Quadripolymer and preparation method

A technology of polymers and monomers, applied in the field of quaternary polymers and preparations, can solve problems such as reducing strength, affecting polycarboxylate water reducing agent water reduction, slump retention performance, and increase in water-cement ratio, so as to overcome compatibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

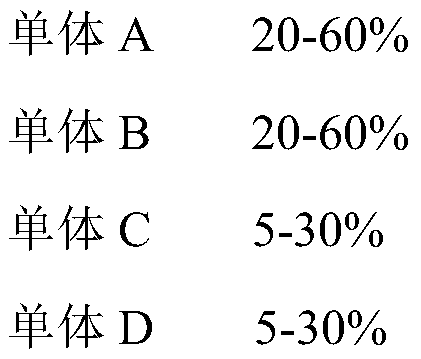

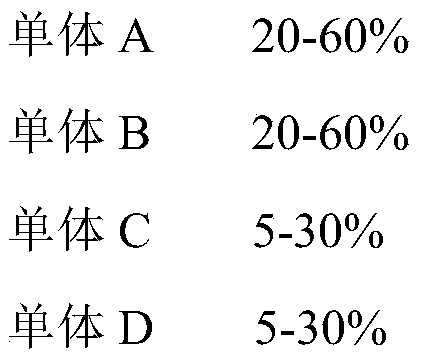

Method used

Image

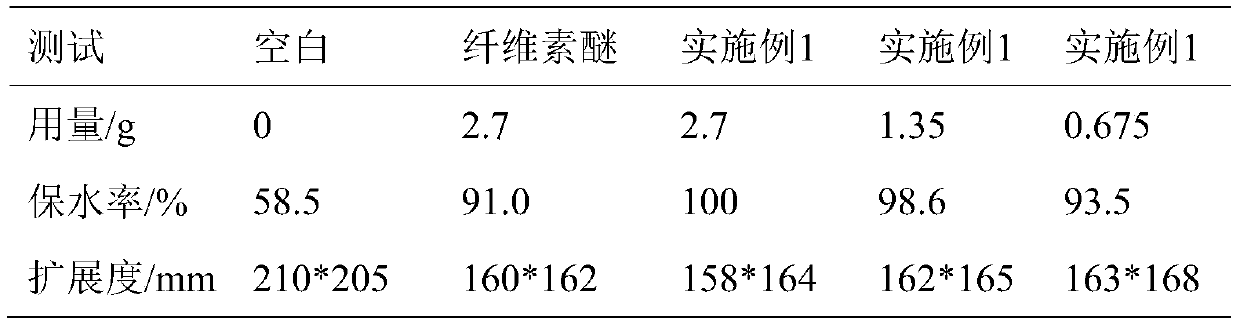

Examples

Embodiment 1

[0026] Add 30% sodium vinylbenzene sulfonate, 30% N,N-dimethylacrylamide, 30% acrylic acid, and 10% methacryloyloxyethyltrimethylammonium chloride to the reaction kettle in sequence, add water and stir Evenly, add 30% sodium hydroxide solution into the reaction kettle, adjust the pH of the system to 7, heat and stir to 45°C, add 0.16g ammonium persulfate, and keep it warm for 1.5 hours to obtain a colorless transparent or light yellow viscous liquid. Dilute with water and continue to stir for 1 hour, then discharge.

Embodiment 2

[0028] Add 60% sodium propylene sulfonate, 20% N,N-dimethylacrylamide, 10% methacrylic acid, and 10% dimethyl diallyl ammonium chloride to the reaction kettle in sequence, add water and stir evenly, and use Add 30% sodium hydroxide solution into the reaction kettle, adjust the pH of the system to 8, heat and stir to 45°C, add 0.20g ammonium persulfate, and keep it warm for 2 hours to obtain a colorless transparent or light yellow viscous liquid, dilute with water and continue Stir for 3 hours and discharge.

Embodiment 3

[0030] Add 40% 2-acryloyloxy-2-methylpropanesulfonic acid, 40% N-vinylpyrrolidone, 10% itaconic acid, and 10% dimethyl diallyl ammonium chloride to the In the reaction kettle, add water and stir evenly, add 30% sodium hydroxide solution into the reaction kettle, adjust the pH of the system to 9, heat and stir to 45°C, add 0.40g ammonium persulfate, and keep warm for 1.5 hours to obtain a colorless and transparent or Pale yellow viscous liquid, dilute with water and continue to stir for 1 hour, then discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com