Method for recovering phosphate in town sewage by using resin loaded with hydrous zirconium oxide

A technology for hydrating zirconia and urban sewage, which is applied in water/sewage treatment, chemical instruments and methods, adsorbed water/sewage treatment, etc. It can solve problems such as no research reports, and achieve stable chemical properties, good effect and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Dissolve 15g of zirconium oxychloride octahydrate in a mixed solution of 100ml of HCl and ethanol, wherein the volume fraction of HCl is 5%, the volume fraction of ethanol is 30%, and the rest is water. Then 5 g of D280 resin was added, followed by continuous stirring at 50°C for 24 hours. Then the D280 resin loaded with zirconium was filtered and added to 50 ml of NaOH solution with a mass fraction of 5%, and the mixture was continuously stirred for 24 hours. Zirconium hydroxide will gradually form a precipitate in the resin D280; then rinse the D280 resin containing zirconium hydroxide with deionized water until the pH of the effluent is 6.5-7.5; then rinse with 50ml of alcohol; finally the D280 resin loaded with zirconium hydroxide Heat at 60°C for 12 hours. It can be made into finished resin D280-Zr loaded with hydrated zirconia.

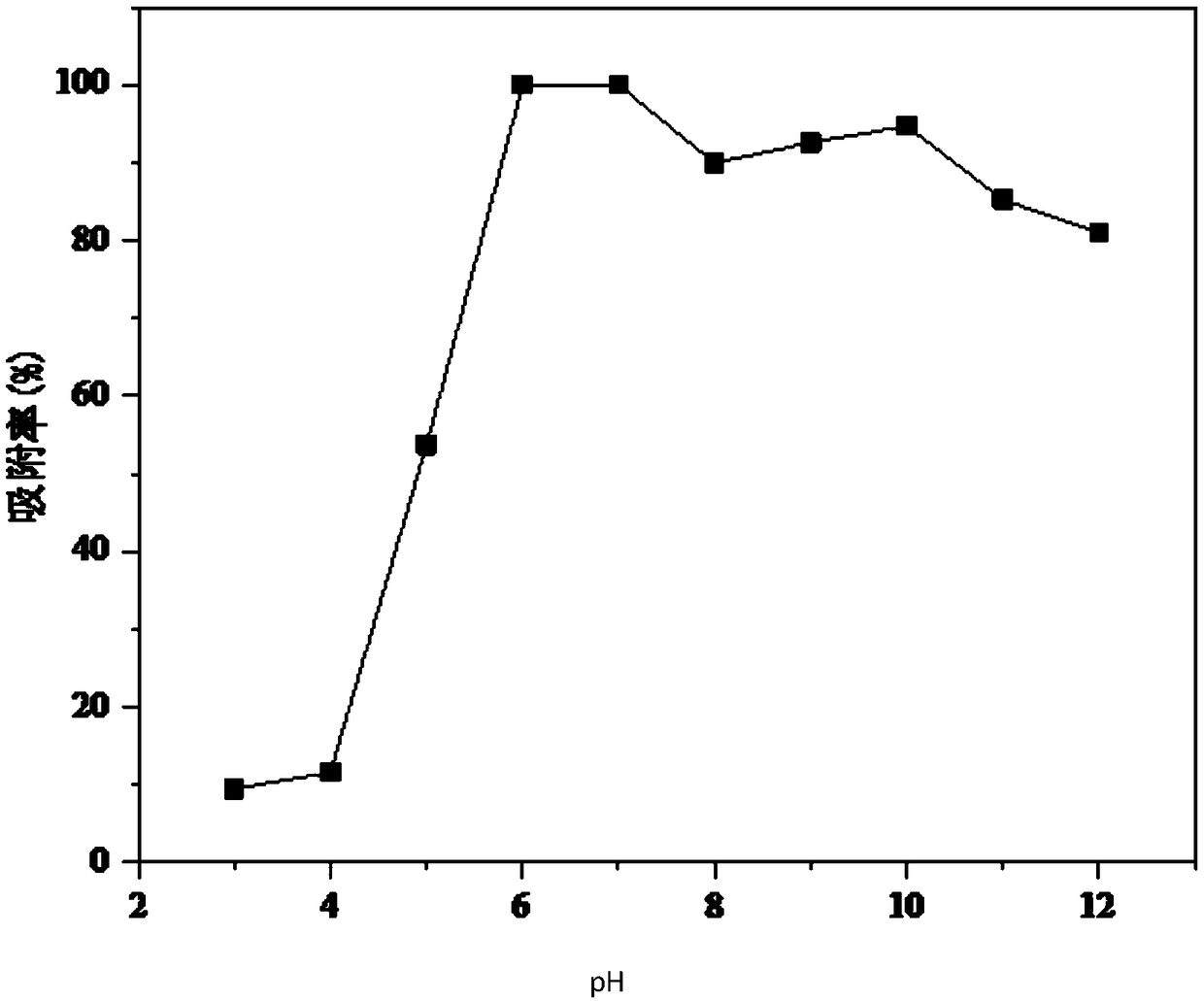

[0031]The effect of pH on the adsorption performance of D280-Zr: Prepare 1L of phosphate solution and put it into ten 150ml Erlenmeyer...

Embodiment 2

[0033] Dissolve 15g of zirconium oxychloride octahydrate in a mixed solution of 100ml of HCl and ethanol, wherein the volume fraction of HCl is 5%, the volume fraction of ethanol is 30%, and the rest is water. Then 5 g of D280 resin was added, followed by continuous stirring at 50°C for 24 hours. Then the D280 resin loaded with zirconium was filtered and added to 50 ml of NaOH solution with a mass fraction of 5%, and the mixture was continuously stirred for 24 hours. Zirconium hydroxide will gradually form a precipitate in the resin D280; then rinse the D280 resin containing zirconium hydroxide with deionized water until the pH of the effluent is 6.5-7.5; then rinse with 50ml of alcohol; finally the D280 resin loaded with zirconium hydroxide Heat at 60°C for 12 hours. It can be made into finished resin D280-Zr loaded with hydrated zirconia.

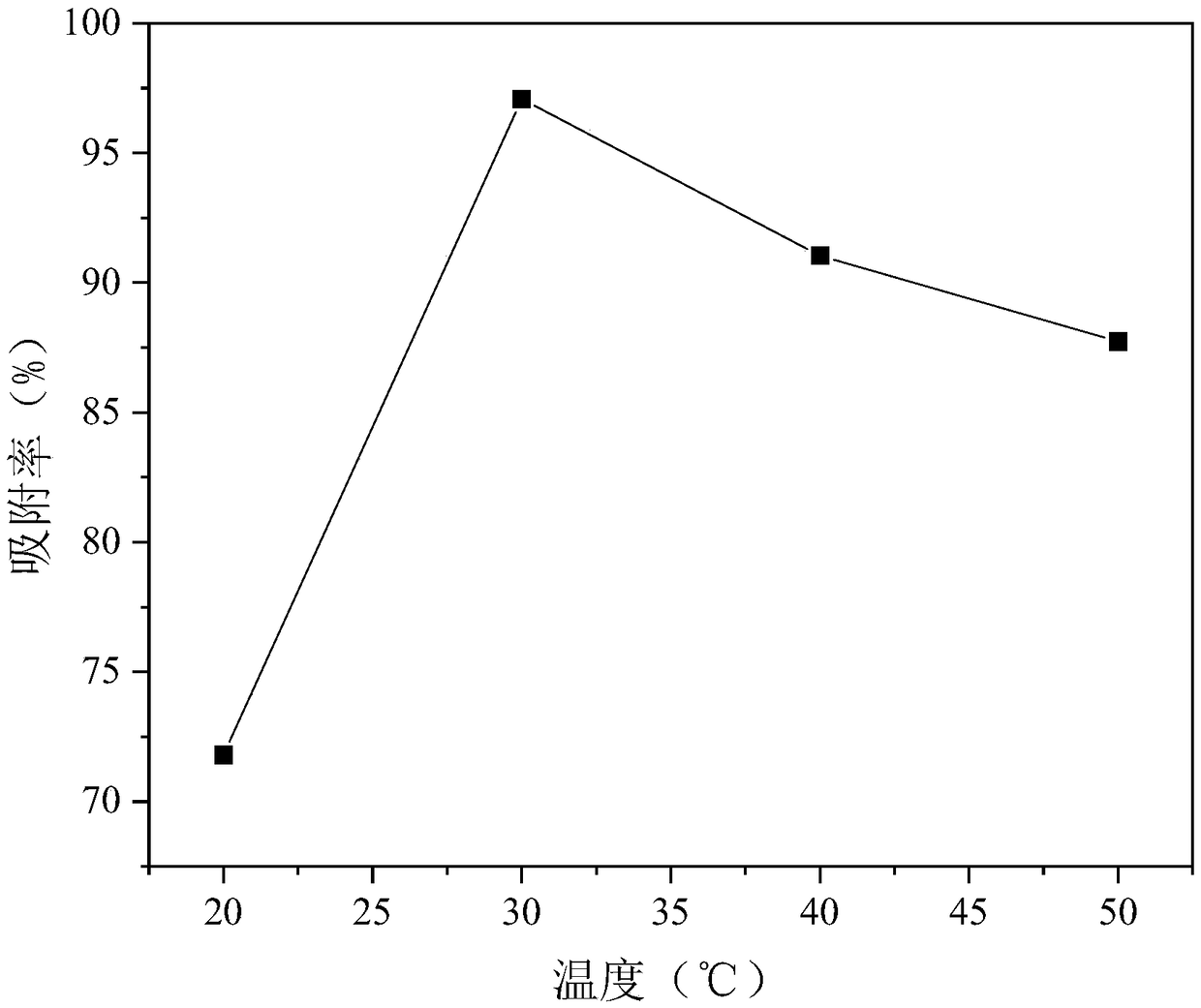

[0034] Selection of reaction temperature: configure 400ml of phosphate solution, put them in four 150ml conical flasks respectively, p...

Embodiment 3

[0036] Dissolve 15g of zirconium oxychloride octahydrate in a mixed solution of 100ml of HCl and ethanol, wherein the volume fraction of HCl is 5%, the volume fraction of ethanol is 30%, and the rest is water. Then 5 g of D280 resin was added, followed by continuous stirring at 50°C for 24 hours. Then the D280 resin loaded with zirconium was filtered and added to 50 ml of NaOH solution with a mass fraction of 5%, and the mixture was continuously stirred for 24 hours. Zirconium hydroxide will gradually form a precipitate in the resin D280; then rinse the D280 resin containing zirconium hydroxide with deionized water until the pH of the effluent is 6.5-7.5; then rinse with 50ml of alcohol; finally the D280 resin loaded with zirconium hydroxide Heat at 60°C for 12 hours. It can be made into finished resin D280-Zr loaded with hydrated zirconia.

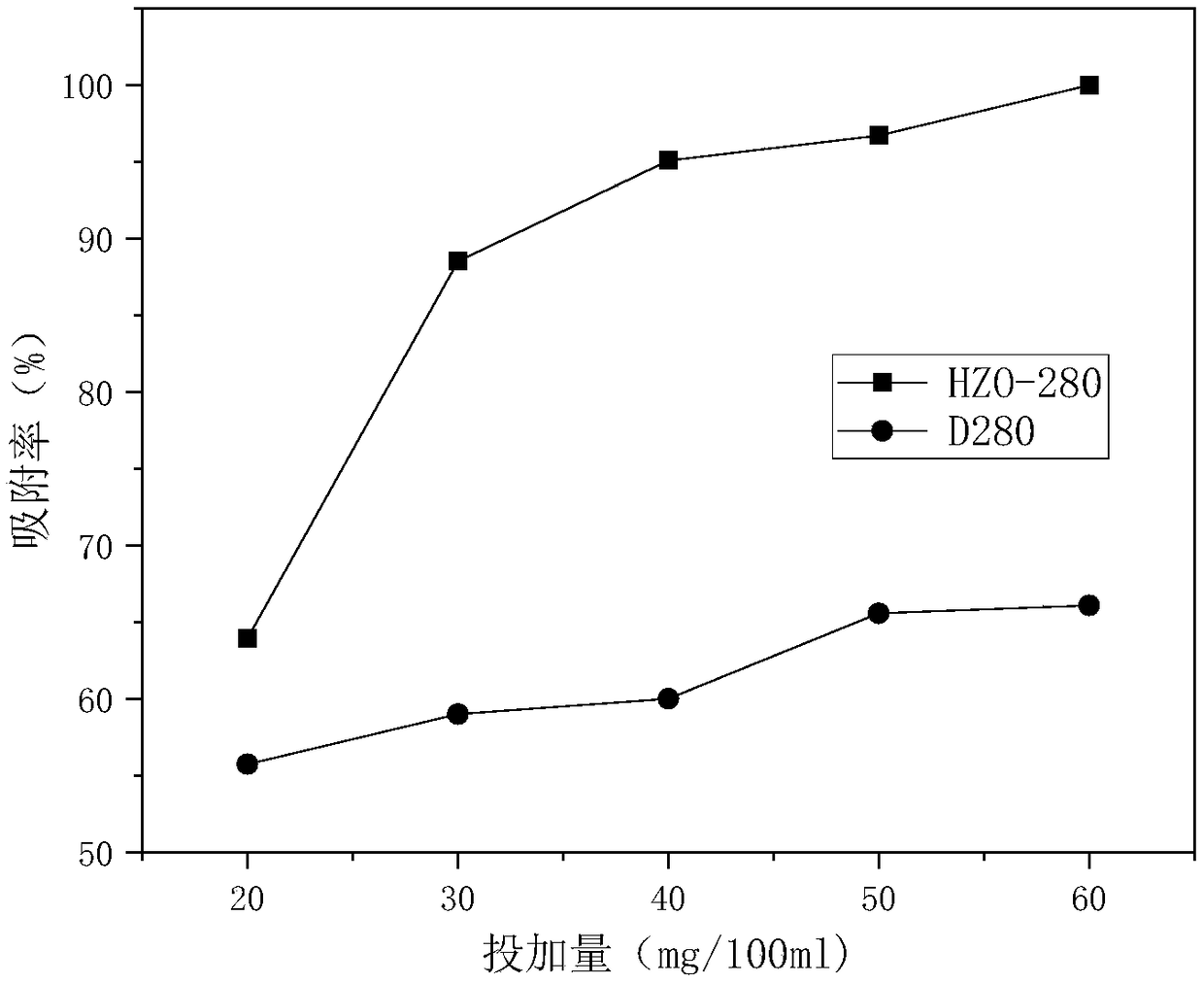

[0037] The choice of dosage: through Example 1 and Example 2, the optimum reaction pH of D280-Zr is 6.5, and the optimum reaction temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com