High-slump-retaining early-strength polycarboxylic acid high-performance water reducing agent and preparation method thereof

An early-strength type, polycarboxylic acid technology, which is applied in the field of synthesis and preparation of polycarboxylic acid-based water-reducing agent for concrete, can solve the problem that the addition amount of compound slump-preserving mother liquor is not easy to control, concrete is easy to segregate, bleeding, and water reduction. It can solve the problems of poor slump retention effect and other problems, so as to solve the problems of poor slump retention, good slump retention and shorten setting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

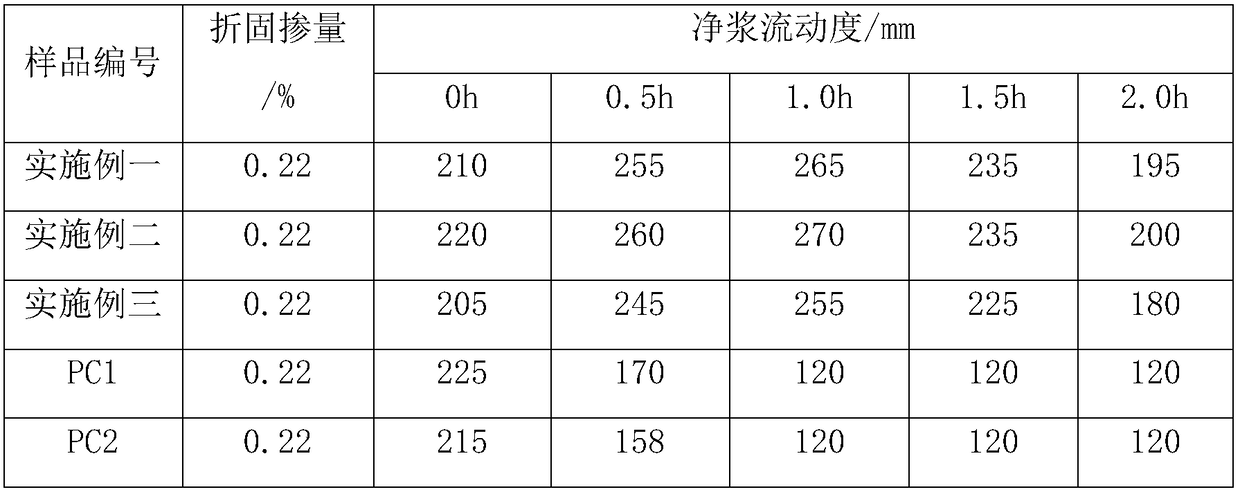

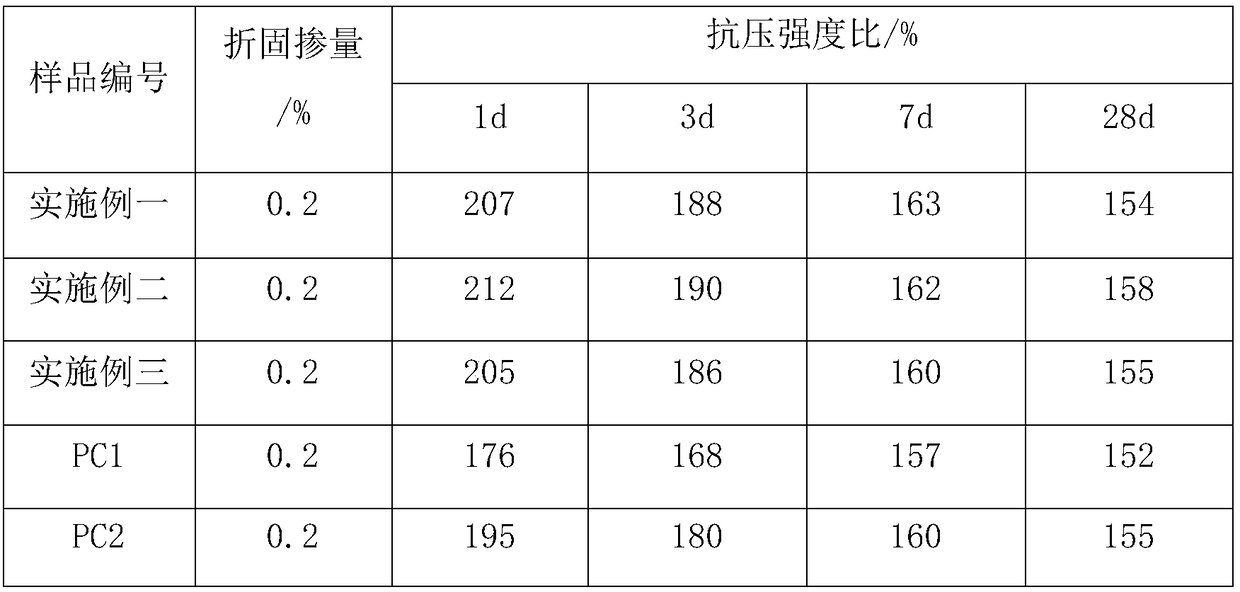

Examples

preparation example Construction

[0025] The preparation method of described high slump retention and early strength type polycarboxylate high-performance water reducer, it comprises the following steps:

[0026] S1. Add an appropriate amount of demineralized water into the container, then slowly add prenyl polyoxyethylene ether into the container, and stir at room temperature to fully dissolve the prenyl polyoxyethylene ether;

[0027] S2. Add acrylic acid, hydroxyethyl acrylate, sodium methacrylsulfonate, 2-acrylamido-2-methylpropanesulfonic acid and acrylamide into the vessel I filled with demineralized water, and stir evenly to obtain a solution A; Ascorbic acid and chain transfer agent are added into vessel II filled with demineralized water, and stirred evenly to obtain solution B;

[0028] S3, adding hydrogen peroxide to the solution in step S1 and stirring at room temperature;

[0029] S4, in the solution of step S3, dropwise add solution A and solution B simultaneously, control solution A and solutio...

Embodiment 1

[0032] The preparation method of high-slump and early-strength polycarboxylate high-performance water reducer comprises the following steps:

[0033] S1. Add 80 parts of demineralized water to the container, then slowly add 100 parts of prenyl polyoxyethylene ether, and stir at room temperature for 20-30 minutes to fully dissolve the isopentenyl polyoxyethylene ether;

[0034] S2. Add 10 parts of acrylic acid, 12 parts of hydroxyethyl acrylate, 0.8 parts of sodium methacrylsulfonate, 0.7 parts of 2-acrylamido-2-methylpropanesulfonic acid and 2 parts of acrylamide into 35 parts of demineralized water , stir evenly to obtain solution A; add 0.16 parts of ascorbic acid and 0.5 part of thioglycolic acid to 45 parts of demineralized water, stir well to obtain solution B;

[0035] S3. Add 0.75 parts of hydrogen peroxide to the solution obtained in step S1, and stir at room temperature for 5-10 minutes;

[0036] S4, in the solution that step S3 obtains, dropwise add solution A and s...

Embodiment 2

[0039] The preparation method of high-slump and early-strength polycarboxylate high-performance water reducer comprises the following steps:

[0040] S1. Add 80 parts of demineralized water to the container, then slowly add 100 parts of prenyl polyoxyethylene ether, and stir at room temperature for 20-30 minutes to fully dissolve the isopentenyl polyoxyethylene ether;

[0041] S2. Add 12 parts of acrylic acid, 10 parts of hydroxyethyl acrylate, 0.7 parts of sodium methacrylsulfonate, 1.2 parts of 2-acrylamido-2-methylpropanesulfonic acid and 1.5 parts of acrylamide to 35 parts of demineralized water , stirred evenly to obtain solution A; 0.14 parts of ascorbic acid and 0.65 parts of mercaptopropionic acid were added to 45 parts of demineralized water, and stirred evenly to obtain solution B;

[0042] S3. Add 0.85 parts of hydrogen peroxide to the solution obtained in step S1, and stir at room temperature for 5-10 minutes;

[0043] S4, in the solution that step S3 obtains, dro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com