Lanthanum oxide-silicon dioxide composite particulate material and preparation method thereof

A technology of silica and composite particles, which is applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problems of complex process and unimproved surface properties of carbon black particles, and achieve simple process and suppress Self-coagulation phenomenon, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation of the sodium silicate solution in the step A adopts reagent Na 2 SiO 3 9H 2O; Soluble lanthanum inorganic salt can be lanthanum nitrate, lanthanum chloride, lanthanum sulfate, and what lanthanum nitrate adopts is La(NO 3 ) 3 , lanthanum chloride uses LaCl 3 ·7H 2 O, lanthanum sulfate is La 2 (SO 4 ) 3 ·8H 2 O; concentrated sulfuric acid is the concentrated sulfuric acid that mass percent is 98%; The water of preparation solution adopts deionized water.

[0034] The preparation of lanthanum oxide-silicon dioxide composite particulate material by adopting three kinds of soluble lanthanum inorganic salts of lanthanum chloride, lanthanum sulfate and lanthanum nitrate in the present invention is explained respectively below:

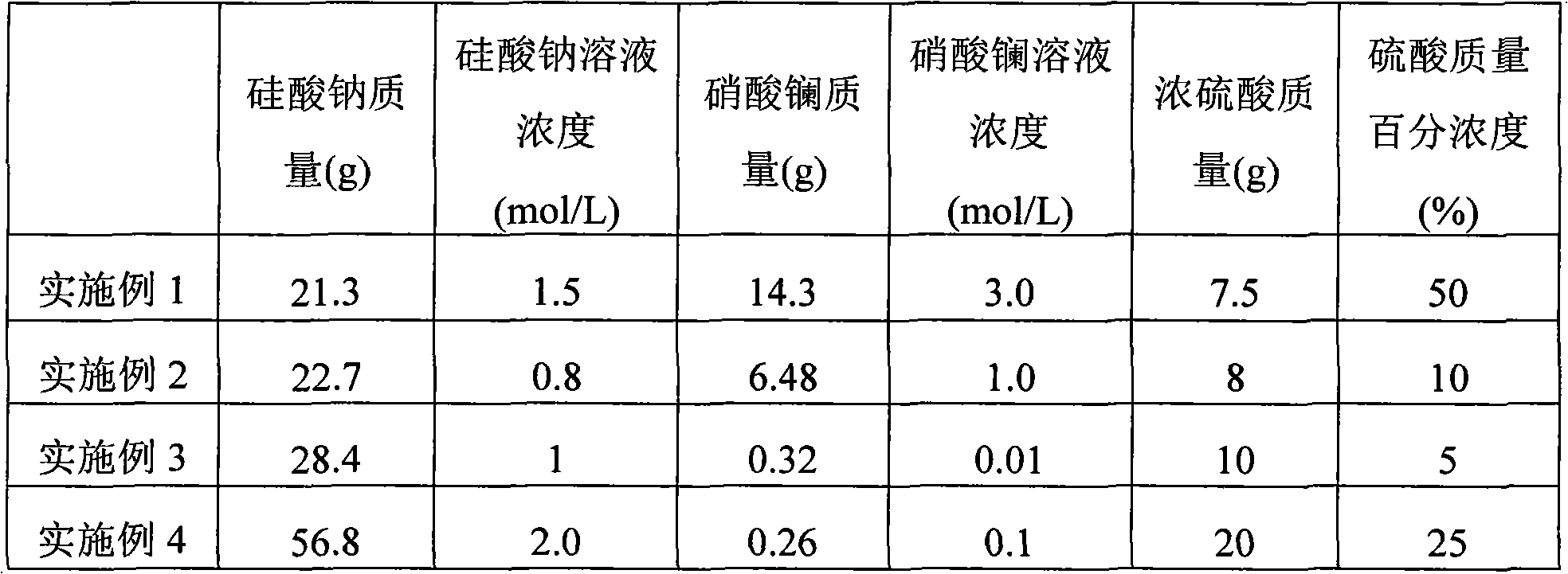

[0035] Table 1. Using sodium silicate and lanthanum nitrate as raw materials

[0036]

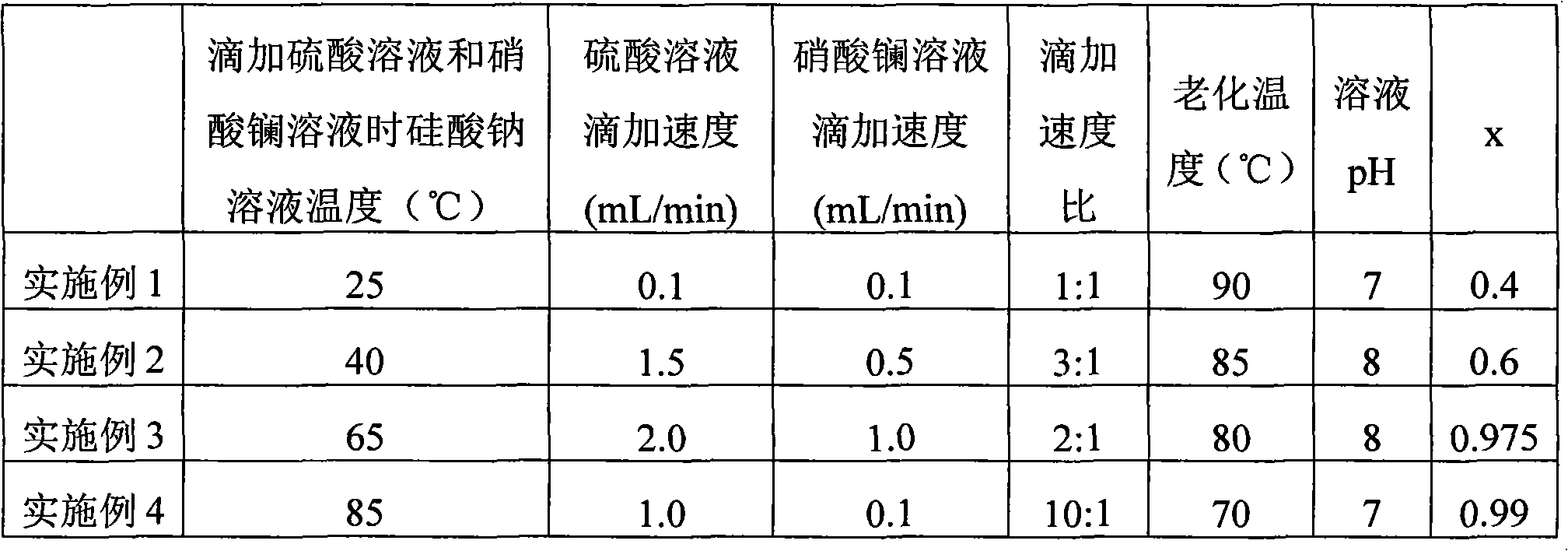

[0037] Table 2. Process parameters in embodiments 1-4

[0038]

[0039] Table 3. Using sodium silicate and lanthanum chloride as r...

Embodiment 1

[0051] A. Weigh 21.3g Na 2 SiO 3 9H 2 O, dissolved in 50mL deionized water to prepare a 1.5M aqueous solution, dissolved in a water bath, and set the temperature of the water bath to 90°C; weigh 14.3g of lanthanum nitrate and dissolve it in 15mL deionized water to prepare a 3.0M aqueous solution, weighing Take 7.5g of concentrated sulfuric acid and slowly add it into water, dilute to 14.7g of sulfuric acid solution with a mass concentration of 50%;

[0052] B. When the temperature of the sodium silicate solution reaches 25°C, start to add sulfuric acid solution and lanthanum nitrate solution dropwise while stirring. 1:1;

[0053] C. When the pH value of the reaction solution was about 2, stop adding the sulfuric acid solution dropwise, and the temperature of the reaction solution was heated to 90°C;

[0054] D. Adjust the pH value to 4 with ammonia water with a volume ratio of 1:1, age for 1 hour, and control the temperature at 90°C;

[0055] E. Adjust the pH value to 7, ...

Embodiment 13

[0058] A. Weigh 56.8g Na 2 SiO 3 9H 2 O, dissolved in 100mL deionized water to prepare a 2.0M aqueous solution, dissolved in a water bath, set the water bath temperature to 70°C; weighed 2.27g of lanthanum nitrate dissolved in 7mL deionized water to prepare a 1M aqueous solution, weighed Slowly add 20g of concentrated sulfuric acid into water, dilute to 78.4g of sulfuric acid solution with a mass concentration of 25%;

[0059] B. When the temperature of the sodium silicate solution reaches 40°C, start to add sulfuric acid solution and lanthanum nitrate solution dropwise while stirring. 10:1;

[0060] C. When the pH value of the reaction solution was about 2, stop adding the sulfuric acid solution dropwise, and the temperature of the reaction solution was heated to 70°C;

[0061] D. Adjust the pH value to 4 with ammonia water with a volume ratio of 1:1, age for 1 hour, and control the temperature at 70°C;

[0062] E. Adjust the pH value to 7, filter, wash and dry.

[0063...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com