Air entraining type poly carboxylic acid high performance water reducing agent and preparation method thereof

A polycarboxylate-based, high-performance technology, applied in the field of concrete water reducing agent and its preparation, can solve the problems of unevenness, poor air-entraining performance, large bubble size, etc., and achieve high water-reducing rate, excellent air-entraining performance, The effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

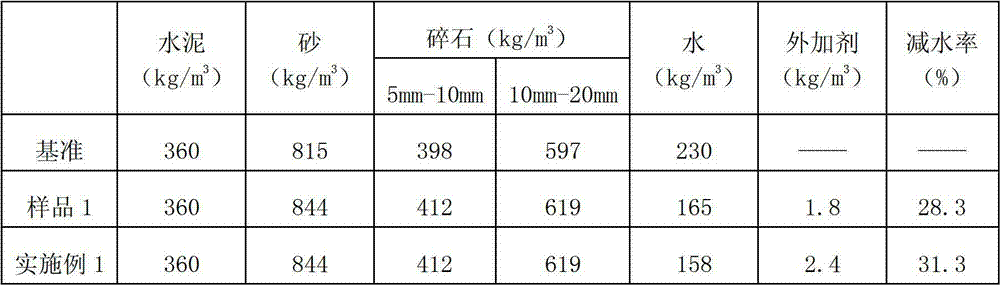

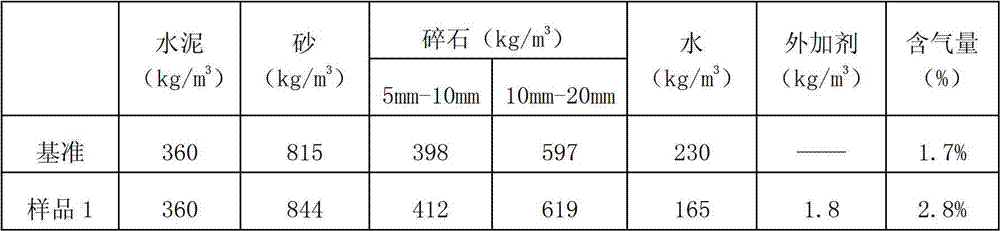

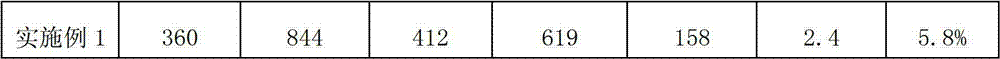

Examples

Embodiment 1

[0036] 0.25mol of monomer A is methyl alkenyl polyoxyethylene with a degree of polymerization of 30-60;

[0037] 0.70mol monomer B is methacrylic acid;

[0038] 0.18mol monomer C is acrylamide;

[0039] 0.05mol monomer D is ethyl acetate;

[0040] Initiator is sodium persulfate;

[0041] The chain transfer agent is a mixture of mercaptoacetic acid and sodium bisulfite in a ratio of 1:2;

[0042] Preparation steps:

[0043] a. Monomer B, monomer C and monomer D equivalent to twice the molar weight of monomer C are dissolved in deionized water, and stirred evenly to obtain a small monomer solution, which is stirred evenly and set aside;

[0044] B, the chain transfer agent is dissolved in deionized water, stirred evenly, and the chain transfer agent solution is obtained for use, and the consumption of the chain transfer agent is 0.1% by weight of the total monomer weight of the reaction;

[0045]c. Put monomer A and deionized water into the reaction container and heat to di...

Embodiment 2

[0048] 0.25mol of monomer A is allyl polyoxyethylene ether with a degree of polymerization of 30-60;

[0049] 0.70mol monomer B is methacrylic acid;

[0050] 0.18mol monomer C is 2-acrylamido-methylpropanesulfonic acid;

[0051] 0.05mol monomer D is ethyl acetate;

[0052] The initiator is a mixture of ammonium persulfate and sodium persulfate in a ratio of 1:1;

[0053] The chain transfer agent is mercaptoacetic acid;

[0054] Preparation steps:

[0055] a. Monomer B, monomer C and monomer D equivalent to twice the molar weight of monomer C are dissolved in deionized water, and stirred evenly to obtain a small monomer solution, which is stirred evenly and set aside;

[0056] B, the chain transfer agent is dissolved in deionized water, stirred evenly, and the chain transfer agent solution is obtained for use, and the consumption of the chain transfer agent is 0.2% by weight of the total monomer weight of the reaction;

[0057] c. Put monomer A and deionized water into the...

Embodiment 3

[0060] 0.25mol of monomer A is polyoxypropylene ether with a degree of polymerization of 30-60;

[0061] 0.70mol monomer B is acrylic acid;

[0062] 0.18mol monomer C is sodium methacrylate;

[0063] 0.05mol monomer D is styrene;

[0064] The initiator is hydrogen peroxide;

[0065] The chain transfer agent is a mixture of mercaptoacetic acid and 2-mercaptopropionic acid in a ratio of 2:1;

[0066] Preparation steps:

[0067] a. Monomer B, monomer C and monomer D equivalent to twice the molar weight of monomer C are dissolved in deionized water, and stirred evenly to obtain a small monomer solution, which is stirred evenly and set aside;

[0068] B, the chain transfer agent is dissolved in deionized water, stirred evenly, and the chain transfer agent solution is obtained for use, and the consumption of the chain transfer agent is 0.25% by weight of the total monomer weight of the reaction;

[0069] c. Put the monomer A and deionized water into the reaction container and h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| gas content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com