High-water-reducing high-adaptability polycarboxylate superplasticizer and preparation method thereof

An adaptable, polycarboxylate technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve problems affecting construction, large loss of fluidity over time, and large difference in cement performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

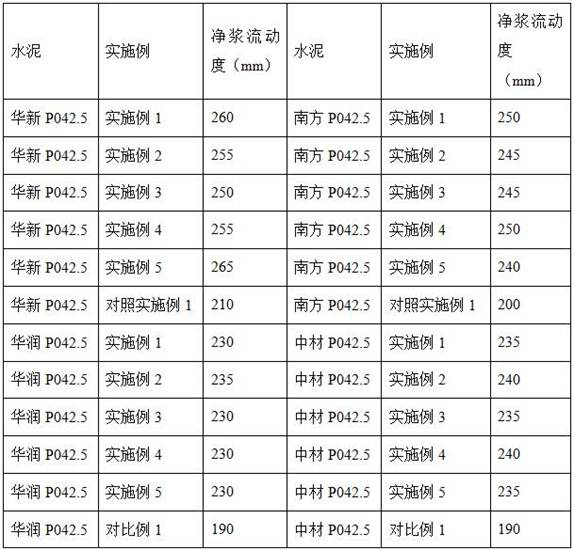

Examples

Embodiment 1

[0032] This embodiment includes the following steps;

[0033] (1) Add 200 parts of bottom water (parts by weight, the same below) into the reactor, and add 360 parts of APEG at room temperature to dissolve;

[0034] (2) After the APEG is dissolved, add 17 parts of hydrogen peroxide and 3 parts of ammonium persulfate, and raise the temperature of the reactor to 50°C;

[0035] (3) Keep the temperature of the reactor at 50°C, slowly add a mixed solution of 3 parts of mercaptoacetic acid, 3 parts of mercaptopropionic acid and 3 parts of ascorbic acid dissolved in 50 parts of deionized water dropwise, and control the rate of dropping, and the drop will be completed within 3-3.5 hours ;

[0036] (4) Slowly add a mixed solution of 30 parts of acrylic acid, 5 parts of sodium methallyl sulfonate, 22 parts of maleic anhydride dissolved in 100 parts of deionized water, control the rate of dropping, and finish dropping in 2.5-3 hours;

[0037] (5) Add dropwise a mixed solution of 3 part...

Embodiment 2

[0040] This embodiment includes the following steps:

[0041] (1) Add 200 parts of bottom water (parts by weight, the same below) into the reactor, and add 360 parts of APEG at room temperature to dissolve;

[0042] (2) After the APEG is dissolved, add 16 parts of hydrogen peroxide and 4 parts of ammonium persulfate, and raise the temperature of the reactor to 60°C;

[0043] (3) Keep the temperature of the reactor at 60°C, slowly add a mixed solution of 3 parts of mercaptoacetic acid, 3 parts of mercaptopropionic acid and 4 parts of ascorbic acid dissolved in 50 parts of deionized water, and control the rate of addition, and the dripping will be completed within 3-3.5 hours ;

[0044] (4) Slowly add a mixed solution of 32 parts of acrylic acid, 4 parts of sodium methallyl sulfonate, 20 parts of maleic anhydride dissolved in 100 parts of deionized water, control the rate of dropping, and finish dropping in 2.5-3 hours;

[0045] (5) Slowly add a mixed solution of 3 parts of fe...

Embodiment 3

[0048] This embodiment includes the following steps:

[0049] (1) Add 180 parts of bottom water (parts by weight, the same below) into the reactor, and add 350 parts of APEG at room temperature to dissolve;

[0050] (2) Add 18 parts of hydrogen peroxide and 3 parts of ammonium persulfate to the bottom water after dissolution, and raise the temperature of the reactor to 50°C;

[0051](3) Keep the temperature of the reactor at 50°C, slowly add 4 parts of mercaptoacetic acid, 4 parts of mercaptopropionic acid and 3 parts of ascorbic acid in 50 parts of deionized water dropwise, and control the rate of addition, and the drop will be completed within 3-3.5 hours ;

[0052] (4) Slowly add a mixed solution of 34 parts of acrylic acid, 6 parts of sodium methallyl sulfonate, 23 parts of maleic anhydride dissolved in 120 parts of deionized water, control the rate of dropping, and finish dropping in 2.5-3 hours;

[0053] (5) Slowly add a mixed solution of 4 parts of ferric sulfate, 3 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com