Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46 results about "Sodium methylallyl sulfonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

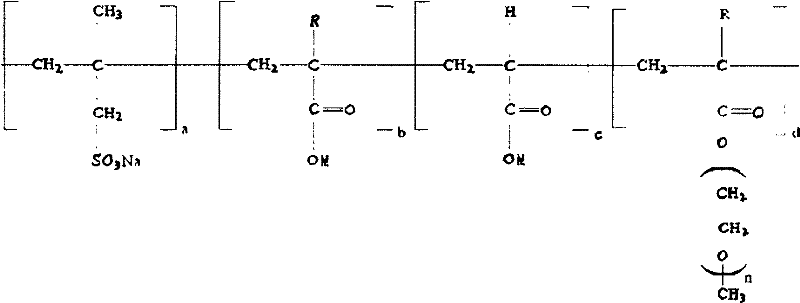

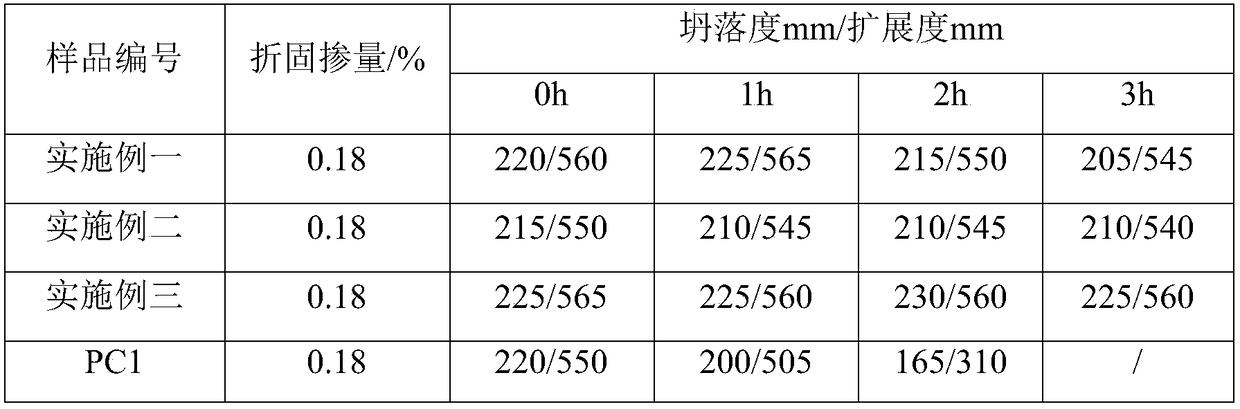

High-early-strength polycarboxylate water reducer and preparation method thereof

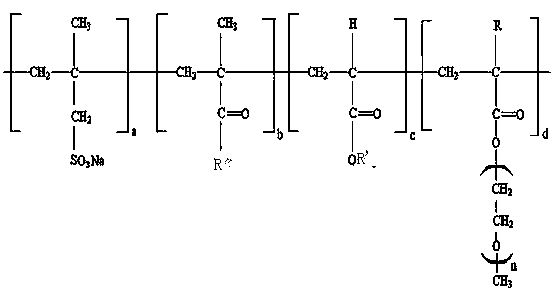

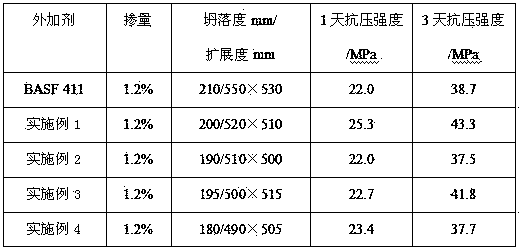

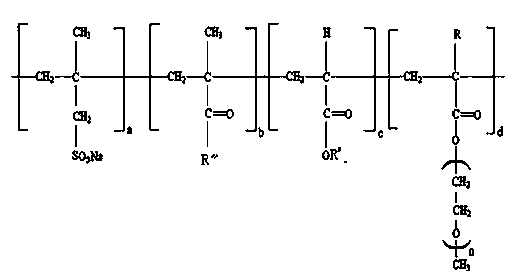

The invention discloses a high-early-strength polycarboxylate water reducer and a preparation method thereof. The high-early-strength polycarboxylate water reducer is a liquid, and has a solid content of 40%. The water reducer containing an esterified alcohol amine group, a sulfonic group, an amido group, a carboxyl group and a methylallyl polyoxyethylene ether side chain is prepared through polymerizing monomers comprising methylallyl polyoxyethylene ether, acrylamide, sodium methylallyl sulfonate, acrylic acid or methacrylic acid, acrylated amine and the like under the action of a molecular weight chain initiator and a chain transferring agent, and neutralizing. The high-early-strength polycarboxylate water reducer has the advantages of low alkali content, high water reduction rate, short coagulation time, suitableness for the construction of prefabricated components, pile tubes, duct pieces and bridges, simple production technology, easily controlled reaction condition, and no environmental pollution.

Owner:湖南加美乐素新材料股份有限公司

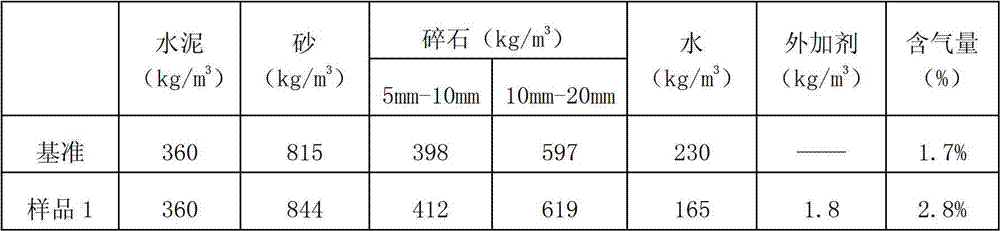

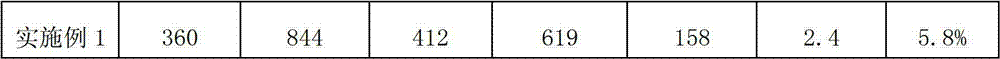

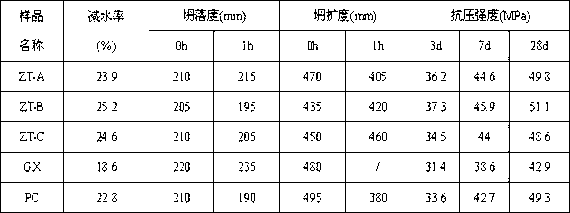

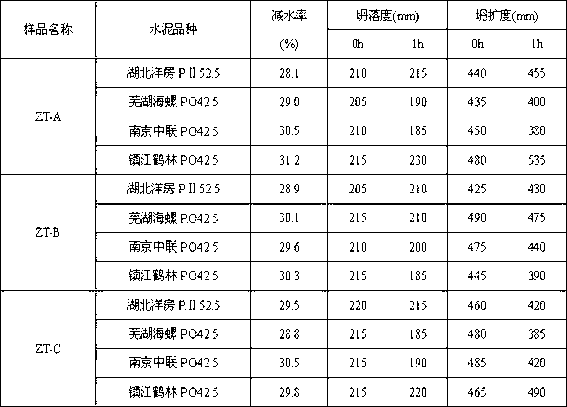

Air entraining type poly carboxylic acid high performance water reducing agent and preparation method thereof

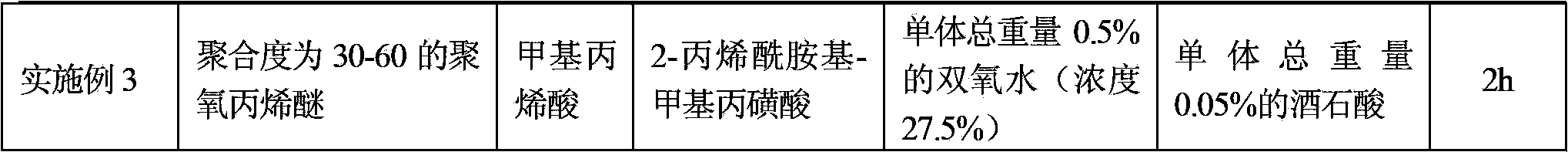

The present invention relates to an air entraining type poly carboxylic acid high performance water reducing agent and a preparation method thereof. According to the water reducing agent, 0.25 mol of a monomer methyl alkenyl polyoxyethelene, allyl polyoxyethelene ether or polyoxypropylene ether with a polymerization degree of 30-60, 0.70 mol of a monomer methacrylic acid or acrylic acid, 0.18 mol of a monomer sodium methylallyl sulfonate, acrylamide or 2-acrylamide-methyl propanesulfonic acid, 0.05 mol of a monomer styrene or ethyl acetate, an initiator agent and a chain transfer agent are subjected to a thermal insulation reaction for 4-5 h at a temperature of 48-52 DEG C by adopting deionized water as a reaction medium to carry out copolymerization to obtain a polymer with a molecular weight of 60000-80000, cooling is performed to a temperature of less than 40 DEG C, and a 40% sodium hydroxide solution is added to adjust the pH value to 6-8 to obtain the finished product. The air entraining type poly carboxylic acid high performance water reducing agent has a high water reducing rate, wherein the water reducing rate can be 30% when the water reduced solid doping amount is 0.2%, and the air entraining of concrete can be 5-7% when the water reduced solid doping amount is 0.2% under the premise of no other air entraining agent compounding.

Owner:LEPING LINGHANG NEW MATERIAL CO LTD

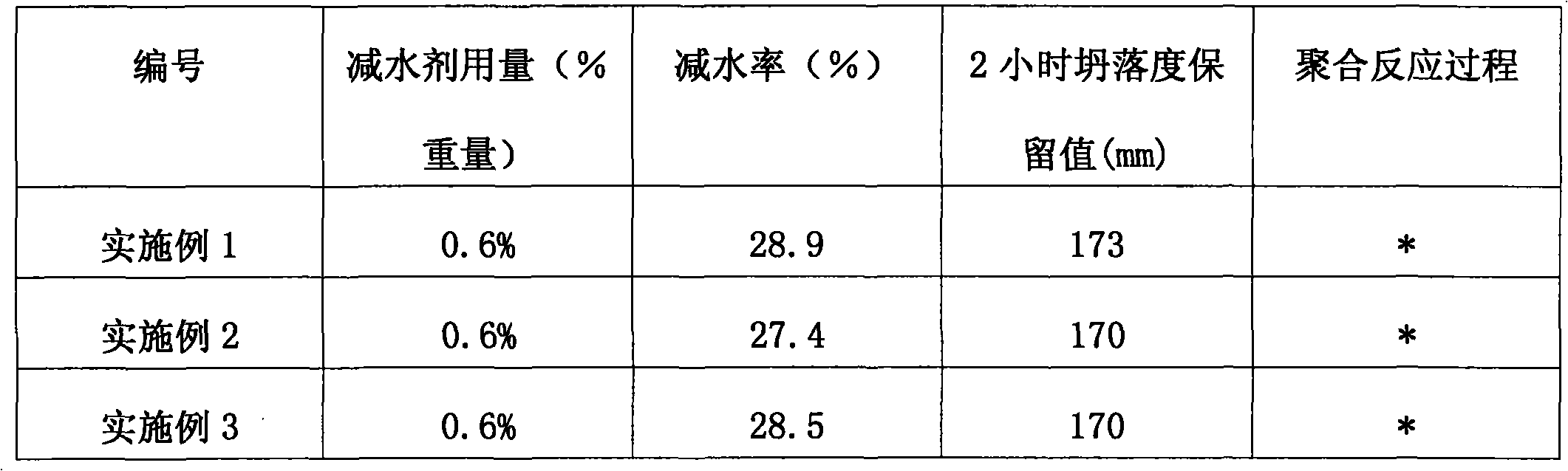

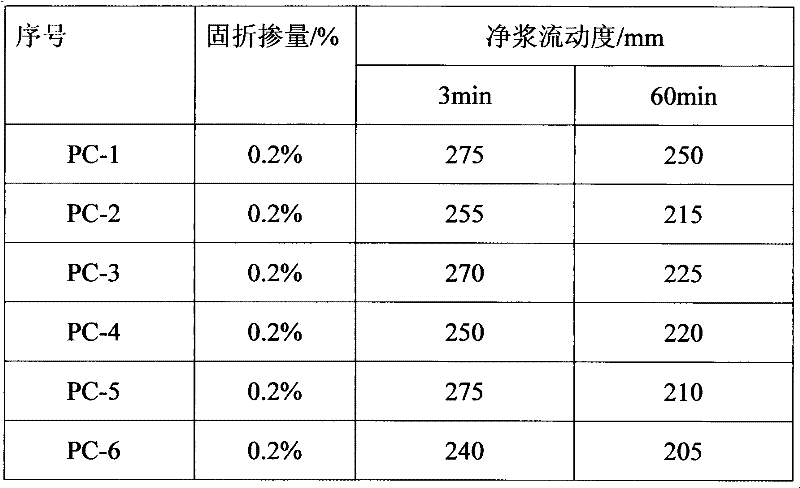

Star polycarboxylic-acid high-performance water reducing agent and preparation method thereof

The invention relates to a star polycarboxylic-acid high-performance water reducing agent which is prepared by the following steps: reacting 3.2-5% of maleic anhydride and 1.2-2% of glycerol to generate a star monomer, and polymerizing the start monomer with 26-32% of methylallylpolyether, 2.4-3% of acrylic acid, 0.4-0.8% of sodium methylallyl sulfonate and other monomers in a water solution under the actions of ammonium persulfate and mercaptopropionic acid. Compared with the prior art, the star polycarboxylic-acid high-performance water reducing agent provided by the invention overcomes thedefects of high doping amount, high slump loss, poor cement adaptability and the like in the existing water reducing agent. Besides, the invention does not use any organic solvent, is simple to operate, can easily control the reaction process, and is green and environment-friendly.

Owner:NANJING RUIDI HIGH TECH

Preparation method of mud-resistant type polycarboxylate superplasticizer

The invention relates to a preparation method of a mud-resistant type polycarboxylate superplasticizer. First, polyethylene glycol monomethyl ether and acrylic acid are used as raw materials and synthetized into polyethylene glycol monomethyl ether methyl acrylate. Then, the prepared polyethylene glycol monomethyl ether methyl acrylate is copolymerized with mixed liquid which is made from the acrylic acid and diacrylamide sodium dimethallyl sulphonate and mixed liquid which is made from ammonium persulfate and mercaptoethanol, alkaline compounds are added to regulate a pH value to 7-8 after reaction, and the mud-resistant type polycarboxylate superplasticizer is obtained. In the preparation method, technical parameters and conditions, such as raw material ratio, the used amount of chain transfer agents and initiators, copolymerization temperature, time and the like are determined. The reaction conditions are mild, the adopted equipment is simple, the equipment investment is small, the technology is reasonable, and the operation is simple and favorable for industrial production.

Owner:江苏汇迪建材有限公司

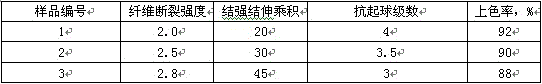

Preparation method of hydrophobically associating polymer inverse emulsion

The invention relates to a preparation method of hydrophobically associating polymer inverse emulsion and belongs to the technical field of water-soluble polymer synthesis. The preparation method comprises the following steps: changing the dissolution or interfacial property of a hydrophobic monomer by virtue of inclusion interaction cyclodextrin, and on this basis, copolymerizing the hydrophobic monomer with water-soluble monomers of acrylamide, sodium acrylate, 2-acrylamido-2-sodium methylallyl sulfonate and the like in inverse emulsion to obtain a hydrophobically associating polymer inverse emulsion product by taking potassium persulphate-tetramethylethylenediamine as a redox initiator system. The preparation method is cheap and easily-available in raw material and simple in process and after treatment; and meanwhile, the product is good in water-solubility, can be dissolved quickly, and has significant thickening property, shearing resistance and temperature and salt resistance, so that the product has an extensive application prospect in the fields of oil field, daily chemical, water treatment and the like.

Owner:陕西亘合石油科技有限公司

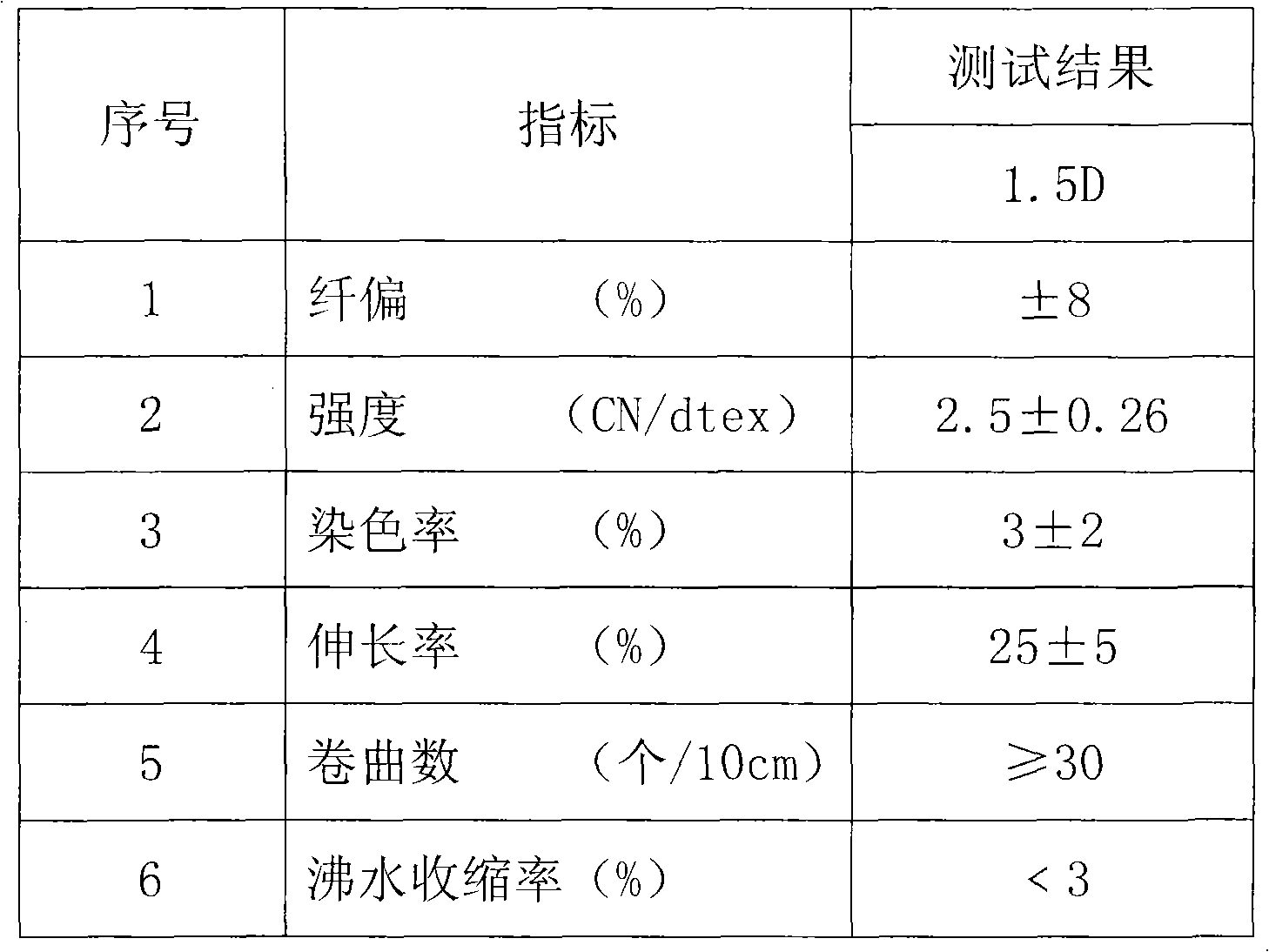

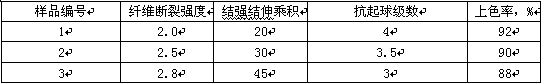

Preparation method of anti-pilling acrylic fiber

ActiveCN101818386AImprove dyeing effectSimple processFilament/thread formingMonocomponent synthetic polymer artificial filamentPolymer scienceAcrylonitrile

The invention discloses a preparation method of anti-pilling acrylic fiber, which comprises the steps: three monomers including 93.5-94.5wt% of acrylonitrile, 5.25-6.05wt% of vinyl acetate and 0.25-0.45% of sodium methylallyl sulfonate are mixed, the concentration of the mixture is regulated to 30-40wt%, water phase suspension polymerization reaction is continuously implemented; the polymer after reaction is terminated by means of chelation reaction and then steam-stripped to separate out unreacted monomer, the unreacted monomer is salt / moisture-removed by a washing filter, then subject to granulation molding and finally dried to result in powdery polymer, the powdery polymer is mixed with and dissolved in DMAC, the powdery polymer-dissolved DMAC is heated up, cooled and filtered to prepare spinning solution, and the spinning solution is subject to spinning, double diffused molding, water washing, oiling, drying and curling to include the draft multiple of 4-7, and the anti-pilling acrylic fiber with the level of anti-pilling performance larger than 4 and the strength of 0.6 + / - 0.2CN / dtex is obtained by shaping through shaping pressure of 120-200kPa.

Owner:JILIN QIFENG CHEM FIBER

Polyether carboxylic acid water reducer and preparation method thereof

The invention provides a polyether carboxylic acid water reducer and a preparation method thereof. The water reducer is prepared from the following components: polypropylene alcohol ether, maleic anhydride, sodium methylallyl sulfonate, acrylamide, 2-hydroxyethyl acrylate, initiator and water.

Owner:马清浩

Polycarboxylic-acid water reducing agent synthesized at normal temperature, and preparation method and application method thereof

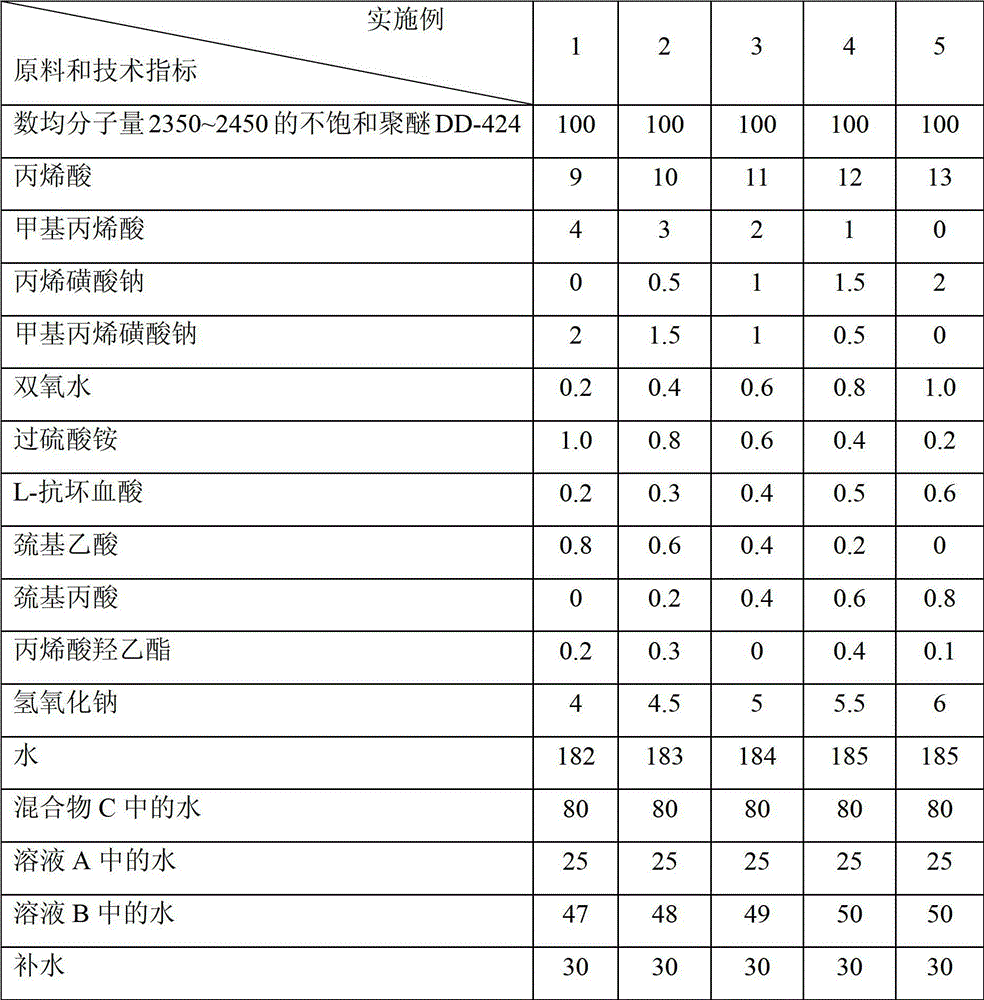

The invention discloses a polycarboxylic-acid water reducing agent synthesized at normal temperature, and a preparation method and application method thereof. The polycarboxylic-acid water reducing agent is prepared from the following components in parts by weight:100 parts of unsaturated polyether DD-424, 9-13 parts of acrylic acid, 0-4 parts of methacrylic acid, 0-2 parts of sodium allylsulfonate, 0-2 parts of sodium methylallyl sulfonate, 0.2-1 part of oxydol, 0.2-1 part of ammonium persulfate, 0.2-0.6 part of L-ascorbic acid, 0-0.8 part of thioglycolic acid, 0-0.8 part of mercaptopropionic acid, 0-0.4 part of 2-hydroxyethyl acrylate, 4-6 parts of sodium hydroxide and 182-185 parts of water. At most one of the methacrylic acid, sodium allylsulfonate and sodium methylallyl sulfonate is 0 part; and at most one of the thioglycolic acid, mercaptopropionic acid and 2-hydroxyethyl acrylate is 0 part. The product disclosed by the invention has the advantages of excellent properties, high water reducing rate and favorable slump retention; and the method is simple and convenient to operate, has the advantages of low energy consumption and no discharge of three wastes, and is beneficial to application to large-scale production.

Owner:SHANGHAI DONGDA CHEM

Method for synthesizing universal polycarboxylic water reducer

The invention relates to universal polycarboxylic water reducer and preparation method thereof. The universal polycarboxylic water reducer is in liquid state, and the solid content of the universal polycarboxylic water reducer is 40%. The universal polycarboxylic water reducer containing carboxyl, sulfonyl and polyoxyethylene side chains is prepared by aggregation of modified polyoxyethylene ether or polyoxypropylene ether with (methyl) acrylic acid or itaconic acid, sodium methylallyl sulfonate and the like under the action of chain initiator and chain transfer agent. The universal polycarboxylic water reducer prepared by the method is low in alkali content and high in water reducing rate. When the universal polycarboxylic water reducer is added into concrete by the cementing material weight ratio of 0.25-10%, operation of the concrete is laborsaving, and cement mixture has high liquidity, falling protection capacity and workability. The universal polycarboxylic water reducer and the preparation method thereof are simple in process, easy to control and free of environment pollution. The polycarboxylic water reducer which is used as an important component of high-performance concrete is widely applicable to pre-mixed and cast-in-situ concrete for various industrial and civil buildings, and especially has excellent performance in high-strength concrete.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

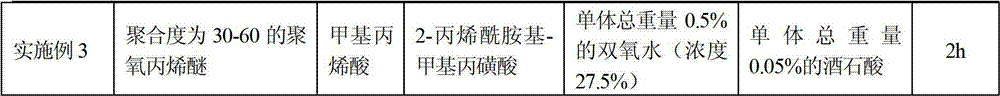

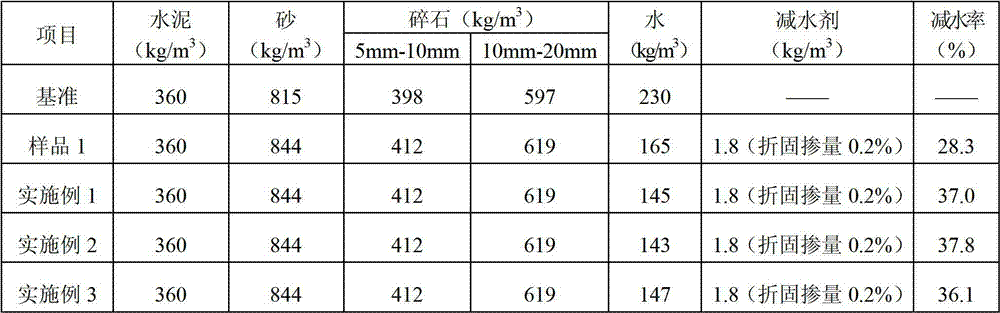

Poly carboxylic acid water reducing agent adopting tartaric acid as chain transfer agent, and preparation method thereof

ActiveCN102952243AHigh water reduction rateEliminate health hazardsPolymer scienceThermal insulation

The present invention relates to a poly carboxylic acid water reducing agent adopting tartaric acid as a chain transfer agent, and a preparation method thereof. The technical scheme comprises that: 0.14 mol of methyl alkenyl polyoxyethelene, allyl polyoxyethelene ether or polyoxypropylene ether with a polymerization degree of 30-60, 0.45 mol of methacrylic acid or acrylic acid, 0.02 mol of sodium methylallyl sulfonate, and 0.15 mol of 2-acrylamide-methyl propanesulfonic acid or acrylamide are subjected to a thermal insulation reaction for 4-5 h at a temperature of 58-62 DEG C in a deionized water medium under effects of an initiator agent and tartaric acid adopted as a chain transfer agent to carry out copolymerization to obtain a polymer with a molecular weight of 70000-120000, cooling is performed, and an alkali solution is added to carry out neutralization to obtain the finished product. According to the present invention, the high performance poly carboxylic acid water reducing agent is prepared, problems of high toxicity, easy flammability, easy explosion and the like can be avoided, and environment pollution and hazards on human body can be reduced.

Owner:天津世纪维鼎科技发展有限公司

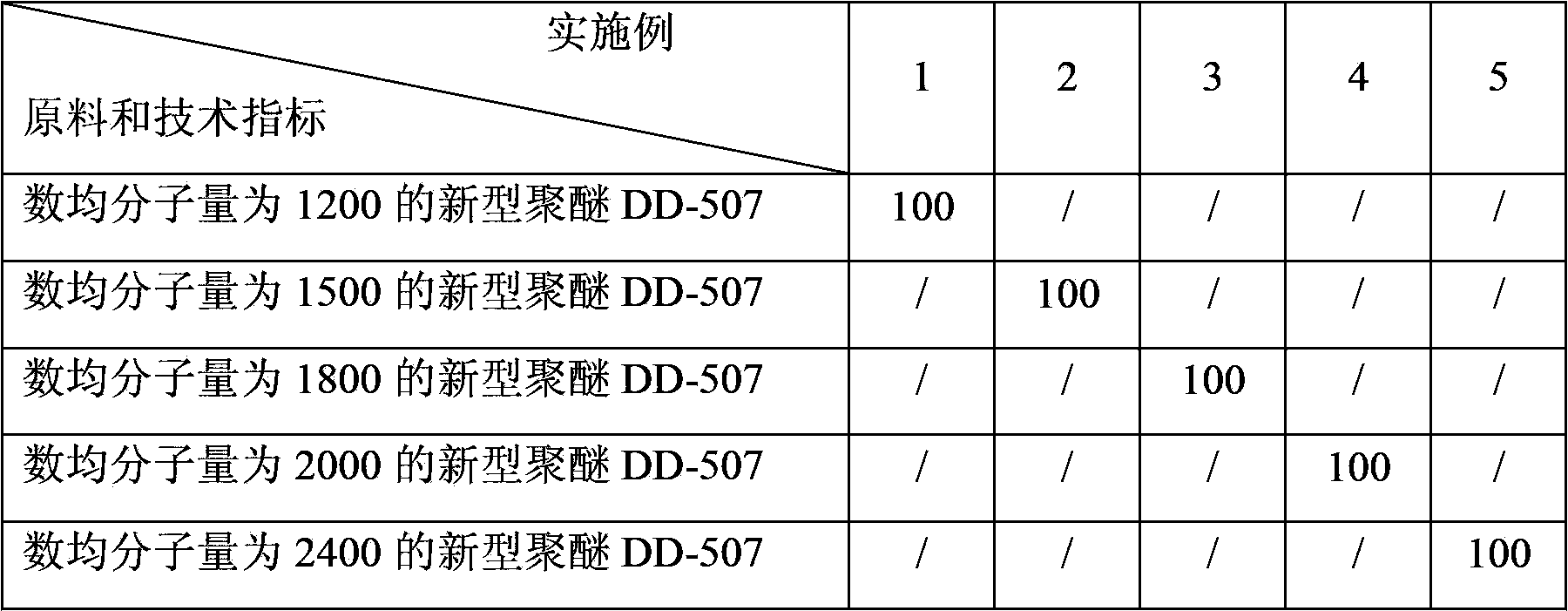

Polycarboxylate water reducer prepared by taking novel polyether as raw material, and preparation and application method thereof

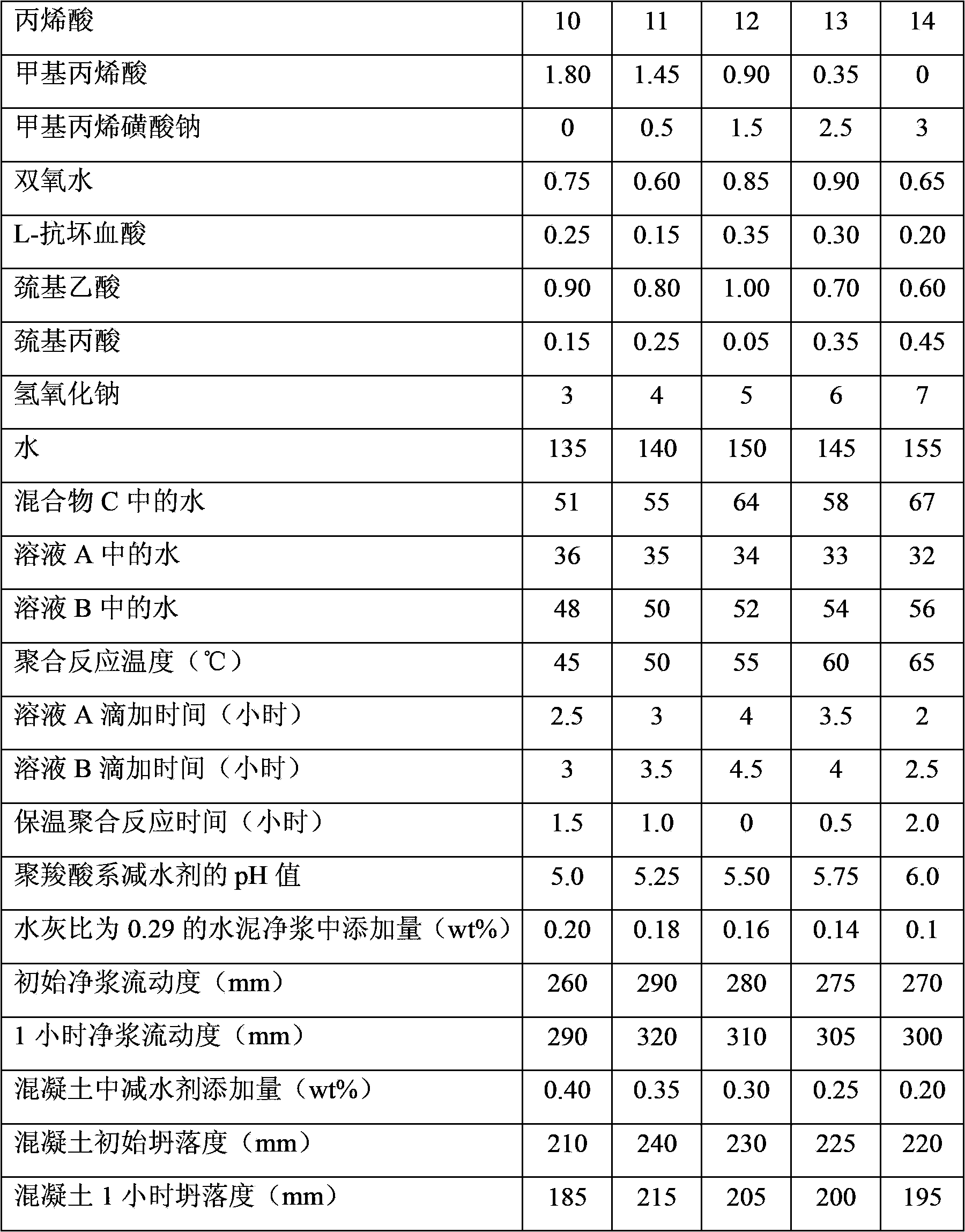

The invention discloses a polycarboxylate water reducer prepared by taking a novel polyether as a raw material, and a preparation method and an application method thereof. The polycarboxylate water reducer comprises the following components in parts by weight: 100 parts of novel polyetherDD-507, 10-14 parts of acrylic acid, 0-1.80 parts of methacrylic acid, 0-3 parts of sodium methylacrylsulfonate, 0.60-0.90 part of hydrogen peroxide, 0.15-0.35 part of L-ascorbic acid, 0.60-1.00 part of thioglycolic acid, 0.05-0.45 part of mercaptopropionic acid, 3-7 part of sodium hydroxide and 135-155 parts of water. The water reducer provided by the invention has the advantages of being high in water reducing rate, good in slump keeping property, low in raw material cost, good in properties, obtained by one-step polymerization and the like, and is applicable to various common engineering and important engineering such as high-speed rail, bridges, dams, airports and the like which are in different zones. The preparation method of the water reducer is simple in technology, convenient to operate and beneficial for large-scale industrialized production.

Owner:SHANGHAI DONGDA CHEM

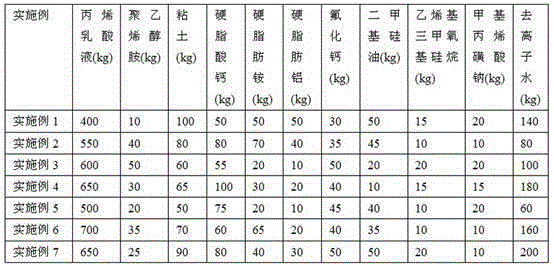

Building waterproof agent

The present invention provides a safe and non-toxic building waterproof agent, and belongs to the field of building additives. The building waterproof agent of the present invention comprises, by weight, 40-70 parts of an acrylic acid emulsion, 1-5 parts of polyvinyl alcohol amine, 5-10 parts of clay, 5-10 parts of calcium stearate, 2-7 parts of ammonium stearate, 1-5 parts of aluminum stearate, 3-5 parts of calcium fluoride, 1-5 parts of dimethyl silicone oil, 1-2 parts of vinyltrimethoxysilane, 1-2 parts of sodium methyl acryl sulfonate, and 6-20 parts of deionized water. The preparation method comprises: uniformly mixingan an acrylic acid emulsion, polyvinyl alcohol amine, clay, calcium stearate, ammonium stearate, aluminum stearate, calcium fluoride and sodium methyl acryl sulfonate to obtain a mixture, heating to a temperature of 30-50 DEG C, stirring dimethyl silicone oil, vinyltrimethoxysilane and deionized water to obtain a mixed material, and slowly adding the mixed material to the mixture. The building waterproof agent of the present invention has characteristics of inexpensive raw materials, simple preparation method and significant waterproof effect.

Owner:QINGDAO WINCHANCE TECH

High-slump-retaining early-strength polycarboxylic acid high-performance water reducing agent and preparation method thereof

InactiveCN109265621AHigh water reduction rateImprove early strengthSodium methylallyl sulfonateUltimate tensile strength

The invention discloses a high-slump-retaining early-strength polycarboxylic acid high-performance water reducing agent, which comprises 100 parts of isopentenyl polyoxyethylene ether, 8-13 parts of acrylic acid, 9-14 parts of hydroxyethyl acrylate, 0.4-1.2 parts of sodium methylallyl sulfonate, 0.5-1.5 parts of 2-acrylamide-2-methyl propanesulfonic acid, 1.4-2.5 parts of acrylamide, 0.5-1 part ofhydrogen peroxide, 0.1-0.22 part of ascorbic acid, 0.4-0.7 part of a chain transfer agent, and 140-180 parts of water. The invention further discloses the preparation method of the high-slump-retaining early-strength polycarboxylic acid high-performance water reducing agent. According to the present invention, with the high-slump-retaining early-strength polycarboxylic acid high-performance waterreducing agent, the concrete mixture can have a certain slump retention ability at the initial stage, the concrete can have characteristics of short setting time and rapid early strength developmentafter the slump retention stage, the late strength cannot be affected, the turnover rate of the template can be improved, the construction progress of the project can be accelerated, and no pollutionis generated during the preparation.

Owner:四川恒泽建材有限公司

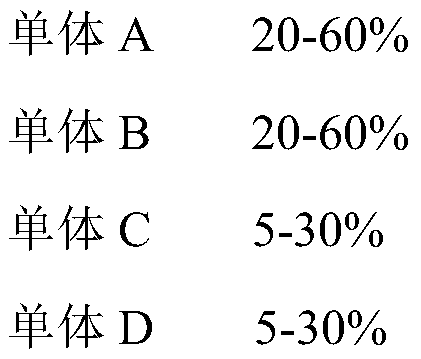

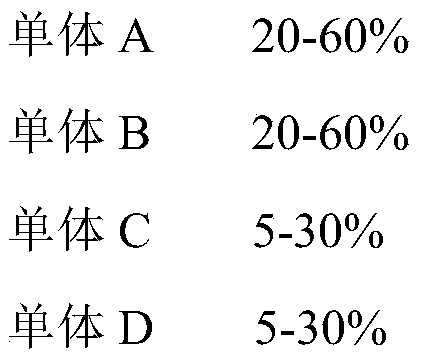

Quadripolymer and preparation method

The invention discloses a quadripolymer and a preparation method. The quadripolymer is prepared by polymerizing a monomer A, a monomer B, a monomer C and a monomer D, wherein the monomer A is sodium vinylbenzenesulfonate, sodium allylsulfonate, 3-allyloxy-2-hydroxyl-1-propylsulfonate, 2-acryloyloxy-2-methylpropane sulfonic acid, 2-acrylamide-2-methylallyl sulfonic acid or sodium methylallyl sulfonate; the monomer B is N,N-dimethacrylamide, N,N-diethyl acrylamide, acrylamide or N-vinyl pyrrolidone; the monomer C is acrylic acid, methacrylic acid or itaconic acid; and the monomer D is methacrylatoethyl trimethyl ammonium chloride, dimethyldiallyl ammonium chloride or acryloyloxyethyltrimethyl ammonium chloride. The quadripolymer disclosed by the invention is a water-soluble polymer with a good development prospect; and due to the properties such as delayed coagulation, thickening and surface activity, the quadripolymer can be applied to chemical fiber, plastics, printing and dyeing, coating, surfactants, antistatic agents, ceramics, washing assistants, petroleum assistants, concrete and mortar assistants.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

Heat-source-free slow-release polycarboxylic acid high-performance water reducing agent and preparation method thereof

The invention discloses a heat-source-free slow-release polycarboxylic acid high-performance water reducing agent, which comprises: 100 parts of isopentenyl polyoxyethylene ether, 6-10 parts of acrylic acid, 9-13 parts of hydroxyethyl acrylate, 5-9 parts of hydroxypropyl acrylate, 1-2 parts of 2-acrylamide-2-methyl propanesulfonic acid, 1-2 parts of sodium methylallyl sulfonate, 0.5-1.5 parts of sodium phosphite, 0.5-1 part of ammonium persulfate, 1-2 parts hydrogen peroxide, and 140-180 parts of water. The invention further discloses a preparation method of the heat-source-free slow-release polycarboxylic acid high-performance water reducing agent. According to the present invention, the preparation method has characteristics of simple production process and low cost, the obtained producthas advantages of high initial water reduction rate and significant sustained release effect, can maintain concrete at a loss-free state for 1-3 h, can effectively solve the problem of rapid slump loss of concrete, and can save the energy consumption.

Owner:四川恒泽建材有限公司

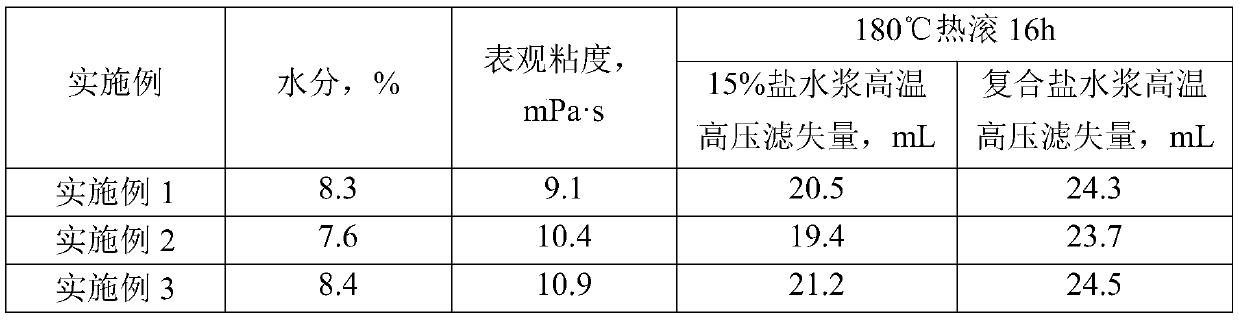

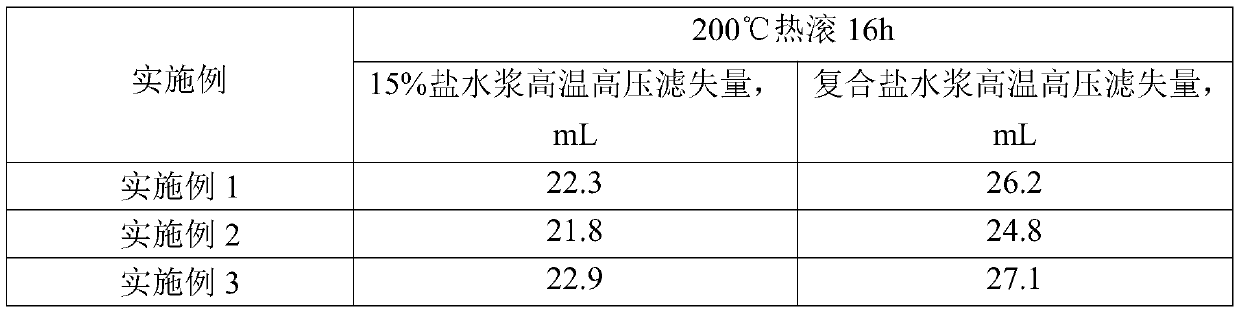

High-temperature salt-resistant fluid loss additive modified gum resin for drilling fluids

ActiveCN110724503AGood filter loss reduction effectControl fluid lossDrilling compositionMeth-Polyvinyl alcohol

The invention discloses a high-temperature salt-resistant fluid loss additive modified gum resin for drilling fluids, wherein the resin is prepared from the following raw materials: 220-240 parts of clear water, 30-40 parts of sodium methylallyl sulfonate, 10-15 parts of N,N-dimethylacrylamide, 0.5-1.0 part of a temperature-resistant monomer, 20-30 parts of methacryloyloxyethyl trimethyl ammoniumchloride, 3-5 parts of a chelating agent, 0.5-1.0 part of an initiator, 25-35 parts of a gum resin, 8-10 parts of a 40% sodium hydroxide solution, 5-10 parts of propylene oxide and 10-20 parts of an additive, wherein the temperature-resistant monomer is 4-vinyl guaiacol, the chelating agent is sodium citrate, the additive is polyvinyl alcohol powder, and the initiator is a combination of an azo initiator and a redox initiator. According to the invention, the high-temperature salt-resistant fluid loss additive modified gum resin has good temperature resistance, good salt resistance and environmental protection performance, solves the problems of poor temperature resistance, poor salt resistance, high production cost and complex process of the fluid loss additive in the existing drilling process, has strong biodegradability, and effectively reduces the pollution to reservoirs and environments.

Owner:石家庄华莱鼎盛科技有限公司

Ether amphoteric polycarboxylic acid based dispersant used for wet grinding of wet-discharged fly ash and preparation method of dispersant

InactiveCN107602774AImprove liquidityImprove homogeneityTransportation and packagingMixingPhosphoric acidCarboxylic acid

The invention provides an ether amphoteric polycarboxylic acid based dispersant used for wet grinding of wet-discharged fly ash and a preparation method of the dispersant. The ether amphoteric polycarboxylic acid based dispersant comprises the following components besides water, in parts by weight, 330-350 parts of a polyether macromonomer, 0.5-3.0 parts of sodium methylallyl sulfonate, 1.5-5.0 parts of hydrogen peroxide, 0.5-1.5 parts of ammonium persulfate, 100.8-153 parts of an initiator, 65.5-112 parts of a small monomer solution, 0.5-2.0 parts of sodium hypophosphite monohydrate, and 5-15parts of liquid-state sodium hydroxide. The method comprises the following steps: 1, performing adding for a first time; 2, controlling a temperature; 3, performing adding for a second time; and 4, performing a curing process. The ether amphoteric polycarboxylic acid based dispersant disclosed by the invention adopts multi-element compounding of a quaternary amine, a quaternary phosphine, a sulfonic acid group, a phosphoric acid group and a carboxylic acid group, and adopts allyl polyoxyethylene ether, methyl allyl polyoxyethylene ether and vinyl butyl ether polyoxyethylene ether to provide steric hindrance effects, wherein the allyl polyoxyethylene ether, the methyl allyl polyoxyethylene ether and the vinyl butyl ether polyoxyethylene ether separately have a molecular weight of 1200-1500, targeted adsorption is performed on different components in the fly ash, the process is simple, the working time is relatively short, and the production is simple and convenient.

Owner:HUBEI UNIV OF TECH

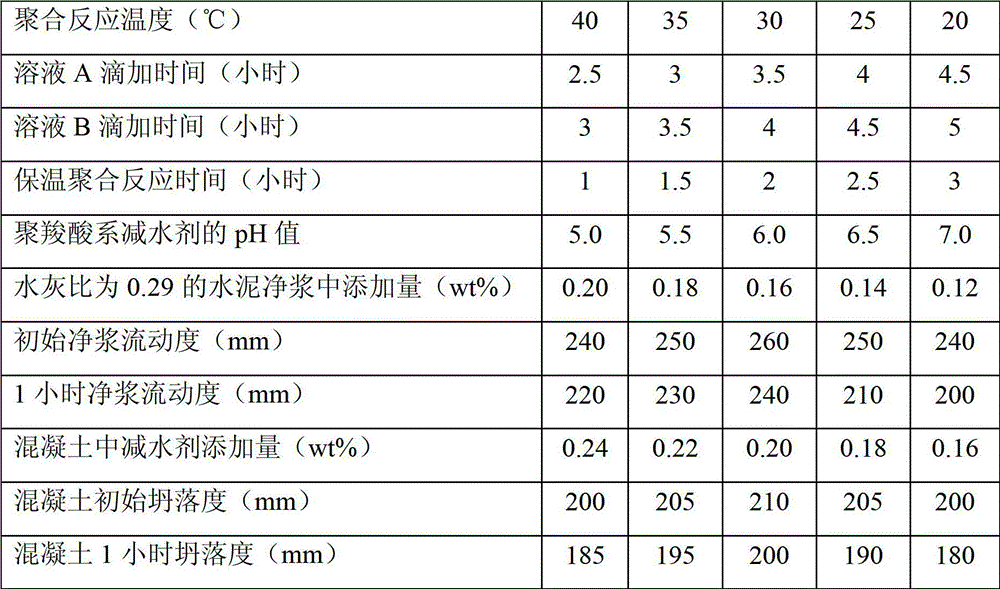

Method for preparing anti-pilling acrylic fibers from acrylonitrile and vinyl acetate

ActiveCN103668532AHas anti-pilling propertiesWet spinning methodsMonocomponent synthetic polymer artificial filamentHigh fracturePolymer science

The invention relates to a method for preparing anti-pilling acrylic fibers from acrylonitrile and vinyl acetate, which comprises the following steps: (1) dissolving a polyacrylonitrile polymer in a 40-60% sodium thiocyanate water solution through a dissolver, wherein in the polyacrylonitrile polymer, the acrylonitrile content is 85-95%, the vinyl acetate content is 5-10%, the sodium methylallyl sulfonate content is less than 1%, and the viscosity-average molecular weight of polyacrylonitrile is 45-65 thousand; (2) after debubbling and filtering a spinning solution, metering through a spinning metering pump, and extruding through spinneret orifices; (3) extruding into a coagulation bath through a spinneret plate to form nascent fibers; (4) sending the fibers into a secondary coagulation bath to form, and carrying out cold drawing, water washing and hot drawing, wherein the total drawing magnification is less than or equal to 12; (5) carrying out hot drying and compaction treatment on the fibers; and (6) thermoforming the fibers. The acrylic fibers prepared by the method have the advantages of high fracture resistance and high pilling resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ternary polymer oil-displacing agent, and its preparing method and use

InactiveCN1247735CHigh viscosityGood temperature and salt resistanceDrilling compositionSulfonatePolymer science

The invention relates to a kind of ternary polymer oil displacement agent and its manufacturing method and usage. The polymer is produced by polymerizing the three constituents of a) 60-99.96% (weight) acrylamide, b) 0.006-25% (weight) methyl propylene sodium sulfonate, c) 0.01-15% (weight) N, N-dimethyl acrylamide, in which the weight percent is calculated by gross amount of the added monomer. The weigh content of sulfonation radical in the polymer is 0.5-22.7%; the constituent b), methyl propylene sodium sulfonate, is acquired by reaction of methyl allyl-chloride and sodium sulfite, with PH controlled in 8.5-10.0. The ternary polymer oil displacement agent in the invention can improve heat-resistance and salt-proof properties of oil displacement agent efficiently in oil recovery process, so it has extensive economic benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing high-strength frost-resistant concrete

InactiveCN107417189AStrictly control the water-cement ratioImprove compactnessSodium BentonitePolyethylene glycol

The invention discloses a method for preparing high-strength frost-resistant concrete. The high-strength frost-resistant concrete is prepared by using acrylic acid, mercapto acetic acid, acryloyloxyethyl trimethyl ammonium chloride, ascorbic acid,allyl polyethenoxy ether, ammonium persulphate, maleic anhydride, allyl polyethylene glycol, sodium p-toluenesulfonate, methyl methacrylate, sodium methylallyl sulfonate and acrylamide, performing hydrogen peroxide alkaline treatment and doping an amphoteric dispersant and an activating agent in HZSM-5 / bentonite nano-material. The frost-resistant concrete prepared from the amphoteric dispersant and activating agent doped HZSM-5 / bentonite compound nano-material has the advantages of easily available preparation materials, low cost, strong frost resistance, good stability and long service life.

Owner:新沂市中诺新材料科技有限公司

High-water-reducing high-adaptability polycarboxylate superplasticizer and preparation method thereof

ActiveCN111808244AImprove adaptabilityBarrier adsorptionSolid waste managementMeth-Vinyltriethoxysilane

Owner:湖南加美乐素新材料股份有限公司

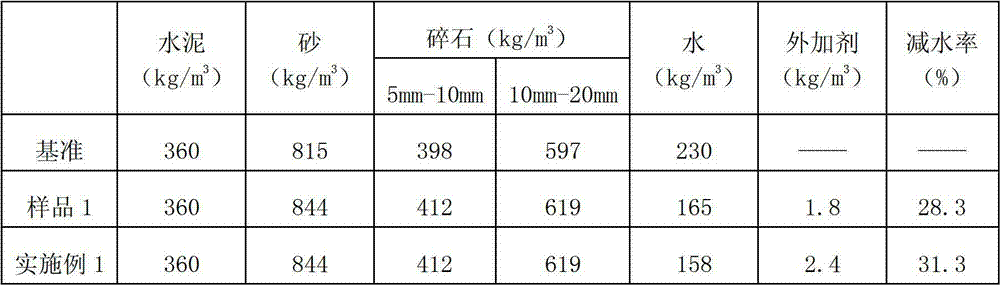

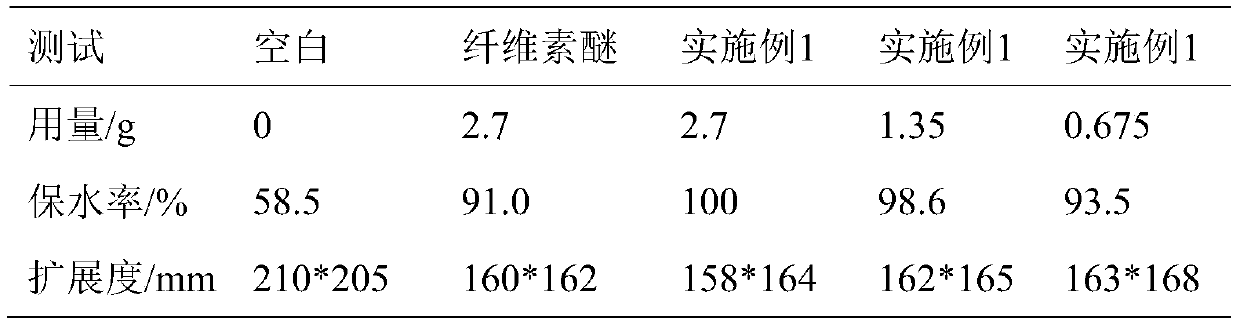

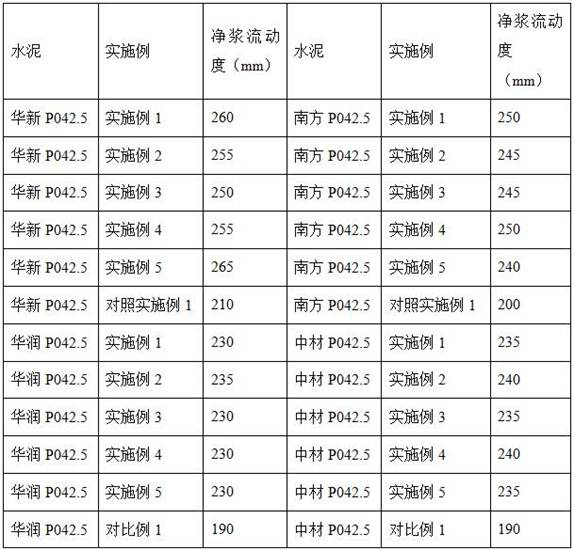

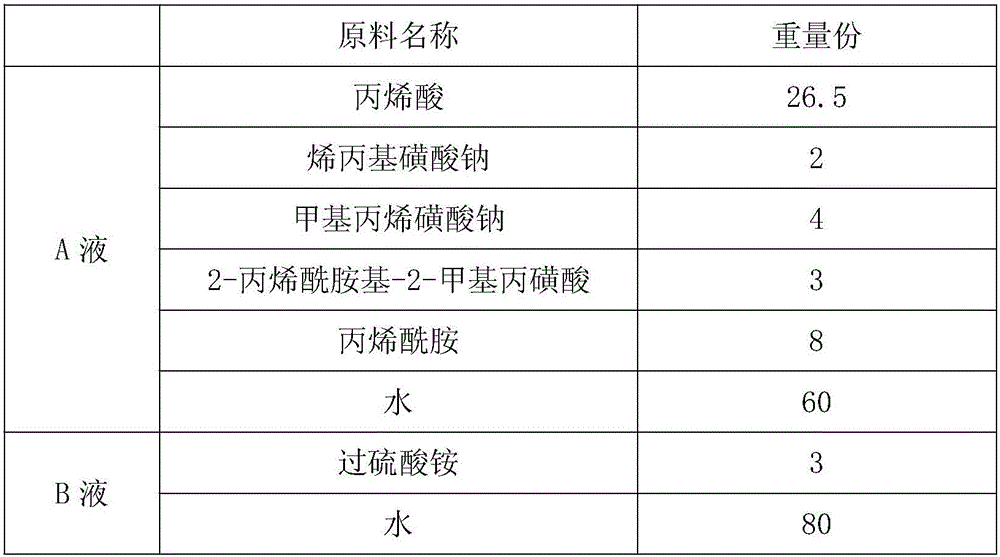

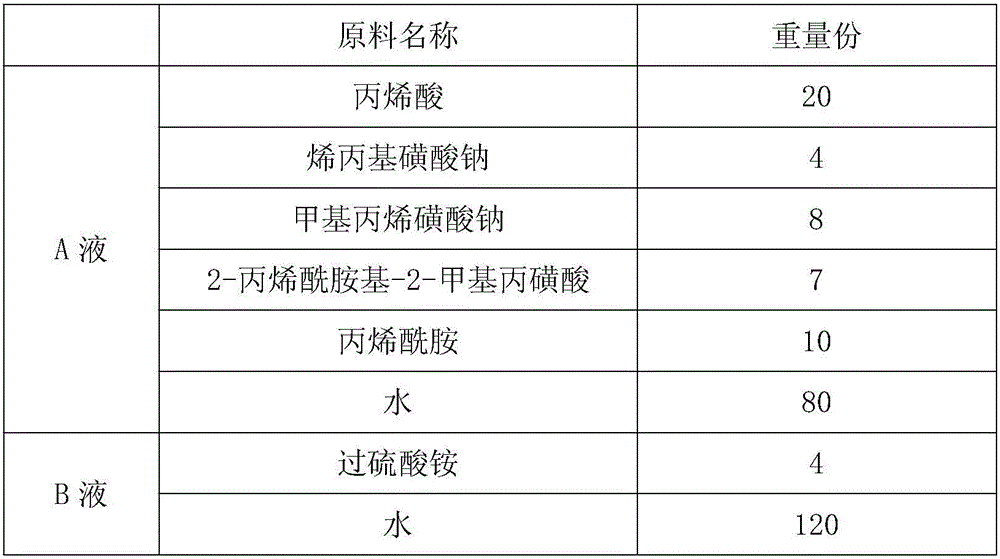

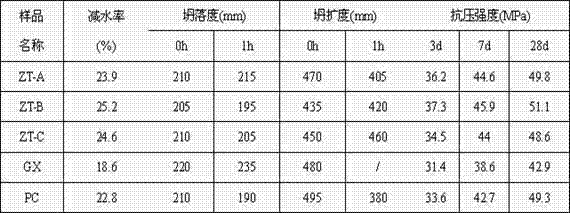

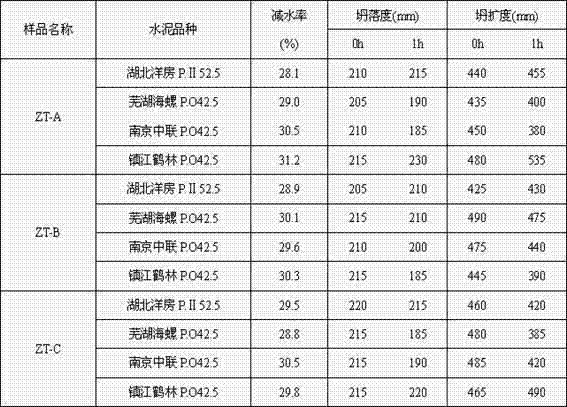

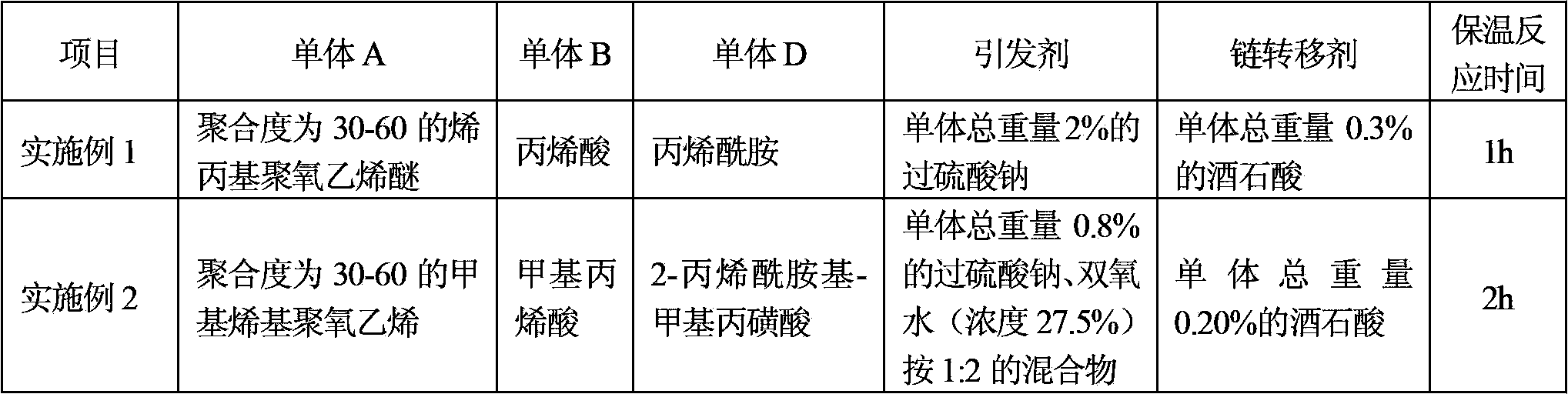

Early strength polycarboxylic high performance water-reducing agent and preparation method thereof

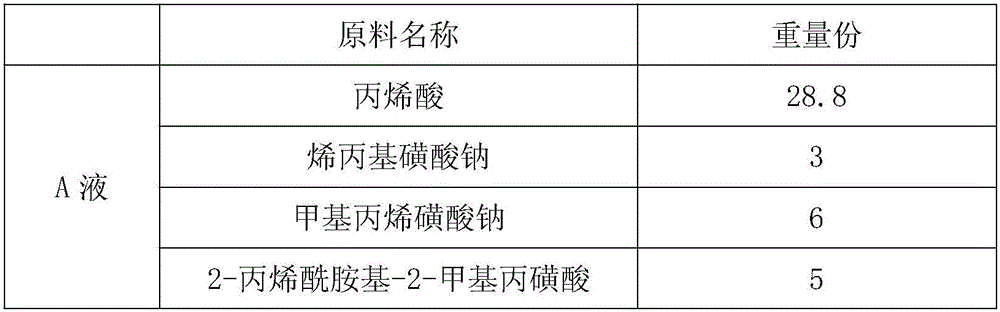

The invention discloses an early strength polycarboxylic high performance water-reducing agent and a preparation method thereof. The water-reducing agent comprises the following raw materials in parts by weight: 200-400 parts of methyl allyl polyethenoxy ether, 200-300 parts of softened water, 115-164 parts of liquid A and 86-137 parts of liquid B, wherein the liquid A comprises acrylic acid, sodium allysulfonate, sodium methylallyl sulfonate, 2-acrylamido-2-methylpropane sulfonic acid, acrylamide and water; the liquid B comprises ammonium persulfate and water. The obtained water-reducing agent has higher water-reducing rate, more importantly, the product has excellent early strength property, can be free of steam curing in construction of many projects and achieve excellent early strength effect and is especially suitable for special concrete construction of precast pipe sections for subways, precast members, and the like. The preparation method of the early strength polycarboxylic high performance water-reducing agent provided by the invention is simple to operate, is convenient in preparation and low in cost and is suitable for large-scale industrial production.

Owner:四川恒泽建材有限公司

Star polycarboxylic-acid high-performance water reducing agent and preparation method thereof

The invention relates to a star polycarboxylic-acid high-performance water reducing agent which is prepared by the following steps: reacting 3.2-5% of maleic anhydride and 1.2-2% of glycerol to generate a star monomer, and polymerizing the start monomer with 26-32% of methylallylpolyether, 2.4-3% of acrylic acid, 0.4-0.8% of sodium methylallyl sulfonate and other monomers in a water solution under the actions of ammonium persulfate and mercaptopropionic acid. Compared with the prior art, the star polycarboxylic-acid high-performance water reducing agent provided by the invention overcomes thedefects of high doping amount, high slump loss, poor cement adaptability and the like in the existing water reducing agent. Besides, the invention does not use any organic solvent, is simple to operate, can easily control the reaction process, and is green and environment-friendly.

Owner:NANJING RUIDI HIGH TECH

Polycarboxylic acid water reducer and synthesis method thereof

The invention discloses a synthesis method of a polycarboxylic acid water reducer. The synthesis method comprises the following steps: S1, preparing raw materials; S2, preparing each raw material intoa solution with a corresponding concentration; S3, uniformly mixing a TPEG dissolved solution, a sodium methylallyl sulfonate dissolved solution, an ammonium persulfate dissolved solution, a polyethylene allyl propionate macro-monomer dissolved solution and a thioglycolic acid dissolved solution according to the following volume ratio: 4 to 5 parts of the TPEG dissolved solution, 1 to 2 parts ofthe sodium methylallyl sulfonate dissolved solution, 1 to 2 parts of the ammonium persulfate dissolved solution and 2 to 4 parts of the polyethylene allyl propionate macro-monomer dissolved solution;then uniformly stirring and raising the temperature to 70 to 75 DEG C; then dropwise adding an acrylic acid solution and a hydrogen peroxide solution into a mixed solution, and finishing dropwise adding within 3 to 4h; S4, dropwise adding the thioglycolic acid dissolved solution into the solution of S3, wherein the dropwise adding amount is 0.05 to 0.1 percent of the total solution volume in S3, and finishing dropwise adding within 3 to 4h; then reacting at 70 to 75 DEG C for 3 to 5h. The invention further discloses the polycarboxylic acid water reducer prepared by adopting the synthesis method.

Owner:山西中铁铁诚建材科技有限公司

Poly carboxylic acid water reducing agent adopting tartaric acid as chain transfer agent, and preparation method thereof

ActiveCN102952243BHigh water reduction rateEliminate health hazardsPolymer scienceThermal insulation

The present invention relates to a poly carboxylic acid water reducing agent adopting tartaric acid as a chain transfer agent, and a preparation method thereof. The technical scheme comprises that: 0.14 mol of methyl alkenyl polyoxyethelene, allyl polyoxyethelene ether or polyoxypropylene ether with a polymerization degree of 30-60, 0.45 mol of methacrylic acid or acrylic acid, 0.02 mol of sodium methylallyl sulfonate, and 0.15 mol of 2-acrylamide-methyl propanesulfonic acid or acrylamide are subjected to a thermal insulation reaction for 4-5 h at a temperature of 58-62 DEG C in a deionized water medium under effects of an initiator agent and tartaric acid adopted as a chain transfer agent to carry out copolymerization to obtain a polymer with a molecular weight of 70000-120000, cooling is performed, and an alkali solution is added to carry out neutralization to obtain the finished product. According to the present invention, the high performance poly carboxylic acid water reducing agent is prepared, problems of high toxicity, easy flammability, easy explosion and the like can be avoided, and environment pollution and hazards on human body can be reduced.

Owner:天津世纪维鼎科技发展有限公司

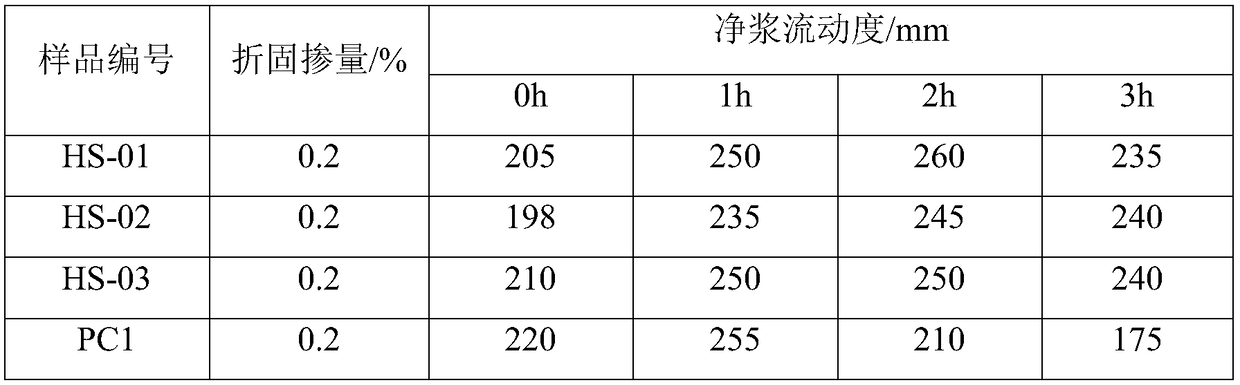

Viscosity-reducing water reducing agent and preparation method and application thereof

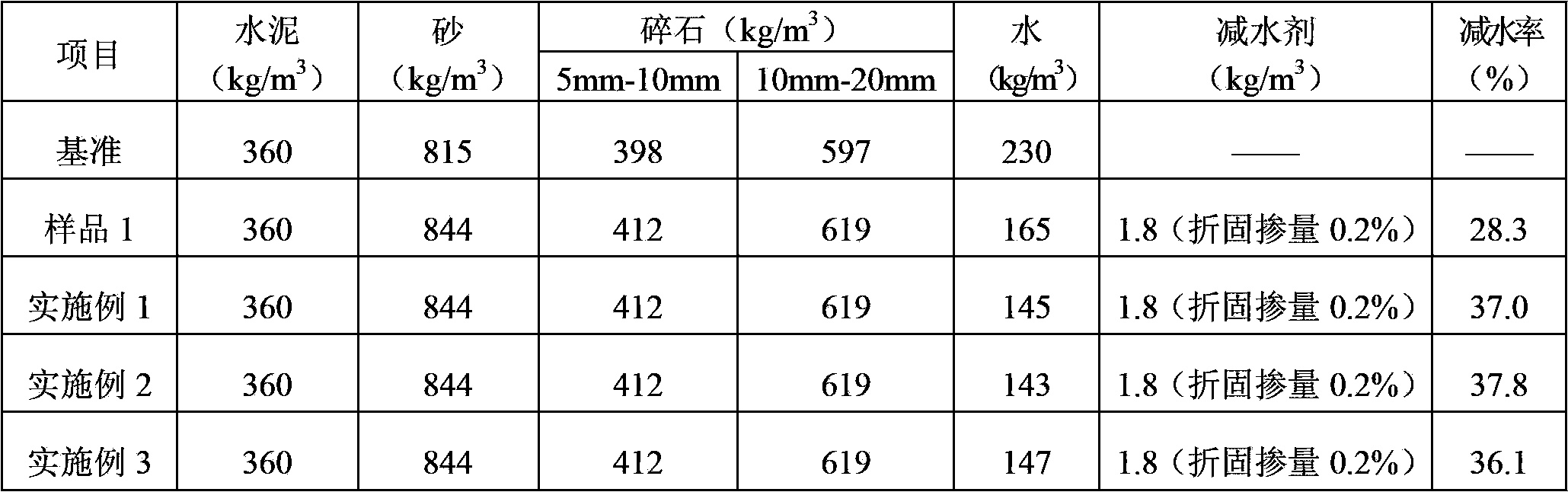

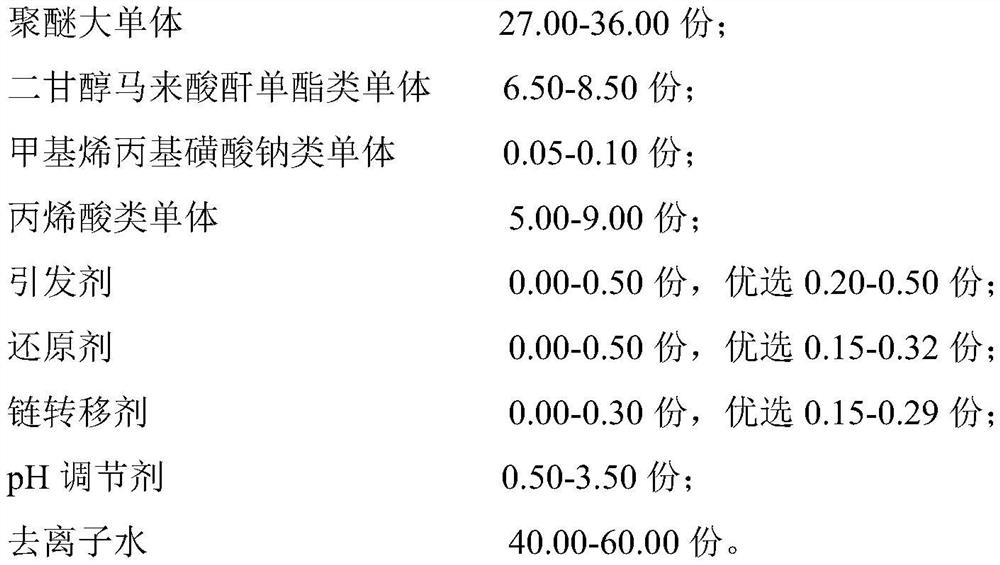

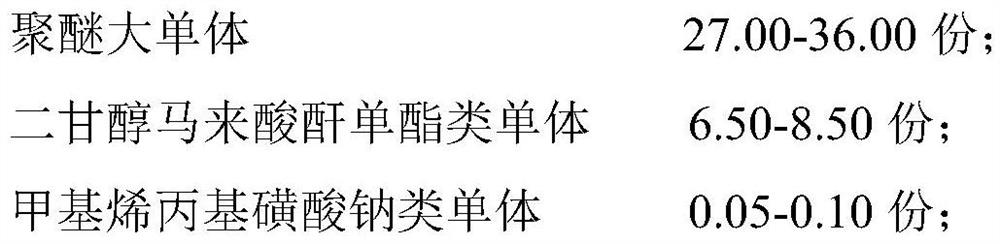

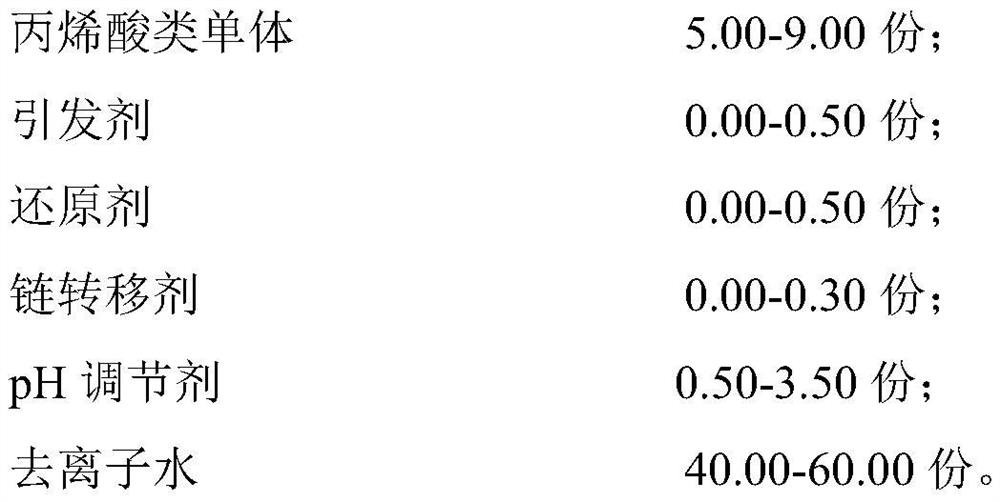

The invention relates to a composition for preparing a viscosity-reducing water reducing agent. The composition comprises a polyether macromonomer, a diethylene glycol maleic anhydride monoester monomer, a sodium methylallyl sulfonate monomer, an acrylic acid monomer, and an optional initiator, a reducing agent and a chain transfer agent. According to the novel viscosity-reducing water reducing agent, the polycarboxylic acid water reducing agent with a viscosity reducing function is synthesized in a water solution through a copolymerization reaction of an oxidation-reduction initiating system under the action of initiation of an oxidation-reduction system, a chain transfer agent and the like, and the water reducing agent is applied to concrete engineering and aims at adjusting the thickness of a water film layer of the viscosity-reducing water reducing agent on the surface of cement particles, and realizing a lubricating effect, and thus the viscosity of the concrete is reduced, the working performance of the concrete is improved, and the problems of high viscosity and low flow rate of high-grade concrete are solved.

Owner:SHANXI SUNWAY INTION TRADE CO LTD

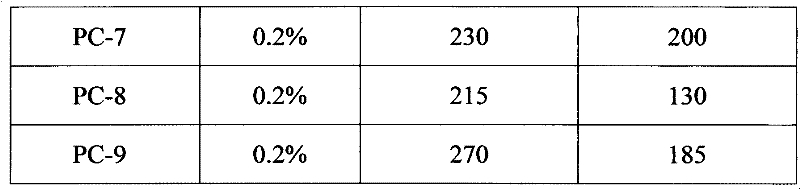

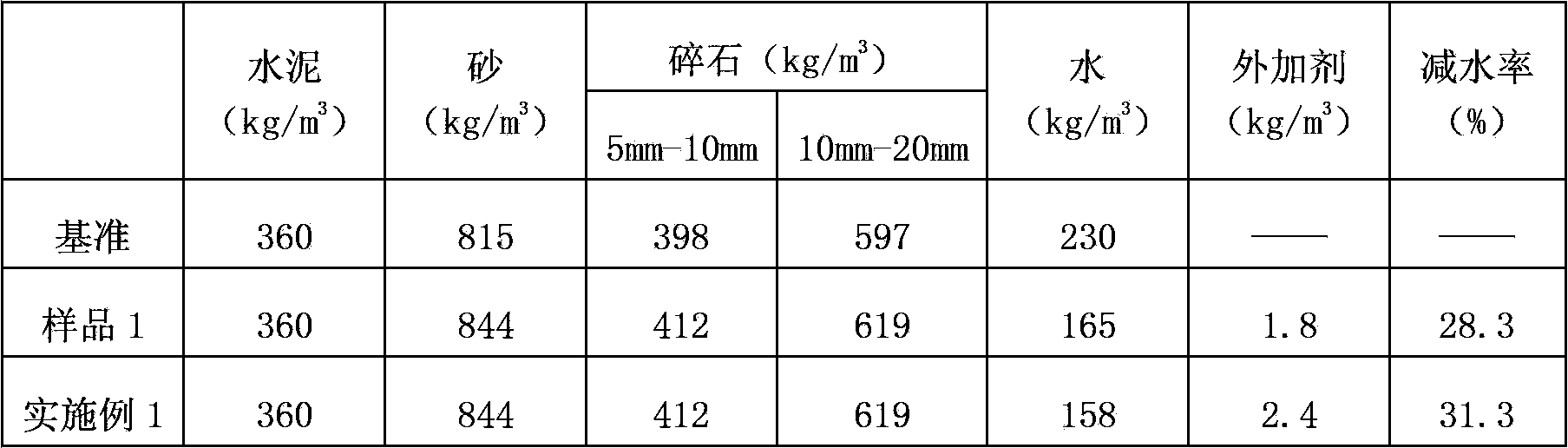

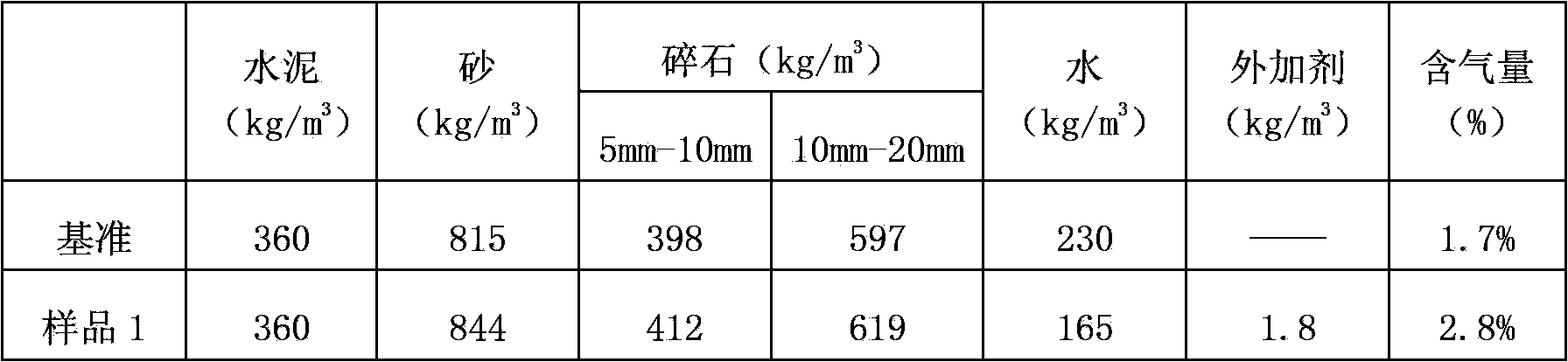

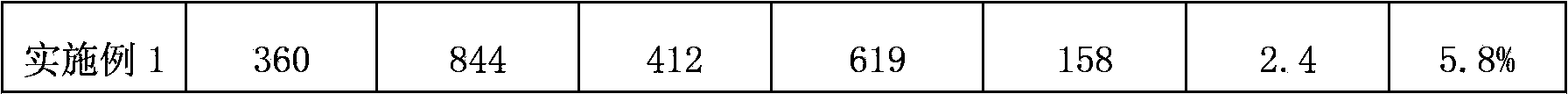

Air entraining type poly carboxylic acid high performance water reducing agent and preparation method thereof

The present invention relates to an air entraining type poly carboxylic acid high performance water reducing agent and a preparation method thereof. According to the water reducing agent, 0.25 mol of a monomer methyl alkenyl polyoxyethelene, allyl polyoxyethelene ether or polyoxypropylene ether with a polymerization degree of 30-60, 0.70 mol of a monomer methacrylic acid or acrylic acid, 0.18 mol of a monomer sodium methylallyl sulfonate, acrylamide or 2-acrylamide-methyl propanesulfonic acid, 0.05 mol of a monomer styrene or ethyl acetate, an initiator agent and a chain transfer agent are subjected to a thermal insulation reaction for 4-5 h at a temperature of 48-52 DEG C by adopting deionized water as a reaction medium to carry out copolymerization to obtain a polymer with a molecular weight of 60000-80000, cooling is performed to a temperature of less than 40 DEG C, and a 40% sodium hydroxide solution is added to adjust the pH value to 6-8 to obtain the finished product. The air entraining type poly carboxylic acid high performance water reducing agent has a high water reducing rate, wherein the water reducing rate can be 30% when the water reduced solid doping amount is 0.2%, and the air entraining of concrete can be 5-7% when the water reduced solid doping amount is 0.2% under the premise of no other air entraining agent compounding.

Owner:LEPING LINGHANG NEW MATERIAL CO LTD

Polycarboxylic-acid water reducing agent synthesized at normal temperature, and preparation method and application method thereof

The invention discloses a polycarboxylic-acid water reducing agent synthesized at normal temperature, and a preparation method and application method thereof. The polycarboxylic-acid water reducing agent is prepared from the following components in parts by weight:100 parts of unsaturated polyether DD-424, 9-13 parts of acrylic acid, 0-4 parts of methacrylic acid, 0-2 parts of sodium allylsulfonate, 0-2 parts of sodium methylallyl sulfonate, 0.2-1 part of oxydol, 0.2-1 part of ammonium persulfate, 0.2-0.6 part of L-ascorbic acid, 0-0.8 part of thioglycolic acid, 0-0.8 part of mercaptopropionic acid, 0-0.4 part of 2-hydroxyethyl acrylate, 4-6 parts of sodium hydroxide and 182-185 parts of water. At most one of the methacrylic acid, sodium allylsulfonate and sodium methylallyl sulfonate is 0 part; and at most one of the thioglycolic acid, mercaptopropionic acid and 2-hydroxyethyl acrylate is 0 part. The product disclosed by the invention has the advantages of excellent properties, high water reducing rate and favorable slump retention; and the method is simple and convenient to operate, has the advantages of low energy consumption and no discharge of three wastes, and is beneficial to application to large-scale production.

Owner:SHANGHAI DONGDA CHEM

Cyanide-free gold plating solution for loudspeaker basin stand

PendingCN114351129AImprove wear resistanceLiquid/solution decomposition chemical coatingPhosphorous acidMeth-

The invention discloses a cyanide-free gold plating solution for a loudspeaker basin stand. The cyanide-free gold plating solution comprises the following raw materials: tetrachloro-alloyed acid, a composite complexing agent, potassium tartrate, sodium methylallyl sulfonate, sodium n-octyl sulfate, a reaction accelerator, a stabilizer, polyacrylamide, a corrosion inhibitor, polyethylene glycol, ethylenediamine and a composite reducing agent, the composite complexing agent is a mixture of 2-amino-5-sulfydryl-1, 3, 4-thiazole, sodium ethylenediamine tetramethylenephosphonate and triammonium citrate; the composite reducing agent is a mixture of sodium hypophosphite, hydroxylamine sulfate, sodium gluconate and ascorbic acid. The cyanide-free gold plating solution for the loudspeaker basin stand is good in stability and high in plating speed, and an obtained plating layer is uniform in thickness, good in brightness and excellent in corrosion resistance, wear resistance and discoloration resistance.

Owner:GANZHOU KINGYUNG TECH CO LTD

Utilize acrylonitrile and methyl methacrylate to prepare the method for anti-pilling acrylic fiber

ActiveCN103668530BHas anti-pilling propertiesMonocomponent synthetic polymer artificial filamentSynthetic polymer filament chemical after-treatmentHigh fractureSodium thiocyanate

The invention relates to a method for preparing anti-pilling acrylic fibers from acrylonitrile and methyl methacrylate, which comprises the following steps: (1) dissolving a polyacrylonitrile polymer in a 40-60% sodium thiocyanate water solution through a dissolver, wherein in the polyacrylonitrile polymer, the acrylonitrile content is 85-95%, the methyl methacrylate content is 5-10%, the sodium methylallyl sulfonate content is less than 1%, and the viscosity-average molecular weight of polyacrylonitrile is 45-65 thousand; (2) after debubbling and filtering a spinning solution, metering through a spinning metering pump, and extruding through spinneret orifices; (3) extruding into a coagulation bath through a spinneret plate to form nascent fibers; (4) sending the fibers into a secondary coagulation bath to form, and carrying out cold drawing, water washing and hot drawing, wherein the total drawing magnification is less than or equal to 12; (5) carrying out hot drying and compaction treatment on the fibers; and (6) thermoforming the fibers. The acrylic fibers prepared by the method have the advantages of high fracture resistance and high pilling resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com