Preparation method of hollow nanometer hydrous zirconium oxide loaded millimeter-level polymer sphere

A hydrated zirconia, hollow nanotechnology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problems that limit the large-scale practical application of nano-adsorbents, are difficult to separate and recycle, and are unfavorable for adsorption beds. application and other problems, to overcome the difficulty of recycling and reuse, easy industrial expansion of production, and fast adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

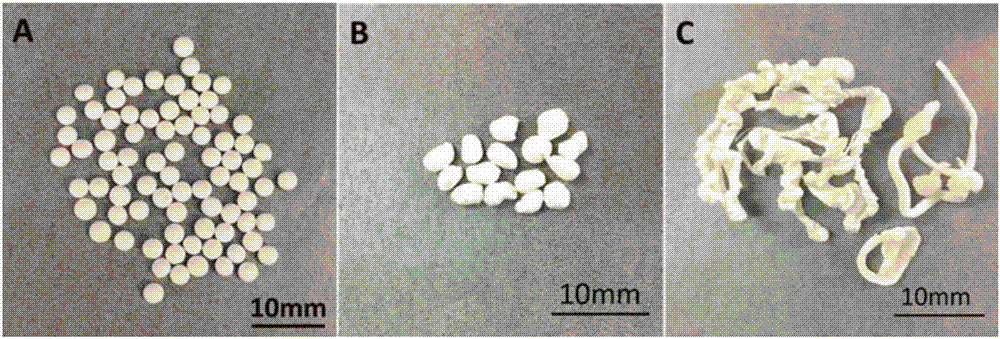

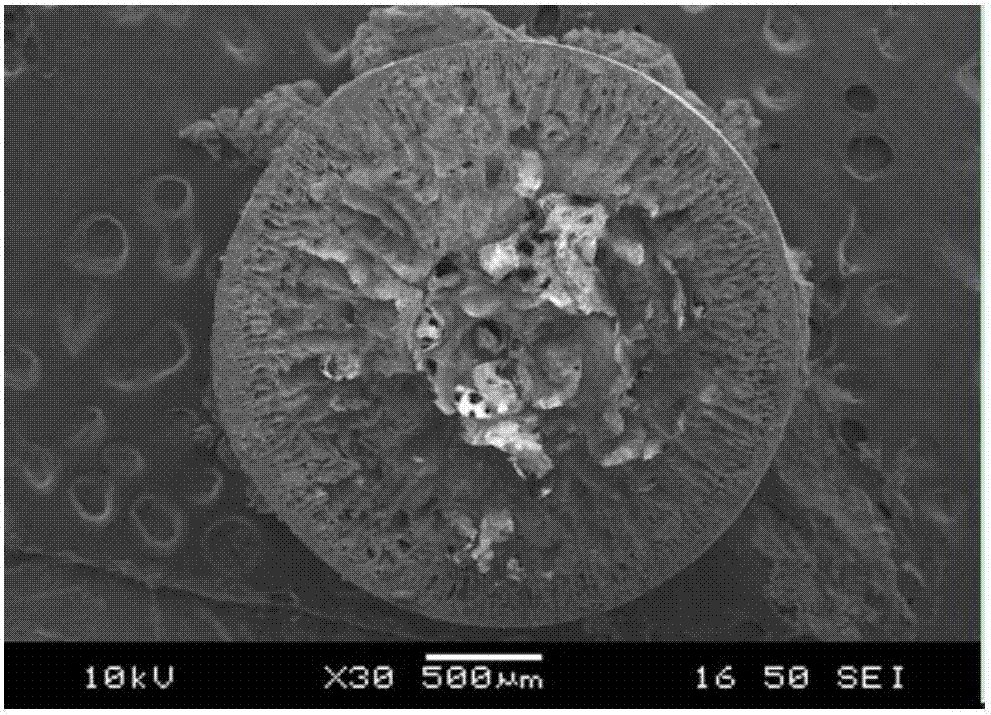

[0039] In step 1, add 130 mL of absolute ethanol to 20 mL of H 2 O and 50 mL of ammonia water were stirred at 30° C. to obtain mixed solution 1. 10 mL of TEOS was added to 190 mL of anhydrous ethanol, and after stirring uniformly, it was added to mixed solution 1. After rapid stirring for 1 minute, the stirring was continued at 30° C. for 20 hours. After the reaction, centrifuge and dry to obtain nano-silica balls.

[0040] In step 2, the silica and 0.83 mL of H 2O and 0.83 g of Brij35 were added to 333 mL of absolute ethanol, sonicated for 2 hours and then stirred for 30 minutes to obtain mixed solution 2. Take 5mL of n-butoxide zirconium solution and add it to 25mL of absolute ethanol, after stirring evenly, suck it up with a syringe, adjust the speed of the syringe pump to 0.3mL / min, drop it into mixed solution 2, and continue to stir at 30°C for 8 hours. After the reaction, centrifuge, age in deionized water for 24 hours, centrifuge again, and reflux for 3 to 4 days. T...

Embodiment 2

[0045] In step 1, add 130 mL of absolute ethanol to 20 mL of H 2 O and 50 mL of ammonia water were stirred at 30° C. to obtain mixed solution 1. 10 mL of TEOS was added to 190 mL of anhydrous ethanol, and after stirring uniformly, it was added to mixed solution 1. After rapid stirring for 1 minute, the stirring was continued at 30° C. for 20 hours. After the reaction, centrifuge and dry to obtain nano-silica balls.

[0046] In step 2, the silica and 0.83 mL of H 2 O and 0.83 g of Brij35 were added to 333 mL of absolute ethanol, sonicated for 2 hours and then stirred for 30 minutes to obtain mixed solution 2. Take 5mL of n-butoxide zirconium solution and add it to 25mL of absolute ethanol, after stirring evenly, suck it up with a syringe, adjust the speed of the syringe pump to 0.3mL / min, drop it into mixed solution 2, and continue to stir at 30°C for 8 hours. After the reaction, centrifuge, age in deionized water for 24 hours, centrifuge again, and reflux for 3 to 4 days. ...

Embodiment 3

[0049] In step 1, add 130 mL of absolute ethanol to 20 mL of H 2 O and 50 mL of ammonia water were stirred at 30° C. to obtain mixed solution 1. 10 mL of TEOS was added to 190 mL of anhydrous ethanol, and after stirring uniformly, it was added to mixed solution 1. After rapid stirring for 1 minute, the stirring was continued at 30° C. for 20 hours. After the reaction, centrifuge and dry to obtain nano-silica balls.

[0050] In step 2, the silica and 0.83 mL of H 2 O and 0.83 g of Brij35 were added to 333 mL of absolute ethanol, sonicated for 2 hours and then stirred for 30 minutes to obtain mixed solution 2. Take 5mL of n-butoxide zirconium solution and add it to 25mL of absolute ethanol. After stirring evenly, suck it up with a syringe, adjust the speed of the syringe pump to 0.25mL / min, drop it into mixed solution 2, and continue stirring at 30°C for 8 hours. After the reaction, centrifuge, age in deionized water for 24 hours, centrifuge again, and reflux for 3 to 4 days....

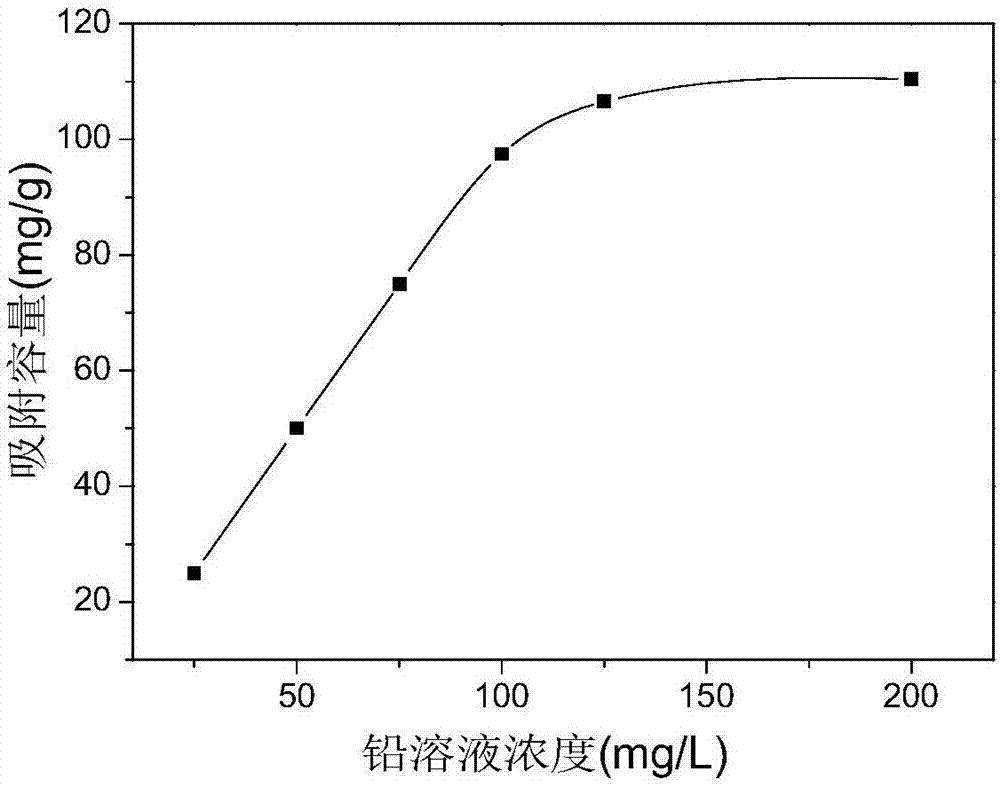

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com