Method for producing active admixture by using foundry waste sand

An active admixture and foundry technology, which is applied in the field of building materials, can solve the problems of difficult restoration of performance, large differences in natural sand, and difficult resource utilization, etc., to inhibit the formation of hydration products, delay cement hydration, The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

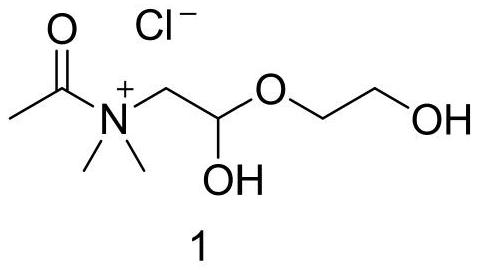

[0034] Preparation of phosphorous monomers:

[0035] Step A21. Mix epichlorohydrin and ethylene glycol, then add boron trifluoride ether solution, stir at 40°C for 60 minutes, then add N,N-dimethylacetamide and isopropanol, and reflux for 8 hours , to obtain intermediate 1; wherein, the molar ratio of epichlorohydrin, ethylene glycol and N,N-dimethylacetamide is 1:1:1;

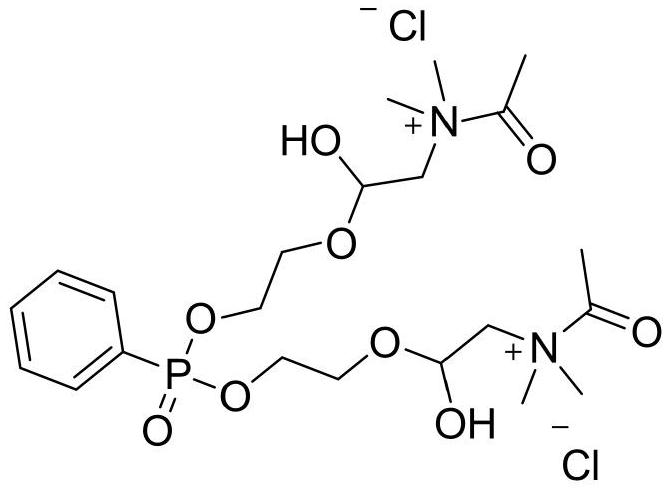

[0036] Step A22. Mix intermediate 1, phenylphosphonic dichloride and N,N-dimethylaniline, and react at 130° C. for 10 h to obtain a phosphorus-containing monomer. Wherein, the molar ratio of intermediate 1 and phenylphosphonic dichloride is 2:1.

Embodiment 2

[0038] Prepare coating solution:

[0039] Step A11, after washing the waste casting sand, crush it until the particle size is less than 3 mm to obtain micropowder; wherein, the waste casting sand is water glass sand;

[0040] Step A12. Under the protection of nitrogen, mix the isophorone diisocyanate after vacuum dehydration with the phosphorus-containing monomer prepared in Example 1, and heat up to 80°C for 3 hours under constant stirring; add dimethylolbutyric acid and Acetone, continue to react for 2 hours; lower the temperature to below 50°C, add triethylamine to neutralize for 30 minutes; add fine powder, then use deionized water to adjust the solid content to 30%, and emulsify under high shear force for 30 minutes to obtain a solid content of about 30% coating solution. Wherein, the molar ratio of the amount of isophorone diisocyanate and the phosphorus-containing monomer is 1:1; the amount of dimethylol butyric acid is 5% of the total mass of the isophorone diisocyana...

Embodiment 3

[0044] Preparation of esterified monomers:

[0045] Stir the mixed acid anhydride and methallyl polyoxyethylene ether at 65°C for 2 hours. After the reaction, wash with saturated saline and sodium bicarbonate solution. After washing, extract with ethyl acetate. Organic The phase was concentrated under reduced pressure to remove the solvent to obtain an esterified monomer. Among them, the relative molecular mass of methallyl polyoxyethylene ether is 2400, and the mixed anhydride is formed by mixing styrene maleic anhydride and octenyl succinic anhydride in a molar ratio of 4:1; styrene maleic anhydride in the mixed anhydride The molar ratio of toric anhydride to methallyl polyoxyethylene ether is 3:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com