A kind of preparation method of nano silver/cellulose composite antibacterial material

A composite antibacterial and cellulose technology, applied in the field of antibacterial materials, can solve the problems of toxic cost of external reducing agent, reduction of antibacterial performance by nano-silver, complicated preparation steps, etc., and achieve the effect of easy industrialization, not easy to self-aggregate, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of nano silver / cellulose composite antibacterial material, comprising the following steps:

[0028] Step one, at -12 ℃, cellulose is dissolved in the mixed solution of sodium hydroxide and urea, and preparation mass percentage is the cellulose solution of 3wt%, and the mixed solution of sodium hydroxide and urea comprises the following mass percentages: Hydroxide Sodium 7wt%, urea 12t%, the rest is water;

[0029] Step 2, adding silver nitrate solution to the cellulose solution obtained in step 1, the mass ratio of silver nitrate and cellulose is 0.01:1, and put into the microwave reactor quickly after stirring;

[0030] Step 3, setting the temperature of the microwave reactor to 50°C and the time to 20 minutes;

[0031] Step 4: Rinse the nano silver / cellulose composite obtained in step 3 with hot water at a temperature of 65° C. until the washing solution is neutral, to obtain a nano silver / cellulose composite material.

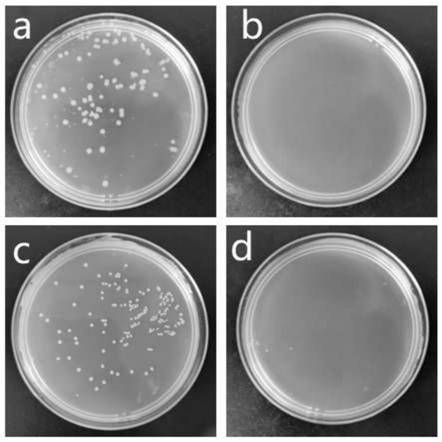

[0032] figure 1 It is a...

Embodiment 2

[0053] A preparation method of nano silver / cellulose composite antibacterial material, comprising the following steps:

[0054] Step 1, dissolving cellulose in a mixed solution of sodium hydroxide and urea at -12°C, preparing a cellulose solution with a mass percentage of 0.5 wt%, and a mixed solution of sodium hydroxide and urea comprising the following mass percentages: hydrogen Sodium oxide 7wt%, urea 12wt%, the rest is water;

[0055] Step 2, adding silver nitrate solution to the cellulose solution obtained in step 1, the mass ratio of silver nitrate and cellulose is 0.01:1, and put into the microwave reactor quickly after stirring;

[0056] Step 3, setting the temperature of the microwave reactor to 40°C and the time to 20 minutes;

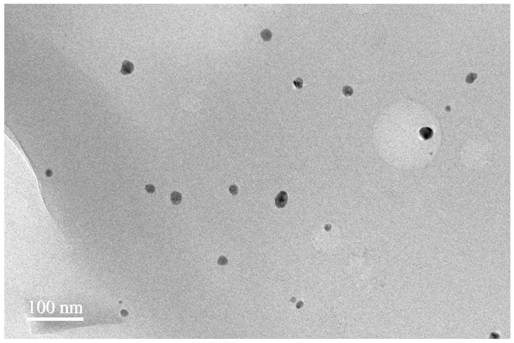

[0057] Step 4, the nano-silver / cellulose composite obtained in step 3 is washed with hot water at 50° C. until the washing solution is neutral to obtain a nano-silver / cellulose composite material. The diameter of the obtained silver nanopart...

Embodiment 3

[0059] A preparation method of nano silver / cellulose composite antibacterial material, comprising the following steps:

[0060] Step one, at -12 ℃, cellulose is dissolved in the mixed solution of sodium hydroxide and urea, and preparation mass percentage is the cellulose solution of 4wt%, and the mixed solution of sodium hydroxide and urea comprises the following mass percentage material: Hydroxide Sodium 7wt%, urea 12wt%, the rest is water;

[0061] Step 2, adding silver nitrate solution to the cellulose solution obtained in step 1, the mass ratio of silver nitrate to cellulose is 0.05:1, and put into the microwave reactor quickly after stirring;

[0062] Step 3, setting the temperature of the microwave reactor to 80°C and the time to 60 minutes;

[0063] Step 4, the nano-silver / cellulose composite obtained in step 3 is rinsed with hot water at 80° C. until the washing solution is neutral to obtain a nano-silver / cellulose composite material. The diameter of the obtained silv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com