Biobased micro-porous polyurethane material and preparation method thereof

A polyurethane material and bio-based technology, applied in the field of bio-based microporous polyurethane materials and preparation, can solve the problems of poor heat resistance, weather resistance and antistatic properties, and achieve low surface hydroxyl activity, reduce aging, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Component A includes the following raw materials:

[0040] 22 parts of polypropylene glycol-glycerol ether,

[0041] 4.2 parts of ethylene glycol,

[0042] 2.6 parts of 3,3-dichloro-4,4-diaminodiphenylmethane,

[0043] 0.25 parts of water,

[0044] 0.28 parts of silicone oil,

[0045] Triethylenediamine (A33) / stannous octoate 0.14 / 0.06 parts;

[0046] Component B includes the following raw materials:

[0047] Nano wollastonite 2.3 parts,

[0048] Bio-based polyether polyol C (water content less than 0.1%) 24.3 parts,

[0049] 42 parts of diphenylmethane diisocyanate.

[0050] The specific preparation method is as follows:

[0051] A component preparation process: 22 parts of polypropylene glycol-glycerol ether (functionality is 3, average molecular weight is 2950, its model is: EPG-217, manufacturer is: Yantai Guangshun Chemical Products Co., Ltd., solid content: 99.9%.), 4.2 parts of ethylene glycol, 2.6 parts of 3,3,3-dichloro-4,4,-diaminodiphenylmethane, 0...

Embodiment 2

[0056] Component A includes the following raw materials:

[0057] 30 parts of polypropylene glycol-glycerol ether,

[0058] 5 parts of propylene glycol,

[0059] 2 parts of dimethylthiotoluenediamine,

[0060] 0.2 parts of water,

[0061] 0.2 parts of silicone oil,

[0062] Triethylenediamine / dibutyltin dilaurate 0.17 / 0.08 parts;

[0063] Component B includes the following raw materials:

[0064] Nano wollastonite 3.5 parts,

[0065] Bio-based polyether polyol C (water content less than 0.1%) 24 parts,

[0066] 35 parts of diphenylmethane diisocyanate.

[0067] The specific preparation method is as follows:

[0068] A component preparation process: 30 parts of polypropylene glycol-glycerol ether (functionality is 3, average molecular weight is 4000), 5 parts of propylene glycol, 2 parts of dimethylthiotoluenediamine, 0.2 parts of water, 0.2 parts Silicone oil, 0.17 parts of 33% triethylenediamine solution (A33) and 0.08 parts of dibutyltin dilaurate were stirred at 20...

Embodiment 3

[0072] Component A includes the following raw materials:

[0073] 40 parts of polypropylene glycol,

[0074] 3.5 parts of 1,4-butanediol,

[0075] Dimethylthiochlorophenylenediamine 1.5 parts,

[0076] 0.4 parts of water,

[0077] 0.35 parts of silicone oil,

[0078] Triethylenediamine / dibutyltin dilaurate 0.23 / 0.07 parts;

[0079] Component B includes the following raw materials:

[0080] Nano wollastonite 6 parts,

[0081] Bio-based polyether polyol C (water content less than 0.1%) 17.95 parts,

[0082] 30 parts of liquefied diphenylmethane diisocyanate.

[0083] Its concrete preparation method is with embodiment 2.

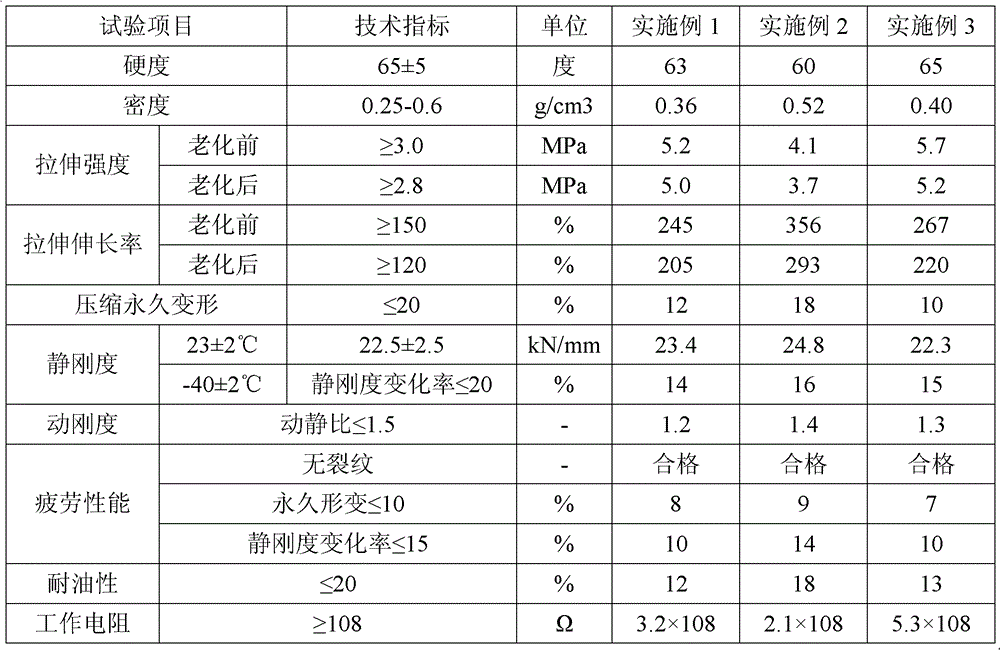

[0084] The materials described are tested according to the following standards:

[0085] ① Determination of isocyanate group content in HG / T 2409-1992 polyurethane prepolymer;

[0086] ②GB / T 10802-1989 flexible polyurethane foam;

[0087] ③GB / T 10800-1989 Rigid polyurethane foam for building heat insulation;

[0088] The technical performance indica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com