Method for continuous preparation of nanometer-sized hydrous zirconia sol using microwave

A technology of hydrated zirconia and zirconia sol, which is applied in zirconia, chemical instruments and methods, nanotechnology for materials and surface science, etc., and can solve the problems of not being able to provide hydrated zirconia sol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

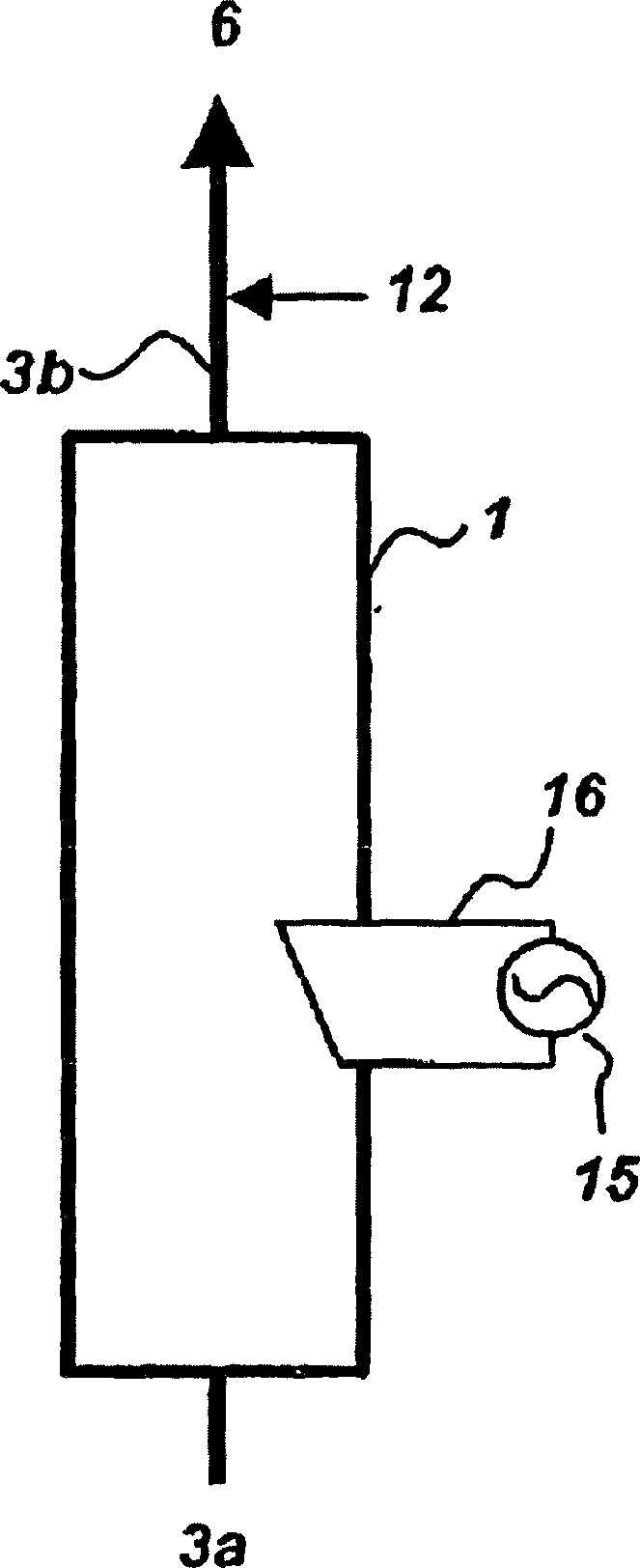

Embodiment 1

[0118] 0.04 mol of zirconium oxychloride and 1 g of hydroxypropyl cellulose were dissolved in 1 liter of a solvent mixture of 1-propanol and water (1.2 molar ratio) to prepare a zirconium salt aqueous solution. At a temperature of about 10° C., the zirconium salt aqueous solution was continuously fed at a flow rate of 403 cc / min into a quartz glass tube having an inner diameter of 16 mm equipped in a stainless steel reactor. Microwaves of 2,450 MHz were irradiated to the solution to heat the solution so that the outlet temperature of the reaction tube could reach 74°C. The pH value of the suspension discharged from the outlet of the reaction tube was controlled to 7.5 by adding 2N ammonia water in the mixer to continuously prepare the hydrated zirconia sol.

[0119] The hydrated zirconia particles were filtered from the obtained hydrated zirconia sol by means of a 20-nm sized filter, followed by repeated washing with distilled water until no Cl was detected. - The hydrated zi...

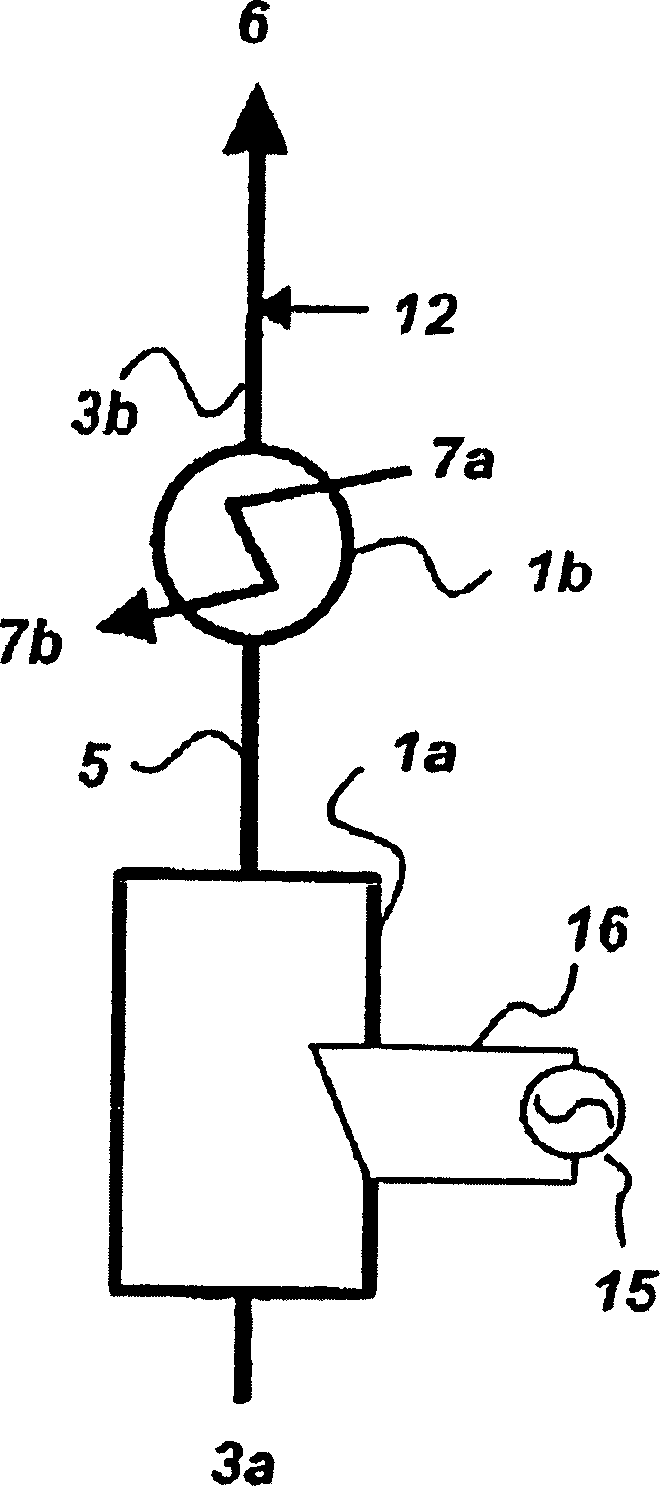

Embodiment 2

[0123] 0.06 mol of zirconium oxychloride and 0.4 g of hydroxypropyl cellulose were dissolved in 1 liter of a solvent mixture of 2-propanol and water (molar ratio 0.8) to prepare a zirconium saline aqueous solution. At a temperature of about 7°C, an aqueous zirconium salt solution was continuously fed at a flow rate of 910 cc / min into a quartz glass tube having an inner diameter of 16 mm provided in the first stainless steel reactor zone. Microwaves of 2,450 MHz were irradiated to the solution to heat the solution so that the outlet temperature of the reaction tube could reach 45°C.

[0124] The intermediate product flowing from the reaction tubes was continuously fed to the reaction tubes of the second reaction zone in the form of a shell-and-tube heat exchanger with 8 stainless steel reaction tubes of internal diameter 6 mm. Steam at about 106°C as a heating medium is supplied to the shell side and compressed so that the temperature of the suspension flowing out from the reac...

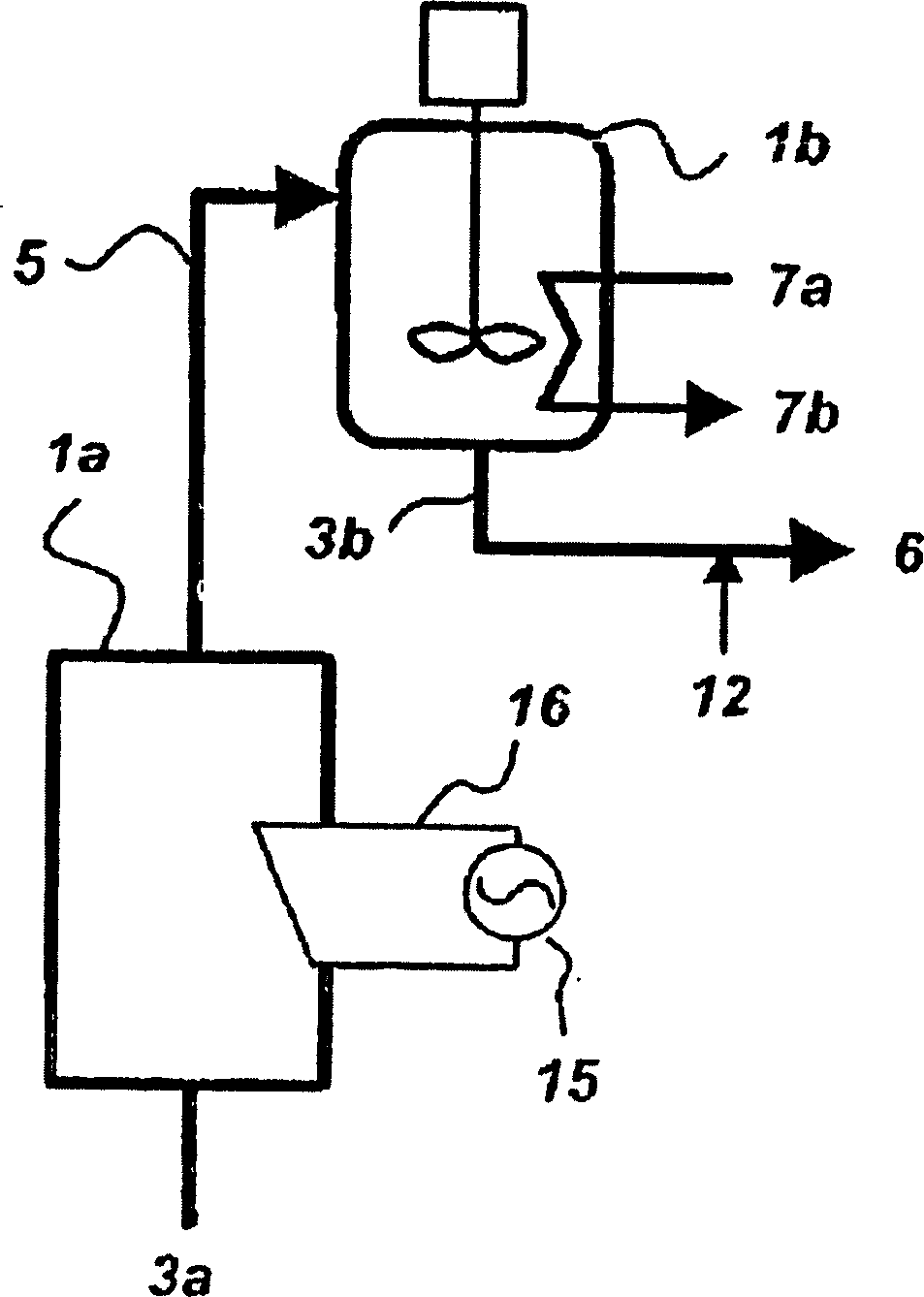

Embodiment 3

[0128] 0.01 mol of zirconium oxychloride and 0.4 g of hydroxypropyl cellulose were dissolved in 1 liter of a solvent mixture of 2-propanol and water (1.6 molar ratio) to prepare a zirconium saline aqueous solution. At a temperature of about 12°C, an aqueous zirconium salt solution was continuously fed at a flow rate of 362 cc / min into a quartz glass tube having an inner diameter of 12 mm provided in the first stainless steel reactor zone. Microwaves of 2,450 MHz were irradiated to the solution to heat the solution so that the outlet temperature of the reaction tube could reach 53°C.

[0129] The intermediate product flowing out from the outlet of the reaction tube was supplied to a second stainless steel reaction zone having a stirring type vessel and an inner diameter of 120 mm and a height of 600 mm. In the second reaction zone, the liquid height is maintained at 400 mm, and the intermediate product is stirred with a stirrer installed in the axial direction of the reactor. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com