Method for continuous preparation of nanometer-sized hydrous zirconia sol

A technology of hydrated zirconia and zirconium sol, which is applied in the field of reconciliation, and can solve the problems of not being able to provide hydrated zirconia sol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

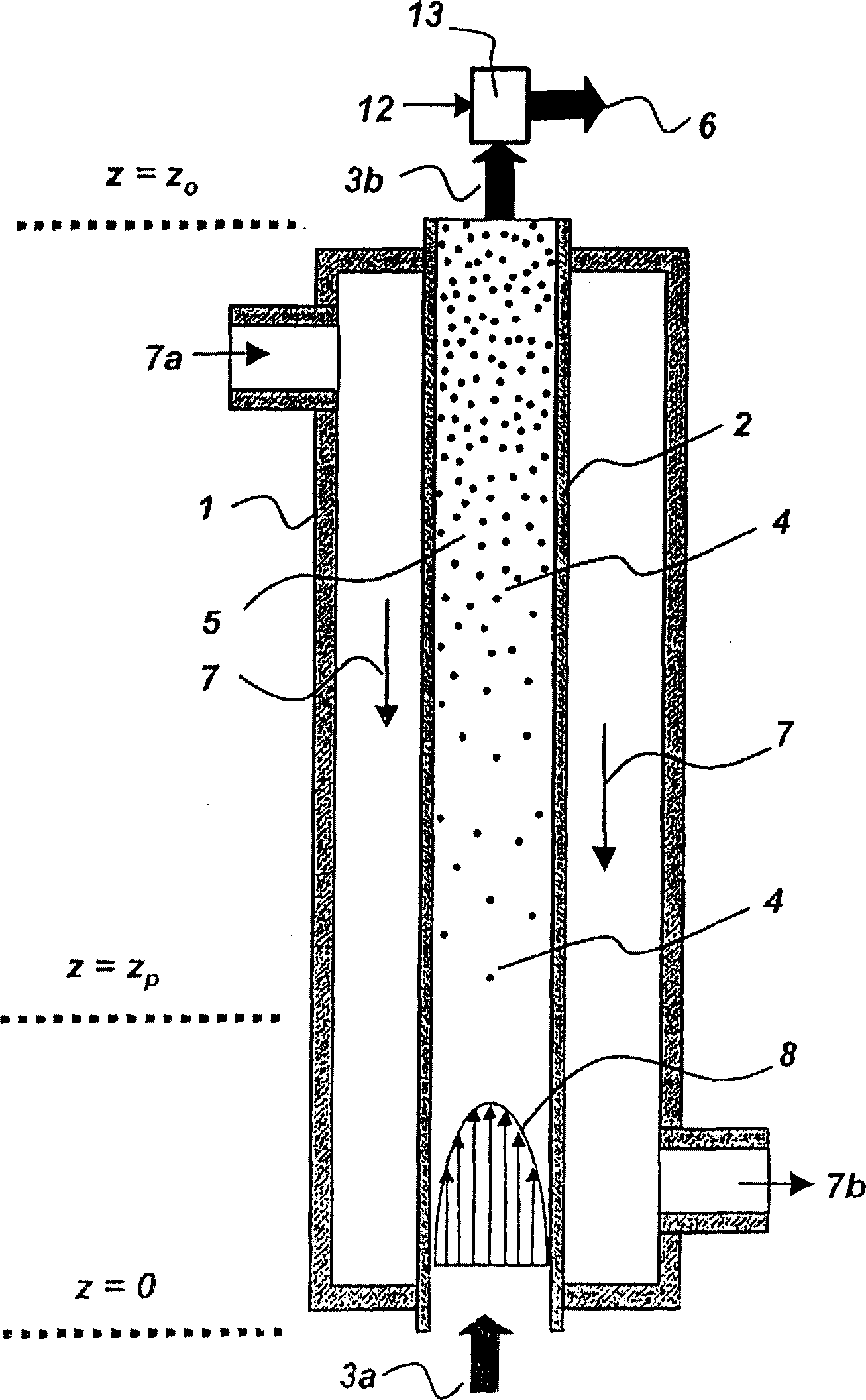

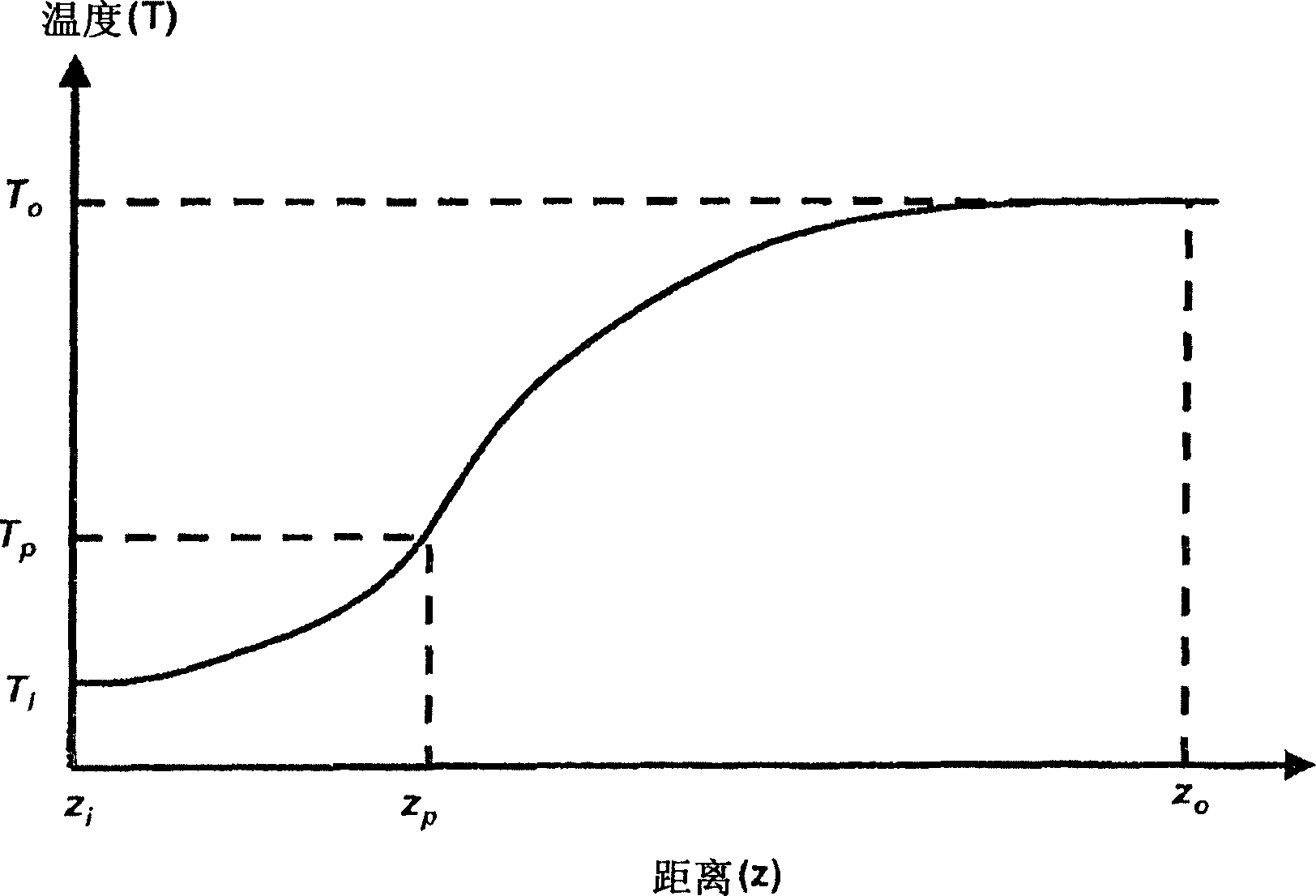

[0103] 0.2 mol of zirconium oxychloride and 1 g of hydroxypropylmethylcellulose were dissolved in 1 liter of a solvent mixture of 2-propanol and water (molar ratio 0.94) to prepare a zirconium saline aqueous solution. Such as Figure 5b As shown, two spiral type reaction tubes each having an inner diameter of 9.5 mm and a length of 5 m and composed of Pyrex glass were installed in a stainless steel vessel to form a condenser type tube reactor. The zirconium salt aqueous solution was supplied to the reaction tube at a flow rate of 403 cc / min at a temperature of about 10°C. A vapor-phase heating medium composed of hot water and ethanol (molar ratio 1:1) was supplied to the inside of the reactor (outside of the reaction tube) at a temperature of 98°C, and then condensed there. As a result, the outlet temperature of the reaction tube could be 74°C. The pH value of the suspension discharged from the outlets of the two reaction tubes was controlled to 9.1 by adding 0.8 N ammonia w...

Embodiment 2

[0108] 0.04 mol of zirconium oxychloride and 0.6 g of hydroxypropyl cellulose were dissolved in 1 liter of a solvent mixture of 1-propanol and water (1.7 molar ratio) to prepare a zirconium salt aqueous solution. Such as Figure 7a As shown, a 37 stainless steel reaction tube with an inner diameter of 3.37 mm and a length of 500 mm forms a shell-tube heat exchange type tubular reactor. An aqueous zirconium salt solution was fed to the reaction tube at a total flow rate of 1150 cc / min at a temperature of about 8°C. A vapor-phase heating medium obtained by heating 2-propanol was supplied to the shell (outside of the reaction tube) of the reactor at a temperature of 84° C., and then condensed there. As a result, the outlet temperature of the reaction tube could be 78°C.

[0109] The hydrated zirconia sol was continuously prepared by adding and mixing 2.0N ammonia water in the discharge pipe of the suspension mixer to control the pH to 5.6.

[0110] Five (5) drops of the result...

Embodiment 3

[0112] 0.2 mol of zirconium oxychloride and 7 g of polyvinyl alcohol were dissolved in 1 liter of a solvent mixture of 2-propanol and water (0.94 molar ratio) to prepare a zirconium salt aqueous solution. Such as Figure 4 As shown, the tubular reactor used had three (3) straight stainless steel tubes of concentric annular cross-section, 300 mm in length, and gauges of 1 / 4 inch, 3 / 8 inch, and 3 / 4 inch, respectively. The zirconium salt aqueous solution was fed to the concentric annulus of the 1 / 4 inch and 3 / 8 inch reaction tubes at a temperature of about 8°C at a flow rate of 30 cc / min. The hydrocarbon-based heat carrier oil heated to 95°C is simultaneously fed into the 1 / 4 inch pipe and between the 3 / 8 inch pipe and the 3 / 4 inch pipe against the flow direction of the zirconium salt aqueous solution, so as to have a concentric The temperature of the suspension at the outlet of the reaction tube of circular cross-section may be 82°C. The suspension was contacted with ammonia g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com