Double-quaternary ammonium positive ion molecule introduced anion-exchange membrane and preparation method thereof

A double quaternary ammonium cation and anion exchange membrane technology, which is applied to the components of fuel cells, etc., can solve the problem of no long alkyl chain design, etc., to improve mechanical properties, increase ion exchange capacity and water content, and improve conduction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

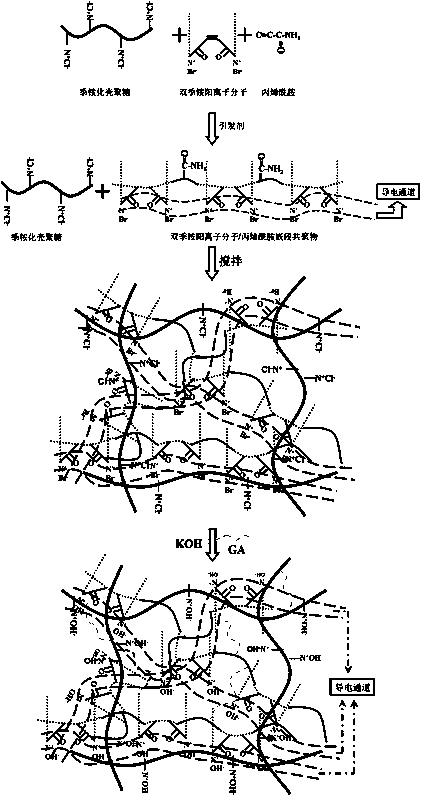

[0033] The preparation method of the anion exchange membrane that introduces diquaternary ammonium cation molecules is as figure 1 shown, follow the steps below:

[0034] (1) Preparation of quaternary ammonium polymers:

[0035] Add isopropanol to chitosan with a degree of deacetylation ≥ 95% to form a chitosan isopropanol solution with a mass concentration of 20%, heat it in a water bath to 80°C under mechanical stirring, and then add an equal volume of 2, 3-Epoxypropyltrimethylammonium chloride aqueous solution, stirred at constant temperature for 8 hours, then distilled under reduced pressure, dried the obtained product at 70°C for 50 minutes, and pulverized into powder to obtain a quaternized ammonium substitution degree of 65%. quaternized chitosan;

[0036] (2) Introduce diquaternary ammonium cation molecules and form membranes:

[0037] Dissolve the quaternized chitosan obtained in step (1) in an acetic acid solution to prepare a quaternized chitosan acetate casting ...

Embodiment 2

[0046] The preparation method of the anion exchange membrane that introduces diquaternary ammonium cation molecules is as figure 1 shown, follow the steps below:

[0047] (1) Preparation of quaternary ammonium polymers:

[0048] Add isopropanol to chitosan with a degree of deacetylation ≥ 95% to form a chitosan isopropanol solution with a mass concentration of 20%, heat it in a water bath to 85°C under mechanical stirring, and then add an equal volume of 2, 3-Epoxypropyltrimethylammonium chloride aqueous solution, stirred at constant temperature for 10 hours, then distilled under reduced pressure, dried the obtained product at 90°C for 30 minutes, and pulverized into powder to obtain a quaternized ammonium substitution degree of 65%. Quaternized chitosan;

[0049] (2) Introduce diquaternary ammonium cation molecules and form membranes:

[0050] Dissolve the quaternized chitosan obtained in step (1) in an acetic acid solution to prepare a quaternized chitosan acetate casting...

Embodiment 3

[0061] The preparation method of the anion exchange membrane that introduces diquaternary ammonium cation molecules is as figure 1 shown, follow the steps below:

[0062] (1) Preparation of quaternary ammonium polymers:

[0063] Add isopropanol to chitosan with a deacetylation degree ≥ 95% to form a chitosan isopropanol solution with a mass concentration of 20%, heat it in a water bath to 90°C under mechanical stirring, and then add an equal volume of 2, 3-Epoxypropyltrimethylammonium chloride aqueous solution, stirred at constant temperature for 12 hours, then distilled under reduced pressure, dried the obtained product at 80°C for 40 minutes, and pulverized into powder to obtain a quaternized ammonium substitution degree of 65%. quaternized chitosan;

[0064] (2) Introduce diquaternary ammonium cation molecules and form membranes:

[0065] Dissolve the quaternized chitosan obtained in step (1) in an acetic acid solution to prepare a quaternized chitosan acetate casting so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com