Preparation method of supported zirconia hydrate with high specific surface area through dispersion modification and application thereof

A high specific surface area, hydrated zirconia technology, applied in chemical instruments and methods, water pollutants, semi-permeable membrane separation, etc., can solve the problems of extra energy consumption and ineffective substances, so as to reduce the use and facilitate mass production , the effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

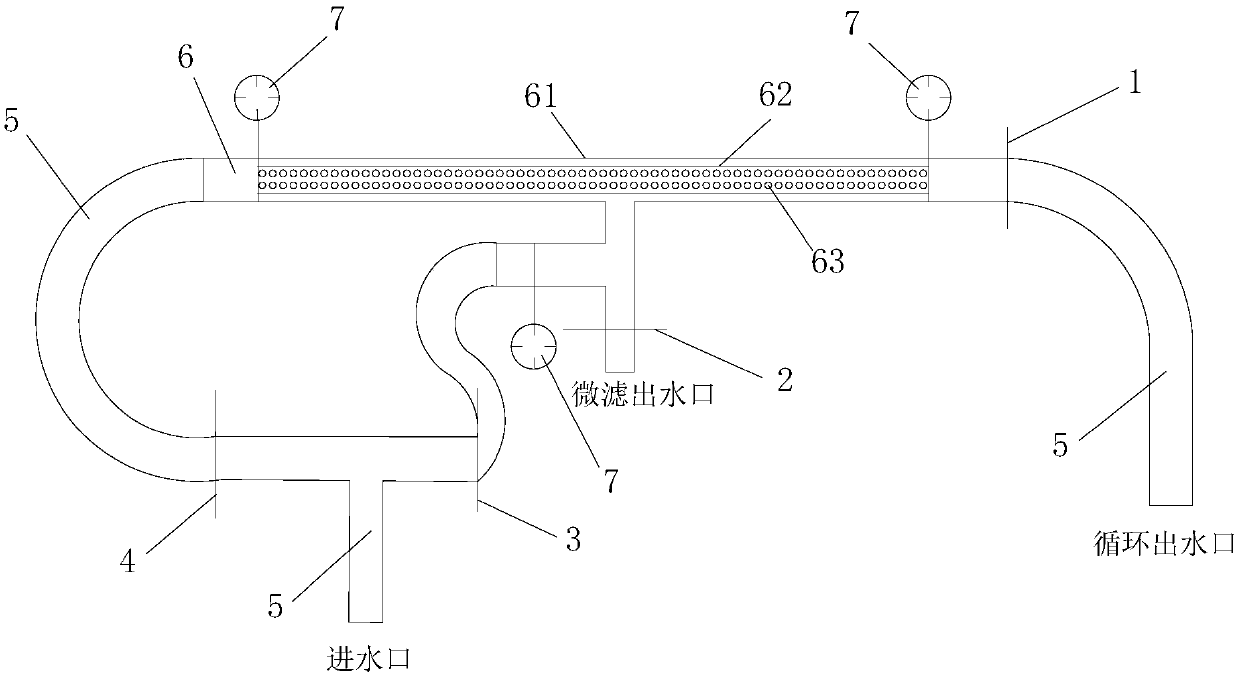

[0043] Example 1, see figure 1 :

[0044] The invention provides a method for preparing high specific surface area supported hydrated zirconia by dispersion modification, which comprises the following steps:

[0045] 1) Prepare 200mL of 4mol / L NaOH solution; dissolve 20g of hydroxypropyl cellulose in 200mL of distilled water at 80°C to make a solution with a mass fraction of 10% separately, mix it with sodium hydroxide solution, and stir evenly to obtain a phase Mixed solution with good capacity;

[0046] 2) dissolving zirconium chloride in a hydrochloric acid solution with a hydrochloric acid mass concentration of 0.4%, adding 20 g of a macroporous cation exchange resin, and reacting at 30° C. for 12 hours to obtain an ion exchange resin adsorbed with zirconium ions;

[0047] 3) Immerse the ion exchange resin adsorbed with zirconium ions in the mixed solution prepared in step 1) and react for 12 hours;

[0048] 4) After the reaction, the product was rinsed with distilled w...

Embodiment 2

[0051] The present invention provides a method for preparing high specific surface area supported hydrated zirconia by dispersion modification, which is basically the same as in Example 1, except that in step 1): 40g of polyvinyl alcohol is dissolved in 200mL of distilled water at 80°C, Separately prepare a solution with a mass fraction of 20%, and then mix it with 200mL of 4mol / L sodium hydroxide solution, and stir evenly to obtain a mixed solution with good compatibility.

[0052] The specific surface area of the product is 18.4352m 2 / g, compared with the same kind of composite adsorption material without dispersion treatment, its specific surface area is increased by 2.0 times.

[0053] The product of this example is filled into a microfiltration membrane tube to obtain a filter column, and the desulfurization wastewater is treated. The initial concentration of zinc ions, equipment and operation method in the desulfurization wastewater are the same as those in Example 1,...

Embodiment 3

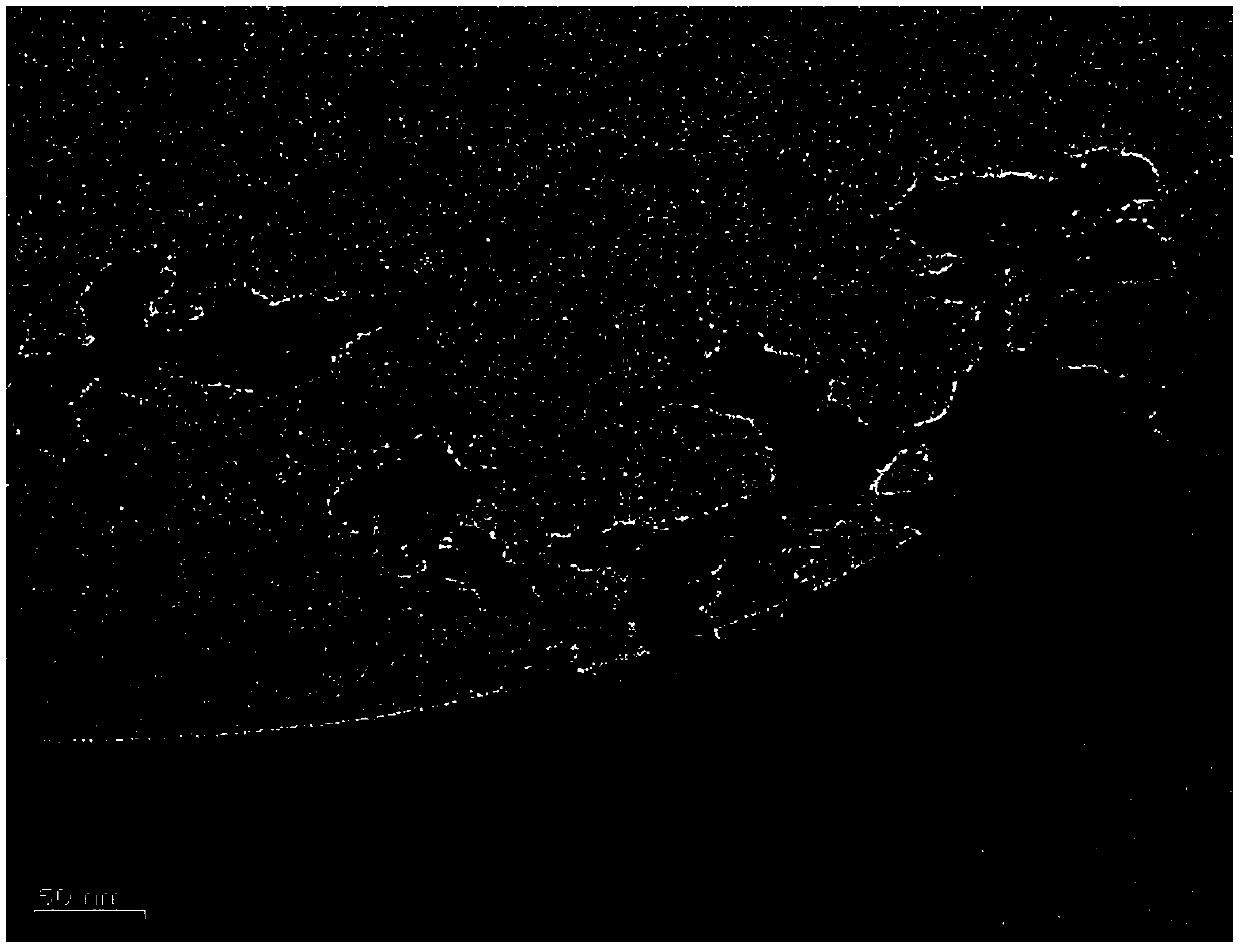

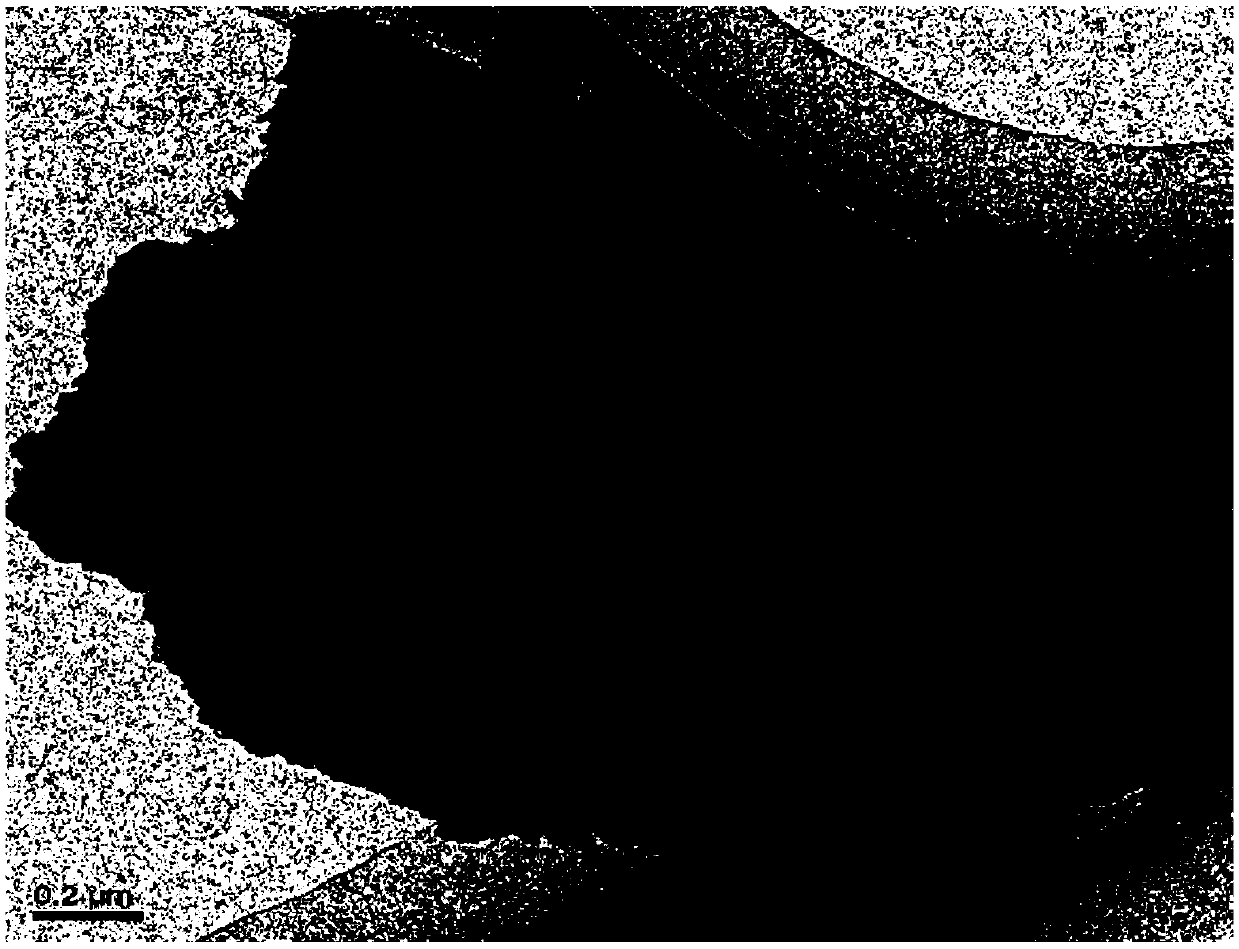

[0054] Example 3, see Figure 2 to Figure 4 :

[0055] The present invention provides a method for preparing high specific surface area loaded hydrated zirconia by dispersion modification, which is basically the same as in Example 1, except for step 1): first prepare a 2mol / L sodium hydroxide solution, and then go to the hydroxide Add 25g of octadecyltrimethylammonium chloride to the sodium solution and stir evenly to fully dissolve the octadecyltrimethylammonium chloride to obtain a mixed solution with good compatibility.

[0056] The specific surface area of the product is 21.7709m 2 / g, compared with the same kind of composite adsorption material without dispersion treatment, its specific surface area is increased by 2.5 times.

[0057] The product of this example is filled into a microfiltration membrane tube to obtain a filter column, and the desulfurization wastewater is treated. The initial concentration of zinc ions in the desulfurization wastewater, the equipment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com