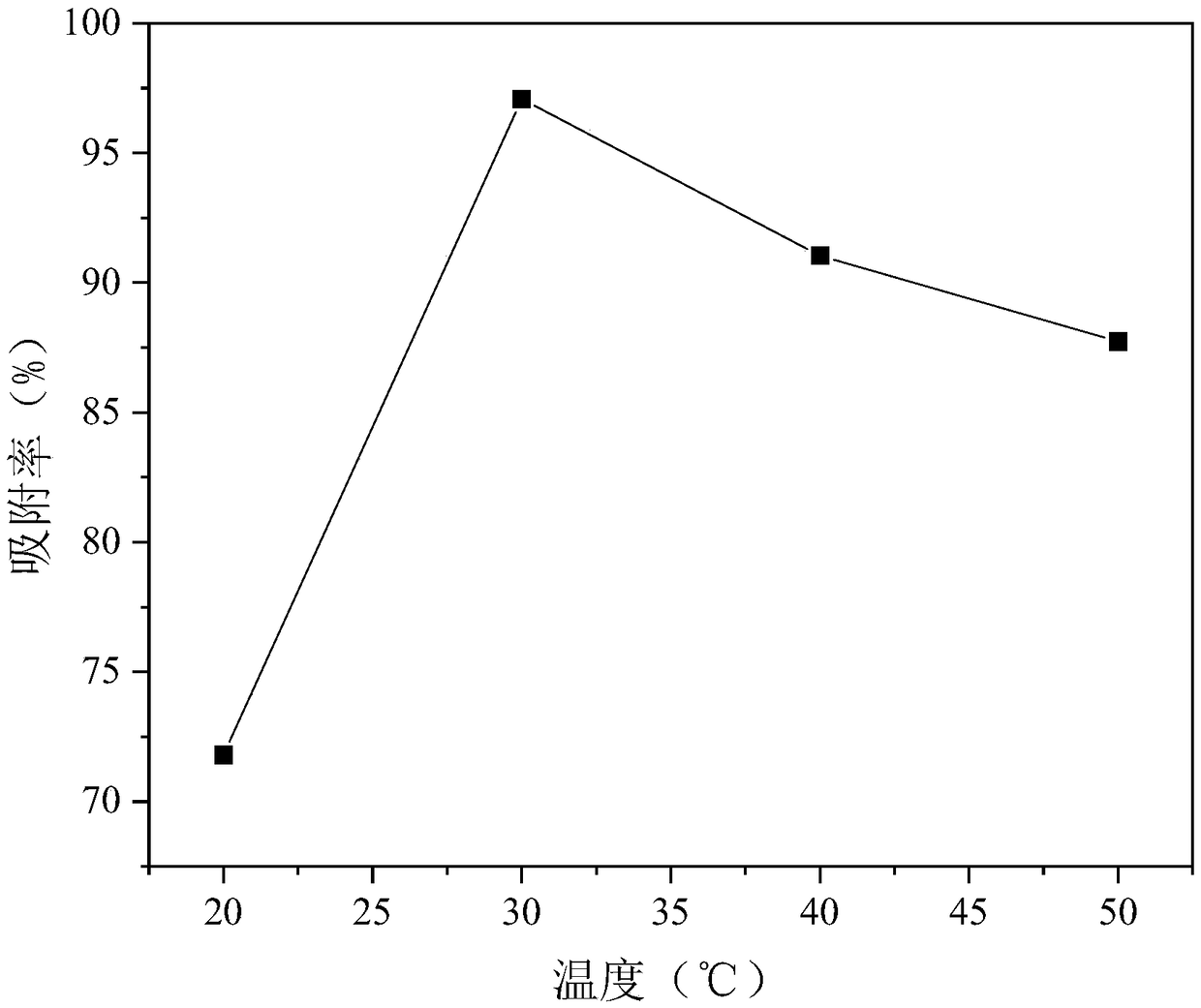

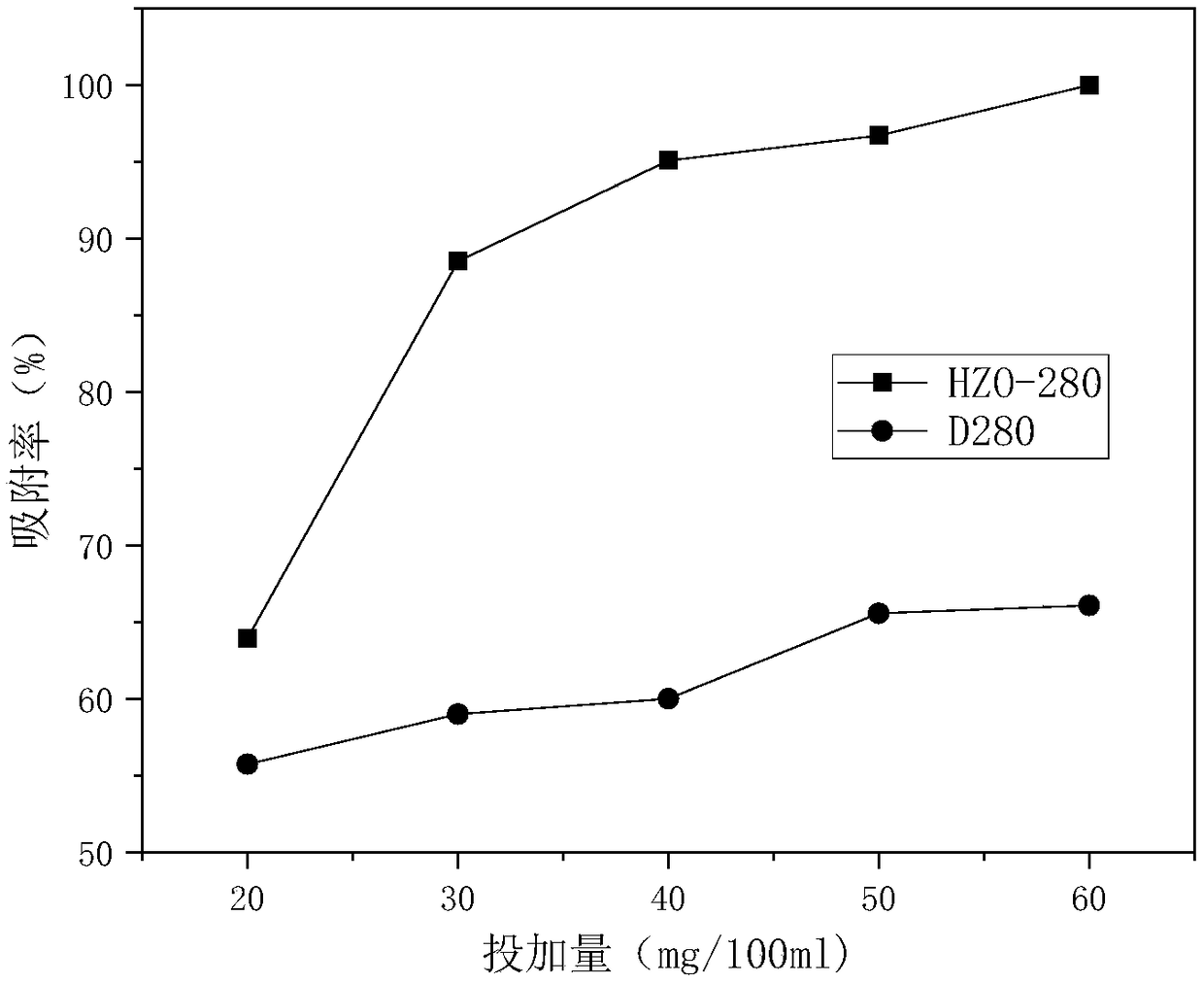

Method for recovering phosphate in town sewage by using resin loaded with hydrous zirconium oxide

ActiveCN109502681ALow priceLow costOther chemical processesWater contaminantsEutrophicationDesorption

The invention discloses a method for recovering phosphate in town sewage by using resin loaded with hydrous zirconium oxide, and belongs to the technical field of treatment of urban sewage. The methodis characterized in that for 4-12mg / L of lower concentration of phosphorus in urban domestic sewage, eutrophication of a water body is easily caused in rivers or lakes due to discharged phosphorus, and the current chemical precipitation method and biological phosphorus-removing method cannot meet stricter and stricter phosphorus discharging requirements, therefore, a high and new technology is desired to enhance removal of the phosphorus in effluents. The method disclosed by the invention has the beneficial effects that the resin D280 loaded with the hydrous zirconium oxide is adopted to recover the phosphate in the town sewage, and when the temperature is 25-30 DEG C and the pH is 6-7, the adsorption capability of D280-Zr can reach 97-100%; further, when containing competitive negative ions, D280-Zr still represents better adaptability and adsorption property; after 6 times of adsorption and desorption circulations, the adsorption rate of D280-Zr can still be maintained at 80% or more; therefore, by adoption of the resin material, the energy consumption can be saved, and further the method has more application value.

Owner:BEIJING UNIV OF TECH

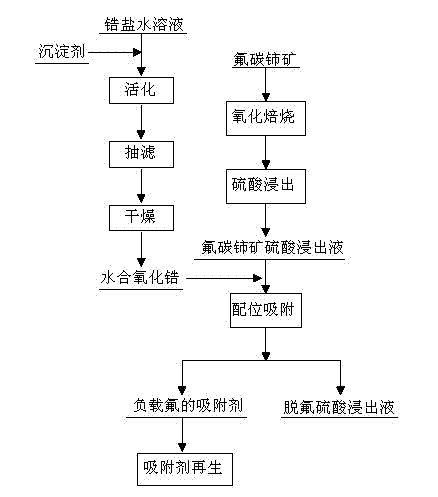

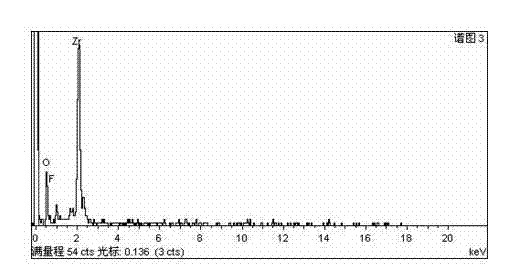

Method for removing fluorine in bastnaesite sulfuric acid leaching liquid by using zirconium-containing adsorbent

InactiveCN102952946AAchieve the purpose of separationImprove the coordination effectProcess efficiency improvementFiltrationSorbent

The invention belongs to the technical field of rare earth wet metallurgy, and particularly relates to a method for removing fluorine in bastnaesite sulfuric acid leaching liquid by using a zirconium-containing adsorbent. The method comprises the following steps of firstly, preparing zirconium salt into solution being 0.05-0.5 mol.L<-1>, stirring and activating by adding a precipitating agent, obtaining zirconium-containing adsorbent hydrated zirconium oxide by drying a solid product obtained by suction filtration, diluting bastnaesite sulfuric acid leaching liquid by 10-100 times by adding water, regulating the acidity to be 0.1-1.0 mol.L<-1>, adding 0.2-1.0g / 50ml of a prepared zirconium-containing adsorbent, oscillating for 10-40 minutes, and then carrying out solid-liquid separation, and obtaining to obtain solid zirconium-containing adsorbent loaded with fluorine and defluorination sulfuric acid leaching liquid. According to the method disclosed by the invention, the generation of three fluorine-containing waste products is reduced through fluorine removing, the environment pollution due to a procedure is greatly relieved, meanwhile, the influence for on the extraction and the separation of follow-up rare earth due to the fluorine can be removed by simultaneously removing the fluorine from sulfuric acid liquid before extraction, the zirconium adsorbent after the adsorption can be reutilized, and the cost is greatly reduced.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com