Polycarboxylic-acid water reducing agent synthesized at normal temperature, and preparation method and application method thereof

A technology of polycarboxylic acid series and water reducing agent, applied in the field of building materials, can solve the problems of high reaction temperature and large production energy consumption, and achieve the effects of low reaction temperature, energy saving and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation before polymerization:

[0035] Preparation of solution A: Weigh 9 parts by weight of acrylic acid, 4 parts by weight of methacrylic acid, 2 parts by weight of sodium methacrylate and 25 parts by weight of water, stir and mix evenly, and prepare dropwise;

[0036] Preparation of solution B: Weigh 0.2 parts by weight of L-ascorbic acid, 0.8 parts by weight of thioglycolic acid, 0.2 parts by weight of hydroxyethyl acrylate and 47 parts by weight of water, stir and mix evenly, and prepare dropwise;

[0037]Preparation of mixture C: Weigh 100 parts by weight of unsaturated polyether DD-424, 0.2 parts by weight of hydrogen peroxide (concentration: 30wt%), 1 part by weight of ammonium persulfate and 80 parts of water, put them into a polymerization reactor, stir evenly, and prepare For polymerization;

[0038] (2) Polymerization: Introduce protective gas nitrogen into the polymerization reactor that has been put into mixture C to drive away the air, start sti...

Embodiment 2~ Embodiment 5

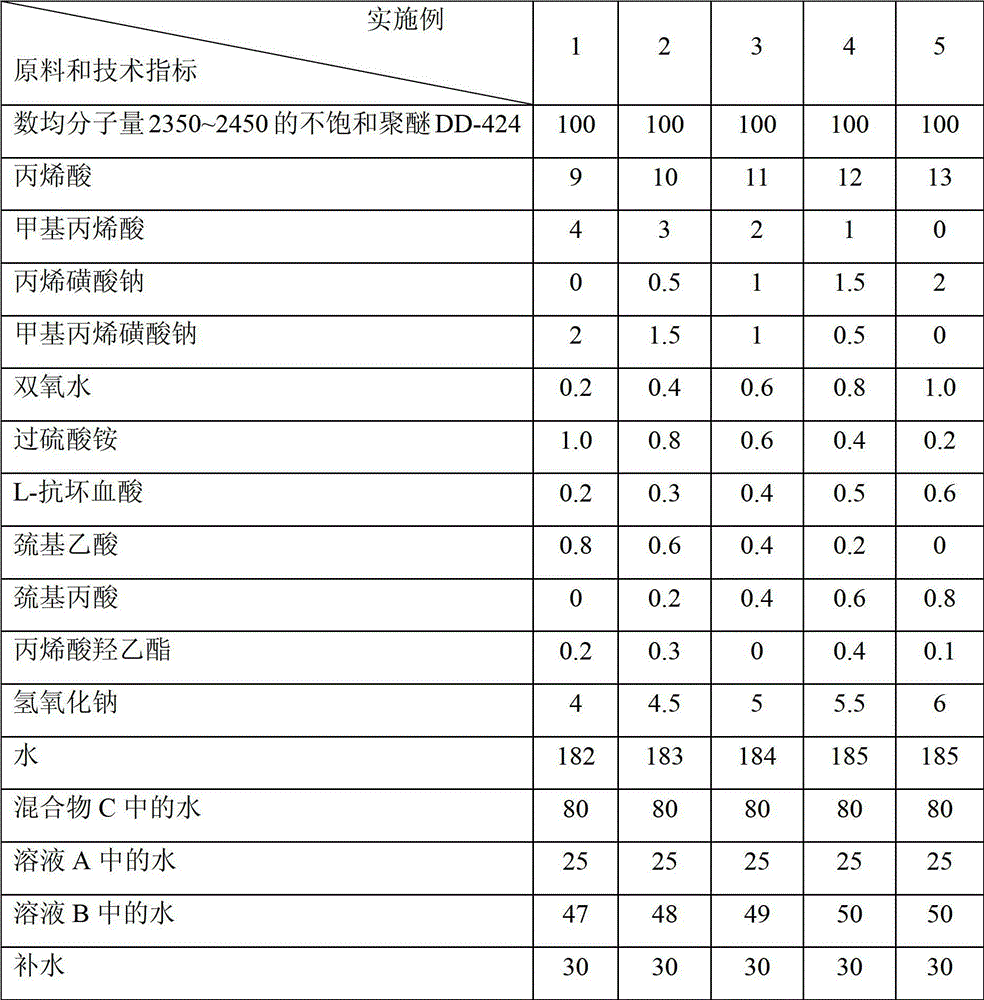

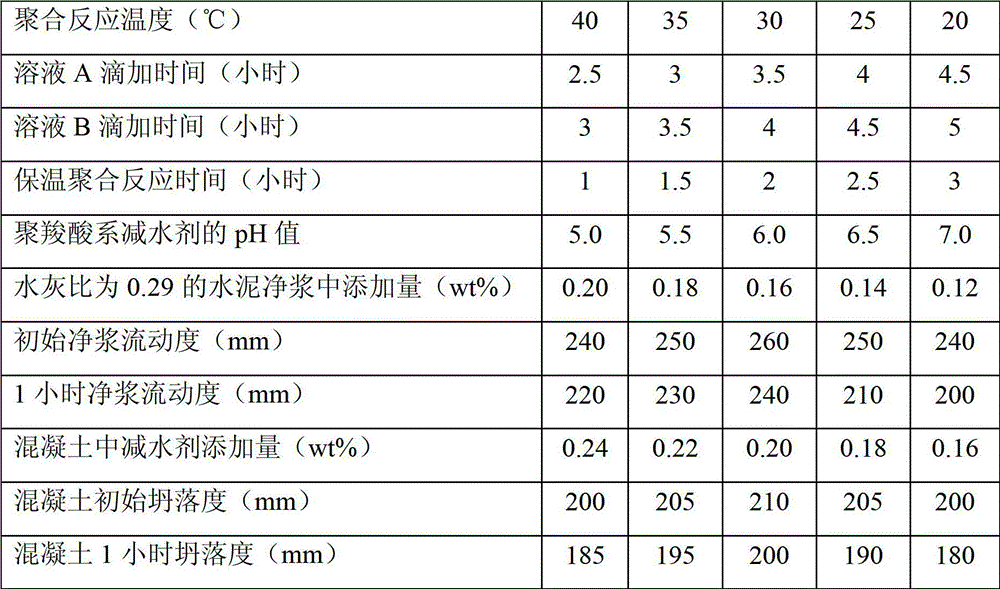

[0042] According to the method and steps of Example 1, prepare the polycarboxylate water reducer synthesized at room temperature according to the formula in Table 1, and add the obtained polycarboxylate water reducer according to the amount shown in Table 1 In the cement paste and concrete, the performance data of the obtained cement paste and concrete are also shown in Table 1.

[0043] Table 1 (the dosage units of each component are parts by weight)

[0044]

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com