Preparation method of grapheme/fluoroether rubber modified by covalent bond of fluorine-containing ionic liquid

An ionic liquid and fluoroether rubber technology, applied in the field of graphene/fluoroether rubber preparation, can solve problems such as poor compatibility, and achieve the effects of easy implementation, excellent comprehensive performance and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the graphene / fluoroether rubber modified by the covalent bond of the fluorine-containing ionic liquid of the present invention specifically comprises the following steps:

[0038] (1), fluorine-containing ionic liquid grafted graphite oxide

[0039]Mix fluorine-containing ionic liquid, graphite oxide and catalyst in an organic solvent, ultrasonically treat the graphite oxide in a water bath for 1-4 hours until the graphite oxide is uniformly dispersed, and then conduct a low-temperature reaction in a nitrogen atmosphere, the reaction temperature is 40°C-60°C, and the reaction time is 6 -48h. Purify the reaction product, remove the ionic liquid and catalyst that did not participate in the reaction, and dry the purified sample to obtain fluorine-containing ionic liquid grafted graphite oxide. The purification treatment method is centrifugal washing, vacuum filtration washing or decompression One or a combination of distillation. The mass ratio ...

Embodiment 1

[0057] 1. Ionic liquid grafted graphite oxide

[0058] Weigh 1g of graphite oxide, 1g of 1-aminopropyl-3-methylimidazolium trifluoromethanesulfonimide, 1g of N,N'-dicyclohexylcarbonimide, 50mg of p-dimethylaminopyridine, and weigh 200mL of N,N-dimethylformamide was placed in the flask. After sonicating in a water bath for 2 h, the reaction was carried out in a nitrogen atmosphere at a controlled temperature of 50° C. for 24 h. The reaction product is purified by centrifugal washing, unreacted ionic liquid and catalyst are removed, and the product is vacuum-dried.

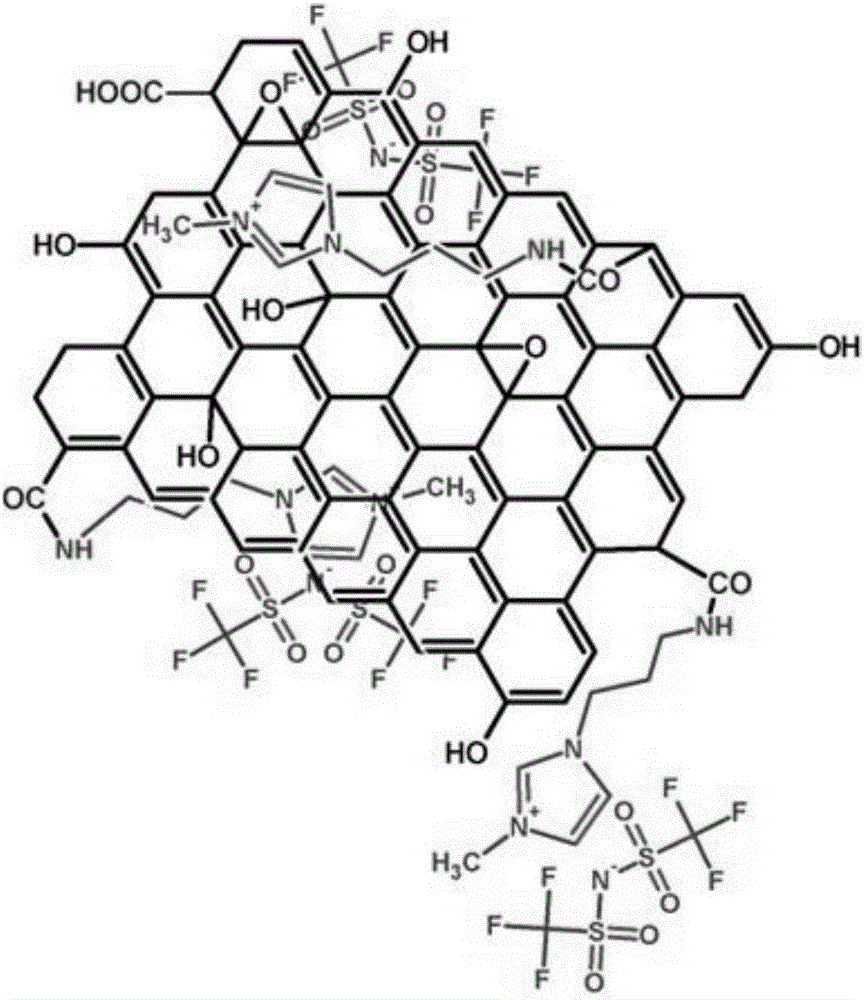

[0059] Such as image 3 Shown is the structural formula of graphite oxide grafted with ionic liquid prepared in Example 1 of the present invention.

[0060] 2. Reduction of ionic liquid grafted graphite oxide

[0061] 1 g of grafted graphite oxide was weighed and placed in a crucible, and heat-treated in an oven at 230° C. for 1 h to obtain a fluffy flocculent ionic liquid-modified redox functional graphene prod...

Embodiment 2

[0069] 1. Ionic liquid grafted graphite oxide

[0070] Weigh 1g of graphite oxide, 2g of 1-aminopropyl-3-methylimidazolium tetrafluoroborate, 1g of N,N'-dicyclohexylcarbimide, 50mg of p-dimethylaminopyridine, weigh 200mL with N , N-dimethylformamide was placed in the flask. After ultrasonic treatment in a water bath for 1 h, the reaction was carried out at 40° C. for 36 h in a nitrogen atmosphere. The reaction product is purified by centrifugal washing, unreacted ionic liquid and catalyst are removed, and the product is vacuum-dried.

[0071] 2. Reduction of ionic liquid grafted graphite oxide

[0072] 1 g of grafted graphite oxide was weighed and placed in a crucible, and heat-treated in an oven at 250° C. for 1 h to obtain a fluffy flocculent ionic liquid-modified redox functional graphene product.

[0073] 3. Mixing and molding of functional graphene and fluoroether rubber

[0074] Weigh 100g fluoroether rubber raw rubber, 1g functional graphene, 4g magnesium oxide, 3g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com